Patents

Literature

71results about How to "Does not affect normal delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

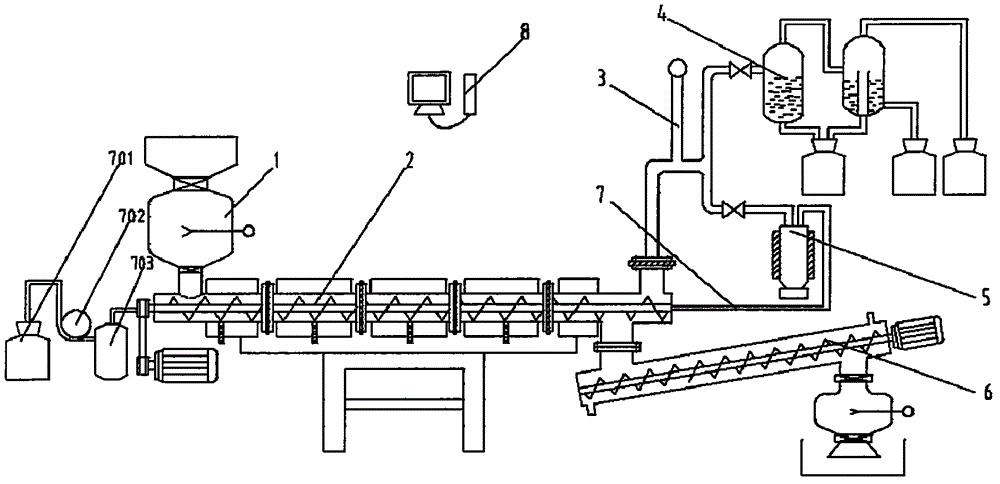

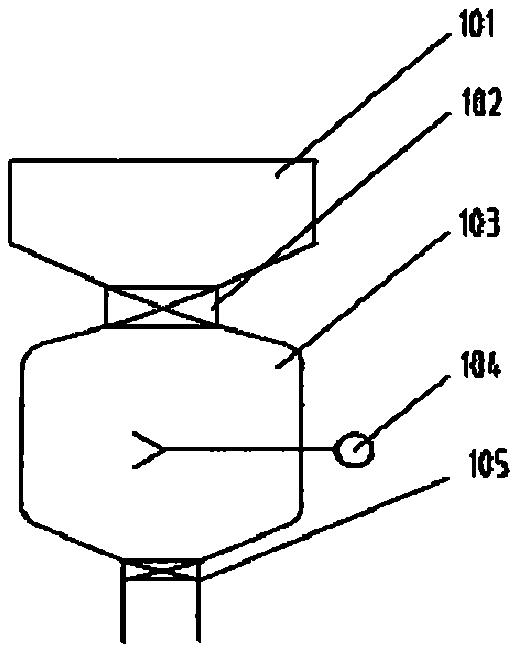

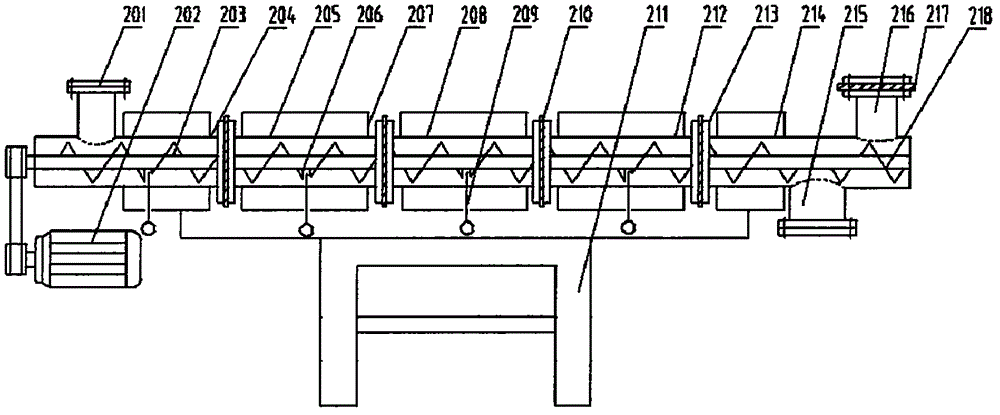

Variable cascade temperature regulation biomass charring device

InactiveCN104861995AMeet the requirements of different heating ratesSolve the problem that the heating rate cannot be adjustedBiofuelsEnergy inputControl systemSeparation technology

The invention discloses a variable cascade temperature regulation biomass charring device. The device mainly comprises a feeding unit, a segmented pyrolysis unit, an oil-gas separation unit, a secondary catalytic cracking unit and a waste heat reuse unit. The whole process is regulated through a reaction control system, and the continuous performing of the pyrolytic reaction is guaranteed through continuous sealed feeding and discharging. According to the pyrolysis portion, a variable cascade segmented heating principle is used, so that multi-stage regulation among different heating sections of a pyrolyzing furnace is achieved, and the requirement for different heating speeds during pyrolysis is met. Meanwhile, the pyrolysis gas condensation separation technology, the secondary catalytic cracking tar removing technology, the charcoal continuous cooling technology, the high-temperature pyrolysis gas waste heat reuse technology, the internal and external combined heating pyrolysis charring technology and the like are integrated. The device is applicable to pyrolysis charring of various biomasses in different conditions.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

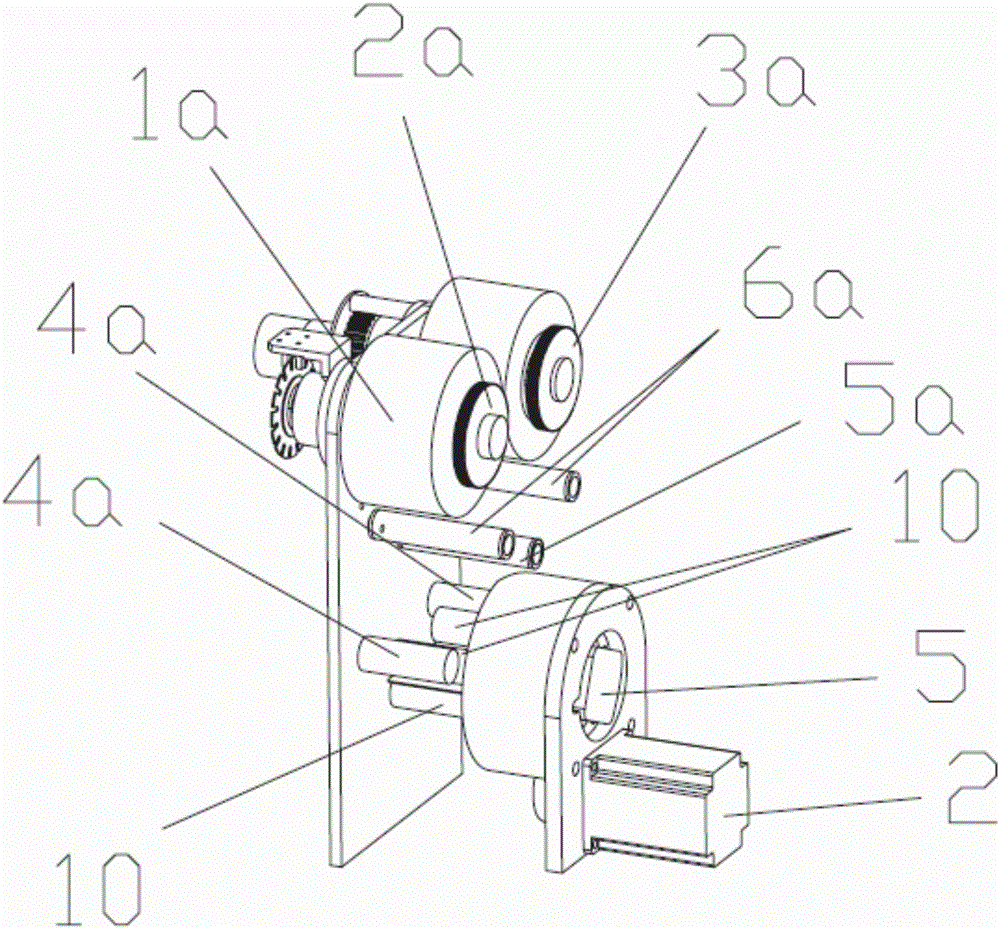

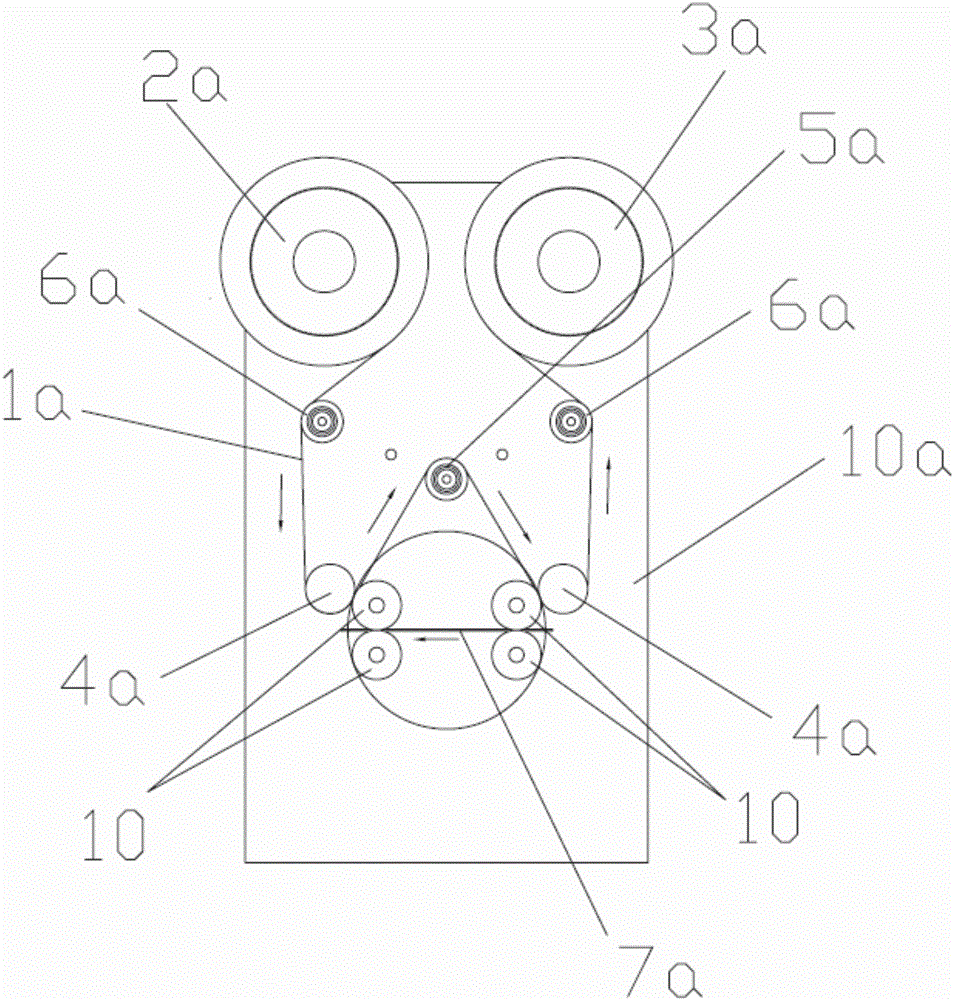

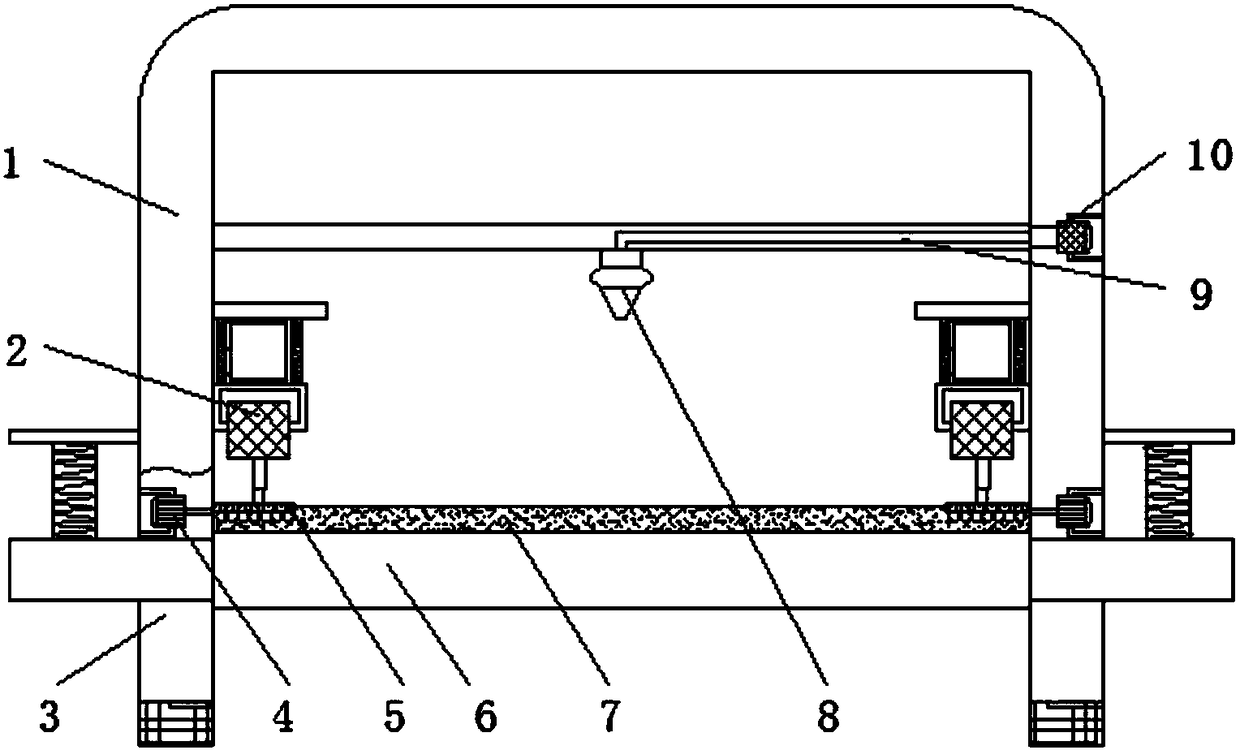

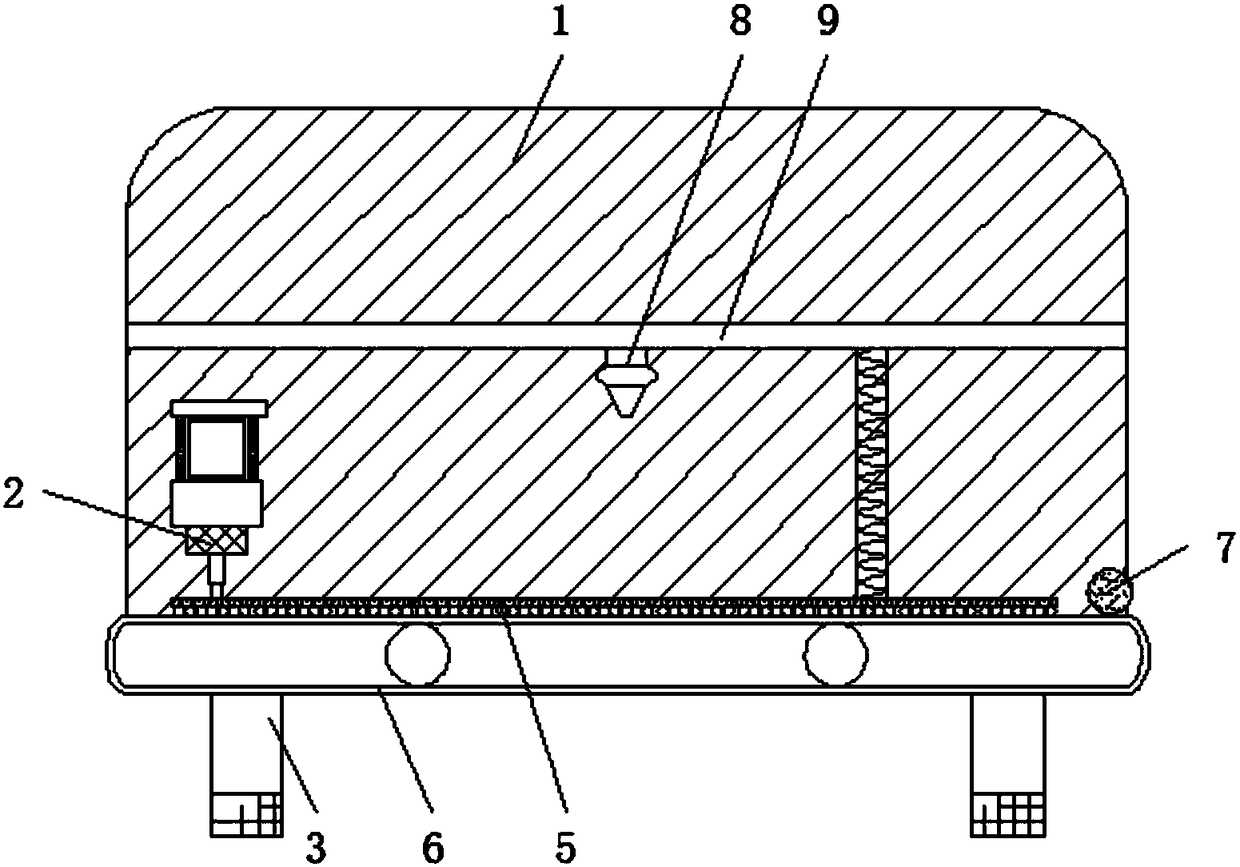

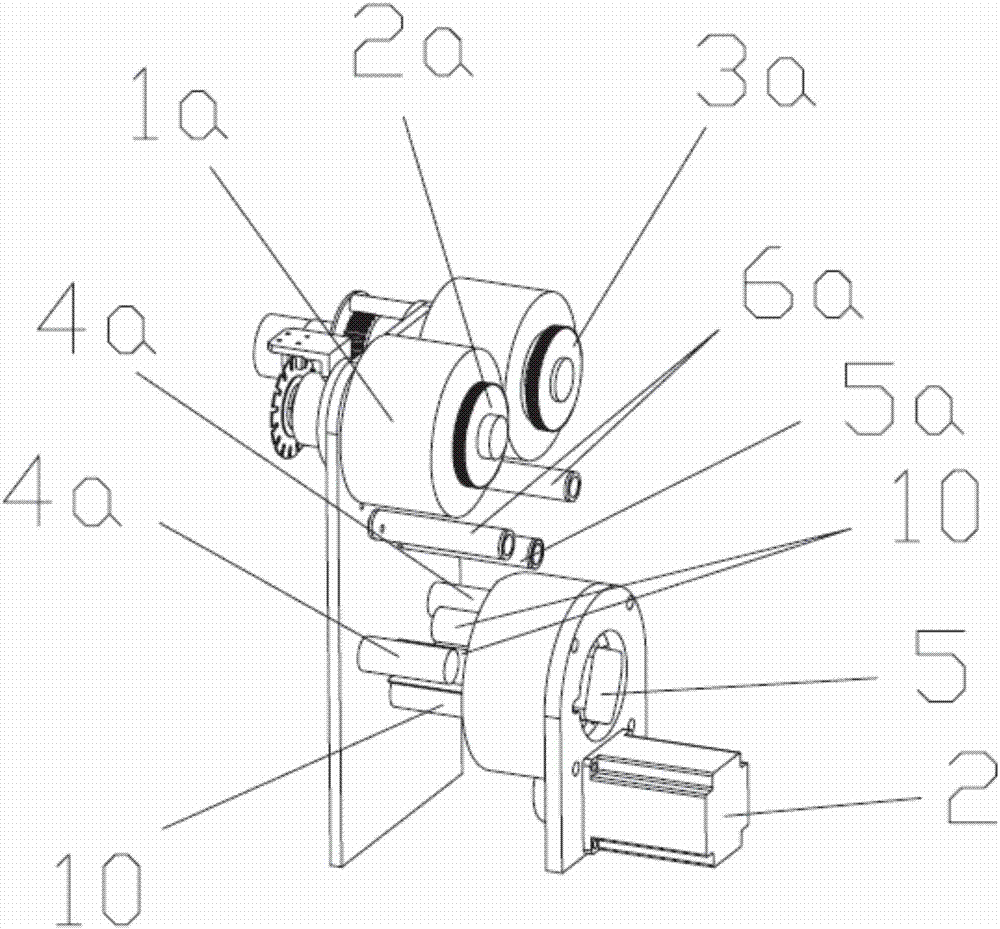

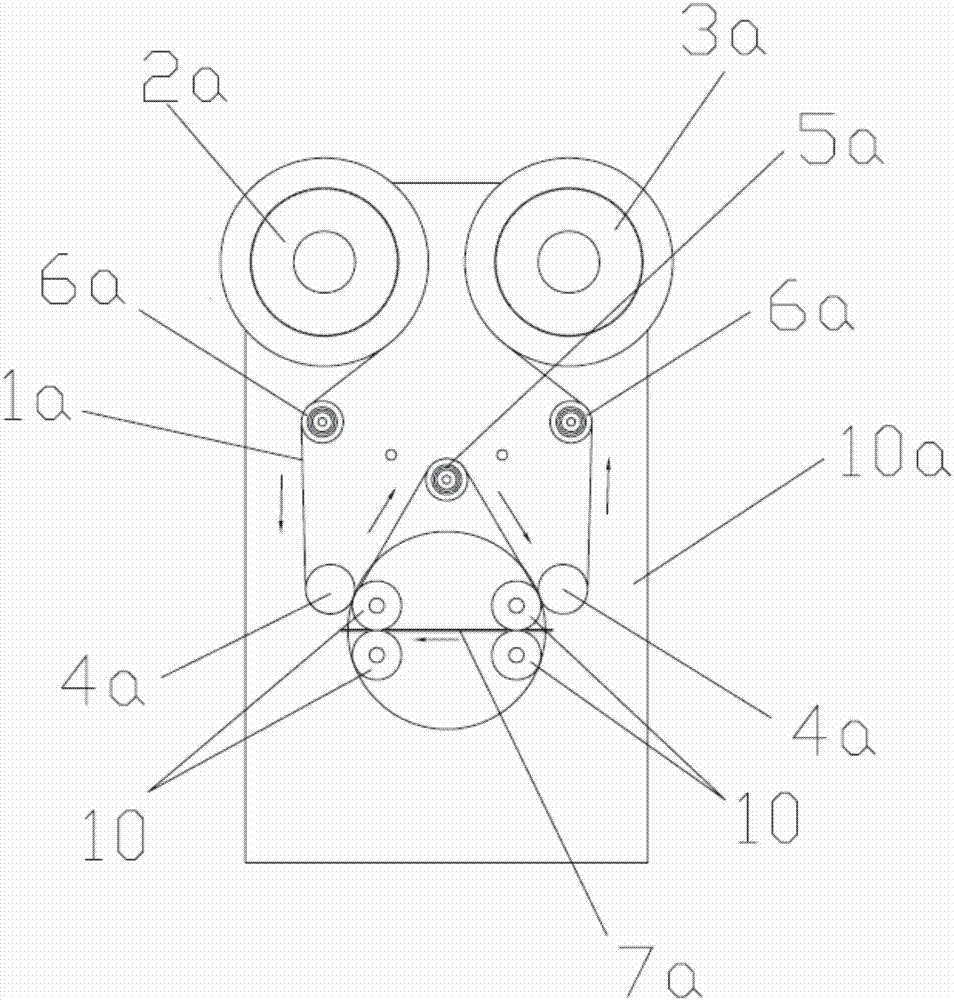

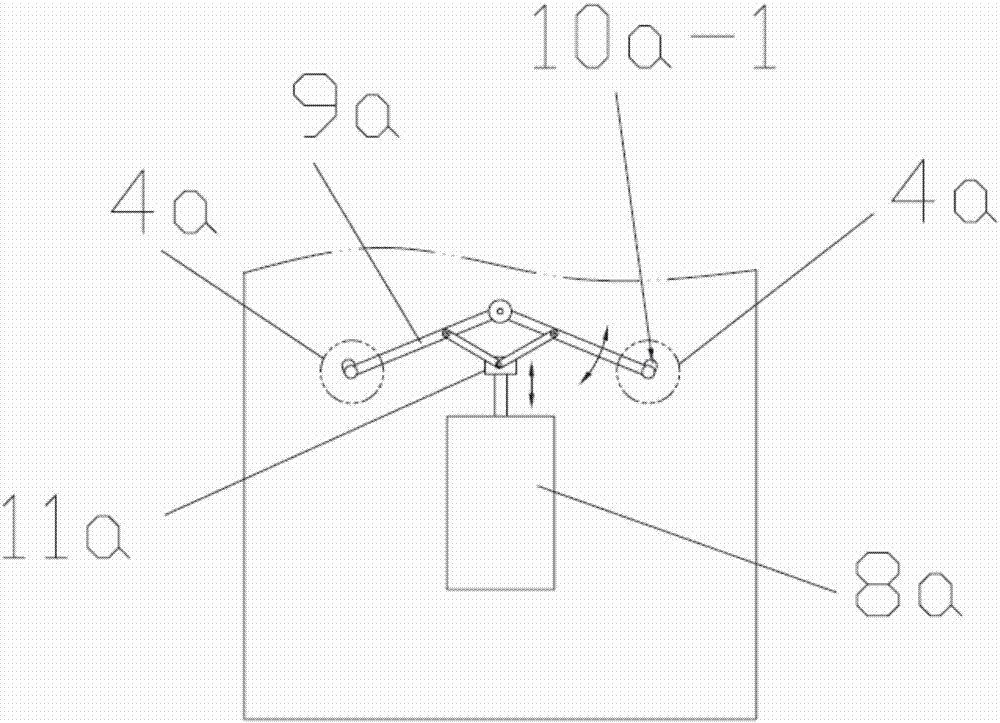

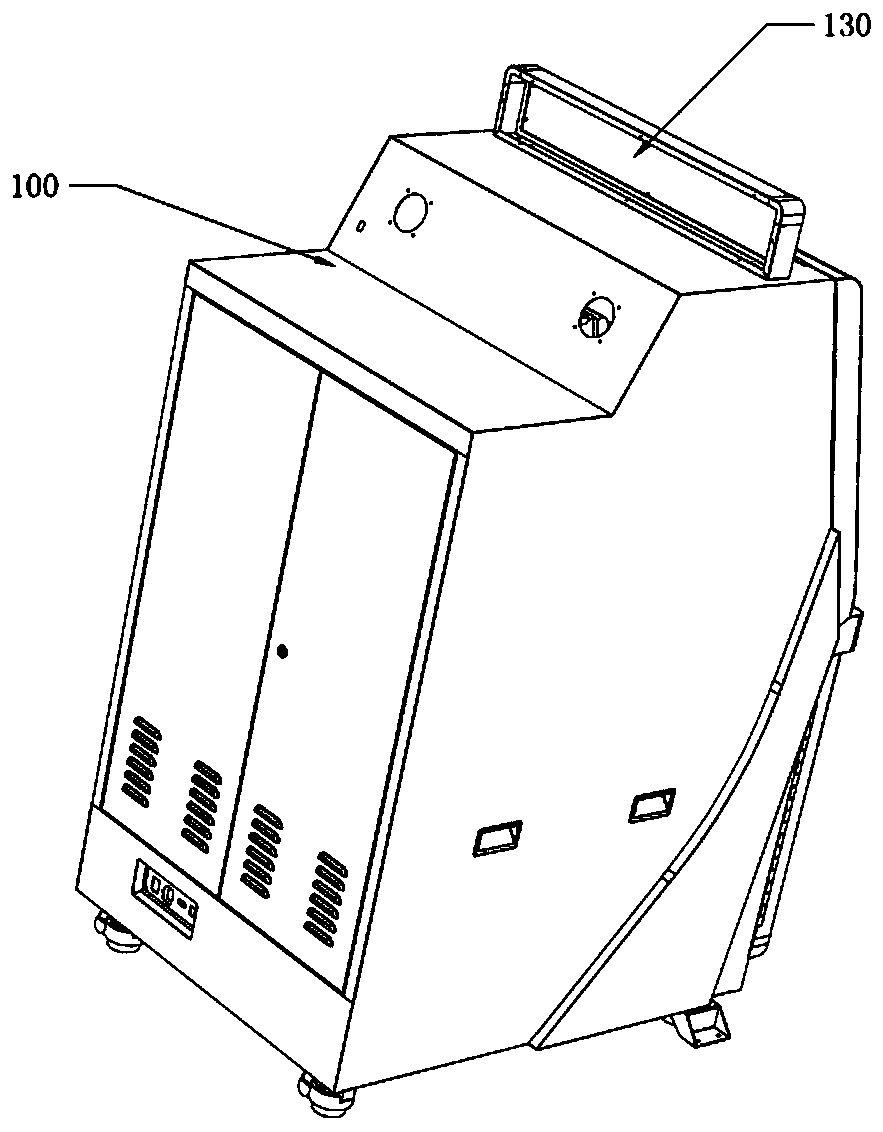

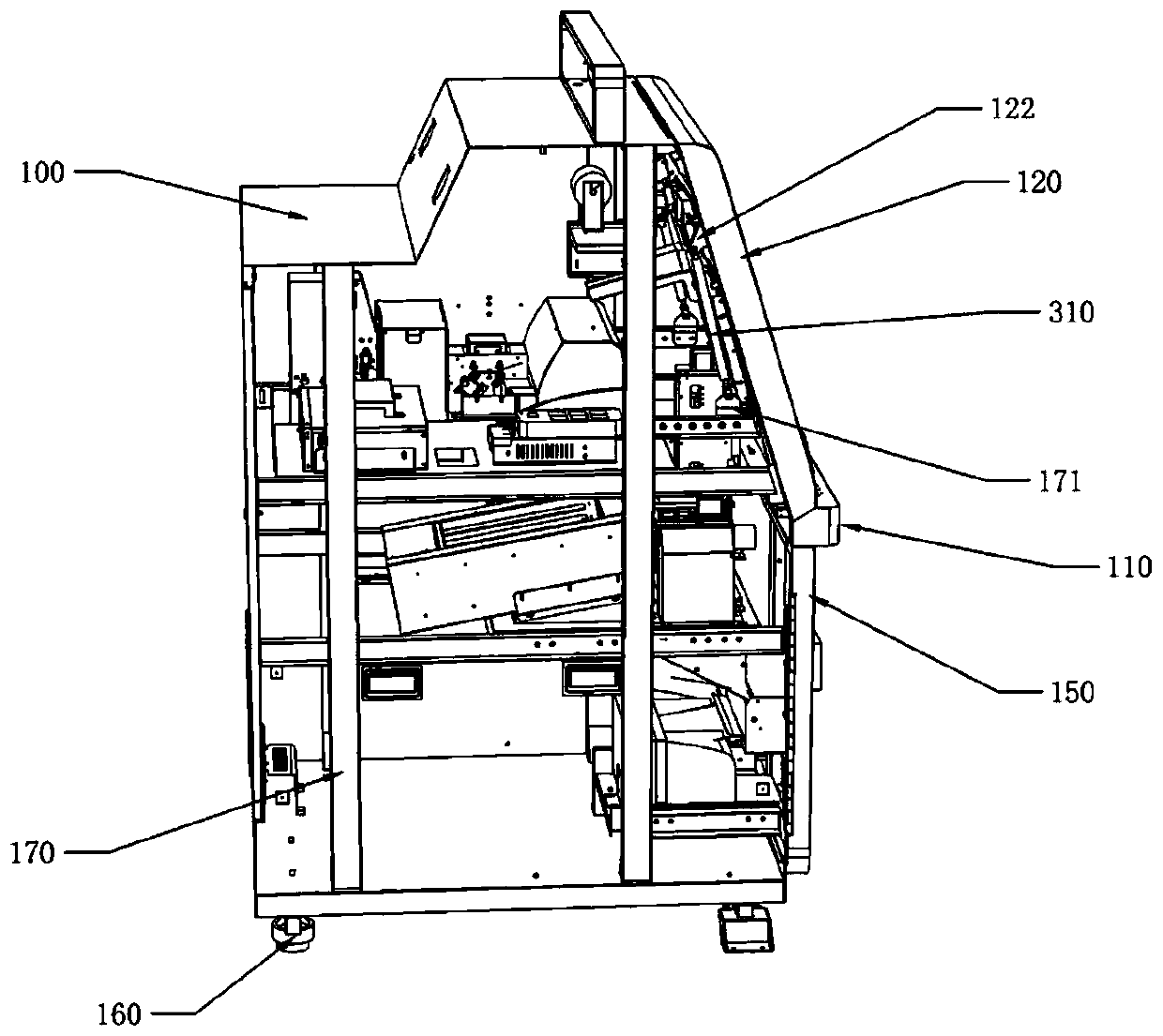

Intelligent card cleaning device capable of cleaning upper cleaning wheels and lower cleaning wheels

