Patents

Literature

30results about How to "Realize the pressing operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

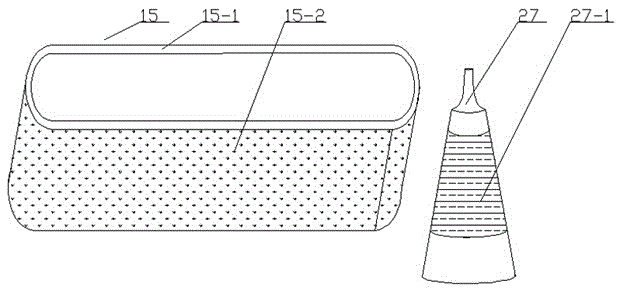

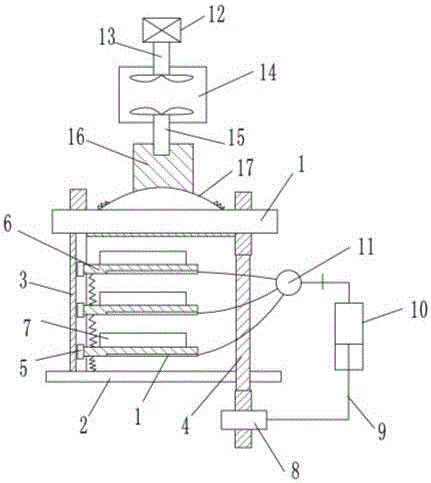

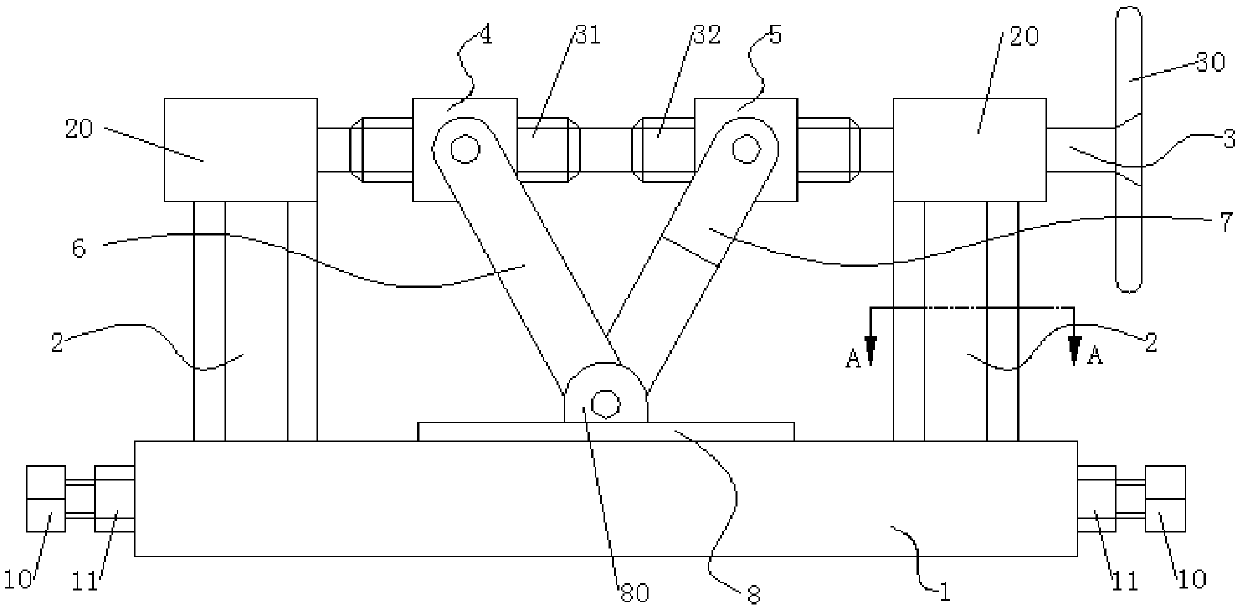

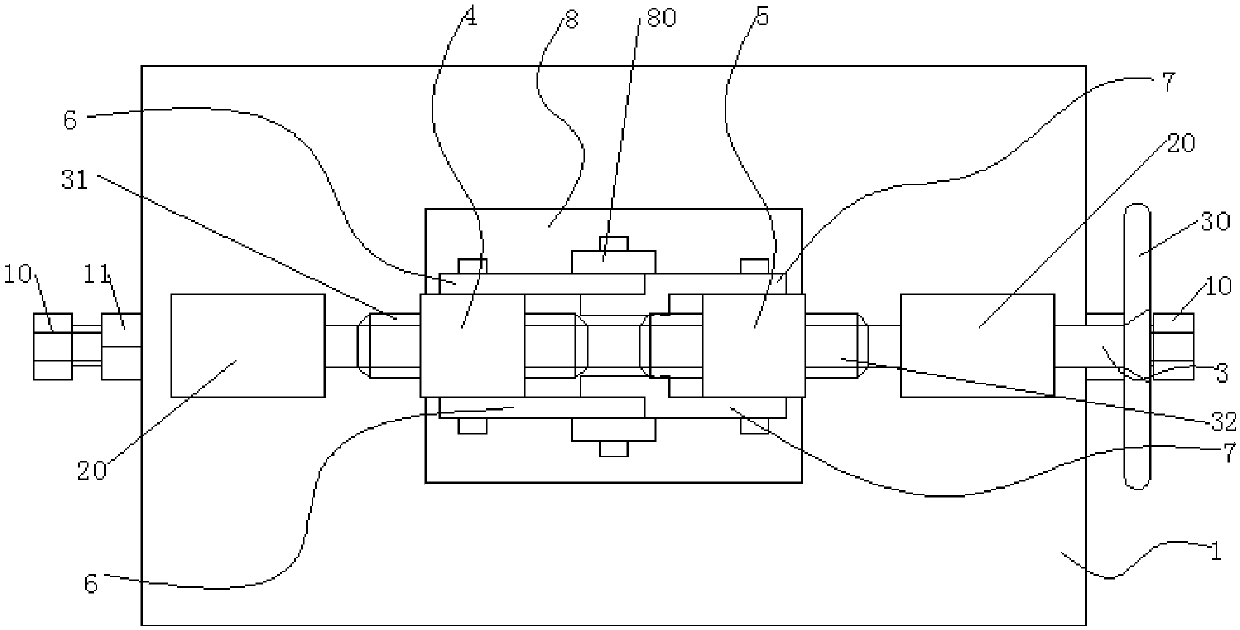

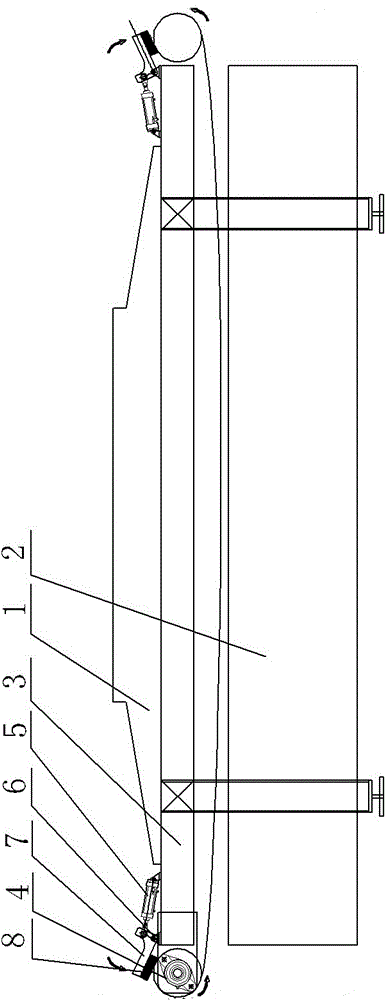

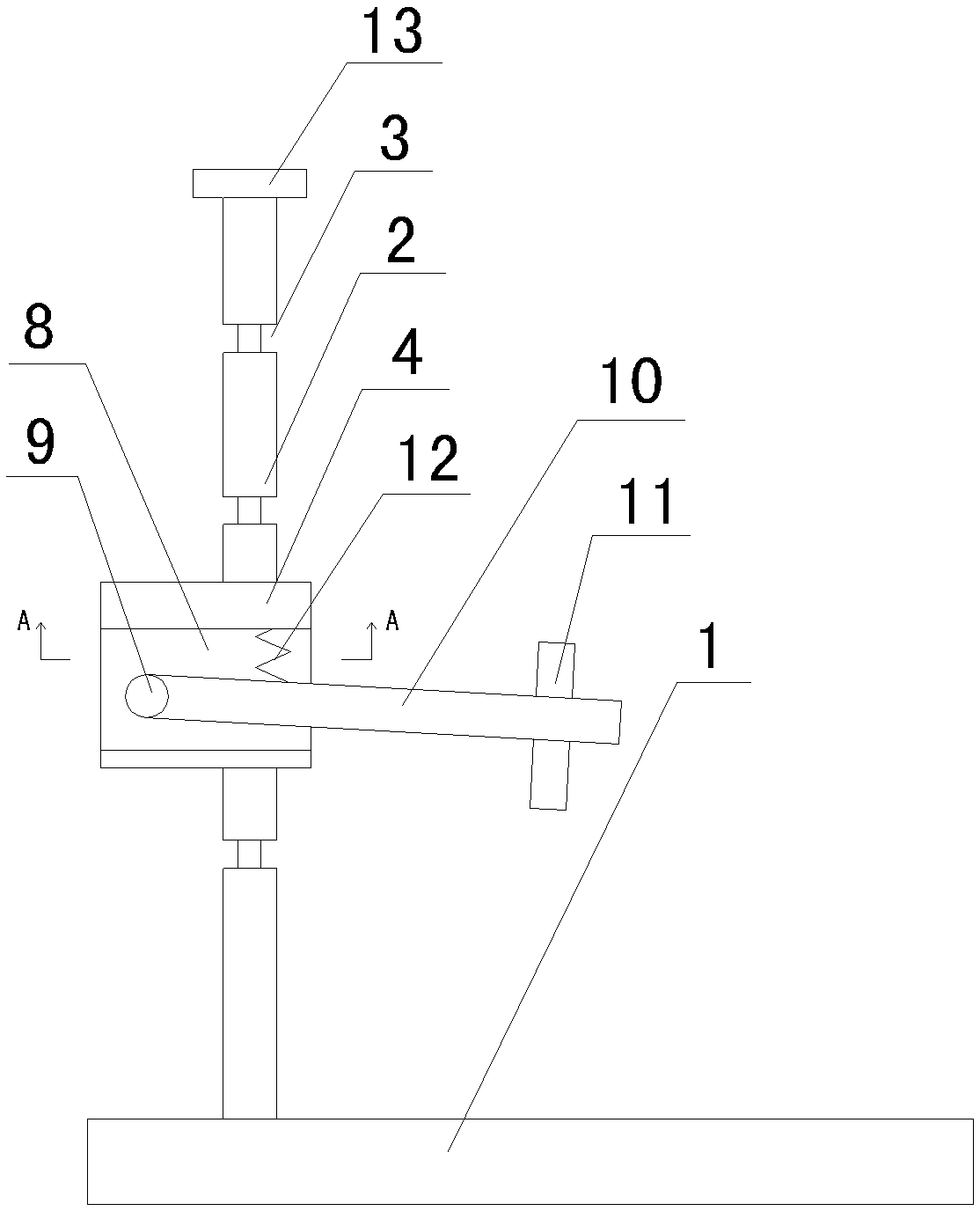

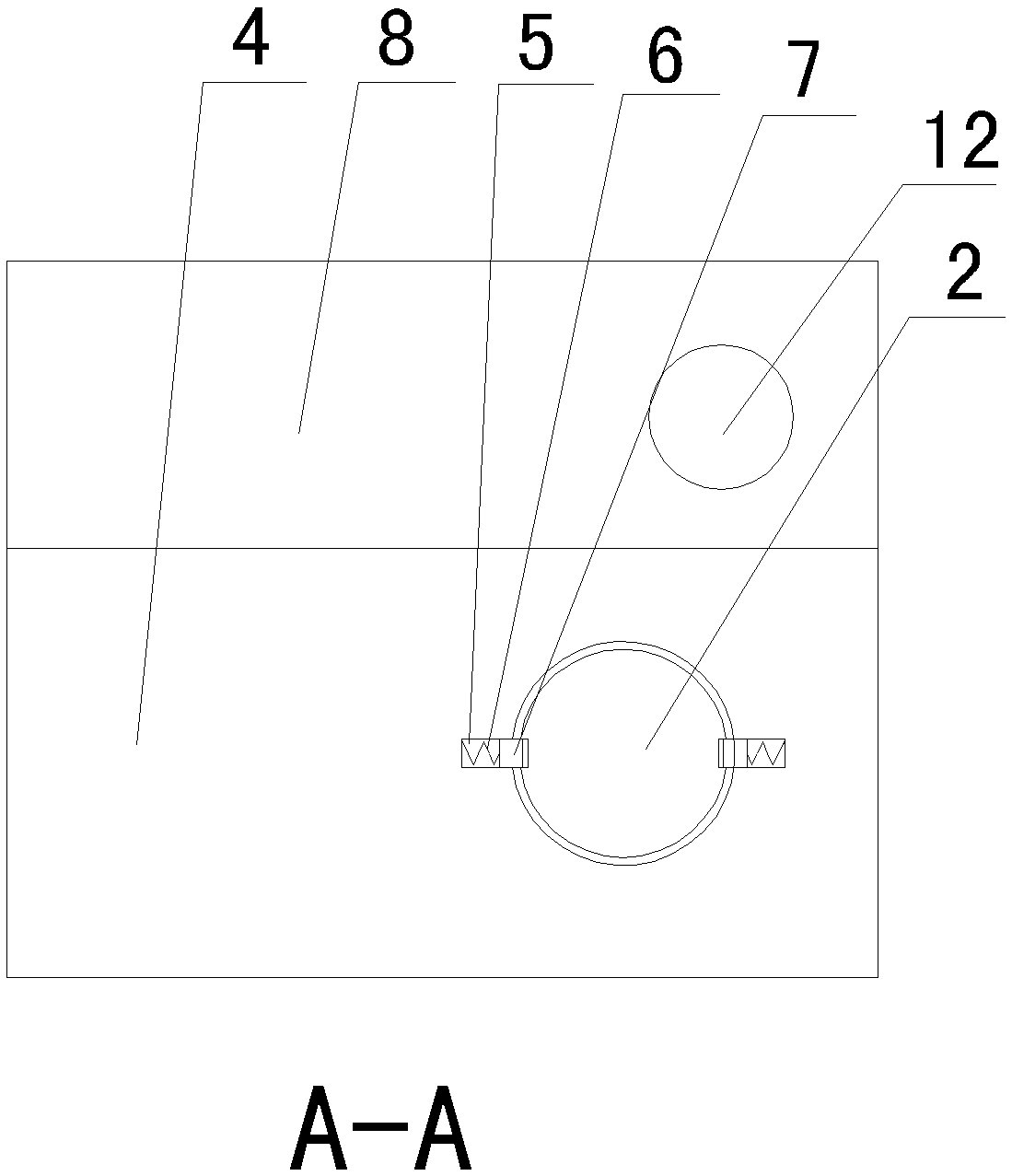

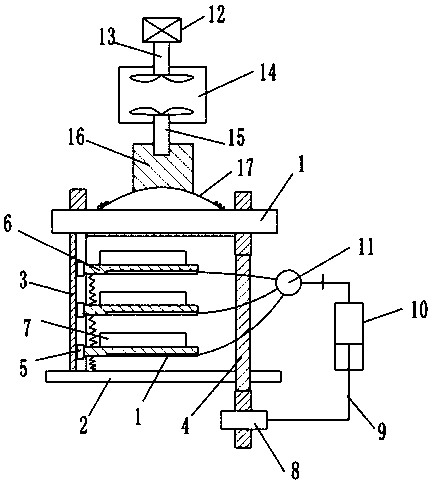

