Patents

Literature

116results about How to "Avoid dust phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

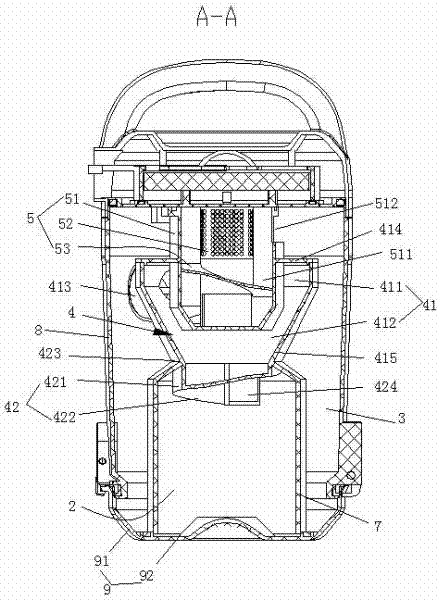

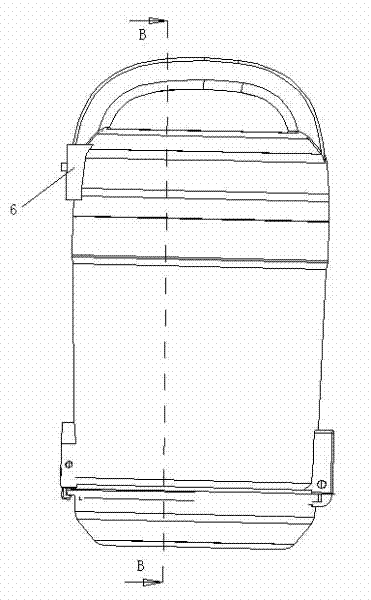

Dust cup of dust collector and dust collector

The invention discloses a dust cup of a dust collector, and the dust cup is provided with an air inlet, a primary dust collection chamber, a secondary dust collection chamber, a primary cyclone separator, a secondary cyclone separator and an air outlet, wherein the secondary dust collection chamber surrounds the primary dust collection chamber; the primary cyclone separator is provided with a primary cyclone channel; the primary cyclone channel comprises a surrounding wall and a baffle; the baffle is spirally extended to the bottom, used for receiving crush as, of the primary dust collection chamber from the bottom of the cyclone chamber so as to form the spirally-extending primary cyclone channel together with the surrounding wall; one end, serving as a crude ash inlet, of the primary cyclone channel is communicated with the primary cyclone chamber; the other end, serving as a primary ash outlet, of the primary cyclone channel is communicated with the primary dust collection chamber;the secondary cyclone separator comprises a cyclone in which a secondary cyclone channel is arranged; the inlet of the secondary cyclone channel is communicated with the primary cyclone chamber, is positioned above the crude ash inlet and is opposite to the crude ash inlet; and the outlet of the secondary cyclone channel is communicated with the air outlet and the secondary dust collection chamber. According to the invention, the crude ash in dust can be prevented from rising, and dust and ash can be excellently separated with high efficiency.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

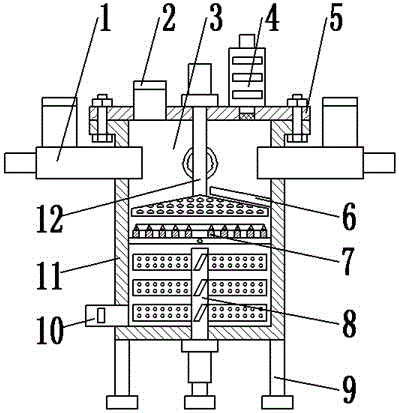

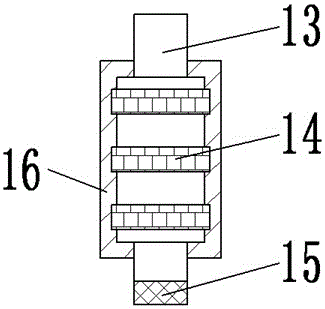

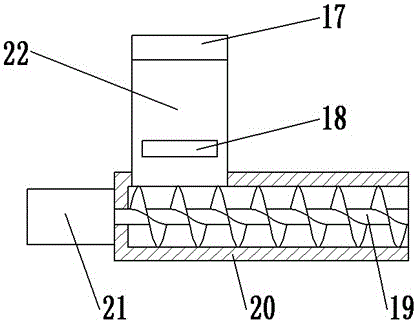

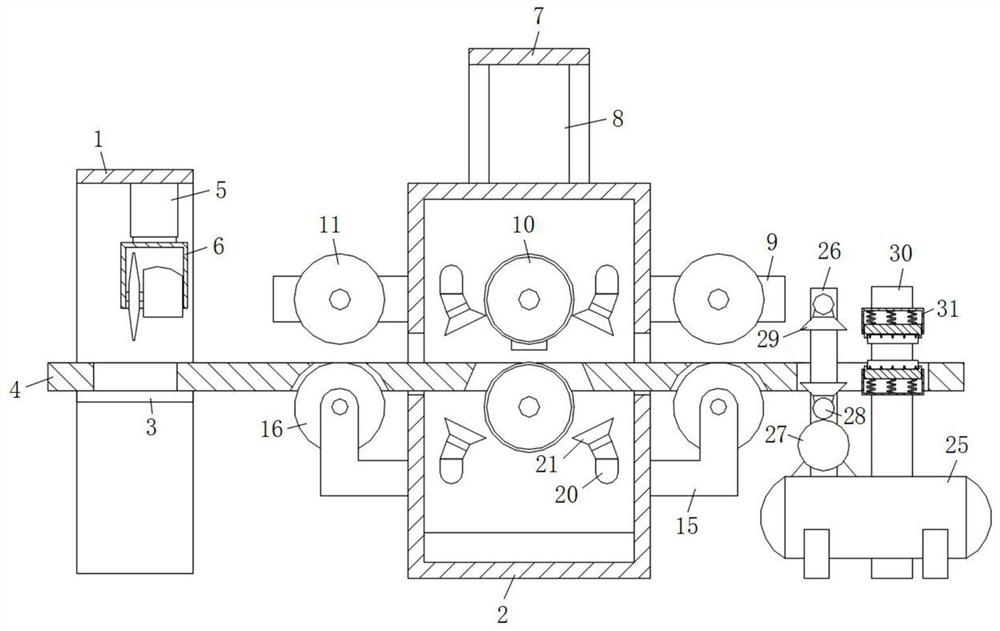

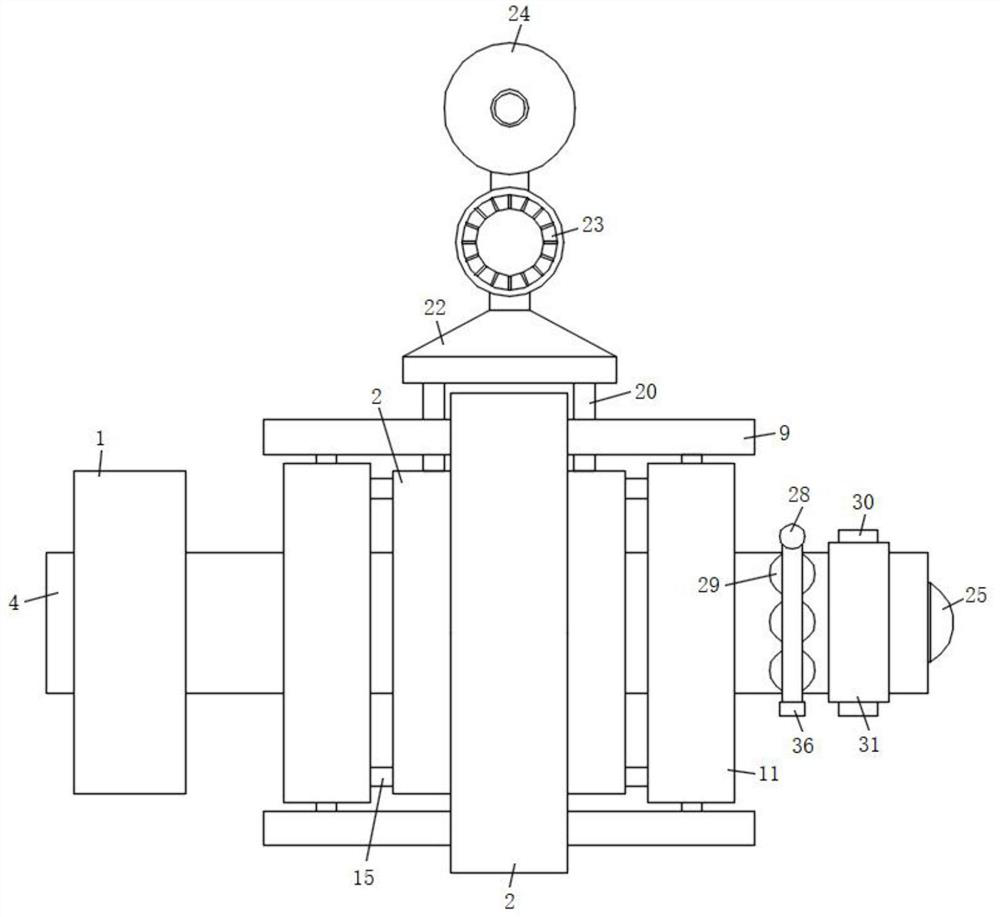

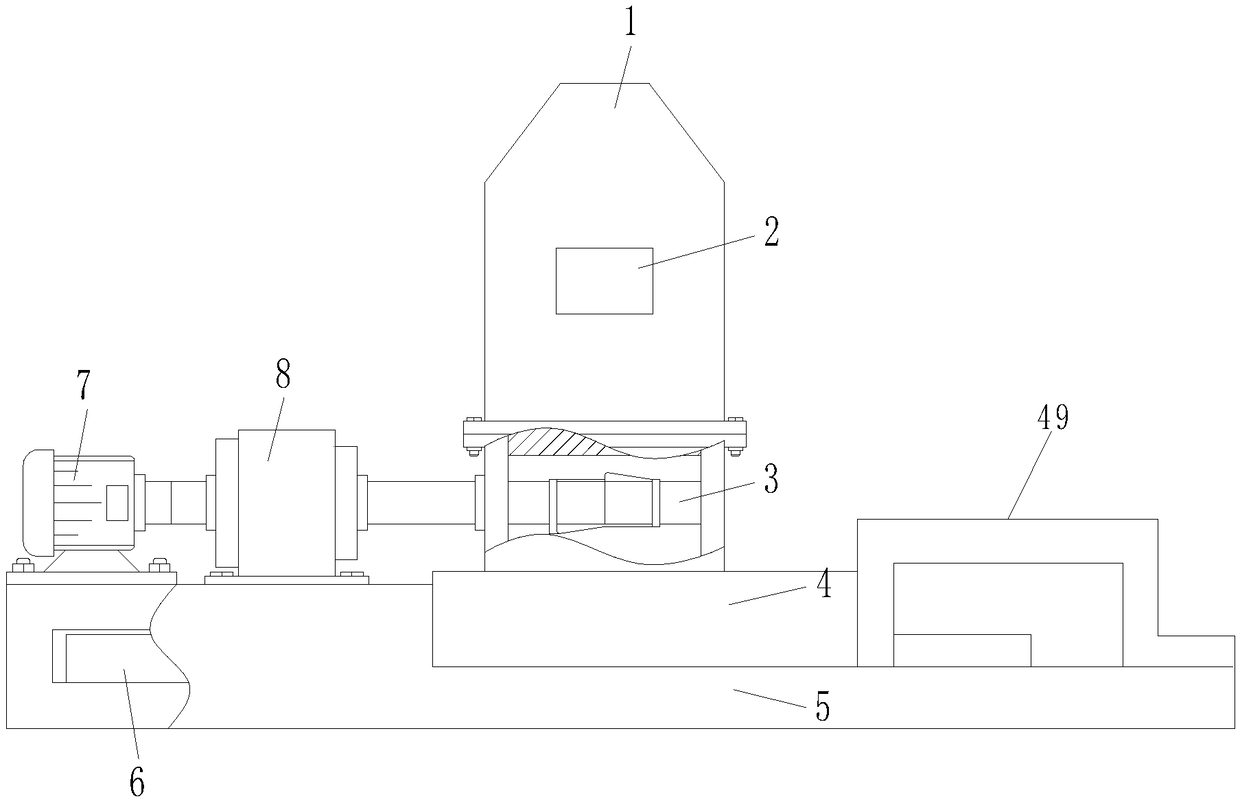

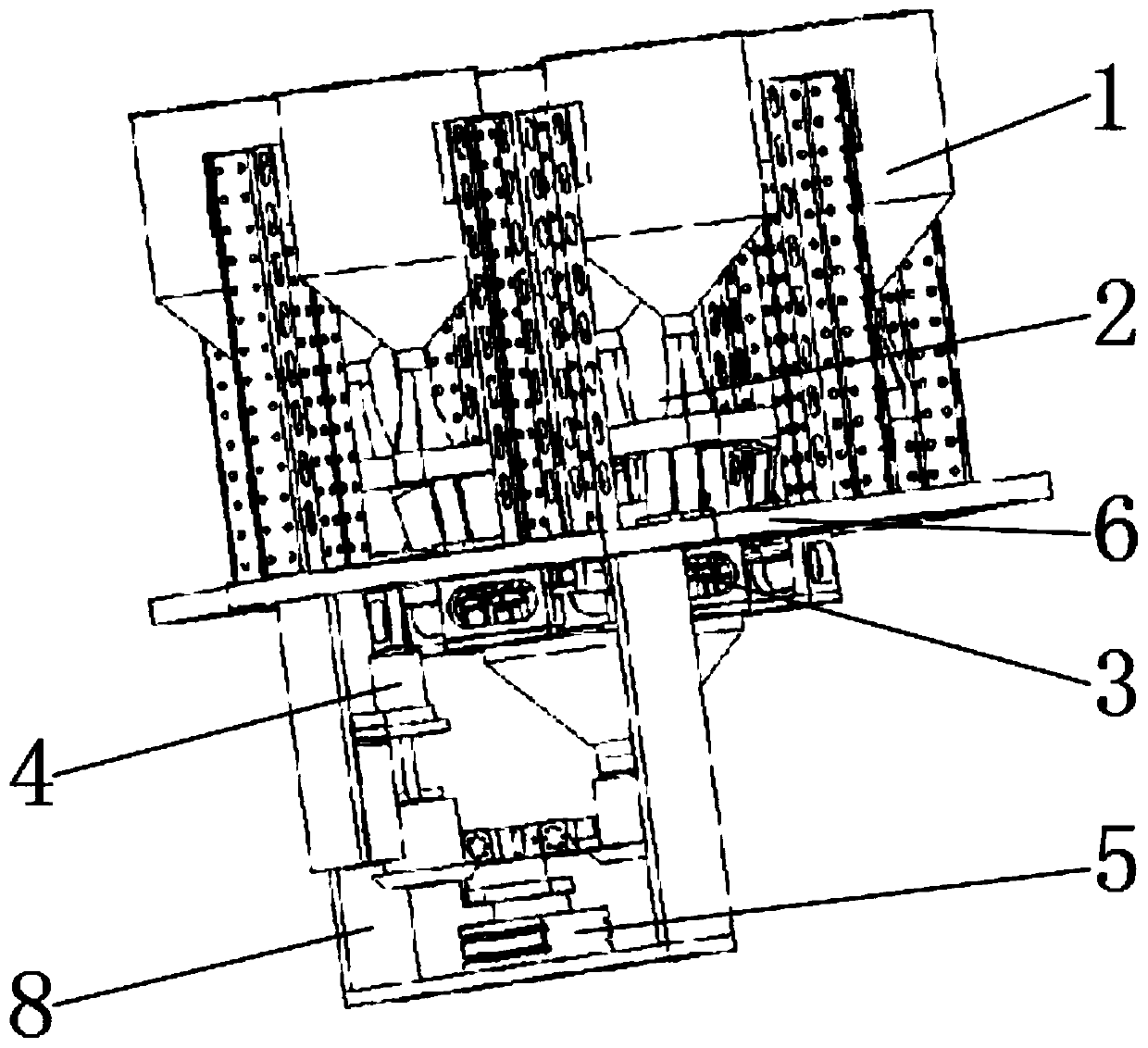

Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

InactiveCN106732040AAvoid pollutionAvoid non-conformitiesDispersed particle filtrationTransportation and packagingEngineeringScrew conveyor

The invention provides lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities. The equipment comprises a tank body and an upper cover, a mixing cavity is formed inside the tank body, an auxiliary feeding pipe and a filtering device are arranged on the upper cover, the filtering device is composed of an exhausting pipe and a filtering tank, and a feeding device is arranged on the side wall of the top of the tank body and composed of a feeding pipe, a feeding screw conveyor, a feeding motor and a material storing tank; a material guiding device, an impurity removing device and a stirring device, the material guiding device is composed of a material guiding motor, a rotating shaft and a material guiding disc, the impurity removing device is composed of multiple concentric electromagnetic rings, and the stirring device is composed of a stirring motor, a stirring shaft and stirring pieces. Raw material dust is prevented from directly causing dust pollution through the filtering device, and recycling of the raw material dust is facilitated, so that unqualified products caused by unbalanced proportion is prevented; mixing degree of raw materials is increased through the stirring device, so that the raw materials are mixed more uniformly.

Owner:SHENZHEN JUOCAN TECH CO LTD

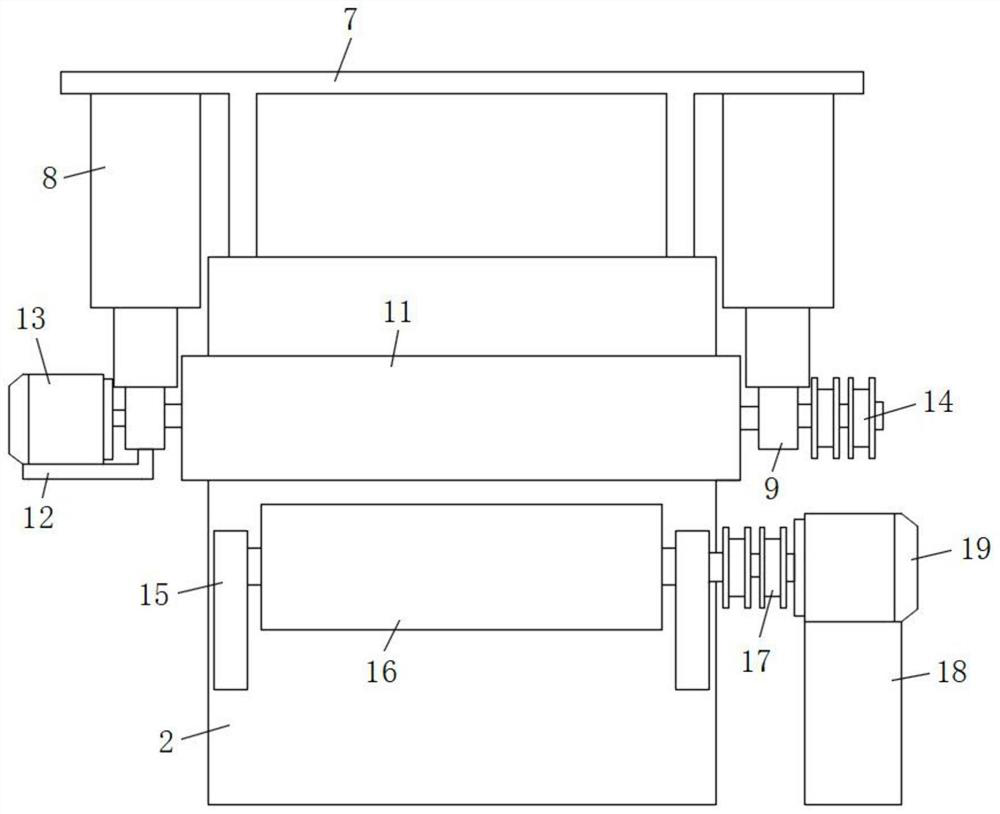

Wood board surface machining treatment device

InactiveCN112496909AContinuous processing is easy to operateAchieve double-sided grindingGrinding drivesProfiling/shaping machinesPolishingWood plank

The invention discloses a wood board surface machining treatment device which comprises a cutting frame and a polishing chamber; a supporting plate is further fixedly connected to the middle of the inner wall of the front end and the middle of the inner wall of the rear end of the cutting frame, rectangular holes are formed in the two sides of a polishing chamber in a penetrating mode, and a working plate is further fixedly connected between the bottom faces of the interiors of the rectangular holes and the top face of the supporting plate; a first air cylinder is fixedly connected to the inner top face of the cutting frame through screws, a cutting machine is fixedly connected to the output end of the first air cylinder through screws, a mounting frame is fixedly connected to the outer top face of the polishing chamber, second air cylinders are fixedly connected to the front side and the rear side of the bottom face of the mounting frame through screws, and mounting strips are fixedlyconnected to the output ends of the second air cylinders through screws; and polishing rollers are rotatably connected to the middles of the two mounting strips and the lower sides of the inner wallsof the front end and the rear end of the polishing chamber correspondingly, and first pushing rollers are further rotatably connected to the two sides of the two mounting strips. The wood board surface machining treatment device is reasonable in design and stable, continuous machining operation of wood boards is easy and convenient, double-face polishing and waxing operation of the wood boards can be achieved at the same time, and the working efficiency of wood board machining is greatly improved.