InactiveCN105149252ASame cleaning effectDoes not affect normal deliveryCleaning using toolsEngineeringSmart card

Owner:GUANGZHOU MINGSEN TECH CO LTD

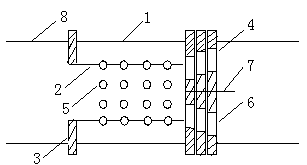

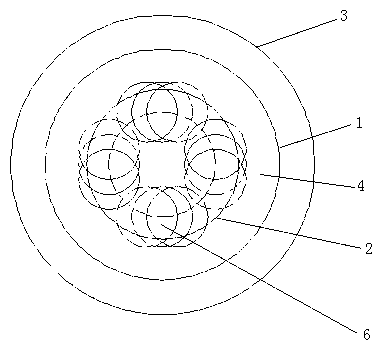

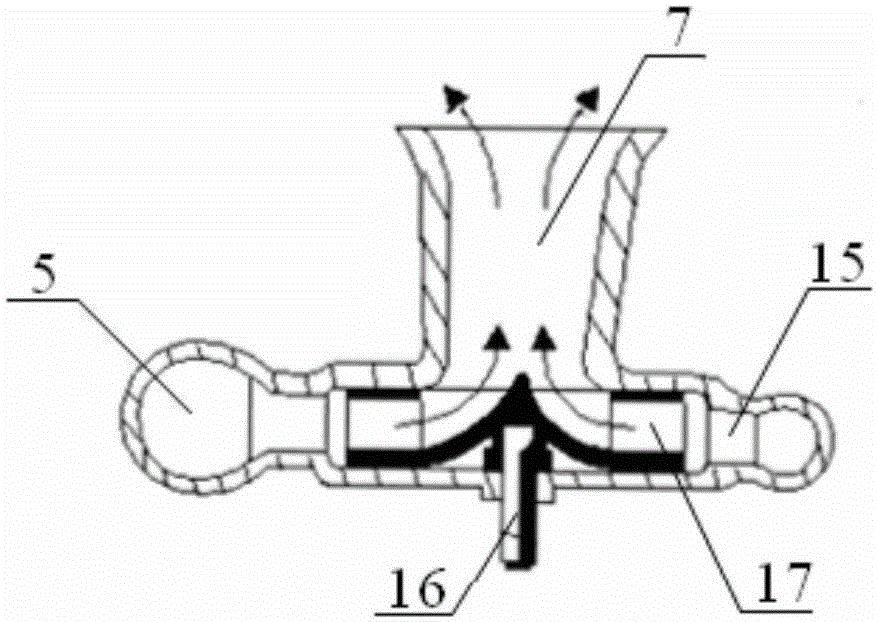

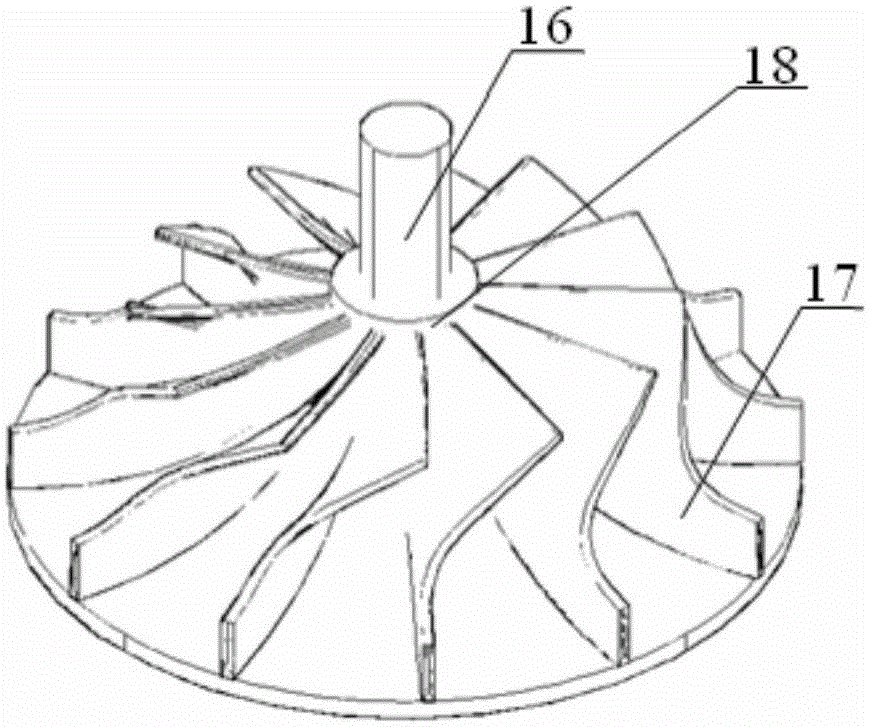

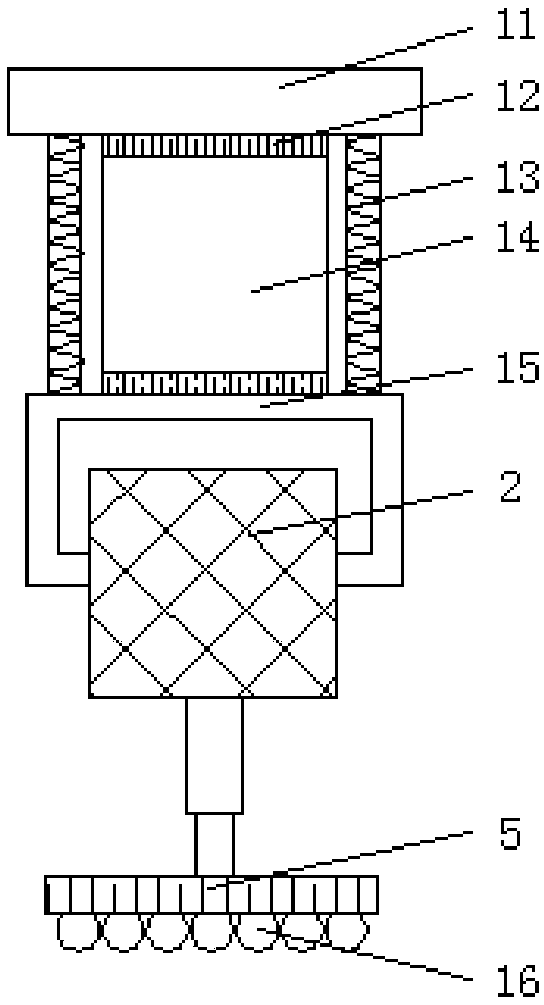

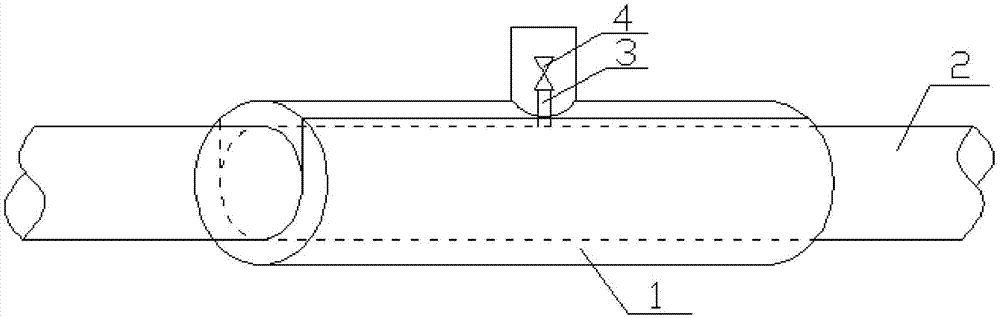

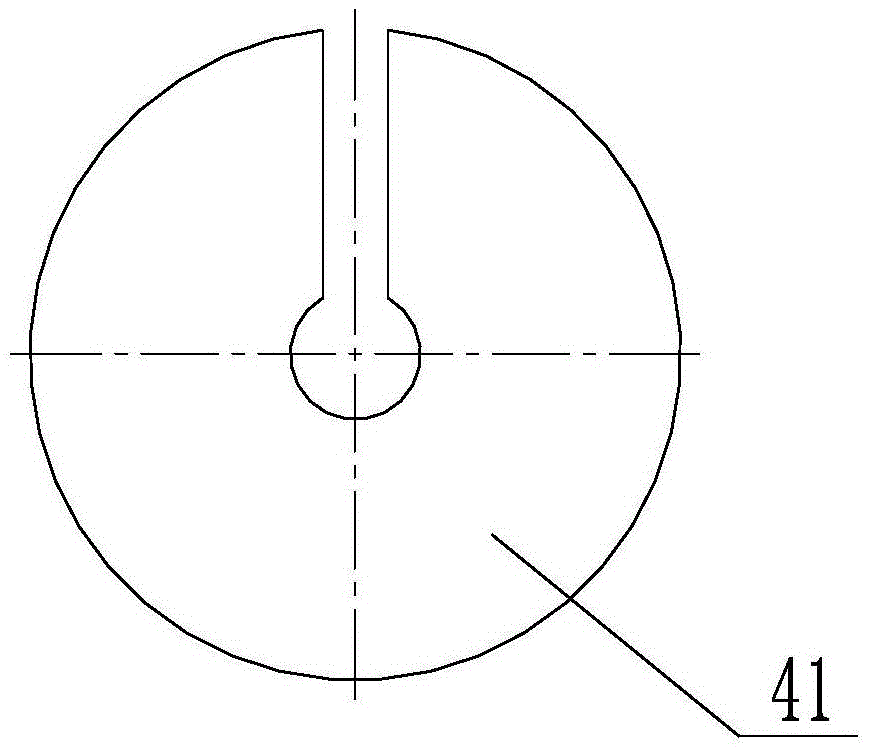

Hole plate mixed spiral flow pipeline energy dissipating device

InactiveCN102705626ALarge adjustment rangeOvercoming Vibration DeficienciesPipe elementsRotational axisEngineering

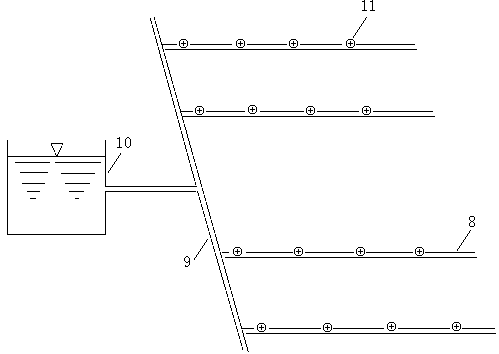

The invention relates to a hole plate mixed spiral flow pipeline energy dissipating device which belongs to the technical field of pipeline water transmission and is characterized in that the hole plate mixed spiral flow pipeline energy dissipating device is in a screen mesh type. The hole plate mixed spiral flow pipeline energy dissipating device consists of an outer pipe 1, an inner pipe 2, a flange 3, a hole plate 4, inclined holes 5, non-inclined holes 6 and a rotating shaft 7, wherein the outer pipe 1 is concentrically connected with the inner pipe 2 through the flange 3, the inclined holes 5 are symmetrically and uniformly formed around the inner pipe 2 in accordance with inclination angles, the inner pipe 2 is connected with the first hole plate 4, the hole plates 4 are connected through the rotating shaft 7 which coincides with the central axis of the outer pipe 1, and each non-inclined hole 6 is formed on each hole plate 4 in the axis direction. According to the hole plate mixed spiral flow pipeline energy dissipating device, the adjusting range of pipeline energy dissipation is greatly increased in a condition that the water transmission flow is not affected, so that the axial and circumferential force balance of the energy dissipating device is realized, the defect of pipe vibration in the process of energy dissipation is completely overcome, the safety and stability of a water transmission system are guaranteed, and the service life is prolonged.

Owner:TAIYUAN UNIV OF TECH

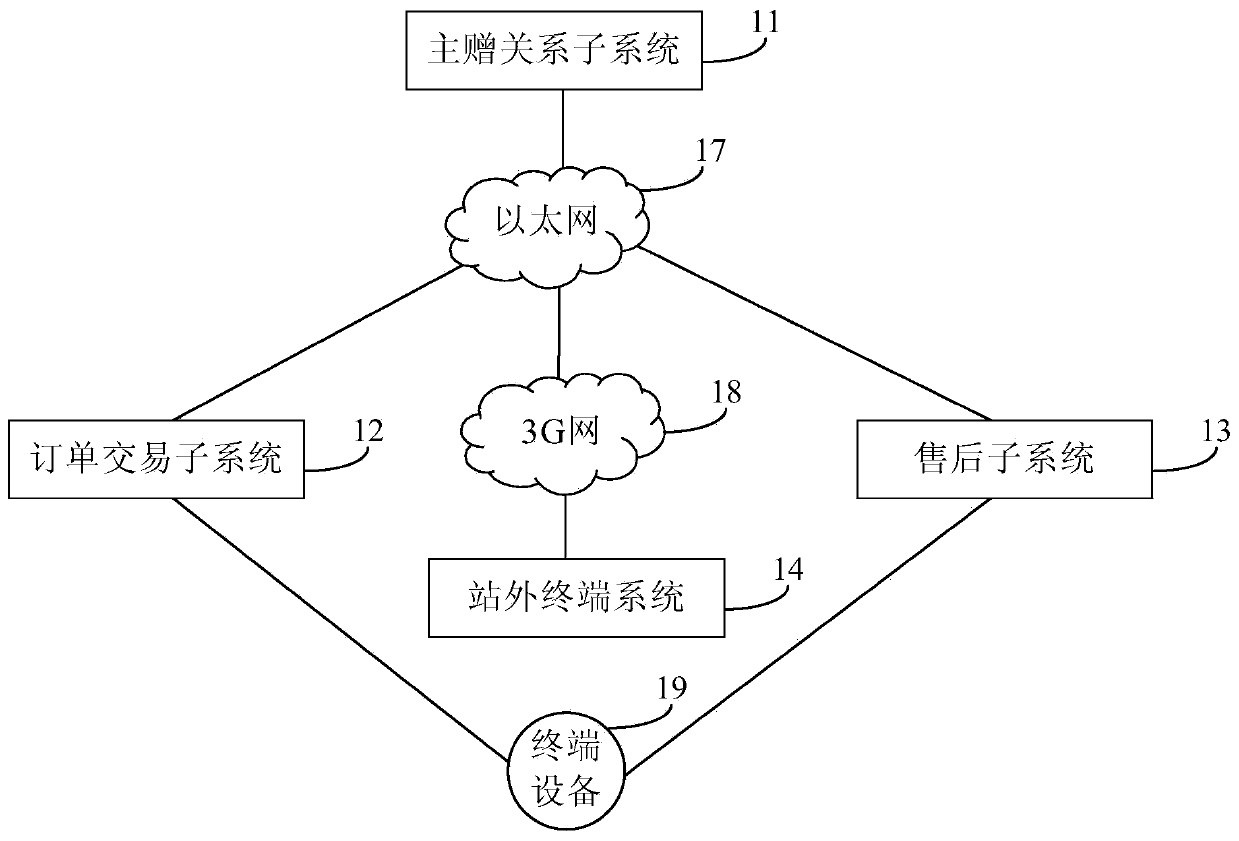

Method, system and terminal device for order processing

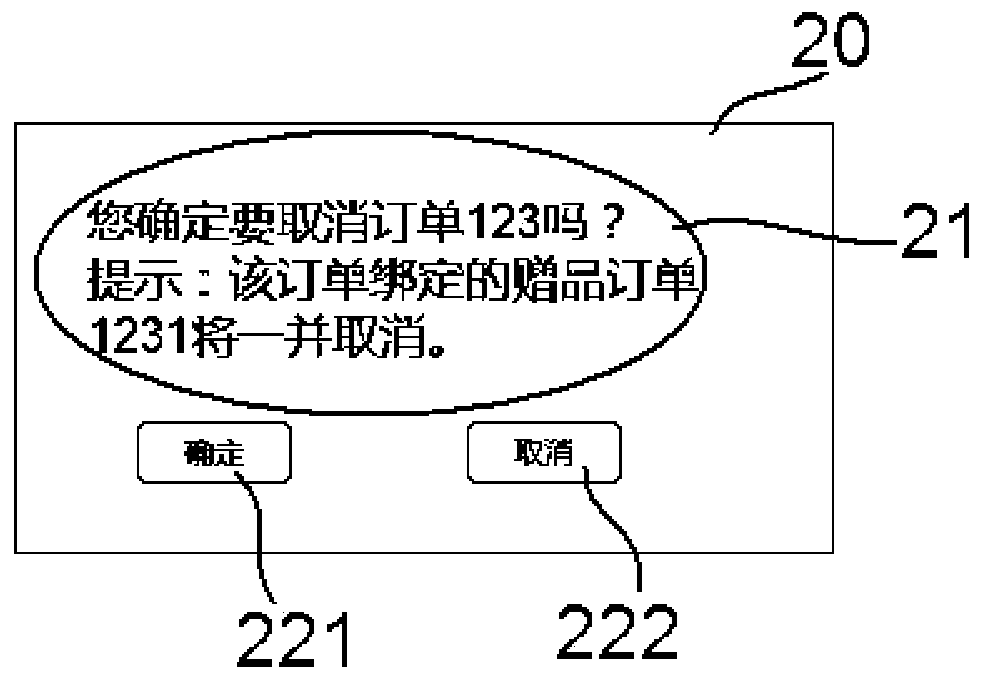

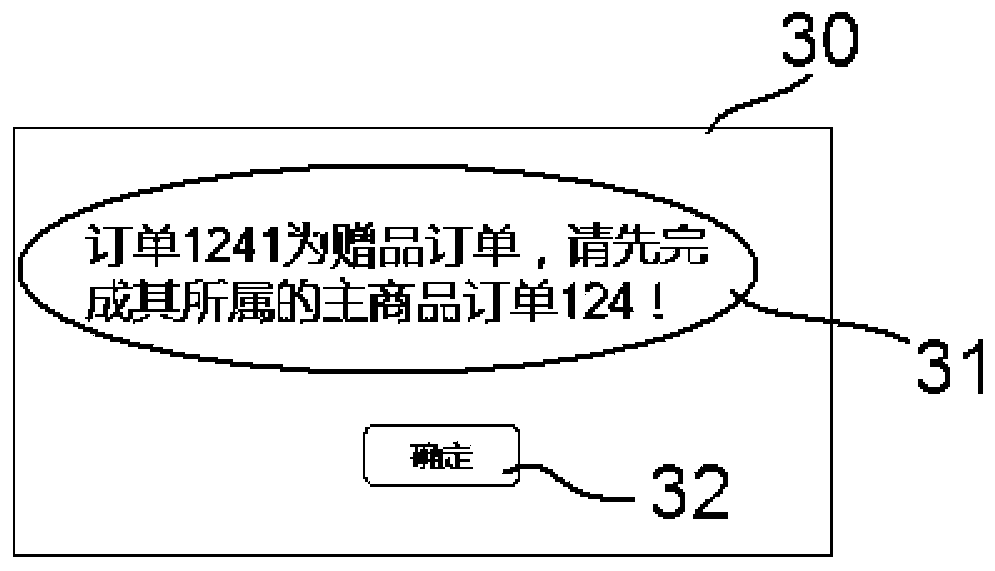

InactiveCN104408628AGuaranteed experienceAvoid gettingCommerceProcess systemsHuman–machine interface

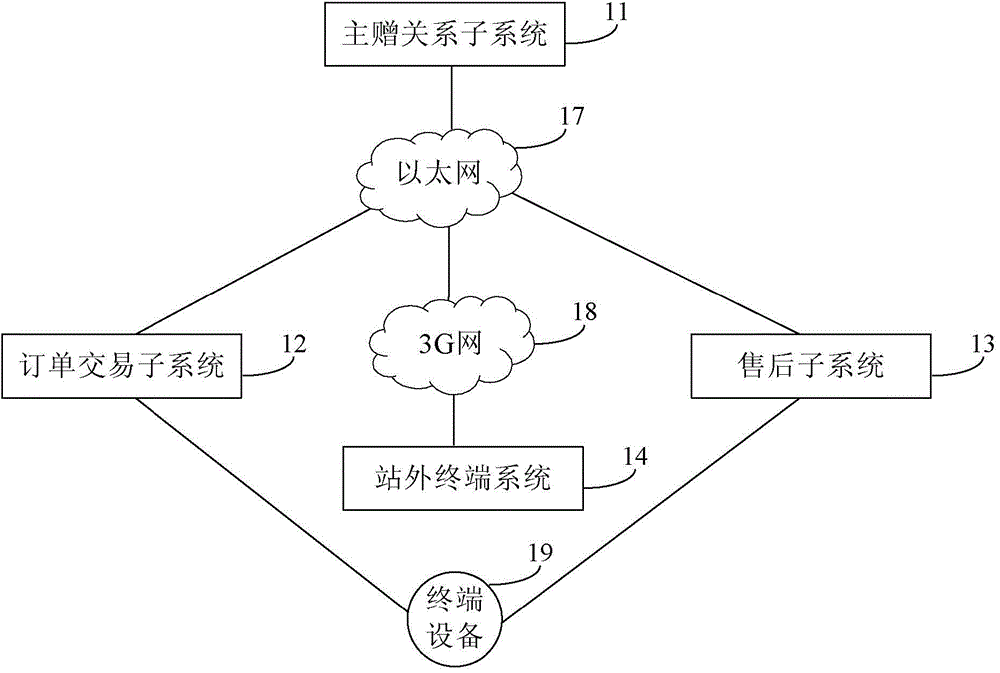

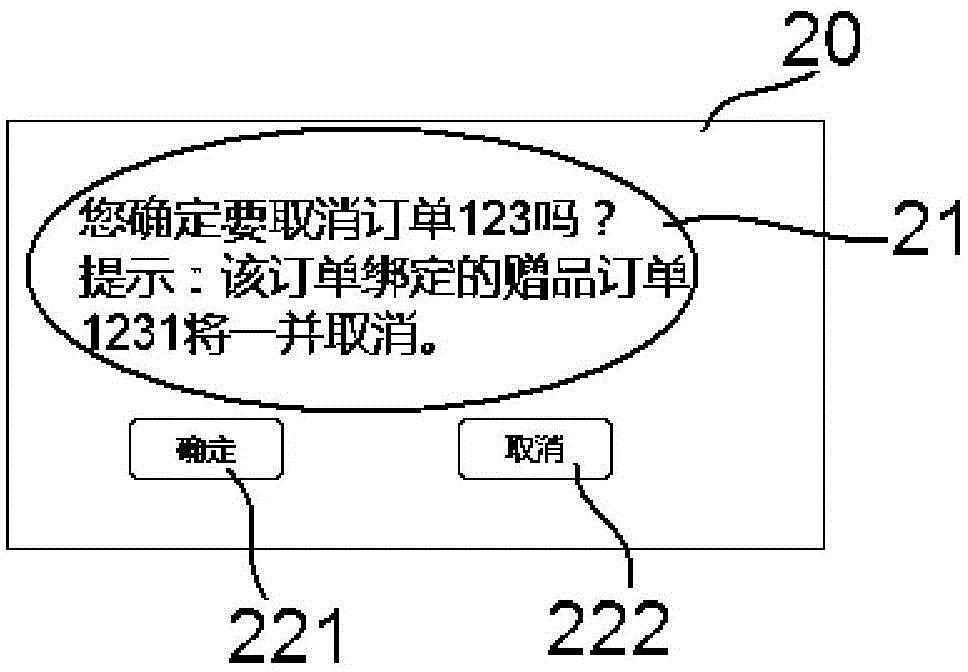

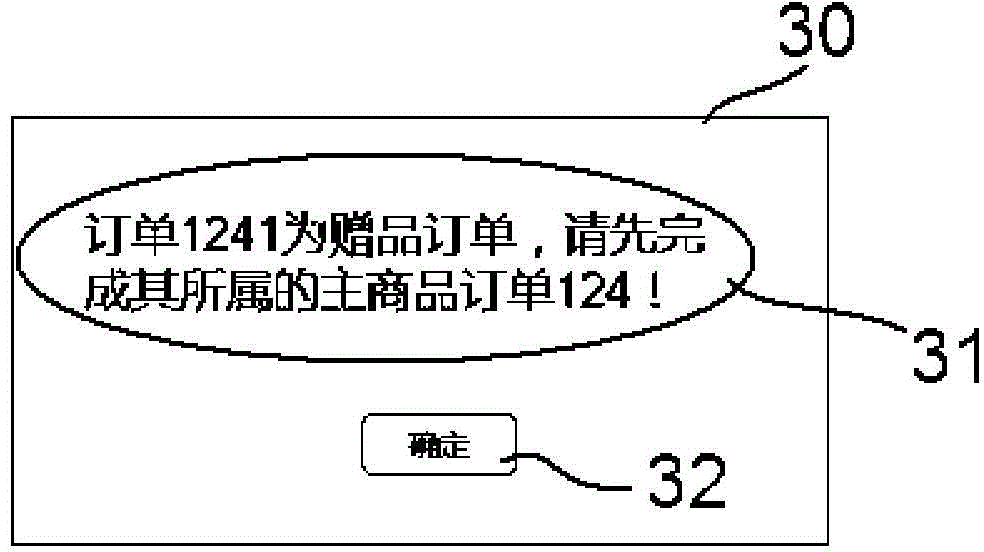

The invention provides a method, a system and a terminal device for order processing, can effectively prevent order division benefit arbitrage behaviors in electronic commerce, further saves manpower and does not influence client experience. The order processing system comprises a main gift relation subsystem used for correspondingly recording a main goods order number and a gift order number after order division and checking whether the received order number is the recorded main goods order number, an order transaction subsystem used for requesting the main gift relation subsystem to check whether the number of a canceled order is the recorded main goods order number after order cancellation information sent by a client is received, if yes, data of a first man-machine interface is outputted, the first man-machine is used for presenting first prompting information for prompting simultaneous cancellation of a main goods order and a gift order and enabling the client to confirm or cancel order cancellation operation.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

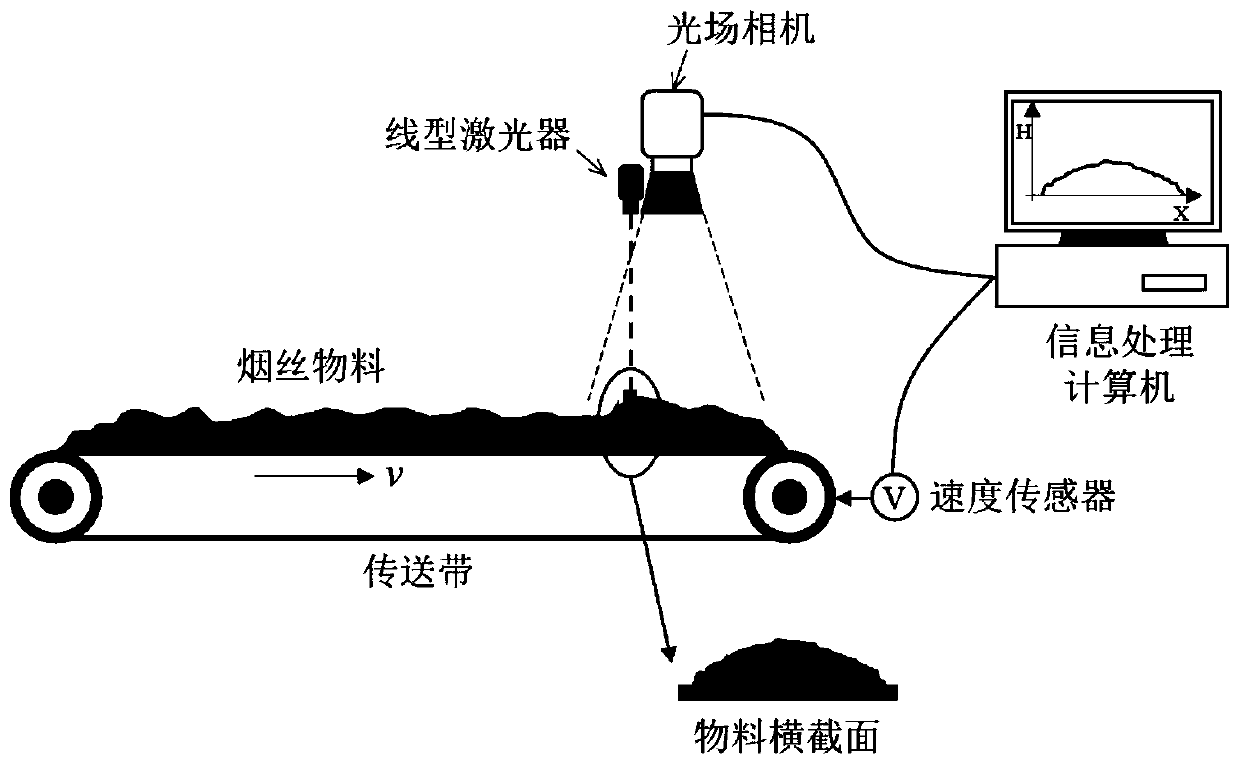

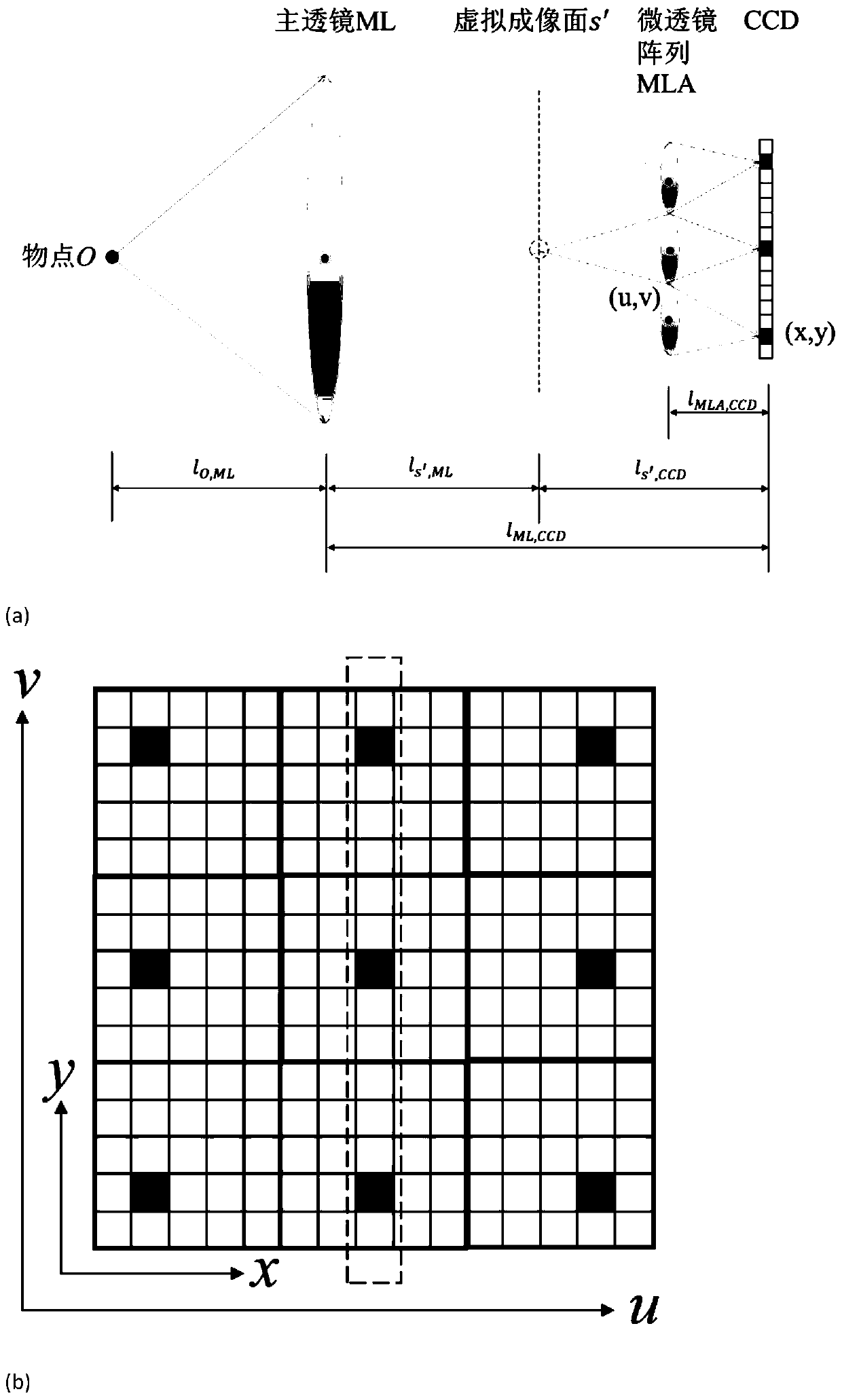

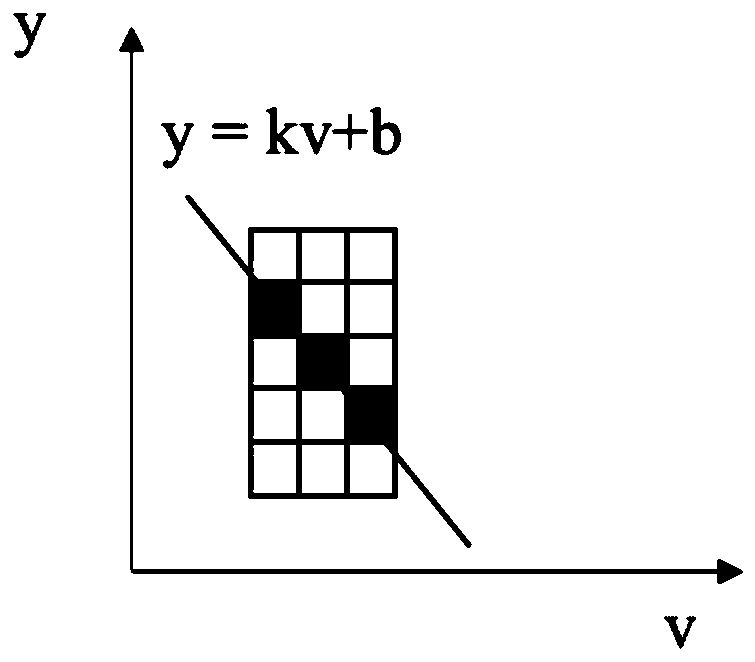

Method and system for detecting tobacco shred material flow on conveying belt based on light field imaging

