A fast cutting device for building steel pipes

A technology for fast cutting and steel pipes, which is applied in the direction of shearing devices, attachments of shearing machines, metal processing equipment, etc. It can solve the problems of inability to cut to fixed lengths, easy sore arms, etc., and achieve the effect of fast cutting and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

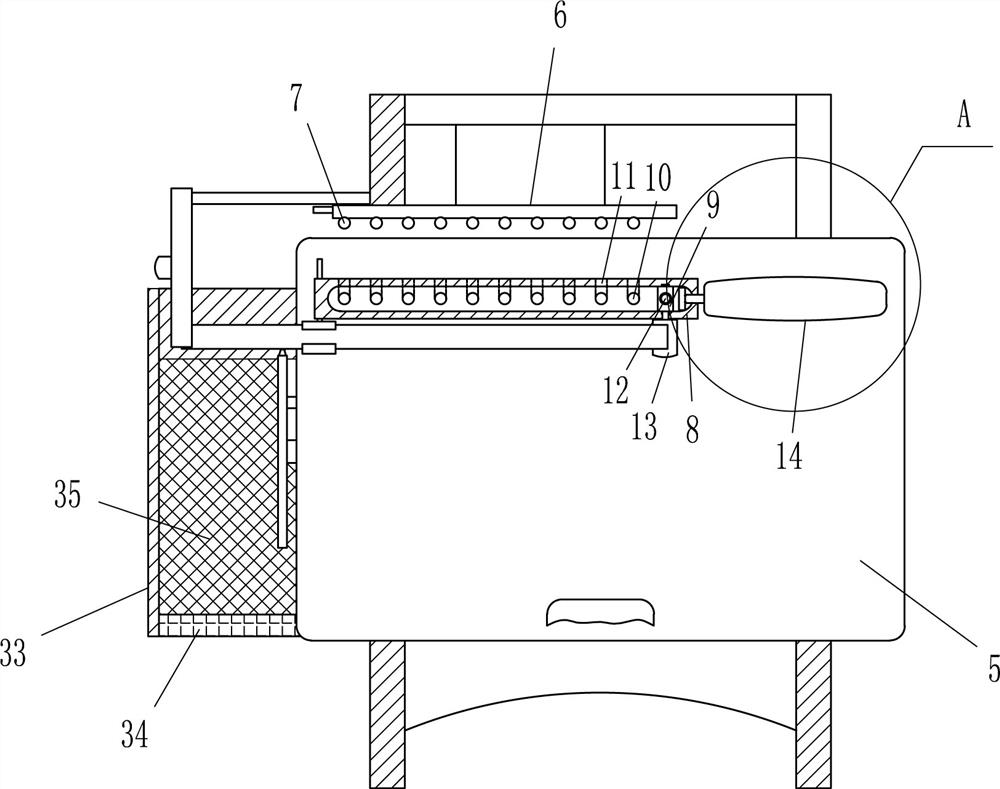

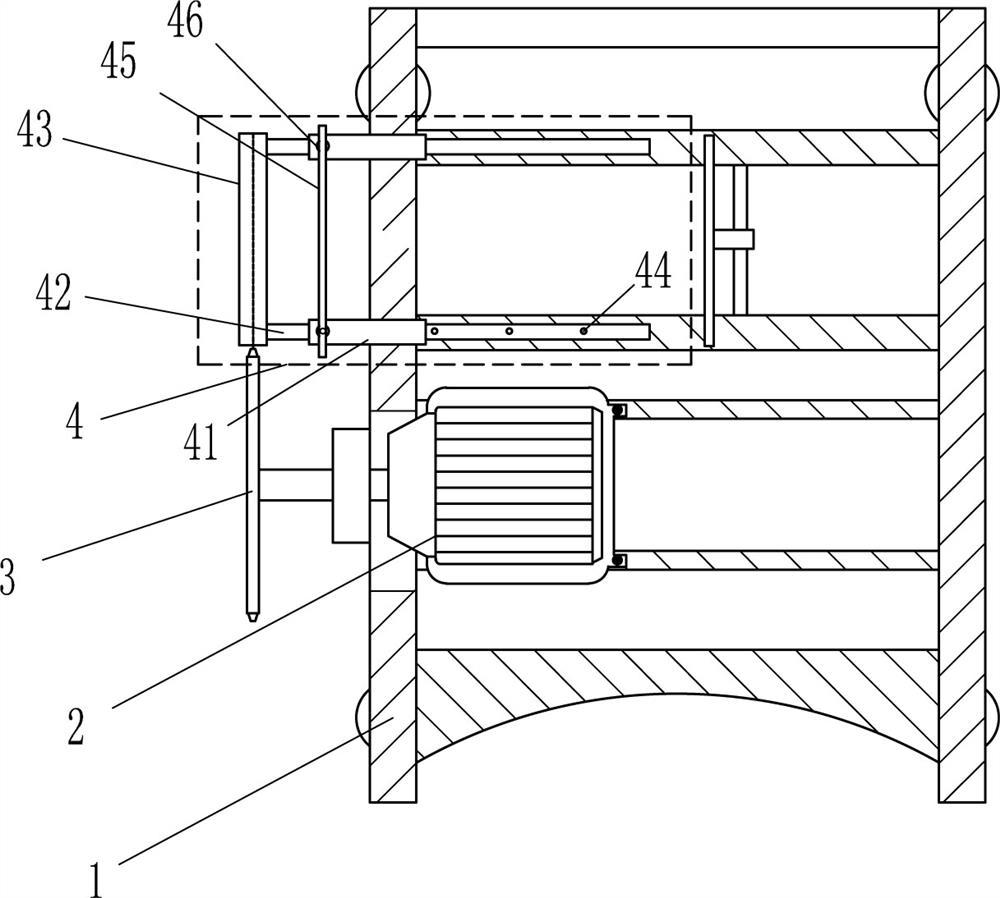

[0021] Such as Figure 1-2 As shown, a rapid cutting device for building steel pipes includes a frame 1, a motor 2, a cutting knife 3, a positioning device 4, a mounting plate 5, a mounting frame 6, a push rod 7, a slide plate 8, a sliding block 9, and an insertion rod 12 , pushing block 13 and pushing device 14, motor 2 is installed in the middle part of frame 1, and cutting knife 3 is arranged on the output shaft of motor 2, and positioning device 4 is installed on frame 1, and positioning device 4 is positioned at motor 2 rear side, and positioning The device 4 is used for adjusting and positioning the required cutting length of the steel pipe. The top of the frame 1 is slidingly provided with a mounting plate 5, the front side of the mounting plate 5 is embedded with a handle, the rear side of the frame 1 is provided with a mounting frame 6, and the mounting frame 6 The front side is evenly provided with ejector rods 7, and the rear side of the top of the mounting plate 5 ...