Owner:怀宁县三兴木业有限公司

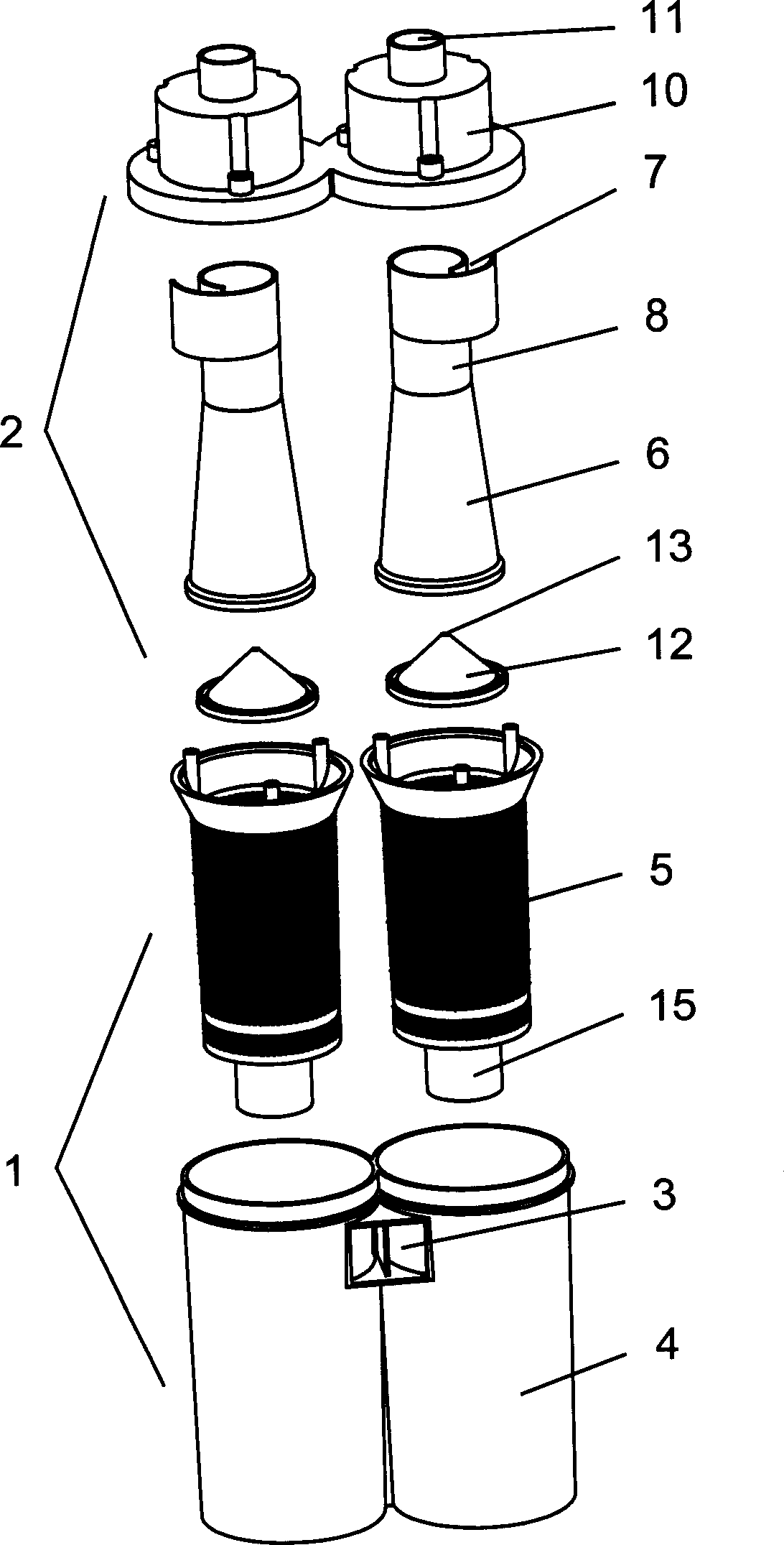

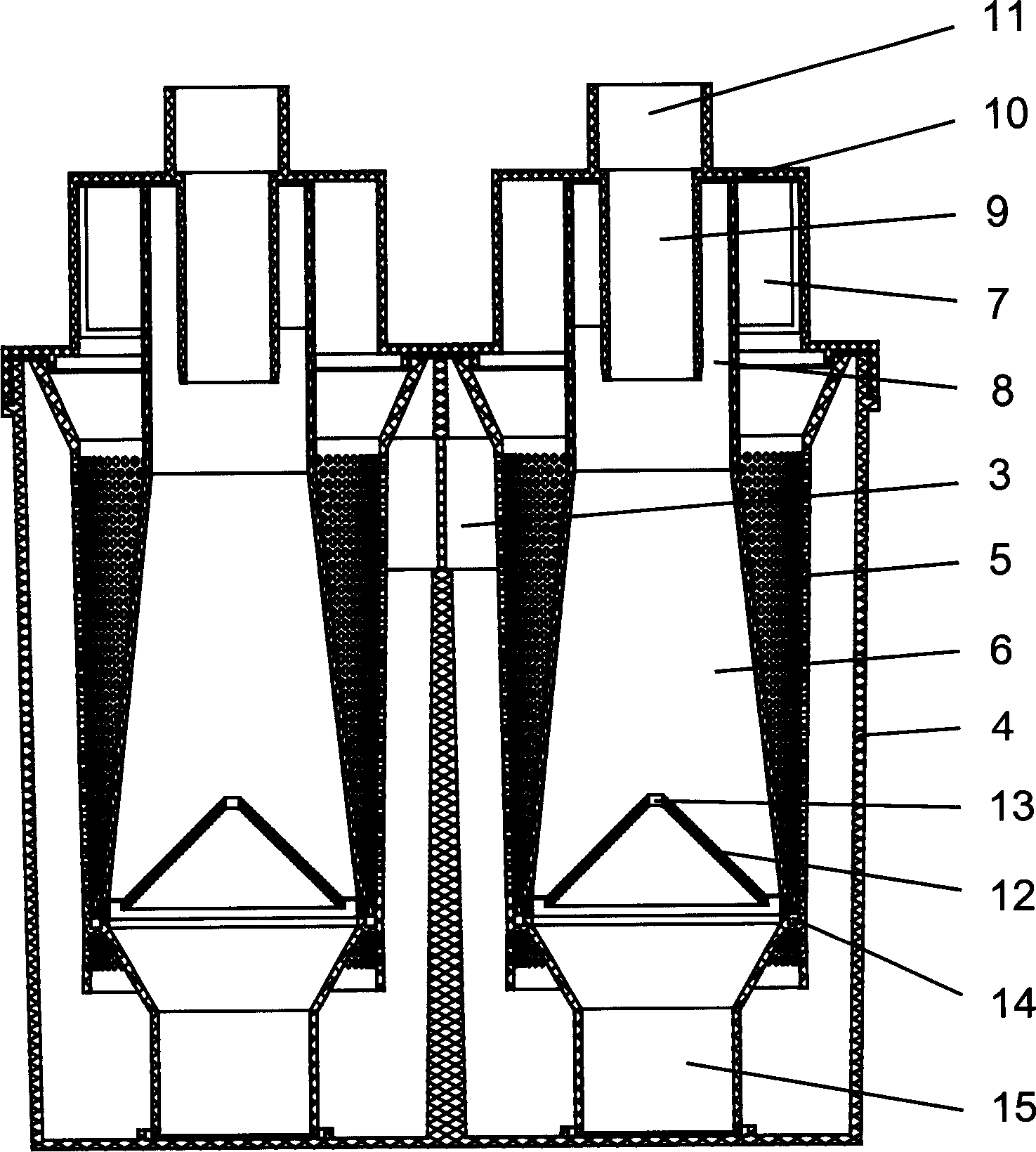

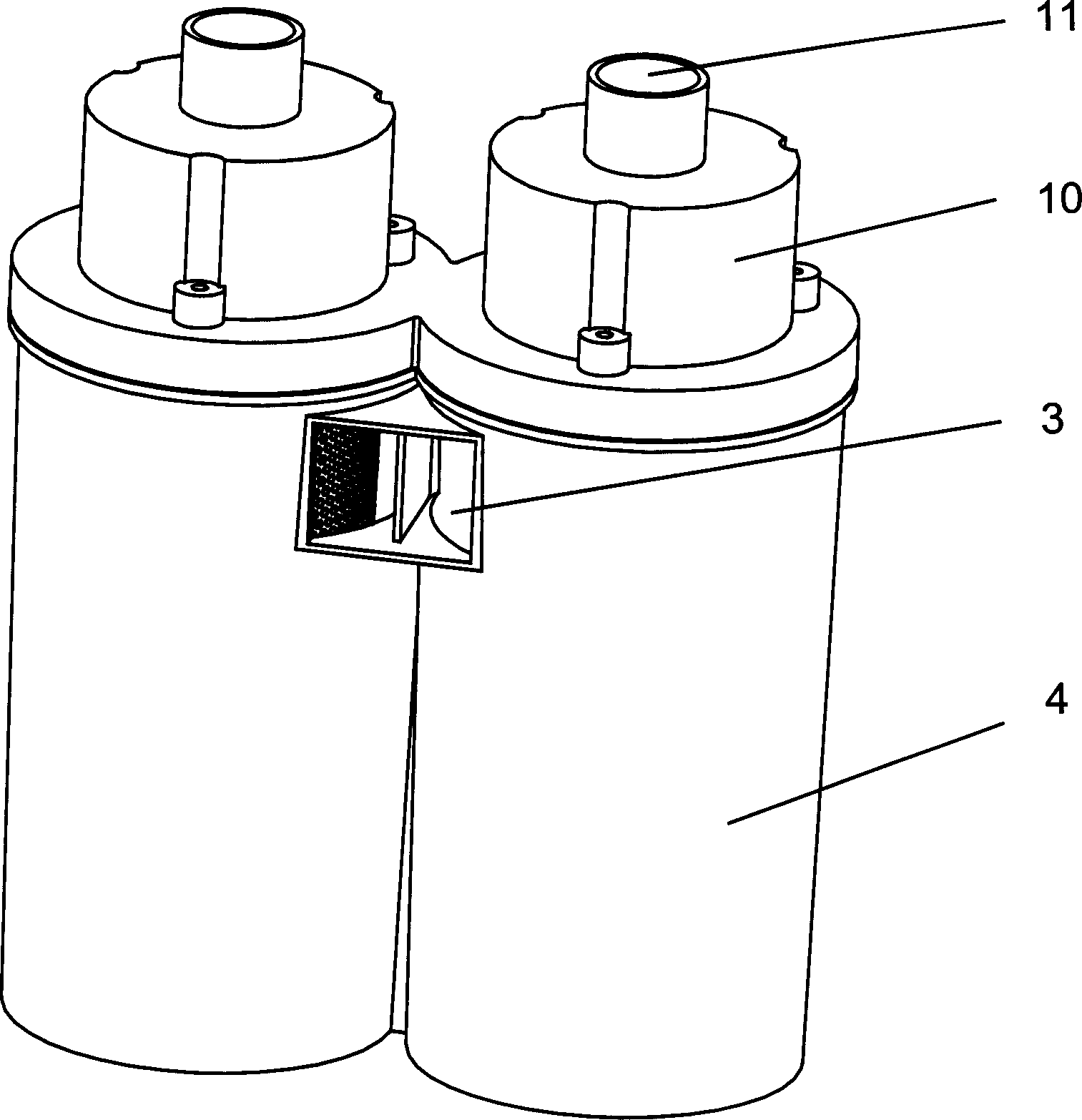

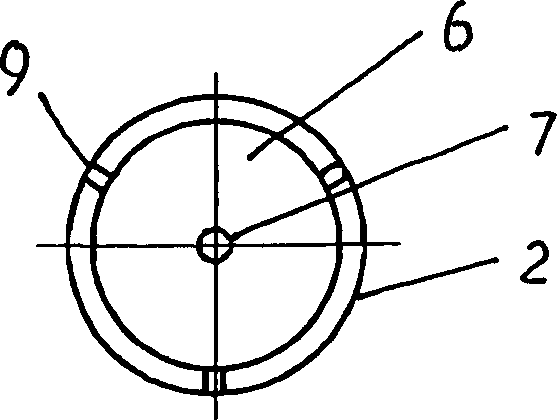

Parallel type dust removing device of vacuum cleaner

ActiveCN1748630AReduce volumeIncrease air volumeSuction filtersReversed direction vortexAir volumeCentrifugation

The vacuum cleaner with parallel dust removing devices includes at least two parallel arranged upstream cyclonic separators, each of which has one downstream separator. The present invention has increased ventilation amount, reduced volume and high dusting efficiency. The downstream cyclonic separators are in diffusion structure and have airflow inside the barrels in rotating and reducing centrifugation state, and have less airflow pressure loss, high dusting effect, no dust flying and no secondary pollution.

Owner:KINGCLEAN ELECTRIC

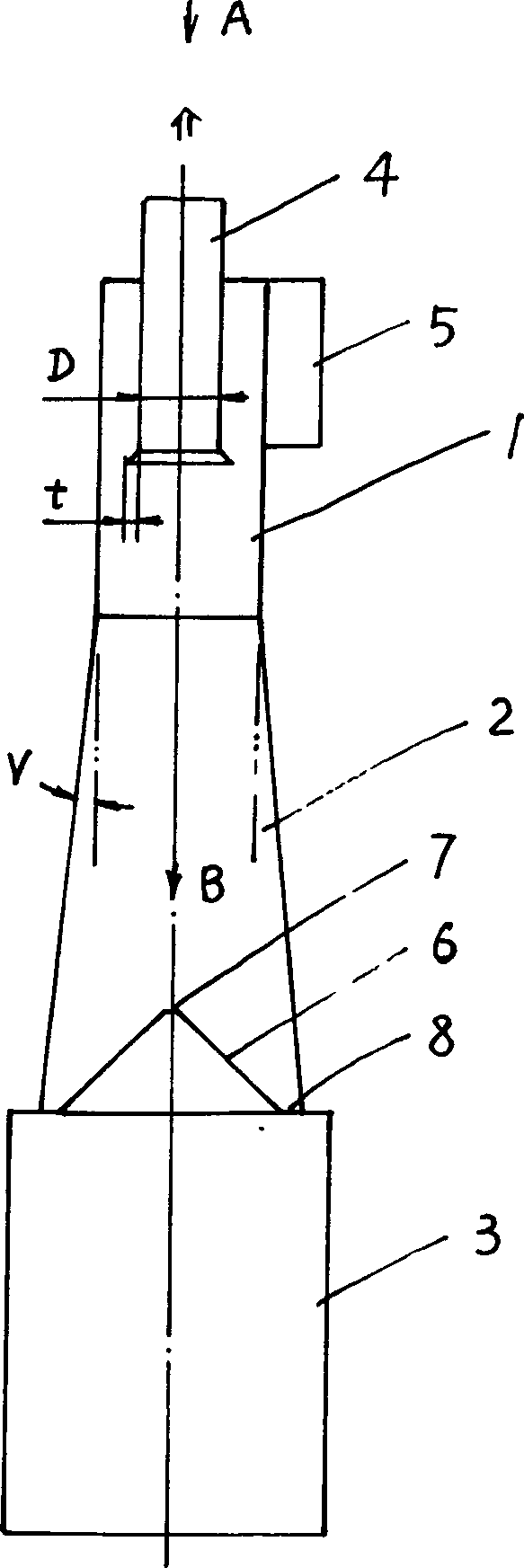

Speed reducing centrifugal duster for cleaner

InactiveCN1377627AVacuuming effect is not affectedSmall airflow pressure lossSuction filtersReversed direction vortexFilter systemEngineering

The speed reducing centrifugal dusting unit of cleaner includes circular cylinder with wind outlet pipe and wind inlet pipe, conic cylinder with small upper part and large lower part, and dust collecting box connected successively from top to bottom. The conic cylinder has mushroom reflecting disc below the wind outlet pipe, and there is reflux hole in the center and ring dust-falling interval between the edge of the disc and the side wall. The unit has small pressure loss, high dust collecting effect, high dust filtering precision, low working noise and no secondary pollution; and is especially suitable for use as secondary filtering system in cleaner to separate fine dust.

