Self-cleaning static rotary pyrolysis device

A self-cleaning, pyrolysis technology, applied in pyrolysis treatment of sludge, indirect heating dry distillation, special forms of dry distillation, etc., can solve the problems of low pyrolysis efficiency, coking and adhesion of materials, etc., and achieves convenient operation and high degree of automation. , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] Aiming at the existing problems, the present invention provides a self-cleaning static rotary pyrolysis device, which is compact and simple in design, easy to operate, stable in operation and high in automation, and can effectively clean up organic solid wastes such as sludge and oil sludge that are easy to coke During the pyrolysis process, sticky coke blocks are produced, which effectively improves the pyrolysis efficiency.

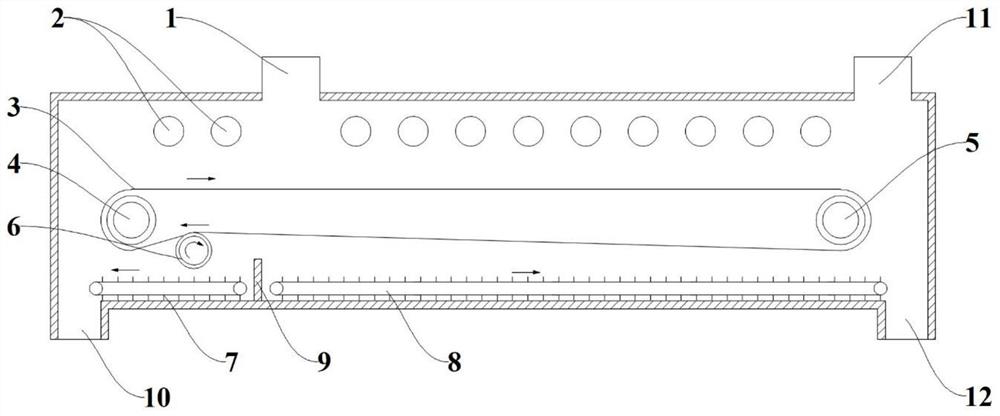

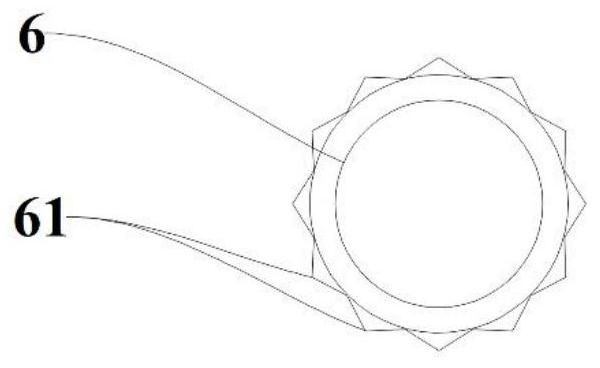

[0027] In order to realize the above technical solutions, such as figure 1 As shown, the embodiment of the present invention provides a self-cleaning static rotary pyrolysis device, including a feed port 1, a plurality of heating pipes 2, a chain plate 3, a driven wheel 4, a driving wheel 5, a coke cleaning wheel 6, a scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com