Preparation system of industrial gas and preparation method of industrial gas

An industrial gas and preparation system technology, which is applied in the petroleum industry, the manufacture of combustible gas, and the gasification of granular/powdered fuels, and can solve the problems of lack of industrial gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] (1) Industrial gas preparation system

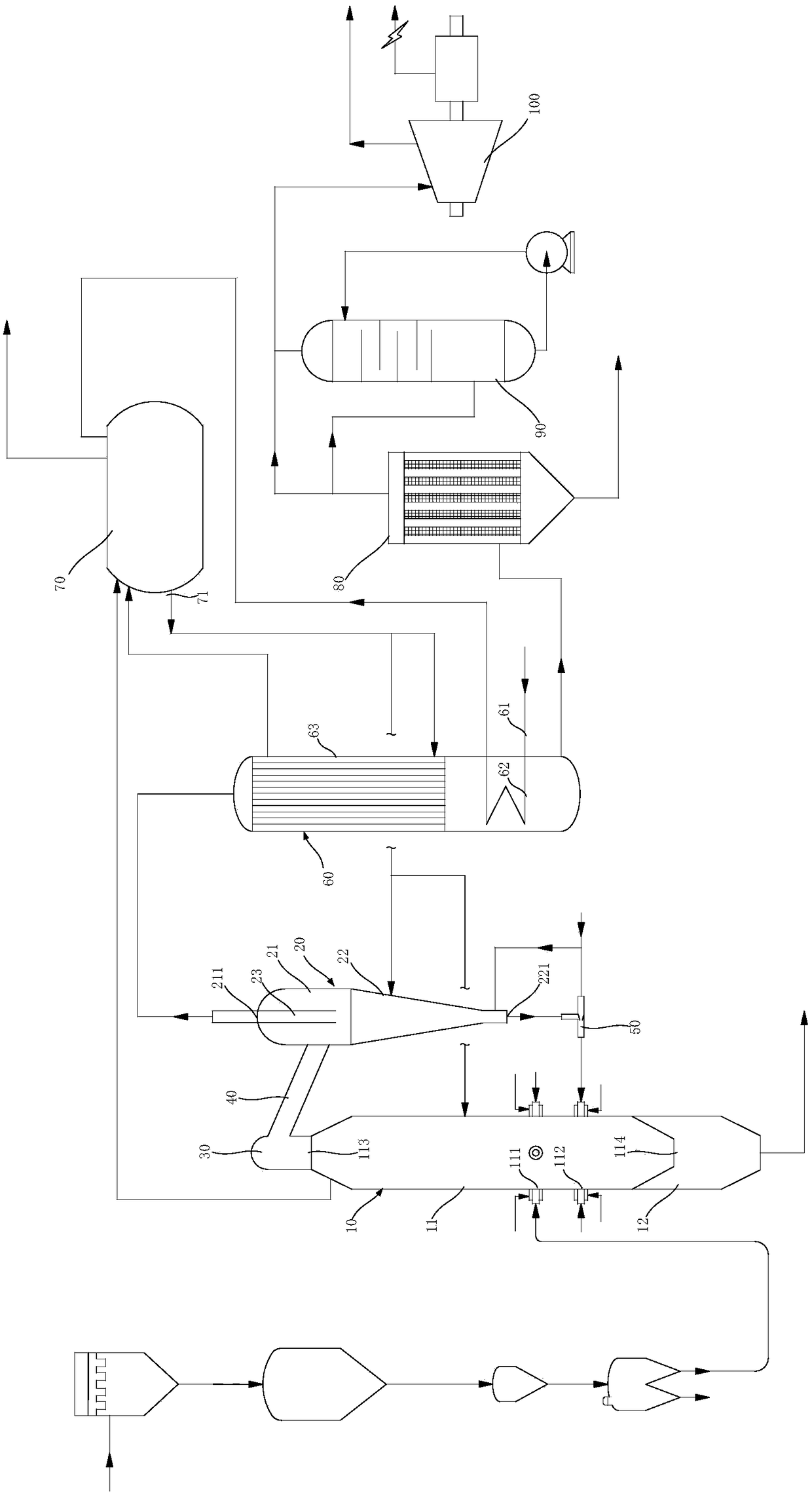

[0090] Such as figure 1 The industrial gas preparation system shown includes a pulverized coal conveying unit, an entrained bed gasifier, a convection waste heat boiler 60, a steam drum 70 and a dust removal unit;

[0091] The pulverized coal conveying unit is used to convey pulverized coal to the first nozzle 111 of the entrained-bed gasifier;

