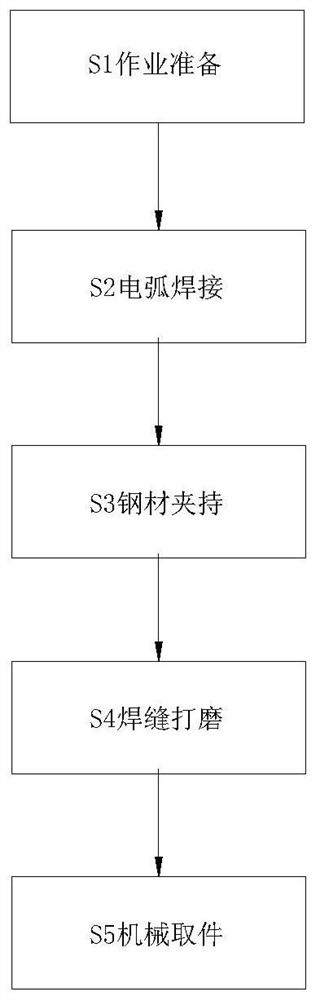

An energy-saving and environment-friendly construction steel welding forming method

A welding forming, energy saving and environmental protection technology, applied in the field of steel processing, can solve the problems of changing the size of C-shaped steel, reducing work efficiency, wasting production materials, etc., to ensure accuracy and stability, improve processing quality, and improve versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

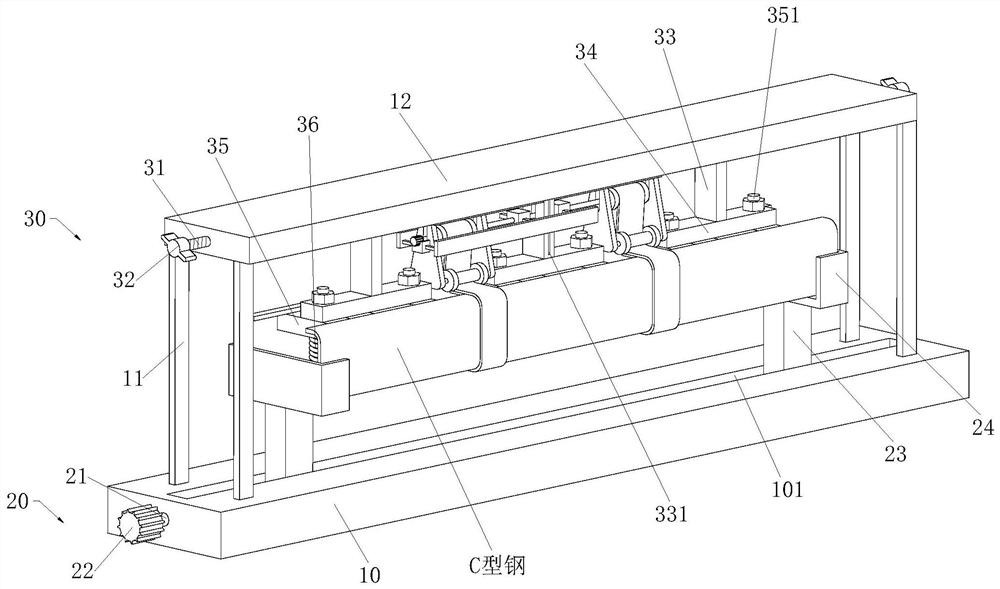

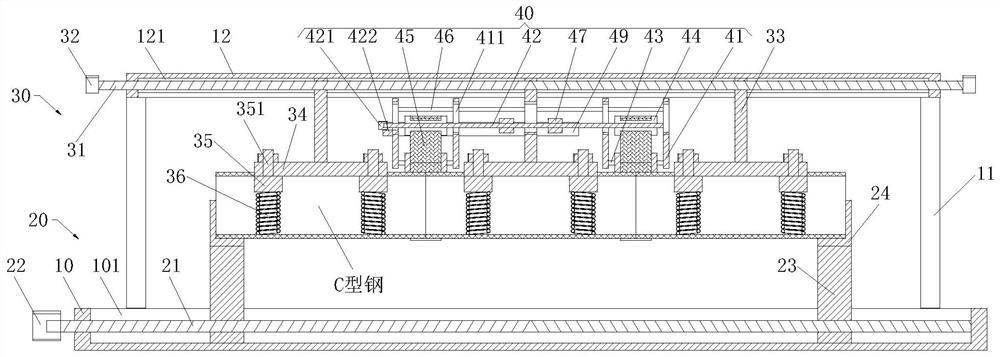

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0039] Such as Figure 2 to Figure 7As shown, an energy-saving and environment-friendly construction steel welding forming method, which uses C-shaped steel processing and manufacturing equipment, the equipment includes a workbench 10 and a cross-shaped chute 101 set at the center of the top of the workbench 10, and the cross-shaped chute 101 is along the The length direction of the workbench 10 extends, the corner of the top of the workbench 10 is provided with a support frame 11, the top of the support frame 11 is fixedly connected with a strip plate 12, and the bottom center of the strip plate 12 is provided with a T-shaped groove 121, The No. 1 T-shaped slot 121 extends along the length direction of the strip plate 12;

[0040] The top of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com