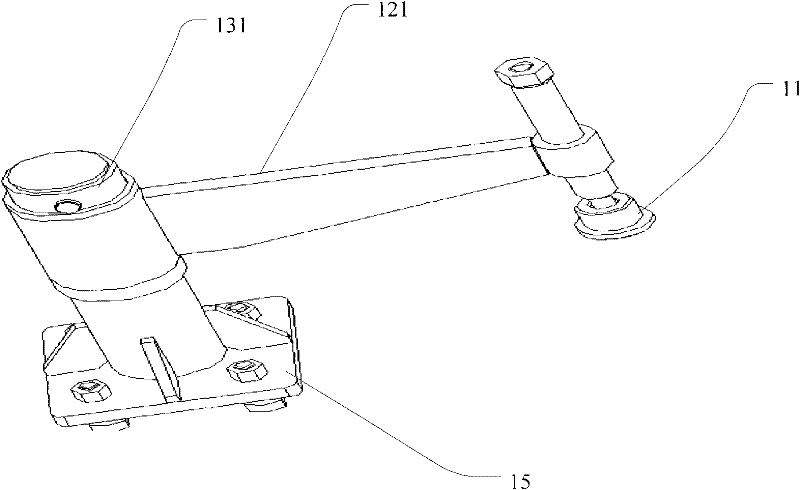

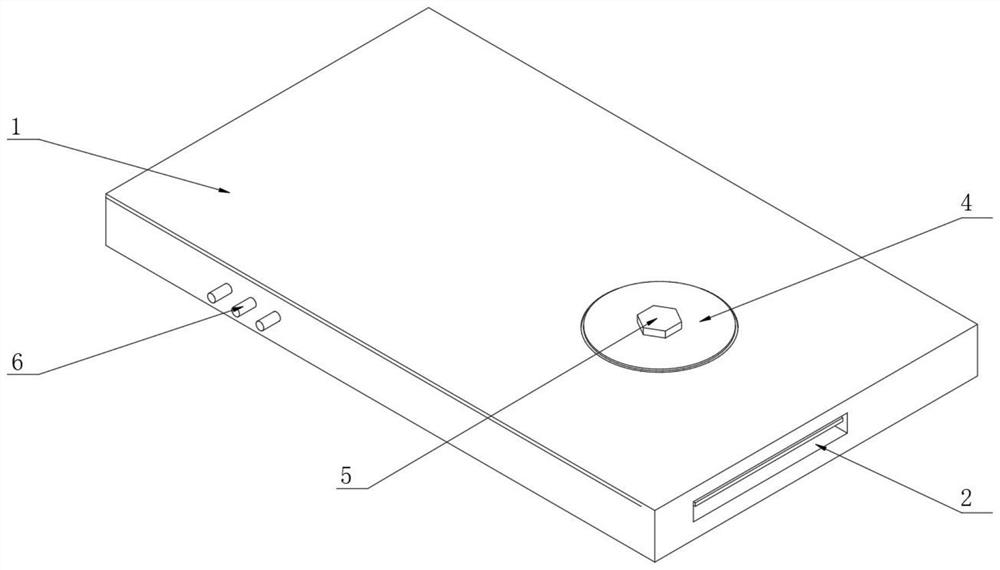

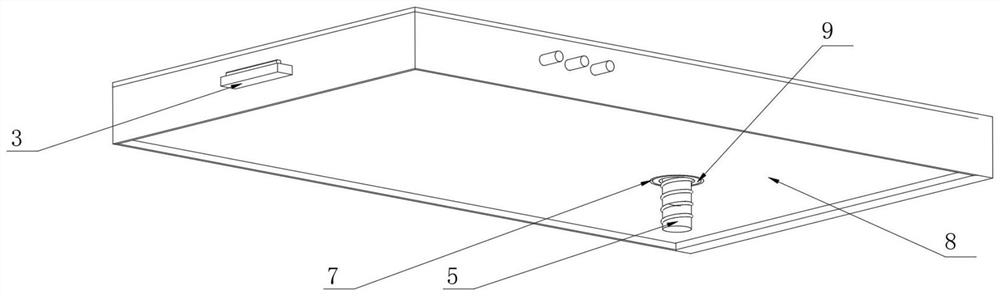

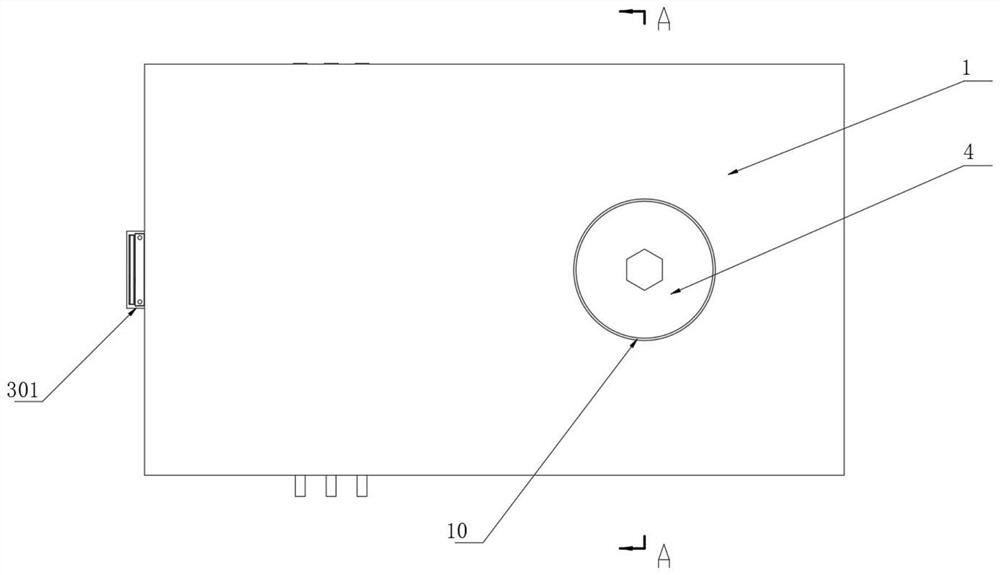

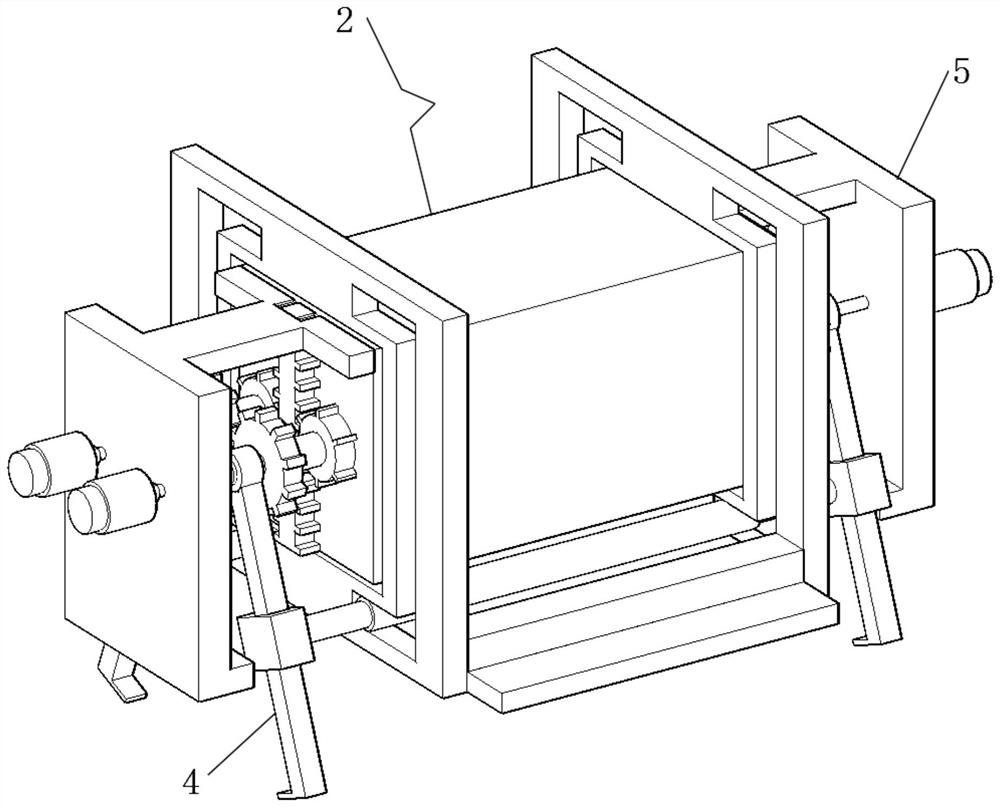

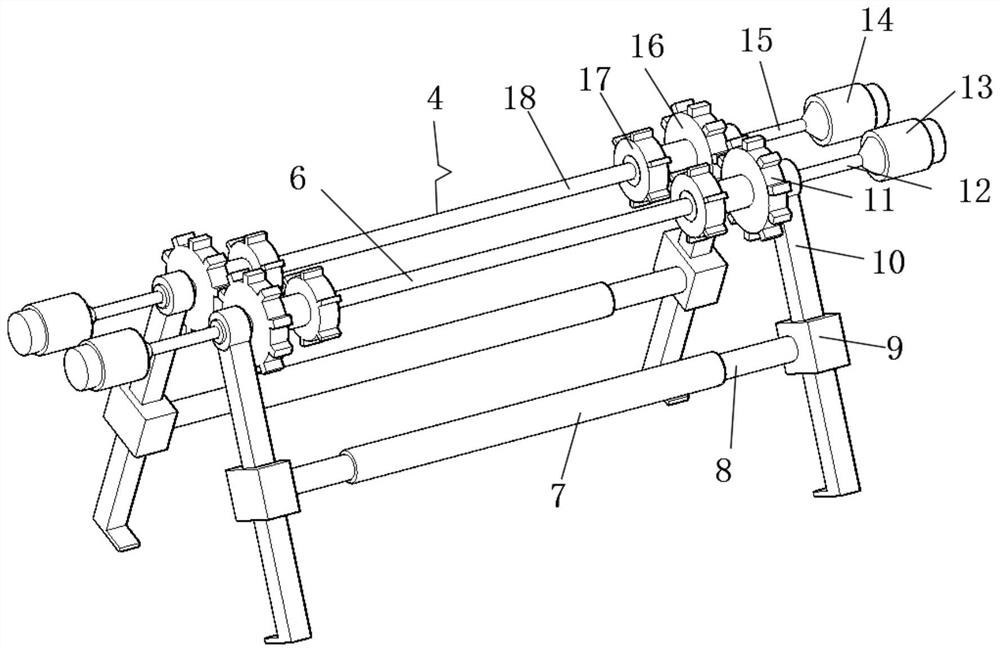

Pressing device

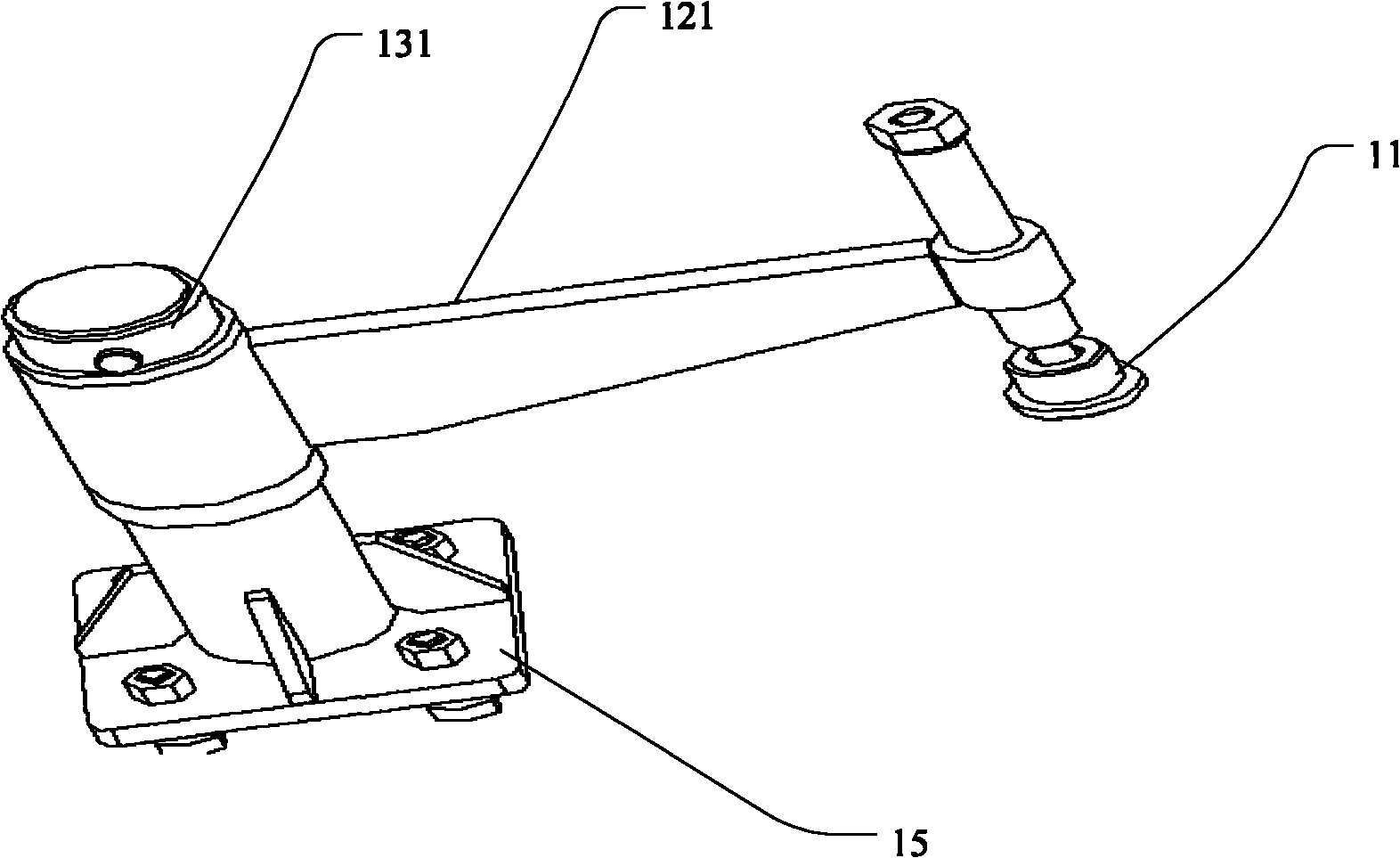

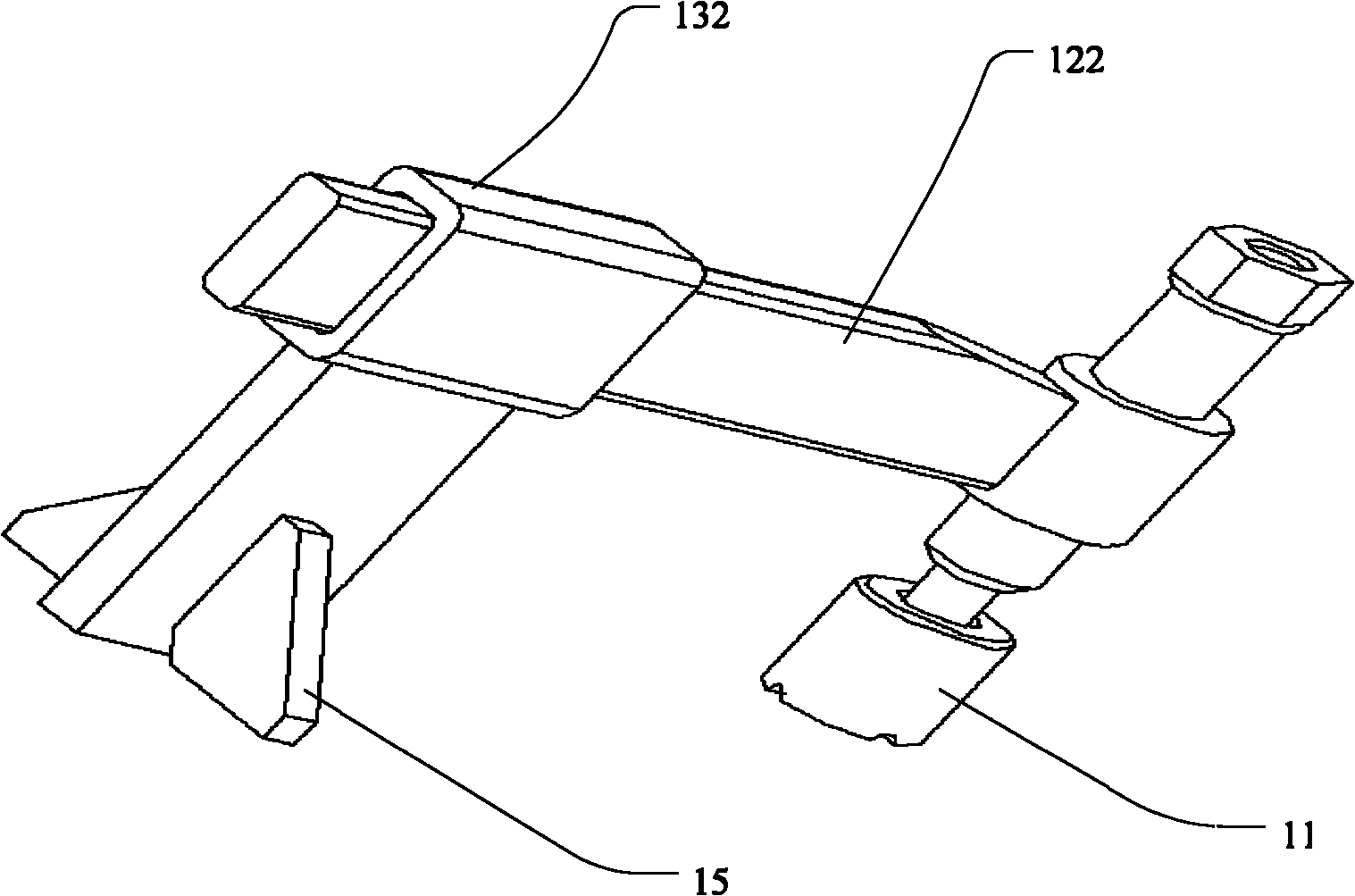

ActiveCN101829969ARealize the pressing operationExpand the pressing rangeWork holdersEngineeringMechanical engineering

