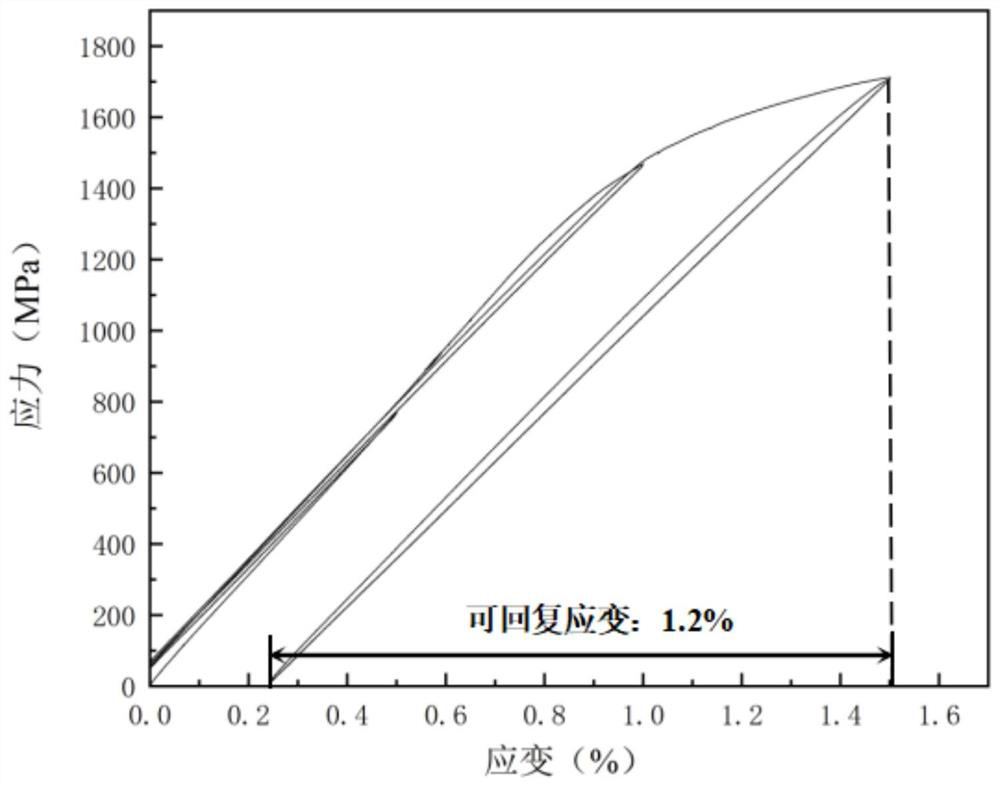

A kind of multi-component fenicoaltizr superelastic alloy and preparation method thereof

A superelastic alloy and multi-component technology, applied in the field of superelastic alloys, to achieve the effects of easy industrial production, inhibition of element segregation, and process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Select metal iron, metal nickel, metal cobalt, metal aluminum, metal titanium, metal zirconium, the alloy composition is as follows (atomic percentage %): Fe=40.5, Ni=30.0, Co=16.0, Al=10.5, Ti=2.5, Zr=0.5.

[0025] The preparation method includes the following steps: performing arc smelting in argon protection, using magnetic stirring technology to mix the metal solution evenly during the smelting process, and sucking and casting into alloy alloy bars;

[0026] The ingot is heated to 1100°C, and after holding for 2 hours, it is hot rolled into a thin plate with a thickness of 15mm at this temperature;

[0027] Air-cooled to room temperature;

[0028] The rolled sheet is subjected to intermediate annealing treatment at 1200 ° C for 30 minutes, followed by water quenching;

[0029] Cold rolling the sheet to a thickness of 2mm at room temperature;

[0030] The solution-treated material was aged at 600°C for 8 hours, and then water quenched.

Embodiment 2

[0032] Select metal iron, metal nickel, metal cobalt, metal aluminum, metal Ti, metal Zr, the alloy composition is as follows (atomic percentage %): Fe=40.5, Ni=30.0, Co=16.0, Al=10.5, Ti=2.5, Zr=0.5.

[0033] The preparation method includes the following steps: arc smelting and casting into alloy ingots; smelting is carried out in argon protection, and a magnetic stirring technology is used to mix the metal solution evenly in the smelting process; and the argon protection is used to protect the casting and cast into a circle with a size of a circle. ingot;

[0034] The ingot is heated to 1100°C and kept for 2h, then hot rolled into a thin plate with a thickness of 15mm at this temperature;

[0035] Air-cooled to room temperature;

[0036] The rolled sheet is subjected to intermediate annealing treatment at 1200 ° C for 30 minutes, followed by water quenching;

[0037] Cold rolling the sheet to a thickness of 2mm at room temperature;

[0038] The solution-treated material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com