ActiveCN110648345ADoes not affect normal deliveryAvoid System Complexity LimitationsImage analysisVolume measurement and fluid deliveryInformation processingEngineering

The invention discloses a method and a system for detecting tobacco shred material flow on a conveying belt based on light field imaging. Tobacco shred material flow on a conveying belt is detected inreal time through a detection system composed of a light field camera, a linear laser, a speed sensor and an information processing computer. The light field camera is used for collecting light fieldinformation of tobacco shred particles to achieve tobacco shred height detection, and the laser is used for enhancing surface texture of the tobacco shred particles to improve measurement accuracy. The speed sensor is used for measuring advancing speed of the conveying belt in real time; and the information processing computer performs data processing on the acquired light field information to obtain the section height of the tobacco shreds and calculates the volume flow of the tobacco shreds according to the speed of the conveying belt. The invention has the advantages that non-contact nondestructive measurement is adopted, normal conveying of tobacco shred materials is not affected, a detection system is simple, system complexity caused by the fact that two or more cameras are needed ina traditional visual detection technology is avoided, the method has the advantages of instantaneity and visualization, and the measurement accuracy is high.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

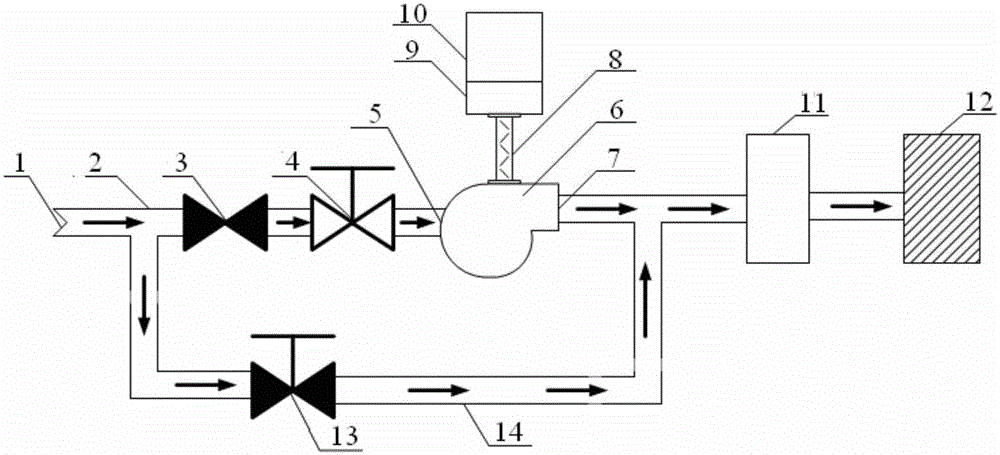

Steam pressure reduction power generation device

InactiveCN105156157AReduce operation and maintenance workloadImprove operational efficiencyBlade accessoriesStatorsSteam pressureEngineering

The invention discloses a steam pressure reduction power generation device which comprises a high-pressure steam inlet and a low-pressure steam device. A radial steam turbine is arranged on a steam pipeline between the high-pressure steam inlet and the low-pressure steam device and connected with a generator. According to the technical problem, superfluous energy in the steam pressure reduction process is recycled, and good energy saving benefits are generated. The generator can be driven to achieve power generation or a water pump, a fan and other energy consumption devices are dragged. The radial steam turbine has the beneficial effects of being low in maintenance workload, low in cost and high in running efficiency. A normal close bypass pipeline is adopted, and when a generator set breaks down and is maintained, a bypass steam pipeline is opened, and normal steam delivery of a factory is not influenced. The generator set needs no energy except steam or other running costs. When downstream steam users intermittently use steam, and pulsation of steam in pipes is caused, a steam storage tank is utilized for buffering pulsation of the steam, and the running stability of the radial steam turbine is improved.

Owner:安徽新宁能源科技有限公司

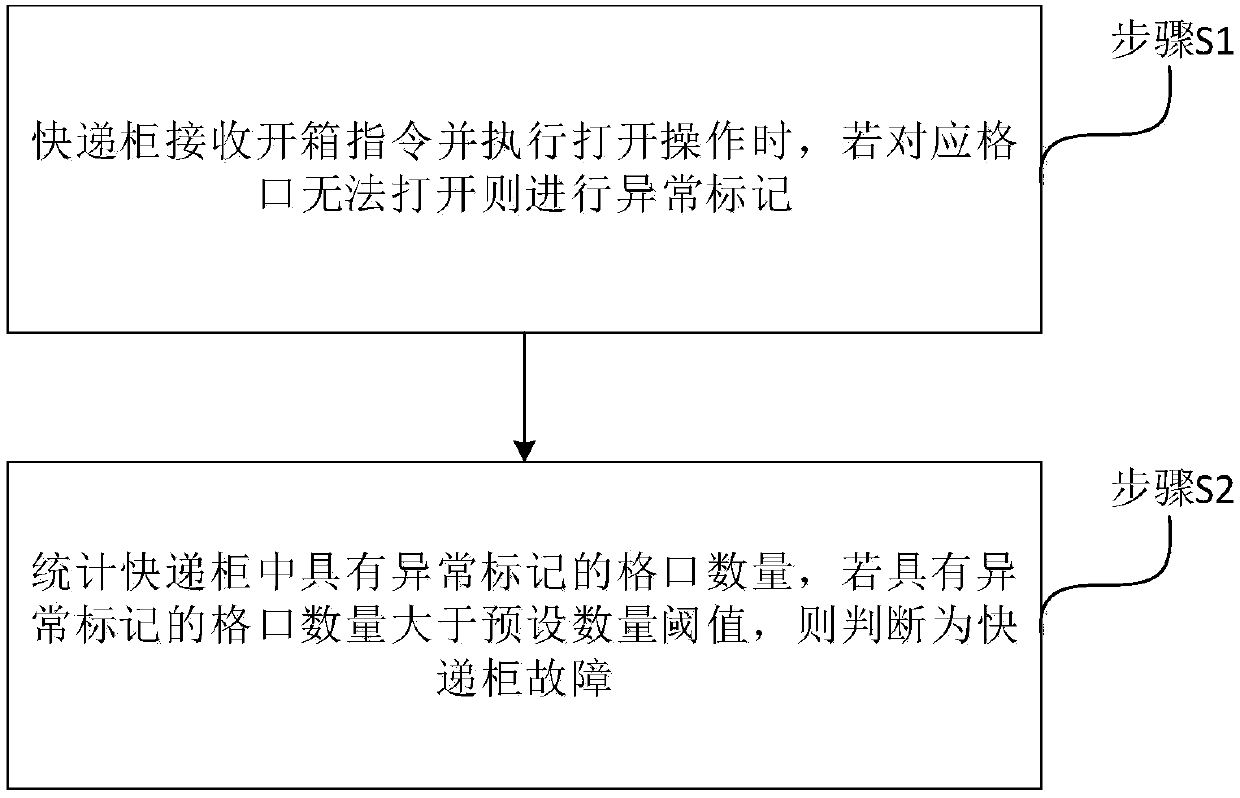

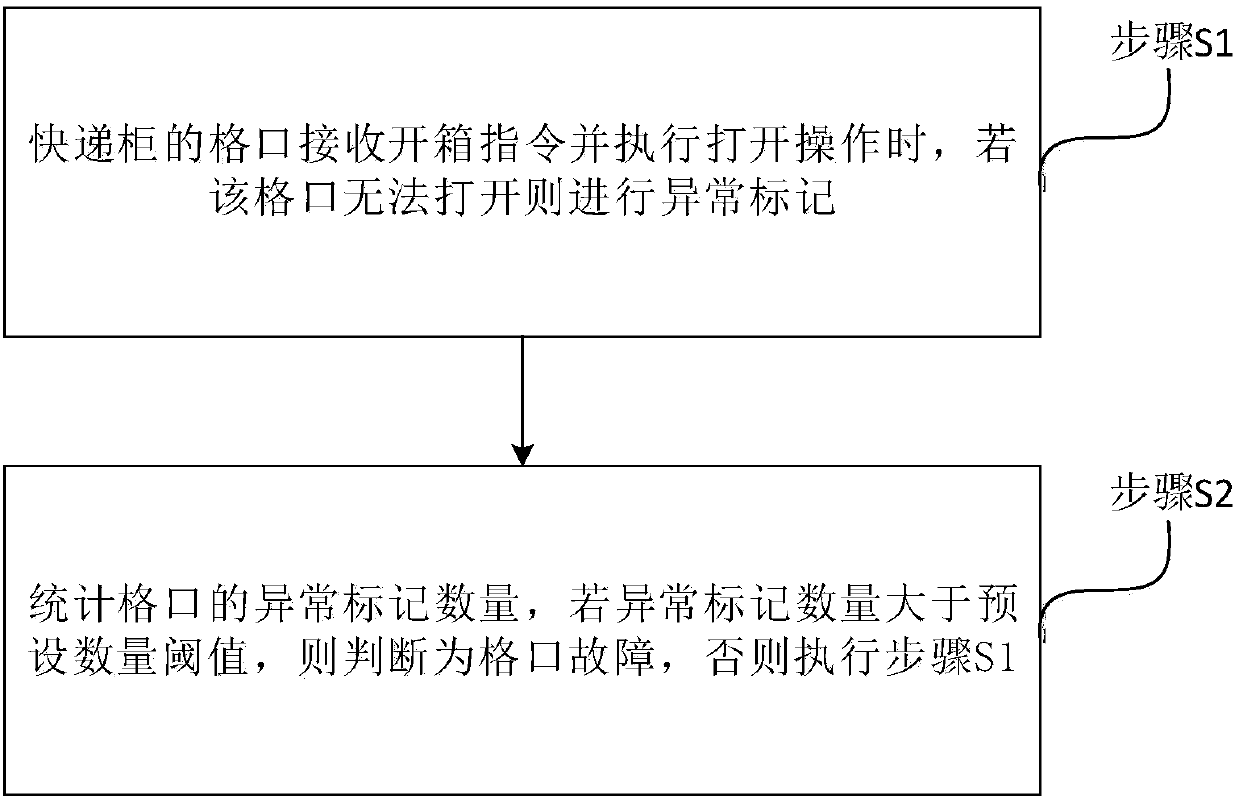

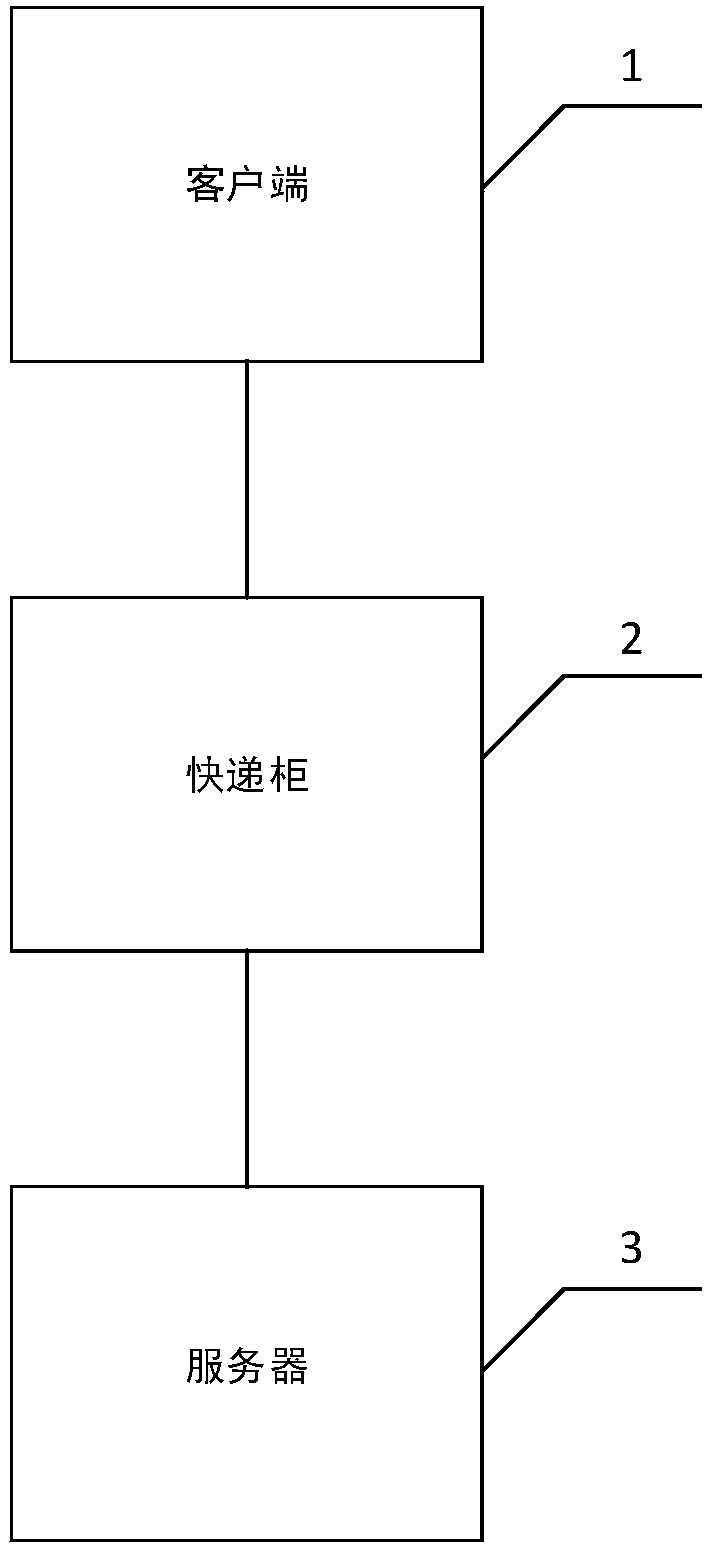

Express cabinet fault judgment method and device

InactiveCN107862388ADoes not affect normal deliveryThe method is simple and fastLogisticsMaterial resourcesTroubleshooting

The invention belongs to the technical field of express cabinets and particularly relates to an express cabinet fault judgment method and device. The invention aims to solve problems of large consumption of time, manpower and material resources to judge whether a smart express cabinet is failed by manpower. The invention provides the express cabinet fault judgment method. The express cabinet comprises multiple lattices. The method comprises a step of carrying out abnormal marking if a corresponding lattice can not be opened when the express cabinet receives a cabinet opening instruction and executes an opening operation, and a step of counting the number of lattices with abnormal marks, and judging that the express cabinet is failed if the number of lattices with the abnormal marks is larger than a preset number threshold. According to the express cabinet fault judgment method provided by the invention, the troubleshooting is carried out without professional maintenance personnel, themethod is simple and quick, and time, manpower and material resources are saved. The invention also provides an express cabinet lattice fault judgment method, a storage device and a processing devicewith the above advantages.

Owner:ZHONGKE FUCHUANG BEIJING TECH

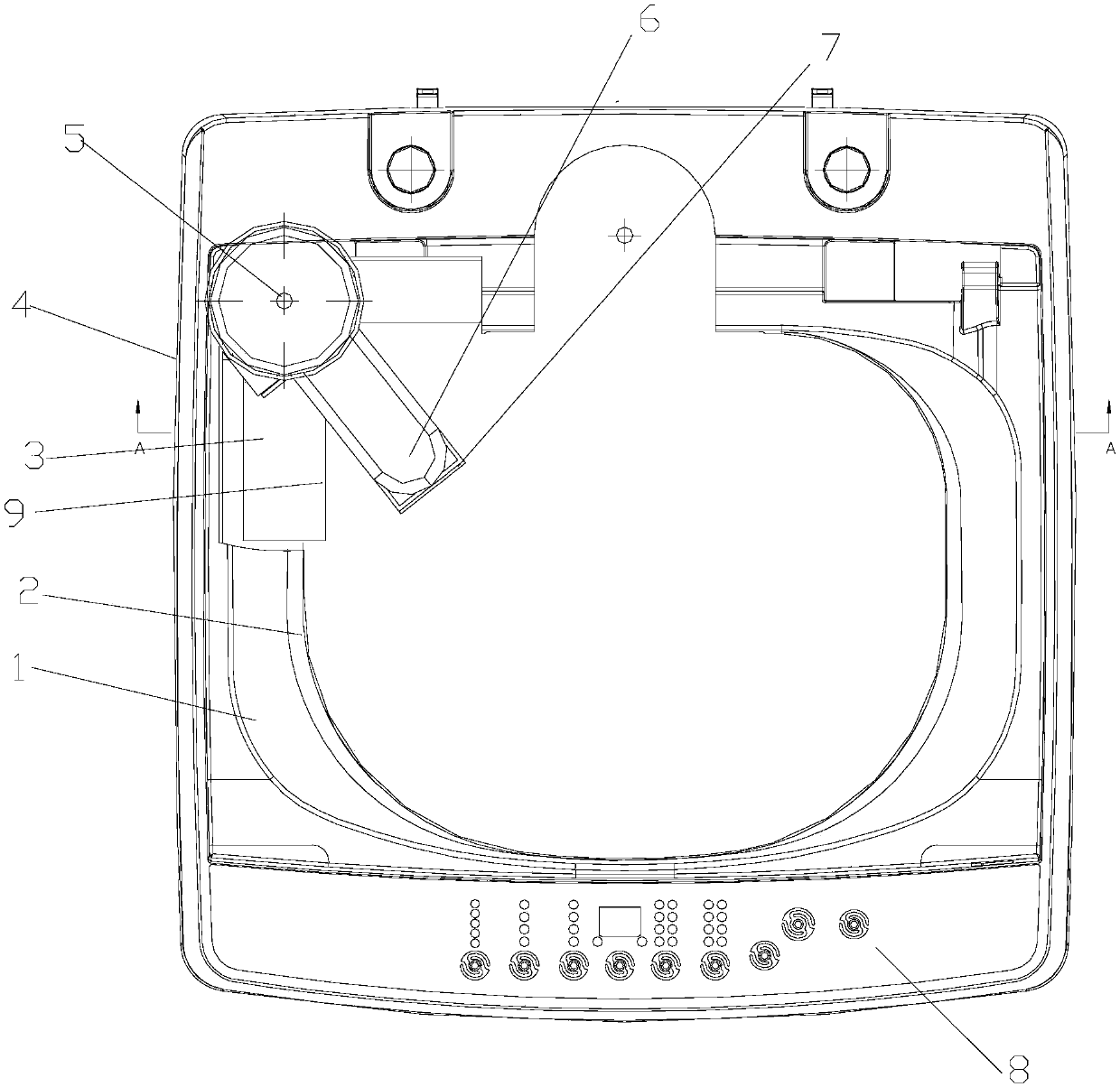

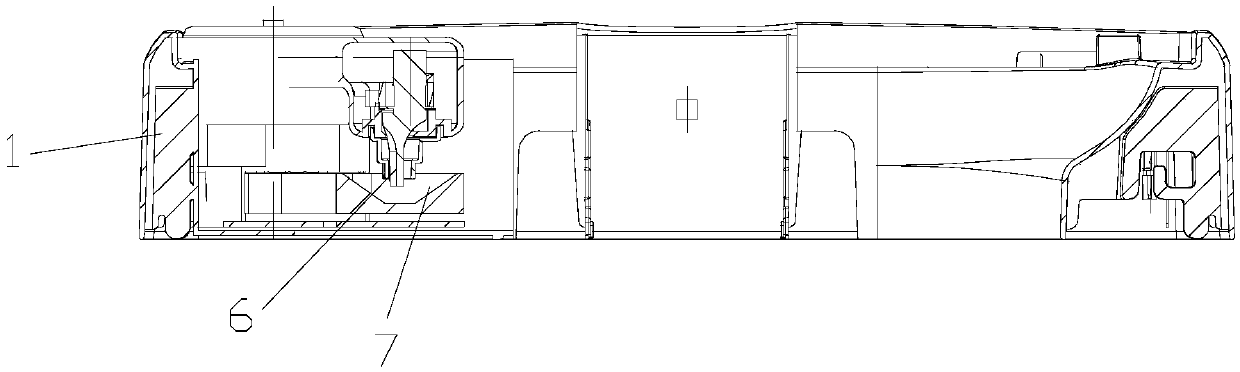

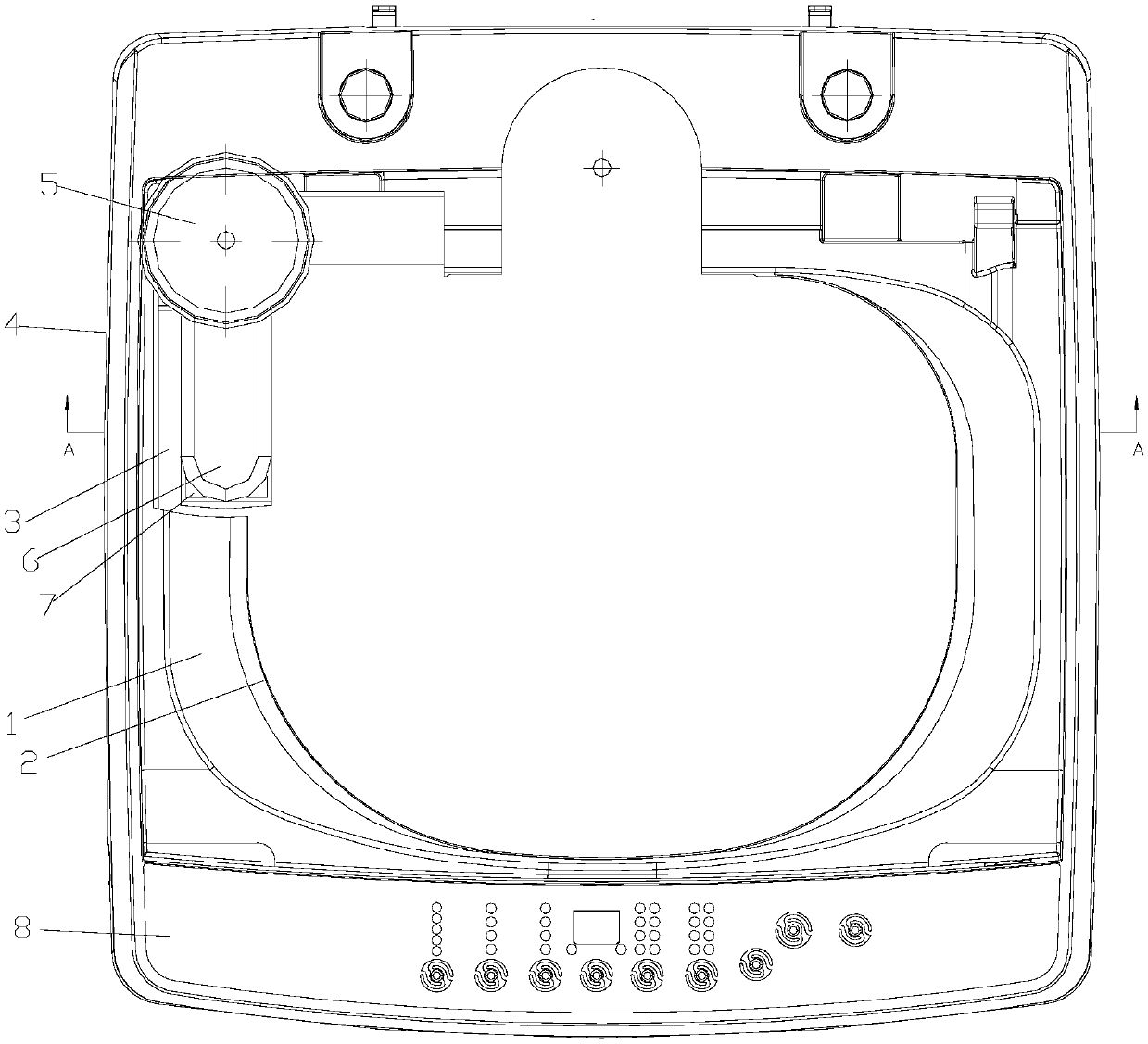

Washing machine with partial pre-washing function

ActiveCN110528223AComplete appearanceMaintain integrityTextiles and paperVibration washing machinesProcess engineeringCavitation

The invention discloses a washing machine with a partial pre-washing function. The washing machine comprises an ultrasonic washing device; the washing machine is provided with an accommodating space for accommodating the ultrasonic washing device, and the ultrasonic washing device can be arranged in the accommodating space in a screw-in / screw-out manner. The whole ultrasonic washing device is embedded in the washing machine and integrally assembled with the washing machine, normal clothes washing is not influenced, and the washing machine is also endowed with the partial pre-washing function.The washing machine partially emits high-frequency ultrasonic waves to initially-wet clothes by utilizing the cavitation function of the ultrasonic waves, so that stains such as oil stains are emulsified under the function of a sound field, solid ions are separated from the clothes, surface purification is achieved, partial stubborn stains are removed, and the partial pre-washing function on the clothes is achieved.

