Waste horizontal screening fluidized pyrolysis device

A garbage and screening technology, applied in incinerators, lighting and heating equipment, combustion types, etc., can solve problems such as dioxin stagnation, incineration process stagnation, incineration state changes, etc., to prevent the formation of dioxins , Prevent pyrolysis stagnation, easy pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

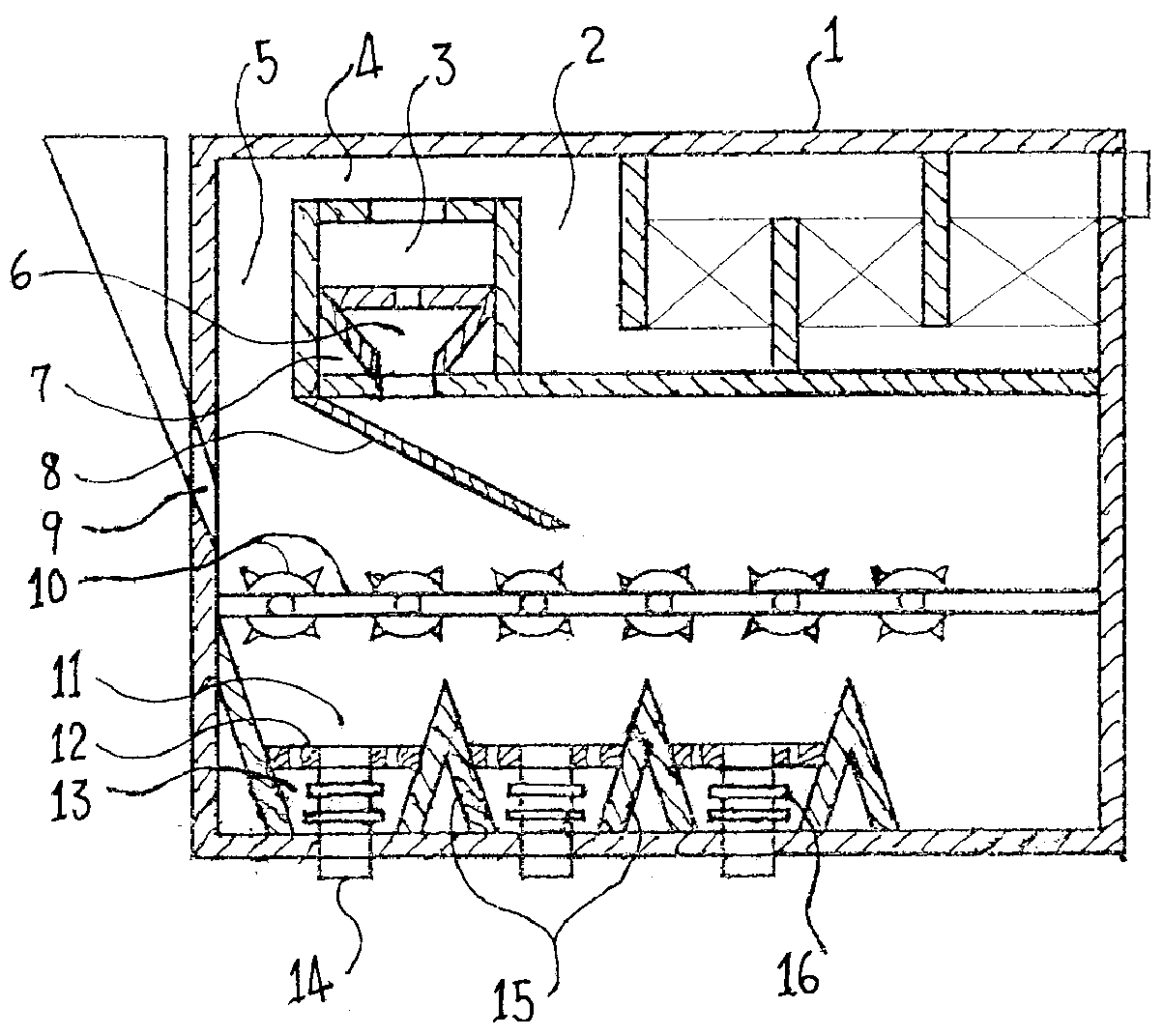

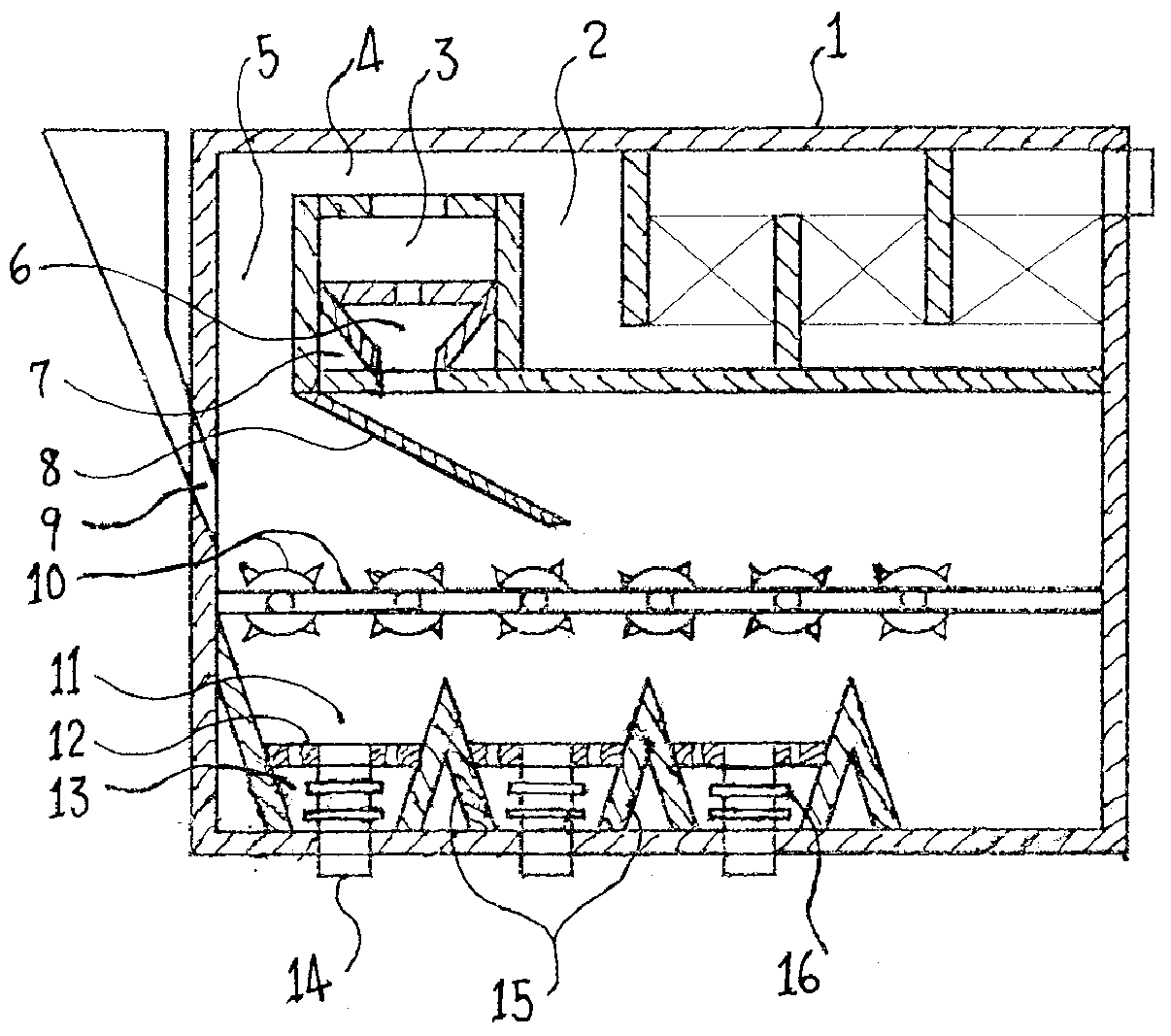

[0025] Such as figure 1As shown, the garbage horizontal screening fluidized pyrolysis device of the present invention includes a cavity 1 with a garbage inlet 9, the garbage inlet 9 is arranged on the retaining wall or side wall of the cavity 1, and the side of the garbage inlet 9 is provided to make the garbage The sieving mechanism 10 for sieving pyrolysis with horizontal movement, the sieving mechanism 10 has six or two sieve rollers arranged at intervals and moving in the same direction, the interval between the sieve rollers can be adjusted, and a gas phase The pyrolysis chamber 3, the gas phase pyrolysis chamber 3, and the screening mechanism 10 are respectively connected with the hot air conveying mechanism, and three solid phase pyrolysis chambers 15 are arranged below the screening mechanism 10, and each solid phase pyrolysis chamber 15 has a connection with each other. Each solid-phase pyrolysis chamber 15 has an ember chamber 11, an air chamber 13, and an ash passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com