Waste granulating device for wood processing

A technology for waste materials and wood, which is applied in the pretreatment and application of wood processing equipment and molding materials, can solve the problems of labor consumption and low efficiency, and achieve the effect of stable operation of the device, easy use, and avoidance of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

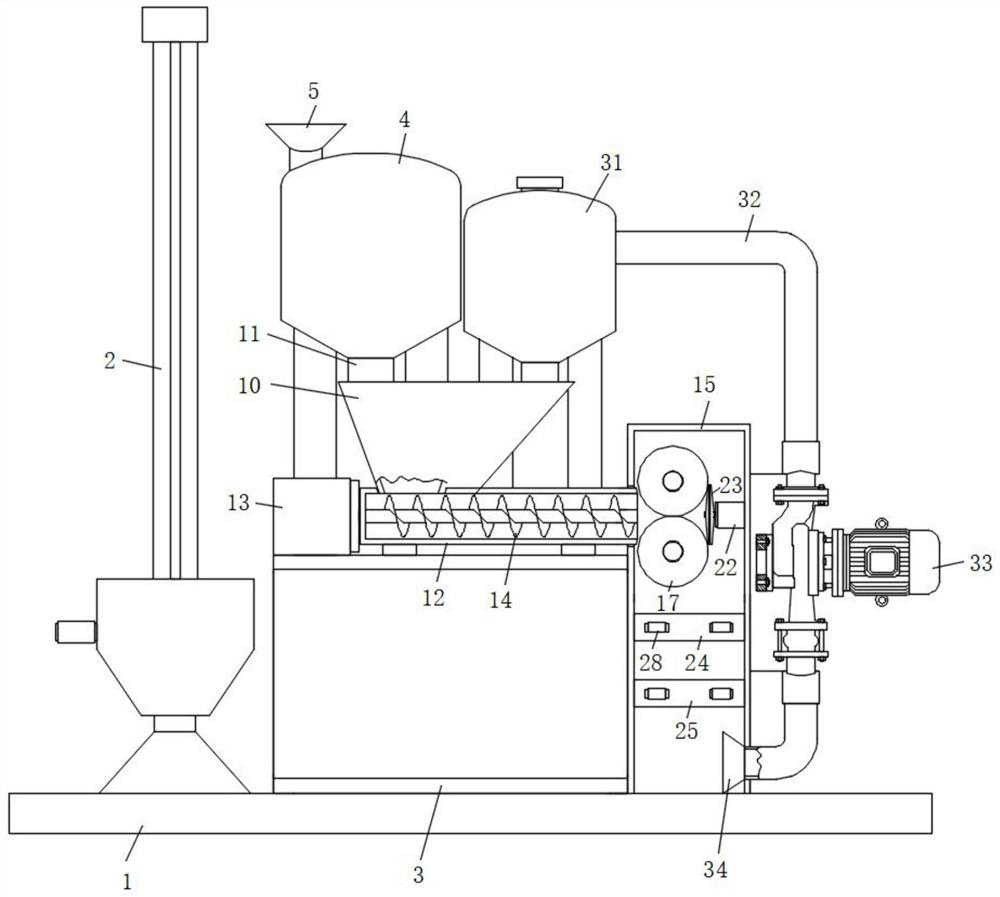

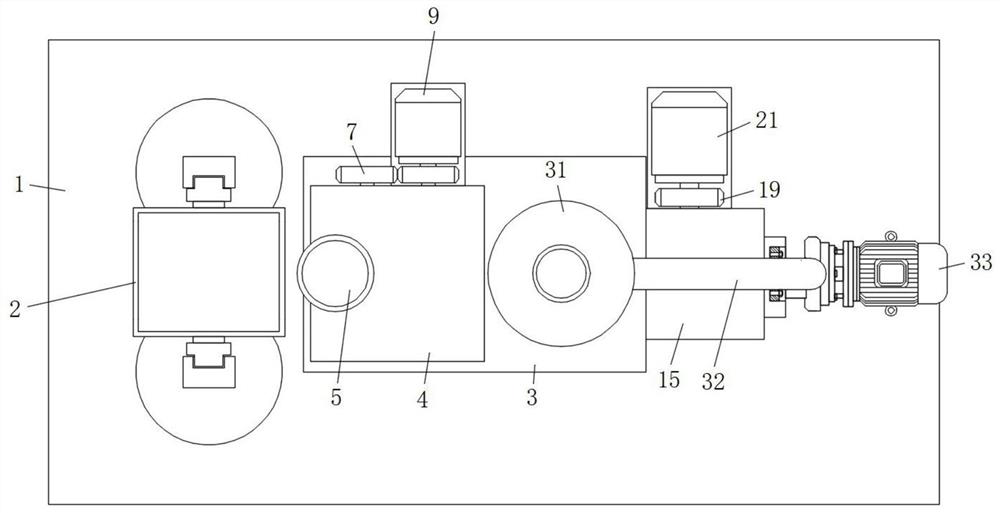

[0030] refer to Figure 1-4, a waste granulation device for wood processing, comprising a workbench 1, a hoist 2 is installed on one side of the top surface of the workbench 1, a fixing seat 3 is fixed in the middle of the top surface of the workbench 1, and the top surface of the fixing seat 3 is close to the hoist A crushing chamber 4 is fixed on one side of the 2, and a feeding funnel 5 is connected through the top surface close to the elevator 2. The inner wall of the front and rear ends of the crushing chamber 4 is rotatably connected with a crushing roller 6, and one end of the two crushing rollers 6 passes through the The side wall of the crushing chamber 4 is rotationally connected by a gear set-7, a support plate 8 is fixedly connected to one side of the rear end surface of the crushing chamber 4, and a servo motor-9 is fixedly connected to the top surface of the support plate 8 by screws, and the servo motor-9 It is fixedly connected with one of the crushing rollers ...