Owner:CRRC TANGSHAN CO LTD

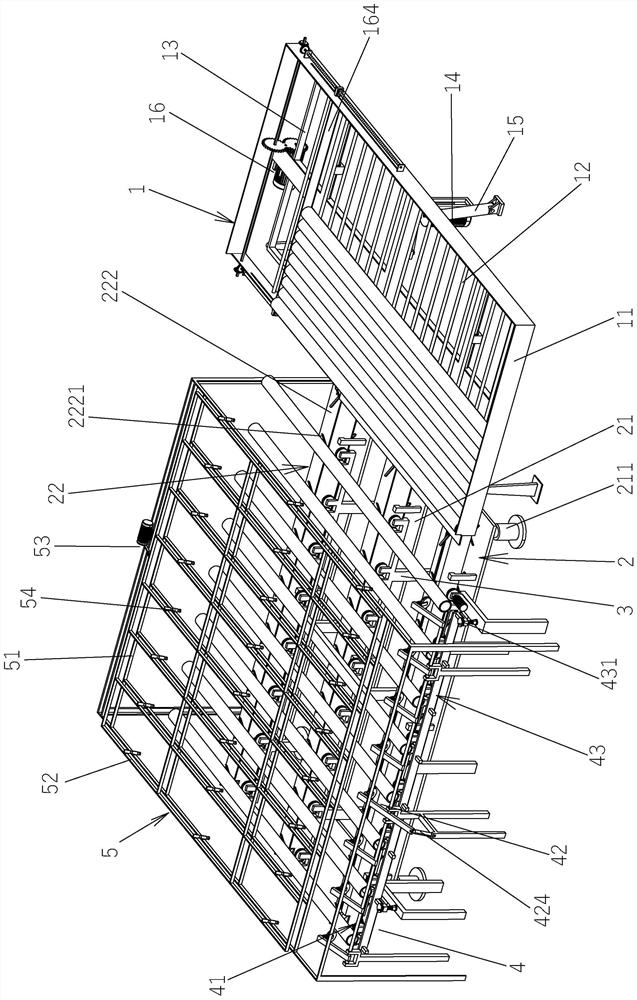

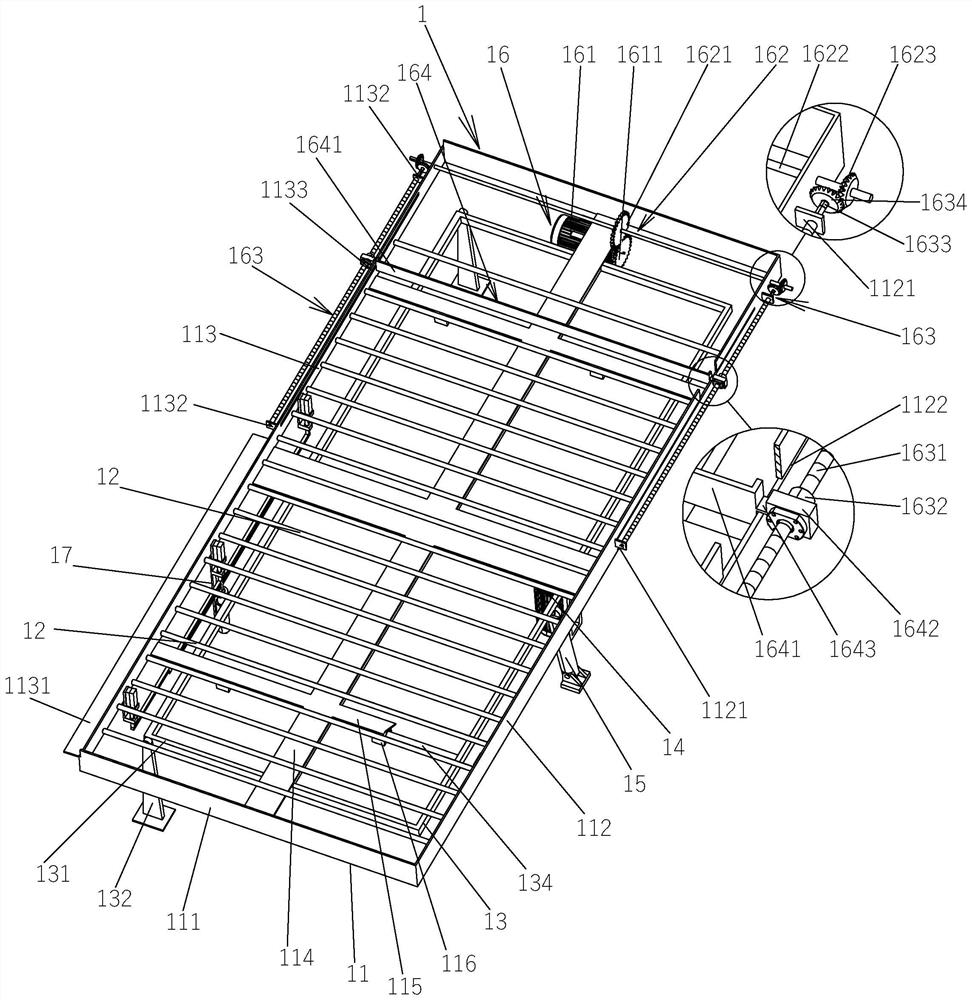

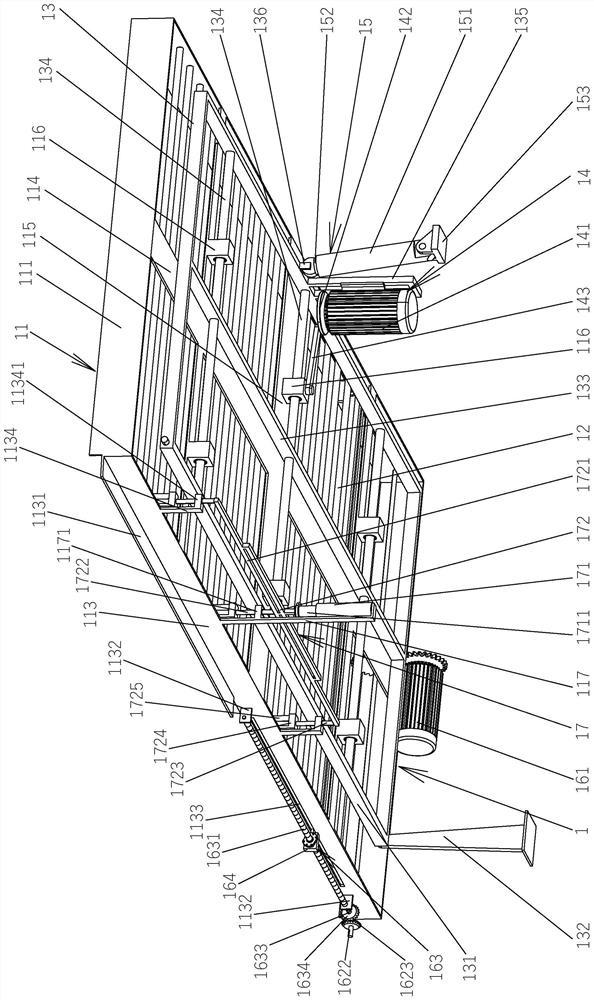

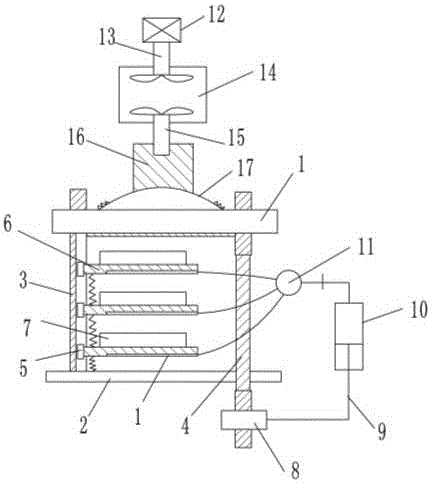

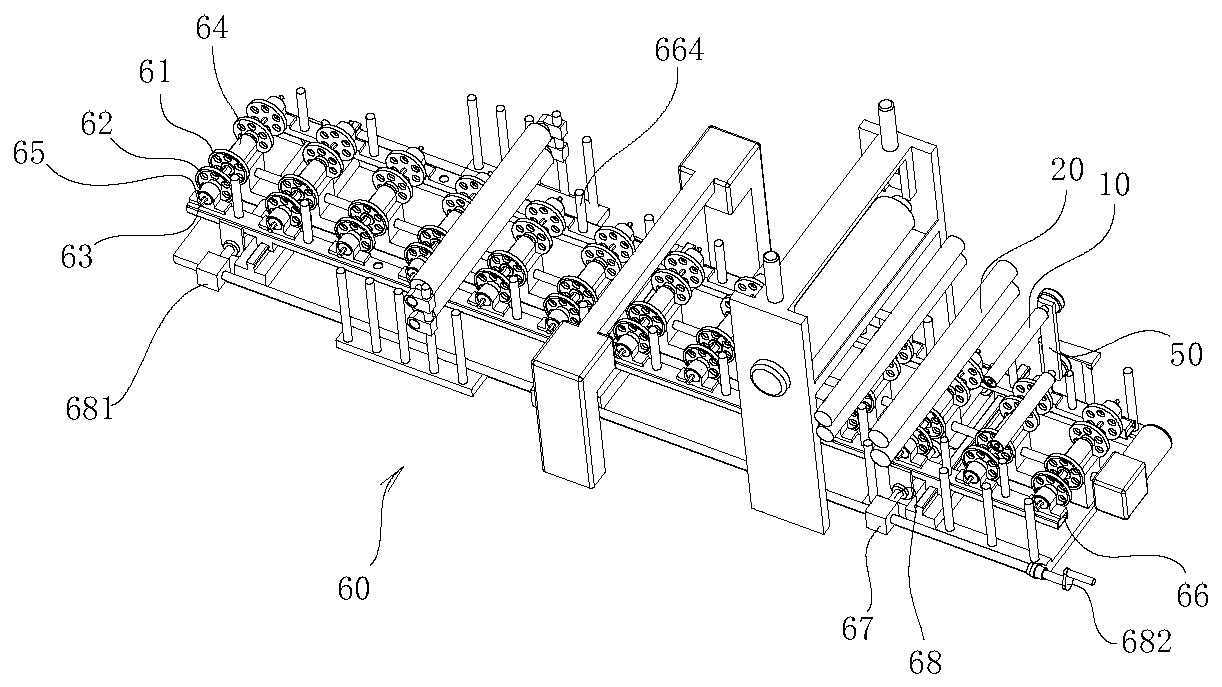

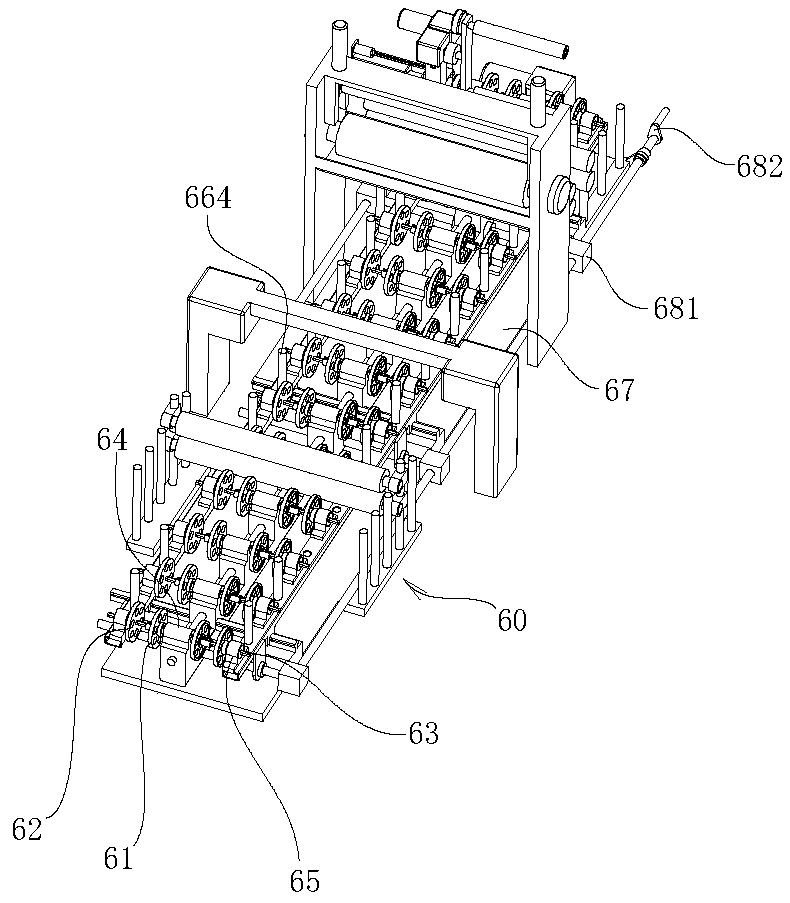

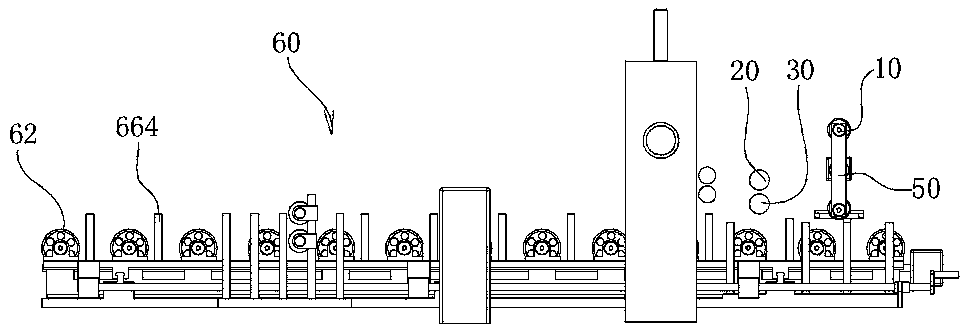

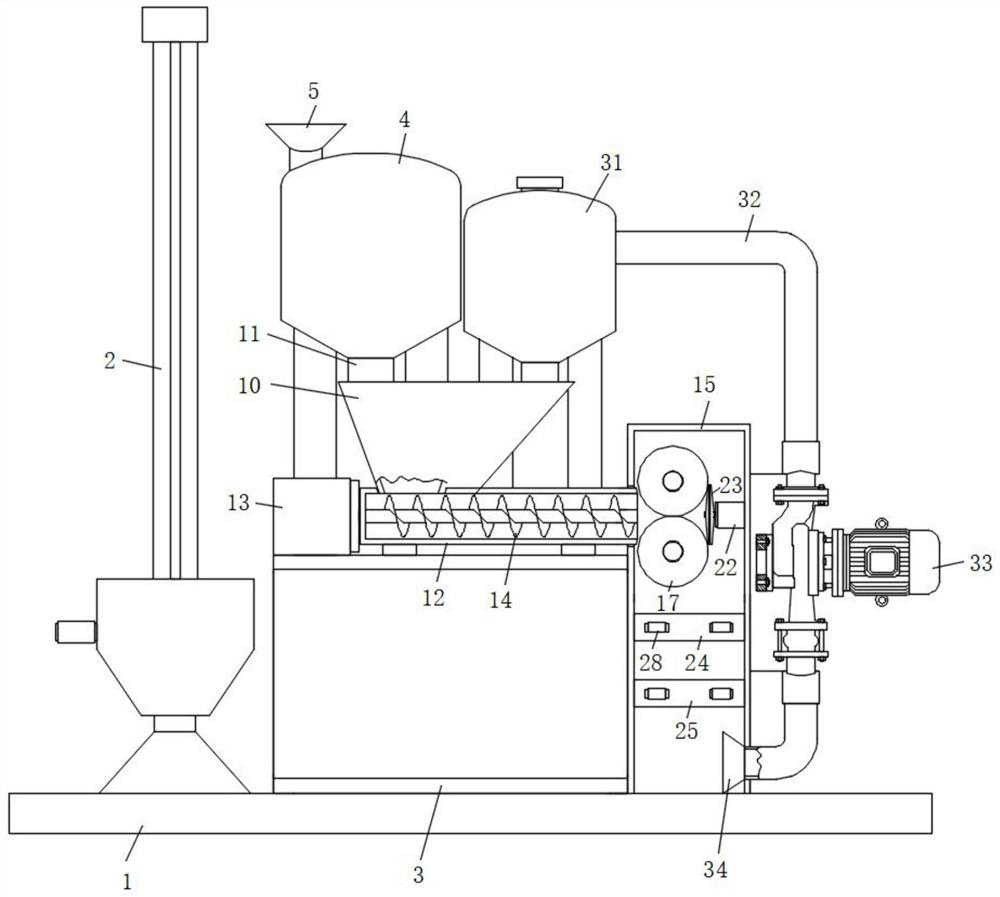

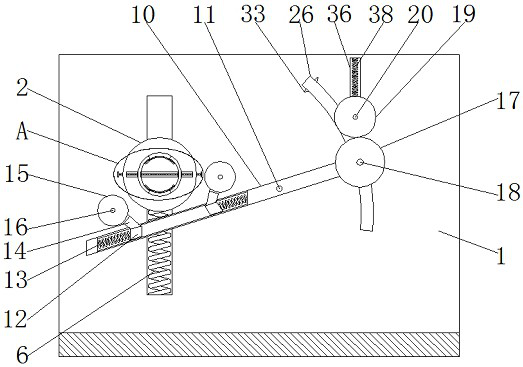

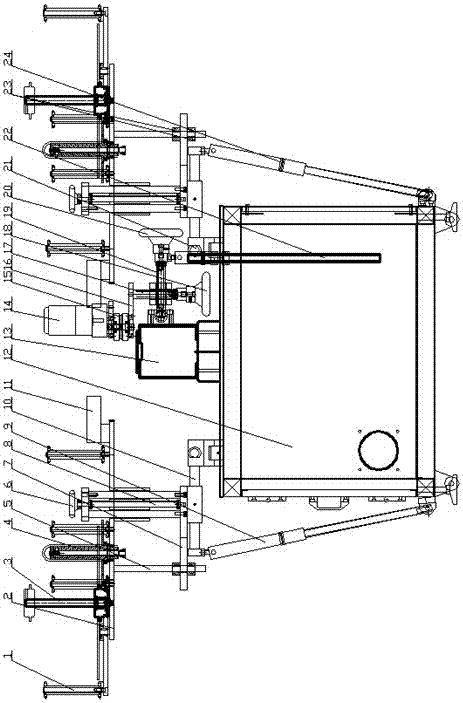

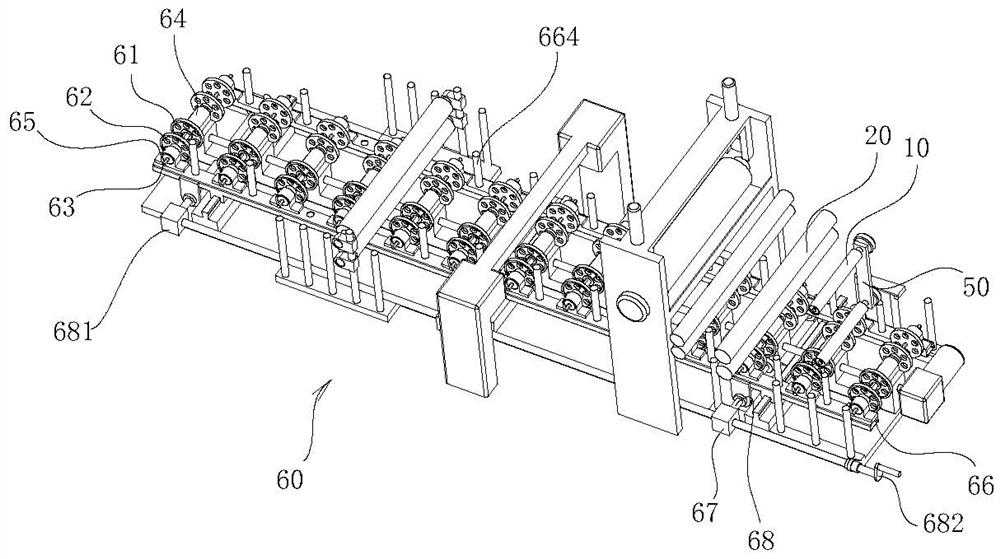

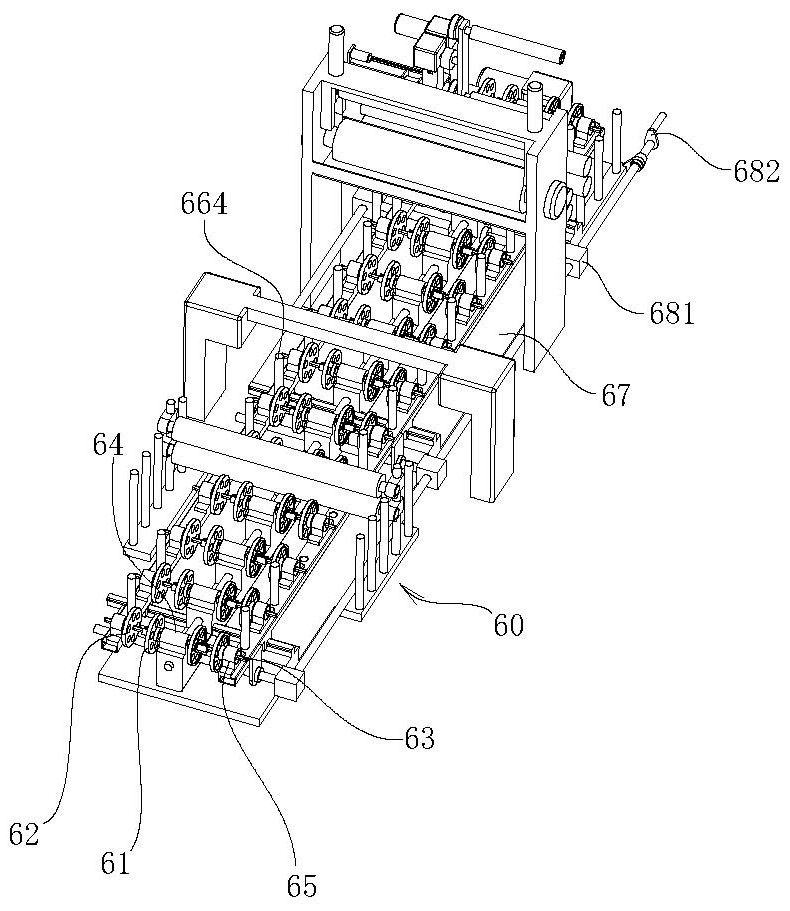

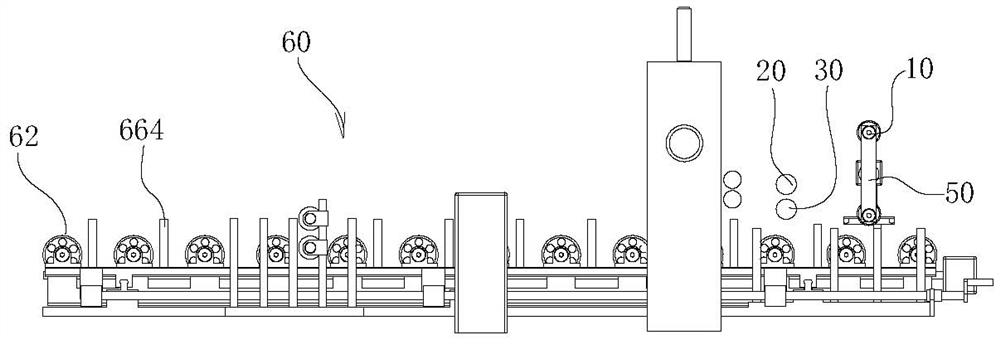

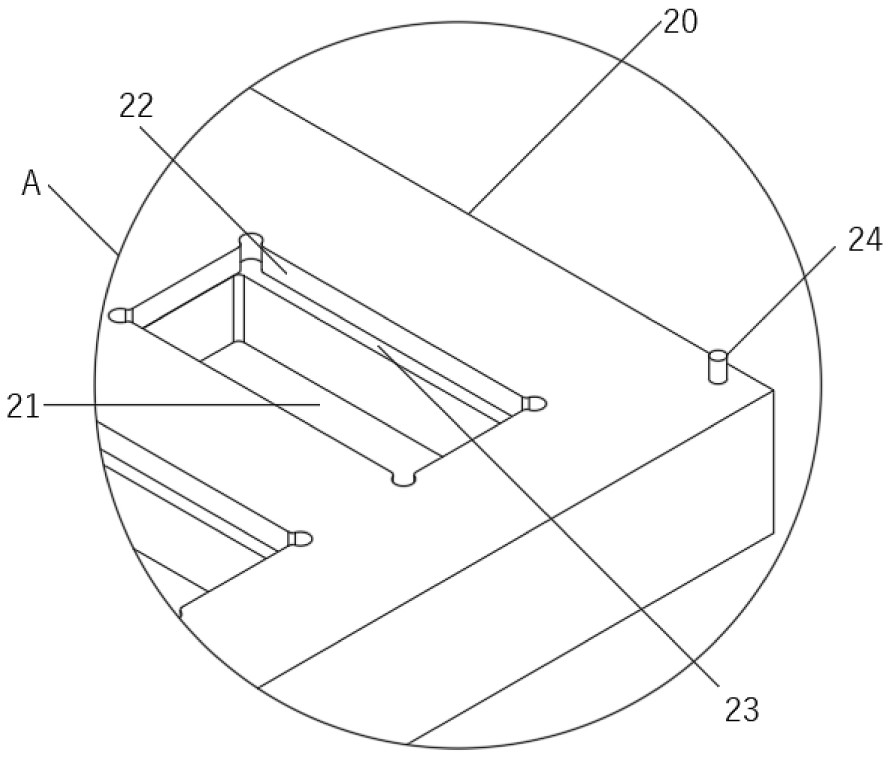

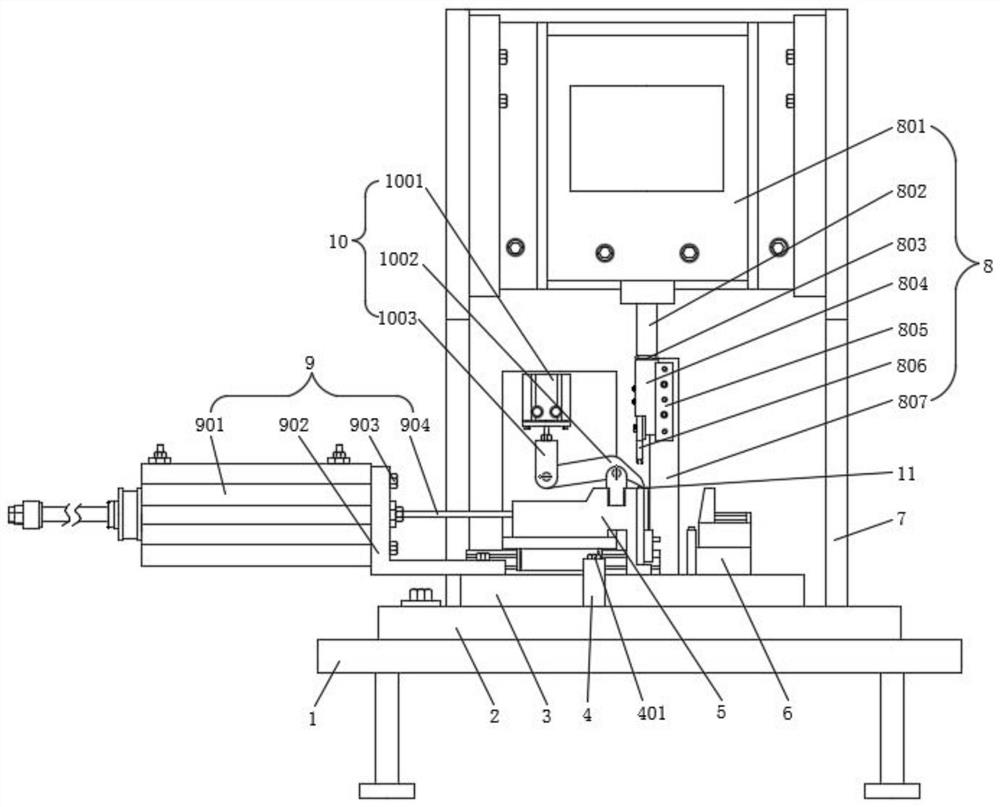

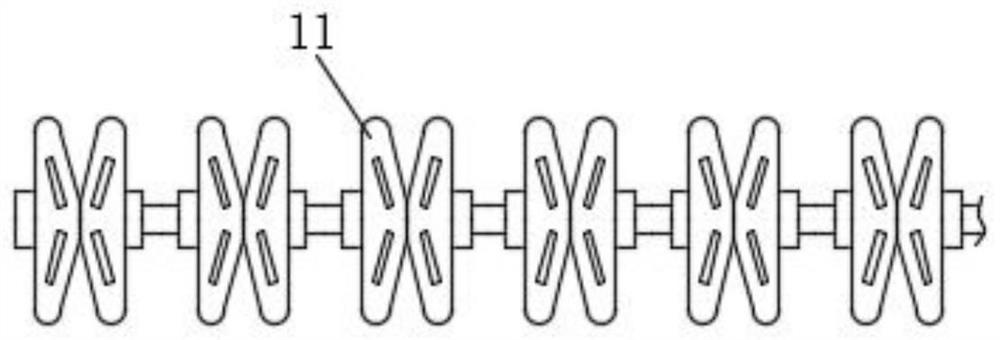

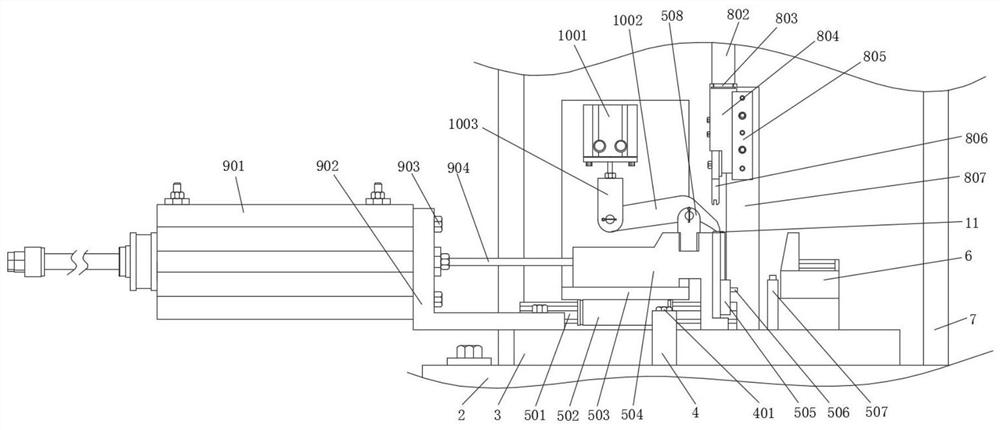

Steel pipe cleaning equipment

PendingCN114472382AAutomate finishingRealize the pressing operationConveyorsHollow article cleaningElectric machineryEngineering

