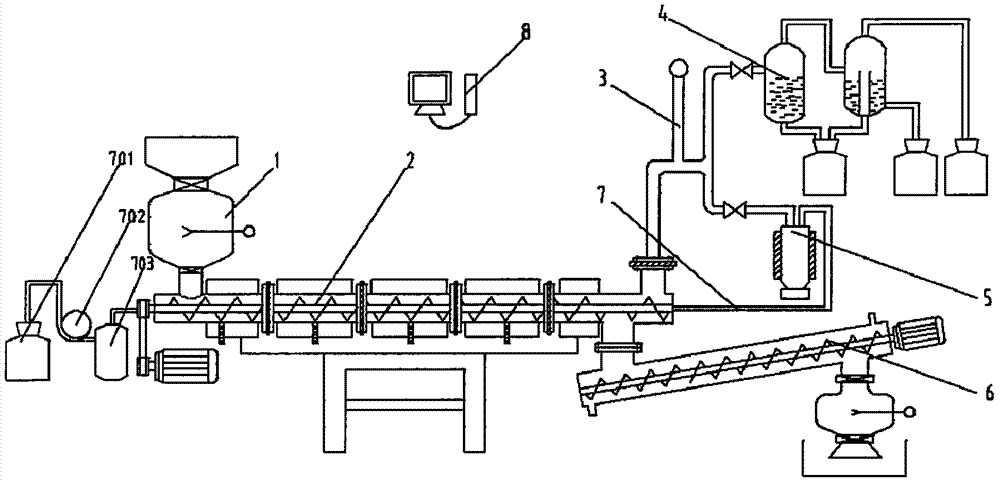

Variable step temperature adjustment biomass continuous carbonization equipment

A biomass and cascade technology, applied in biofuels, special forms of dry distillation, petroleum industry, etc., can solve problems such as uncontrollable heating rate, achieve the effects of avoiding errors, uniform heating, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Example: Production of biochar using corn stalks

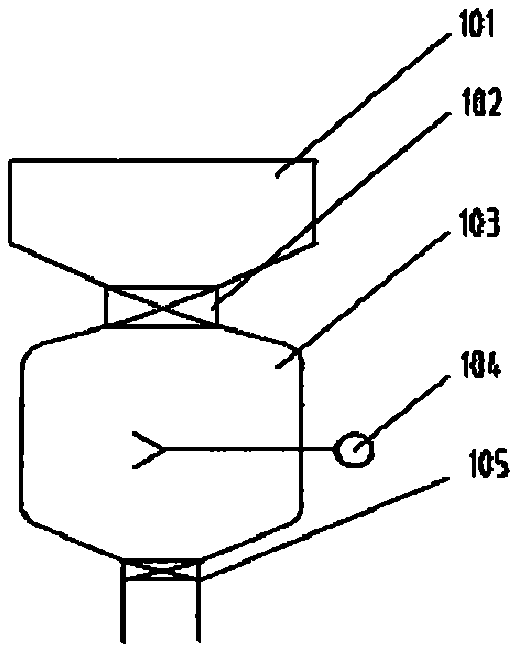

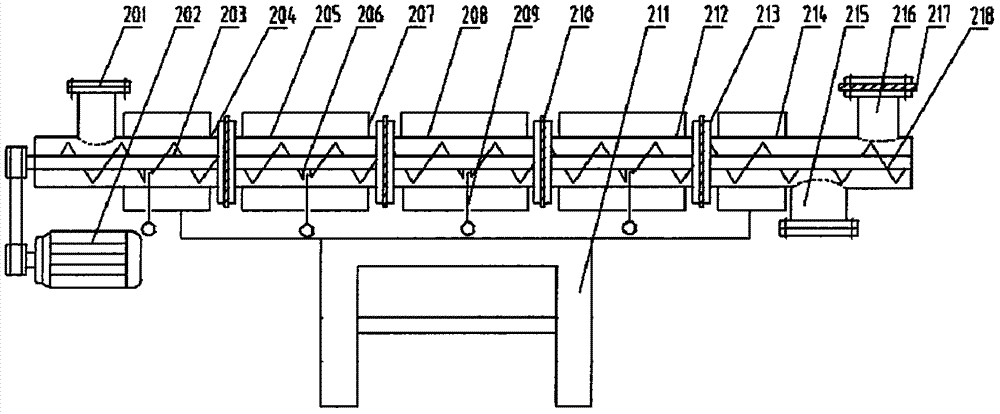

[0037] Biochar is produced by adopting the variable step temperature-adjusted biomass continuous carbonization equipment of the present invention, the raw material is corn stalks, the length is about 3-4mm, the moisture content is 10-20%, and the density is about 100kg / m 3 , first close the lower airtight valve of the feeding device, open the upper airtight valve, temporarily store the raw materials in the lower silo, and then open the upper airtight valve and the lower airtight valve alternately after the reaction starts. Then turn on the heating wire switch of the pyrolysis furnace to heat the temperature of each section of the furnace wall to the set value, and at this time open the feed valve and the feed variable frequency motor. The temperature rise rate and the final pyrolysis temperature of the biomass raw material are controlled by different temperature settings at each stage of the pyrolysis furnace and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com