Reaction system and method for carbon-containing materials

A reaction system and material technology, applied in the petroleum industry, the manufacture of combustible gas, etc., can solve the problems of large fluctuations in electricity prices, economic uneconomical, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

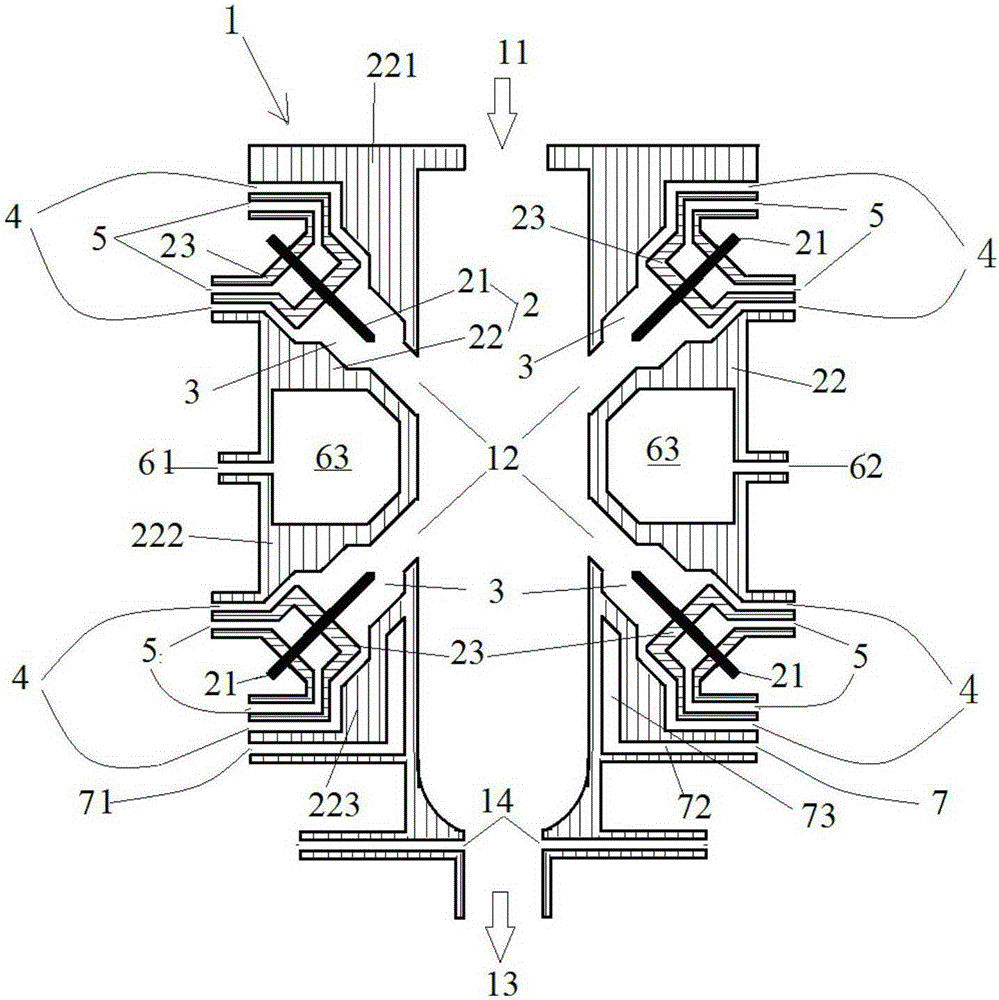

[0089] use figure 2 The reactor in is used as the high-temperature cracking gasification reactor 84 in the present invention to carry out the experiment of hydrogen production from coal direct liquefaction residue and coal tar by thermal plasma treatment, and the properties of liquefaction residue and coal tar are shown in Table 2.

[0090] Table 2

[0091]

[0092]The coal liquefaction residue with a particle size of about 50 microns is fed into a medium-temperature pyrolysis reactor for pyrolysis reaction. The operating temperature is 700 degrees Celsius and the operating pressure is normal pressure. The residence time of the coal liquefaction residue in the high-temperature pyrolysis gasification reaction is 20 Minutes, gaseous pyrolysis products and solid pyrolysis products are obtained, and the gaseous pyrolysis products are dedusted to obtain product gas.

[0093] All the solid products at a temperature of 500 degrees Celsius are fed into a solid-liquid mixer, and ar...

Embodiment 3

[0096] use figure 2 The reactor in the present invention is used as the high-temperature cracking gasification reactor 84 in the present invention to carry out the hydrogen production experiment after the direct liquefaction residue of thermal plasma treatment coal is mixed with coal to make coal-water slurry, and the properties of liquefaction residue and coal are shown in Table 3 .

[0097] table 3

[0098]

[0099] The coal liquefaction residue with a particle size of about 50 microns is fed into a medium-temperature pyrolysis reactor for pyrolysis reaction. The operating temperature is 700 degrees Celsius and the operating pressure is normal pressure. The residence time of the coal liquefaction residue in the high-temperature pyrolysis gasification reaction is 20 Minutes, gaseous pyrolysis products and solid pyrolysis products are obtained, and the gaseous pyrolysis products are dedusted to obtain product gas.

[0100] Mix the solid product pyrolyzed at 700 degrees Ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com