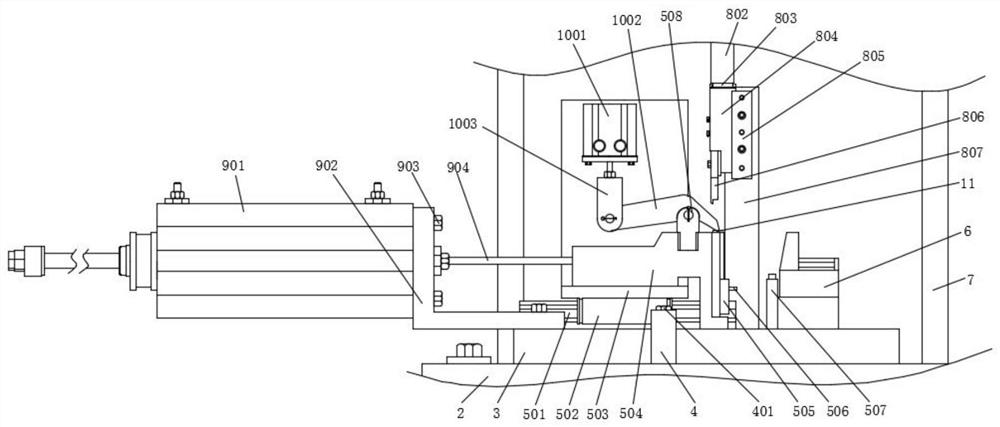

Steel pipe cleaning equipment comprises a steel pipe arrangement mechanism which can achieve gathering and neatening operation of a plurality of steel pipes and send the steel pipes outwards after sequentially lifting the steel pipes; the steel pipe conveying mechanism is arranged on one side of the steel pipe arrangement mechanism, can store the steel pipes sent out by the steel pipe arrangement mechanism and comprises a lifting platform, a plurality of conveying belt devices and a conveying motor device, each conveying belt device comprises a pair of conveying belt support plates and a conveying belt body, and a plurality of V-shaped supports capable of containing the steel pipes are arranged in the middle of each conveying belt body; the plurality of steel pipe supporting mechanisms are arranged in the lifting platform of the steel pipe conveying mechanism in a penetrating manner; the inner wall cleaning mechanism is arranged on the side, adjacent to the steel pipe arranging mechanism, of the steel pipe conveying mechanism and comprises a steel pipe rotating device, a steel pipe pressing device and a lifting spray head device. The steel pipe spraying mechanism is arranged on the upper portion of the steel pipe conveying mechanism. Automatic operation of clearing and discharging and conveying in the steel pipe cleaning process is achieved, the cleaning effect on the inner wall and the outer wall of the steel pipe is ideal, and the working efficiency is improved.

Owner:SUZHOU GOLDEN WAY STEEL TUBE

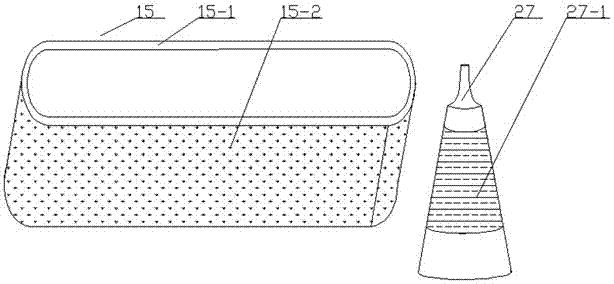

Labelling device for bottled drink

InactiveCN105644871AGood compression effectPrevent fallingLabelling short rigid containersLabelling machinesElectric machineryEngineering

The invention discloses a labelling device for bottled drink. The labelling device comprises a drink bottle transmitting device, two label paper rotating disks, a rack and a label pressing protective wheel, wherein the drink bottle transmitting device is arranged at one side of the rack in an L-shaped shape; the label paper rotating disks are fixed on the rack through movable adjusting support pillars and are positioned at two sides of the drink bottle transmitting device; the label pressing protective wheel is fixed at one side of the label paper rotating disks along the transmitting direction of the drink bottle transmitting device; the label pressing protective wheel comprises a first vertical support rod, a horizontal fixing rod, a second vertical support rod and a wheel guard; a first adjusting knob is arranged on the first vertical support rod; the horizontal fixing rod and one end of the first vertical support rod are connected; a second adjusting knob is arranged in the middle of the horizontal fixing rod; the second vertical support rod is fixed on the horizontal fixing rod; a third adjusting knob is arranged in the middle of the second vertical support rod; the wheel guard is arranged on a fixing plate above the second vertical support rod; and a driving motor is arranged above the wheel guard. The labelling device for the bottled drink, disclosed by the invention, has the advantages of simple structure, convenience in use and high laminating strength of labels.

Owner:湖南湘鹰食品科技有限公司

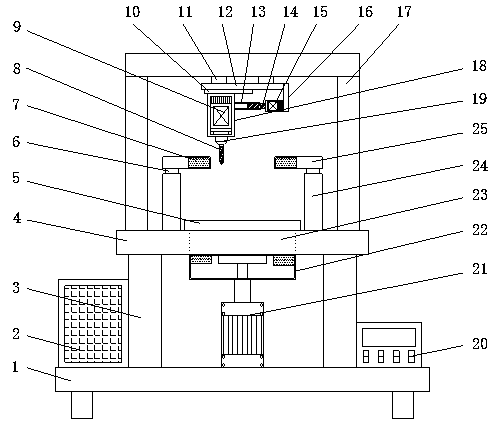

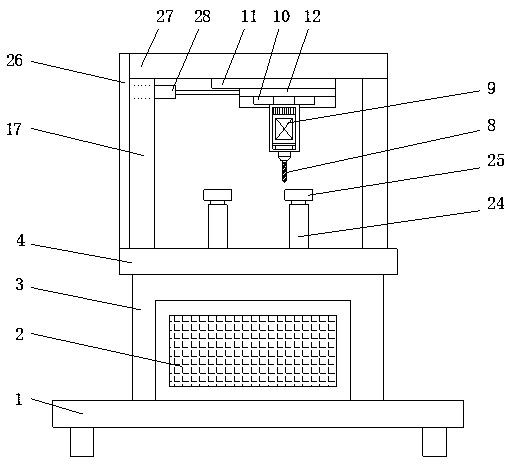

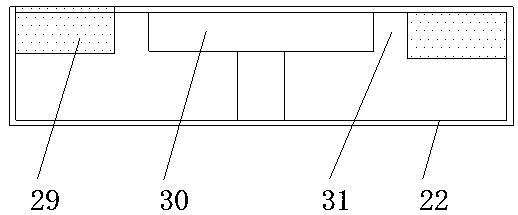

Electronic component control board punching device

PendingCN109014320AAvoid circuit damageAvoid workpiece damagePositioning apparatusMetal-working holdersMagnetEngineering

The invention discloses an electronic component control board punching device. The electronic component control board punching device comprises a base, a drilling machine and an air cylinder. A support plate is mounted on the upper portion of the base. A workbench is mounted on the upper portion of the support plate. The air cylinder is mounted on the upper portion of the part, on the inner side of the support plate, of the base. The output end of the air cylinder is provided with a control console. The upper portion of the workbench is provided with a pillar. The top of the pillar is providedwith a top plate. The bottom of the top plate is provided with a second sliding rail. The bottom of the second sliding rail is provided with a mounting plate. The bottom of the mounting plate is provided with a first sliding rail. A side plate is mounted on one side of the mounting plate. A motor is mounted on the inner side of the side plate. A screw is mounted on the output end of the motor. Byarranging a first magnet, a second magnet, the air cylinder, the control console, the first sliding rail, the motor, an electric push rod, the drilling machine and a controller structure, the problems that a pressing mechanism is not perfect, and the drilling operation precision is low are solved.

Owner:HENAN NORMAL UNIV

Processing method of particle board

InactiveCN106738180AEasy to demouldEven by forceFlat articlesDomestic articlesWood shavingsParticle board

The invention belongs to the technical field of artificial board production and particularly discloses a processing method of a particle board. The processing method comprises raw material preparation, screening, flaking, drying, storing, mixing, mould feeing, hot pressing and inspecting and storing, wherein in the step of hot pressing, a motor is started, a second rotation shaft rotates to generate down pressing force, a down-pressing block drives a hydraulic block to move downward together so as to push an up-pressing plate to move downward and down press a particle board and heating plates; meanwhile, the particle board is extruded between the heating plates to realize a pressing operation of the particle board; and after the pressing of the particle board, the motor is turned off, a flexible connector and a spring recover deformation to promote separation of the heating plates, and then the upper surface of the particle board is separated from the lower surface of the heating plate. The scheme provides a processing method of a particle board, wherein the pressing plate is under uniform stress, and the pressed particle board easily falls off and is not crushed.

Owner:重庆木园春木业有限公司

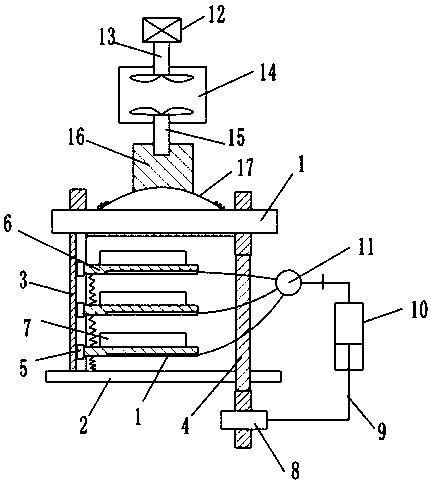

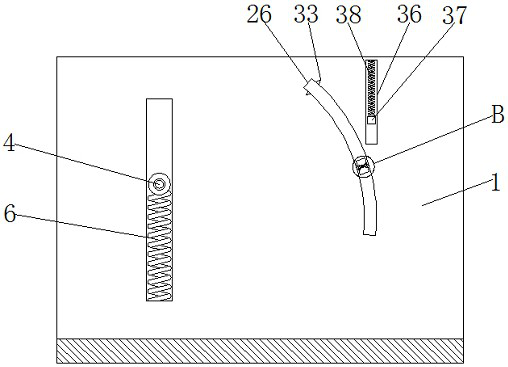

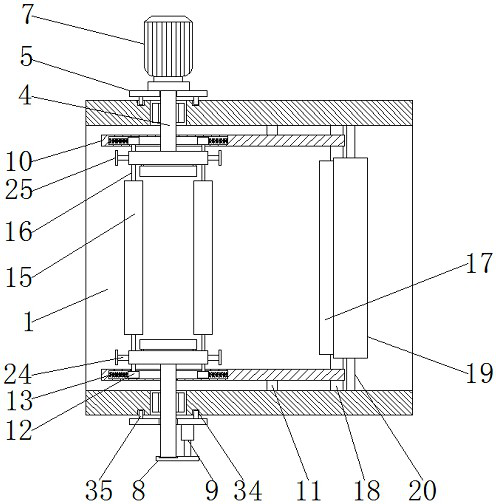

Hot press with demolding function

InactiveCN106827120AEven by forceConvenient pressing workPlywood pressesVeneer pressesMechanical engineeringWater tanks

The invention belongs to the field of presses, and particularly discloses a hot press with the demolding function. The hot press comprises an upper pressing plate and a fixing plate; the two ends of the upper pressing plate are connected with a first supporting frame and a second supporting frame in a sliding mode respectively; a plurality of sliding blocks are arranged in the first supporting frame; heating plates are arranged on the sliding blocks and are connected through springs; a motor is arranged above the upper pressing plate and is fixedly connected to a first rotating shaft, and the first rotating shaft is rotationally connected to a water tank; the water tank is rotationally connected to a second rotating shaft; a plurality of blades are arranged on the opposite ends of the first rotating shaft and the second rotating shaft; the second rotating shaft is fixedly connected to a lower pressing block; a hydraulic block is arranged at the bottom of the lower pressing block; a hollow cavity is formed in the hydraulic block; and the two ends of the hydraulic block are fixedly connected to the upper pressing plate through flexible connecting pieces. The invention provides the hot press with the demolding function. The hot press with the demolding function has the advantages that the upper pressing plate is stressed uniformly, and a plate is easy to demold and can be kept from being crushed.

Owner:重庆木园春木业有限公司

Coating film production line

PendingCN110654620AReduce material scrap lossGuaranteed continuous supplyWrapping material feeding apparatusWrappingComposite materialProduction line

The invention relates to a coating film production line. The production line comprises a plurality of roller rods for arranging roll materials, wherein the sides of the roller rods are provided with first film rollers and second film rollers, the first film rollers and the second film rollers are arranged in the up-down direction, the sides of the first film rollers and the second film rollers areprovided with first pressing heads and second pressing heads correspondingly, and a driving mechanism drives the first pressing heads and the second pressing heads to be close to or far away from roller bodies of the first film rollers and the second film rollers. The system can ensure continuous feeding of films, and the problem of material abandonment loss caused by replacing film rolls is reduced.

Owner:田开林

A kind of processing method of chipboard

InactiveCN106738180BEven by forceConvenient pressing workDomestic articlesFlat articlesWood shavingsParticle board

Owner:重庆木园春木业有限公司

Compression adjuster for smart food getting machine discharge pipe machining

InactiveCN109514326AImprove stroke stabilityAvoid shakingMetal working apparatusCompression deviceMachining

The invention discloses a compression adjuster for smart food getting machine discharge pipe machining. The compression adjuster comprises a manual lifting adjustment device, a support base located onthe manual lifting adjustment device and an elastic support base plate located on the support base; and a compression device is mounted at the upper end of the elastic support base plate, and the compression device comprises a fixed pressing support base, a sliding pressing support base, a tightening member, a stud and a screw handle. The compression adjuster can improve the stroke stability of alifting platform in the lifting process, prevents the lifting platform from swaying, can well compress a discharging pipe, prevents the discharging pipe from swaying, facilitates machining operationof the discharging pipe, and can prevent damage to the surface of the discharge pipe in the compressing process of the discharge pipe.

