Coating film production line

A production line and film coating technology, which is applied in packaging, wrapping objects, transportation packaging, etc., can solve the problems such as the failure of the film and film to align, the scrap of sheet and film, and economic losses, and achieve the effect of reducing the loss of material scrap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

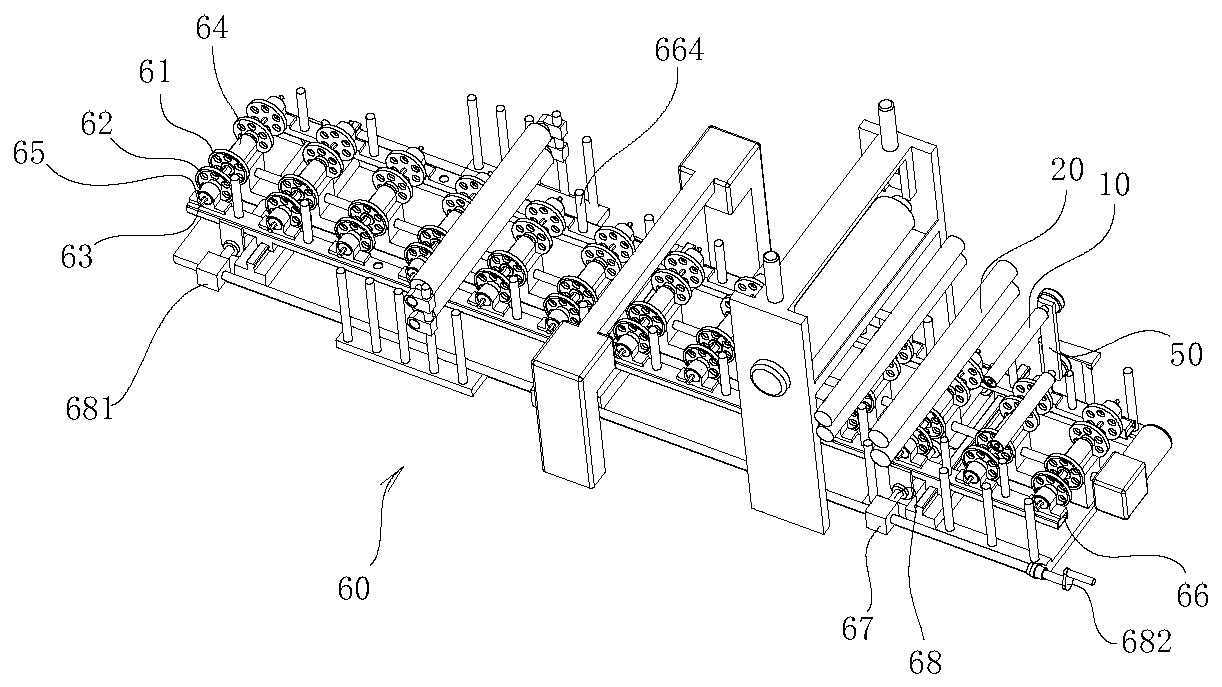

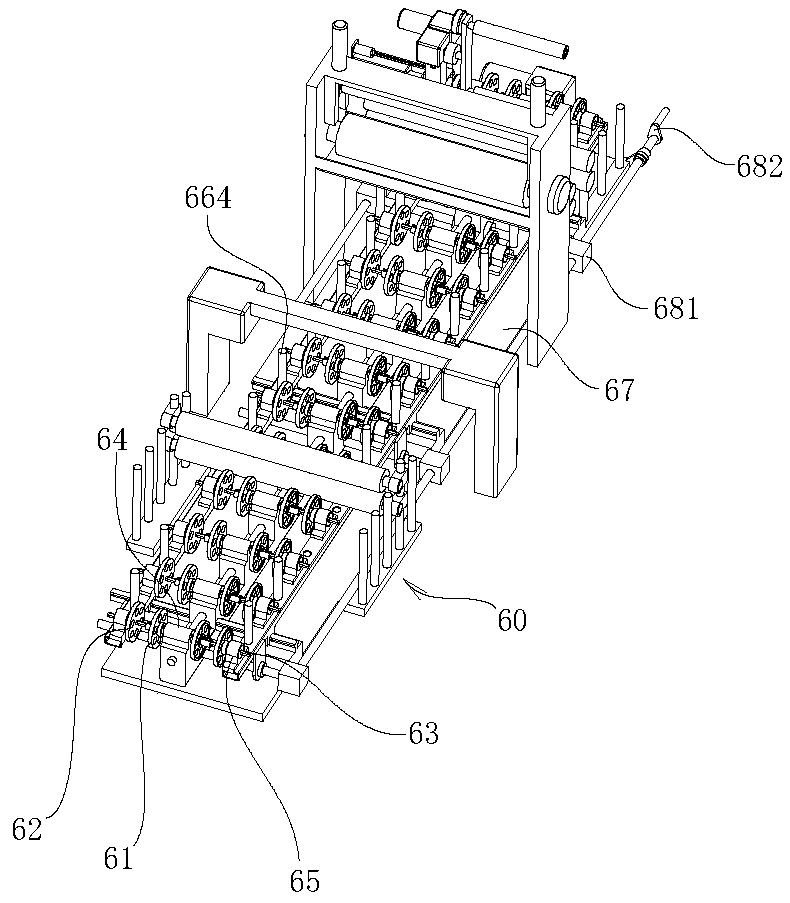

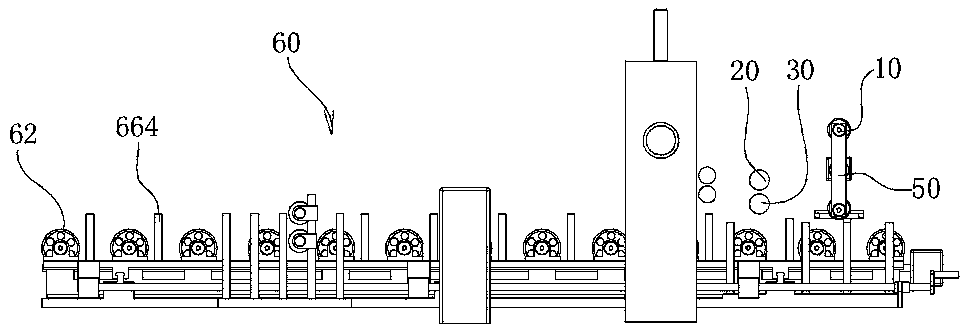

[0026] refer to Figure 1 to Figure 10 , the structural features of this coating film production line are described in detail as follows:

[0027] The coating film production line includes a plurality of roll bars 10 for installing roll materials, first and second film rolls 20, 30 are arranged on the side of the roll bar 10, and the first and second film rolls 20, 30 are up and down direction, the first and second film rollers 20 and 30 are provided with first and second pressure heads 70 and 80 respectively, and the driving mechanism drives the first and second pressure heads 70 and 80 to be connected with the first and second film rollers. The roll bodies of the two film rolls 20, 30 approach or move away;

[0028] combine Figure 9 to Figure 10 As shown, when the film is actually used, the film roll is installed on the roller bar 10, and the film roll is horizontally supported by the roll bar, and a double-sided adhesive tape is placed in advance on one end of the roll m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com