Embodiment 2

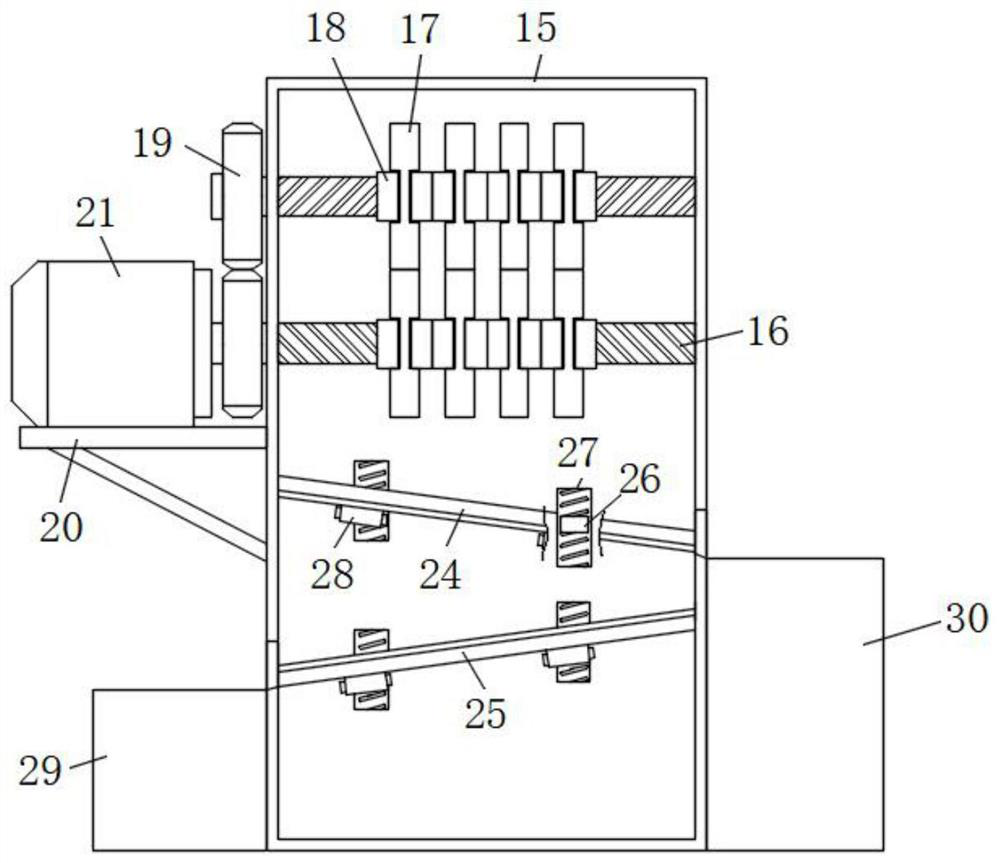

[0033] like figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, multiple crushing blades 23 are provided and evenly distributed on the output rod of the servo motor 22, and the crushing blades 23 are located in the middle of the two crushing rollers 6, and the servo The motor four 22 is fixed on the inner side wall of the screening chamber 15 by screws.

[0034] In this embodiment, a plurality of crushing blades 23 are fixedly connected to the output rod of the servo motor 22, thereby making it easier to cut the strip-shaped material after the wood waste is pressed, and greatly improving the production efficiency of wood pellets.

Embodiment 3

[0036] like figure 1 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are two crushing rollers 6 symmetrically distributed on both sides of the inner wall of the crushing chamber 4, and the crushing teeth on the two crushing rollers 6 are arranged alternately.

[0037] The inner walls on both sides of the material guide dish 10 are inclined from outside to inside.

[0038] In this embodiment, the crushing teeth on the two crushing rollers 6 are staggered, so that the crushing effect of waste wood is better, and the inner walls on both sides of the material guide plate 10 are inclined from outside to inside, so that the crushed wood chips can be automatically dropped. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com