Owner:李兆林

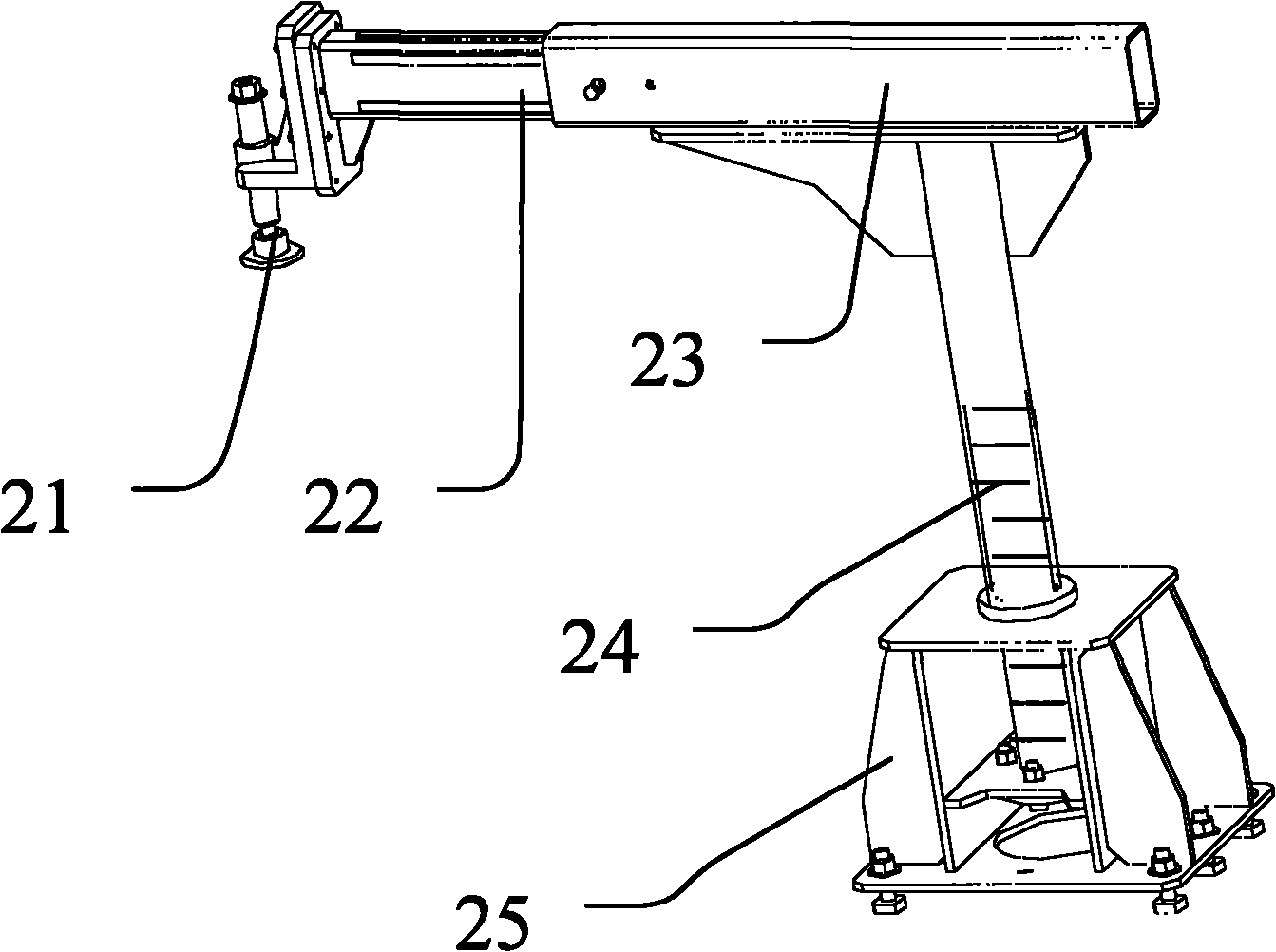

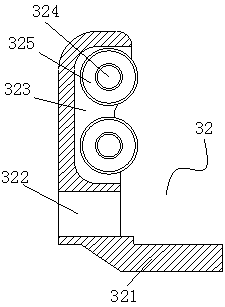

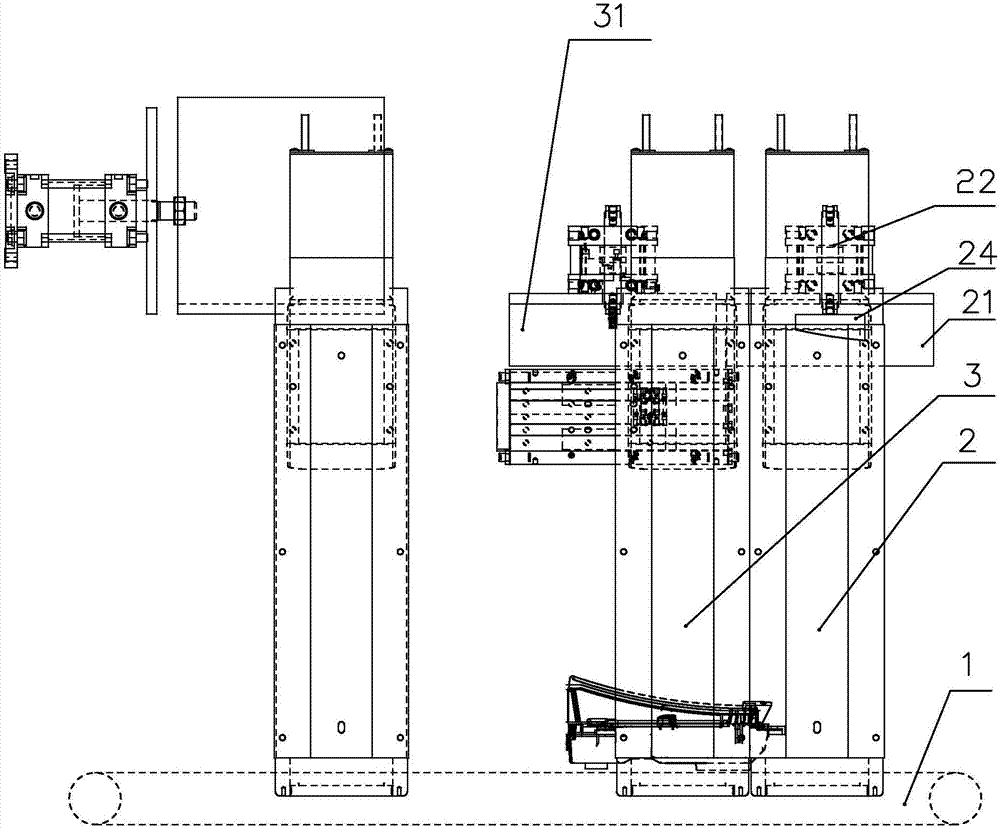

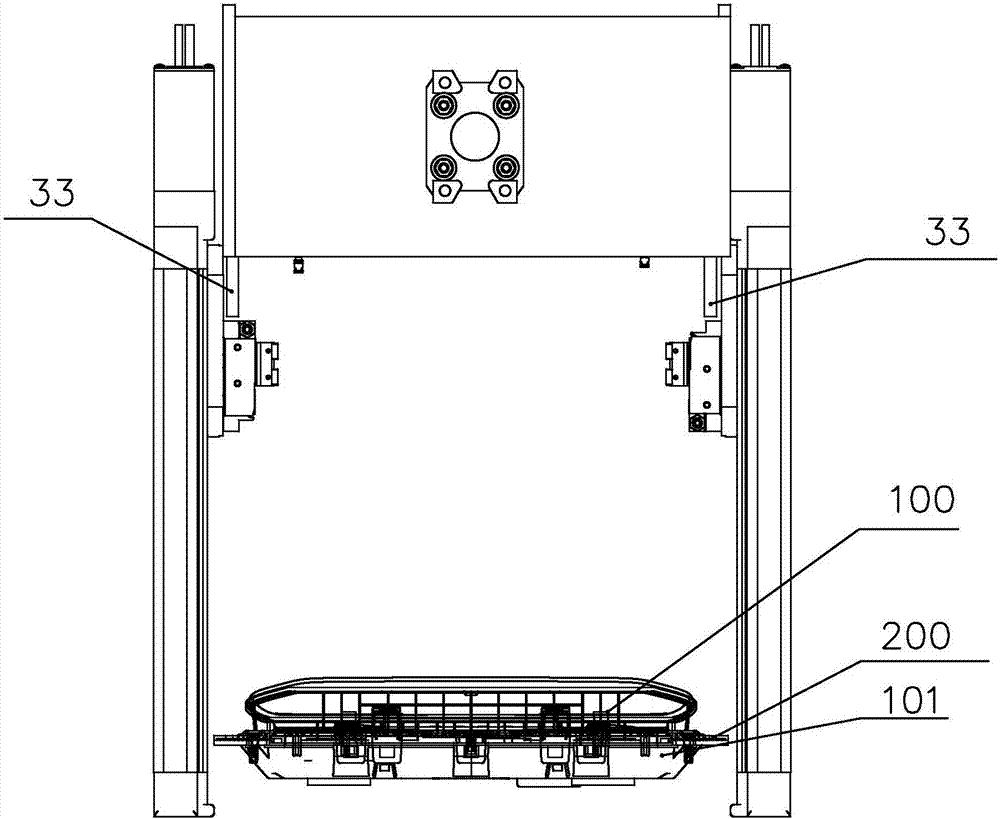

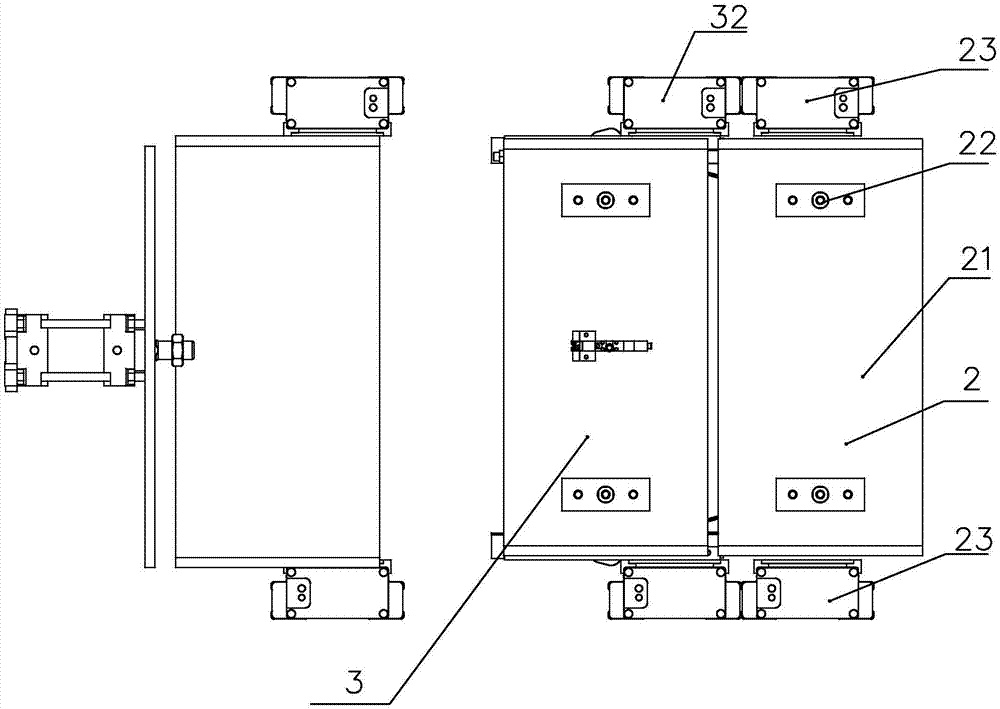

Auxiliary mounting device for automatic automobile instrument producing line

InactiveCN106881875ARealize the pressing operationEasy to installMetal working apparatusDashboardProduction line

The invention discloses an auxiliary mounting device for an automatic automobile instrument producing line, belongs to the technical field of automobile instrument mounting, and solves the problems that in the conventional automobile instrument producing line, due to manual mounting of screen rings, manpower is wasted, the production efficiency is low and the production cost is high. The auxiliary mounting device comprises a conveying assembly, a press fitting assembly and vertical moving assemblies, wherein the press fitting assembly is arranged above the conveying assembly; the press fitting assembly comprises a first sliding table, two press fitting cylinders, and two first supports which are arranged side by side; the first sliding table is arranged between the two first supports; the first sliding table is slidably connected with the two first supports through the vertical moving assemblies respectively; the two press fitting cylinders are vertically fixedly connected to the first sliding table; pressure heads are mounted at the end parts of piston rods of the press fitting cylinders. The auxiliary mounting device is used for mounting the screen rings.

Owner:AEROSPACE HI TECH HLDG GROUP

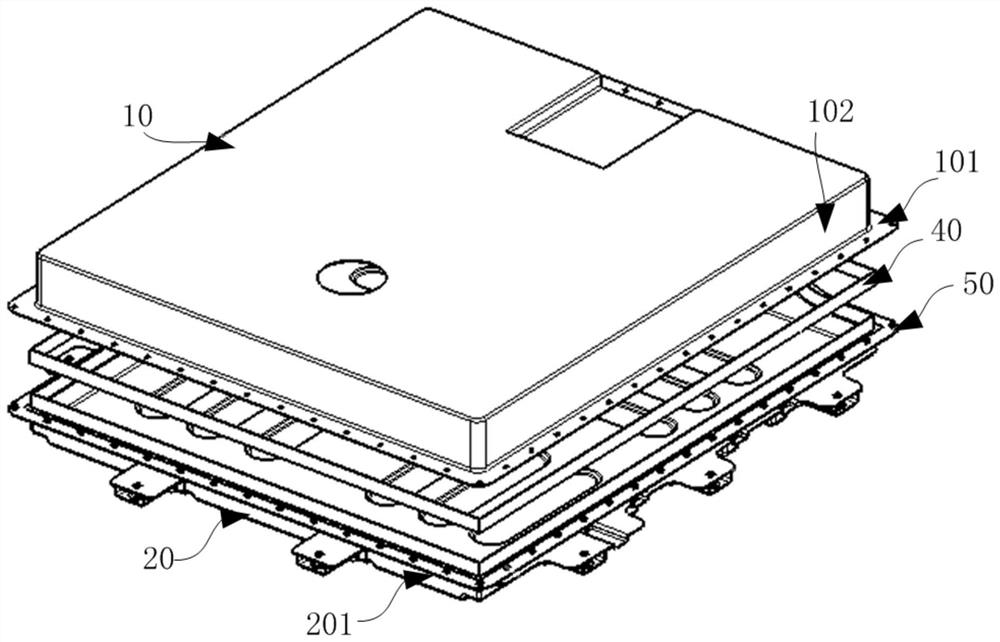

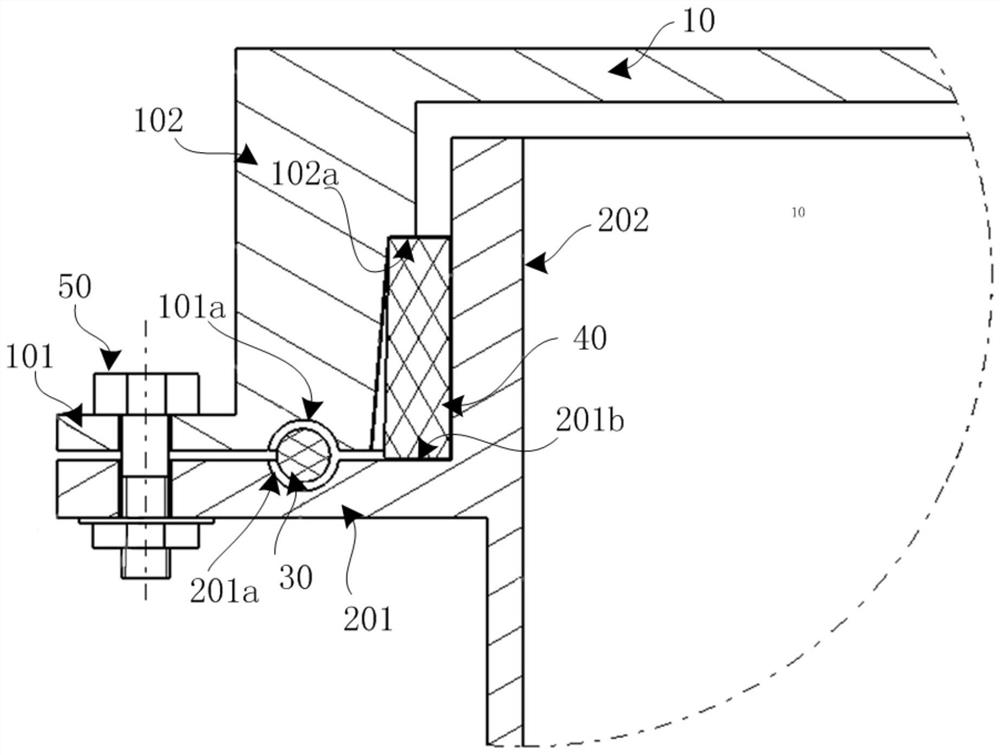

Double-sealing structure type battery pack box body and electric vehicle

PendingCN114171828ADouble seal implementationReduce material requirementsBattery isolationBatteriesElectrical batteryElectric cars

The invention discloses a double-sealing structure type battery pack box body and an electric automobile, the battery pack box body comprises a lower box body and an upper box body, the upper box body is provided with a first annular side wall, the lower box body is provided with a second annular side wall, the first annular side wall and the second annular side wall are respectively provided with a first annular flange and a second annular flange which extend outwards, a first annular sealing piece is arranged between the two; a second annular sealing piece is arranged between the first annular side wall and the second annular side wall in an up-down pressing connection mode. According to the scheme, the first annular flange and the second annular flange form the space capable of accommodating the first annular sealing element, and the space between the side walls of the upper box body and the lower box body is used as the space for accommodating the second annular sealing element, so that two seals are formed, and double seals of the battery pack box body can be realized on the premise of simple processing and lower cost. The second annular sealing piece adopts an up-down compression joint mode, the assembly is simple, dust, water and the like are more easily prevented from entering, and the sealing effect of the second sealing piece is improved.

Owner:SAIC MOTOR

Terminal cutting-off and press-fitting device with L-shaped stamping head

PendingCN113369560AImprove cutting efficiencyImprove pressing efficiencyContact member manufacturingShearing machinesBusiness enterpriseEngineering

The invention discloses a terminal cutting-off and press-fitting device with an L-shaped stamping head, and relates to the technical field of terminal cutting-off and press-fitting. The terminal cutting-off and press-fitting device comprises a workbench, a bottom plate and a supporting frame, wherein the bottom plate is connected with a lower supporting plate through a clamping block and a clamping bolt, the upper end of the lower supporting plate is sequentially provided with a pushing assembly, a sliding block assembly and a workpiece limiting seat, the sliding block assembly is matched with a clamping assembly above to clamp terminals, each terminal is of a U-shaped linear array sheet structure, a cutting-off assembly is arranged at the side end of the clamping assembly and comprises the stamping head, and the lower end of the stamping head is of an L-shaped protruding structure and can be matched with the terminal. With the terminal cutting-off and press-fitting device with the L-shaped stamping head, the processing requirements of enterprises on large-batch terminal feeding, cutting and press-fitting are met, unqualified terminal cutting-off and press-fitting caused by misoperation of employees of the enterprises are avoided, then the rejection rate of the enterprises is reduced, the cutting-off and press-fitting efficiencies of the terminals are improved, and the phenomena of bending and unevenness of the terminals due to overlarge feeding thrust are effectively avoided.

Owner:YAXIN (HUAIHUA) ELECTRONICS CO LTD

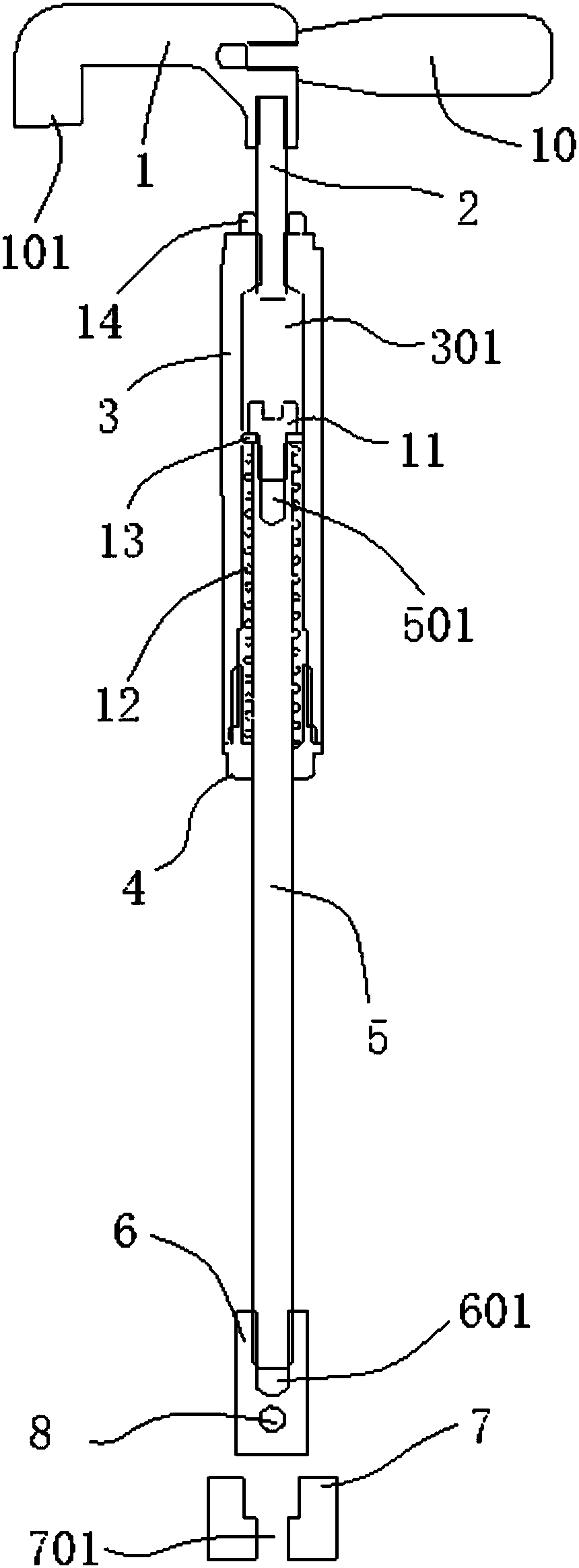

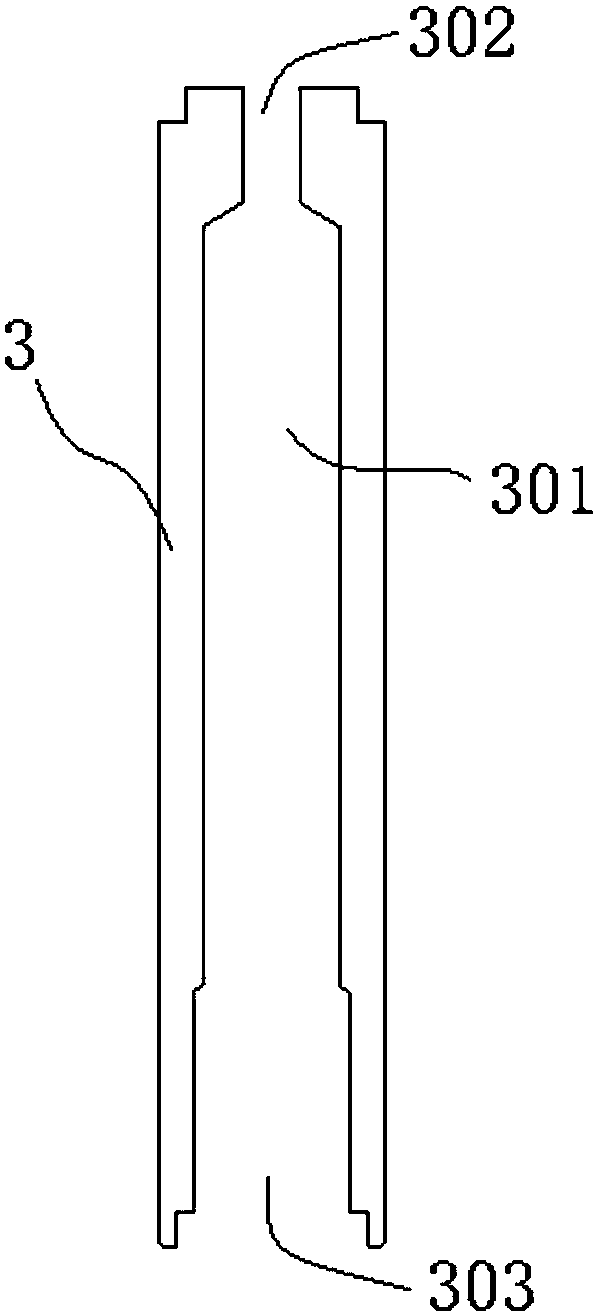

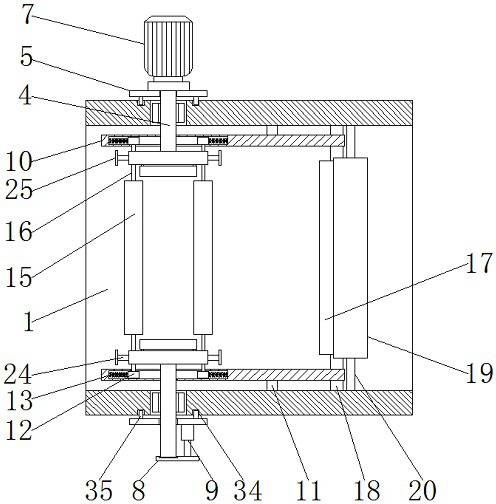

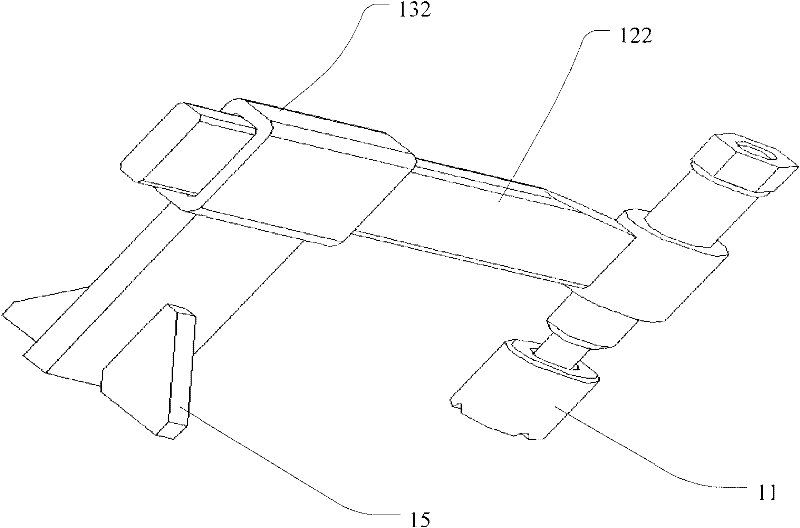

Clamping mechanism

InactiveCN108296693ASmall footprintSolve the technical defect that it is not convenient to perform compaction operation on the above application environmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRestoring force

