Fused salt-oily sludge thermochemical conversion fluidized bed reactor, system and application of molten salt-oily sludge thermochemical conversion fluidized bed reactor

A fluidized bed reactor, thermochemical conversion technology, applied in chemical instruments and methods, pyrolysis treatment of sludge, chemical/physical processes, etc., can solve the problem of heat carrier cannot be recycled, secondary pollution, large energy loss, etc. problem, to achieve the effect of lower temperature, high-efficiency pyrolysis, no flow and heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

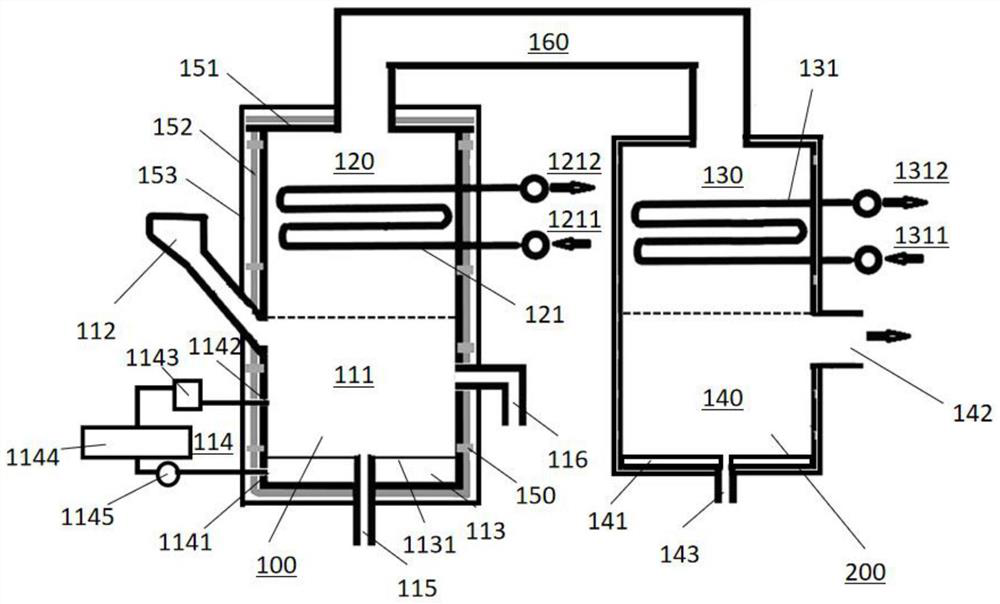

[0042] like figure 1 As shown, embodiment 1 proposes a molten salt-oily sludge thermochemical conversion fluidized bed reactor, including a first chamber 100 and a second chamber 200, and the first chamber 100 and the second chamber 200 Connected through the channel structure.

[0043] A reaction device 110 and a first cooling chamber 120 are disposed in the first chamber 100 .

[0044] The second cooling chamber 130 and the condensation chamber 140 are disposed in the second chamber 200 .

[0045] The reaction device 110, the first cooling chamber 120, the second cooling chamber 130 and the condensation chamber 140 are connected in sequence.

[0046] The reaction device 110 is provided with a reaction chamber 111 , an oily sludge feeding device 112 , a high temperature molten salt chamber 113 , a molten salt circulation device 114 , a first discharge port 115 and a second discharge port 116 .

[0047] Wherein, the oily sludge feeding device 112 communicates with the reacti...

Embodiment 2

[0067] Embodiment 2 proposes utilizing the device of embodiment 1 to carry out the method for molten salt-oily sludge thermochemical conversion reaction, comprises the following steps:

[0068] (1) Pass the high-temperature molten salt with a temperature of 580°C in the high-temperature molten salt chamber 113 into the reaction chamber 111, and feed the oily sludge into the reaction chamber 111 through the oily sludge feeding device 112 under an oxygen-free environment, 600 The pyrolysis reaction is carried out at a temperature of ℃ to obtain pyrolysis gas and sludge particles. The sludge particles are discharged through the first discharge port 115 and the second discharge port 116 respectively, and the pyrolysis gas is passed into the first cooling chamber 120. After the reaction The molten salt flows back to the high-temperature molten salt chamber 113 through the molten salt circulation device 114 . Among them, the working temperature of the oily sludge feeding device is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com