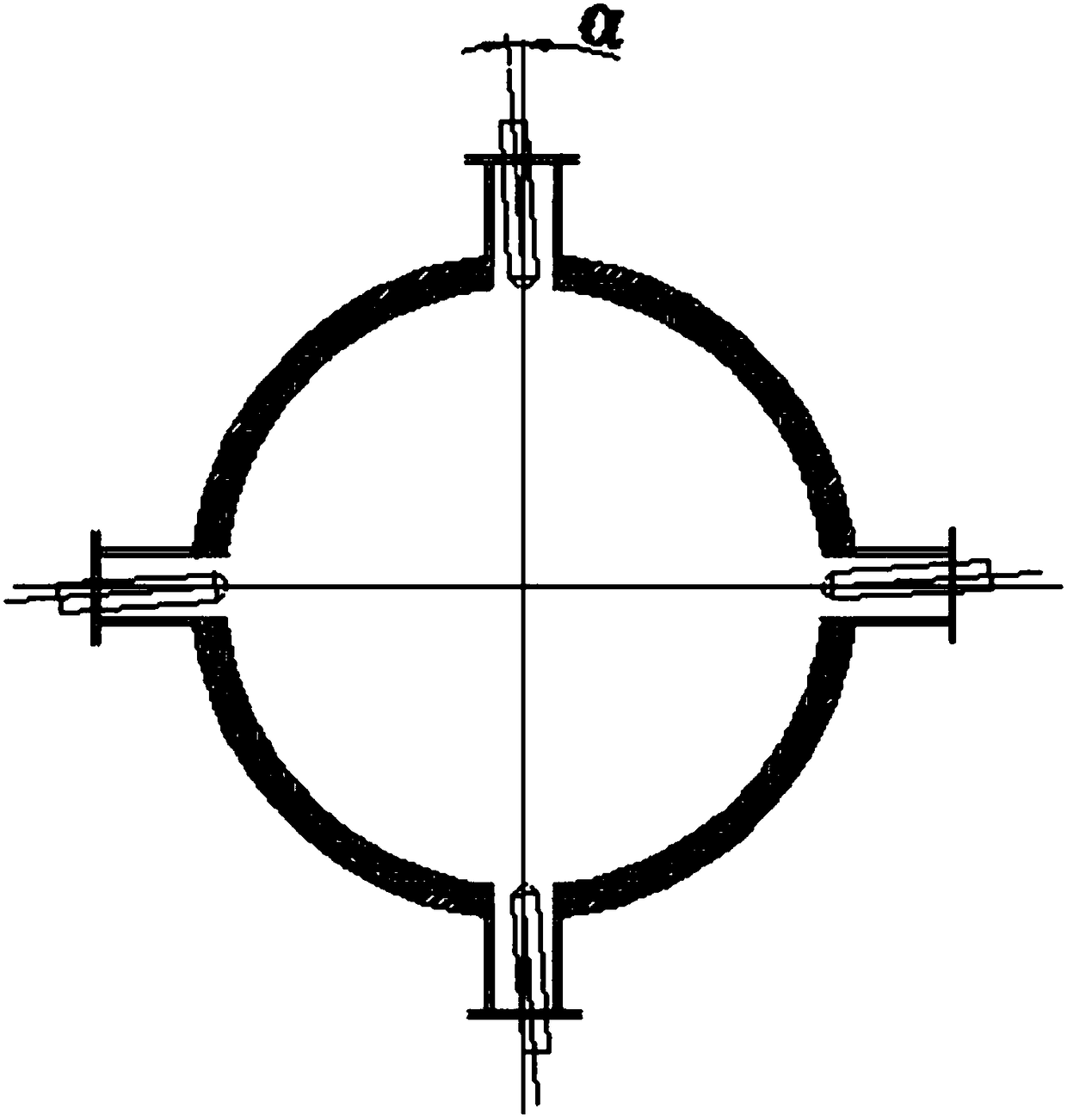

[0092] The entrained-bed gasification furnace has a gasification furnace body 10 and a cyclone separation chamber 20; the gasification furnace body 10 has a gasification chamber 11 and a collection chamber 12 located at the lower part of the gasification chamber 11; A nozzle 111, the first nozzle 111 is used to pass pulverized coal and oxygen into the gasification chamber 11; the top of the gasification chamber 11 is provided with a first synthesis gas outlet 113; the cyclone separation chamber 20 has a second synthesis gas outlet 211 and The fly ash outlet 221; the cyclone separation chamber 2...