The invention discloses a clamping mechanism. A compressing portion is arranged at one end of a pressure block; the other end of the pressure block is fixedly connected with the top end of a first connection rod; the bottom end of the first connection rod is fixedly connected with the top end of a shaft sleeve; the bottom end of the shaft sleeve is fixedly connected with a locking sleeve; a cavityis formed in the shaft sleeve; telescopic elastic parts and a limiting blocking piece are arranged inside the cavity; the top end of a second connection rod penetrates through the locking sleeve andis fixedly connected with the limiting blocking piece; the telescopic elastic parts are evenly distributed on the peripheral side of the second connection rod and located between the limiting blockingpiece and the locking sleeve; the second connection rod and the locking sleeve are in sliding fit; the bottom end of the second connection rod is fixedly arranged on a connection block; the connection block is connected with a base through a connection shaft; and the base is provided with a sixth mounting hole used for being connected with an outer structure. The clamping mechanism provided by the invention is small in space occupation, clamping of to-be-compressed boards is achieved by cooperation with lifting of the pressure block and elastic restoring force of the telescopic elastic parts,the conception is exquisite, and operation is flexible.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Plate spot-welding and clamping structure of vending machine box body

InactiveCN107685214ARealize clamping and pressingGuaranteed aestheticsWelding/cutting auxillary devicesAuxillary welding devicesHinge angleLeft handed

The invention discloses a spot welding and clamping mechanism for the box plate of an automatic vending machine. The lower end is slidingly connected with the welding bottom plate, the upper end of the column frame is provided with a bearing seat, and the rotating main shaft is rotationally connected with the bearing seat through a bearing. One side is provided with a right-handed thread, the first threaded sleeve is connected with the left-handed thread through a spiral pair, the second threaded sleeve is connected with the right-handed thread through a spiral pair, the pressure plate is provided with a hinged seat, and the upper end of the first connecting rod It is hinged with the threaded sleeve one, the lower end is hinged with the hinged seat, the upper end of the second connecting rod is hinged with the threaded sleeve two, and the lower end is hinged with the hinged seat, so as to realize the clamping and pressing of the welding of the sheet metal parts on the vending machine box, and reduce spot welding deformation Quantity, to ensure the aesthetics of sheet metal parts.

Owner:WUHU YIZE SMALL & MEDIUM ENTERPRISE PUBLIC SERVICE CO LTD

Winding device for building waterproof coiled material manufacturing and using method thereof

ActiveCN112173805AConvenient roll fixing operationEasy to disassemble and operateWebs handlingHydraulic cylinderConstruction engineering

The invention discloses a winding device for building waterproof coiled material manufacturing and a using method thereof. The winding device comprises a shell and a circular plate. According to the winding device, by arranging a hydraulic cylinder and a clamping mechanism, winding drum fixing operation of building waterproof coiled materials can be conveniently achieved through the clamping mechanism, production operation is facilitated, dismounting operation of the building waterproof coiled materials can be conveniently achieved through the effect of the hydraulic cylinder, and the production efficiency is improved; and by arranging a first guide roller, a second guide roller and a third guide roller, pressing operation on the building waterproof coiled materials can be achieved throughthe first guide roller so that the winding effect can be good, and clamping of the building waterproof coiled materials can be achieved through the action of the second guide roller and the third guide roller so that quantitative winding operation of the building waterproof coiled materials can be achieved according to the gravity effect, and use is convenient. The winding device has the advantages of being capable of achieving quantitative winding and convenient to operate.

Owner:HUZHOU PINCHUANG INCUBATOR

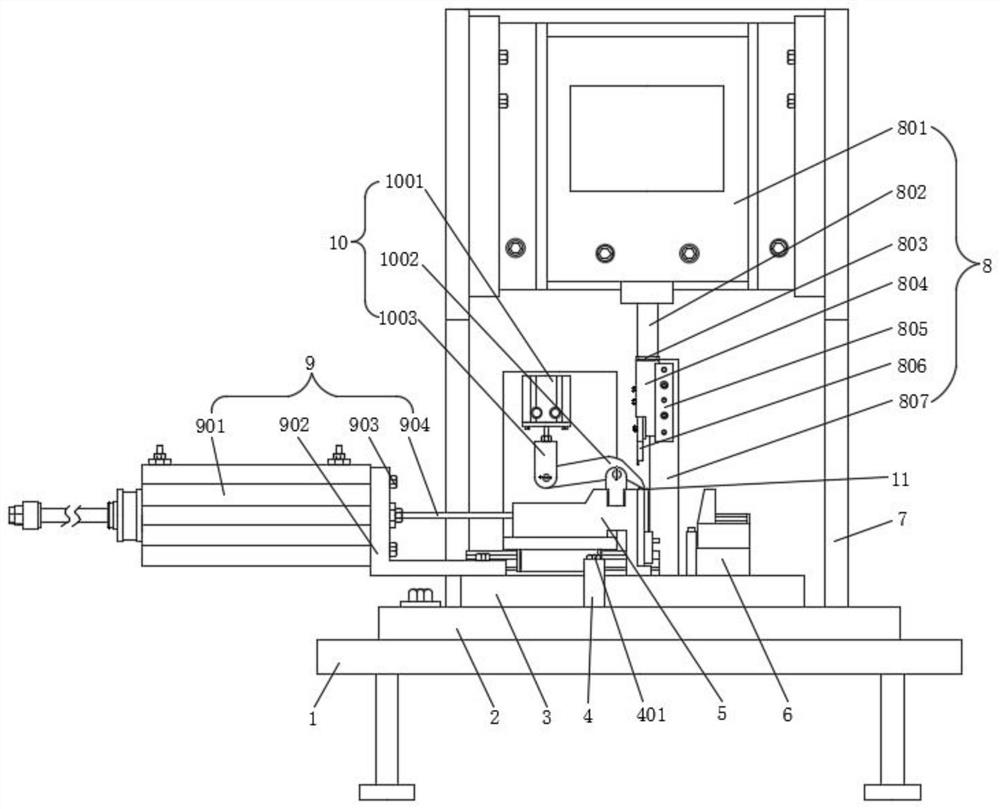

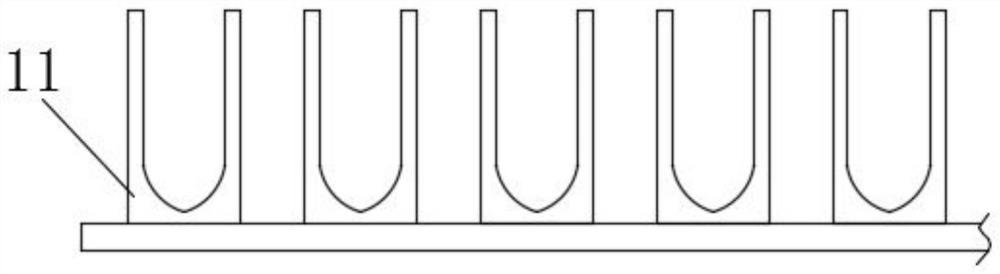

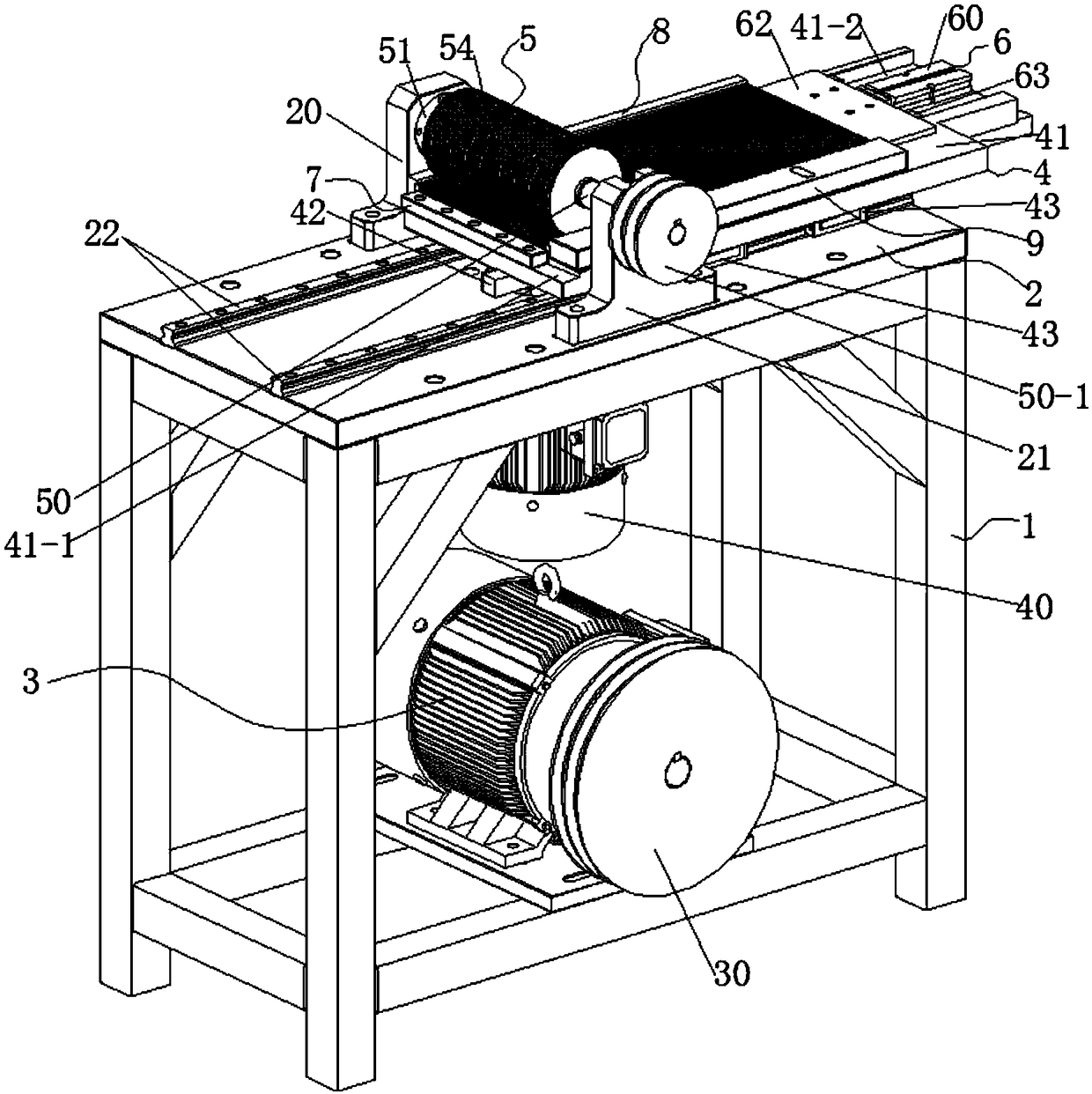

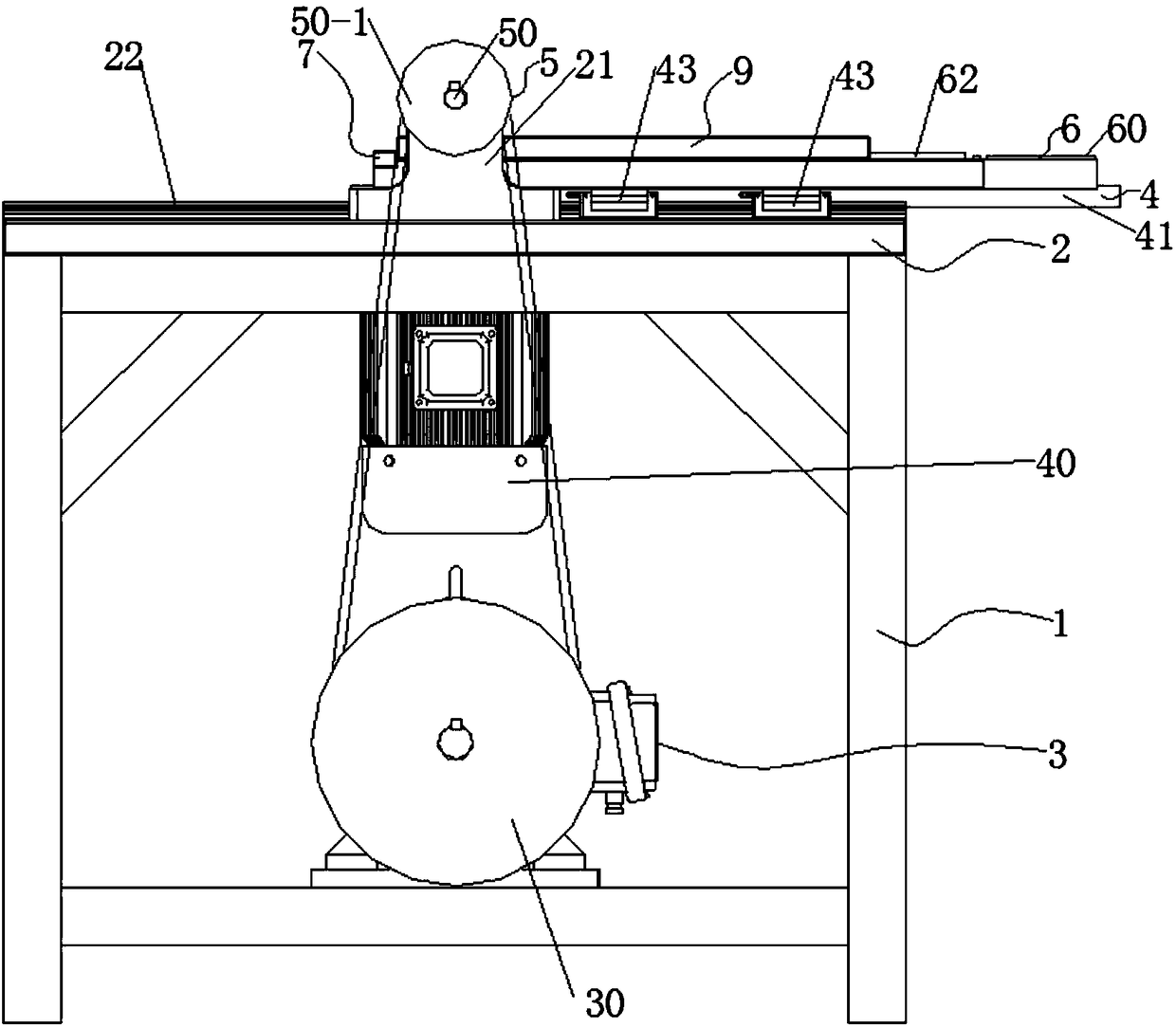

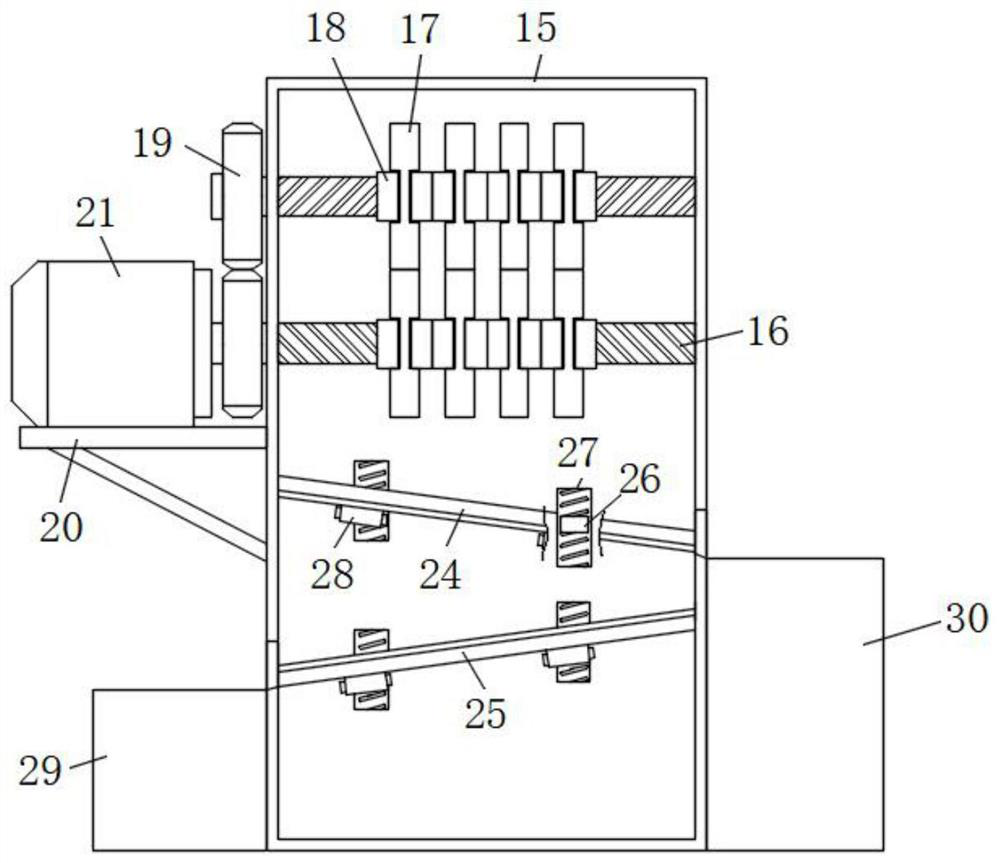

Machining device for clamping strip in glass slide box for laboratory

The invention discloses a machining device for a clamping strip in a glass slide box for a laboratory. The device comprises a machine frame, a platform plate, a three-phase asynchronous alternating current motor, a stepping sliding table assembly, a cutter roller assembly, a feeding pressing mechanism, an end rod, a first side plate and a second side plate. The platform plate is fixedly connectedwith the top end of the machine frame, the three-phase asynchronous alternating current motor is connected with the lower end of the machine frame, an output shaft of the three-phase asynchronous alternating current motor is provided with a large belt wheel, one side of the platform plate is provided with a first bearing pedestal, the other side of the platform plate is provided with a second bearing pedestal, the second bearing pedestal is provided with a slot, the middle is provided with two parallel guide rails, one end of the cutter roller assembly is rotationally connected with the firstbearing pedestal, the other end of the cutter roller assembly is rotationally connected with the second bearing pedestal, the stepping sliding table assembly is composed of a stepping motor, a slidingplatform, a rack and a sliding block, the cutter roller assembly replacing efficiency is improved, the device is applicable to machining different specifications of clamping strips and high in university, the production cost is reduced, pressing operation after feeding is achieved through the feeding pressing mechanism, and material returning is avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