Owner:HEFEI HAIER WASHING MACHINE +1

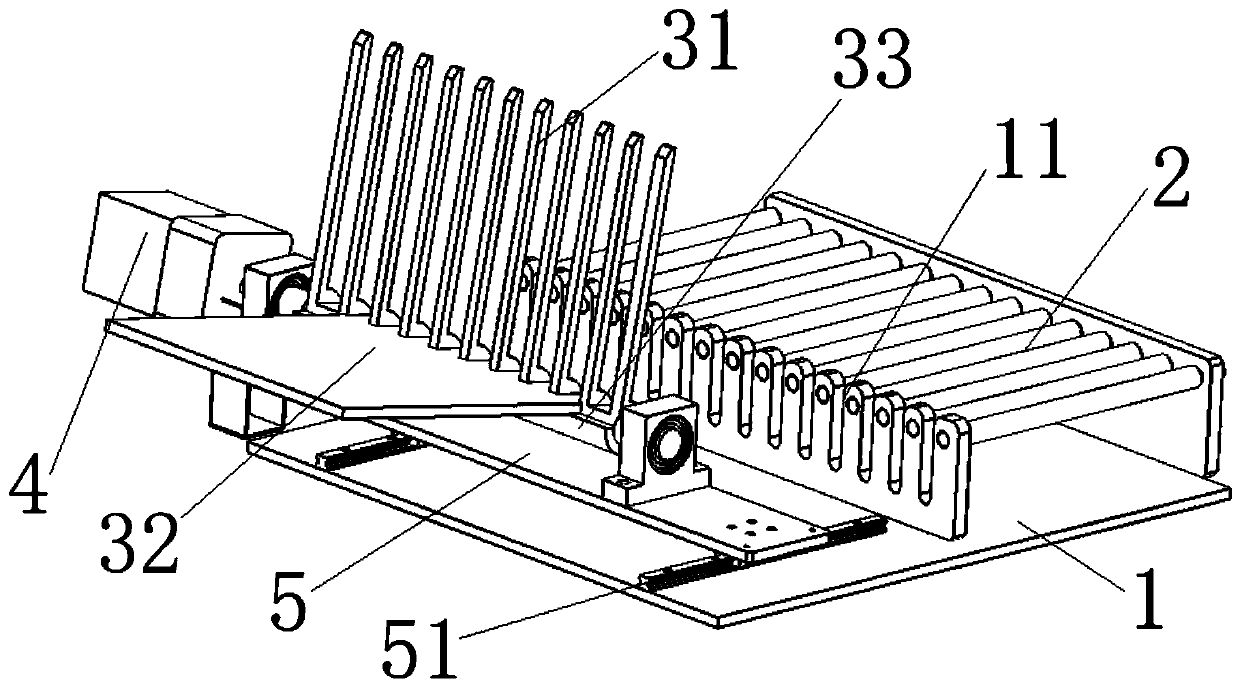

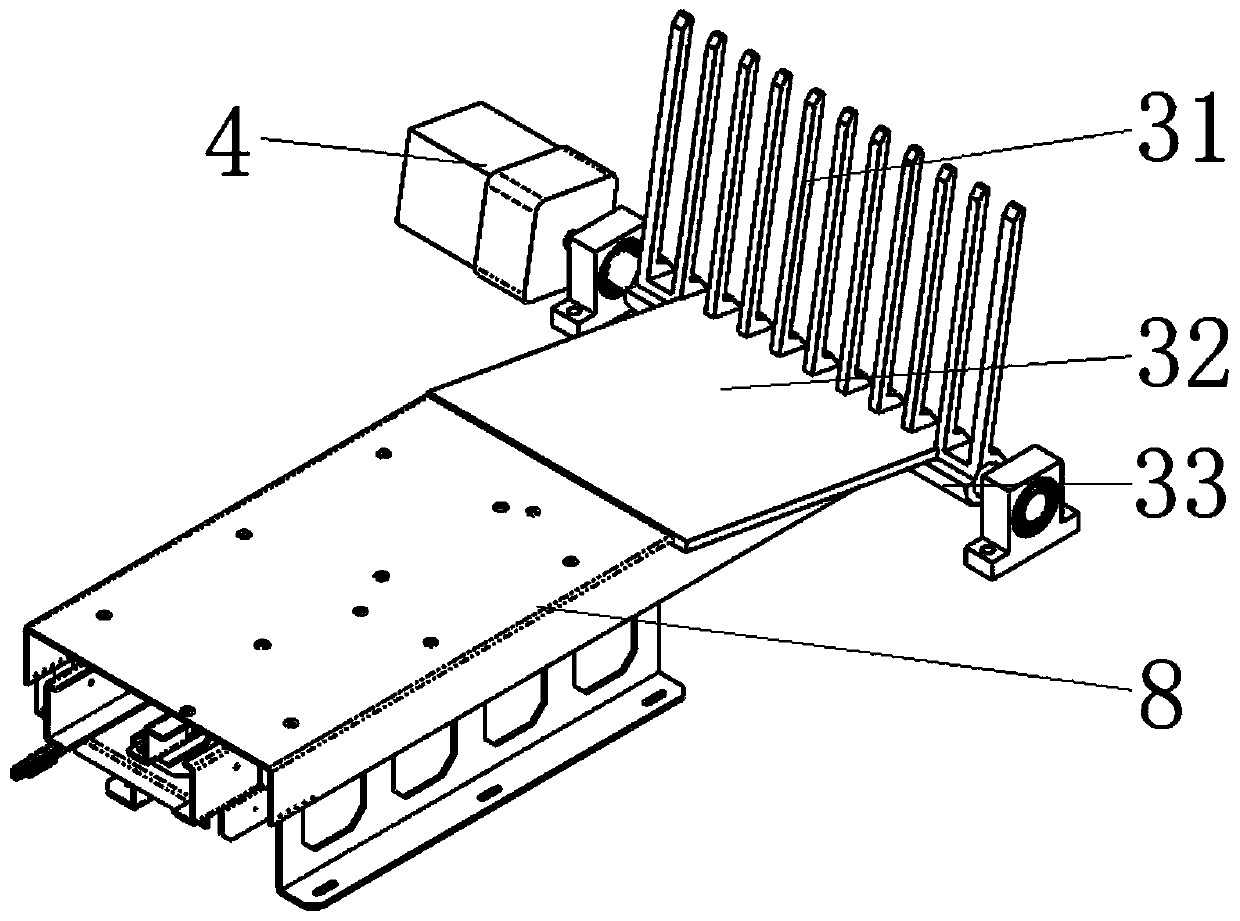

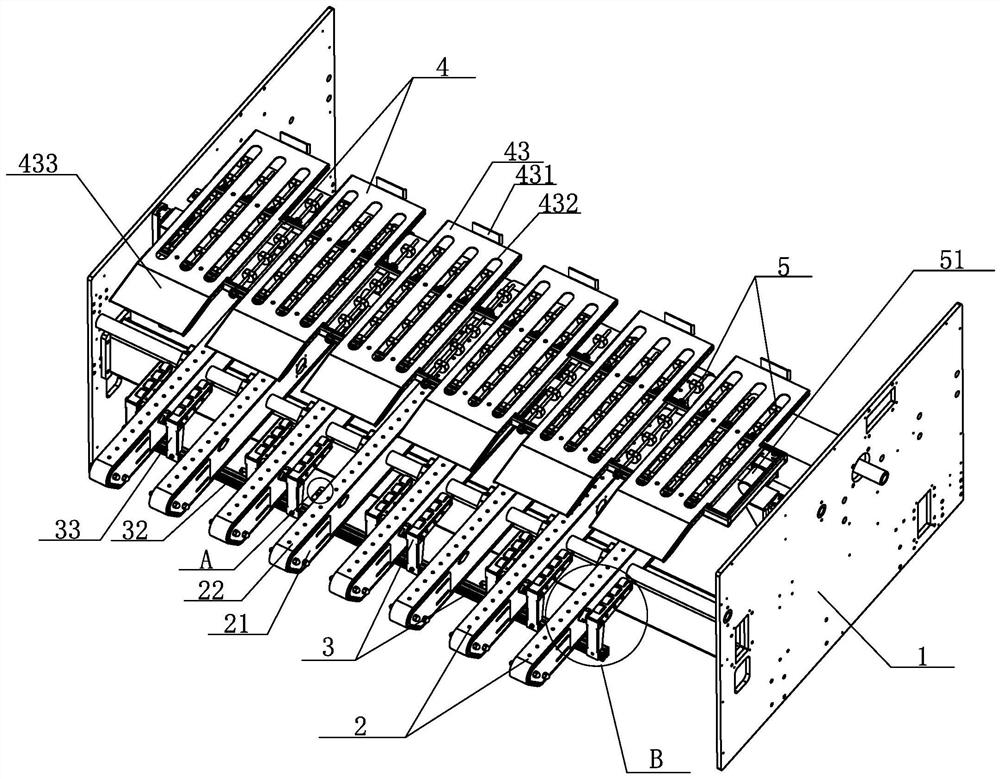

Feeding and discharging device and detection equipment

PendingCN111115269AReduce manufacturing costSmall footprintControl devices for conveyorsCharge manipulationRobot handTransfer line

Owner:JOINT STARS TECH

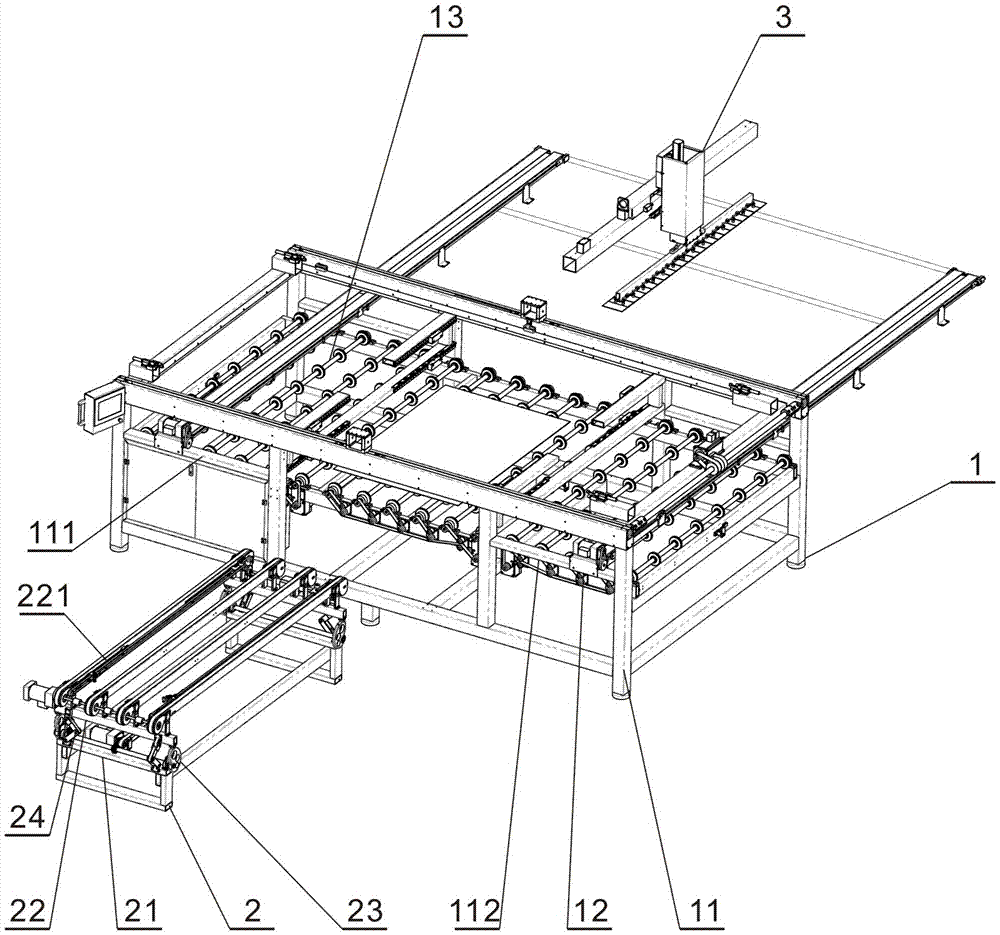

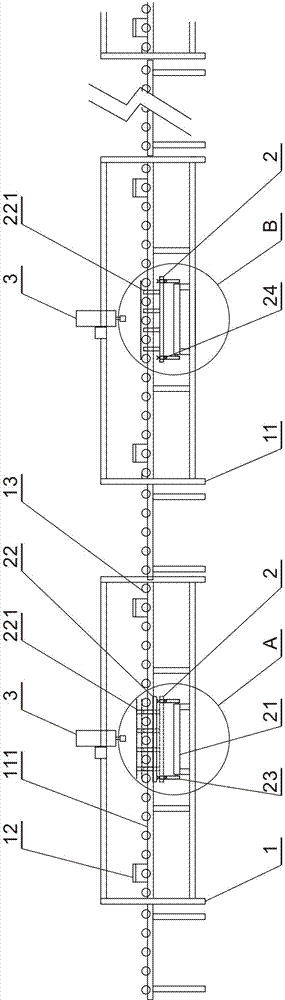

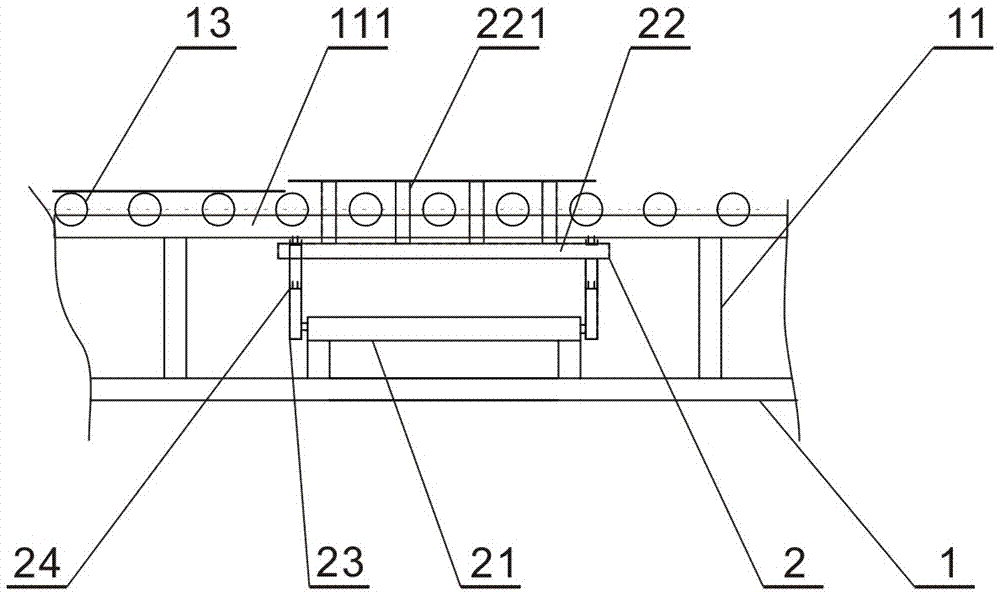

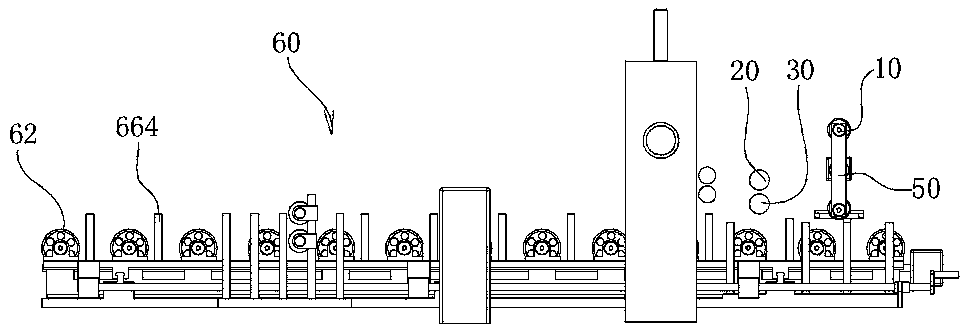

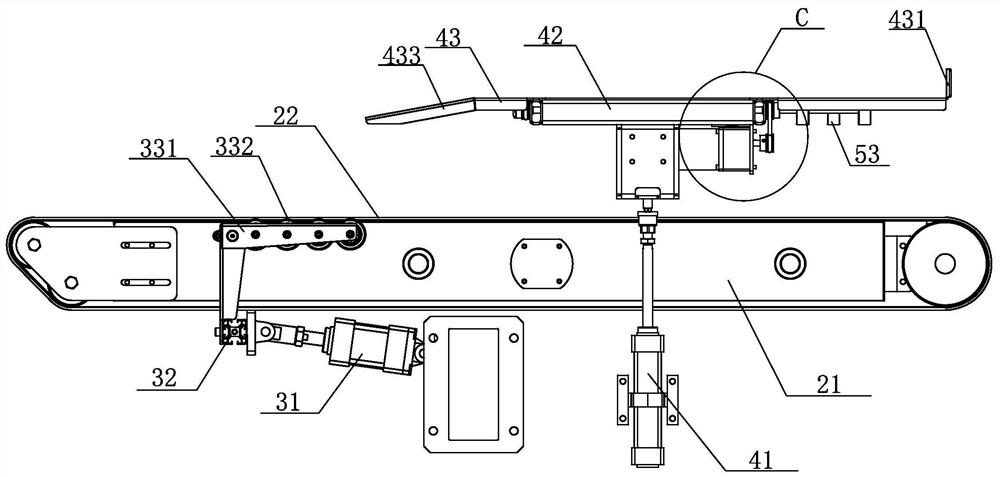

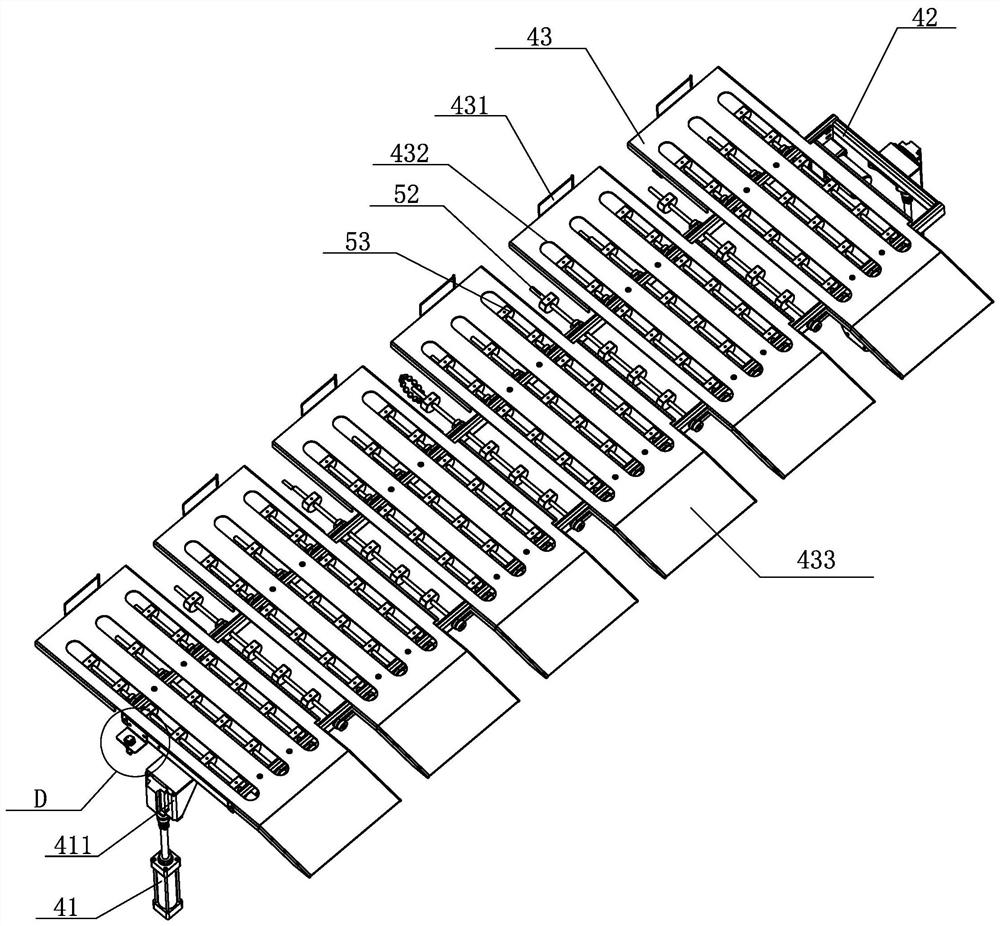

Three-dimensional conveying device for automatic photovoltaic cell string typesetter

ActiveCN105449049AEasy to connect and convertSmall footprintFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a three-dimensional conveying device for an automatic photovoltaic cell string typesetter. The three-dimensional conveying device comprises a longitudinal conveying line, a working platform and an automatic typesetter, wherein the working platform is arranged on any conveying machine frame in the longitudinal conveying line; and the automatic typesetter is arranged corresponding to the working platform, and is connected with the conveying machine frame. The working platform is embedded in the longitudinal conveying line, a synchronous belt on an upper platform can be higher or lower than a rolling wheel driving rod of the longitudinal conveying line via a lifting device, while impact on normal glass conveying of the longitudinal conveying line is avoided when the synchronous belt is at both the two working condition positions, so that the problem in arranging a plurality of working positions on the same longitudinal conveying line is solved, multiple positions can be connected and changed conveniently, the occupied space is small, the conveying speed is fast, and the production efficiency is high.

Owner:上海豪力起重机械有限公司

Sofa cover fabric automatic cutting device

InactiveCN108060574APlay a role in stabilityGuaranteed stabilitySevering textilesEngineeringConveyor belt

The invention discloses a sofa cover fabric automatic cutting device. The device comprises a device body and a conveyor belt, and the conveyor belt is arranged in the device body; connecting plates are symmetrically fixed in the device body, the bottoms of the connecting plates are connected with fixing frames through connecting columns, and rubber pads are symmetrically fixed on the two sides ofeach connecting column. In the device, first electric telescopic rods are symmetrically arranged in the device body, a pressing plate is fixed at the bottoms of the first electric telescopic rods, andthe bottom of the pressing plate is connected with a plurality of balls in a rolling mode at equal intervals; when a fabric is conveyed on the conveying belt, the first electric telescopic rods are started, so that the two ends of the top of the fabric are arranged at the bottoms of the balls, and the two ends of the fabric can be aligned and conveyed, and it is guaranteed that the fabric is notdeflected during cutting; meanwhile, due to the arrangement of the balls, normal conveying of the fabric can be guaranteed, and the practicability is high.

Owner:海宁天荣纺织有限公司

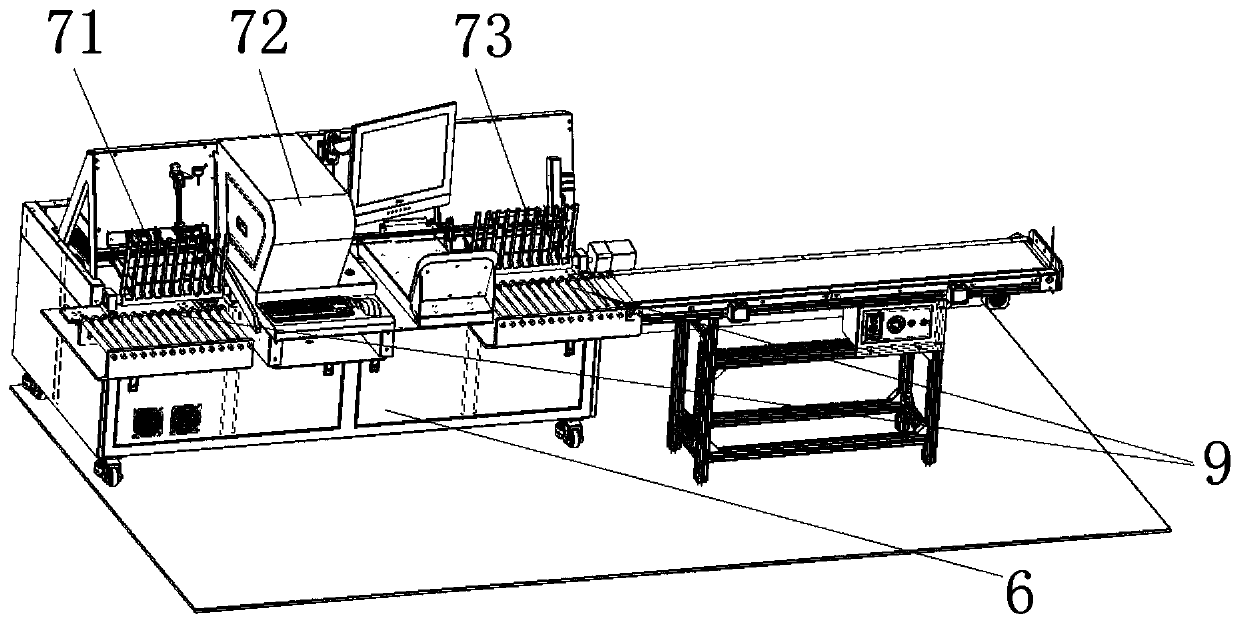

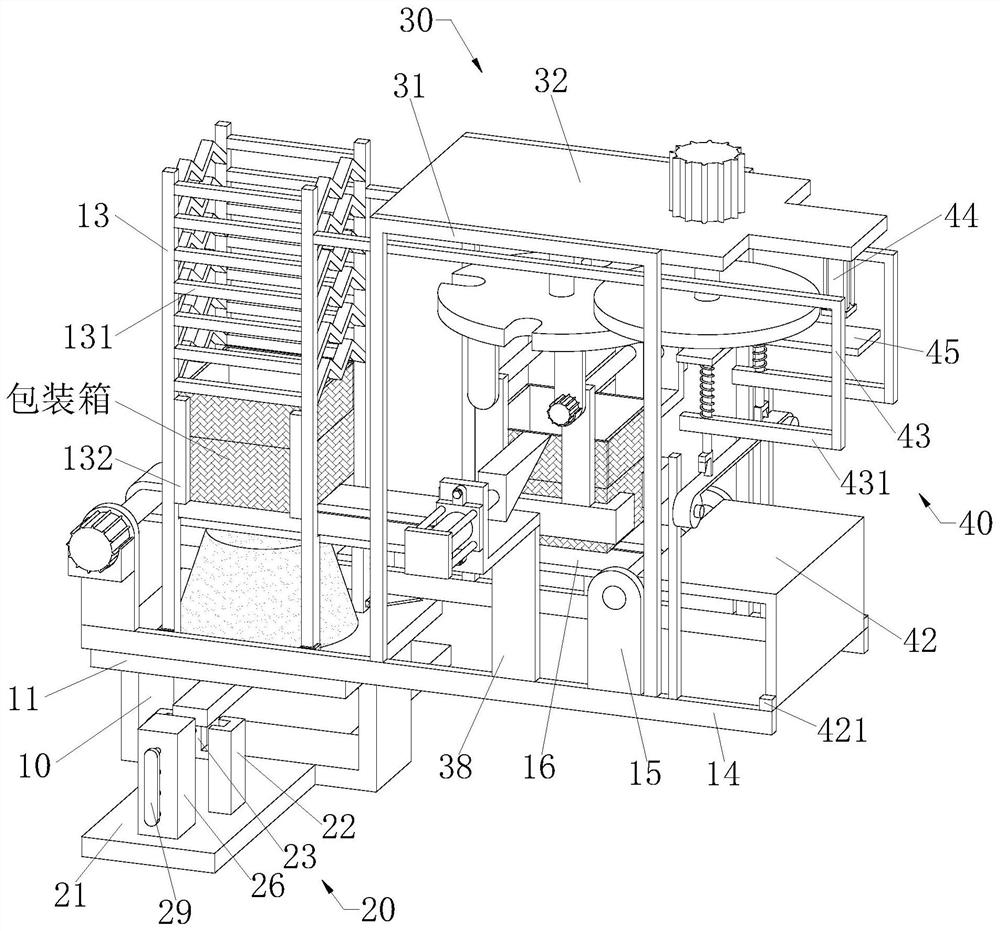

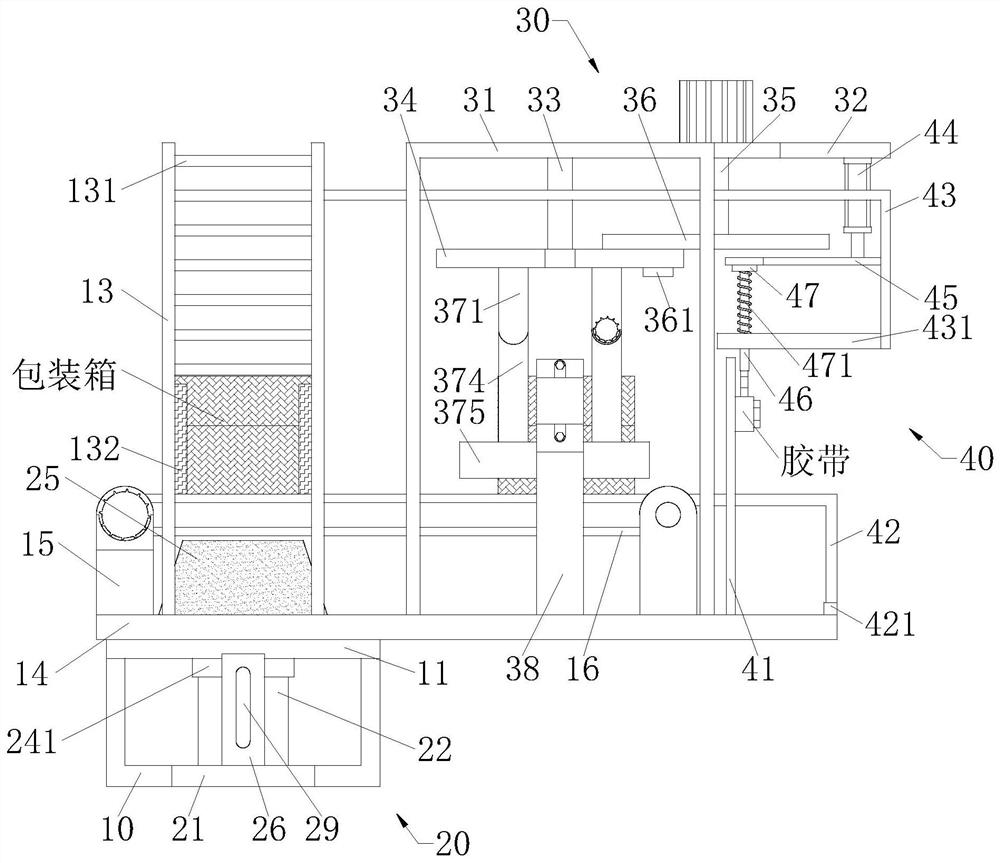

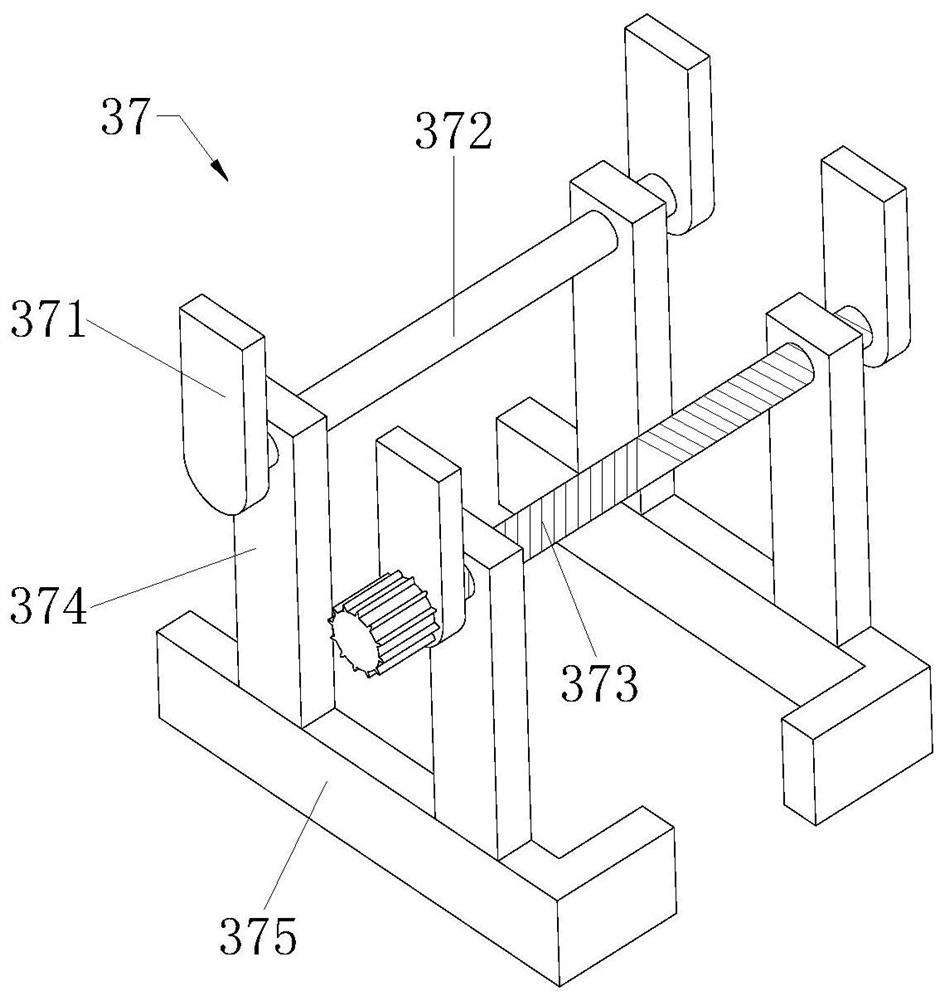

Automatic quick sealing equipment for express packaging box of storage sorting center

InactiveCN113104253ARealize equidistant adjustmentImprove the processing positionWrapper twisting/gatheringCircular discEngineering