Owner:KINGCLEAN ELECTRIC

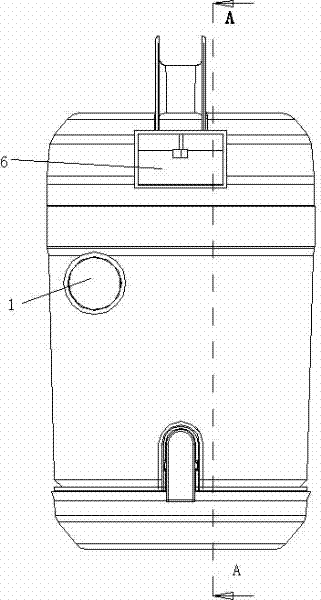

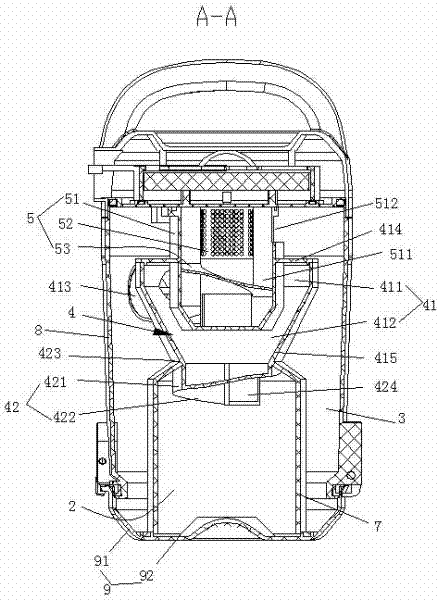

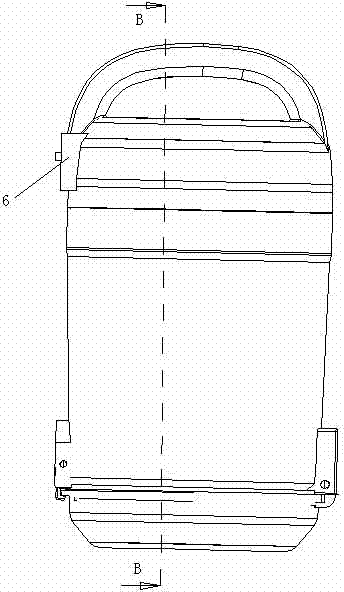

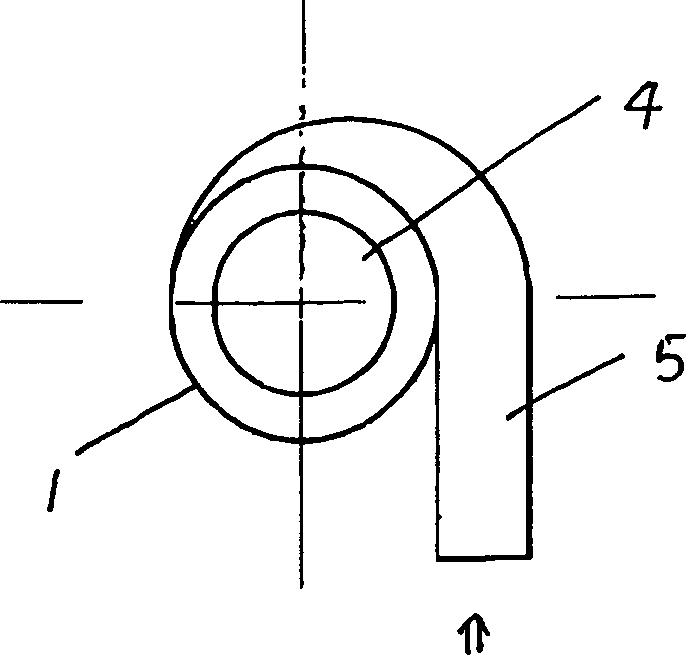

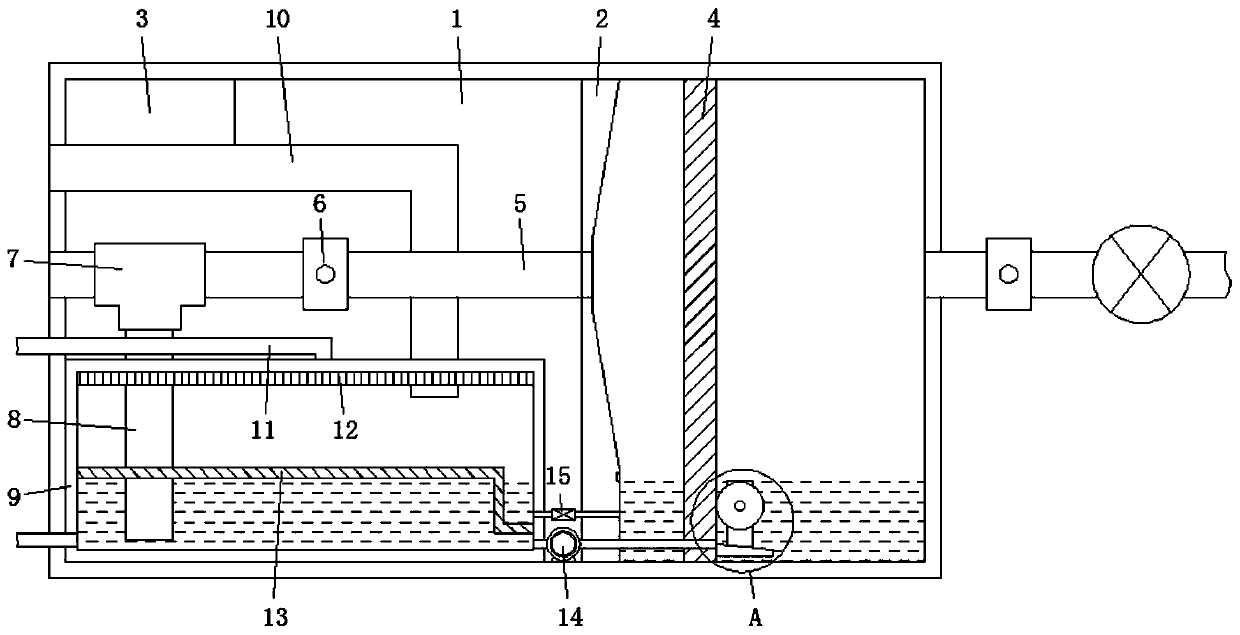

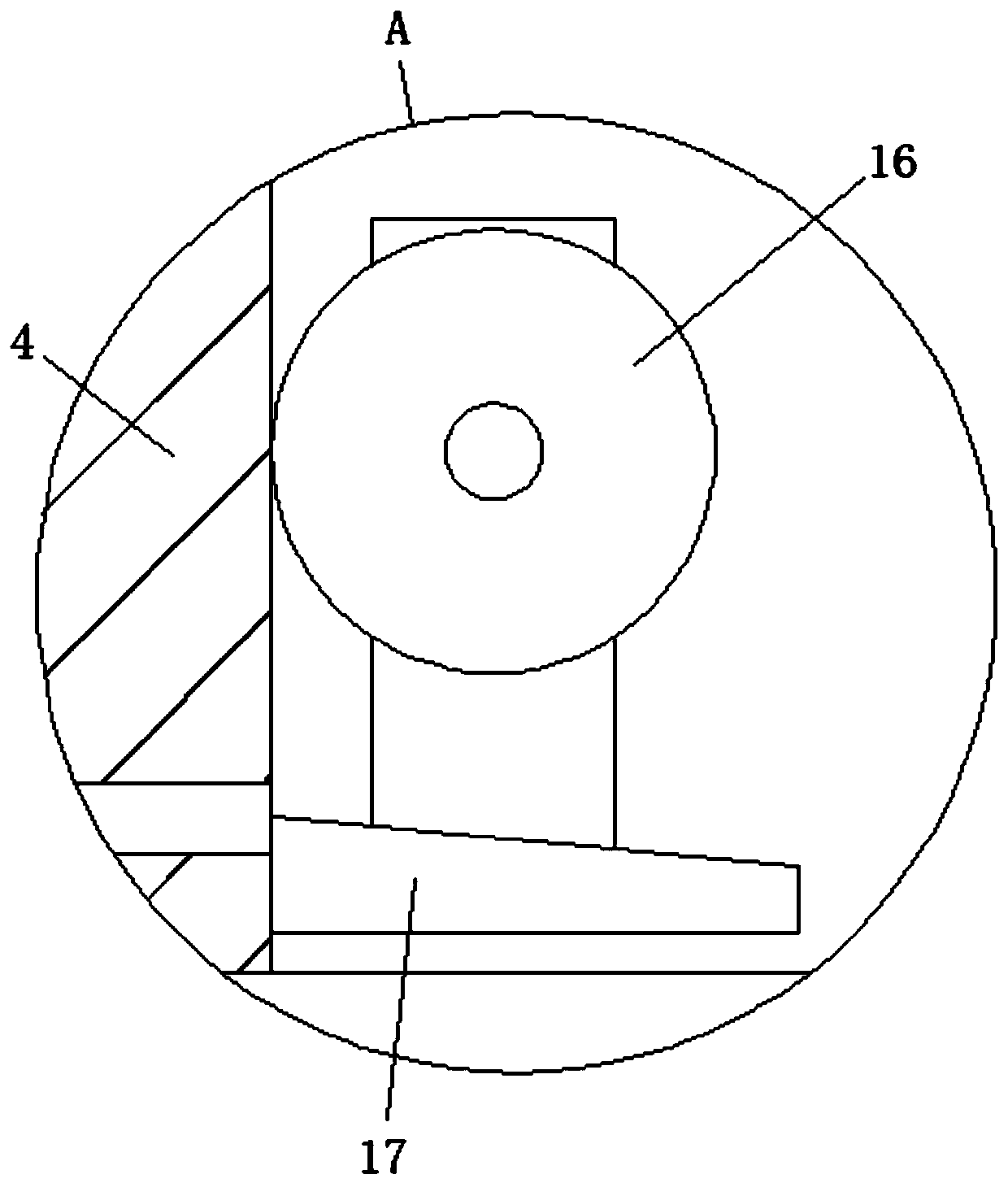

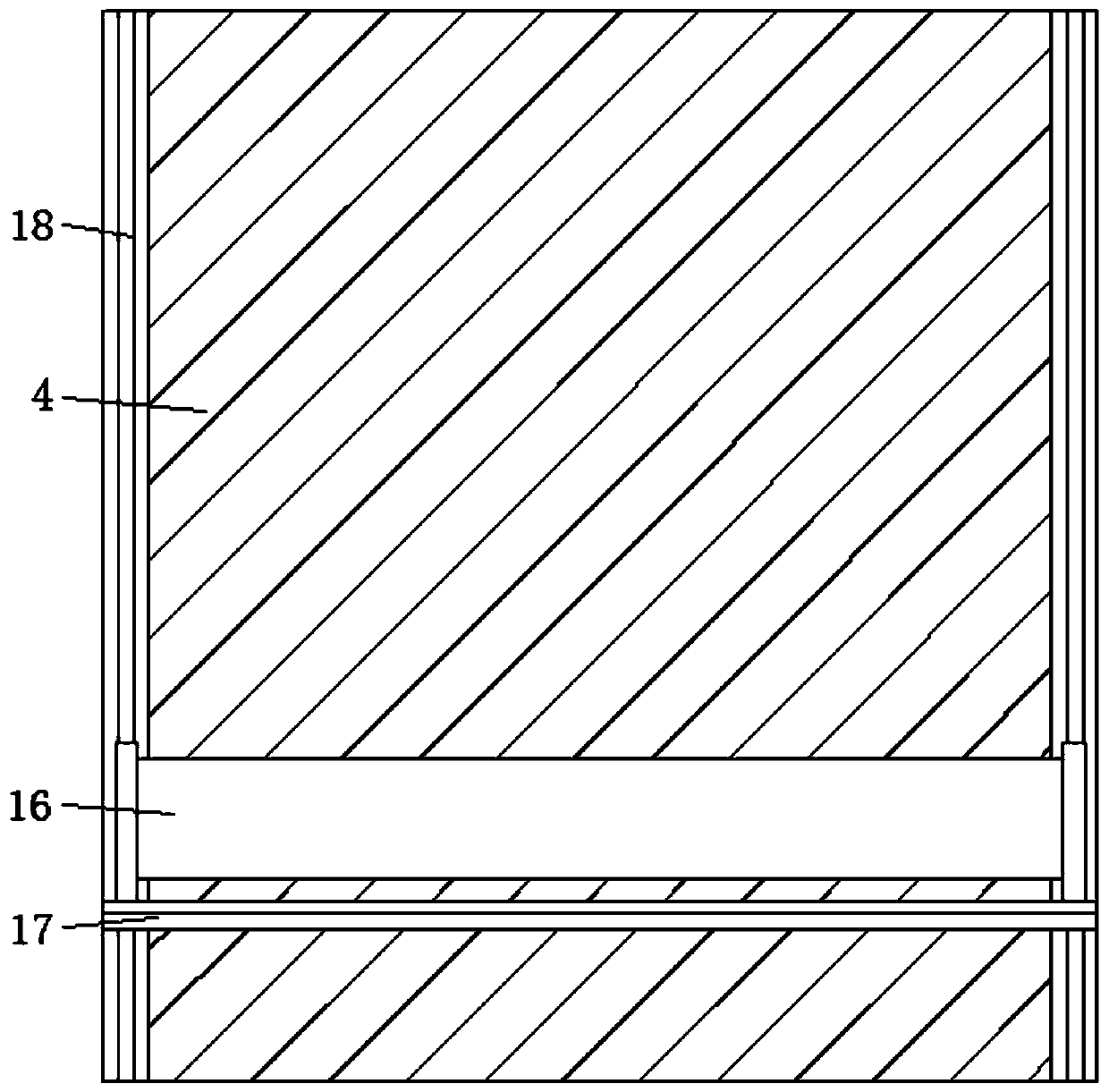

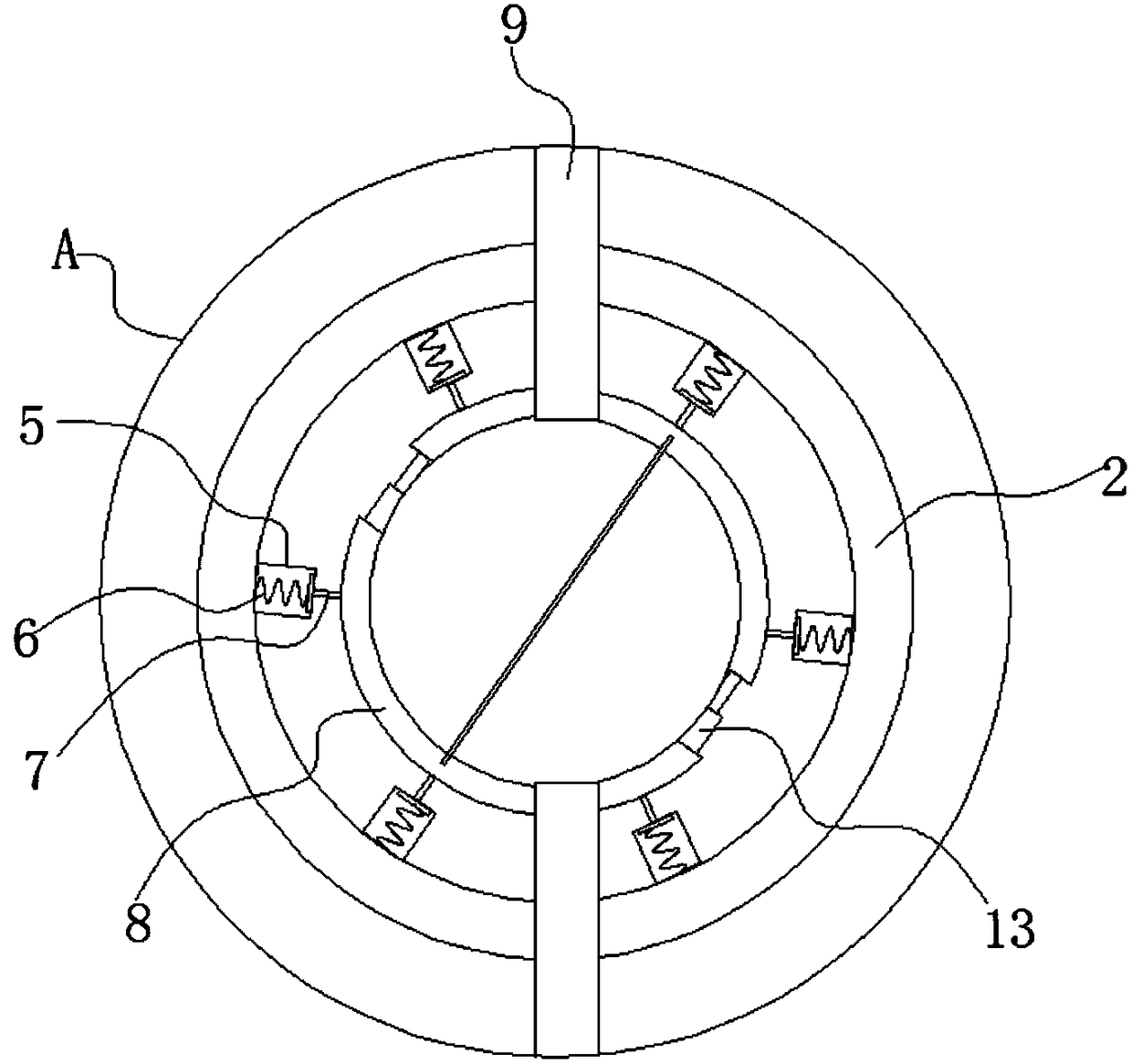

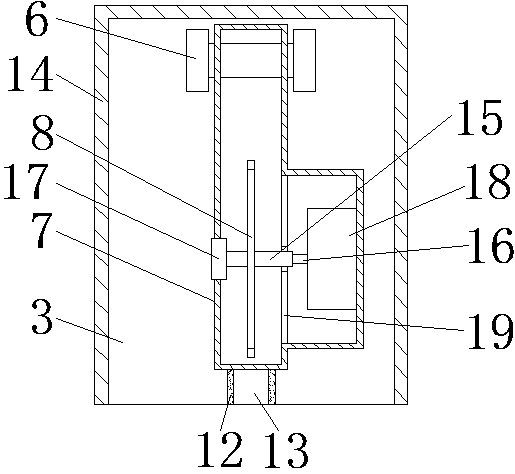

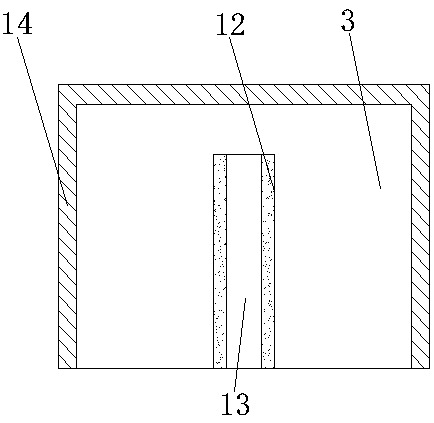

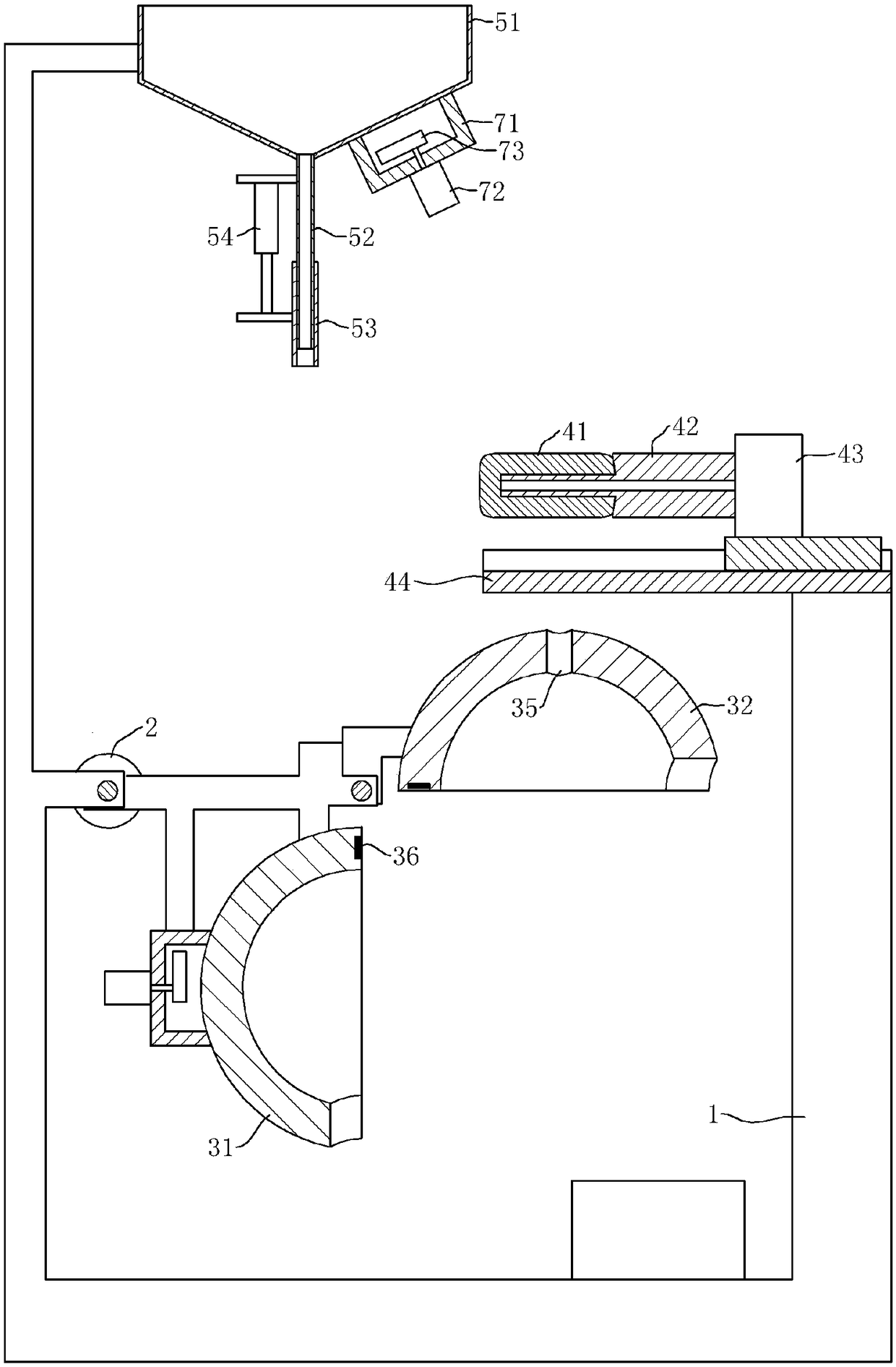

Dust cup device of dust collector and dust collector

InactiveCN102334955AAvoid dust phenomenonEasy to separateSuction filtersDust collectorWaste management

The invention discloses a dust cup device of a dust collector. The dust cup device is provided with an air inlet, a primary dust collecting chamber, a secondary dust collecting chamber, a primary cyclone separator, a secondary cyclone separator and an air outlet. The secondary dust collecting chamber surrounds the primary dust collecting chamber. The primary cyclone separator comprises a primary cyclone chamber and a primary cyclone passage. The primary cyclone passage comprises a surrounding wall and a partition plate, and the partition plate is extended from the bottom of the cyclone chamber to the crude dust receiving bottom of the primary dust collecting chamber, is spiral and forms the primary cyclone passage together with the surrounding wall. The secondary cyclone separator comprises a cyclone, a mesh filter and a flow deflector. The flow deflector is spirally extended from the bottom of the cyclone to the top of the cyclone, is positioned between the inner wall of the cyclone and the outer wall of the mesh filter and forms a spiral secondary cyclone passage together with the inner wall of the cyclone and the outer wall of the mesh filter. Because the dust cup device is provided with the primary spiral cyclone passage and the secondary spiral cyclone passage, the speed of the dust can be fully reduced, and the separation effect is good.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

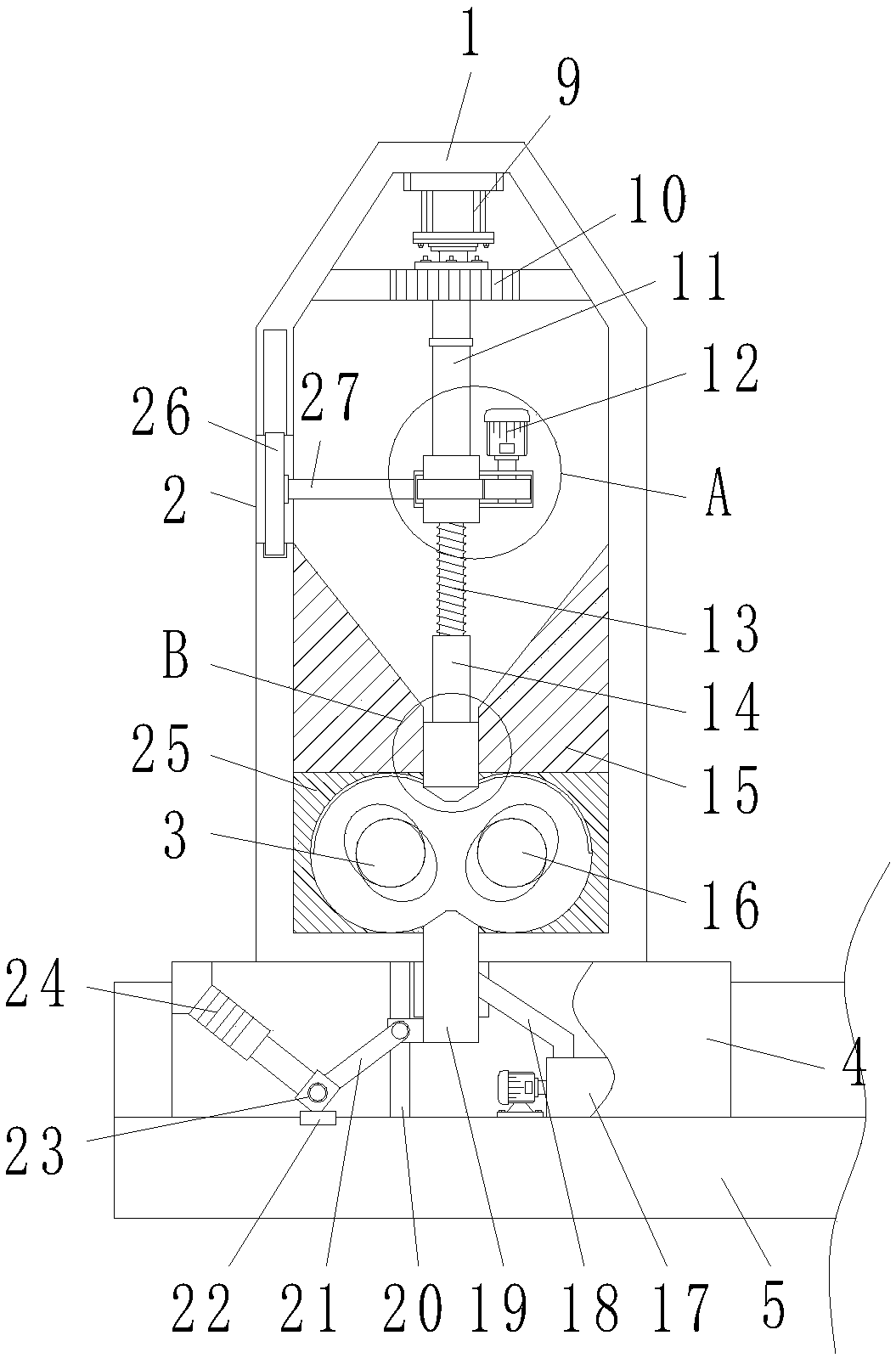

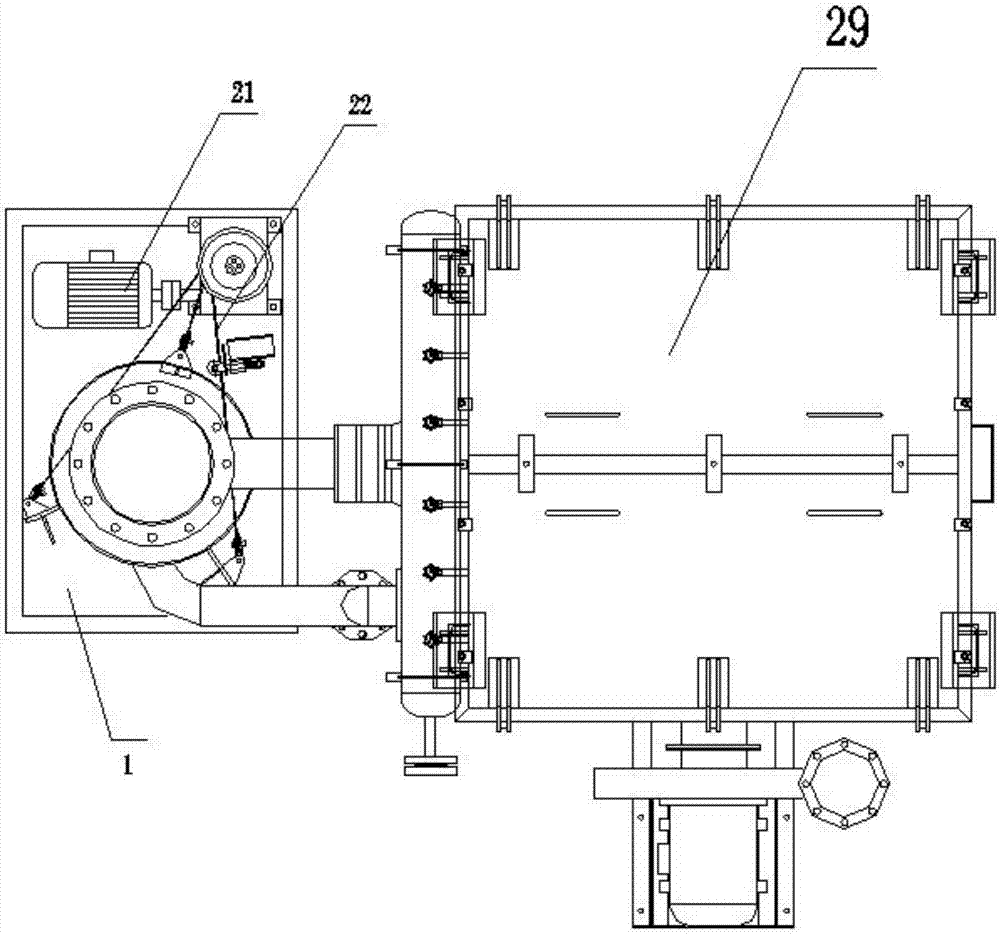

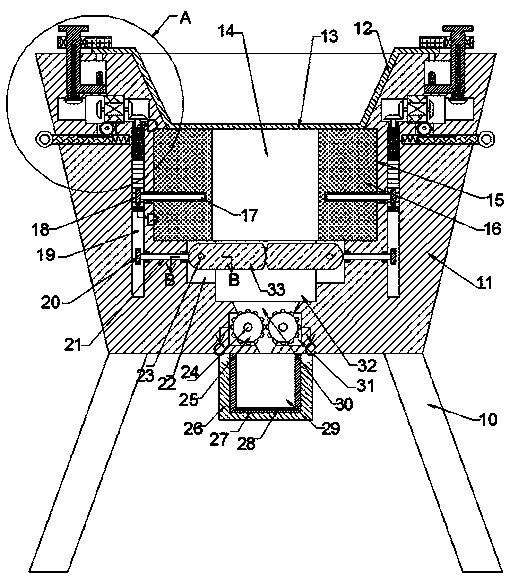

Internal mixer with dust-sucking and cooling device

ActiveCN108995068AAvoid burnsAvoid crushing the rubberUsing liquid separation agentDirt cleaningMotor driveGear drive

The invention discloses an internal mixer with a dust-sucking and cooling device. The internal mixer comprises an internal mixer body; a feeding port is formed in the outer wall of one side of the internal mixer body; a feeding hopper and a mixing chamber are arranged in the internal mixer body; the feeding hopper is positioned above the mixing chamber; an upper top bolt is arranged in the middleposition of the feeding hopper; the internal mixer is provided with a second motor, a screw rod, a second guide rod, a fixed base, a driving gear, a driven gear, a screw rod sleeve, a water pump, a dust-sucking pipeline, a centripetal annular spray head and a side wall; during unloading, a PLC controller controls a first motor to start to work, the first motor drives the driving gear through a rotating shaft to rotate, the driving gear is engaged with the driven gear, the driven gear drives the screw rod sleeve to rotate, and the screw rod sleeve is screwed with the screw rod when rotating, sothat the aim of ascending the screw rod is fulfilled, and the second guide rod drives the upper top bolt to move upwards when the screw rod ascends until one end of the second guide rod is contactedwith the screw rod sleeve; the upper top bolt is started in the unloading process, so that the discharging pressure of a lower top bolt can be reduced; in addition, when an adhesive material is cooled, dust is removed and the removed dust is fused into water for cooling, so that the processes are reduced and environmental friendliness is achieved.

Owner:沧州启航橡胶制品有限公司

Pebble coal sealing discharge device

InactiveCN102284341APrevent spontaneous combustionTimely dumpingGrain treatmentsSpontaneous combustionSlag

The invention discloses a pebble coal discharge mechanism of a coal mill, in particular a pebble coal sealing discharge device. It includes a pebble coal drop port and a sealing box, the pebble coal drop port and the seal box are connected together through a conveying pipeline, a primary shut-off valve and a secondary shut-off valve are set on the pipeline, and a storage and transportation bin is set at the lower end of the sealing device, and the storage and transportation small The lower end of the warehouse is equipped with a weighing device, and the outlet of the lower end of the sealed box is connected with a telescopic joint. The sealed box is also provided with a cylinder to control the telescopic movement of the telescopic joint. The edge of the material inlet is in sealing contact. After adopting the above-mentioned structure, the entire slag discharge process can be carried out under completely closed conditions to avoid dust and powder spraying; using a sealed slag discharge device plus negative pressure and water spraying treatment can further eliminate dust and coal gangue spontaneous combustion Occurrence; At the same time, load-bearing sensors are installed to completely avoid the accumulation of pebbles and coal. Dumping by special forklifts does not require manual handling and reduces labor output.

Owner:WEIYU POWER EQUIP YANGZHONG CITY

Intelligent electrical automatic dust removal device

ActiveCN111001253AAffect the dust removal effect of pretreatmentImprove the effect of secondary dust removalCombination devicesDust controlEnvironmental engineering

The invention belongs to the technical field of dust removal devices, and discloses an intelligent electric automatic dust removal device, which comprises a control device, a device shell and an air inlet assembly connected to the air inlet end of the device shell, wherein a partition plate is arranged in the device shell, and divides the interior of the device shell into two treatment cavities, the control device is installed in any one treatment cavity, a first filtering screen is mounted in one treatment cavity, a first air outlet pipe is mounted in the other treatment cavity, a water tankis mounted below the first air outlet pipe, and the first air outlet pipe and the air inlet assembly are each provided with a detection device. Based on the arrangement of the detection device, the air inlet dust content and the air outlet dust content of the dust removal device are effectively detected, it is judged that the first filtering screen is damaged if the air outlet dust content is higher than a preset value, and at the moment, the air outlet direction of the dust removal device is adjusted to enter the water tank so as to carry out secondary dust removal, so that the pretreatment dust removal effect of the dust removal device is guaranteed.