Embodiment 2

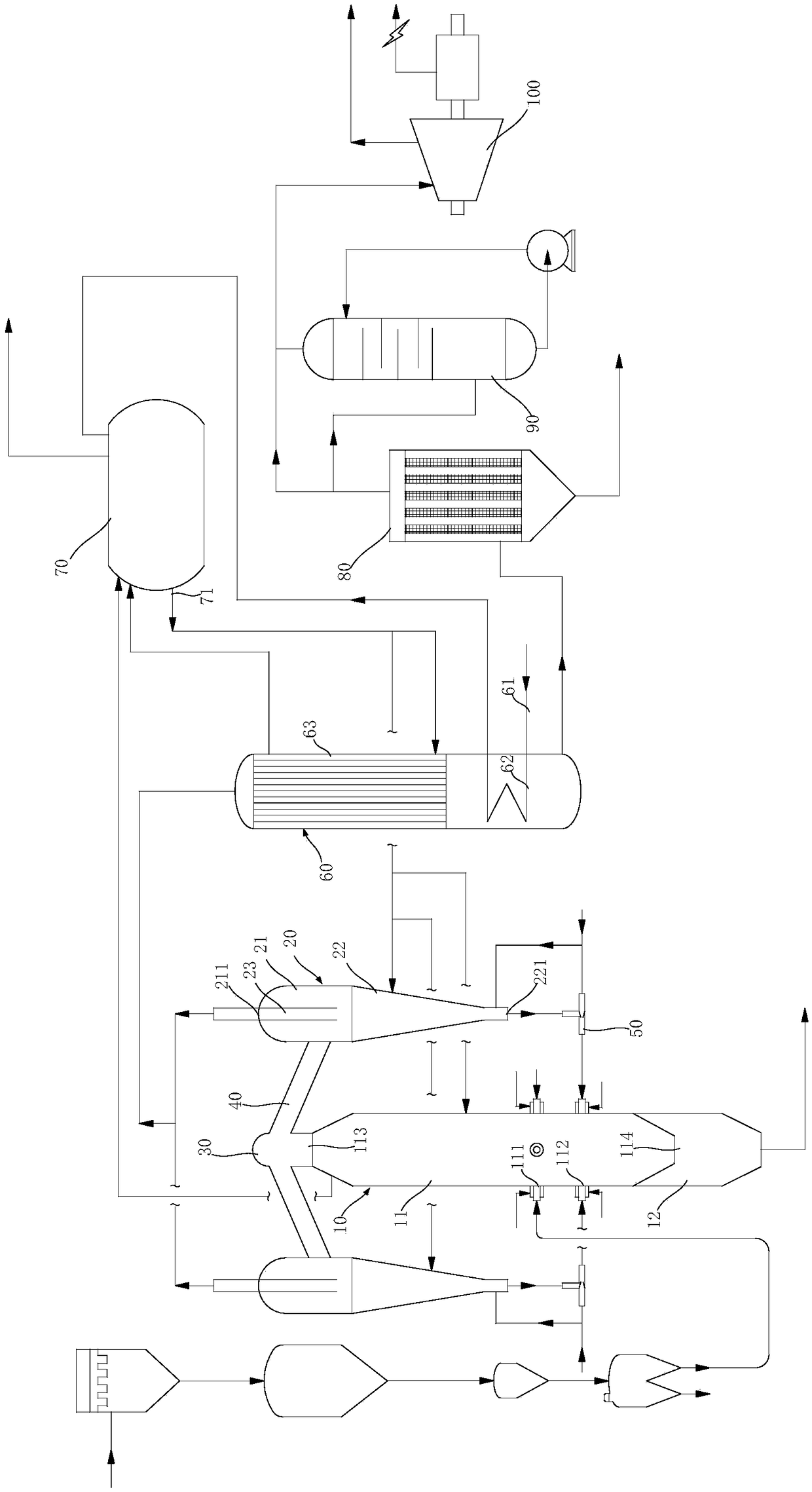

[0125] (1) Industrial gas preparation system

[0126] Such as figure 2 In the preparation system shown, the height of the gasification chamber 11 is 8D, the distance between the first nozzle 111 and the top of the gasification chamber 11 is 6D, and the distance between the first nozzle 111 and the second nozzle 112 is 2D; among them, the gasification scale 1500t dry coal / day, the operating pressure of the entrained bed gasifier is 0.4MPaG, the absolute pressure is 0.5MPa, the gasification scale / operating pressure of the entrained bed gasifier>1500t dry coal / day / MPa, cyclone separation The number of chambers 20 is a positive integer ≥ (1500t dry coal / day / 0.5MPa) / (1500t dry coal / day / MPa), so the number of cyclone separation chambers 20 in this embodiment is 2; the rest are the same The preparation system of Example 1.

[0127] (2) Preparation method of industrial gas

[0128] Using the preparation method of the above preparation system, the oxygen consumption is 25700Nm 3 / h, the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com