Owner:深汉铁甲物流(武汉)有限公司

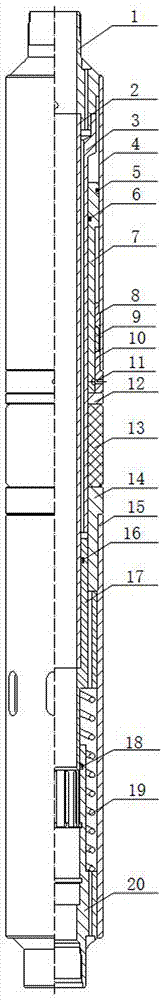

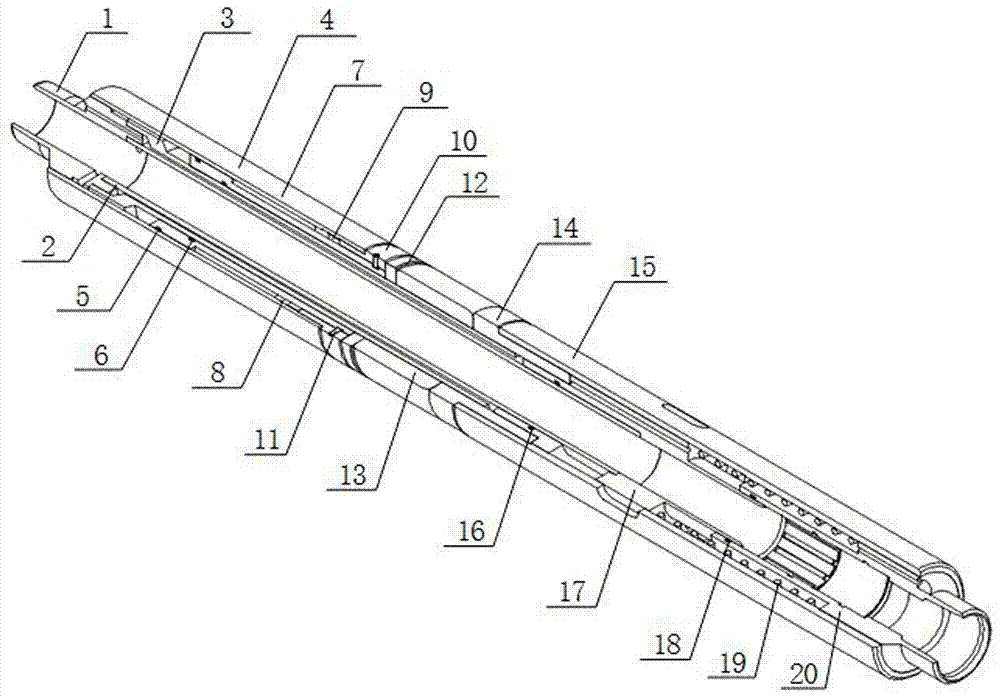

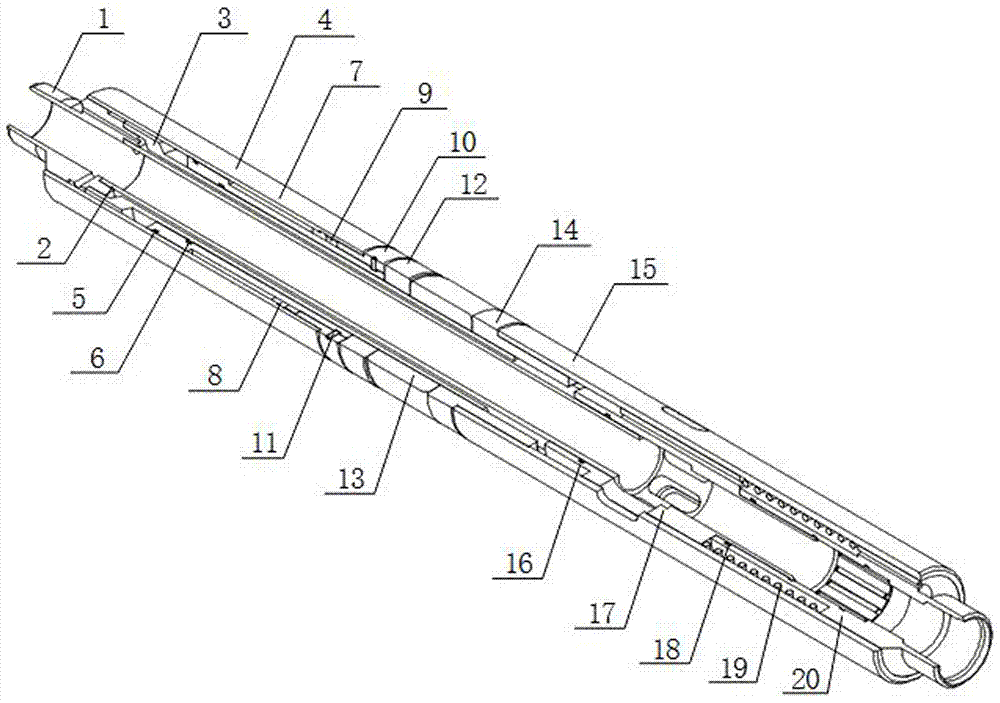

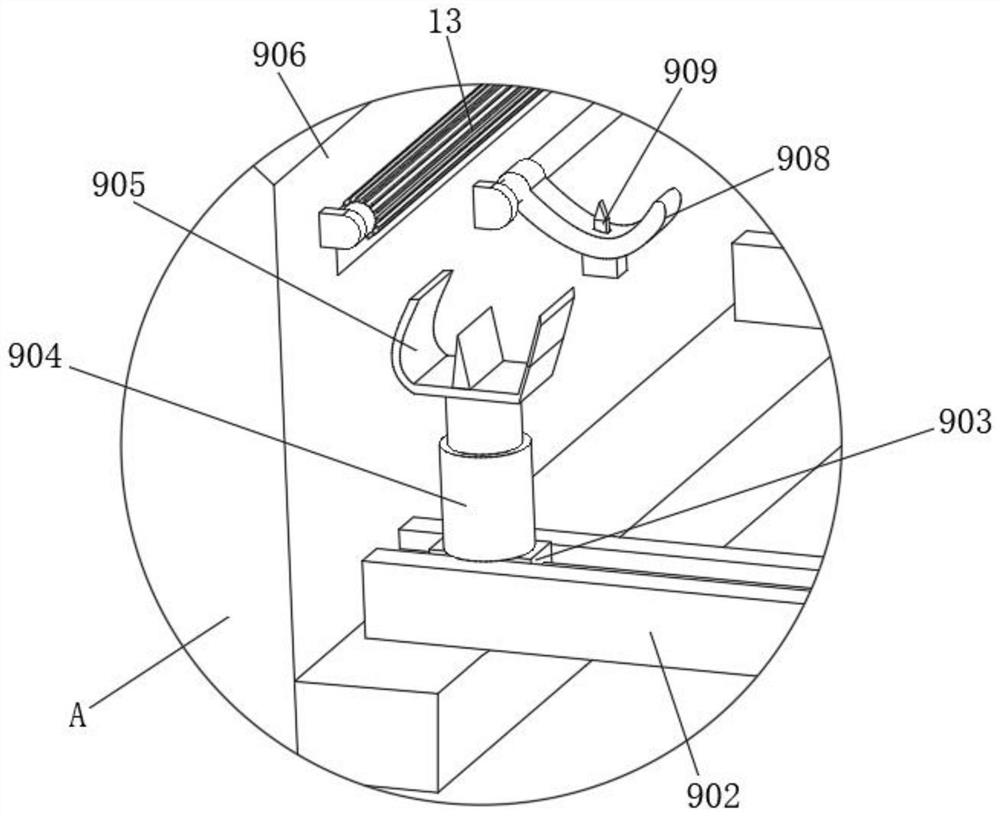

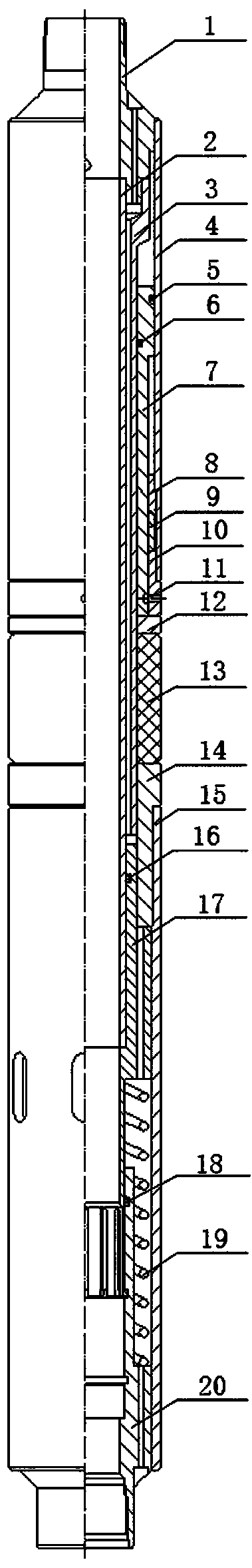

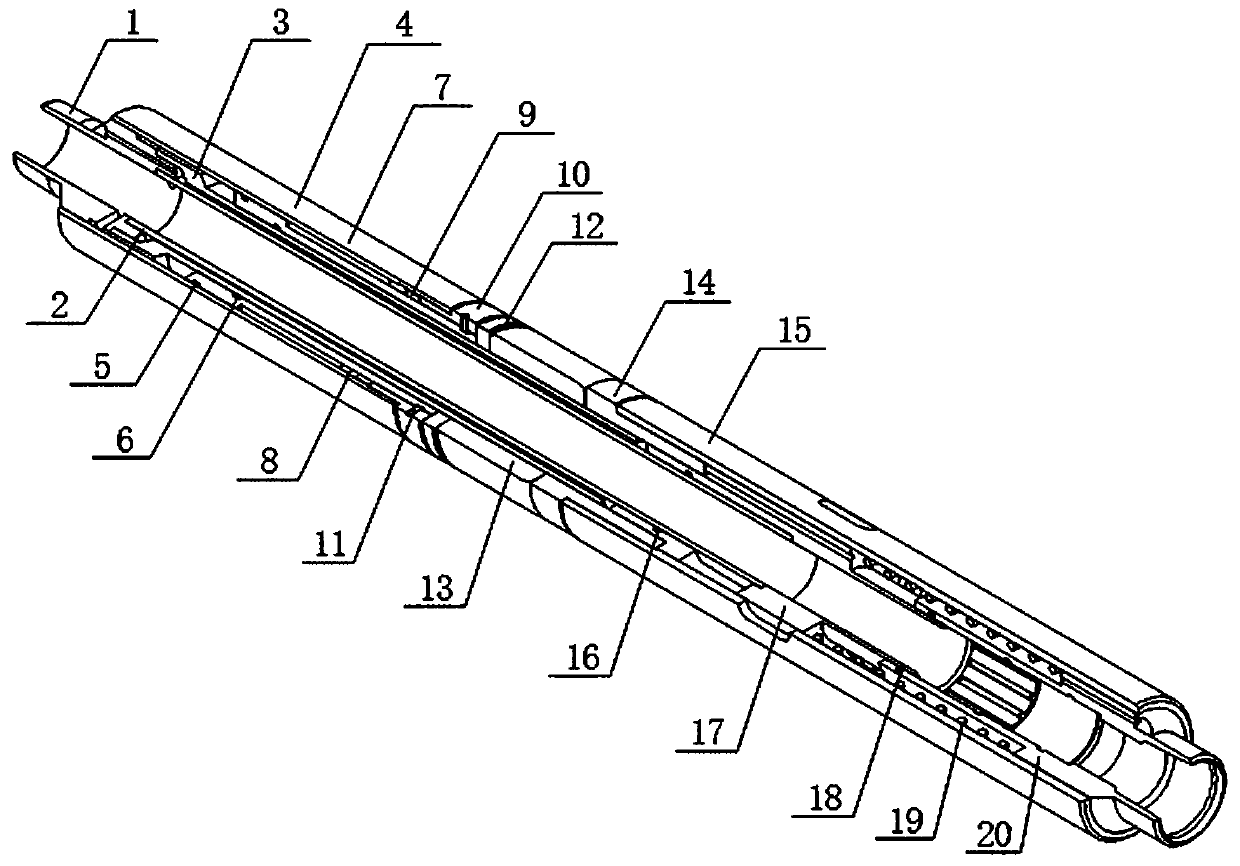

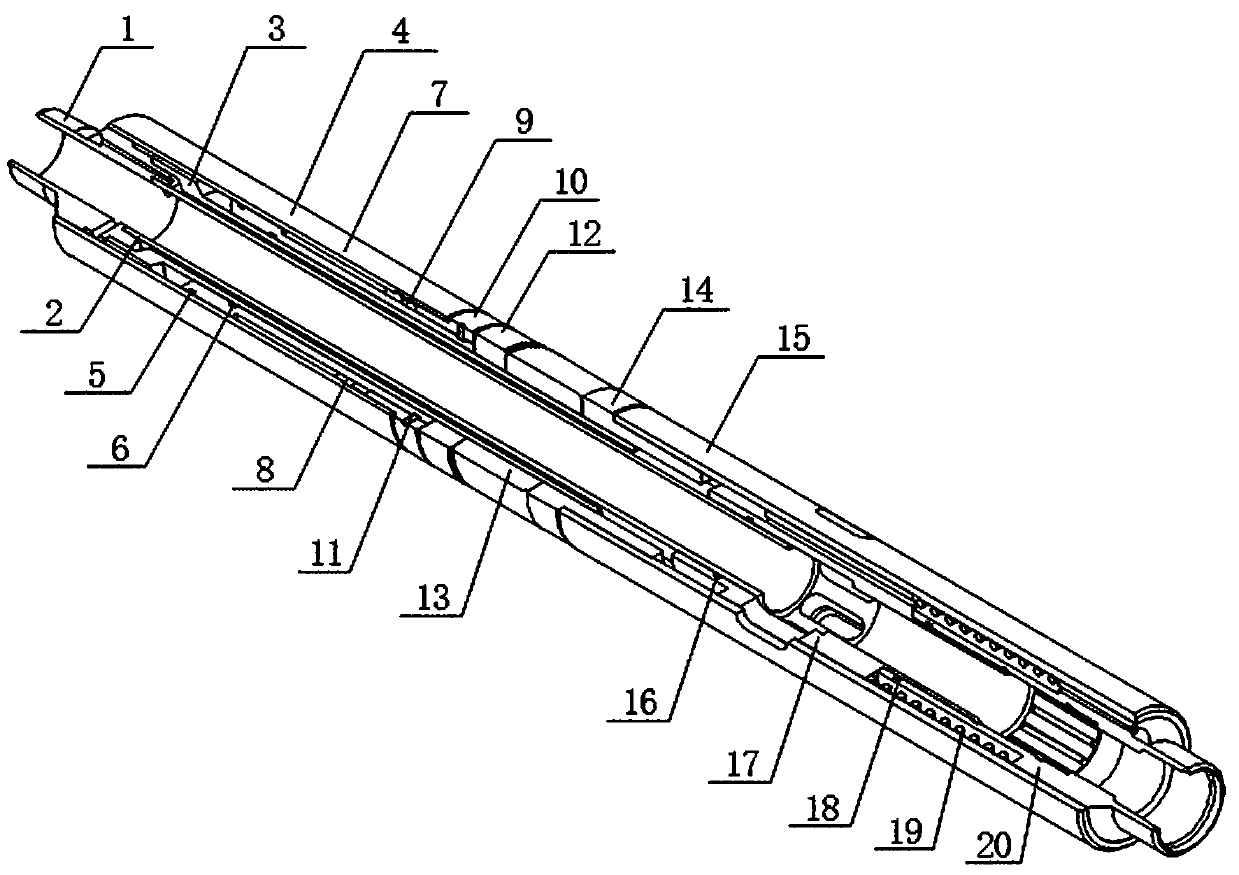

Self-packing dual-channel fluid control stepless fracture sliding sleeve device

InactiveCN107448170AReduce tool-to-tool connectionsImprove reliabilityFluid removalWell/borehole valve arrangementsPistonWellhead

The invention belongs to the technical field of a petrol engineering technology, and discloses a self-packing dual-channel fluid control stepless fracture sliding sleeve device. The self-packing dual-channel fluid control stepless fracture sliding sleeve device comprises an upper flow distribution joint, an inner center pipe connected with the upper flow distribution joint, an outer center pipe, an outer sleeve cylinder, an upper pressing ring at the lower part of the outer sleeve cylinder, a piston between the upper pressing ring and the outer center pipe, a lock ring stopping ring at the lower part of the outer sleeve cylinder, a lock ring on the piston, and a separating ring, a rubber cylinder, a lower pressing ring, a slide sleeve, a lower joint and a flow distribution sleeve cylinder; the separating ring, the rubber cylinder, the lower pressing ring, the slide sleeve, the lower joint and the flow distribution sleeve cylinder are arranged beneath the upper pressing ring orderly; the lower pressing ring is connected to the middle of the outer center pipe and the flow distribution sleeve cylinder, and the slide sleeve is connected to the middle of the lower end of the inner center pipe and the flow distribution sleeve cylinder; the lower joint is connected to the lower end of the flow distribution sleeve cylinder. The technical scheme has the advantages of realizing the integrated design of a packer and the slide sleeve, reducing connection between tools, improving the tool reliability, saving construction cost, and improving the multi-grade segmental cracking efficiency; except for a regular oil flow channel with large drift diameter, the device is further provided with an independent second fluid control channel, thus the hydraulic control of underground tools at the well head is realized and the normal conveying of the oil fluid is not influenced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

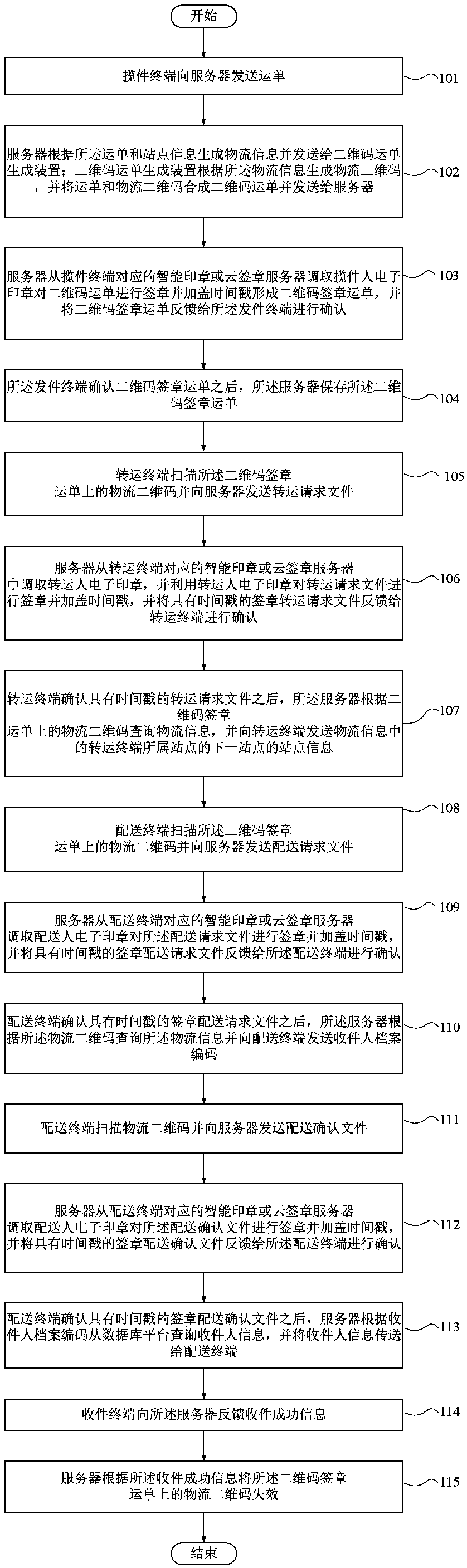

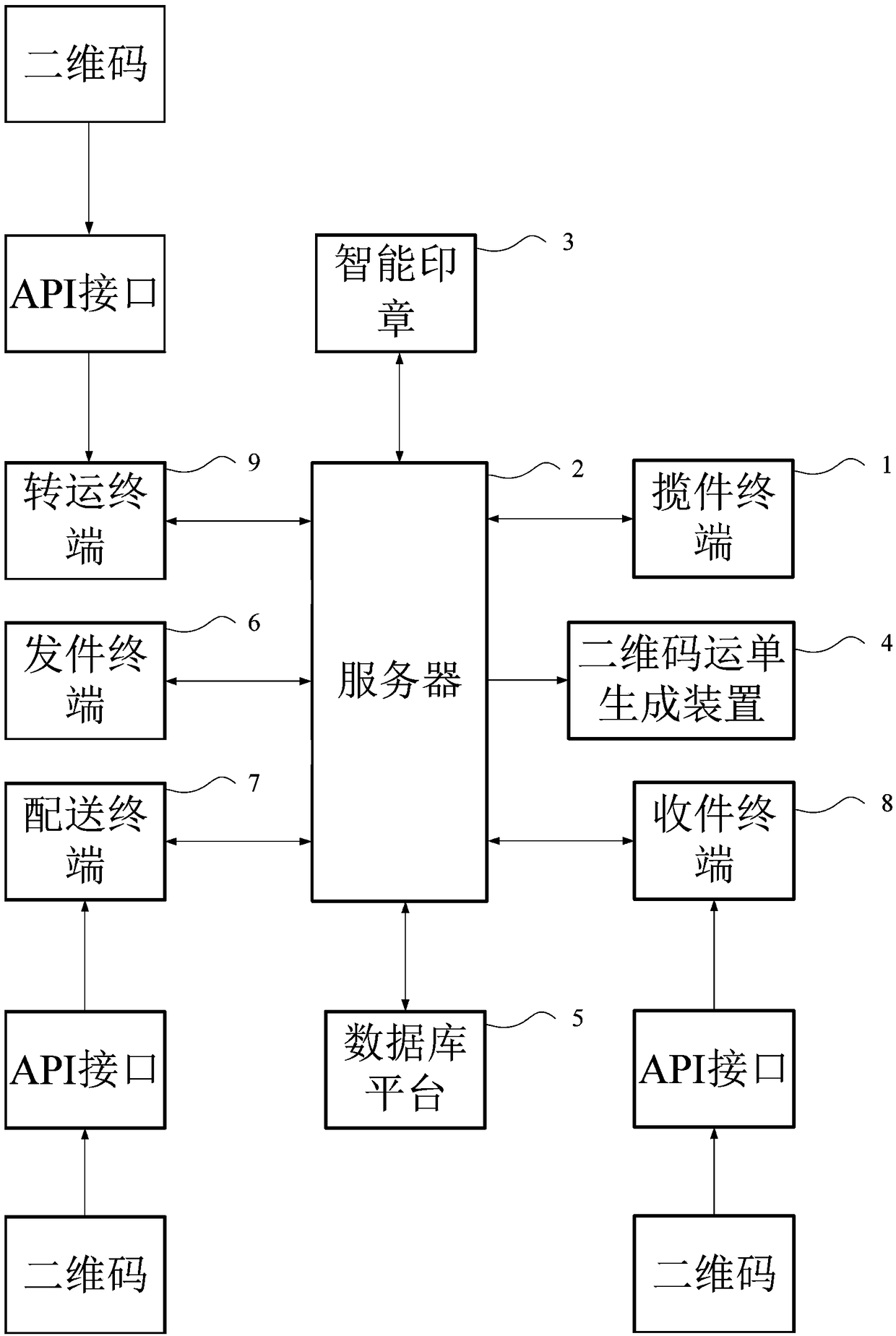

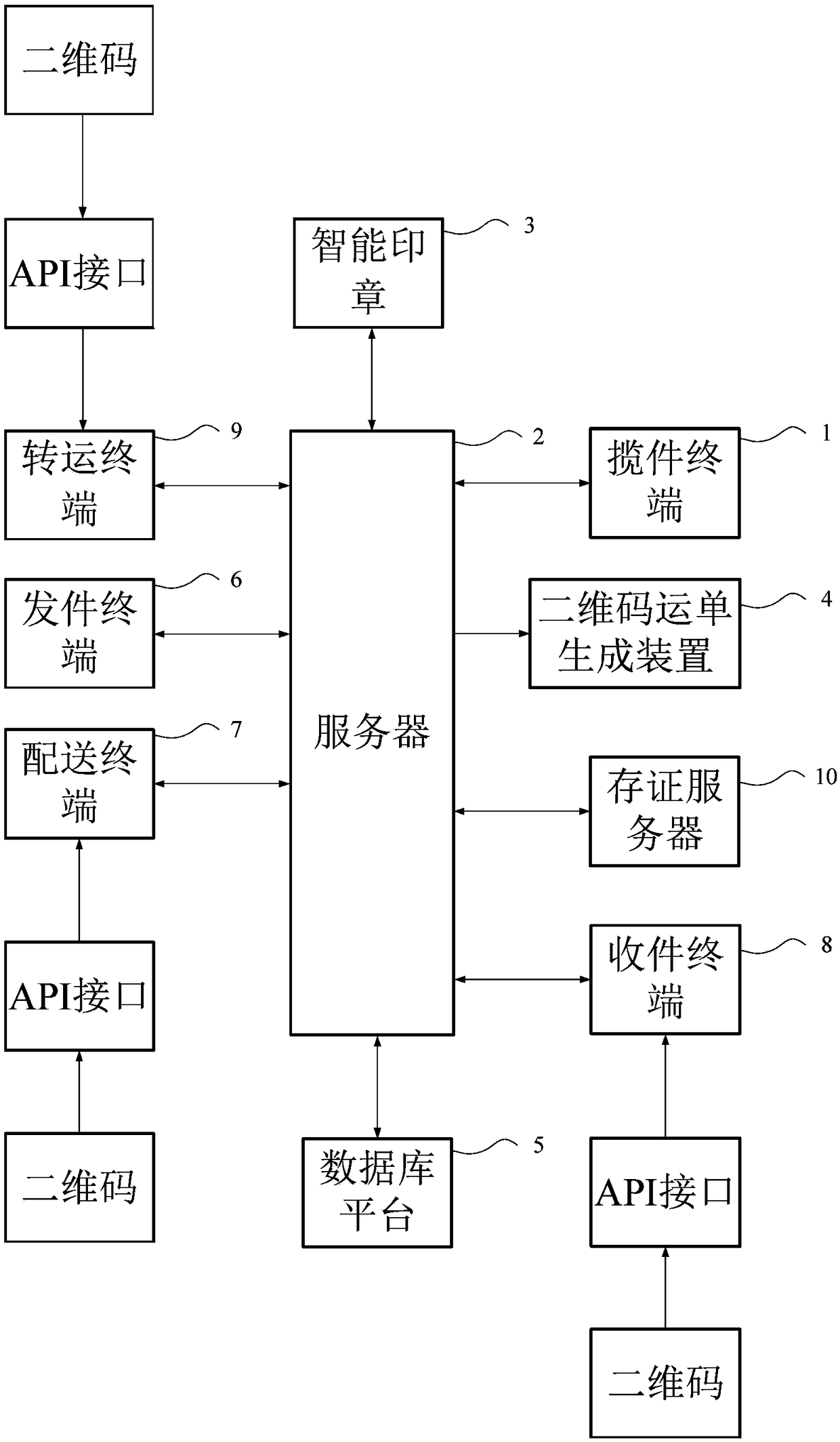

Security management and control method and system for logistics information, and computer storage medium

InactiveCN108717611AGuaranteed transmission efficiencyPrevent leakageMemory record carrier reading problemsCo-operative working arrangementsLogistics managementTimestamp

The invention provides a security management and control method and system for logistics information, and a computer storage medium. The method comprises the following steps that: an express deliverycollection terminal sends a waybill to a server; the server generates the logistics information according to the waybill and site information, and a two-dimensional code waybill generation device generates a logistics two-dimensional code according to the logistics information, and combines the waybill and the logistics two-dimensional code into a two-dimensional code waybill; the two-dimensionalcode waybill is signed and stamped with a timestamp to form a two-dimensional code signature waybill; a transfer terminal scans the logistics two-dimensional code on the two-dimensional code signaturewaybill to transfer articles; a distribution terminal scans the logistics two-dimensional code on the two-dimensional code signature waybill to distribute articles; after distribution is finished, anexpress delivery receiving terminal feeds back express delivery picking-up success information to the server; and the server causes the logistics two-dimensional code to fail. By use of the method, while the personal information of an addressee and an addresser is not leaked, logistics transfer efficiency is improved.