Owner:茂名市茂南奥邦涂料有限公司

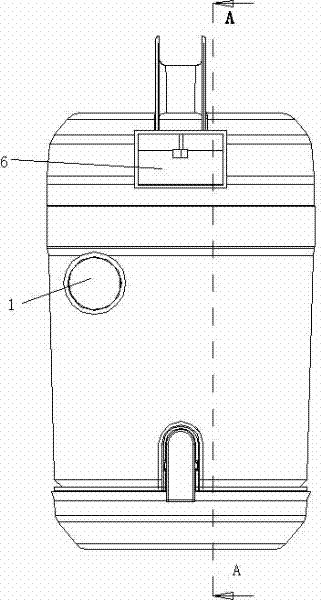

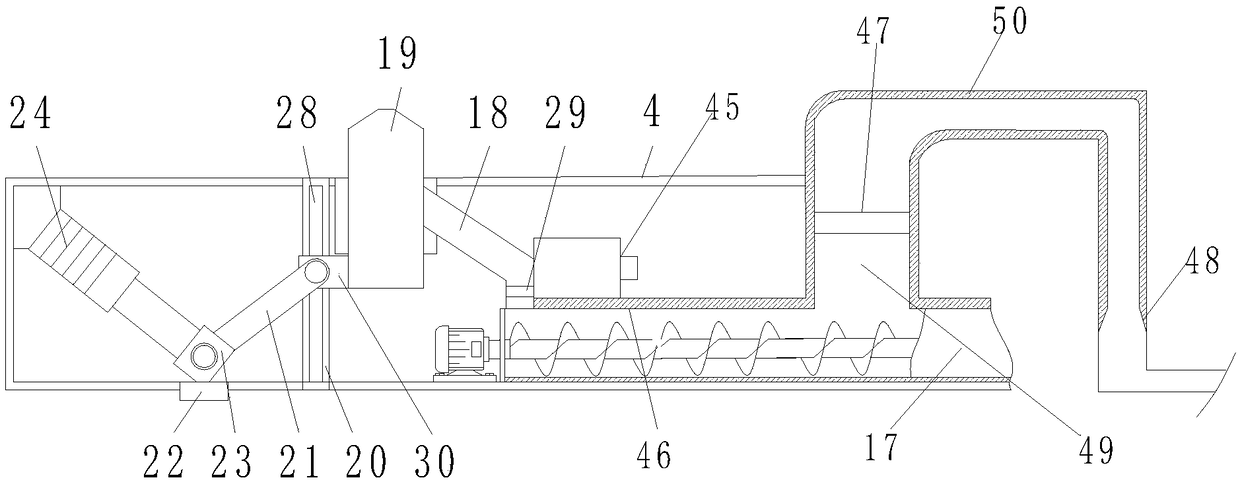

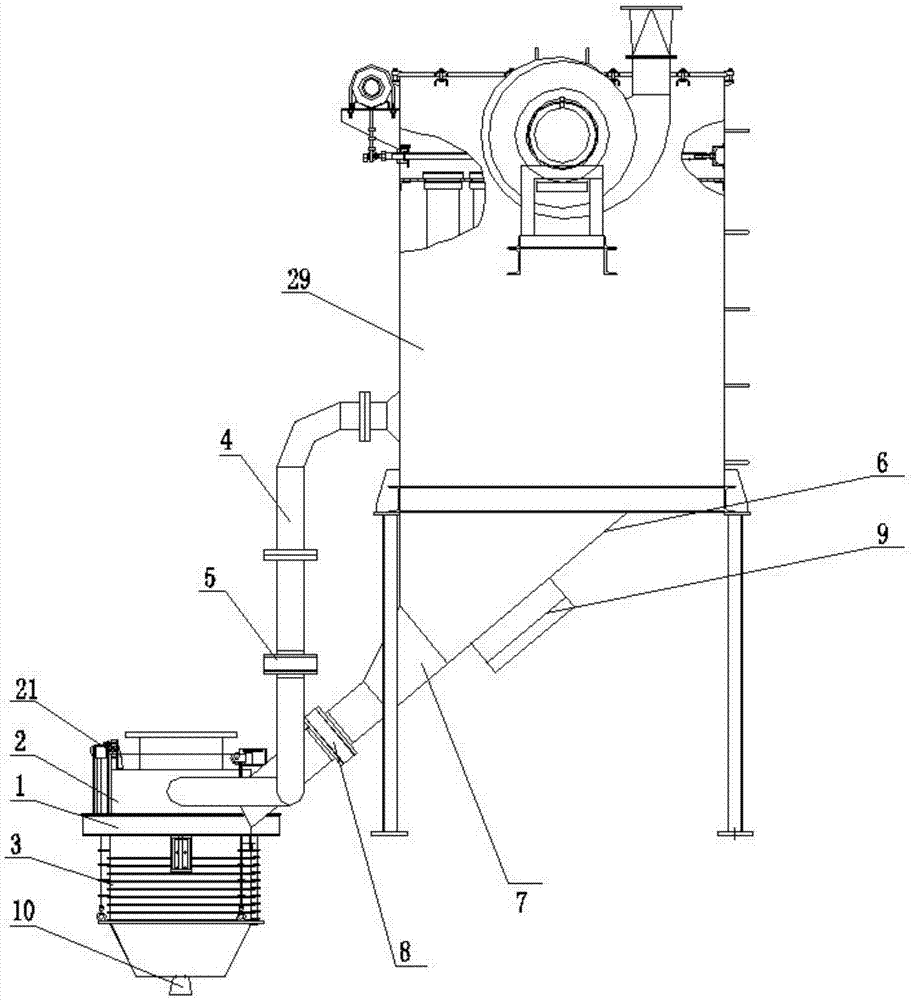

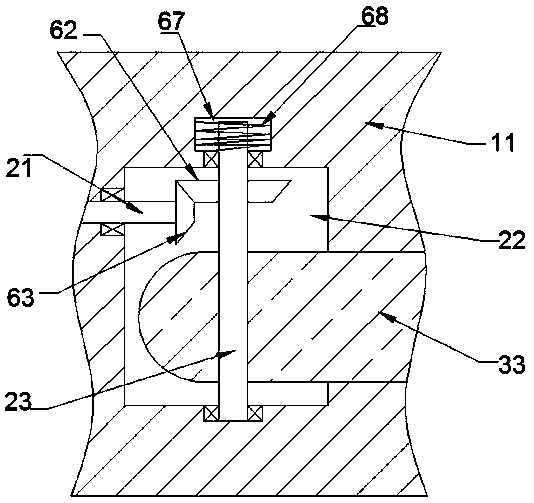

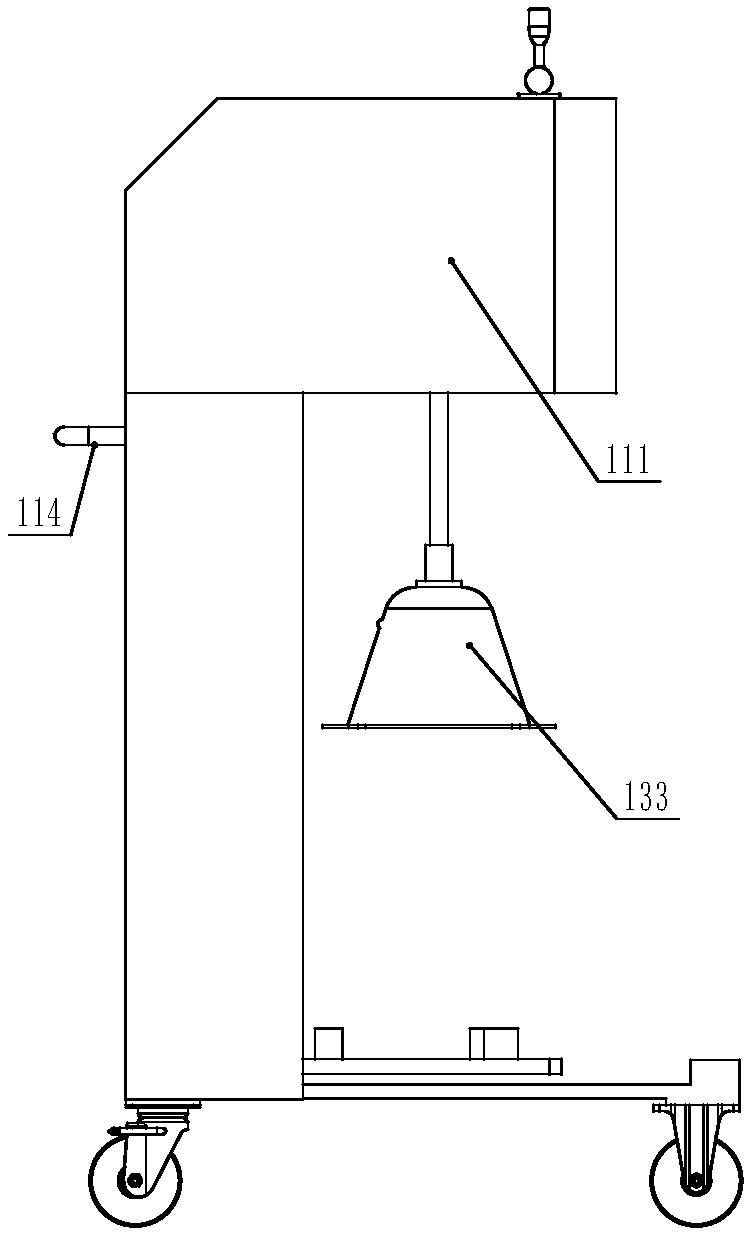

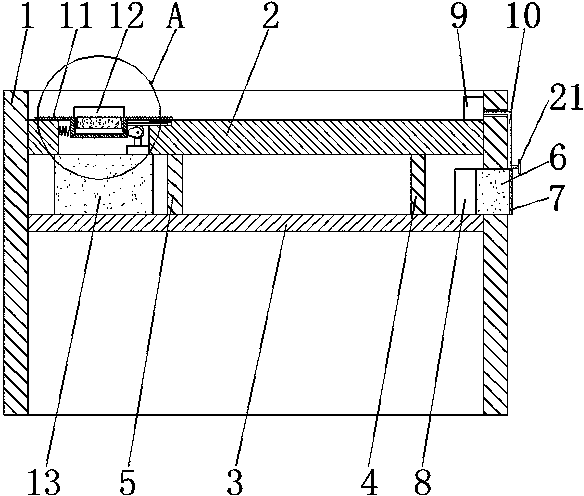

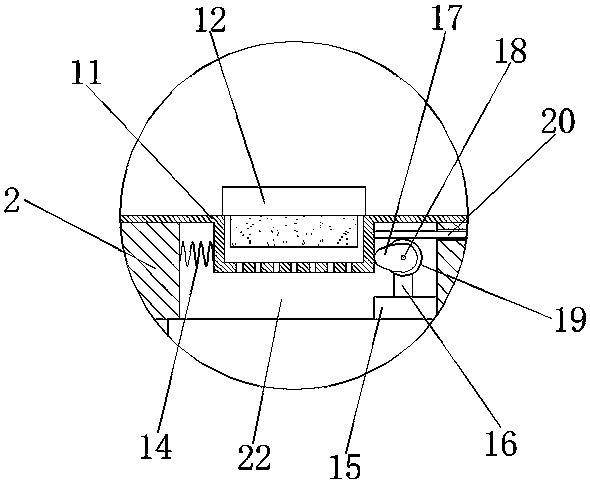

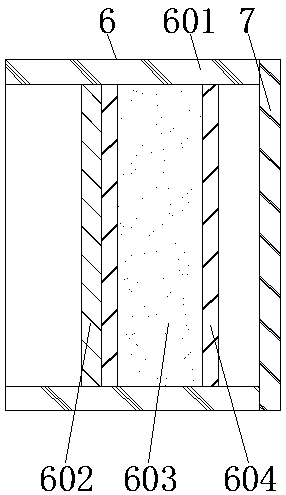

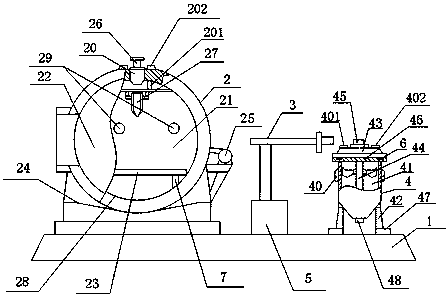

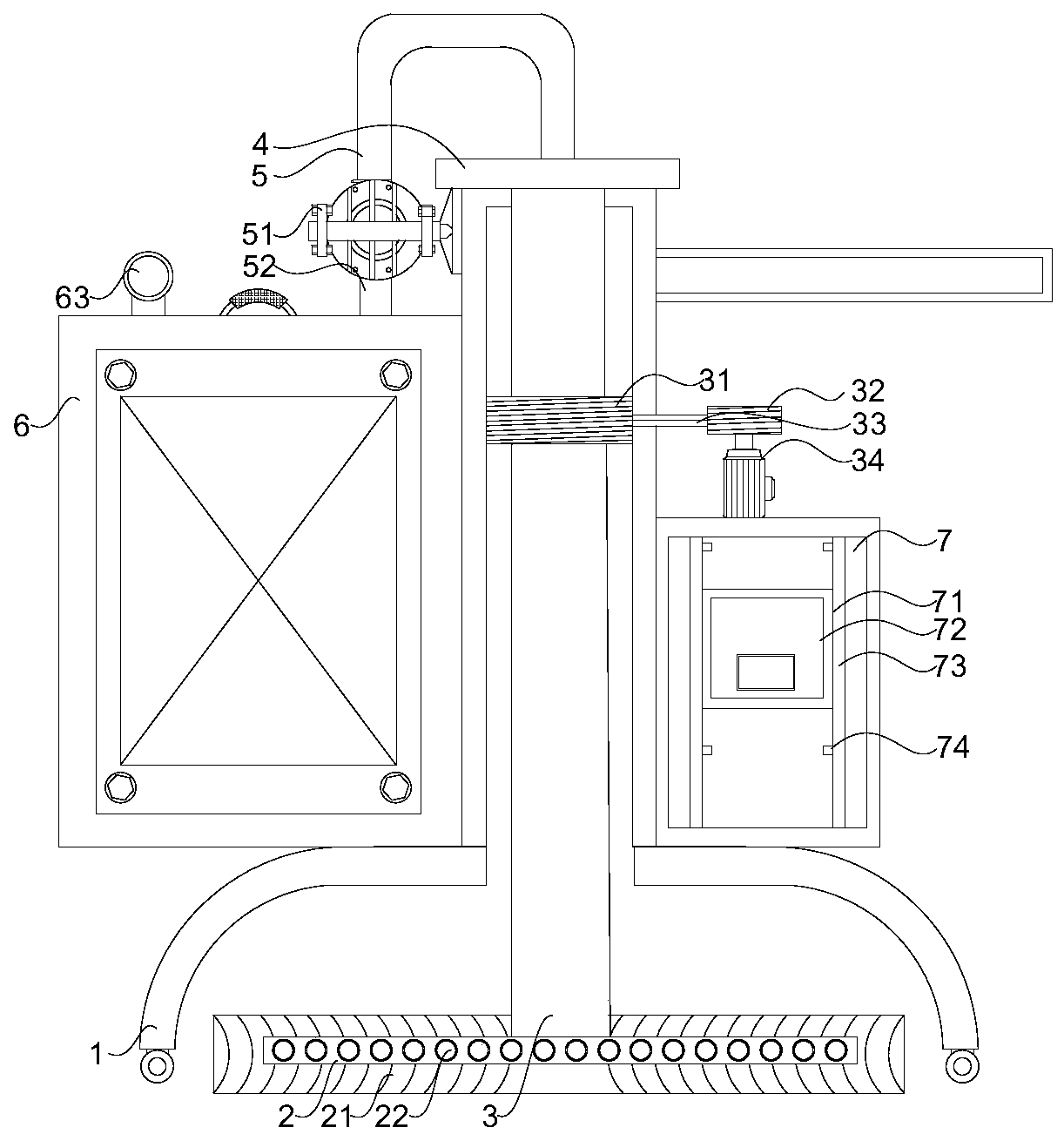

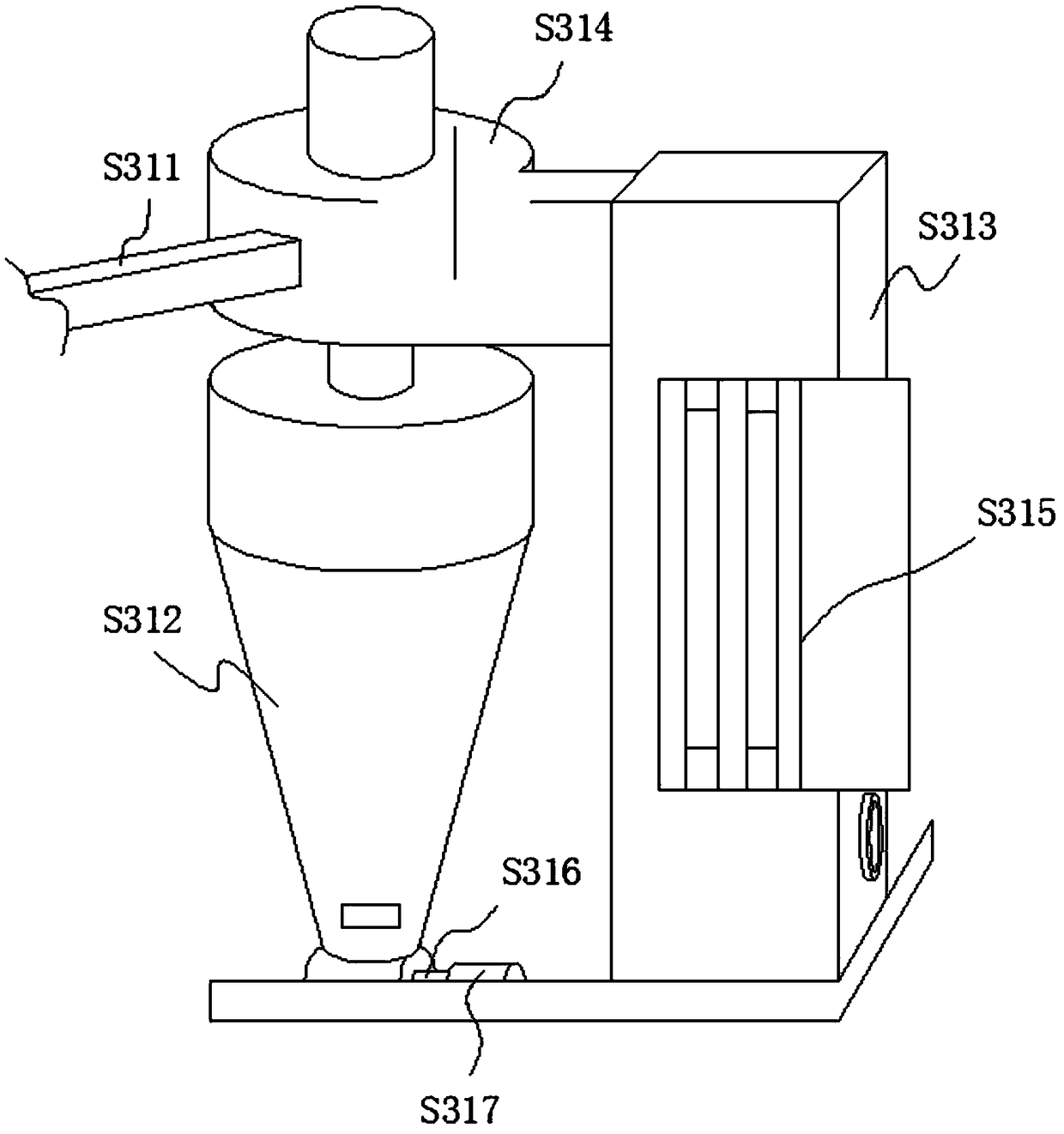

Coal ash bulk device

InactiveCN107253620AAvoid dust phenomenonPurify the working environmentLoading/unloadingBaghouseWorking environment

The invention relates to a coal ash bulk device. The coal ash bulk device comprises a base, a bulk machine body, a telescopic pipe and a cloth bag dust remover. The bulk machine body is fixed on the base, the telescopic pipe is arranged under the base and connected with the bulk machine body, and the bulk machine body is connected with the cloth bag dust remover through a first pipeline; a manual butterfly valve is arranged on the first pipeline, a lower box body of the cloth bag dust remover is connected with the bulk machine body through a second pipeline, and a pneumatic gate valve is arranged on the second pipeline; a vibrator is arranged on the lower box body, the telescopic pipe is a double sleeving pipe, and a material detaching head is arranged at the bottom of the telescopic pipe. According to the coal ash bulk device, a problem of dust raising generated during ash unloading of an ash bin is solved, working environment of a loading area is purified, and running and maintaining cost are reduced.

Owner:JIANGSU ZHONGNENG POWER EQUIP

Preparation method of unsaturated fatty acid microcapsules

PendingCN112716014AHigh utilization rate of raw materialsReduce pollutionFood preservationFood shapingUnsaturated fatty acidEmulsion

The invention discloses a preparation method of unsaturated fatty acid microcapsules, which comprises the following steps: adding water into a vacuum emulsification tank provided with a gas-solid separator, blowing a wall material, an emulsifier and an antioxidant into the water in the vacuum emulsification tank by using inert gas through the gas-solid separator, and carrying out shear emulsification to obtain a pre-emulsified liquid; adding an unsaturated fatty acid core material into the pre-emulsified liquid, and sequentially performing shearing, emulsifying and homogenizing to obtain emulsified liquid; sterilizing the emulsified liquid; and carrying out spray drying on the sterilized emulsion, and sieving the obtained powder product to obtain the unsaturated fatty acid microcapsule. When the emulsified liquid is prepared, the vacuum emulsifying tank provided with the gas-solid separator is adopted for shearing and emulsifying, so that the utilization rate of raw materials is effectively improved; and the emulsified liquid is sterilized and then subjected to spray drying, so that the microcapsules are prevented from deteriorating under the action of microorganisms, and the shelf life of the product is prolonged.

