Oil return device of compressor, compressor and air conditioner

A compressor and cavity technology, which is applied in the field of compressors, can solve the problems of compressor oil reduction, affecting compressor performance, etc., and achieve the effects of reducing loss, improving performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

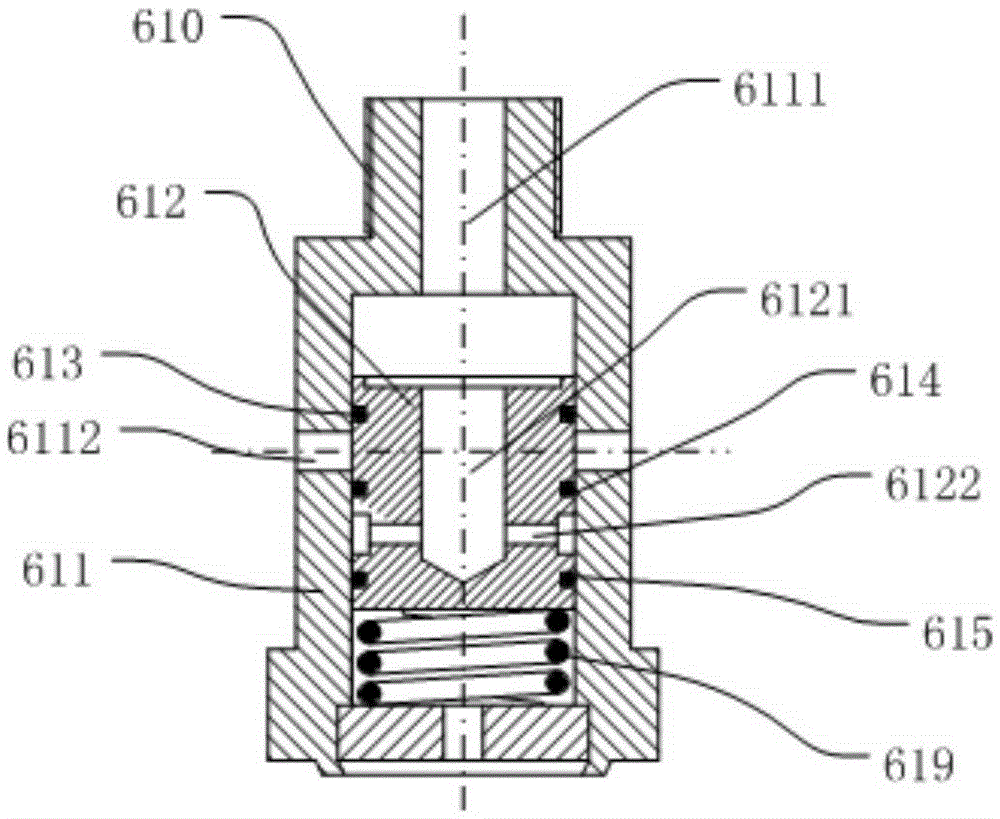

[0030] like Figure 2-3 As shown, the oil return valve 61 in this embodiment includes a valve housing 611 and a valve core 612. A cavity with an upper end opening 6111 is formed in the valve housing 611, and the valve core 612 is arranged in the cavity. And can slide up and down along the inner wall of the cavity in the cavity, so that the valve core 612 has a first position and a second position in the cavity, wherein, in the first position, the oil return valve 61 is in an open state, and in the second position, the oil return valve 61 is in a closed state. Preferably, an elastic member 619 is provided on the lower side of the valve core 612, and the elastic member 619 is preferably a coil spring. In the absence of external force, the valve core 612 acts on the elastic force of the elastic member 619 Down, it can slide from the second position to the first position.

[0031] Specifically, a valve casing oil leakage hole 6112 is opened on the side wall of the valve casing 6...

Embodiment 2

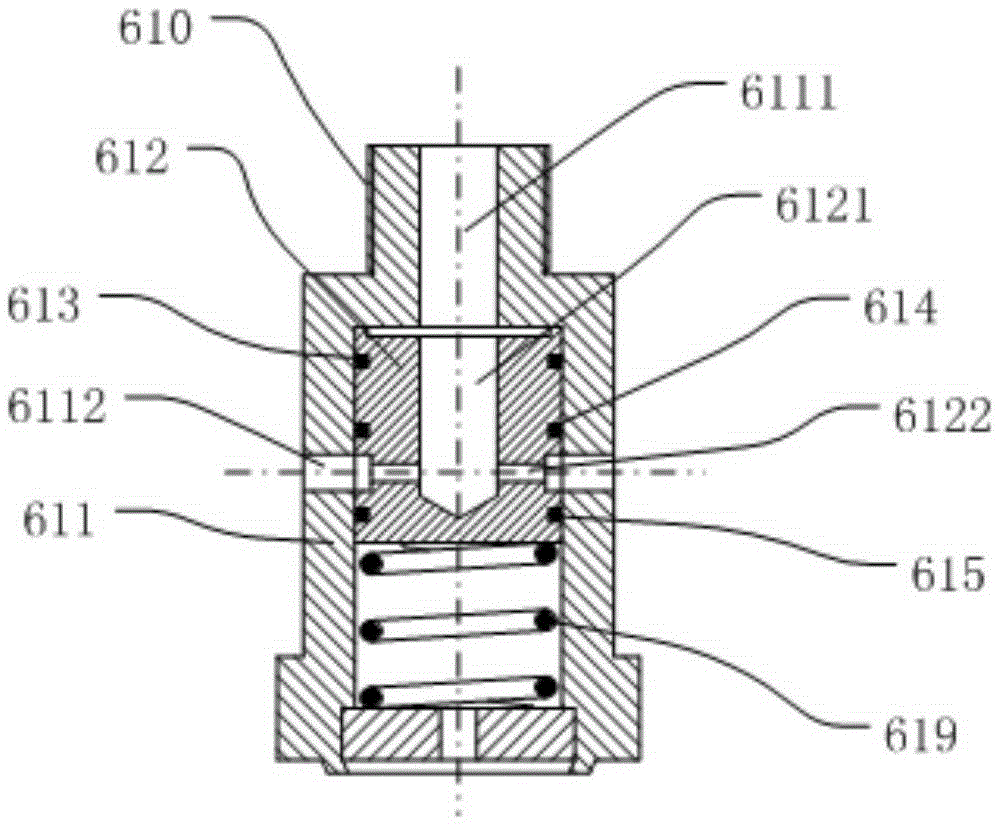

[0034] like Figure 4-5 As shown, the oil return valve 61 in this embodiment is the same as the first embodiment, and also includes a valve casing 611 and a valve core 612, and a cavity with an upper end opening 6111 is formed in the valve casing 611, and the valve core 612 is arranged in the cavity, and can slide up and down along the inner wall of the cavity in the cavity, so that the valve core 612 has a first position and a second position in the cavity, wherein, in the first In the first position, the oil return valve 61 is in an open state, and in the second position, the oil return valve 61 is in a closed state. Preferably, an elastic member 619 is provided on the lower side of the valve core 612, and the elastic member 619 is preferably a coil spring. In the absence of external force, the valve core 612 acts on the elastic force of the elastic member 619 Down, it can slide from the second position to the first position.

[0035] The difference between this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com