Owner:胡金钱

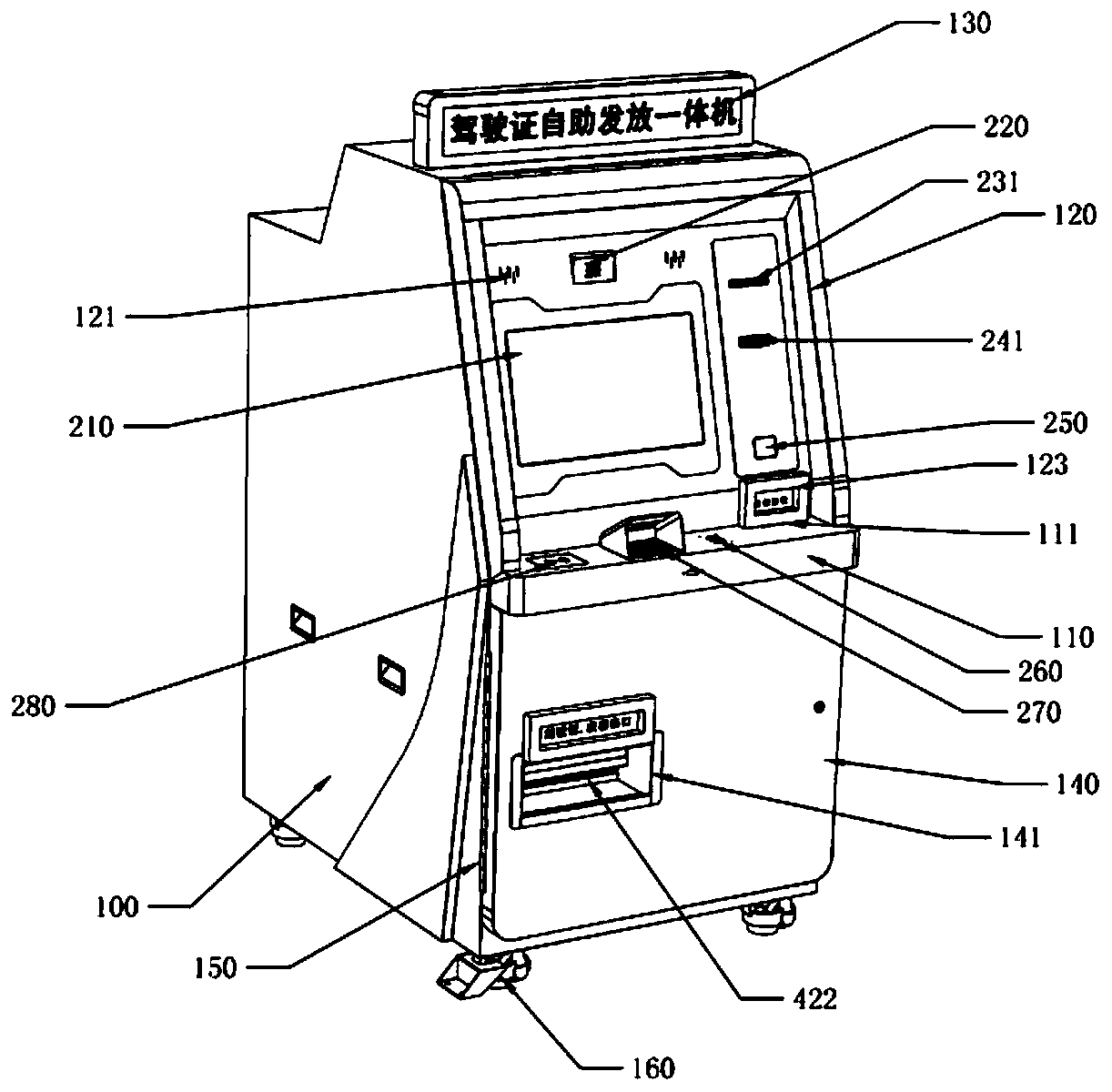

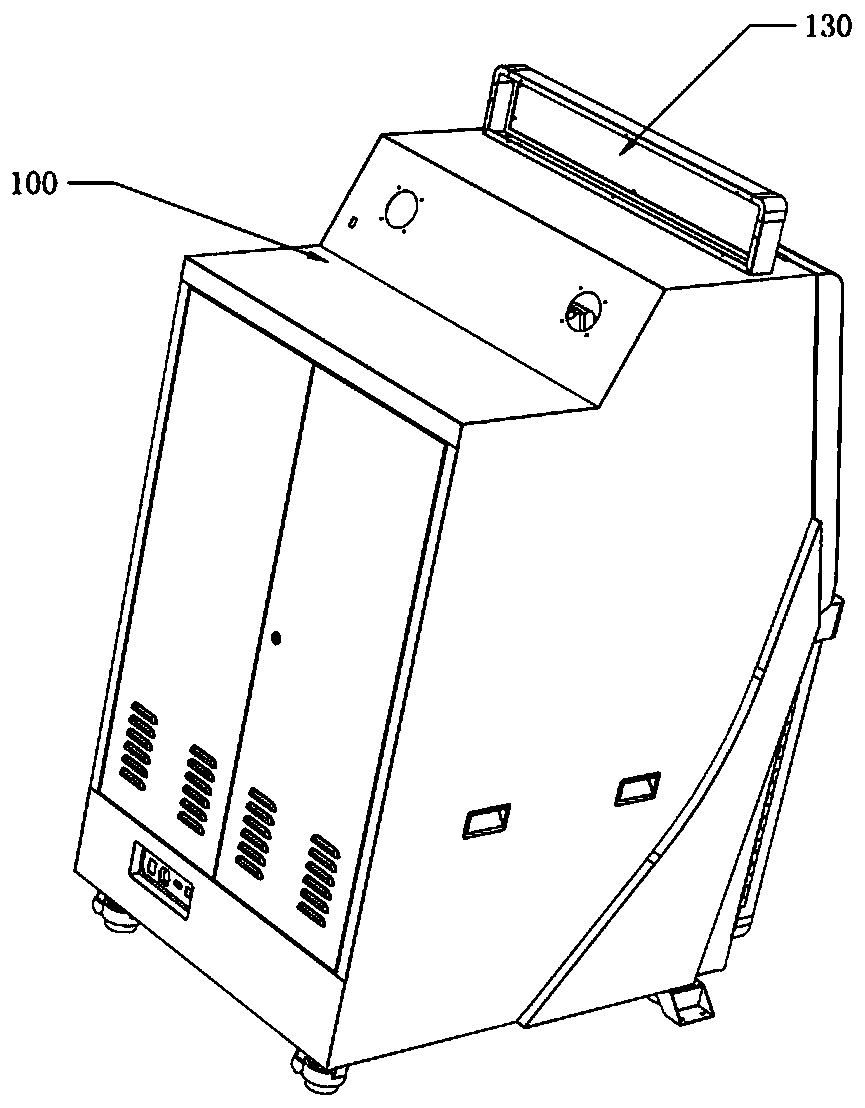

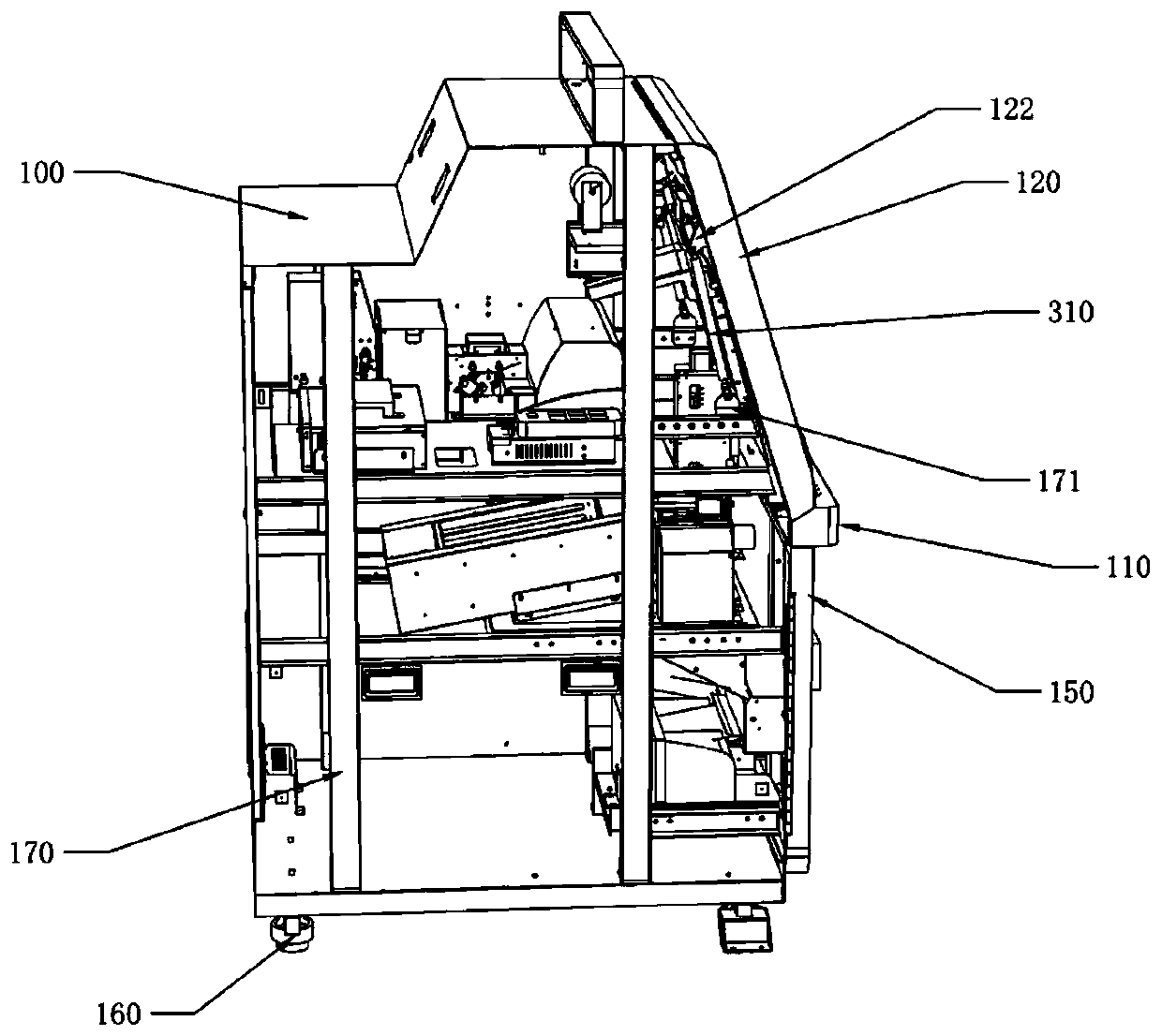

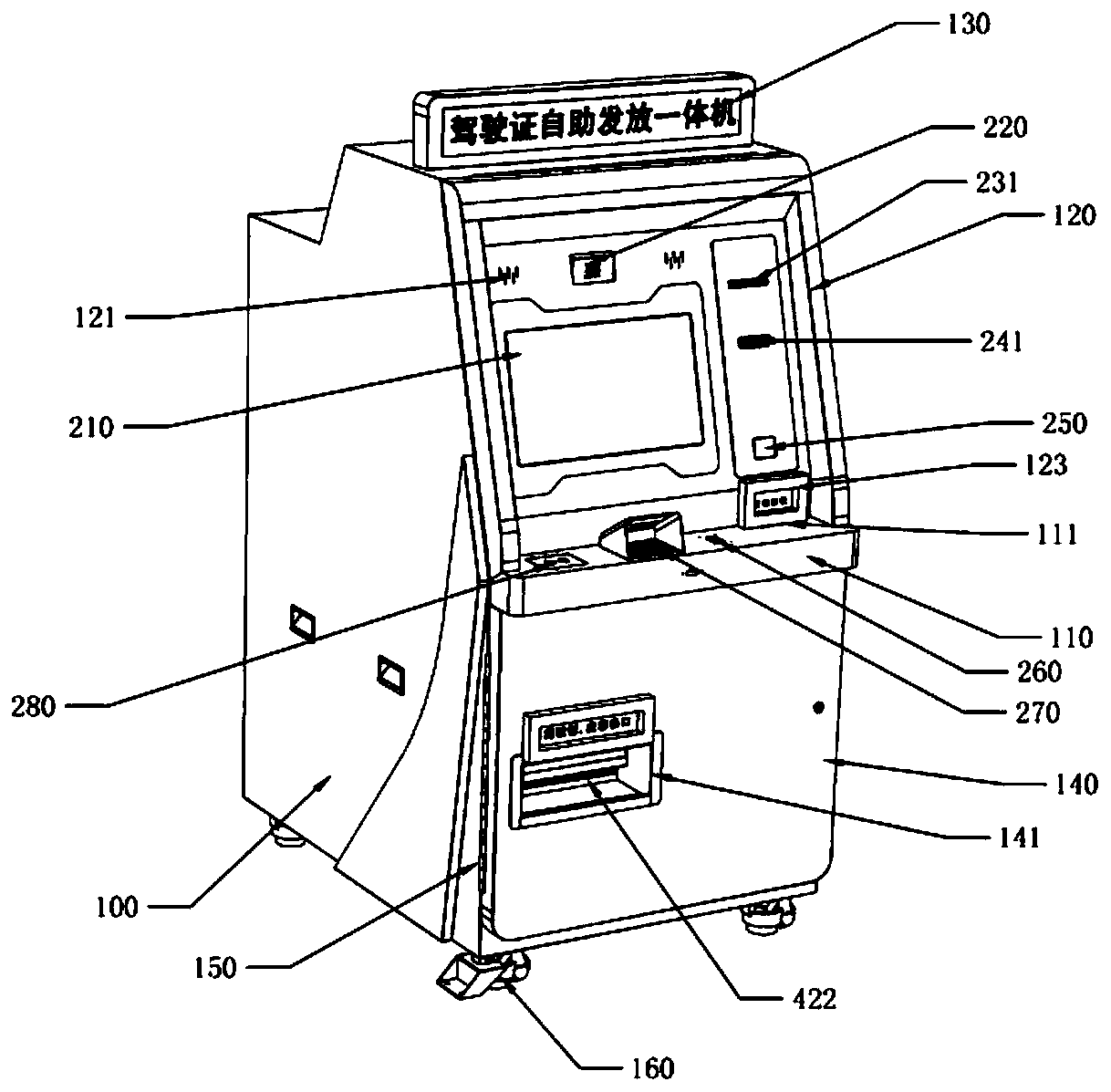

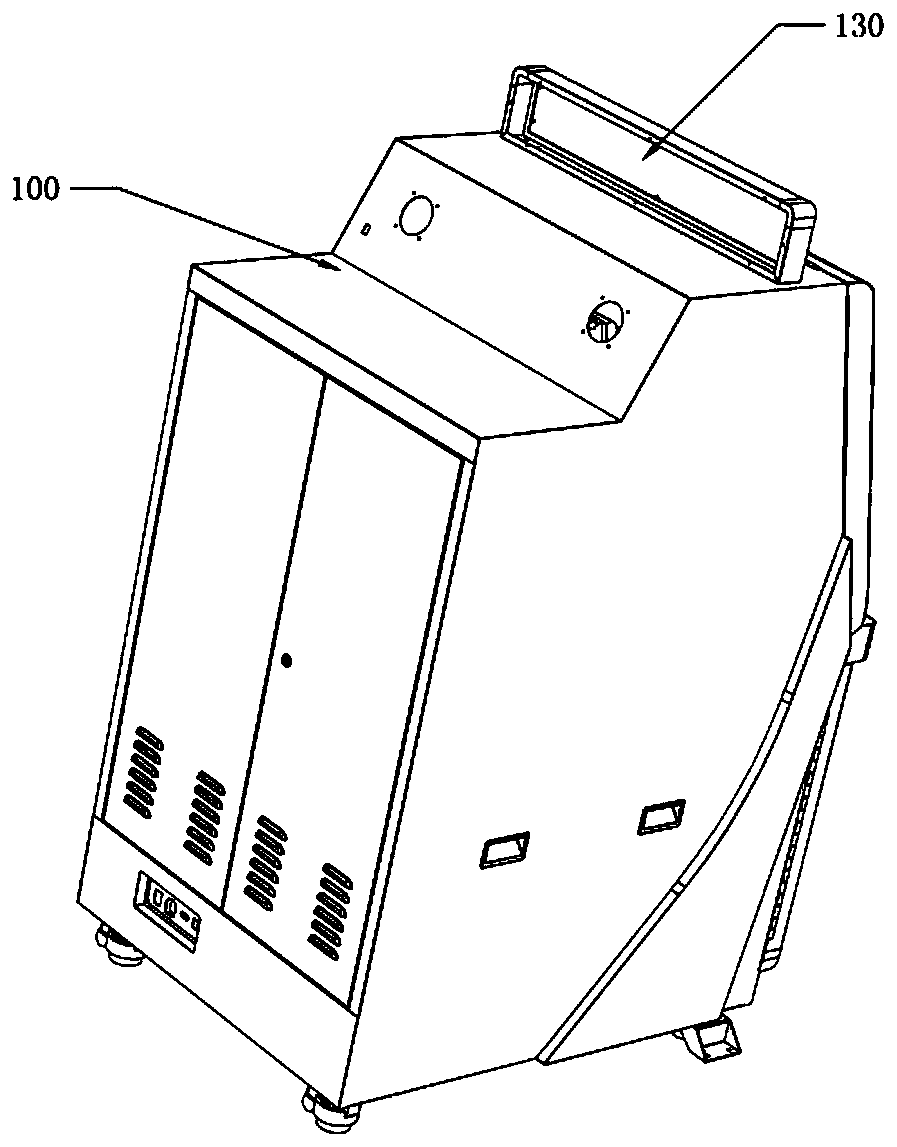

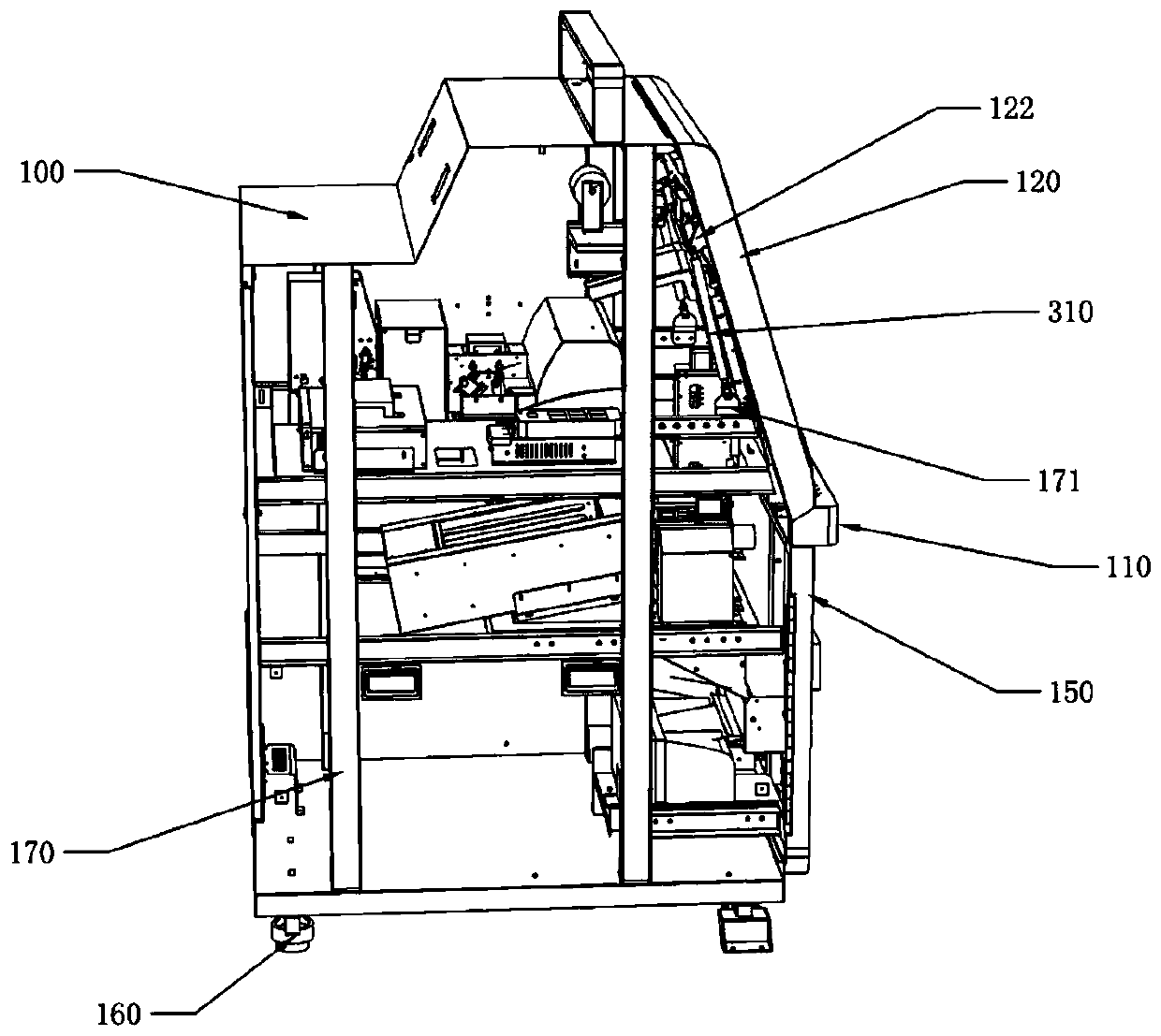

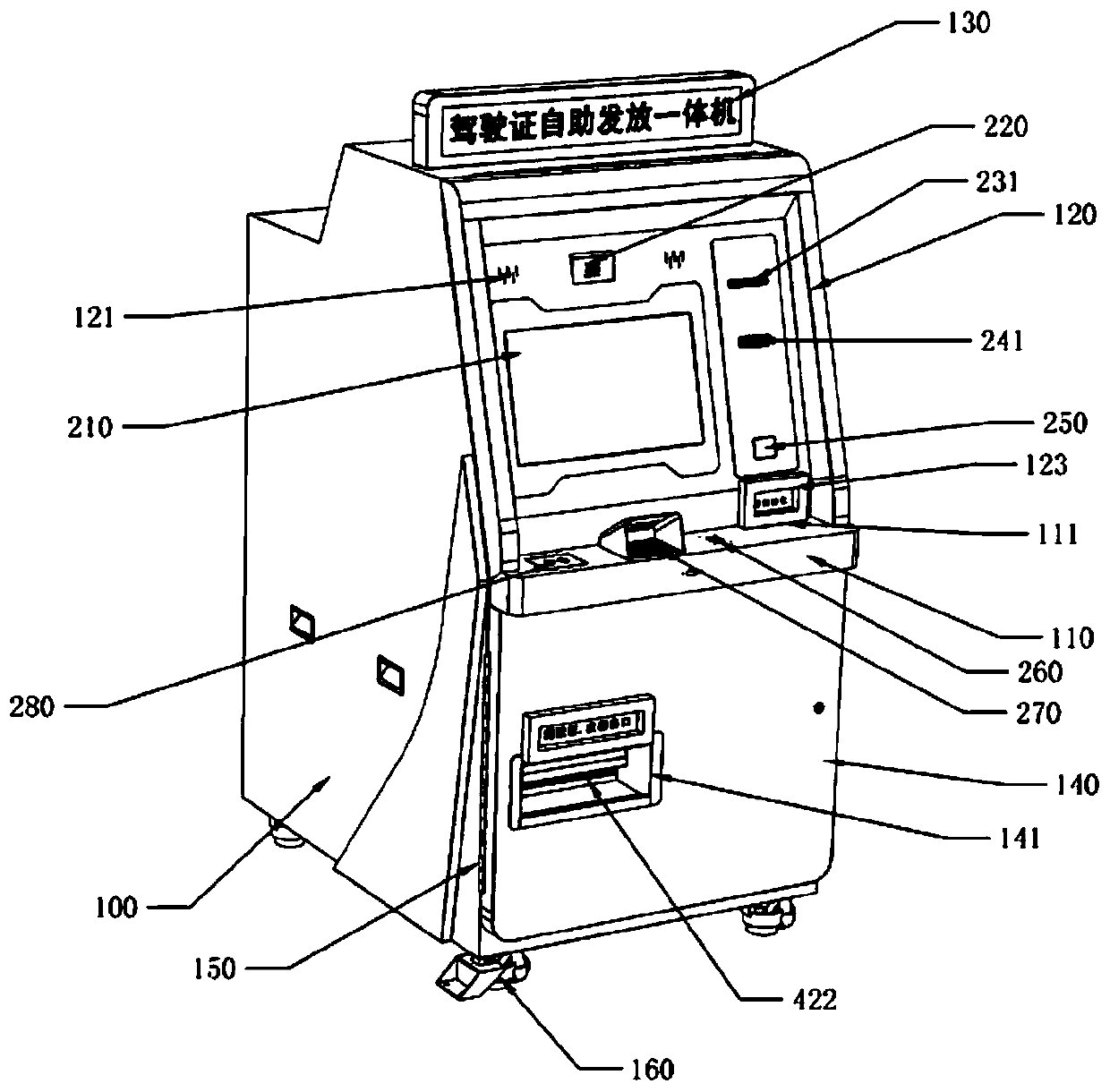

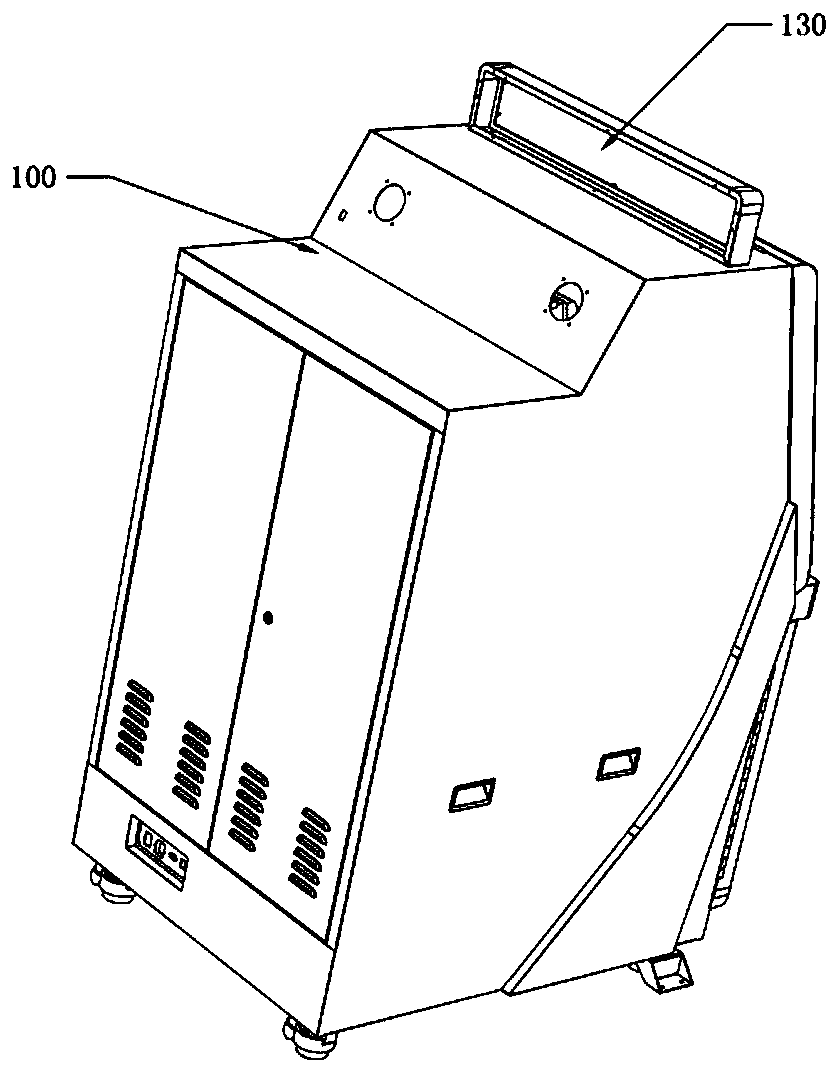

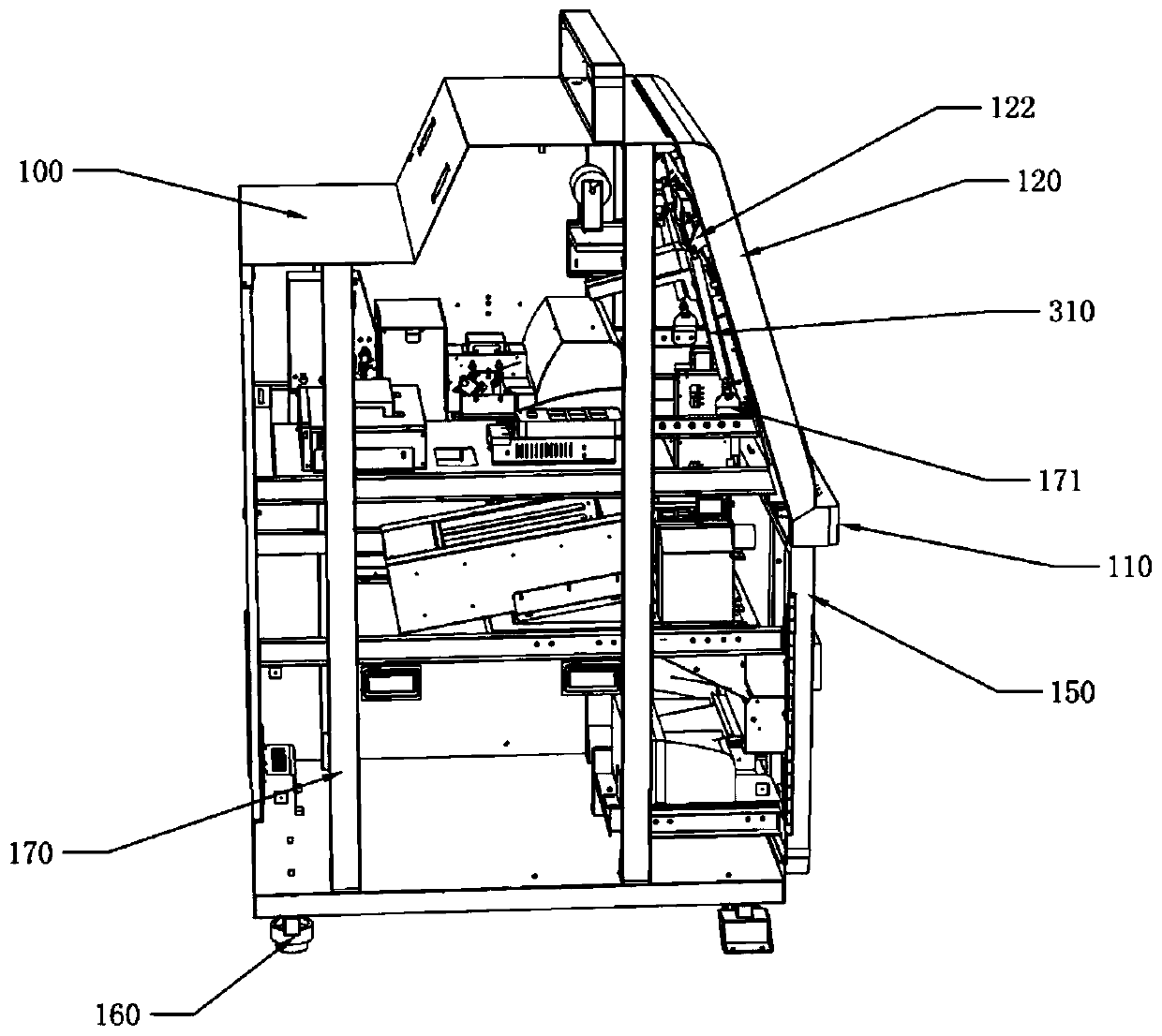

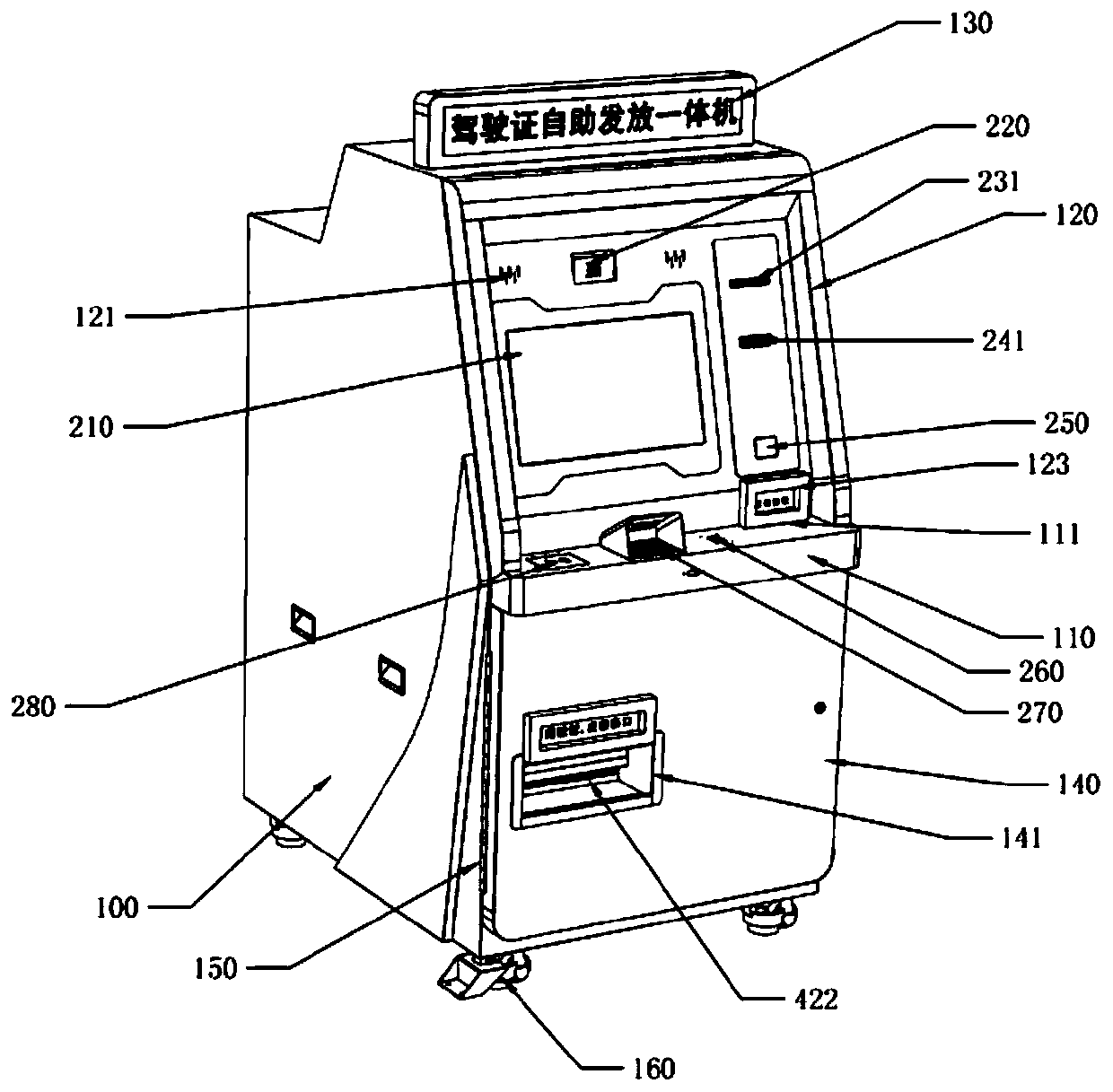

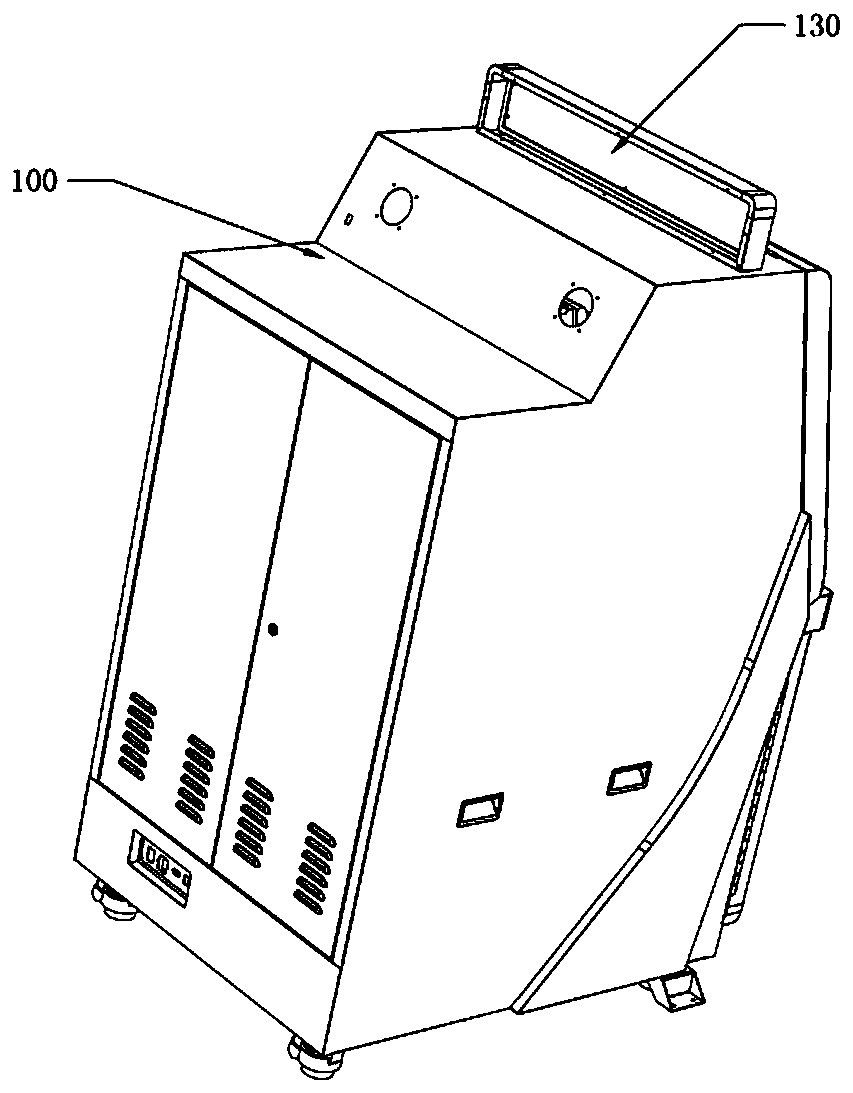

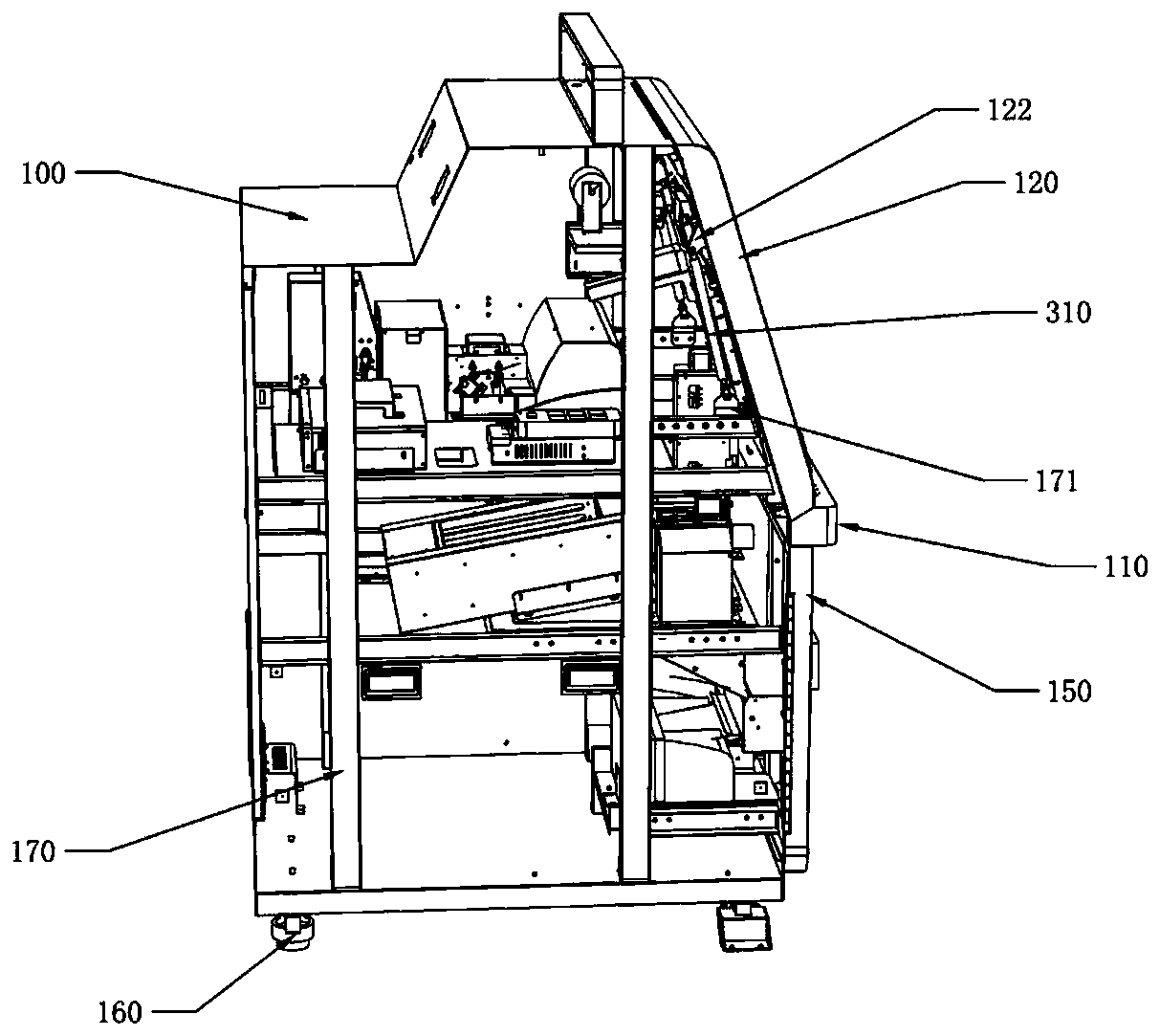

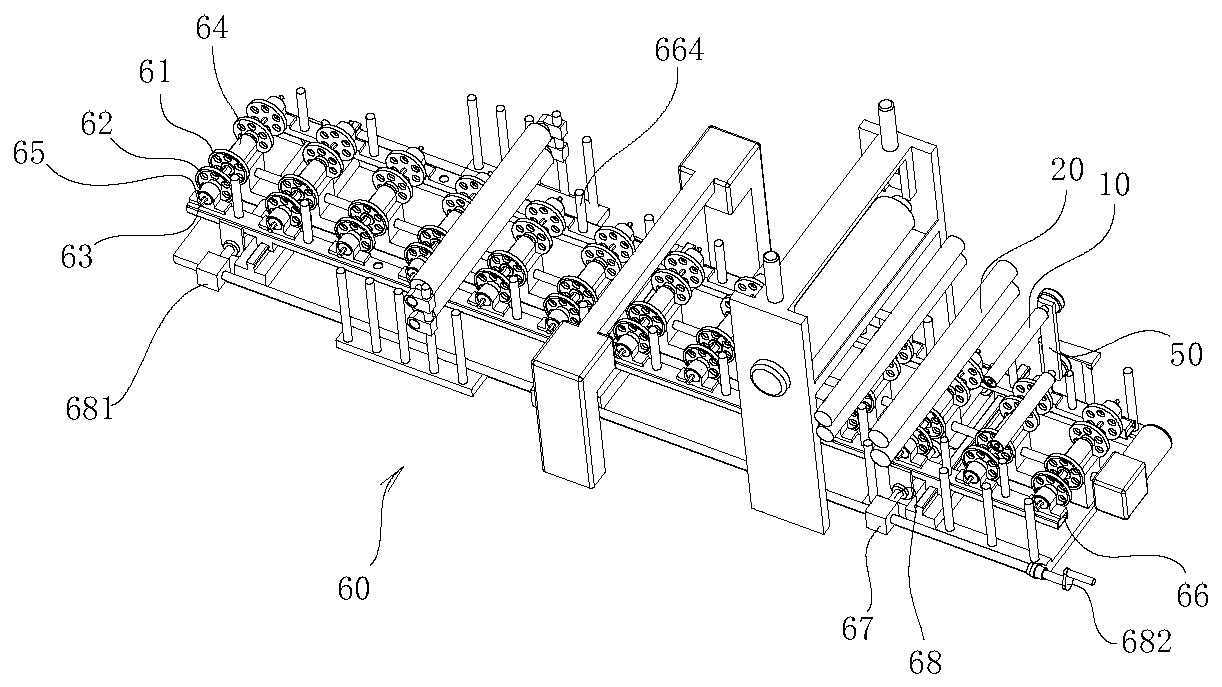

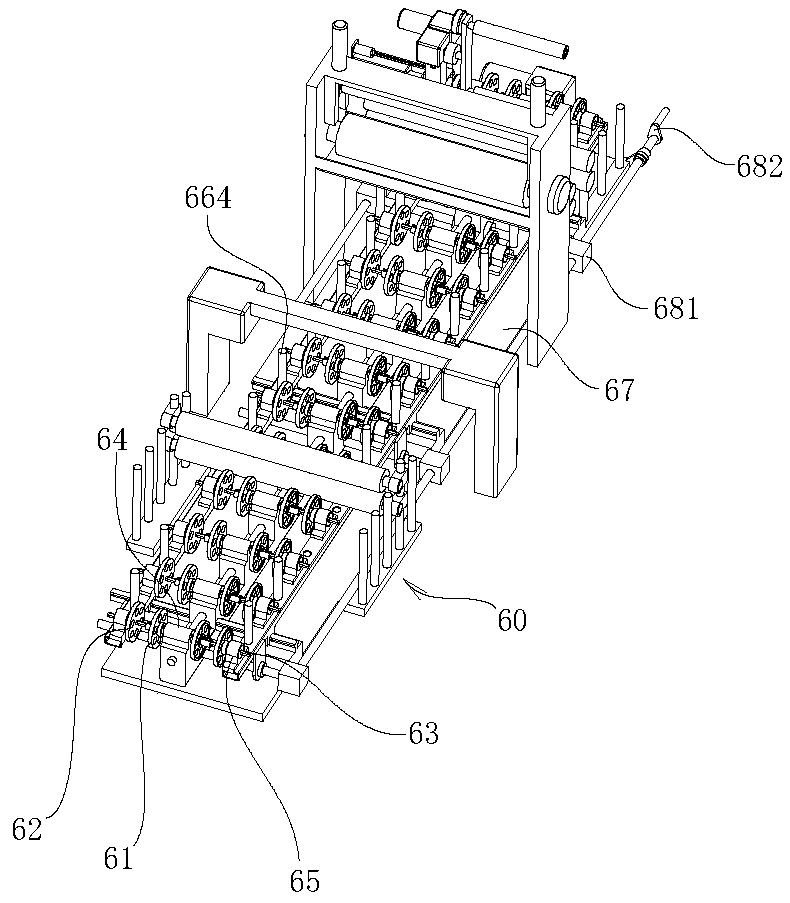

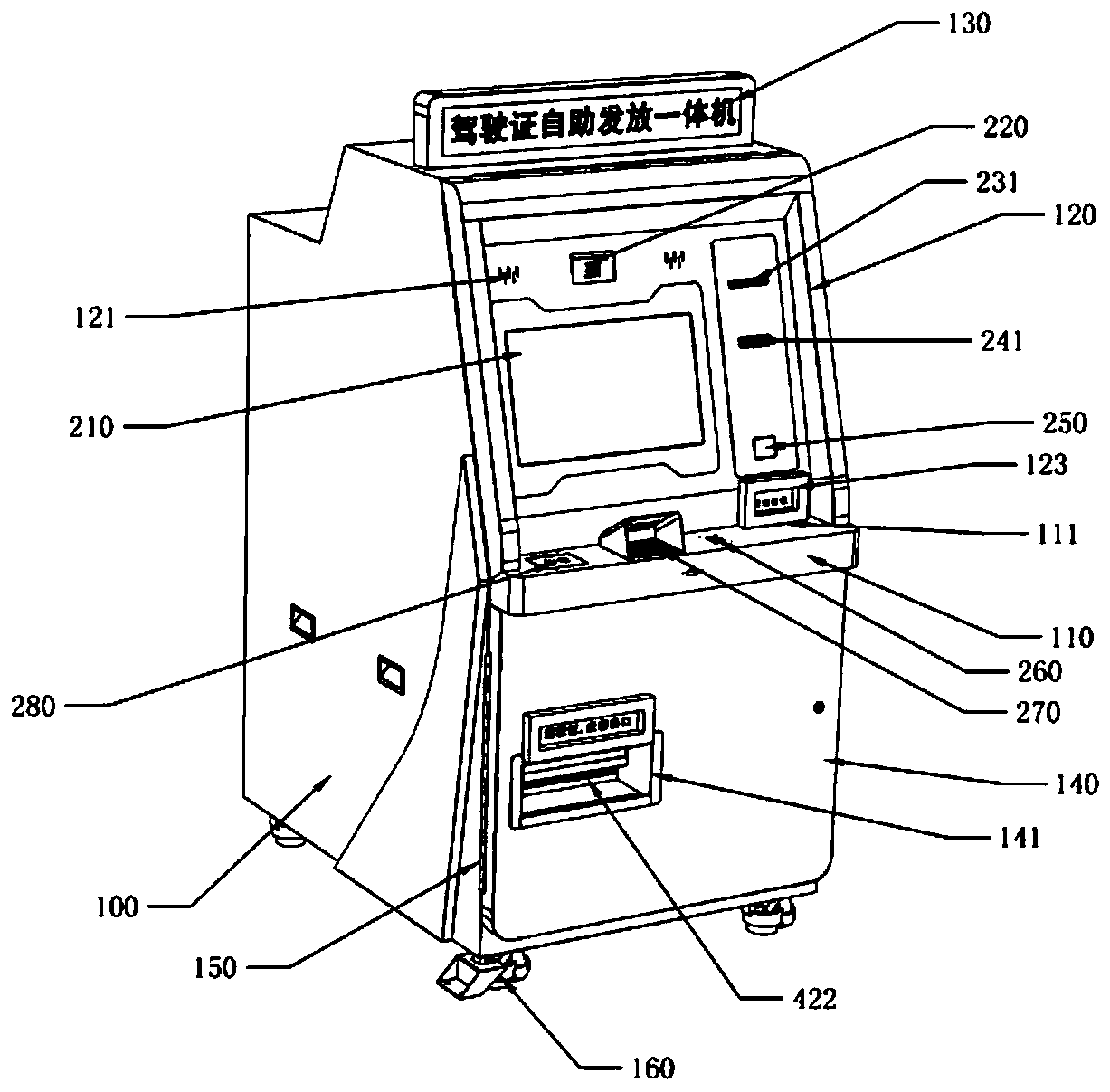

Dispensing module and driving license self-service dispenser thereof

PendingCN110136365ARealize automatic distributionEasy to pick upApparatus for meter-controlled dispensingComputer moduleEngineering

The invention discloses a dispensing module and a driving license self-service dispenser thereof. The dispensing module comprises dispensing side covers, wherein the dispensing side covers are arranged on dispensing side plates; two dispensing side covers and two dispensing side plates are respectively arranged and fixed on a dispensing bottom plate, and the dispensing bottom plate and the dispensing side covers are assembled and fixed with a rack through a dispensing connecting frame respectively; a dispensing clapboard is arranged between the two dispensing side plates and close to the dispensing bottom plate, the dispensing side plates are provided with a through dispensing guide groove, a first dispensing support plate and a second dispensing support plate are respectively fixed on thedispensing side plates and are respectively assembled and fixed with a first dispensing shaft, the first dispensing shaft and a dispensing sliding block can be axially and slidably assembled, a boltpasses through the dispensing sliding block and the dispensing guide groove and then is assembled and fixed with a dispensing push plate, and one ends of the two dispensing side plates, which are faraway from a first dispensing end plate, are respectively assembled and fixed with a second dispensing end plate; and the first dispensing end plate forms dispensing gaps with the dispensing bottom plate and the dispensing clapboard respectively.

Owner:WEIRONG TECH CO LTD

Control method for drivers' license self-service issuing machine

ActiveCN110136364ARealize automatic distributionEasy to pick upApparatus for meter-controlled dispensingComputer moduleDriver's license

The present invention discloses a control method for drivers' license self-service issuing machine. The machine mainly has following steps: firstly conveying paper from a paper feeding module to a rotating module, then feeding to a first printer through a reversing module for first printing, and then returning to the rotating module from the first printer for a 180 degree flip, again conveying tothe first printer for printing, after the printing is completed, conveying into the rotation module for a 180 degree reverse flip, then sending to a second printer through the reversing module, afterthe second printer finishes printing the paper, sending the paper to a cutting module, cutting the paper through the cutting module into primary page and secondary page, then loading the primary pageinto a plastic sealing bag through a film taking module, sending to a plastic sealing module for heating and plastic sealing then discharging, and discharging the secondary page directly through the plastic sealing module. And at the same time, the method realizes self-issuing of a leather case through a dispensing module. The method can realize automatic issuance of a driver's license and recycling of an old licence, thereby greatly facilitating a driver to obtain the driver's license, reducing window pressure, and conforming to convenience measures currently implemented by the government.

Owner:WEIRONG TECH CO LTD

Film getting module and driving license self-service issuing machine comprising same

The invention discloses a film getting module and a driving license self-service issuing machine comprising the same. The film getting module comprises a film getting bottom plate, a film getting topplate and a film getting position sensing plate. The film getting bottom plate and the film getting top plate are assembled and fixed through two film getting supporting plates. The face-to-face end faces of the two film getting supporting plates are fixedly provided with film getting sliding rails correspondingly. The film getting sliding rails are slidably matched with a film getting sliding block. The film getting sliding block is fixed to a film getting connecting plate. The two ends of the film getting connecting plate are assembled and fixed to a film getting driving plate and a film getting power plate correspondingly. The film getting driving plate is assembled to a film getting threaded rod in a screw-thread fit mode. The film getting threaded rod is assembled and fixed to a filmgetting motor shaft of a film getting motor. The film getting position sensing plate is located on the portion between a film getting position contact end and a film getting position sensing end and is hinged to a film getting power supporting plate through a pin shaft. The film getting power supporting plate is fixed to the film getting power plate. One end of a film getting pipe is provided witha suction disk and communicates with the suction disk, and the other end of the film getting pipe communicates with a suction port of a film getting air pump through an air pipe.

Owner:WEIRONG TECH CO LTD

Order processing system

PendingCN111476638AGuaranteed experienceAvoid gettingBuying/selling/leasing transactionsLogisticsHuman–machine interfaceSoftware engineering

The invention provides a system for processing orders, which can effectively prevent order splitting and profit making behaviors in electronic commerce, saves manpower and does not influence customerexperience. The system for processing the order comprises a main donation relation subsystem which is used for correspondingly recording a main commodity order number and a gift order number after order splitting and checking whether the received order number is the recorded main commodity order number or not; an order transaction subsystem which is used for requesting the main donation relation subsystem to check whether the cancelled order is a recorded main commodity order number or not under the condition of receiving order cancelling information sent by a client; if yes, outputting the data of a first human-computer interface, wherein the first human-computer interface is used for presenting first prompt information to prompt a client that the main commodity order and the gift order are to be canceled at the same time, so the client confirms or cancels the order canceling operation.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

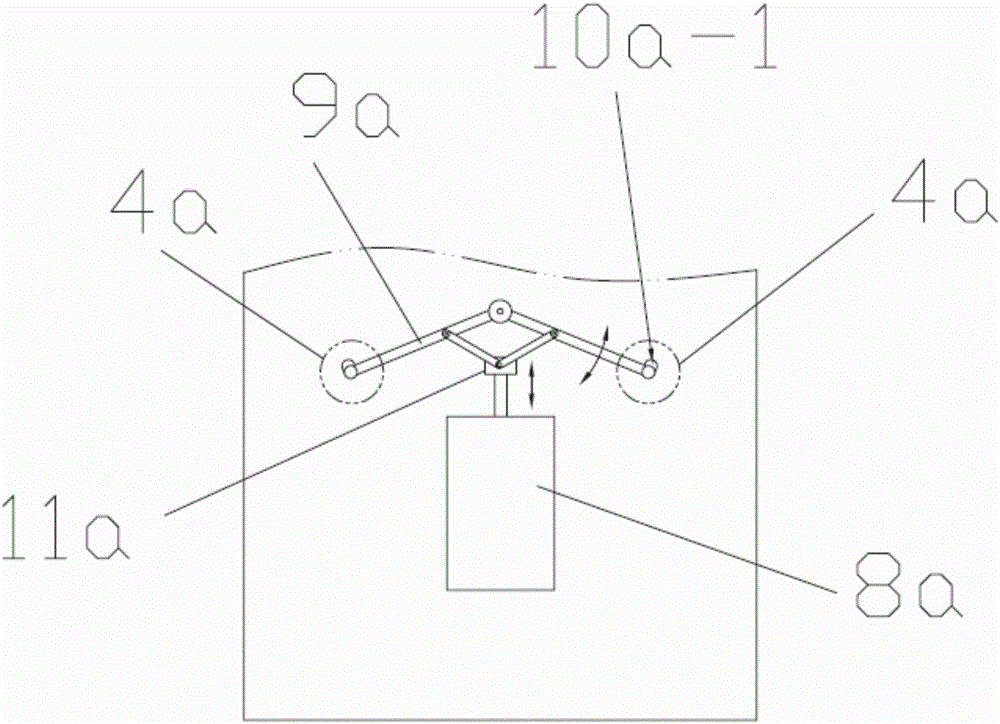

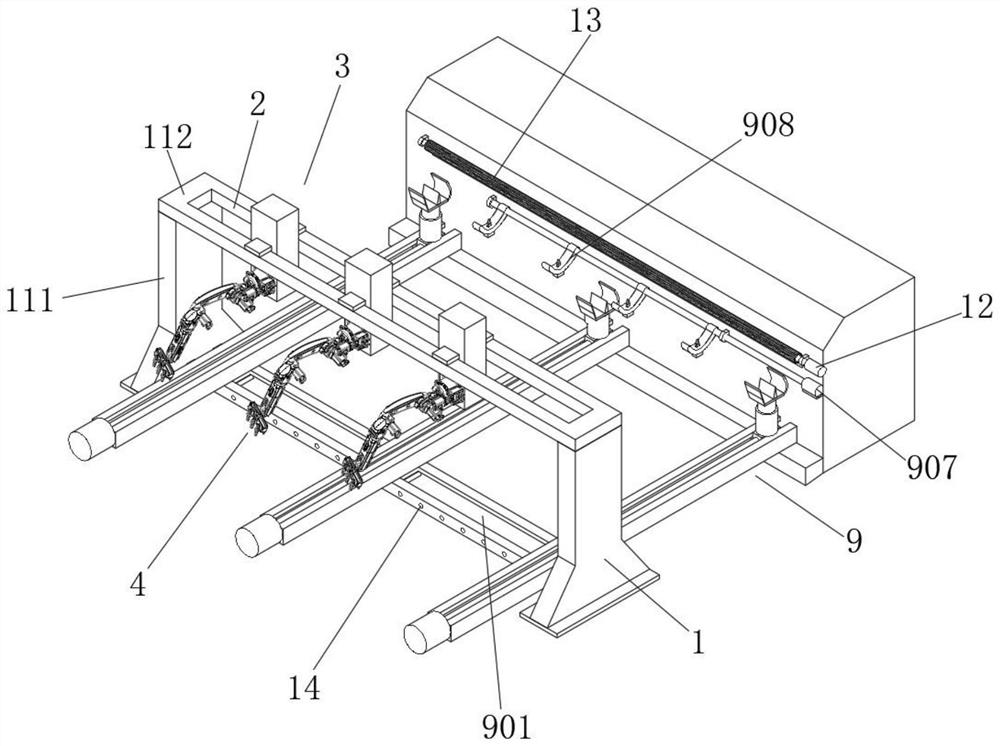

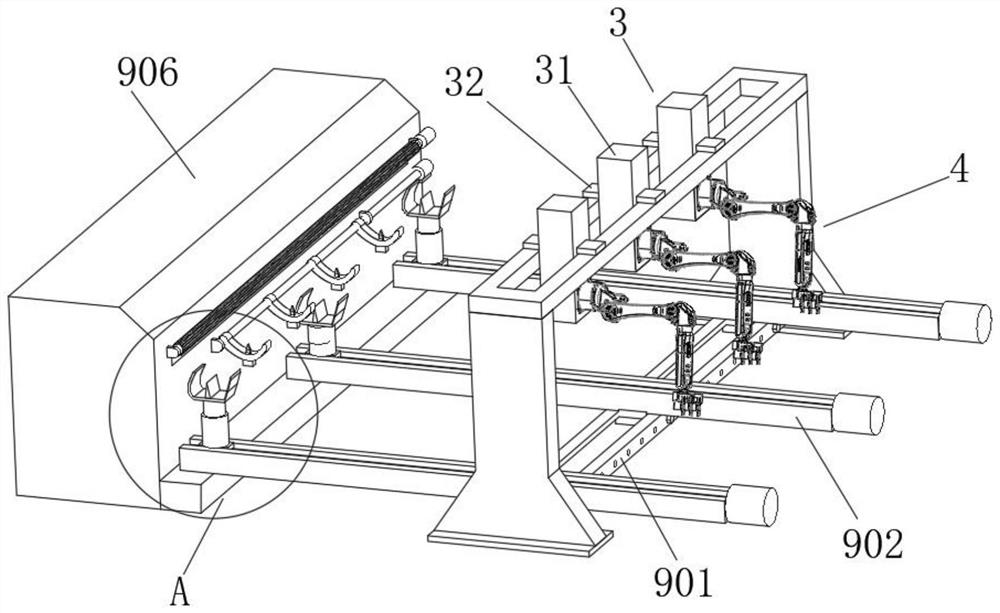

Automatic steel bar binding system

ActiveCN113733341ADoes not affect normal deliveryTo achieve different binding needsCeramic shaping apparatusRebarMechanical engineering