Owner:浙江远大生物科技有限公司 +1

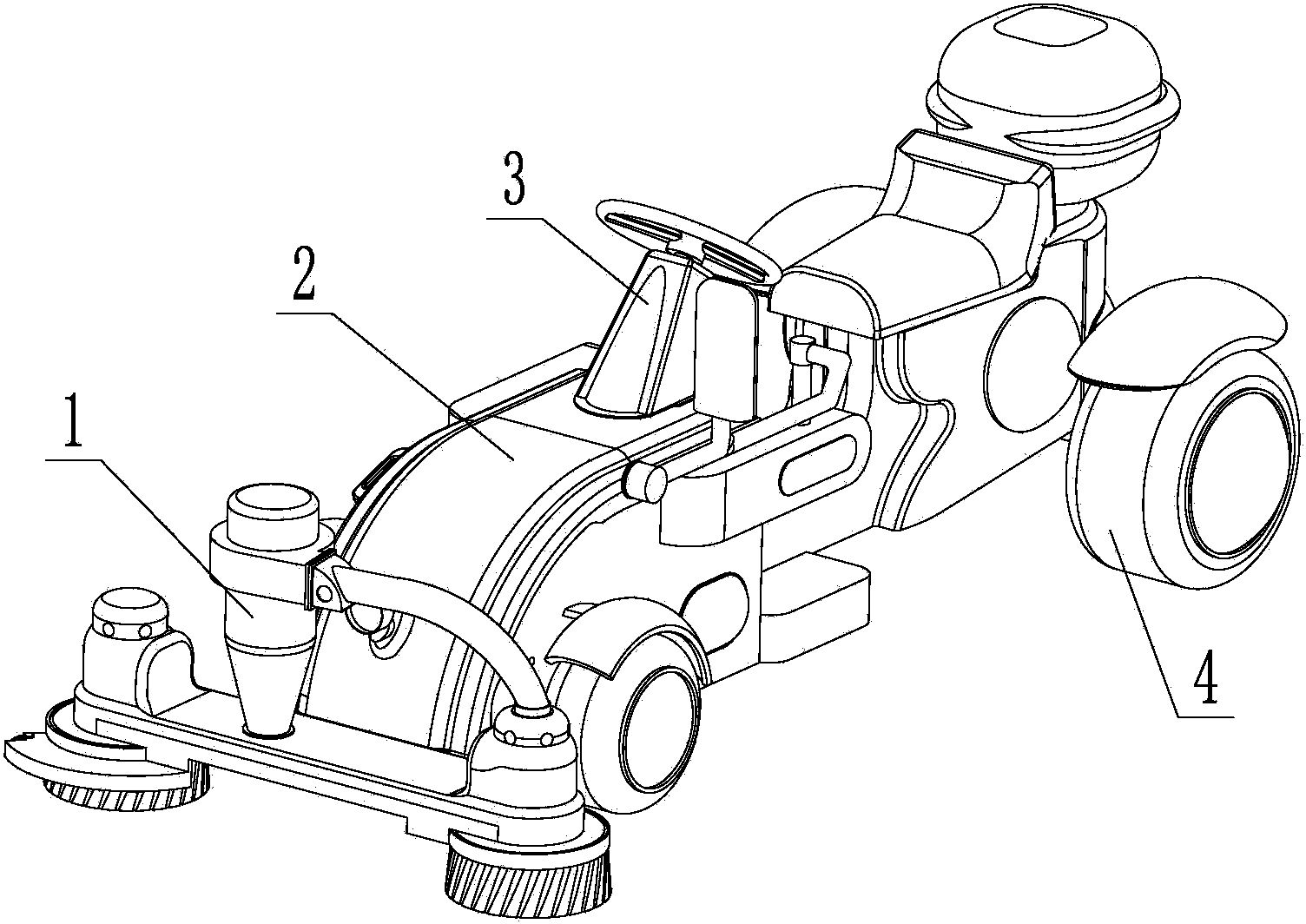

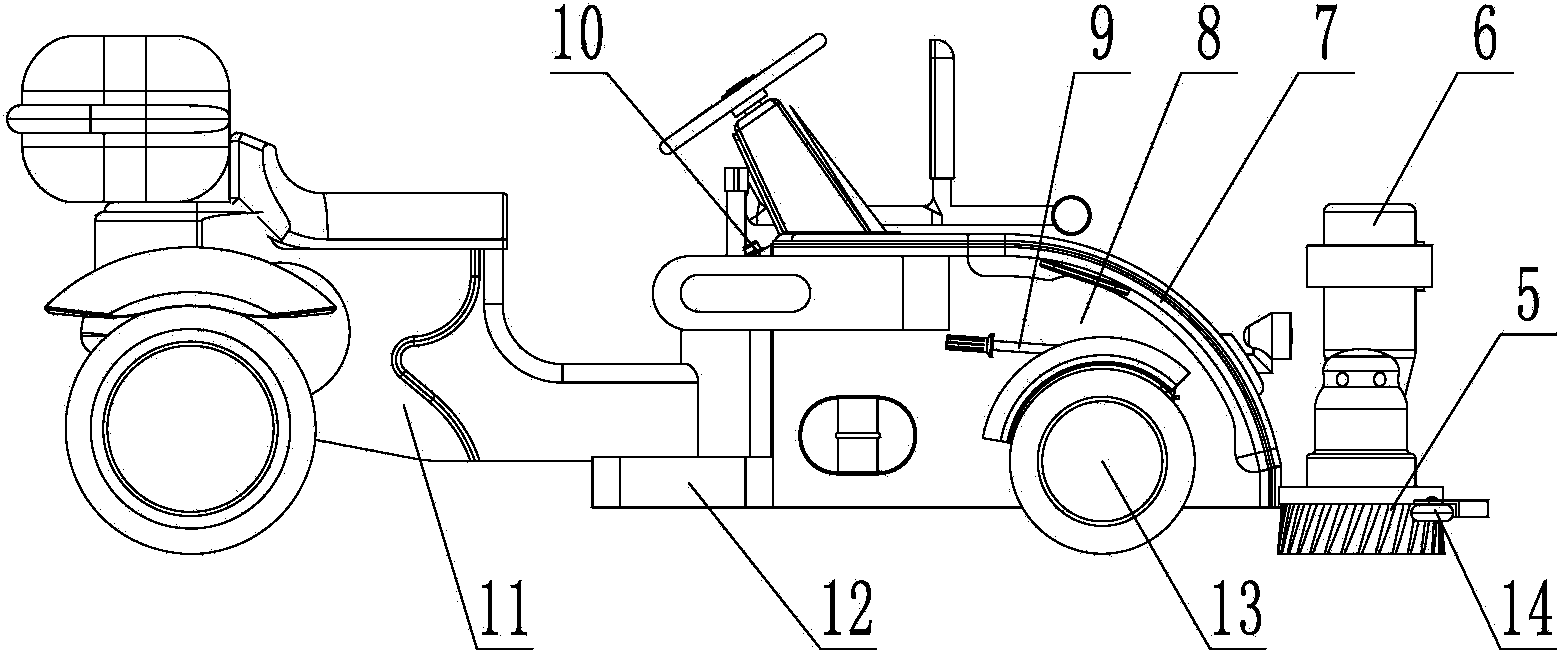

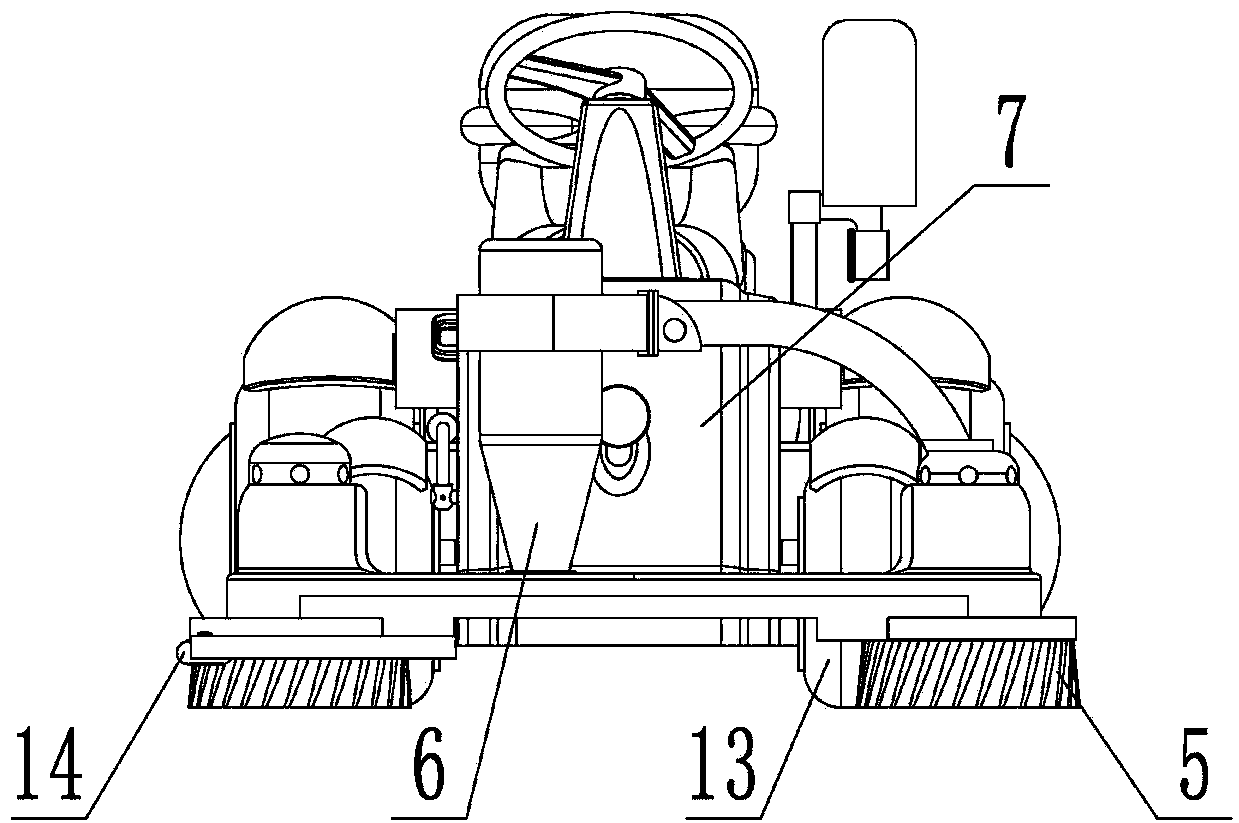

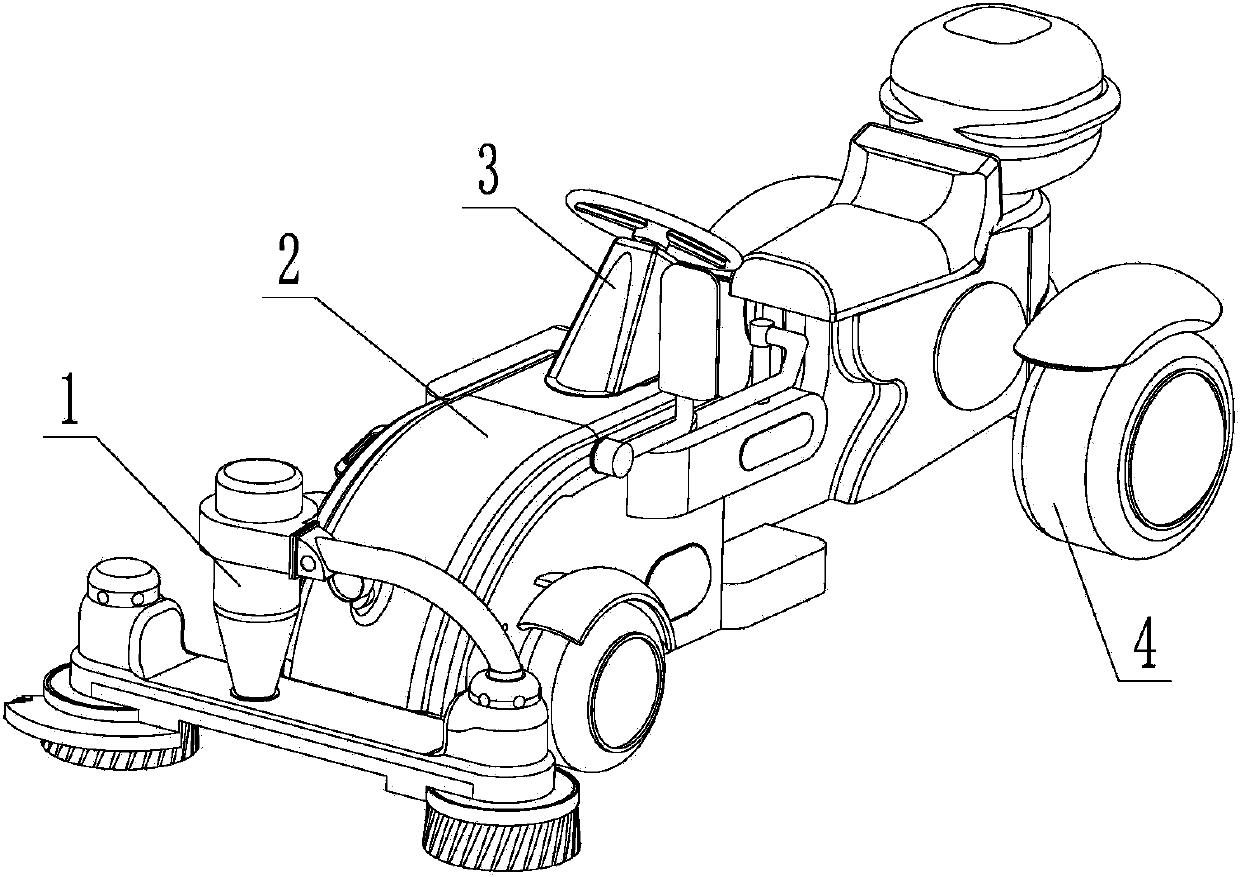

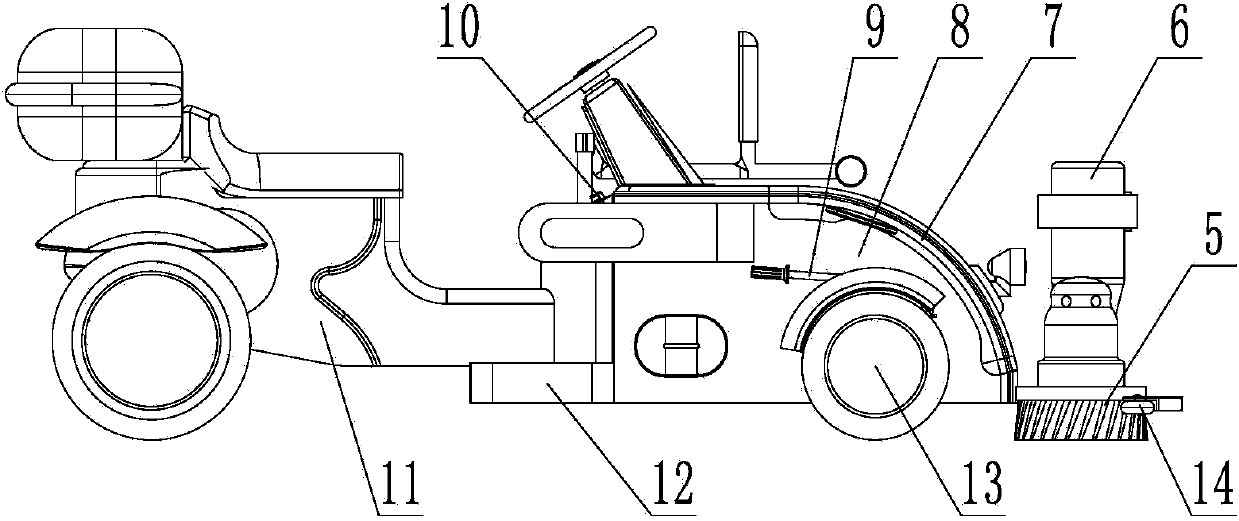

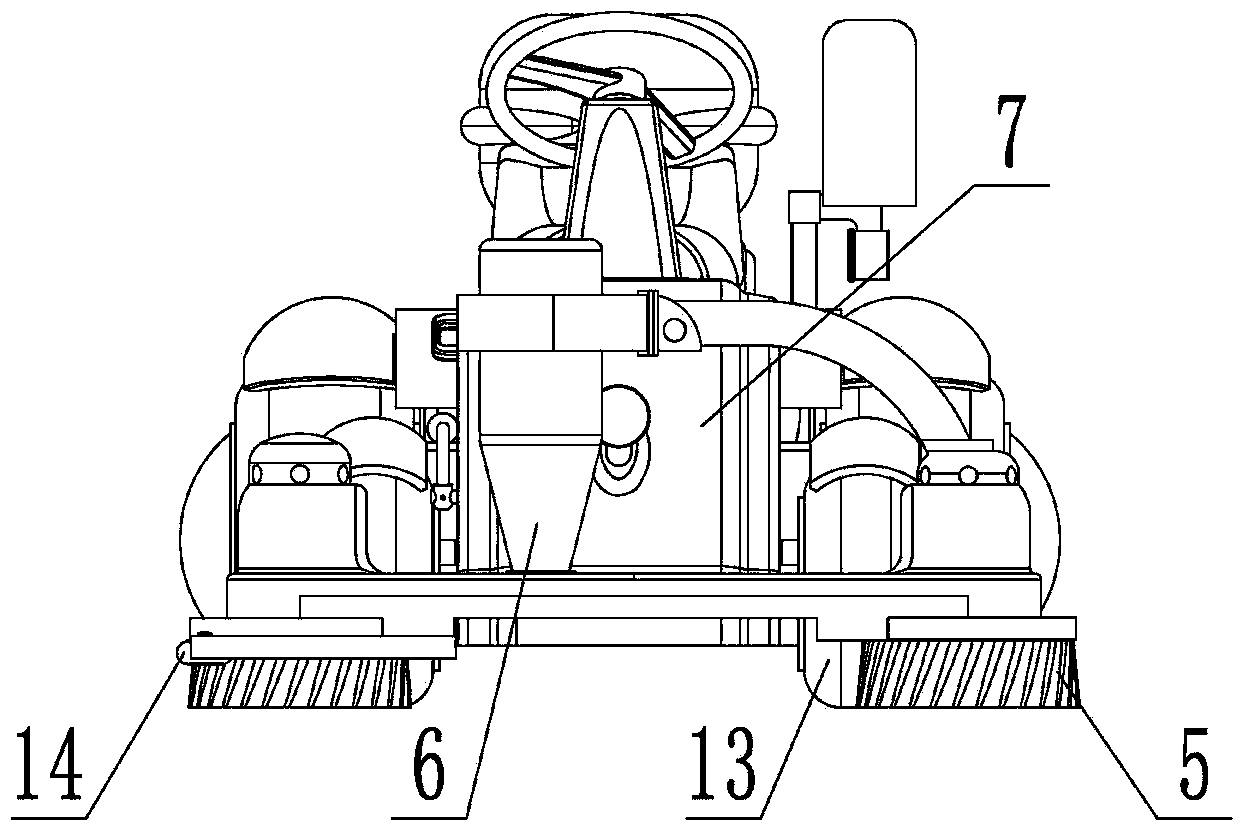

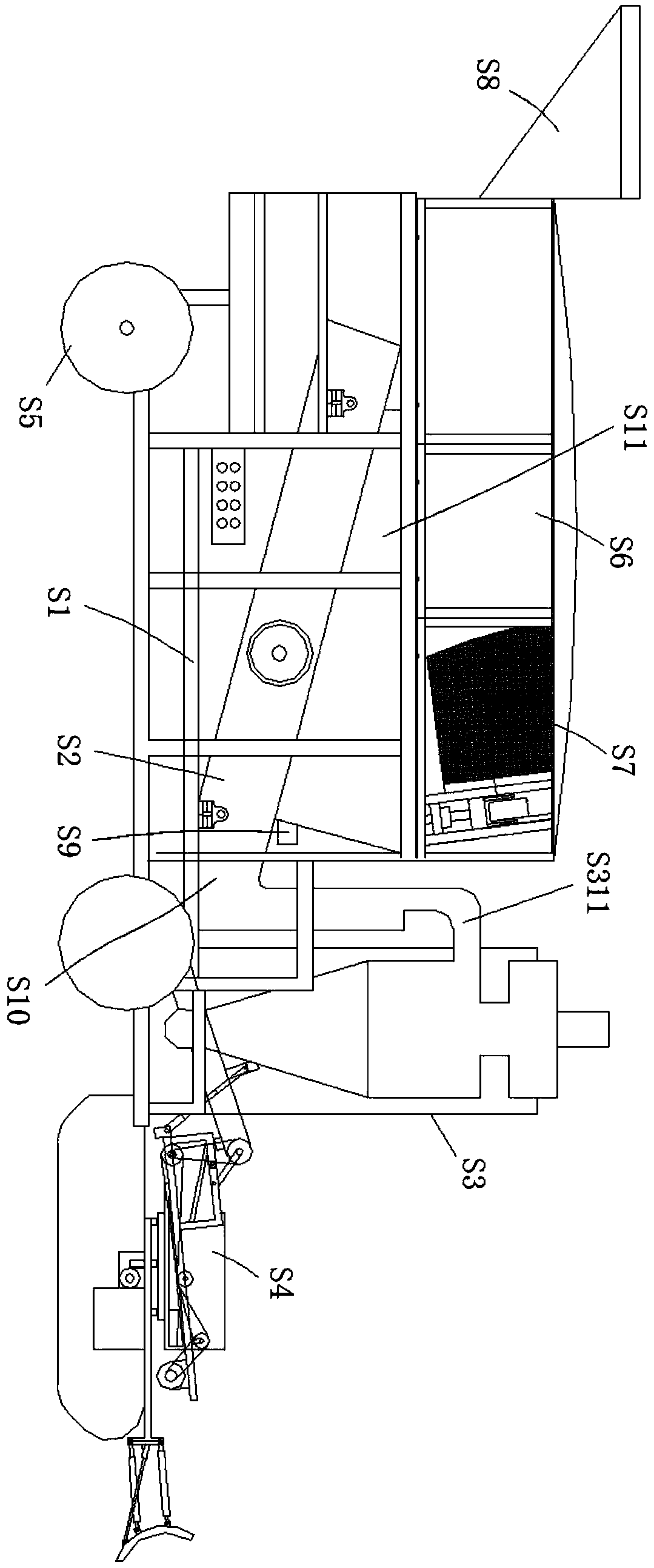

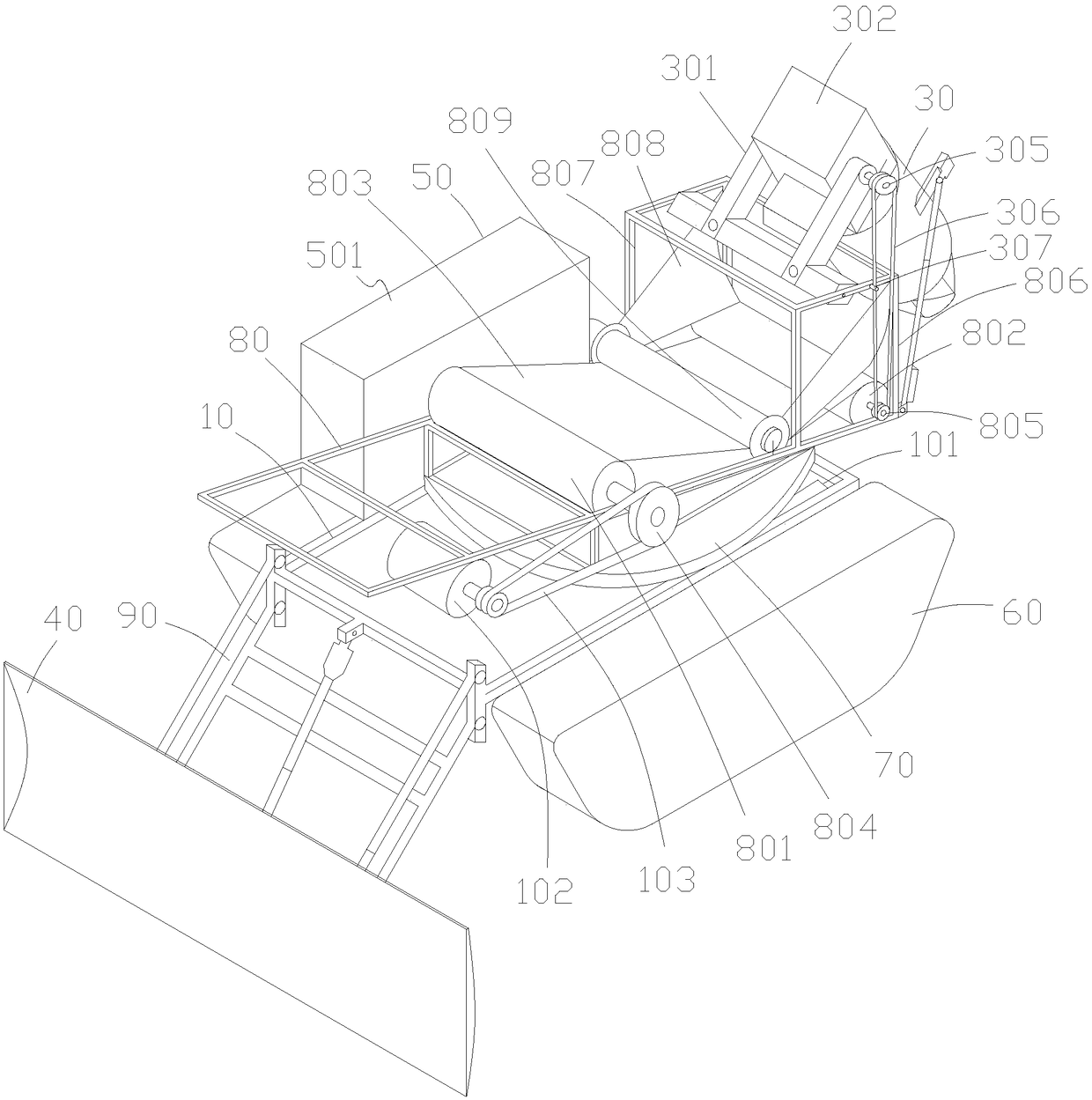

Multifunctional urban road cleaning vehicle

The invention discloses a multifunctional urban road cleaning vehicle, which comprises a vehicle body, a cleaning part, a control part and a walking part. A technical key point is that a pre-posed cleaning component also comprises a dust suction part; a pre-posed lifting mechanism comprises a balancing frame for mounting rotating brush heads and upper and lower rotating plates hinged to the balancing frame respectively; the other ends of the two rotating plates are hinged to a rotating structural plate respectively; the balancing frame, a connecting plate and the rotating plates form a quadrangular structure; the connecting plate is fixedly arranged on the upper rotating plate; a connecting plate tension spring is arranged between the other end of the connecting plate and a vehicle frame; the diameter of a main brush roller is greater than that of an auxiliary brush roller; a main dust collection box is arranged on the auxiliary brush roller side; an auxiliary dust collection box is arranged on the main brush roller side; baffle plates are arranged on the upper parts of the main and auxiliary brush rollers; the baffle plate of the main brush roller is connected with the auxiliary dust collection box; the baffle plate of the auxiliary brush roller is connected with the main dust collection box; a main cleaning mechanism also comprises a brush roller regulation mechanism. According to the multifunctional urban road cleaning vehicle, the problems of poor cleaning effects, short service cycle of the brush rollers, high dust raising rate in a cleaning process and the like of a conventional cleaning vehicle are solved.

