High-efficiency production technique for preparing fuel oil by pyrolyzing biomass

A biomass pyrolysis and production process technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of low pyrolysis yield, undeveloped production scale, immature technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

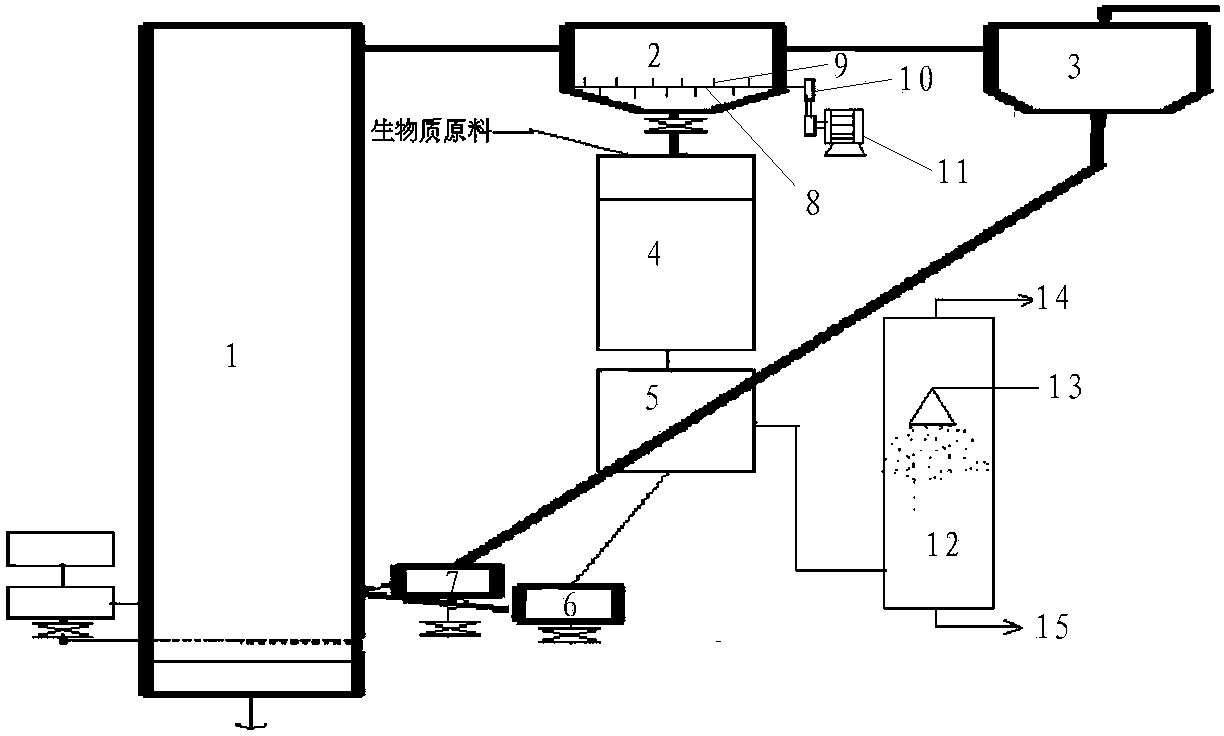

[0020] see figure 1 , firstly, a self-mixing downward circulating fluidized bed reaction device is given, which includes a fluidized bed regenerator 1, an inertial separator 2, a pyrolysis reactor 4, a semi-coke separator 6, and a semi-coke return device 6 connected in sequence Composed circulation system; the upper outlet of the inertia separator 2 is connected to the cyclone separator 3, and the lower outlet of the cyclone separator 3 is connected to the fluidized bed regenerator 1 through the heat carrier return device 7; the pyrolysis gas outlet of the semi-coke separator 5 Connected to the spray tower 12, the spray tower 12 is provided with a spray port 13 inside, a pyrolysis dry gas outlet 14 at the top, and a fuel oil outlet 15 at the bottom. A high-temperature heat transfer device is installed at the lower end of the inertia separator 2 at the solid material discharge port, which includes a motor 11 and a gearbox 10 to drive and rotate the material shaft 8 (the speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com