A stamping packaging automation integrated equipment

A technology of integrated equipment and punching dies, which is applied in the field of stamping and packaging automation integrated equipment, can solve the problems of low production efficiency, high cost, and large space occupied by equipment, so as to save space occupied by equipment, ingenious mold structure design, labor cost and occupation. The effect of ground space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

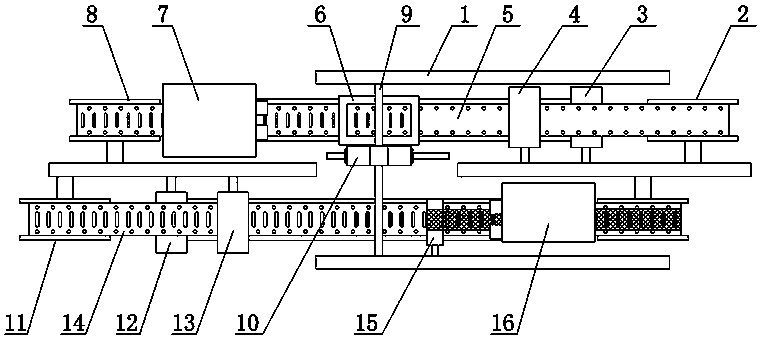

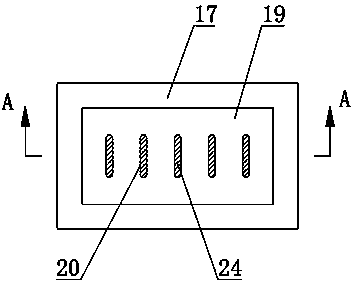

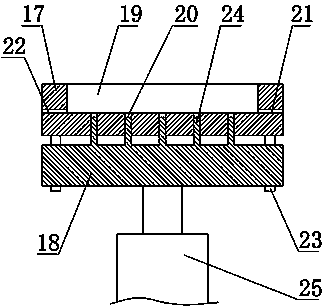

[0026] Such as figure 1 As shown, a stamping and packaging automation integrated equipment, including a bracket 1, a material tape feeding mechanism, a material tape dragging mechanism 7, a reverse die 6, a suction mechanism 10, a carrier tape feeding mechanism, a film coating mechanism 15 and a carrier tape dragging mechanism Mechanism 16, the support 1 is provided with a strip groove along its length direction, the strip feeding mechanism is arranged at the entrance of the strip groove, the strip 5 is assembled in the strip groove, and the reverse die 6 is arranged at the strip groove In the middle part of the back punching die 6, the product is stamped out from the bottom to the top of the material belt 5, and a material belt dragging device capable of intermittently dragg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com