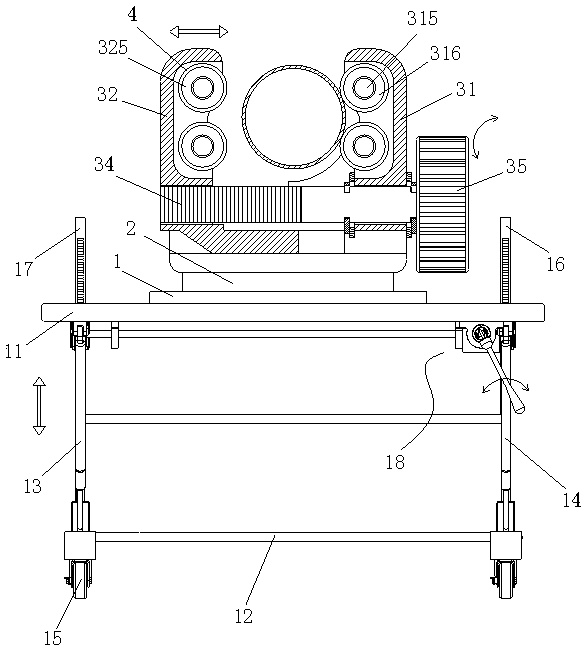

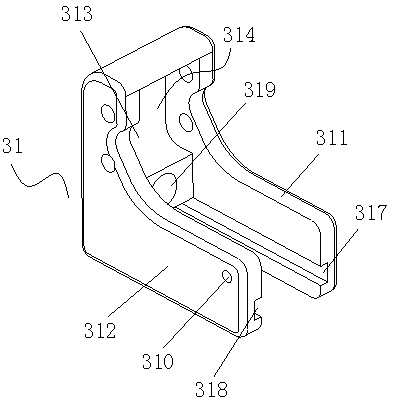

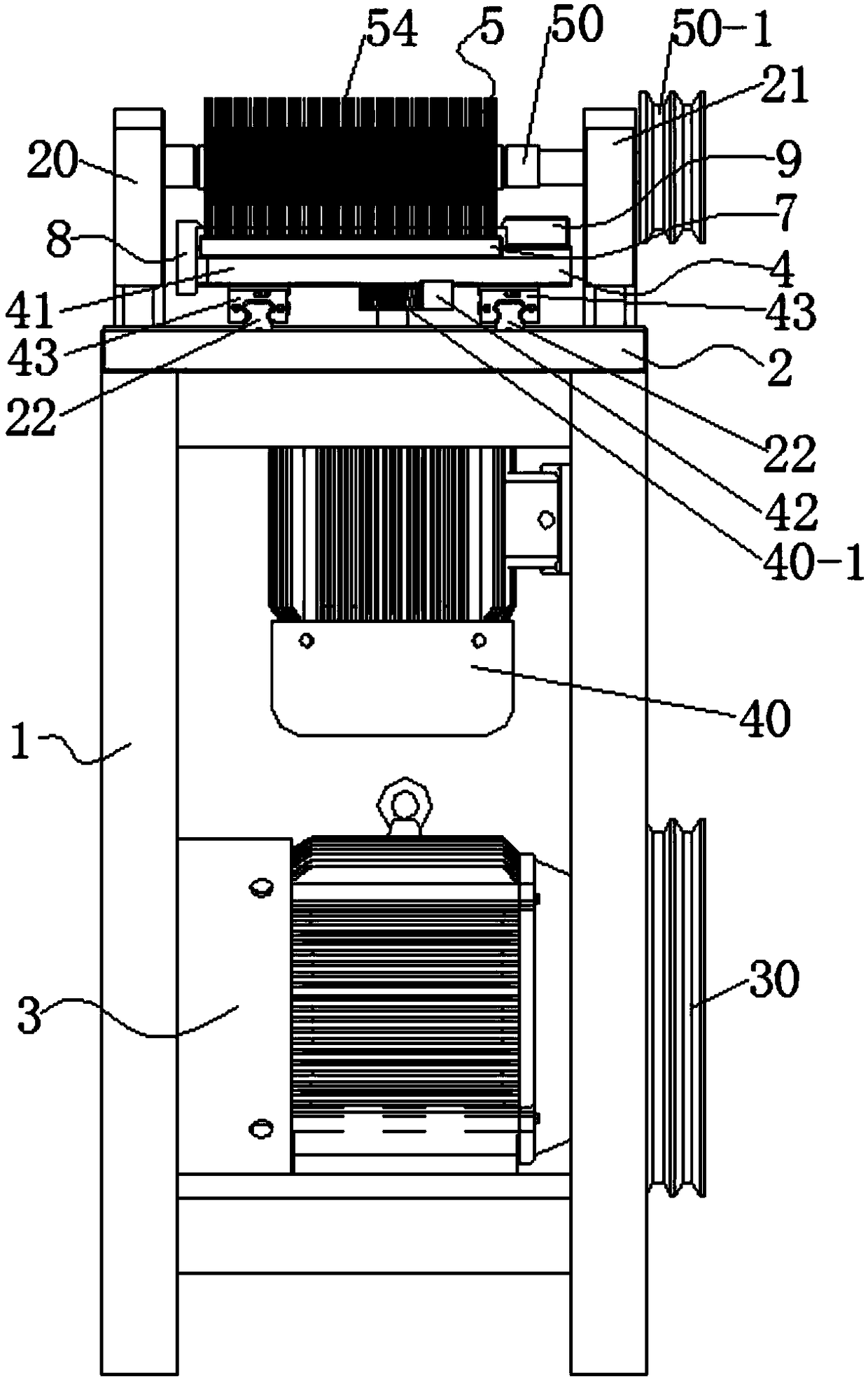

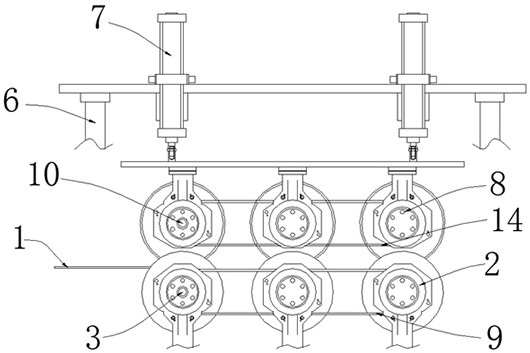

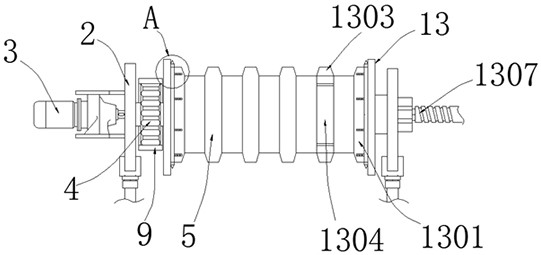

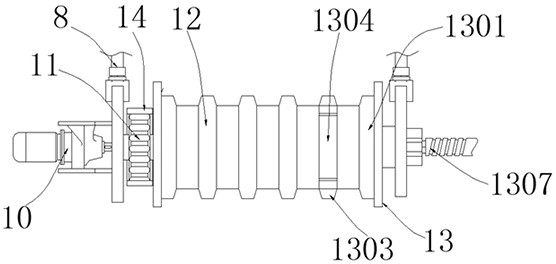

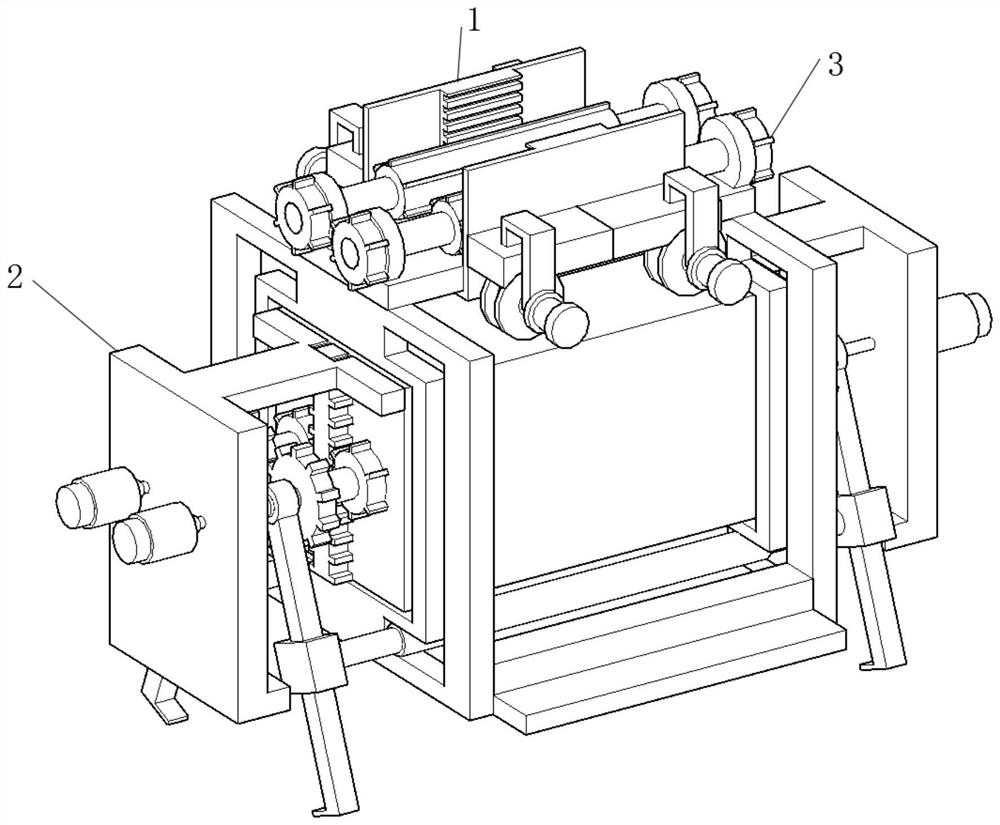

Reinforcing rib pressing machine for color steel tile and its application method

ActiveCN113333538BImproved aesthetics and dimensional accuracyReduce volumeMetal sawing devicesOther manufacturing equipments/toolsGear wheelTransmission belt

Owner:南通德泰隆钢结构工程有限公司

Laminating machine high-temperature cloth take-up and pay-off self-cleaning device

InactiveCN106113894AAutomatically achieves cleanabilityAutomated RecyclingLamination ancillary operationsLaminationSolar cellLow vacuum

The invention relates to the technical field of solar cell module package and lamination, in particular to a laminating machine high-temperature cloth take-up and pay-off self-cleaning device. The laminating machine high-temperature cloth take-up and pay-off self-cleaning device can automatically achieve high-temperature cloth cleaning and recovery, does not damage the high-temperature cloth, improves the efficiency, saves the cost and comprises a laminating machine upper vacuum chamber and a laminating machine lower vacuum chamber, wherein a take-up support is arranged between the laminating machine upper vacuum chamber and the laminating machine lower vacuum chamber, take-up and pay-off reels are respectively arranged on two sides of the take-up support, cleaning pressing air cylinders are arranged on the inner sides of the take-up and pay-off reels, and macromolecular cleaning blocks are arranged on piston rods of the cleaning pressing air cylinders.

Owner:SUPER UNION PRECISION ENG WUXI

Waste granulating device for wood processing

InactiveCN112454602ATimely recyclingImprove working environmentSievingScreeningGear wheelWorking environment

The invention discloses a waste granulating device for wood processing. The waste granulating device comprises a workbench, an elevator is installed on one side of the top face of the workbench, a fixing base is fixed to the middle of the top face of the workbench, a smashing chamber is fixed to the side, close to the elevator, of the top face of the fixing base, a feeding hopper is further connected to the side, close to the elevator, of the top face in a penetrating mode, crushing rollers are rotatably connected to the inner walls of the front end and the rear end of the smashing chamber, one ends of the two crushing rollers penetrate through the side wall of the smashing chamber and are rotatably connected through a first gear set, a supporting plate is further fixedly connected to oneside of the rear end face of the smashing chamber, and a first servo motor is fixedly connected to the top face of the supporting plate through screws. The device is reasonable in design and stable inoperation, pressing operation of wood waste materials with different specification requirements can be achieved, wood powder which is not pressed can be recycled in time, the phenomenon of dust raising is well avoided, and the working environment of waste wood granulation is greatly improved.

Owner:怀宁县三兴木业有限公司

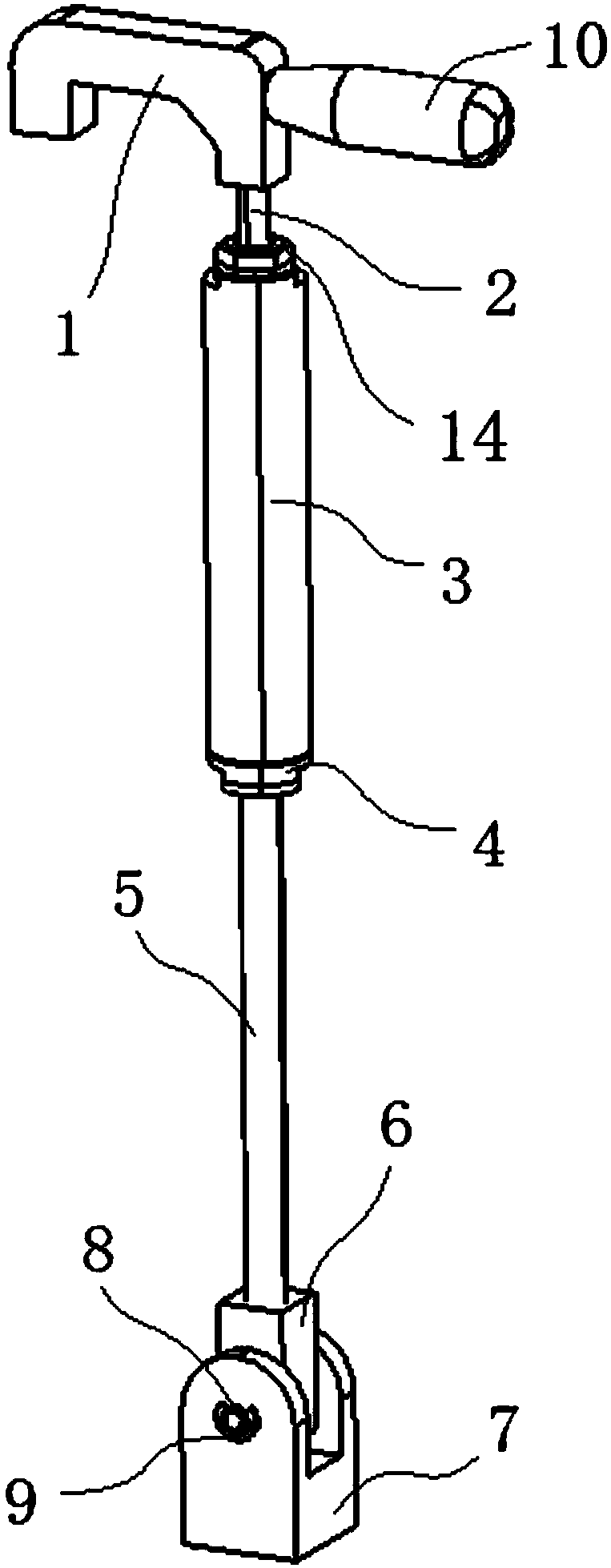

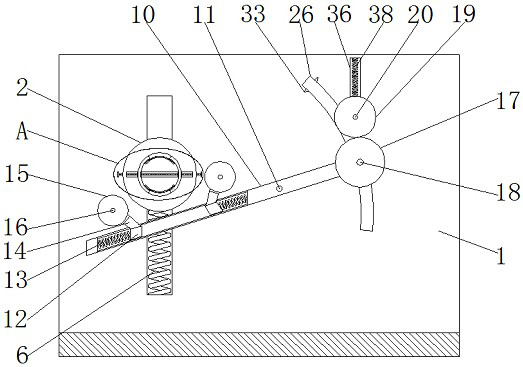

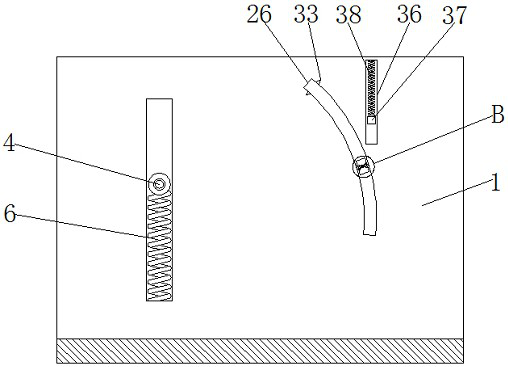

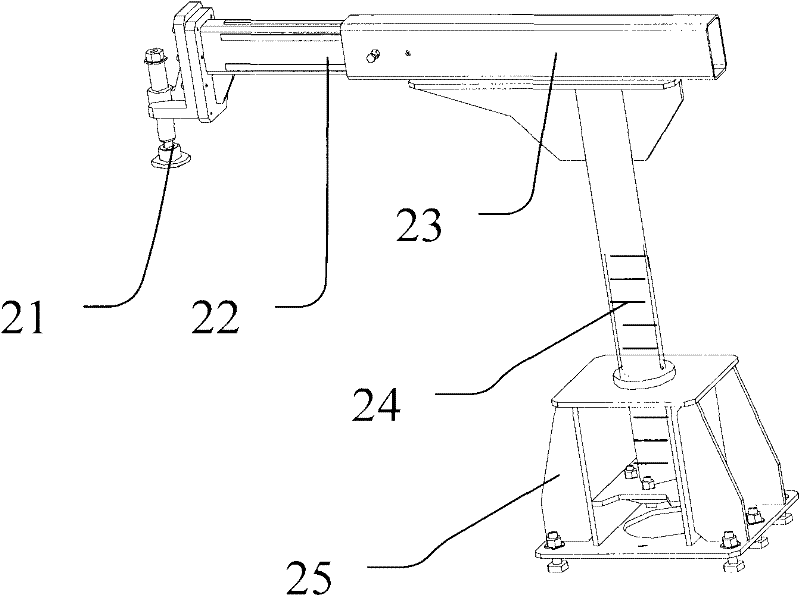

An external lifting and fixing device of a spectrometer

ActiveCN106895913BEasy to moveRealize the pressing operationRadiation pyrometryMaterial analysis by optical meansEngineeringSpectrometer

The invention relates to the technical field of external fixing of a spectrometer, in particular to an external liftable fixing device of a spectrometer. Compaction operation of different sizes of samples can be achieved and detection results are ensured. The fixing device comprises a base. A vertically arranged guide rod is installed on the base. At least two annular grooves are arranged in the side part of the guide rod at a certain interval. A compression seat sleeves the guide rod. At least two transversally arranged accommodating grooves are arranged in a through hole inner wall, cooperating with the guide rod, of the compaction seat. Clamp blocks cooperating with the annular grooves are installed in the accommodating grooves through transversal compression springs. A transversal groove is installed in one side of the compaction seat. The interior of the transversal groove is connected with one end of the press rod through a rotation shaft. A press block is installed on the other end of the press rod. A vertical compression spring is installed between the press rod and the inner wall of the upper end of the transversal groove.

Owner:WUXI JINYIBO INSTR TECH CO LTD

Winding device for manufacturing waterproof membrane for building and its application method

ActiveCN112173805BConvenient roll fixing operationEasy to disassemble and operateWebs handlingHydraulic cylinderConstruction engineering

The invention discloses a rolling device for building waterproof coiled material and a using method thereof, which comprises a shell and a circular plate. The present invention is provided with a hydraulic cylinder and a clamping mechanism, which can conveniently realize the reel fixing operation of the building waterproof coiled material through the clamping mechanism, which is convenient for production operation, and can conveniently realize the fixing operation of the building waterproof coiled material through the function of the hydraulic cylinder. The disassembly operation can improve the production efficiency; by setting the first guide roller, the second guide roller and the third guide roller, the first guide roller can realize the pressing operation of the building waterproof membrane, so that the winding effect is good. The function of the second guide roller and the third guide roller can realize the clamping of the building waterproof membrane, and can realize the quantitative winding operation of the building waterproof membrane according to the action of gravity, which is convenient to use. The invention has the advantages of realizing quantitative winding and convenient operation.