Owner:DALIAN HENGSHI ENERGY SAVING EQUIP

Environment-friendly combustion furnace platform

ActiveCN110440297AEasy to closeAutomate collection operationsDomestic stoves or rangesLighting and heating apparatusCombustion chamberCombustor

The invention relates to the field of furnace platforms, in particular to an environment-friendly combustion furnace platform comprising a furnace platform body fixedly arranged on a triangular support. A combustor with a forward opening is arranged in the furnace platform body. An installation cavity is formed in the top end face of the furnace platform body and communicates with the combustor. An iron pan is arranged in the installation cavity. Tight-pushing assemblies are symmetrically arranged in the positions, on the left and right sides of the installation cavity, of the furnace platformbody and are used for pushing the iron pan tightly fixedly. The environment-friendly combustion furnace platform is simple in structure and simple and convenient to use, plant ash can be collected automatically, labor intensity can be lowered greatly, collection efficiency is improved, meanwhile closing operation of the combustor can be achieved automatically in the collection process, the raiseddust phenomenon can be prevented, and the environmental protection property is improved. In addition, compared with traditional furnace platform equipment, the environment-friendly combustion furnaceplatform has the significant advantages that a pan body is simple and convenient to disassemble and assemble, and cleaning is convenient, and the environment-friendly combustion furnace platform is suitable for use and popularization.

Owner:江西高信前沿科技有限公司

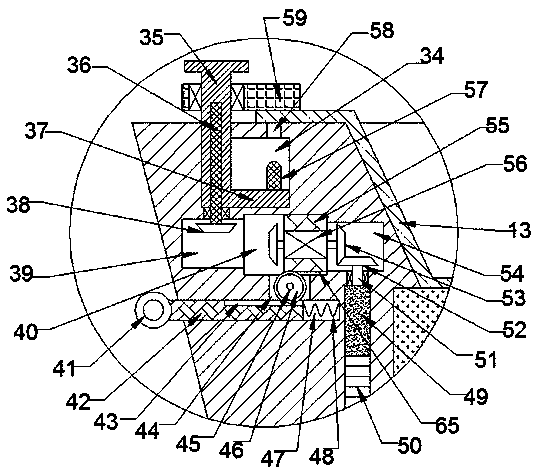

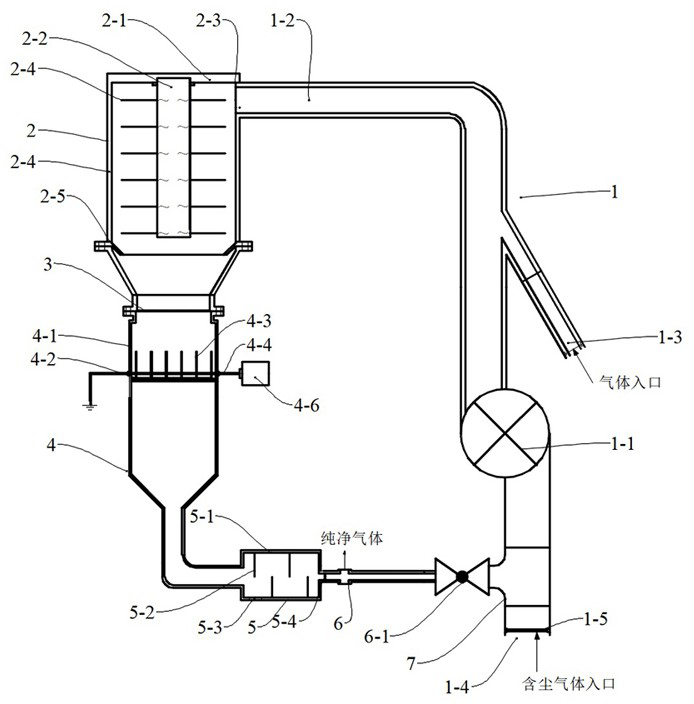

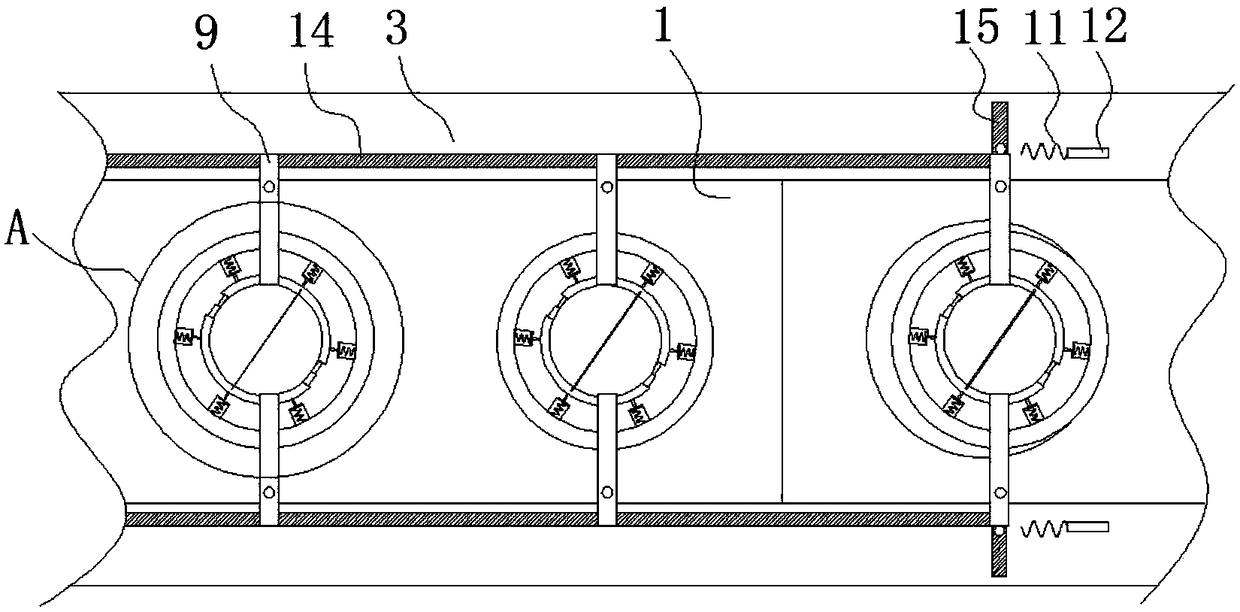

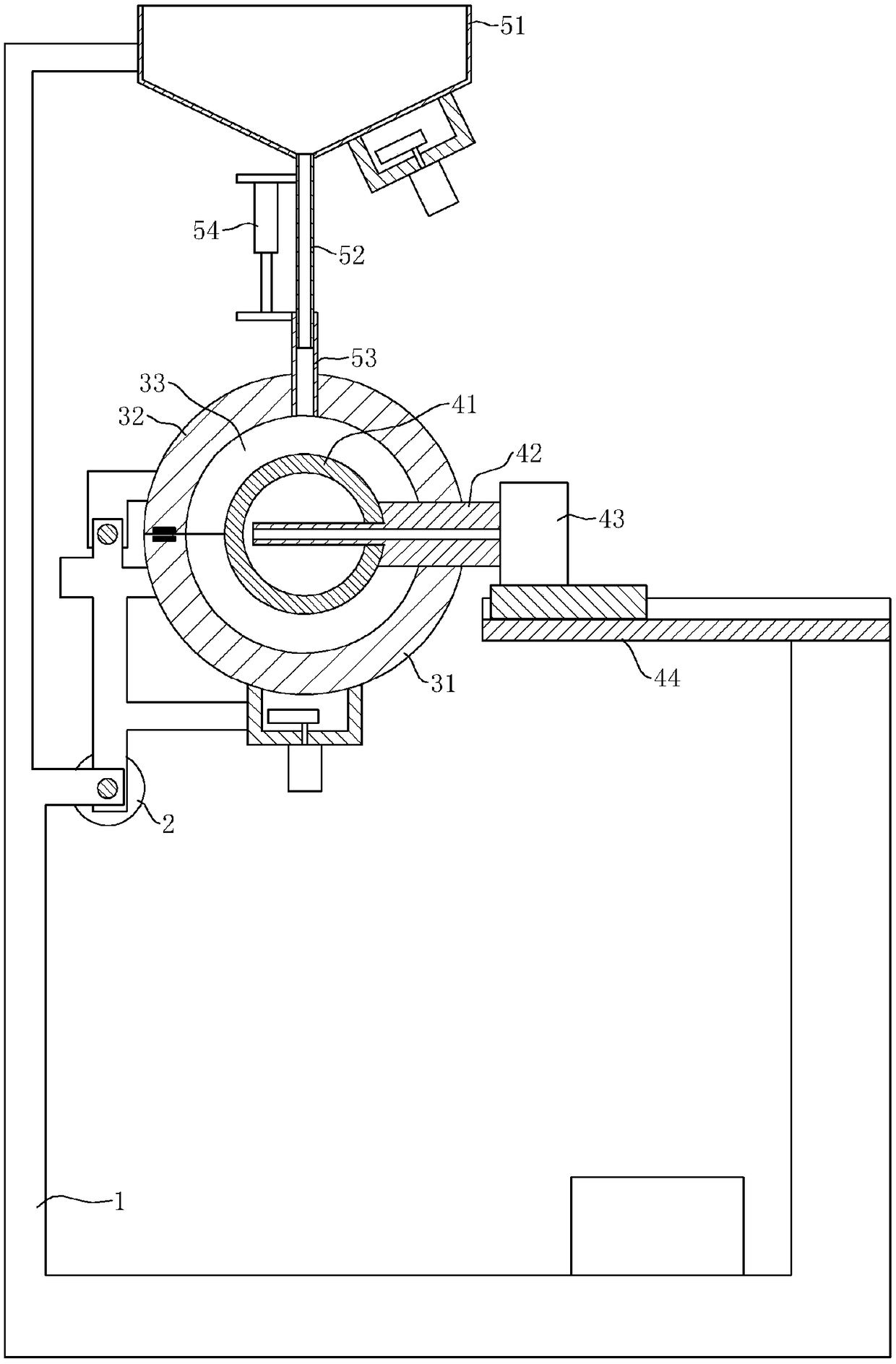

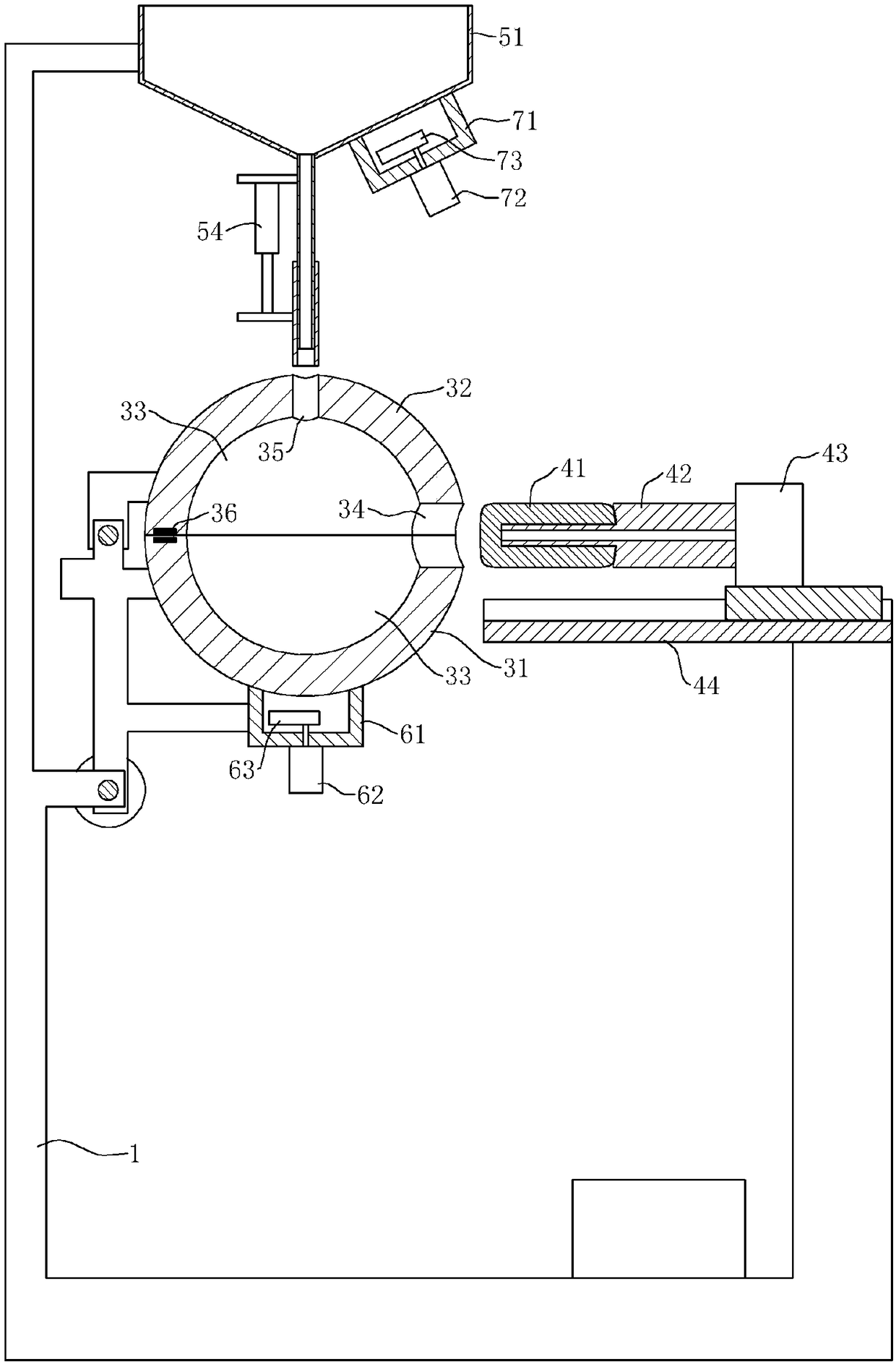

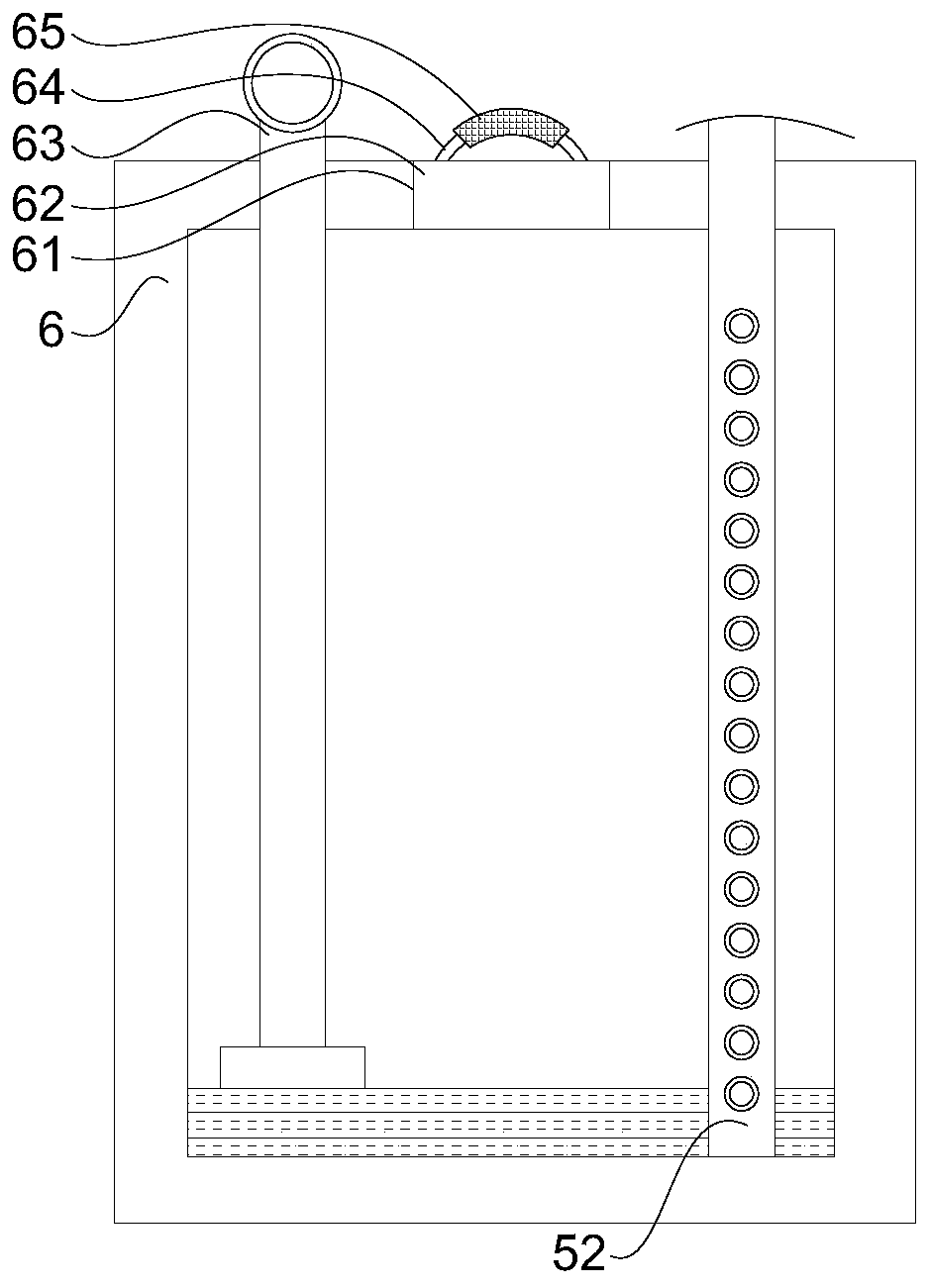

Circulating cyclone electrocoagulation environmental-protection device and method for industrial dust removal

ActiveCN111604176AAvoid pollutionAvoid enteringHuman health protectionCombination devicesForeign matterElectrocoagulation

The invention discloses a circulating cyclone electrocoagulation environmental-protection device and method for industrial dust removal. The device is composed of a power air supply system, a cyclonecharged device, a spider-web reinforcement charged device, a coagulation dust collection device, a dust collection device and a pure-gas outlet pipe network which are connected in sequence; dust blocking sheets are installed at a dust-containing gas inlet and the outlet pipe network and are mainly used for preventing foreign matters from entering a dust remover; and a dust blocking plate at the outlet of a collector prevents residual large-particle dust from polluting clean air, and every two layers of burr electrodes in a cyclone are staggered in a 45-degree manner. On the one hand, the confusion degree of a flow field is increased, and the probability of dust collision is increased; on the other hand, the anti-corona phenomenon is inhibited to a greater extent, and the situation that local overhigh field strength is caused due to too-close distance of electrode rods is prevented; a dust collecting chamber further coagulates the charged dust, and the dust becomes large particles whichare easy to clean; and in order to prevent the high-concentration dust from suppressing the corona phenomenon, clean air can be mixed through a check valve, and the dust removal efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

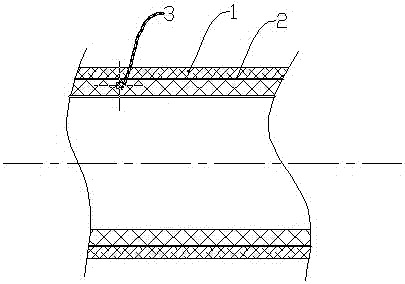

Fuel-resistant anti-static oil delivery pipe

The invention relates to an oil delivery pipe structure containing high polymer materials, in particular to a fuel-resistant anti-static oil delivery pipe. A pipeline of the fuel-resistant anti-static oil delivery pipe is divided into three layers sequentially including a reinforced layer, an adhesive layer and a fuel-resistant anti-static layer from outside to inside; the reinforced layer is a high polymer material, and the fuel-resistant anti-static layer is a fuel-resistant anti-static high polymer material. The fuel-resistant anti-static oil delivery pipe disclosed by the invention has fuel-resistant and anti-static functions, and is simple in manufacturing process.

Owner:江苏法利沃环保科技有限公司

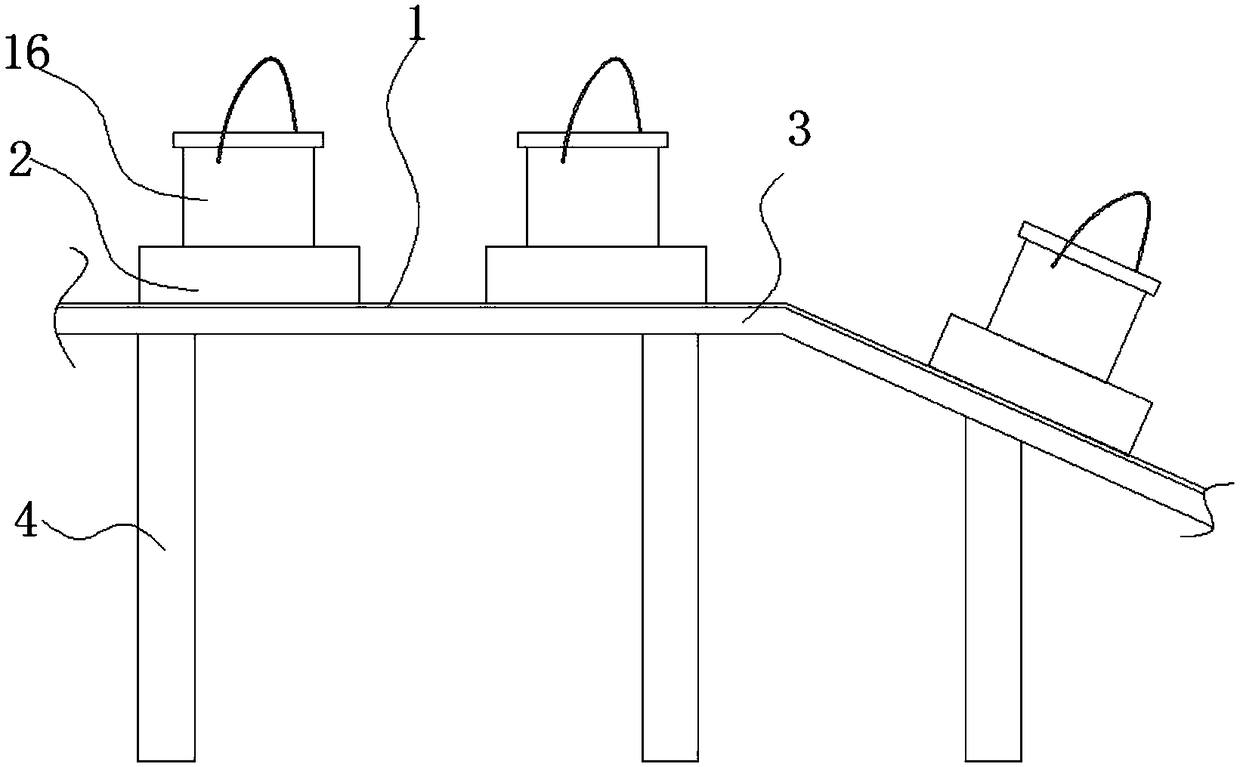

Refractory castable conveying device

The invention discloses a refractory castable conveying device. The refractory castable conveying device comprises a conveying belt; a support plate is contacted with the bottom of the conveying belt,and is always parallel to the conveying belt; an extension spring is welded at the top of the support plate; a bolt is inserted in one end of the extension spring; a support rod is glued at the bottom of the support plate; a fixed ring is glued at the top of the conveying belt; a spring shell is welded on the inner wall of the fixed ring; a spring is glued on the inner wall of the spring shell; apush rod is glued at one end of the spring; a clamping plate is welded at the end, far from the spring, of the push rod; a silica gel pad is glued on the inner wall of the clamping plate; a transportation barrel is contacted with the silica gel pad; the top of the clamping plate is connected with a connecting rod; the bottom of the connecting rod is connected with a slide block; the transportation barrel can be clamped by the clamping plate through the spring; the bolt is inserted in the connecting rod to conveniently disassemble the transportation barrel; the device is convenient to load andunload the transportation barrel and convey castables, and can prevent flying dust and the human body injury.