The invention relates to the field of automatic steel bar binding, in particular to an automatic steel bar binding system. The automatic steel bar binding system comprises a truss, a first sliding table mounted at the top of the truss, three second sliding tables vertically mounted at the top of the first sliding table, mechanical arms mounted on mounting seats at the bottoms of the second sliding tables, and a conveying mechanism for conveying multiple bundles of steel bars, wherein the conveying mechanism comprises a first sliding frame welded to the inner side of the truss, and the first sliding frame is connected with a conveying frame in a sliding mode. According to the system, by arranging the conveying mechanism, multi-bundle conveying can be achieved, the conveying efficiency is improved, normal conveying of a reinforcing steel bar conveyor is not affected even when reinforcing steel bars with the small bundle number are conveyed and bundled, meanwhile, through cooperation of third sliding tables and binding guns, the distance between the binding guns can be automatically adjusted according to needs, different binding requirements are met, continuous operation can be achieved, use is convenient and fast, operation efficiency is greatly improved, and labor intensity is reduced.

Owner:北京好运达智创科技有限公司

Self-sealing dual-channel hydraulic control stepless fracturing sliding sleeve device

InactiveCN107448170BReduce connectionsImprove reliabilityFluid removalWell/borehole valve arrangementsFluid controlIntegrated design

The invention belongs to the technical field of petroleum engineering, and discloses a self-sealing dual-channel liquid-controlled stepless fracturing sliding sleeve device, which includes an upper distribution joint, an inner central pipe connected to the upper distribution joint, an outer central pipe, an outer sleeve, and a lower part of the outer sleeve The upper pressure ring, the piston between the upper pressure ring and the outer central tube, the locking ring retaining ring at the lower part of the outer sleeve, the locking ring on the piston, the spacer ring, the rubber sleeve, and the lower pressure ring arranged in sequence under the upper pressure ring , sliding sleeve, lower joint and distribution sleeve, the lower pressure ring is connected between the outer central tube and the distribution sleeve, the sliding sleeve is connected between the lower end of the inner central tube and the distribution sleeve, and the lower joint is connected to the lower end of the distribution sleeve. This technical solution realizes the integrated design of packer and sliding sleeve, reduces the connection between tools, improves the reliability of tools, saves construction costs, and improves the efficiency of multi-stage fracturing. In addition to the conventional large-diameter oil flow channel, it also has an independent first Two hydraulic control channels realize the hydraulic control of downhole tools at the wellhead without affecting the normal delivery of oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Reversing module and driving license self-service issue machine comprising reversing module

PendingCN110136362ARealize automatic distributionEasy to pick upApparatus for meter-controlled dispensingComputer moduleEngineering

The invention discloses a reversing module and a driving license self-service issue machine comprising the reversing module. The reversing module comprises a reversing top shell and a reversing bottomshell, wherein the two sides of the reversing top shell and the two sides of the reversing bottom shell are assembled and fixed to reversing side plates respectively, and a first reversing channel isformed between the reversing top shell and the reversing bottom shell; a first reversing channel plate is fixed between two reversing side plates, a second reversing channel plate is fixed between the other two reversing side plates, a second reversing channel is formed between the first reversing channel plate and the second reversing channel plate, the ends, close to a rotating outlet, of the first reversing channel and the second reversing channel are communicated, and the first reversing channel and the second reversing channel are communicated with a paper inlet of a first printer and apaper inlet of a second printer respectively; and a third reversing shaft is arranged at the communicating position of the first reversing channel and the second reversing channel, a reversing plate is installed on the third reversing shaft, and a reversing end plate is arranged at the end, close to a rotating module, of the reversing plate. Through the driving license self-service issue machine,automatic issue of a driving license and old license recovery can be realized, therefore, it is quite convenient for a driver to get a driving license, and burden on a service window is relieved.

Owner:WEIRONG TECH CO LTD

Coating film production line

PendingCN110654620AReduce material scrap lossGuaranteed continuous supplyWrapping material feeding apparatusWrappingComposite materialProduction line

The invention relates to a coating film production line. The production line comprises a plurality of roller rods for arranging roll materials, wherein the sides of the roller rods are provided with first film rollers and second film rollers, the first film rollers and the second film rollers are arranged in the up-down direction, the sides of the first film rollers and the second film rollers areprovided with first pressing heads and second pressing heads correspondingly, and a driving mechanism drives the first pressing heads and the second pressing heads to be close to or far away from roller bodies of the first film rollers and the second film rollers. The system can ensure continuous feeding of films, and the problem of material abandonment loss caused by replacing film rolls is reduced.

Owner:田开林

Branch line connecting technology adopting no valve during hot tapping

InactiveCN102784966ADoes not affect normal deliveryReduce construction costsBranching pipesEngineeringLine tubing

The invention relates to a branch line connecting technology adopting no valve during hot tapping. The technology comprises the following steps: mounting and welding paired semicircular non-sealing head four-way pipes to a to-be-bored main pipeline; butting to-be-connected branch lines with the connection ports of the four-way pipes; and mounting a temporary bored gate valve, a boring machine and a bored connecting box on operation ports of the four-way pipes while well supporting the temporary bored gate valve, the boring machine and the bored connecting box. The boring machine is used for boring, and is dismantled after the boring is fulfilled; and formation sealing pies and blind plates are mounted on the operation ports. The technology has the benefits that the normal delivery of a pipeline cannot be impacted during the construction process; the technology is simple; the operation is convenient; and no valve is arranged between the main pipeline and branch lines, so as to reduce cost and follow-up maintenance and potential safety hazards.