Owner:HUZHOU PINCHUANG INCUBATOR

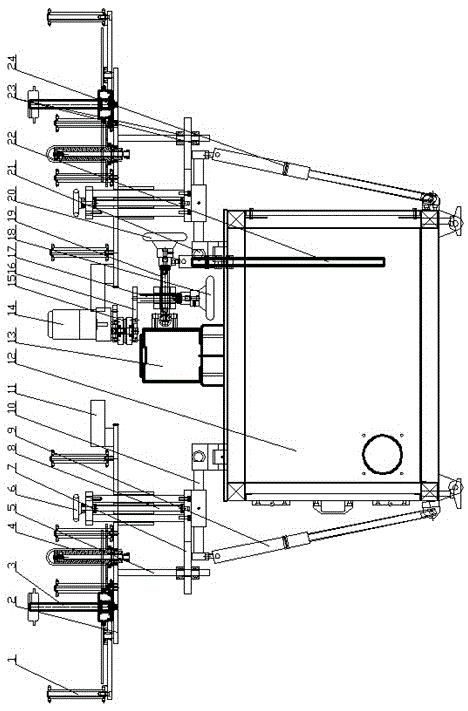

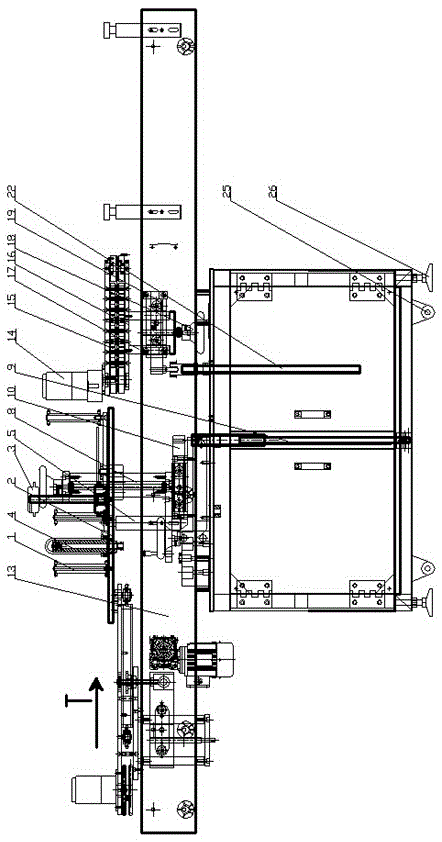

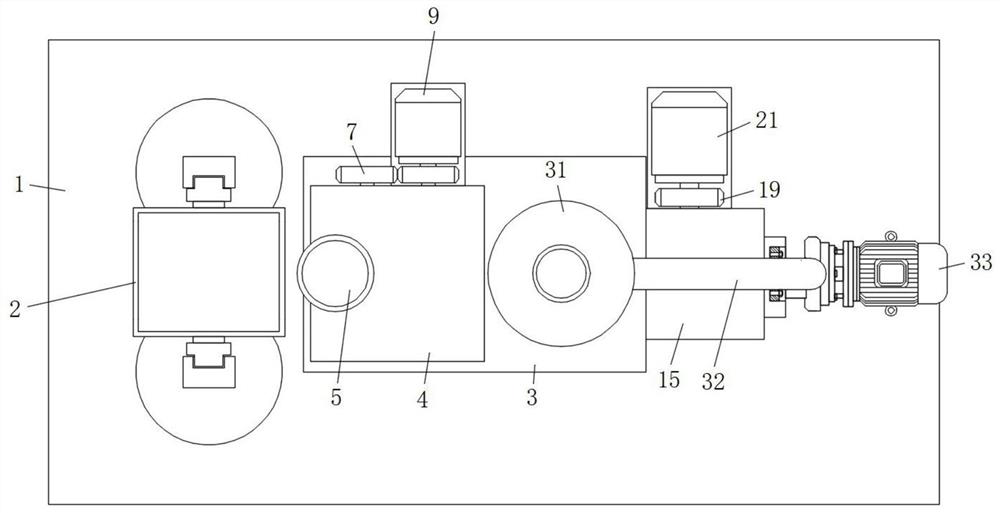

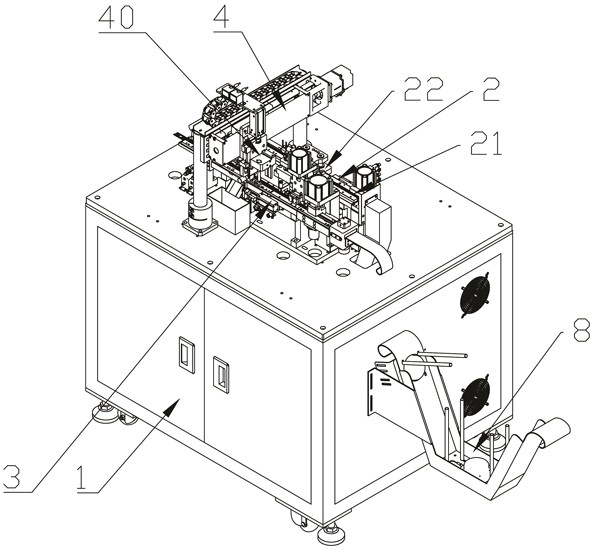

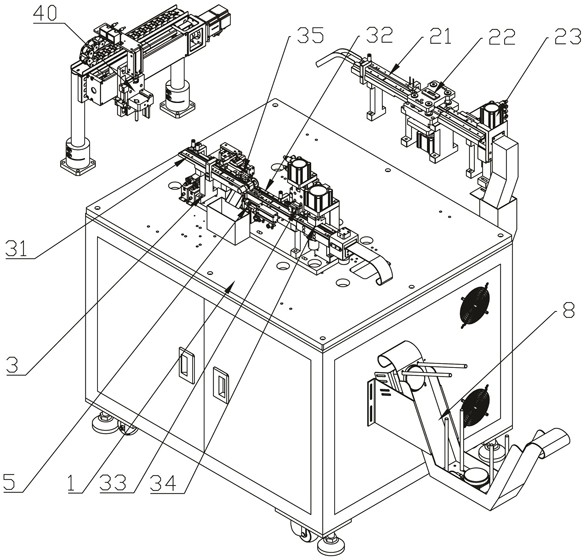

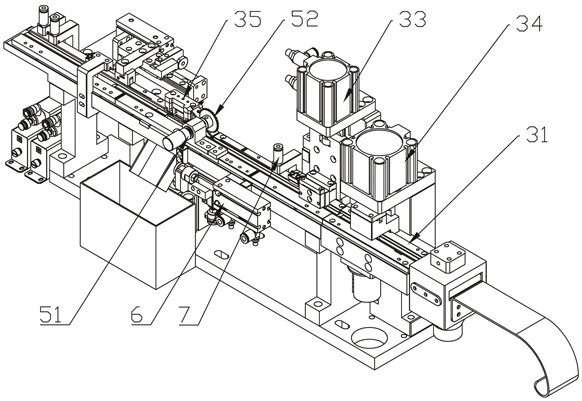

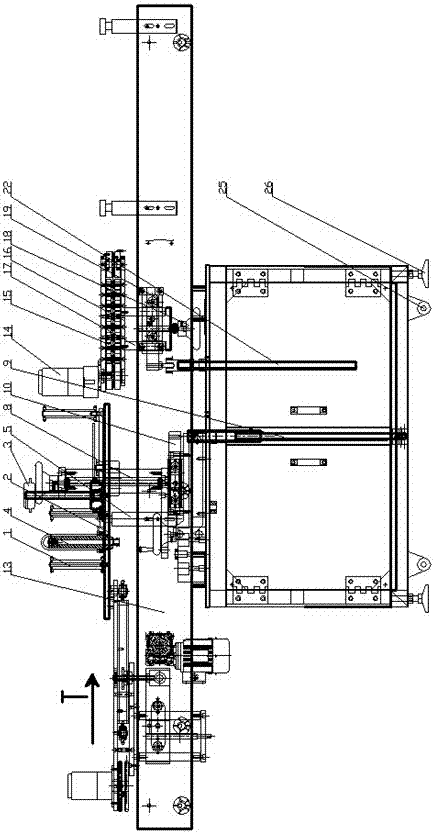

Automatic assembling equipment for universal serial bus interface

PendingCN114654525AMeet the needs of three-in-one press-fit assemblySatisfy the pressing operationDomestic articlesCoatingsEngineeringBus interface

The invention discloses automatic assembling equipment for a universal serial bus interface, which comprises a base station main body, and an interface pressing plate material belt conveying and cutting mechanism, a composite material belt conveying and pressing mechanism and an interface pressing plate carrying mechanism which are arranged on the base station main body, the interface pressing plate material belt conveying and cutting mechanism comprises an interface pressing plate material belt conveying guide rail and an interface pressing plate cutting and ejecting station, the composite material belt conveying and pressing mechanism comprises a composite material belt conveying guide rail, an interface pressing plate feeding station, a pressing station and a protection foot trimming station, and the interface pressing plate carrying mechanism comprises an interface pressing plate picking part. The three-in-one press-fit assembly requirement of the universal serial bus interface is met, press-fit operation is achieved after the blanked parts are transferred and overlapped, automatic operation is efficient and smooth, and the requirement for operation associated with a forming injection molding machine is met. And high-precision material stacking alignment can be realized. And the injection molding buffer design is adopted, speed matching and coordinated operation with a molding injection molding machine can be achieved, the production period is greatly shortened, and the production efficiency and the product percent of pass are both greatly improved.

Owner:昆山大途精密机械有限公司

Heat press machine with demoulding function

InactiveCN106827120BEven by forceConvenient pressing workPlywood pressesVeneer pressesElectric machineryEngineering

The invention belongs to the field of presses, and particularly discloses a hot press with the demolding function. The hot press comprises an upper pressing plate and a fixing plate; the two ends of the upper pressing plate are connected with a first supporting frame and a second supporting frame in a sliding mode respectively; a plurality of sliding blocks are arranged in the first supporting frame; heating plates are arranged on the sliding blocks and are connected through springs; a motor is arranged above the upper pressing plate and is fixedly connected to a first rotating shaft, and the first rotating shaft is rotationally connected to a water tank; the water tank is rotationally connected to a second rotating shaft; a plurality of blades are arranged on the opposite ends of the first rotating shaft and the second rotating shaft; the second rotating shaft is fixedly connected to a lower pressing block; a hydraulic block is arranged at the bottom of the lower pressing block; a hollow cavity is formed in the hydraulic block; and the two ends of the hydraulic block are fixedly connected to the upper pressing plate through flexible connecting pieces. The invention provides the hot press with the demolding function. The hot press with the demolding function has the advantages that the upper pressing plate is stressed uniformly, and a plate is easy to demold and can be kept from being crushed.

Owner:重庆木园春木业有限公司

A bottled beverage labeling device

InactiveCN105644871BGood compression effectPrevent fallingLabelling short rigid containersLabelling machinesEngineeringLabelling

The invention discloses a labelling device for bottled drink. The labelling device comprises a drink bottle transmitting device, two label paper rotating disks, a rack and a label pressing protective wheel, wherein the drink bottle transmitting device is arranged at one side of the rack in an L-shaped shape; the label paper rotating disks are fixed on the rack through movable adjusting support pillars and are positioned at two sides of the drink bottle transmitting device; the label pressing protective wheel is fixed at one side of the label paper rotating disks along the transmitting direction of the drink bottle transmitting device; the label pressing protective wheel comprises a first vertical support rod, a horizontal fixing rod, a second vertical support rod and a wheel guard; a first adjusting knob is arranged on the first vertical support rod; the horizontal fixing rod and one end of the first vertical support rod are connected; a second adjusting knob is arranged in the middle of the horizontal fixing rod; the second vertical support rod is fixed on the horizontal fixing rod; a third adjusting knob is arranged in the middle of the second vertical support rod; the wheel guard is arranged on a fixing plate above the second vertical support rod; and a driving motor is arranged above the wheel guard. The labelling device for the bottled drink, disclosed by the invention, has the advantages of simple structure, convenience in use and high laminating strength of labels.

Owner:湖南湘鹰食品科技有限公司

Coating method

ActiveCN110775681BGuaranteed continuous supplyRealize separation operationWrapping material feeding apparatusWebs handlingProduction lineAdhesive belt

The invention relates to a film coating method. The film coating method comprises the steps of coating glue on one end of a film roll in advance or sticking a bonding adhesive tape; separating a firstfilm roller from a second film roller; covering one end of a film on the film roll on an upper roll rod on the first film roller, and enabling a first pressure head to be abutted against the first film roller so as to realize the compression of one end of the film on the film roll on the upper roll rod; and when the film roll on a lower roller rod is close to be stopped from using, enabling the first film roller and the second film roller to be close to one another by a lifting mechanism, and enabling one end of the film on the film roll on the upper roller rod to be bonded with the upper surface of the film on the lower roller rod which is used in advance; starting a cutting knife to perform cutting operation on the joint of the film on the lower roller rod and the film on the film rollof the upper roller rod; and separating the first pressure head from the first film roller, enabling the first film roller and the second film roller to be far away from one another by the lifting mechanism, enabling one end of the film on the film roll on the upper roller rod to be in a free state, starting other devices of a production line, and performing film coating operation on a plate.

Owner:田开林

Pressing device

ActiveCN101829969BRealize the pressing operationExpand the pressing rangeWork holdersEngineeringMechanical engineering

Owner:CRRC TANGSHAN CO LTD

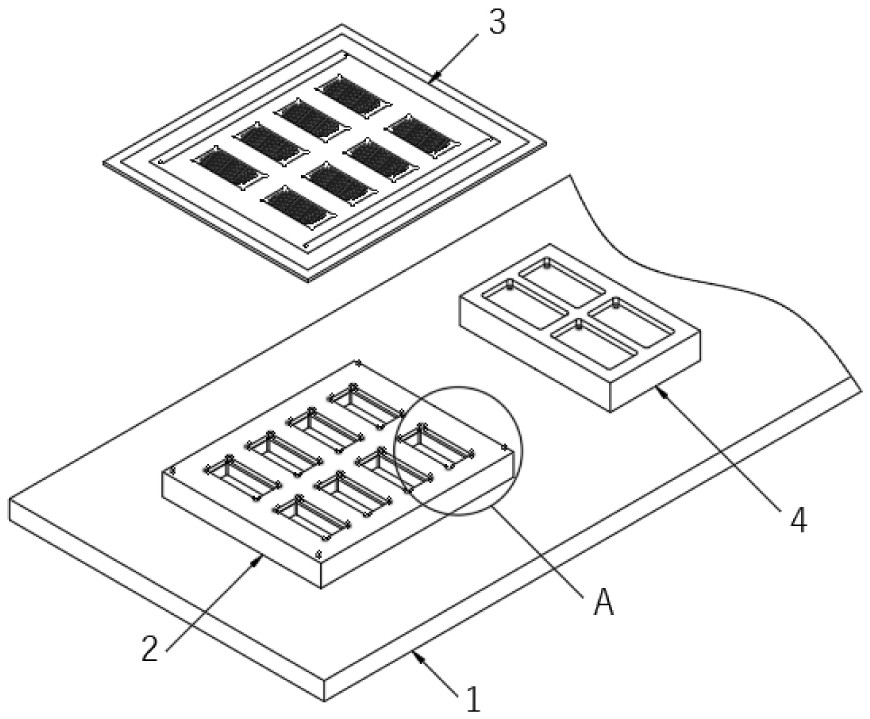

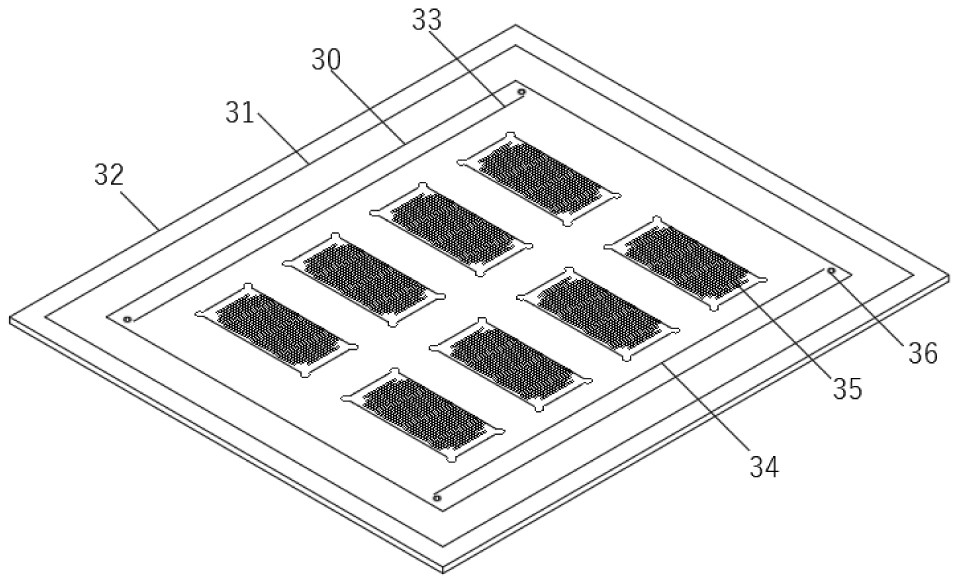

Tool for detecting coating condition of heat-conducting silicone grease

PendingCN114739259AEasy to observeRealize the pressing operationColor measuring devicesMechanical thickness measurementsEngineeringWorkbench

The invention relates to the technical field of IGBT (Insulated Gate Bipolar Translator) module coating detection tools, in particular to a heat-conducting silicone grease coating condition detection tool, which comprises a placement mold arranged on a working table, the placement mold comprises a rectangular plate, a plurality of placement grooves arranged in a matrix manner are formed in the rectangular plate, grooves are formed in the groove walls of the tops of the placement grooves, and the grooves are communicated with the placement mold. A steel mesh is arranged above the placing die, a mounting die is further arranged on the working table, the mounting die comprises a die plate arranged on the working table, a plurality of detection grooves communicated with the outside are formed in the die plate, four screw holes arranged in a matrix mode are formed in the bottom wall of each detection groove, an annular groove is formed in the working table, and the mounting die is arranged in the annular groove. A pressing device is arranged at the position of the annular groove, an ejection device is arranged at the bottom of the working table top, and the ejection device comprises a hydraulic cylinder arranged below the working table top. The coating condition can be observed by naked eyes, operation and use are convenient, and convenience is brought to a user.

Owner:YANTAI TAIXIN ELECTRONICS TECH CO LTD

Terminal cutting and press-fitting device with H-shaped stamping head

PendingCN113843445ASimple structureEasy to useContact member manufacturingShearing machinesBackplaneEngineering

The invention discloses a terminal cutting and press-fitting device with an H-shaped stamping head, and relates to the technical field of terminal cutting and press-fitting processing. The terminal cutting and press-fitting device comprises a workbench and a bottom plate, wherein the upper surface of the bottom plate is connected with a lower supporting plate through a clamping block and a clamping bolt; a pushing assembly is arranged at one side of the lower supporting plate; one side, away from the pushing assembly, of a slide block assembly is equipped with a workpiece limiting base for placing a workpiece; the slide block assembly is matched with a clamping assembly above, and can clamp a terminal; a cutting assembly for cutting off the terminal is arranged at the side end of the clamping assembly and above the slide block assembly; the cutting assembly comprises a stamping head; and the lower end part of the stamping head is in the shape of an H-shaped bump structure, and can be matched with the terminal. The terminal cutting and press-fitting device meets processing needs, on large-batch terminal loading, cutting and press-fitting, of enterprises, avoids unqualified terminal cutting or press-fitting due to misoperation of enterprise staff, reduces a rejection rate of the enterprises, improves cutting and press-fitting efficiency of the terminal, and improves economic benefits.

Owner:YAXIN (HUAIHUA) ELECTRONICS CO LTD

A high-strength fireproof insulation board

ActiveCN113737975BEffective dispersionAvoid irresistibleHeat proofingFire proofingThermal insulationAdhesive

The invention relates to the technical field of thermal insulation boards, in particular to a high-strength fireproof thermal insulation board, which includes a protective shell board and a thermal insulation board body. The lower surface is fixedly connected with a heat conduction plate layer, and the heat insulation plate layer and the heat conduction plate layer are fixedly connected by an adhesive. When the present invention is used, it is received or released through the lower surface of the first heat transfer contact plate. The heat transferred by the connection plate, and the heat is transferred from the corresponding second extension frame through the first connection plate, and the heat can be transferred through the second extension frame with the heat conduction plate layer, so as to realize the derivation of the high temperature generated inside, and use the installation There are multiple inventions to effectively disperse heat. Compared with the prior art, it avoids the inability to effectively resist the fire source in the later stage, thereby greatly improving the fire resistance of the invention and effectively reducing its internal temperature.

Owner:山东基舜节能建材有限公司

Integrated forming device for steel plate machining

PendingCN112139302AEasy to quit workRealize the pressing operationEjection devicesSteel platesMoulding device

The invention discloses an integrated forming device for steel plate machining. The integrated forming device comprises a steel plate machining forming device body; a first machining part is arrangedat the bottom of the inner end of the steel plate machining forming device body; a second machining part is connected to the center of the first machining part; the first machining part comprises an acting end and a mounting connecting rack; the acting end is arranged in the center of the inner end of the first machining part; the mounting linkage rack is connected to the side end of the acting end; and the acting end comprises a first rotating rod, a pressing rod, a guide column, a sliding block frame, a rail frame, first meshing teeth, a first output shaft, a first motor, a second motor, a second output shaft, second meshing teeth, a transmission fluted disc and a second rotating rod; and the first motor and the second motor are both arranged on one side of the inner end of the acting end. According to the integrated forming device for the steel plate machining provided by the invention, through the arrangement of the first machining part and the second machining part, the purpose ofintegrally folding the inner end is achieved.

Owner:吴堂荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com