Owner:长兴鼎峰铸材科技股份有限公司

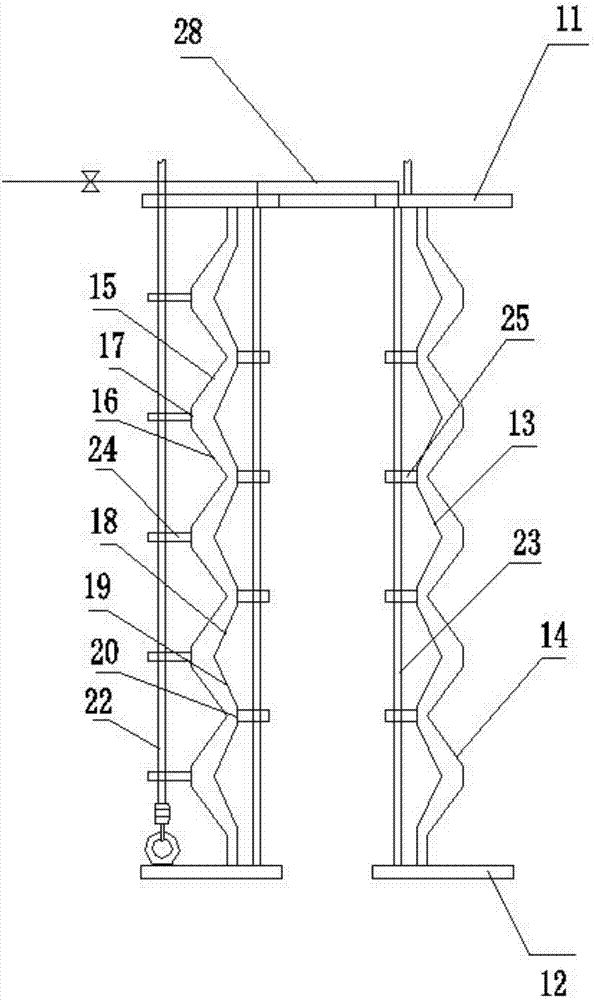

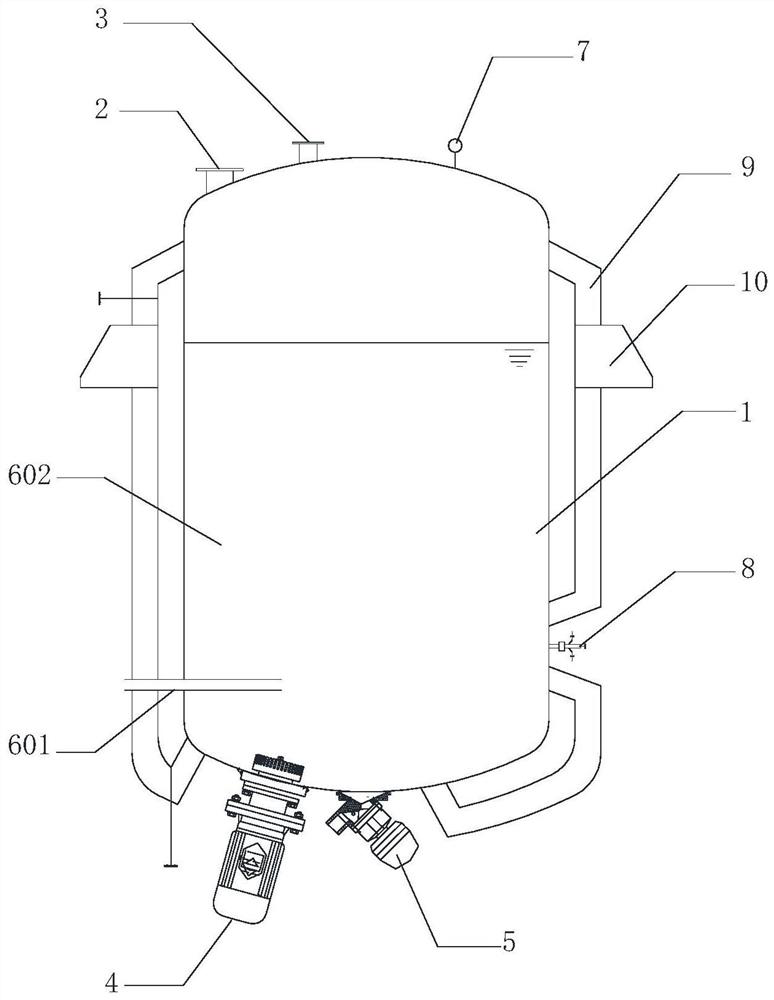

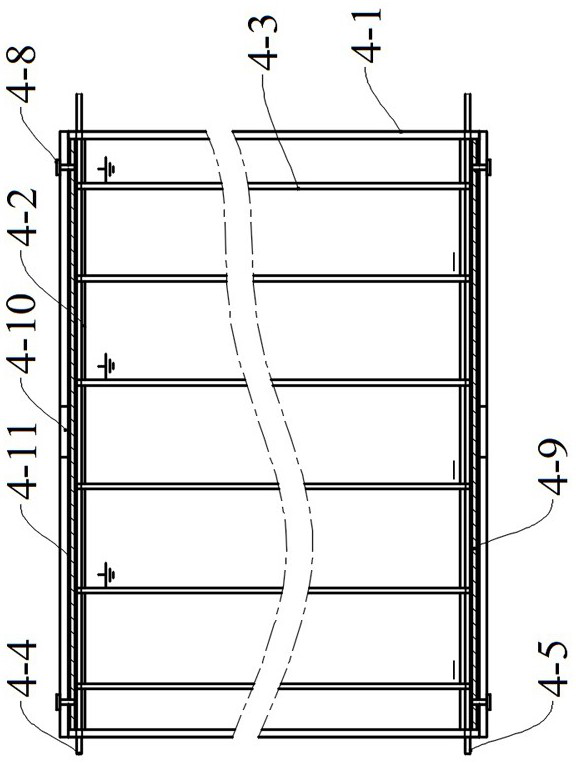

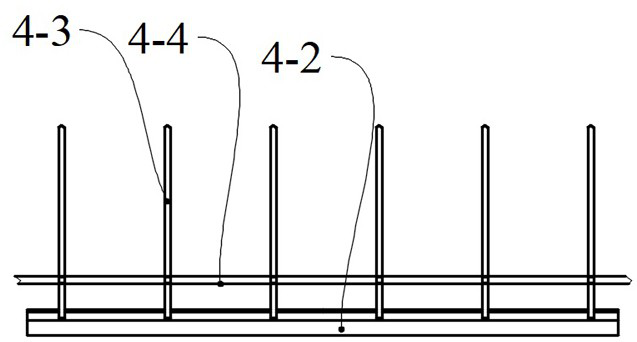

Portable reinforcement sleeve grouting material stirring device

PendingCN107901234AEasy to operateImprove construction efficiencyCement mixing apparatusInlet valveSlurry

The invention discloses a portable reinforcement sleeve grouting material stirring device. The portable reinforcement sleeve grouting material stirring device comprises a frame; the frame is detachably provided with a grouting tank; a stirring shaft is inserted in the grouting tank; multiple stirring paddles are arranged on the outer wall of the stirring shaft; the frame is provided with a stirring driving motor capable of driving the stirring shaft to rotate in a fixed-shaft manner; the grouting tank is hinged with an upper cover matched with a tank opening of the grouting tank in an opening / closing manner; the upper cover is provided with an intake valve; and a discharge hole is formed in the bottom of the grouting tank. In the operation process, the whole stirring and grouting processesare both performed in the same grouting tank without transferring slurry among different storage devices in different stations, so that the slurry missing and losing phenomenon in the material transfer process is effectively prevented; the sealing of the stirring tank is guaranteed through the upper cover after stirring, so that the dust flying phenomenon is prevented, and the material loss in conversion of stirring and grouting stations is further prevented; and meanwhile, the portable reinforcement sleeve grouting material stirring device is simple and feasible in whole operation process and higher in construction efficiency.

Owner:BEIJING MUNICIPAL ENG RES INST +1

Wet condition impermeable breathable material and preparation method thereof

ActiveCN103174111AImprove plasticityImprove anti-seepage functionMarine site engineeringPolymer scienceLiquid state

The invention relates to a wet condition impermeable breathable materials which comprises aggregate particles and a hydrophobic resin film and hydrophobic grease, wherein the hydrophobic resin film is arranged on the aggregate particles, the hydrophobic grease is added to the hydrophobic resin film and is in a solid state below the temperature of 50 DEG C, the adding weight ratio of the hydrophobic grease and the hydrophobic resin film is 0.01-0.5:100. The hydrophobic grease is enabled to coat the aggregate particles and powder particles arranged on the surface of the hydrophobic resin film by means of adding of the hydrophobic grease so that the phenomenon of dust flying in the process of construction is prevented. Meanwhile, due to the facts that the hydrophobic grease is added and the hydrophobic grease is in a solid state below the temperature of 50 DEG C, the hydrophobic grease can be changed to be in a liquid state by means of heating when the wet condition impermeable breathable materials are manufactured. Due to the fact that hydrophobic grease is added in the liquid state, the mobility is good. The hydrophobic grease can be changed to be solid after being uniformly stirred and placed when the temperature is lowered to be below 50 DEG C, and therefore the plasticity of the wet condition impermeable breathable materials is enabled to be increased.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Modified guanidine gum fracturing fluid as well as preparation method and application thereof

InactiveCN103805156ANo secondary pollutionSolving the Self-Agglomeration ProblemDrilling compositionFracturing fluidPollution

The invention relates to a modified guanidine gum fracturing fluid as well as a preparation method and an application thereof. The fracturing fluid contains nano materials, wherein the nano materials comprise MgC2O4, Al(OH)3, gamma-Al2O3, SiO2, TiO2 and ZnO; the particle sizes of the nano materials are 1-100nm; the specific surface area is 9-550m<2> / g; the guanidine gum is hydroxypropyl (HPG) and carboxymethyl hydroxypropyl (CMHPG); and the mass fraction is 0.1-1.5%. The adopted nano materials and dispersing aids are nontoxic and environment-friendly materials, secondary pollution is not caused, the nano materials are dispersed into the dispersing aids in advance, transportation and operation of superfine nano powder materials applied to an oil field are facilitated, the dispersing method is simple, and strong in field operability, has a broad application prospect in fracturing production stimulation of a high-temperature deep well in exploration and development of low-permeability oil and gas fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Classroom platform for education

InactiveCN107802092AAuto clearReduce labor intensityPulpitsCombination devicesActivated carbonReciprocating motion

The invention discloses a classroom platform for education. The classroom platform for education comprises fixing plates, a table board, a cross plate, a first partition plate, a second partition plate, a filter device, a shell, an air purification membrane, an activated carbon layer, a filter screen, water suction cloth, an exhaust fan, a water tank, a water pipe, a blackboard eraser placing box,a blackboard eraser, a dust collection box, a spring, a connecting block, a supporting column, a cam, an output shaft, a motor, a guide rod, a valve and a groove. The classroom platform for educationis reasonable in structure and novel in design, the blackboard eraser placing box is enabled to make reciprocating motion to and fro along the direction of the guide rod through the cam and the spring, so that the blackboard eraser can collide with the inner wall of the blackboard eraser placing box, dust on the blackboard eraser enters the dust collection box from through holes, thus dust on theblackboard eraser can be automatically removed, the labor intensity in cleaning the blackboard of students and teachers is alleviated, and the phenomenon of dust raise during dust cleaning also can be avoided; through the filter device, the air quality near the platform can be effectively improved, and dust in the air can be effectively reduced.

Owner:刘轩

Multifunctional snow sweeper

The invention discloses a multifunctional snow sweeper. The multifunctional snow sweeper comprises a vehicle body, a cleaning part, a control part and a walking part, wherein the vehicle body comprises front and back vehicle bodies. The multifunctional snow sweeper is technically characterized in that a main dust collecting box is arranged beside a secondary brush roll; a secondary dust collecting box is arranged beside a main brush roll; the upper parts of the main brush roll and the secondary brush roll are provided with baffle plates; the baffle plate of the main brush roll is connected with the secondary dust collecting box; the baffle plate of the secondary brush roll is connected with the main dust collecting box; a dual-roll mechanism further comprises a brush roll adjusting mechanism; the brush roll adjusting mechanism comprises a hoisting rod which is used for limiting the secondary brush roll and is fixed on a frame, a connecting rod and a main brush frame for limiting the main brush roll which are coaxially hinged to the same end of the hoisting rod, a main brush roll tension spring arranged between the connecting rod and the main brush frame, a support rod fixed at the tail end of the connecting rod, a universal wheel arranged at the bottom of the support rod, and an adjusting rod screwed on the support rod; the control part comprises a steering wheel for controlling a back driving part, and an operation panel. The multifunctional snow sweeper has the advantages of wide application range, high cleaning efficiency, environmental friendliness, energy saving, easiness in operation, low use cost, avoidance of raised dust in a cleaning process, and the like.

Owner:DALIAN HENGSHI ENERGY SAVING EQUIP

Flying dust inhibitor for environmental protection and preparation method thereof

The invention discloses a flying dust inhibitor for environmental protection. The flying dust inhibitor comprises the following components (in percentage by mass): 55-60 percent of water; 18-23 percent of a reinforcing agent; 5-10 percent of a coagulant; 7-12 percent of a surfactant; 2-5 percent of a bacteriostatic agent; silicic acid gel is alternately generated through a sodium silicate solutionand a calcium chloride solution; a layer of silicic acid gel film is formed on the surface of the dust in a wet environment to reinforce dust and avoid dust raising phenomenon; bentonite is added into the flying dust inhibitor, the moisture loss of dust can be reduced, moisture is locked in molecules for a long time and the surface of the dust is kept moist so as to achieve the flying dust inhibition function, improve the moisture retention and the adhesion of the flying dust inhibitor, ensure the humidity of the silicic acid gel layer formed on the surface of the dust, improve the adhesion strength of the silicic acid gel layer formed on the surface of the dust, effectively inhibit the flying dust flying, and provide the long-term flying dust flying.

Owner:李骏

Cutting device for building construction

InactiveCN107791400ALow densityAvoid dust phenomenonWorking accessoriesStone-like material working toolsArchitectural engineeringAcoustic board

The invention discloses a cutting device for building construction, which comprises a placement plate, a dust collection groove, a base, an ash discharge tank, an exhaust fan, a connecting block, a casing, a cutting tool, a water pipe, a micro water pump, a water tank, a sound-absorbing board, Cut grooves, baffles, connecting shafts, output shafts, bearings, motors, spacers and stops. The invention has a reasonable structure. The water in the water tank is extracted by a micro-water pump. The water can flow from the end of the water pipe to the cutting tool through the water pipe. The exhaust fan extracts the dust in the dust collection groove. When the cutting tool cuts the object to be cut , prevent the waste and dust generated by the objects from causing dust, reduce the dust density on the construction site, and ensure the health of the construction workers to a certain extent; the sound-absorbing panels and sound-insulating panels can effectively reduce the noise generated by the cutting tool when cutting Noise, to avoid the negative impact of noise on construction personnel, and reduce noise pollution.