Embodiment 2

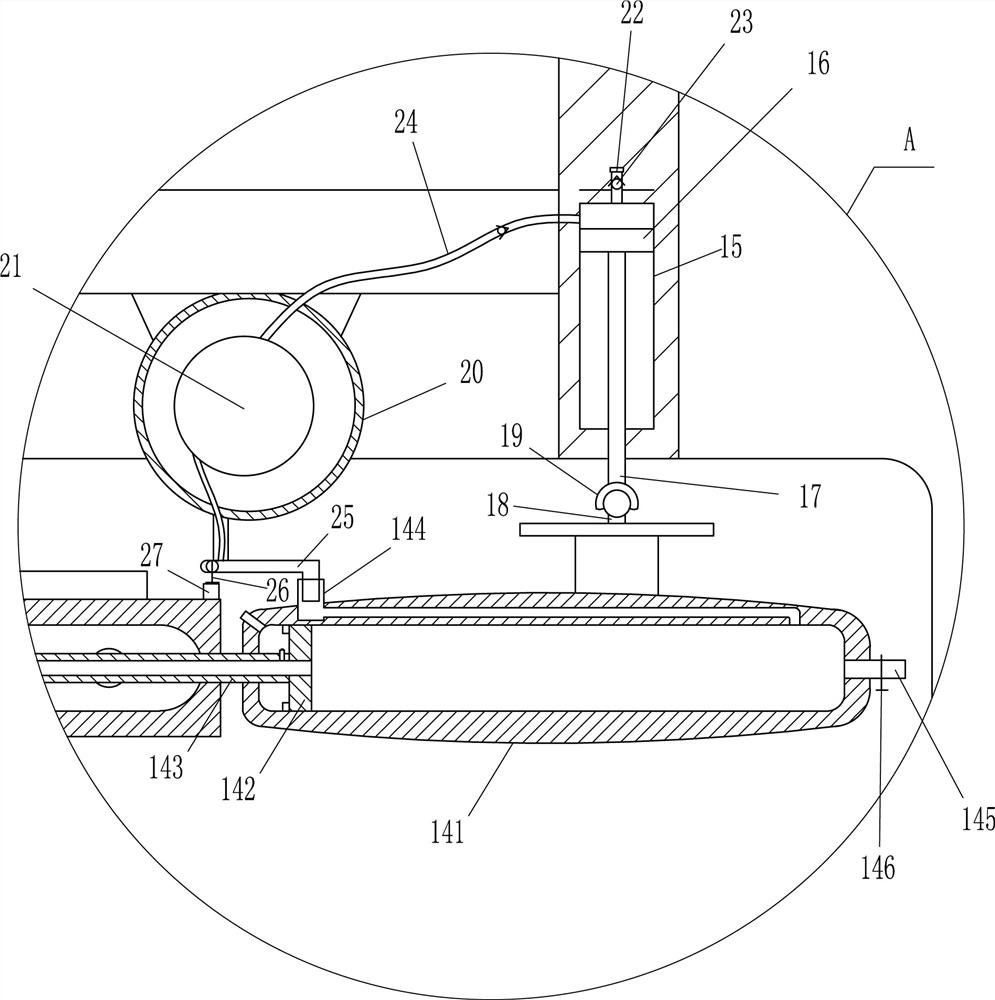

[0025] Such as figure 2 , image 3 and Figure 4As shown, on the basis of Embodiment 1, the pushing device 14 includes a first cylinder 141, a first piston 142, a through pipe 143, an air intake pipe 144, an air outlet pipe 145, a valve 146, a block 147, an air outlet 148, The second piston 149, the moving rod 1410, the push block 1411 and the air outlet branch pipe 1412, the rear side of the top of the mounting plate 5 is provided with a first cylinder 141, and the first cylinder 141 is movably provided with a first piston 142, the first piston 142 The middle part is embedded with a through pipe 143, and the left part of the rear side of the first cylinder 141 is provided with an intake pipe 144. A valve 146 is arranged on the air outlet pipe 145, a stopper 147 is arranged on the left part of the first cylinder body 141, an air outlet port 148 is arranged on the rear side of the left part of the first cylinder body 141, and a second piston 149 is movable in the through pip...

Embodiment 3

[0029] Such as figure 1 and Figure 5 As shown, on the basis of Embodiment 2, it also includes a mounting block 28, a fixed block 29, a moving block 30, a connecting rod 31 and an elastic member 32, and the rear left part of the mounting plate 5 is set by bolts There is a mounting block 28, the mounting block 28 is provided with a fixed block 29, the front side of the fixed block 29 is provided with a through hole, a connecting rod 31 is movably arranged in the through hole, and a moving block 30 is arranged on the front side of the connecting rod 31, An elastic member 32 is disposed between the moving block 30 and the connecting rod 31 , and the elastic member 32 is a tension spring.

[0030] The staff places the steel pipe between the fixed block 29 and the movable block 30, and one end of the steel pipe rests on the push block 13. When the mounting plate 5 moves forward, the elastic member 32 resets and drives the movable block 30 to move backward. The fixed clamping bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com