Automatic quick sealing equipment for express packaging box of storage sorting center

A packing box and fast technology, which is applied in the directions of packing sealing/fastening, packaging, transportation packing, etc., can solve the problems of packing box processing position offset, affecting the packing box processing effect, and unable to center the packing box, so as to save manufacturing Cost, ease of folding, and the effect of reducing flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

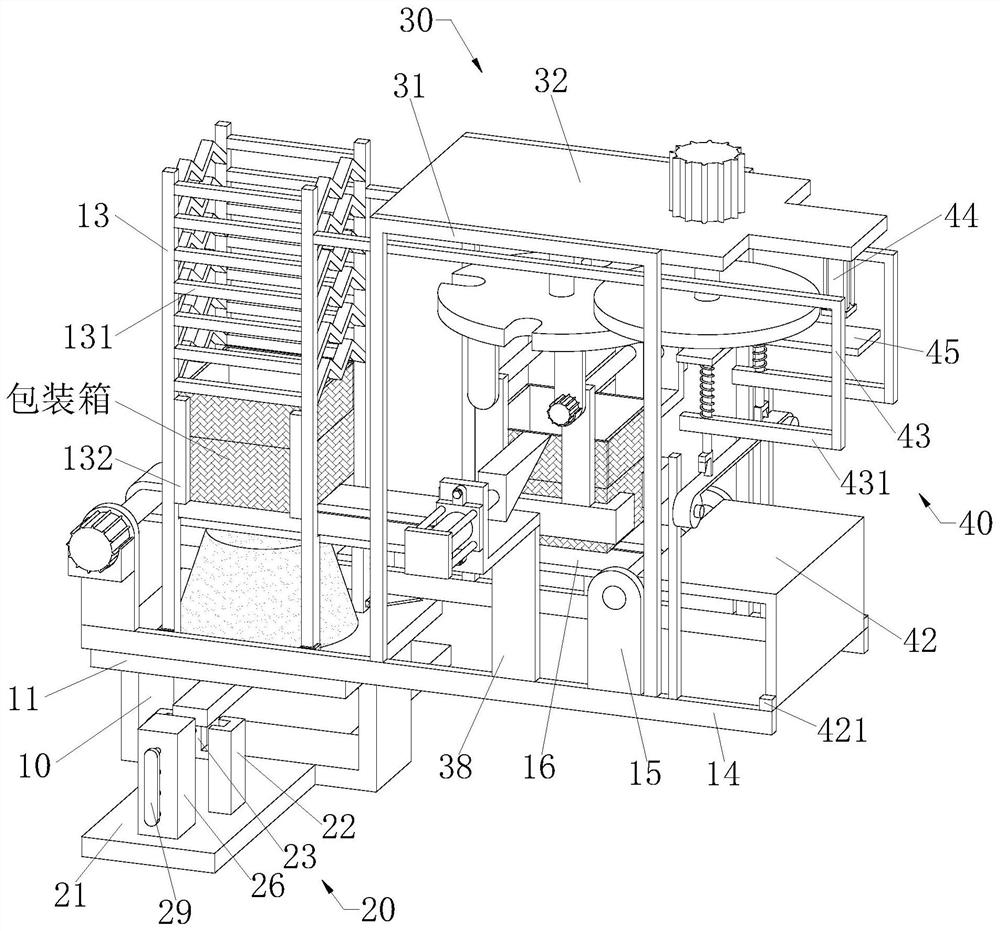

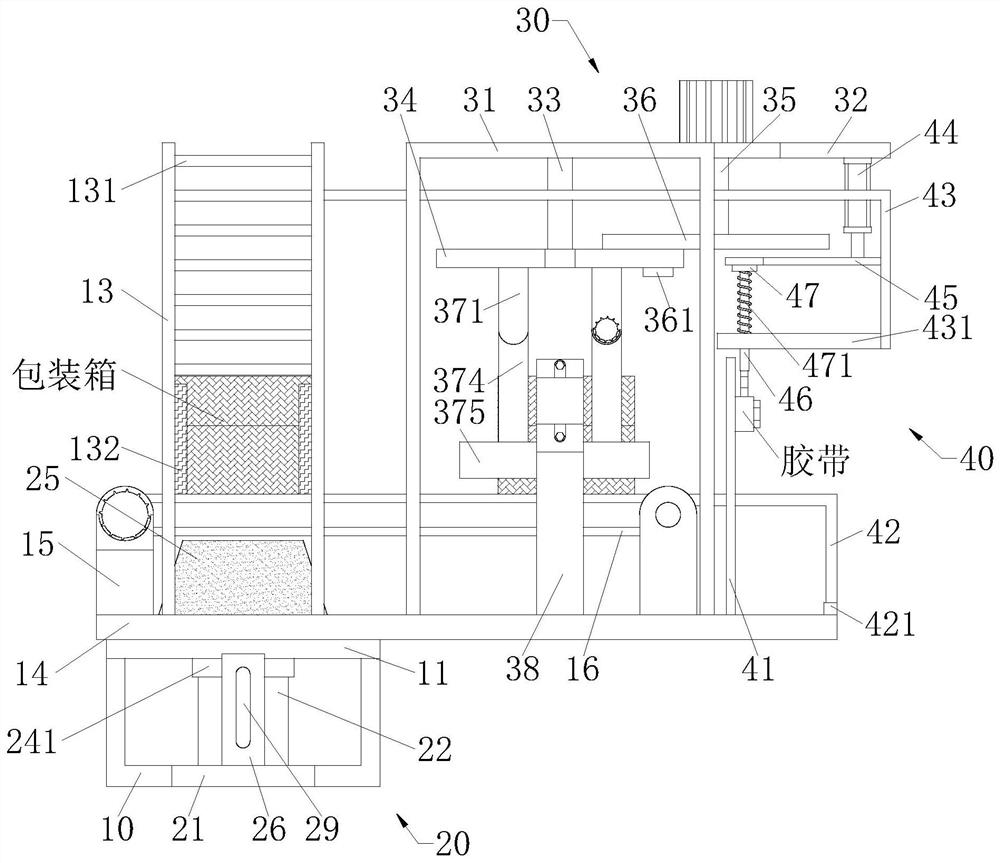

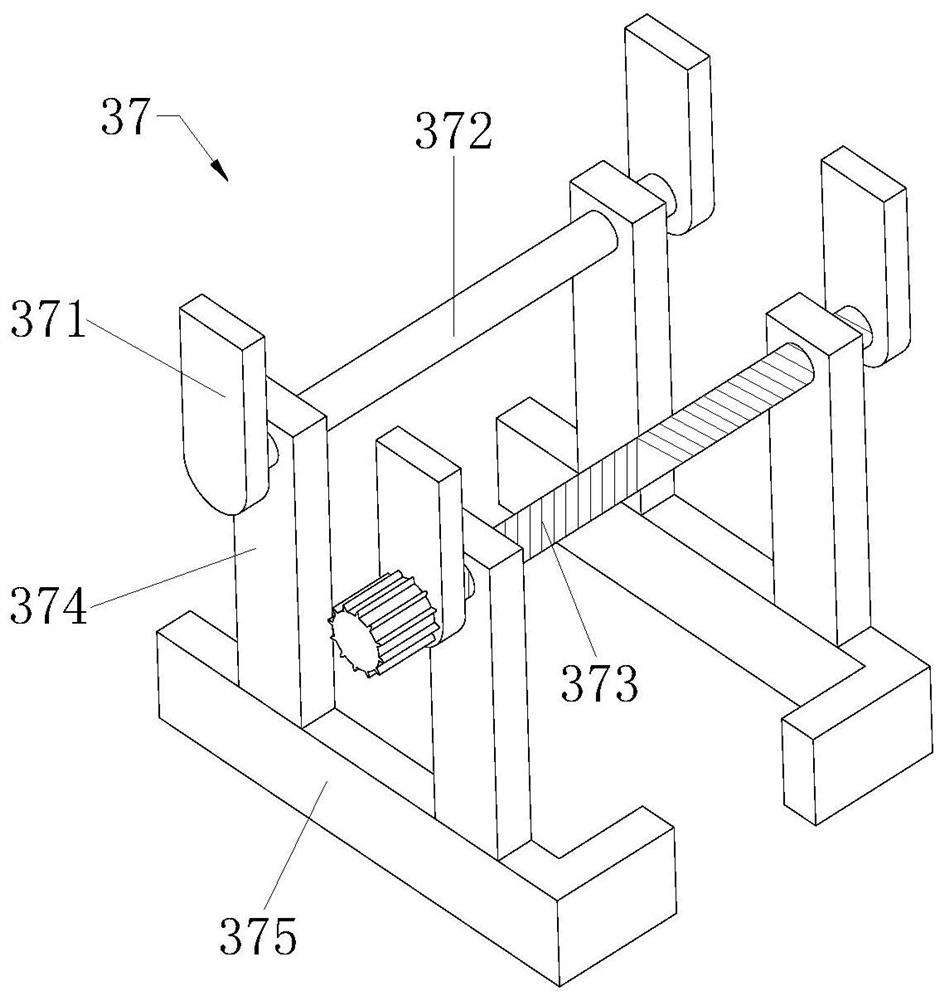

[0033] Such as Figure 1 to Figure 9 As shown, an automatic fast sealing equipment for express packaging boxes in a warehouse sorting center, the equipment includes a U-shaped seat 10 with an opening facing upwards, the front end of the U-shaped seat 10 is a U-shaped structure, and two groups of vertical boxes in the U-shaped seat 10 The top of the straight section is fixedly connected with a bottom plate 11. The top of the bottom plate 11 is in a square structure. T-shaped grooves 111 are provided at the diagonals of the top of the bottom plate 11. The T-shaped grooves 111 extend along the length direction of the bottom plate 11 diagonals. There is a distance between the sets of T-shaped slots 111 and they are symmetrical to each other. The center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com