Owner:HENAN ZHONGTUO PIPELINE ENG

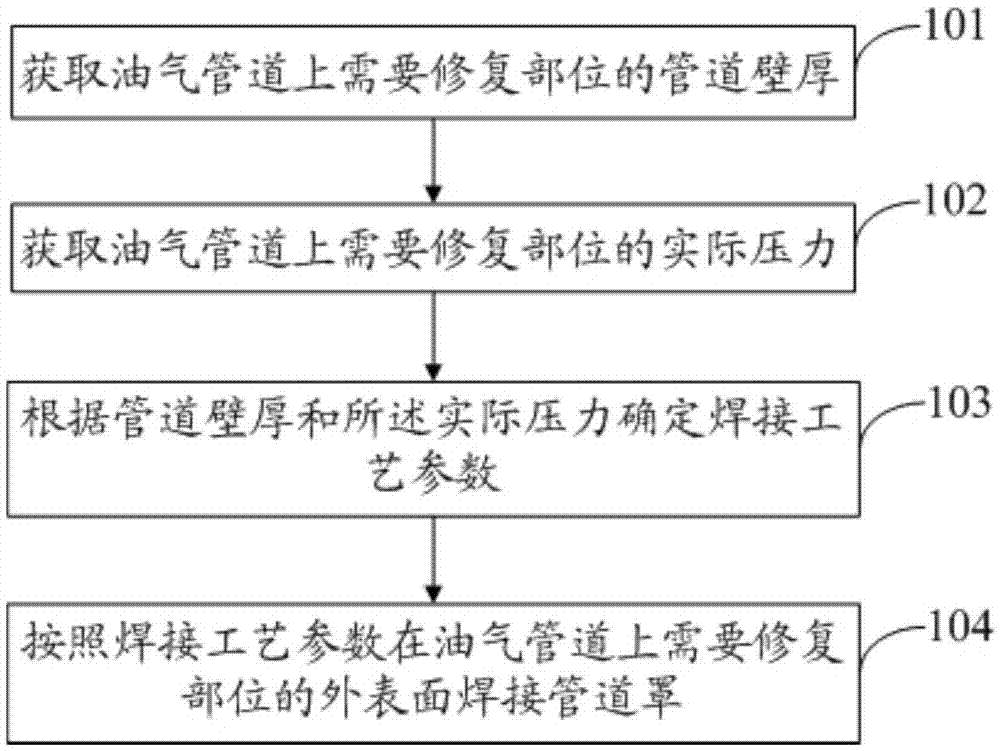

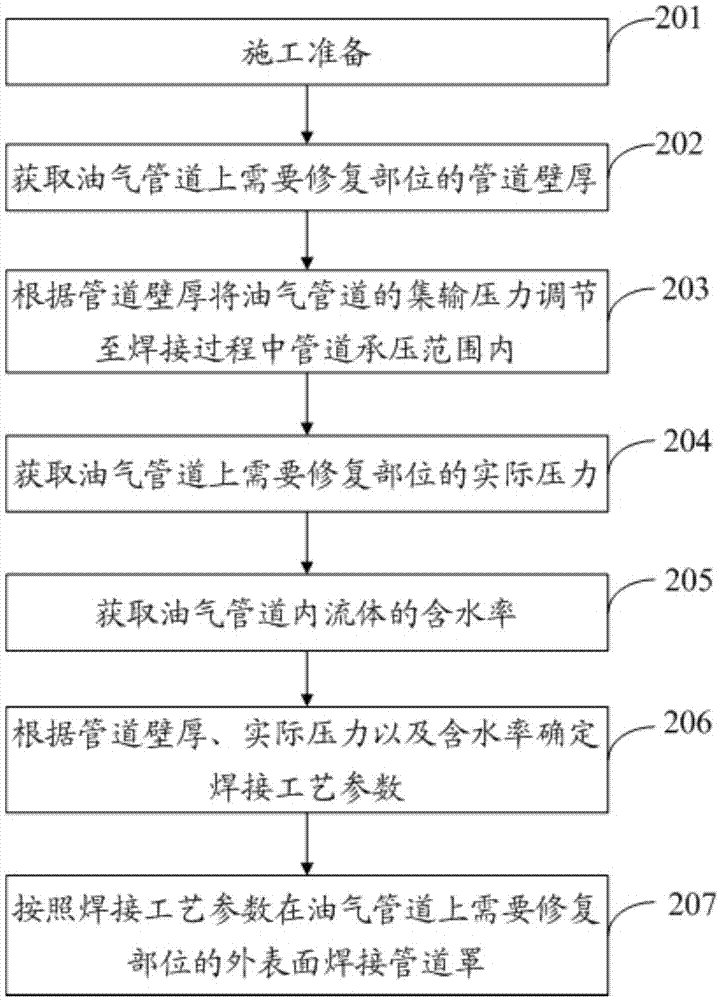

Method for rehabilitating oil-gas pipeline without transportation interruption

ActiveCN106862782AAvoid safety accidentsAvoid shortingMetal working apparatusWelding apparatusPower flowEngineering

The present invention discloses a method for rehabilitating an oil-gas pipeline without transportation interruption, and belongs to the technical field of oil-gas pipeline rehabilitation. The method for rehabilitating an oil-gas pipeline comprises the following steps: step a, obtaining a pipeline wall thickness of a to-be-repaired part of an oil-gas pipeline; step b, obtaining an actual pressure of the to-be-repaired part of the oil-gas pipeline; step c, determining welding process parameters based on the pipeline wall thickness and the actual pressure, the welding process parameters including a diameter of a welding rod, an output current of an electric welding machine, and electric welding time; and step d, welding a pipeline casing to the outside surface of the to-be-repaired part of the oil-gas pipeline. By means of this method, an oil-gas pipeline can be rehabilitated without transportation interruption with high rehabilitation efficiency, low labor intensity of an operator, and no environmental pollution.

Owner:PETROCHINA CO LTD

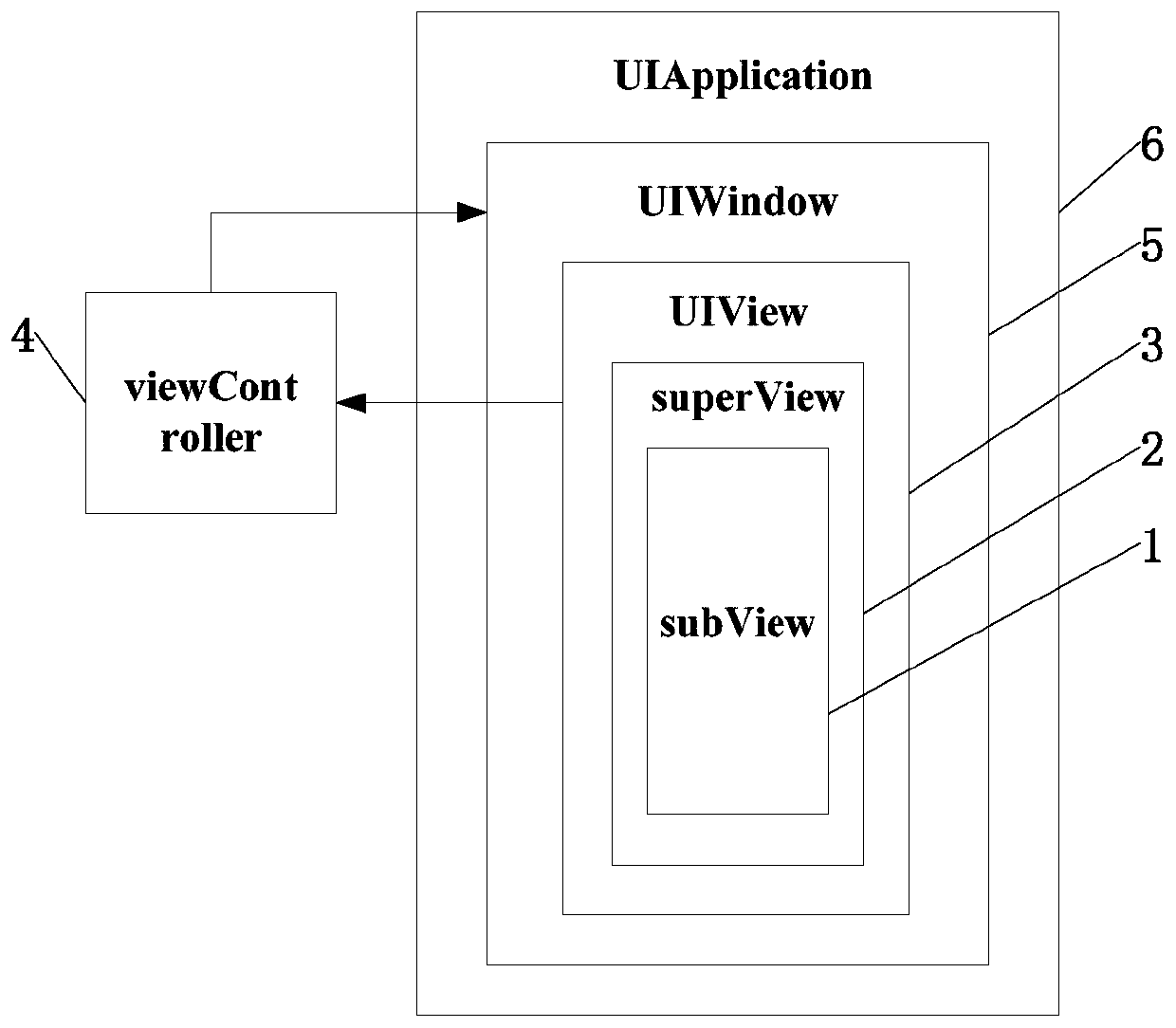

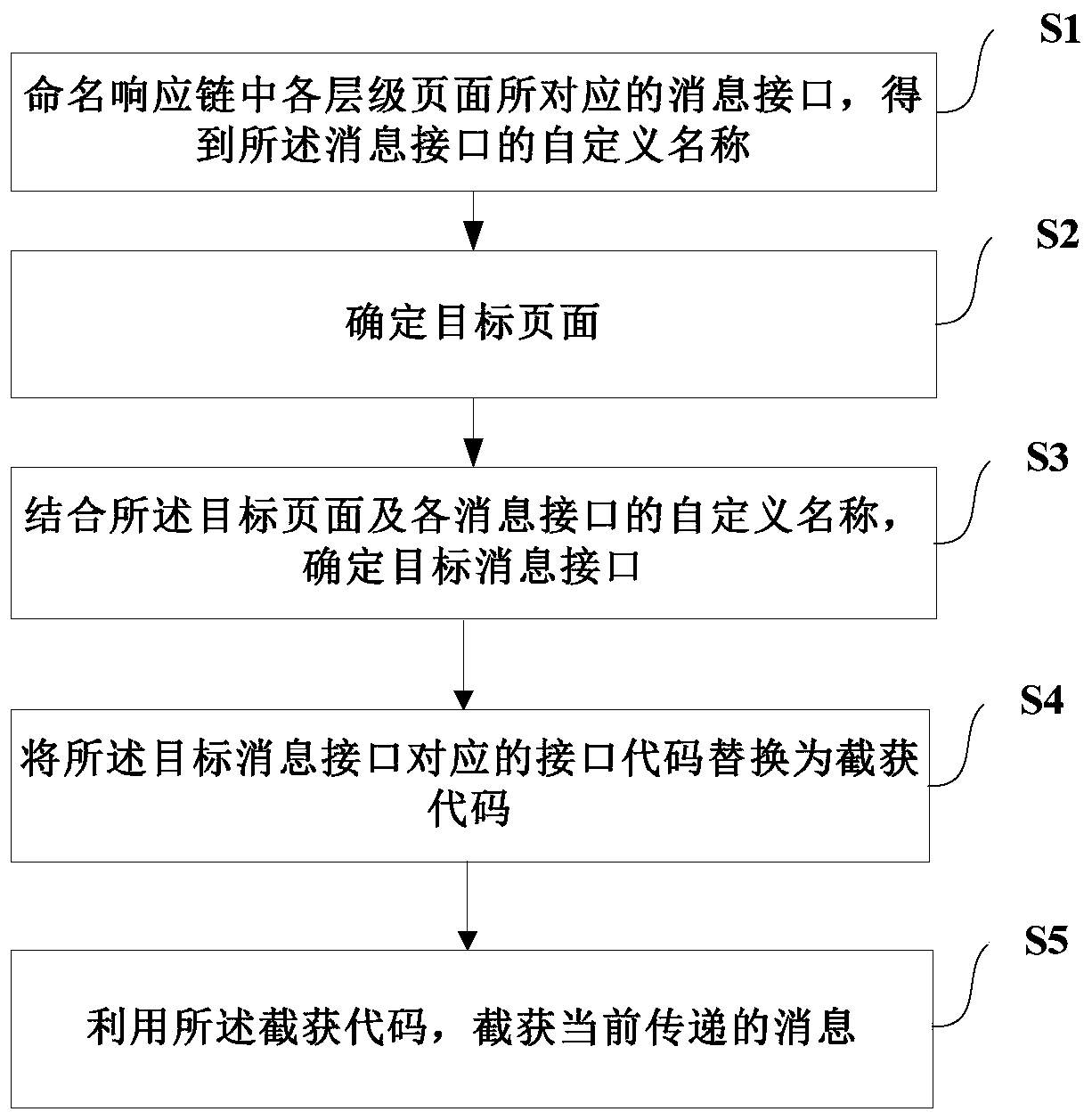

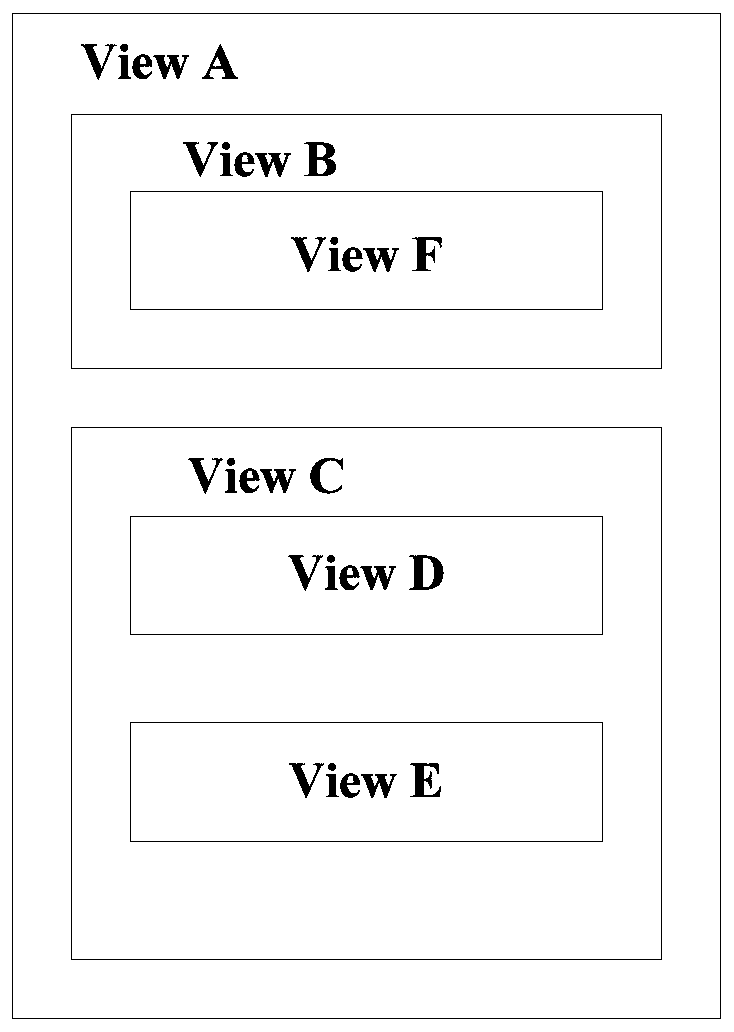

Message interception method and device, electronic equipment and storage medium

ActiveCN110597647ANormal deliveryDoes not affect normal deliveryInterprogram communicationComputer hardwareMessage passing

The embodiment of the invention provides a message interception method and device, electronic equipment and a storage medium. The method comprises the steps: naming a message interface corresponding to each hierarchical page in a response chain, and obtaining a custom name of the message interface; determining a target page; determining a target message interface in combination with the target page and the custom name of each message interface; replacing an interface code corresponding to the target message interface with an interception code; and intercepting and capturing a currently transmitted message by utilizing the interception and capture code. Therefore, according to the message transmission method provided by the invention, the required message can be accurately intercepted in the page of the specified hierarchy, and meanwhile, the normal transmission of the message is not influenced.

Owner:WUBA

Paperboard sampling machine

InactiveCN113928902AQuick guide rangeQuick lifting actionWithdrawing sample devicesArticle deliveryControl engineeringPaperboard

The invention disposes a paperboard sampling machine. The machine comprises a supporting rack, a controller, a longitudinal conveying mechanism, a guide mechanism, a lifting mechanism and a transverse conveying mechanism, the longitudinal conveying mechanism, the guide mechanism and the lifting mechanism are all arranged on the supporting rack, the transverse conveying mechanism is arranged on the lifting mechanism, the longitudinal conveying mechanism is used for achieving longitudinal conveying of paperboards, the guide mechanism is used for guiding and moving a certain moving paperboard on the longitudinal conveying mechanism to the lifting mechanism, the lifting mechanism is used for achieving lifting of the paperboard located on the lifting mechanism and the transverse conveying mechanism, and the transverse conveying mechanism is used for achieving transverse conveying of the paperboard on the lifting mechanism. According to the sampling machine, manual paperboard sampling operation is replaced by a mechanical operation mode, the sampling operation safety is greatly improved, meanwhile, the guide mechanism in the sampling machine is rapid in execution action, the selected paperboards can be rapidly separated on a conveying line, then the sampling operation can be smoothly completed, and the sampling reliability is guaranteed.

Owner:SHANDONG SENY MACHINERY

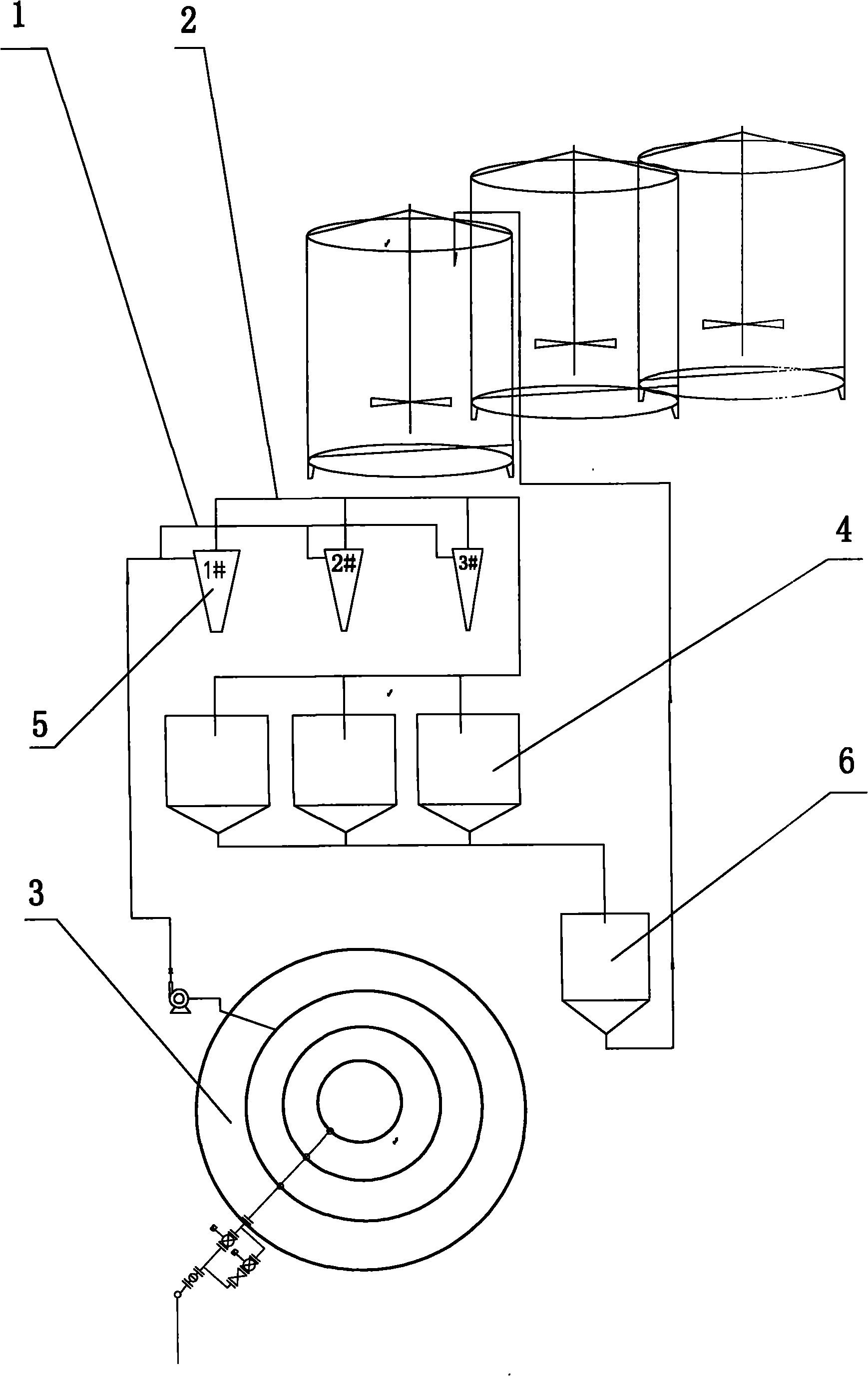

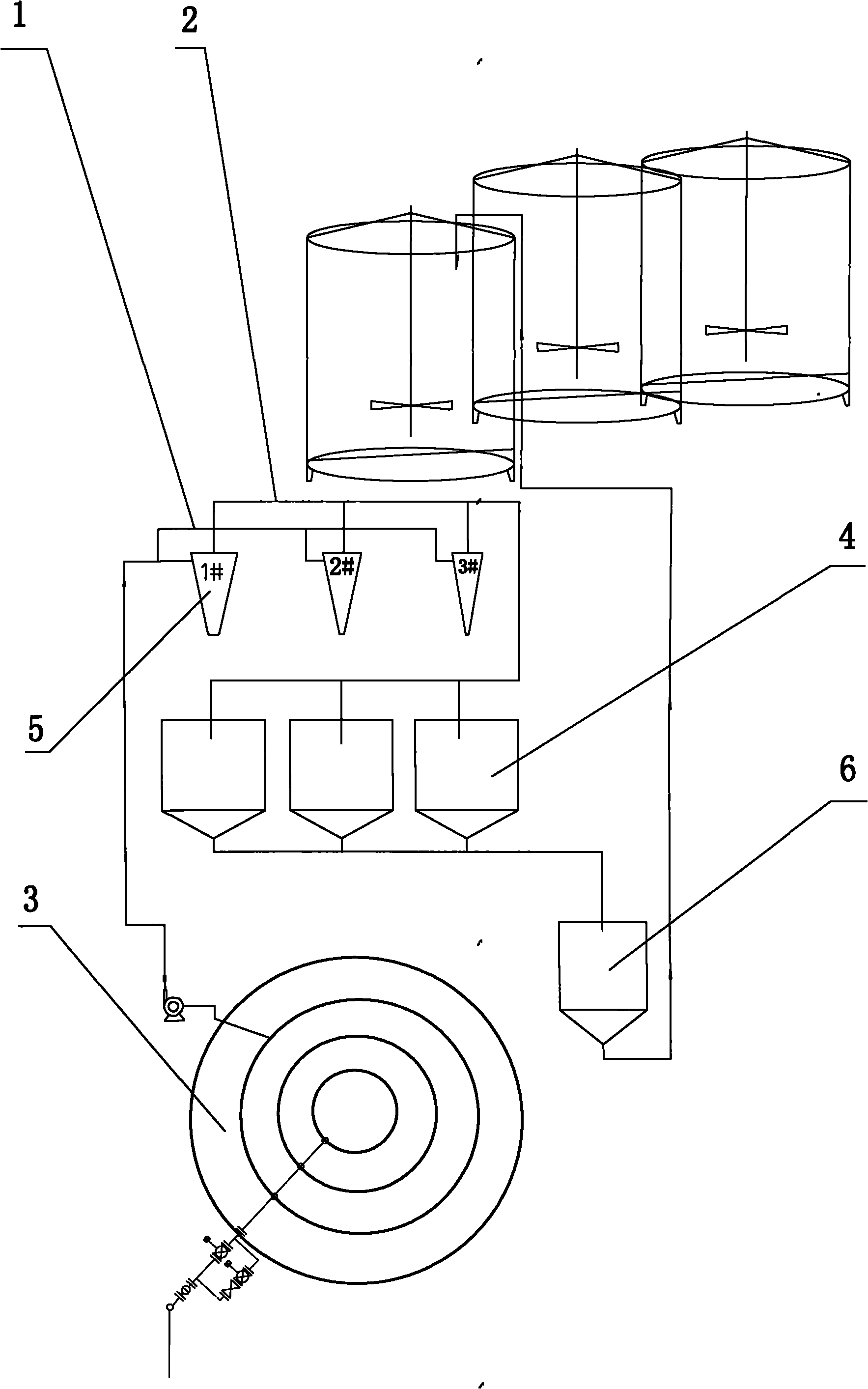

Impurity removal system for mesona chinensis liquid

ActiveCN102172441ADoes not affect normal deliveryDoes not affect normal workCentrifugal force sediment separationSolid solvent extractionLiquid storage tankProcess engineering

The invention discloses an impurity removal system for a mesona chinensis liquid. The system comprises a filtering device arranged between a boiling extraction process and a concentration process; the filtering device is communicated with an extraction pot and a liquid storage tank through a liquid inlet main pipe and a liquid outlet main pipe respectively, and composed of multiple reverse parallel conical cylinders (No.1, No.2, No.3,...,No.N); an impurity removal port is arranged at the bottom conical tail of each conical cylinder; the liquid inlet of each conical cylinder is arranged on the cylindrical wall at the upper part of the conical cylinder and tangentially communicated with a liquid inlet pipe; the liquid outlet of each conical cylinder is arranged at the top of the conical cylinder and connected with a liquid outlet pipe; each liquid inlet pipe is communicated in parallel with the liquid inlet main pipe, and each liquid outlet pipe is communicated in parallel with the liquid outlet main pipe; and each liquid inlet pipe and each liquid outlet pipe are respectively provided with a control valve. According to the invention, because the combined conical cylinders are used as a filtering device, the filtered impurities can be discharged anytime so as to avoid the influence on the normal conveying of the mesona chinensis liquid between the previous process and the next process and guarantee the normal production.

Owner:广西灵山县宇峰保健食品有限公司

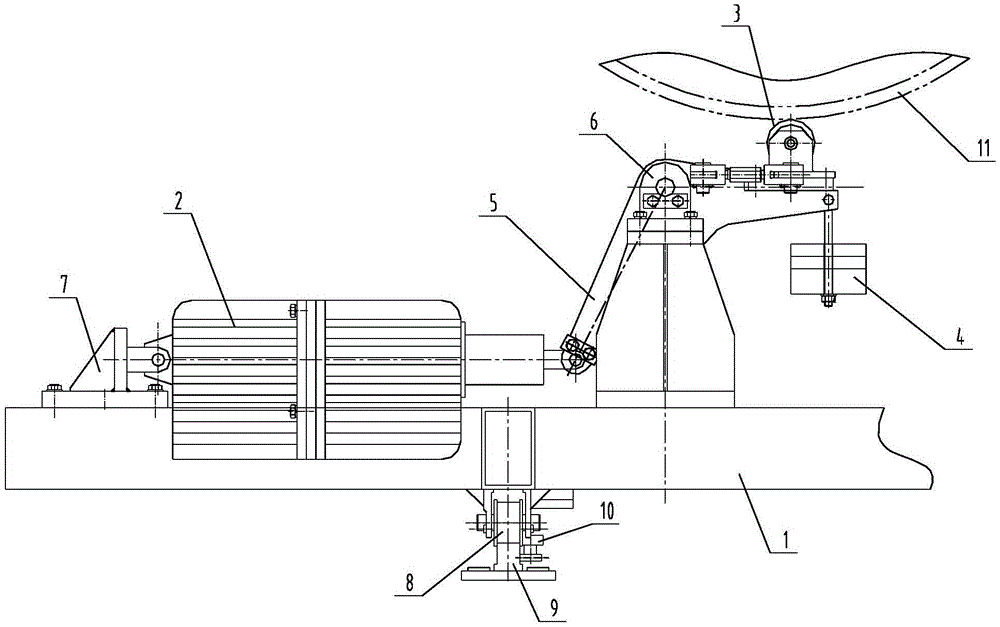

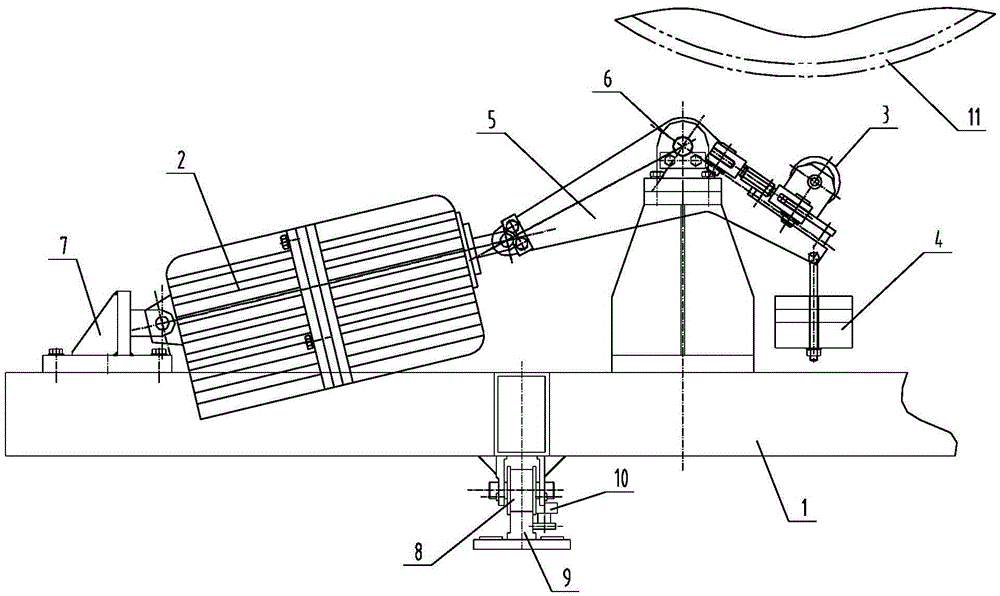

Following mechanism used during spiral welding pipe cutting and operation method of mechanism

ActiveCN105642999ADoes not affect normal deliveryCompact structureTube shearing machinesShearing machine accessoriesDrop weightEngineering

The invention relates to a following mechanism used during spiral welding pipe cutting and an operation method of the following mechanism. The following mechanism comprises a following platform, an electric-hydraulic pusher, an L-shaped swing arm, a cutter wheel and a dropping weight. A walking wheel is arranged at the bottom of the following platform and can drive the following platform to walk along a rail parallel to the conveying direction of a spiral welding pipe; the fixed end of the electric-hydraulic pusher is hinged to the following platform, and the middle portion of the L-shaped swing arm is hinged to a support; two ends of the L-shaped swing arm are suspended, one end of the L-shaped swing arm is hinged to the stretching-out end of the electric-hydraulic pusher, the cutter wheel is arranged on the upper portion of the other end of the L-shaped swing arm, and the dropping weight is arranged on the lower portion of the other end of the L-shaped swing arm; and the axis of the cutter wheel is parallel to the axis direction of the spiral welding pipe, and a weight assembly is arranged in the dropping weight and is composed of a plurality of weights with different thickness specifications. The lever principle and the dropping weight capable of adjusting the weight of the weights are used for achieving rapid joint and separation of the following mechanism and the moving spiral steel pipe while the electric-hydraulic pusher and the cutter wheel are adopted to achieve the following action, accuracy and reliability of pipe cutting action are ensured, and the pipe cutting yield is improved greatly.

Owner:中冶辽宁德龙钢管有限公司

A smart card cleaning device capable of cleaning upper and lower cleaning rollers

InactiveCN105149252BSame cleaning effectDoes not affect normal deliveryCleaning using toolsEngineeringSmart card

The invention discloses a smart card cleaning device that can clean upper and lower cleaning rollers. It includes a card surface dust removal mechanism and a cleaning belt conveying mechanism. The card surface dust removal mechanism includes a fixed frame, two sets of cleaning roller sets, and two sets of driving wheels. A flip power mechanism for the overall rotation of the cleaning roller set and a card transport power mechanism for driving the rotation of each cleaning roller in the two sets of cleaning roller sets. Each set of cleaning roller sets includes a pair of two cleaning rollers; the guide wheel set includes Two cleaning belt pressing wheels arranged outside the two cleaning rollers located above, the two cleaning belt pressing wheels press the cleaning belt on the two cleaning rollers located above; the two cleaning belts The pressing wheel is connected with a pressing control mechanism. The cleaning device of the present invention can clean the upper and lower cleaning rollers, and does not affect the normal transportation of the card when cleaning any cleaning roller.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Paper feeding module and driving license self-service issuing machine

PendingCN110127401ARealize automatic distributionEasy to pick upApparatus for meter-controlled dispensingArticle feedersComputer modulePulp and paper industry

The invention discloses a paper feeding module and a driving license self-service issuing machine. The paper feeding module comprises a paper feeding top shell and a paper feeding bottom shell, wherein a paper placement cavity is formed in the paper feeding top shell and is divided into a paper placement cavity and an electric cavity through a paper placement baffle plate; the paper placement cavity is used for placing paper; the end surface of the paper is pressed against a paper placement bottom plate; a first paper feeding shaft, a second paper feeding shaft and a third paper feeding shaftare arranged between the paper placement bottom plate and the paper feeding bottom shell; a first paper feeding roller, a second paper feeding roller and a third paper feeding roller are respectivelyarranged on the first paper feeding shaft, the second paper feeding shaft and the third paper feeding shaft and are higher than the top surface of the paper placement bottom plate; a fourth paper feeding shaft and a fifth paper feeding shaft are arranged on the paper feeding top shell; one-way bearings are arranged at corresponding parts of the fourth paper feeding shaft and the second paper feeding roller; and a fifth paper feeding roller is arranged on the fifth paper feeding shaft and is mutually matched with the third paper feeding roller so as to convey paper.

Owner:WEIRONG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com