Owner:哈建薇

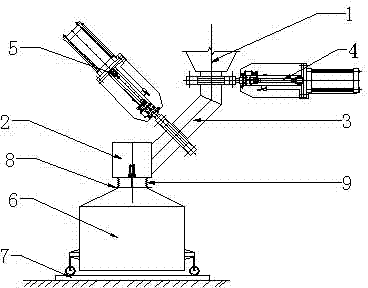

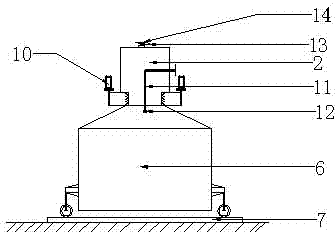

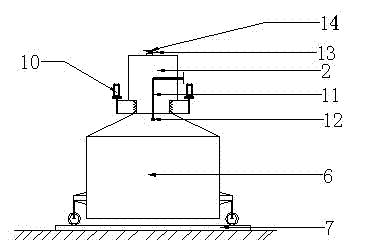

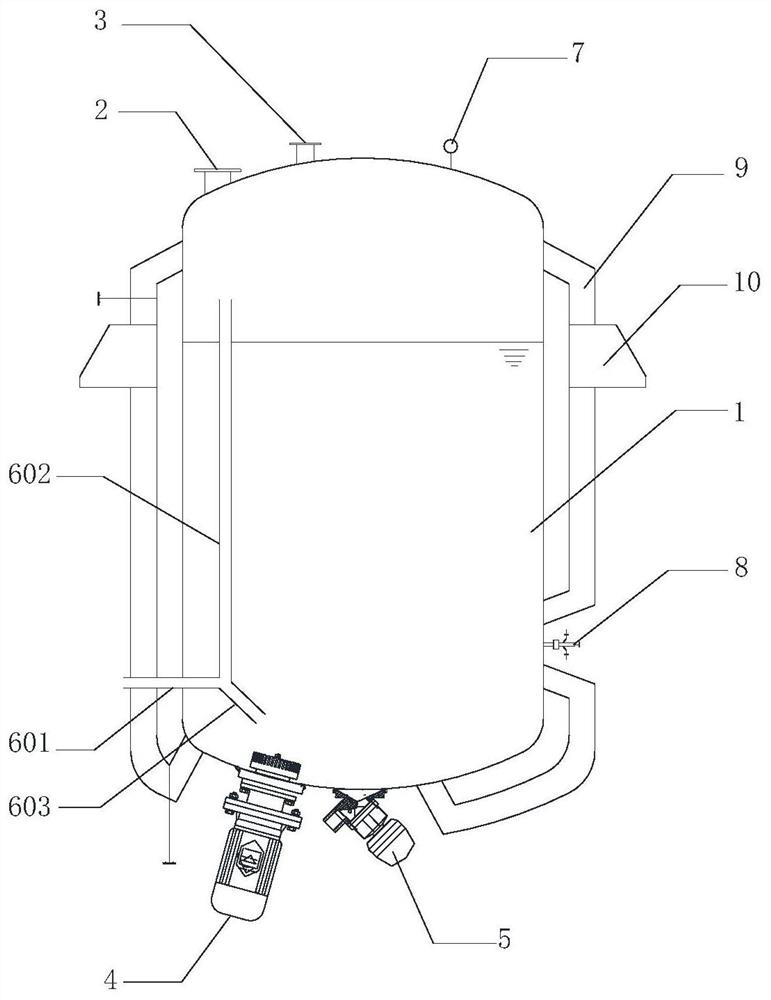

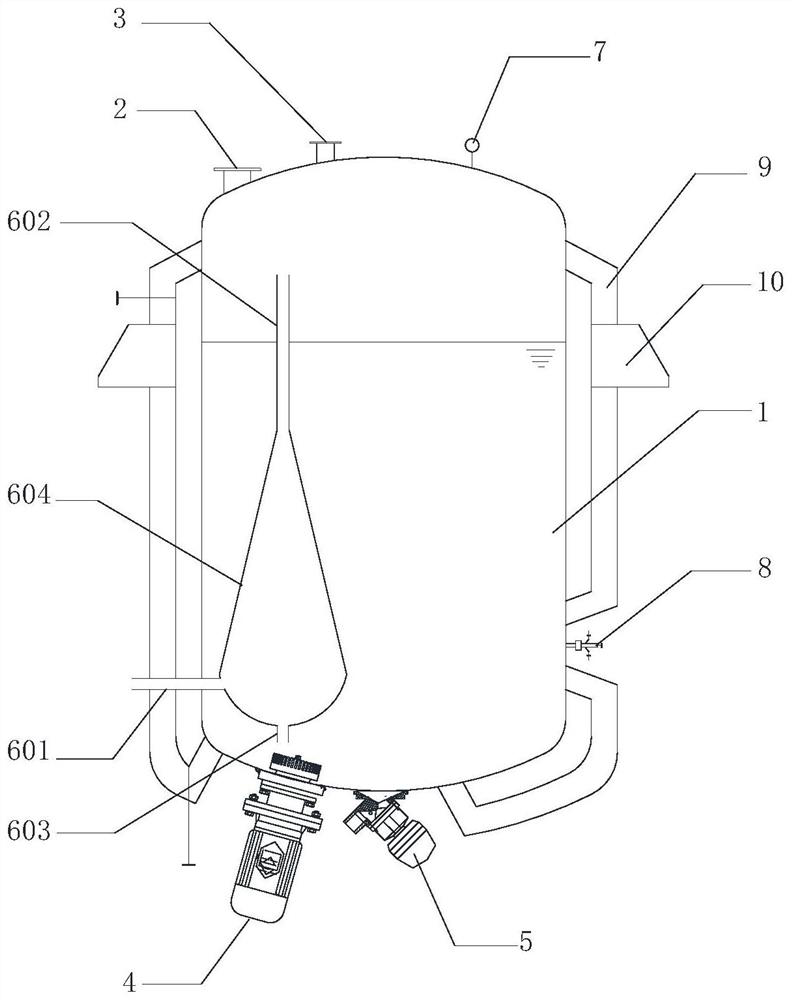

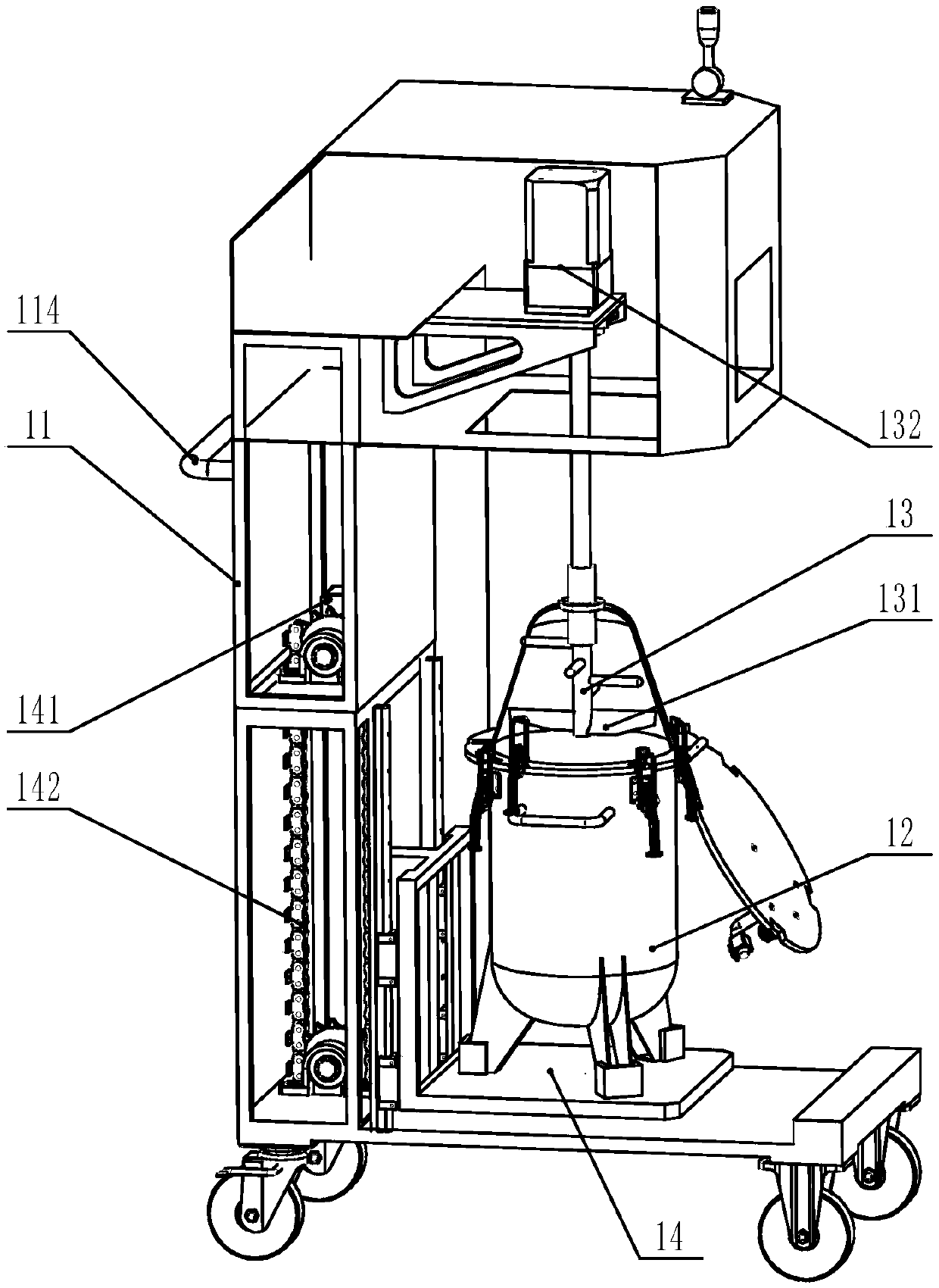

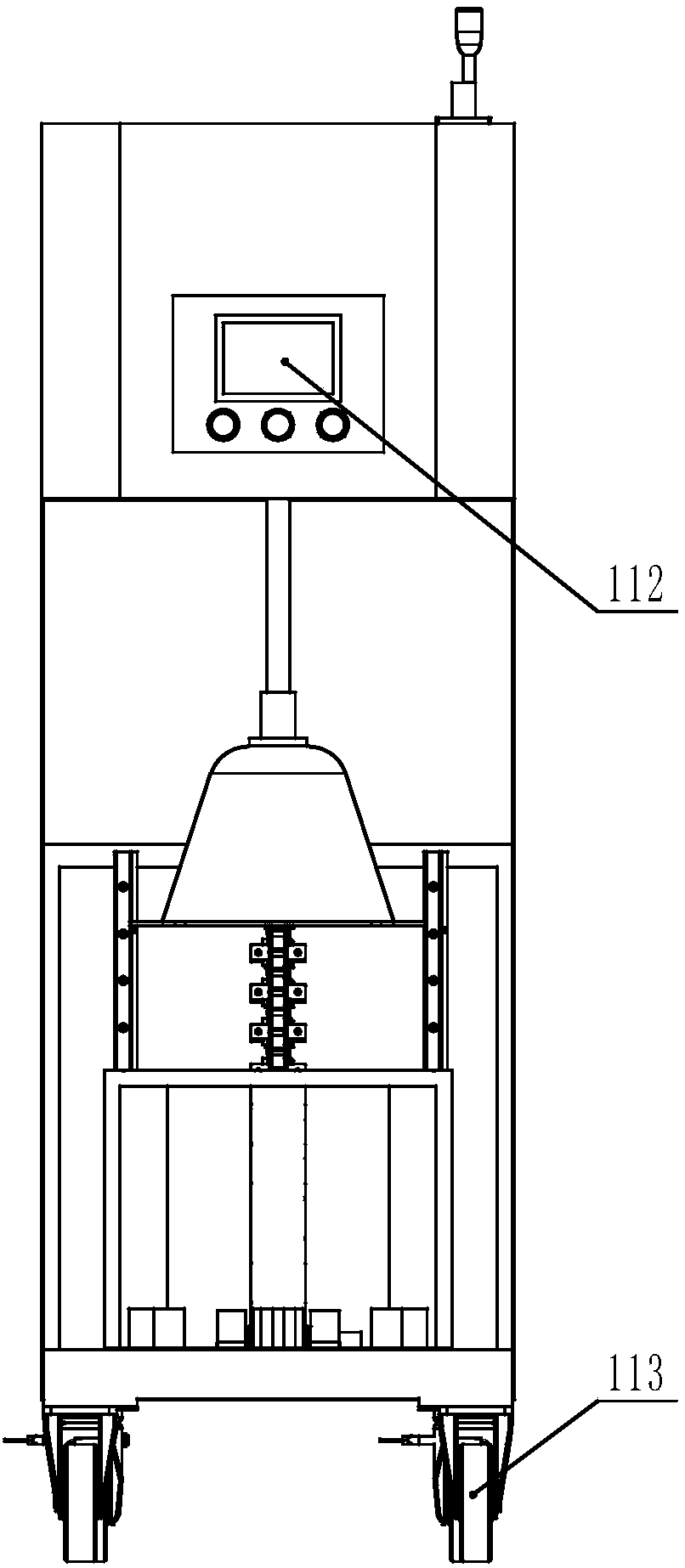

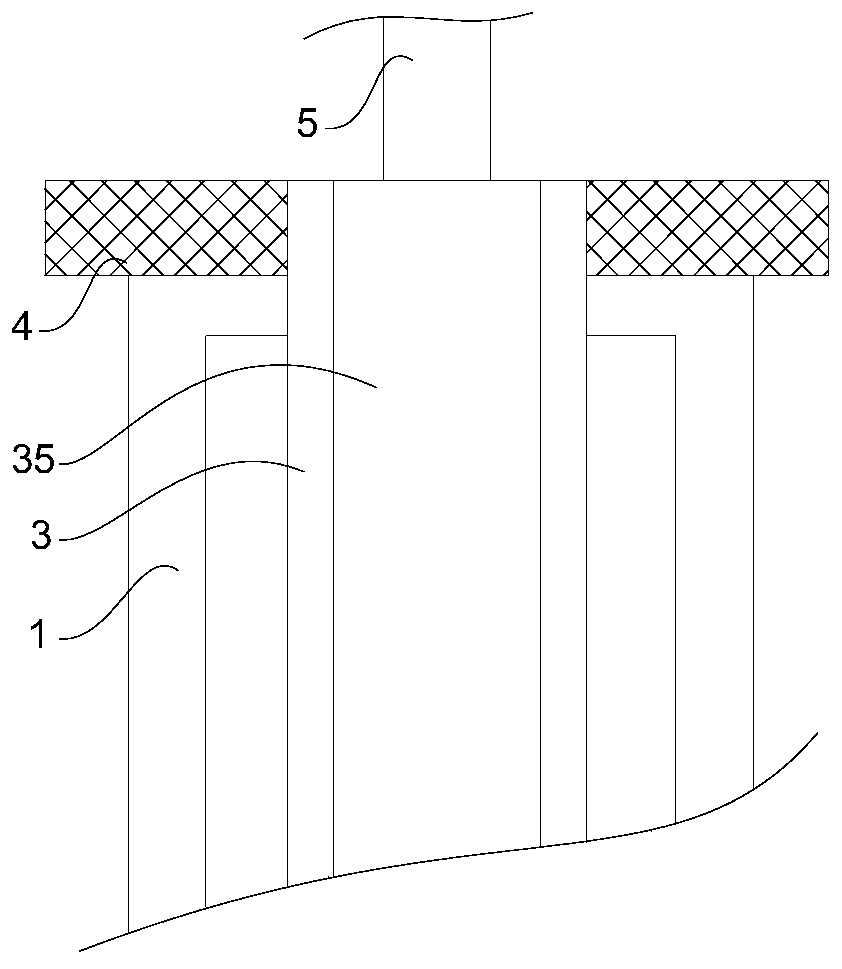

Vacuum forming device for gypsum mold

ActiveCN106583648BImprove processing efficiencyReduce labor costsFoundry mouldsFoundry coresCasting moldVacuum mixing

The invention relates to a gypsum casting mold vacuum forming device. The gypsum casting mold vacuum forming device comprises a positioning base, a vacuum forming cabin, a transfer lifting arm and a gypsum vacuum mixing cabin; the vacuum forming cabin and the transfer lifting arm are both mounted on the positioning base through a positioning mechanism; the gypsum vacuum mixing cabin is respectively connected with the positioning base and the vacuum forming cabin through the transfer lifting arm; the gypsum mixing cabin includes a mixing tank, a support leg, a sealing cover, a stirring device and a stirring driving device; and the vacuum forming cavity includes a vacuum chamber, a sealing door, a positioning table, a support frame, a negative-pressure pump, a drainage pipe and a casting tank. On the one hand, the gypsum casting mold vacuum forming device can effectively improve the working efficiency of gypsum mold forming and the mold forming quality and precision, and overcomes the defect that a traditional gypsum mold cannot prepare a fine mold; and on the other hand, the gypsum casting mold vacuum forming device can effectively improve the gypsum mold machining efficiency and reduce the labor cost, effectively prevents the gypsum powder flying phenomenon in the machining process, greatly improves the gypsum mold forming production environment, and reduces the material loss.

Owner:HENAN ZHENGXU TECH CO LTD

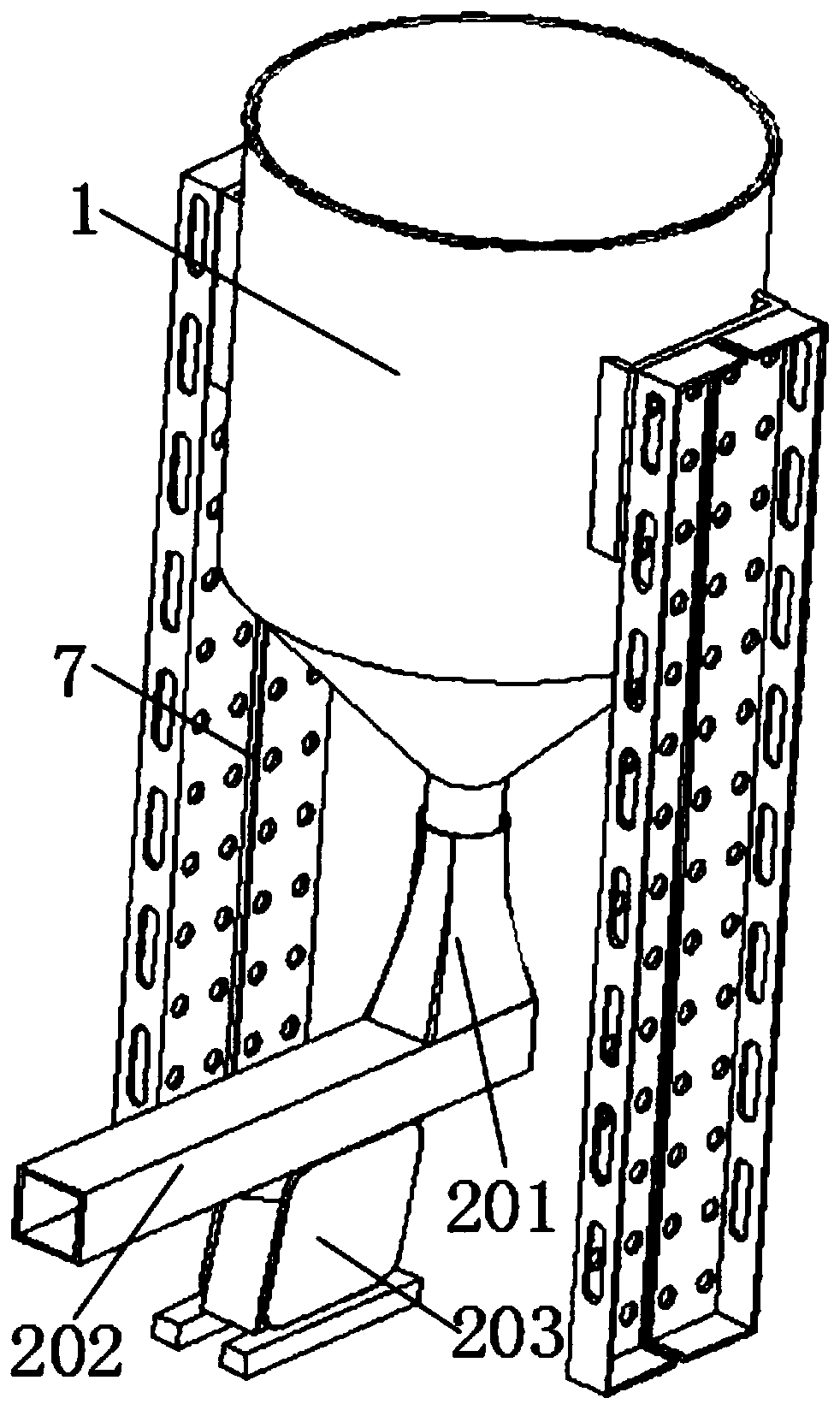

Novel special batching machine for food heating bags

PendingCN110052196AConvenient blankingAvoid dustRotary stirring mixersTransportation and packagingPurchase costEngineering

The invention discloses a novel special batching machine for food heating bags. The novel special batching machine for food heating bags comprises a first support frame, a second support frame is arranged at the upper end of the first support frame, a storage barrel is arranged in the second support frame, and a linear feeding mechanism is connected to the lower end of the storage barrel. The novel special batching machine for food heating bags has the advantages that an original feeding and weighing mode is changed to prevent flying dust during feeding and weighing, so that materials are weighed and metered more accurately and can be stirred quickly, and a stirring mechanism can be separated from a stirring box; a cover of the rapid stirring mechanism can prevent the flying dust during stirring, feeding and stirring can be alternatively carried out, the materials inside the stirring box can discharge conveniently to prevent the flying dust during stirring and bagging, and accordinglyboth labor and time cost are saved effectively; a stirring and discharging alternating mechanism substitutes for a stirring device and a screw feeder in the prior art, and accordingly purchased cost of equipment can be saved.

Owner:长兴顶盛科技有限公司

Method for ecological and environment-friendly recycling of rubber for preparing ultrafine rubber powder

ActiveCN107696334AGood effectPrevent coagulationPlastic recyclingMechanical material recoveryEnvironmental resistancePrill

The invention relates to the technical field of rubber recycling, in particular to a method for ecological and environment-friendly recycling of rubber for preparing ultrafine rubber powder. The method for ecological and environment-friendly recycling of rubber for preparing ultrafine rubber powder comprises the following steps that firstly, waste tire rubber is sorted and pulverized; secondly, rubber particles, a chain terminator and an emulgator are scattered in an organic solvent, scattering liquid is obtained, then, grinding particles are adopted for grinding the scattering liquid, and scattering emulsion is obtained; thirdly, the scattering emulsion is sent into a plunger type high-pressure homogenizer, materials are in opposite collision through high-pressure conveying, then, the grinding particles continuously grind large-particle rubber powder into fine particles, the homogenizer further refines scattering liquid, and rubber powder emulsion is obtained; and fourthly, the rubberpowder emulsion is subjected to centrifuging and drying, and micron-order rubber powder is obtained. The large particle rubber powder is ground into the micron-order rubber powder in the solvent system, gathering of the rubber particles in the grinding process is prevented, and the size of the micron-order rubber particles is uniform.

Owner:ZHEJIANG SANMEN EASTSEA RUBBER FACTORY

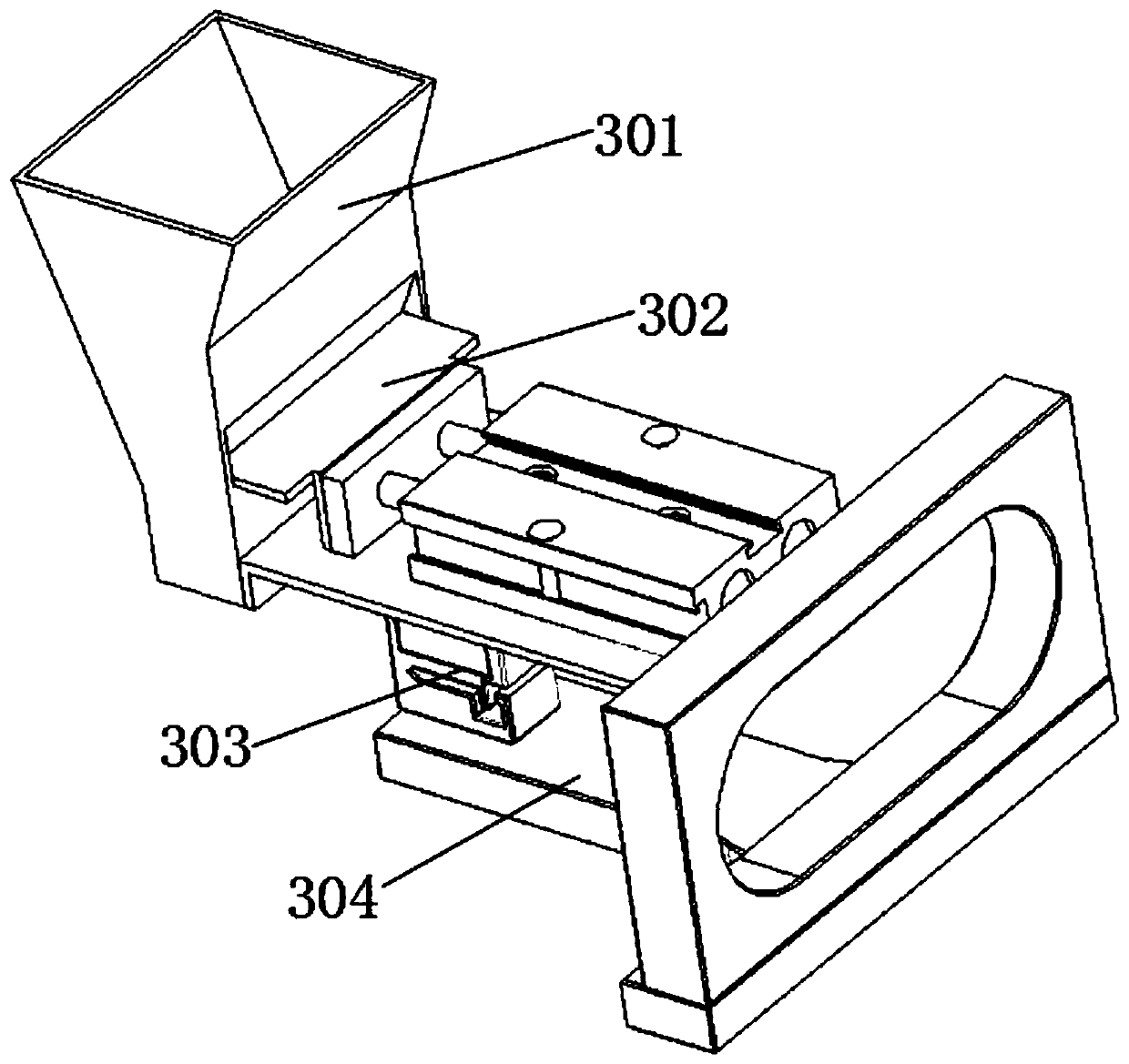

Coke particle preparation device

InactiveCN109456810AAvoid dust phenomenonAchieve environmental protection effectSolid fuelsAir pumpEngineering

The invention discloses a coke particle preparation device which comprises a die, an extrusion device, a feeding device, a rack and a stepping motor; the die comprises a fixed die and a moving die; the moving die is vertically and rotationally connected with the fixed die; a spherical cavity is formed between one faces, close to each other, of the moving die and the fixed die after the moving dieand the fixed die are mutually buckled; the extrusion device comprises an air bag, a conduit, an air pump and a linear module; the fixed die and the linear module are fixedly connected with the rack respectively; the air bag is pneumatically communicated with the air pump through the conduit; the die is provided with a first through hole into which the conduit is inserted; the stepping motor is fixedly connected with the rack; the fixed die is fixedly connected with an output shaft of the stepping motor; the feeding device comprises a hopper and a telescopic pipe; the hopper is fixedly connected with the rack; the telescopic pipe is fixedly connected with the hopper and is communicated with the internal space of the hopper; and the moving die is provided with a second through hole into which the telescopic pipe is inserted. The coke particle preparation device has the advantages that carbon powder can be prepared into hollow coke particles, and raising dust is avoided and has the effects of energy conservation and environmental protection.

Owner:张宏宇

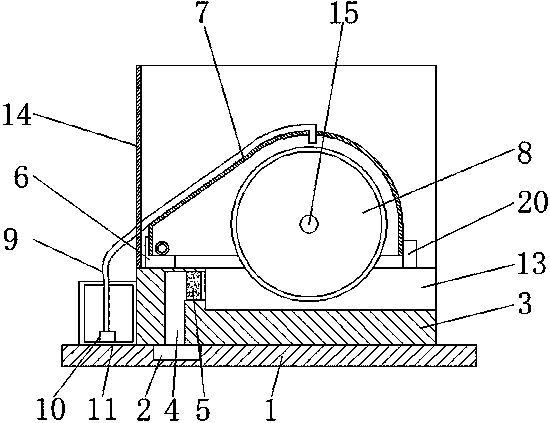

Road cleaning equipment

The invention discloses road cleaning equipment. The road cleaning equipment comprises at least a cleaning equipment body; a rotary disc is arranged below the cleaning equipment body; the outer sidesof the rotary discs are wrapped with cleaning brushes; a water outlet is formed in each rotary disc; a rotary shaft is inserted in the center of each rotary disc; one end of each rotary shaft penetrates through a driven belt wheel and is fixed on a bearing; a driving belt wheel is arranged on one side of the driven belt wheel; an annular belt is arranged between the driven belt wheel and the driving belt wheel; a reduction motor is arranged on an input end of driving belt wheel; a water inlet passage is formed in the rotary shaft; one end of the water inlet passage communicates with a water inlet pipe; one end of the water inlet passage is connected to a water storage tank; a water inlet is formed in the top of the water storage tank; and a buckle cover which is matched with the water inlet covers the water inlet. The road cleaning equipment is simple in style and novel in structure, and road cleaning work can be finished on the premise of avoiding dust raising phenomena.

Owner:徐州荣腾机车有限公司

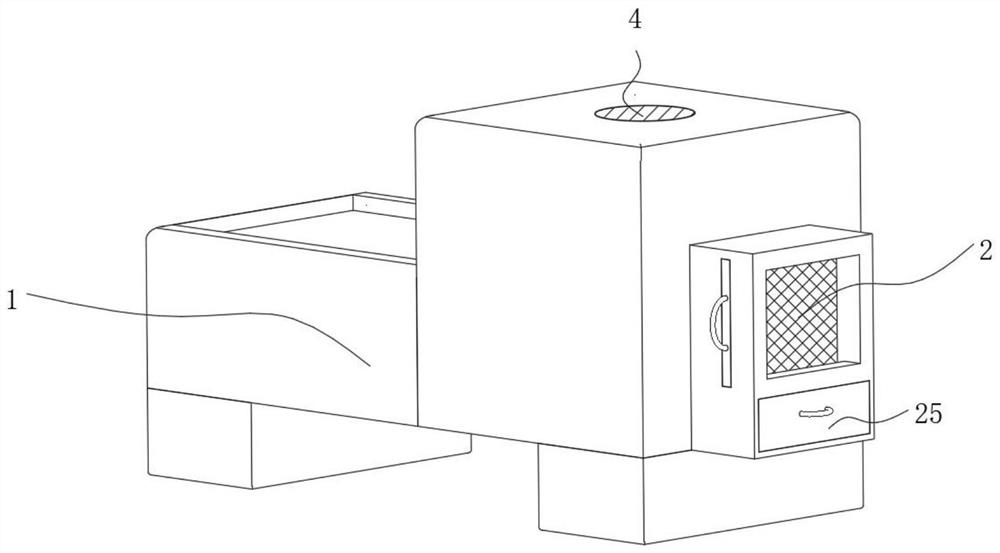

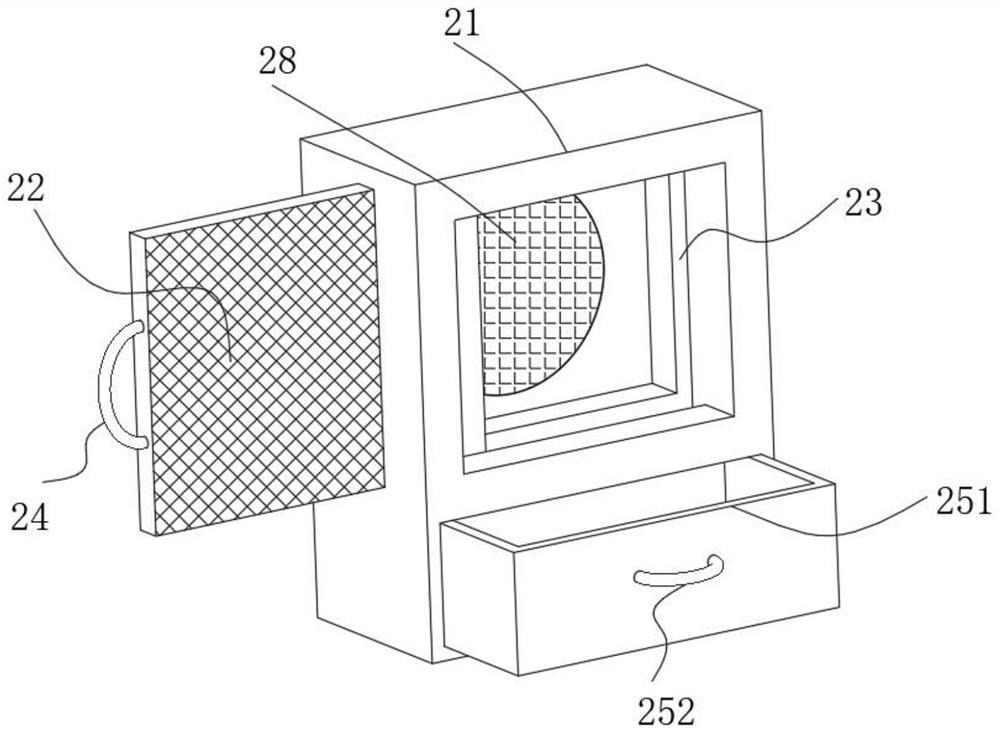

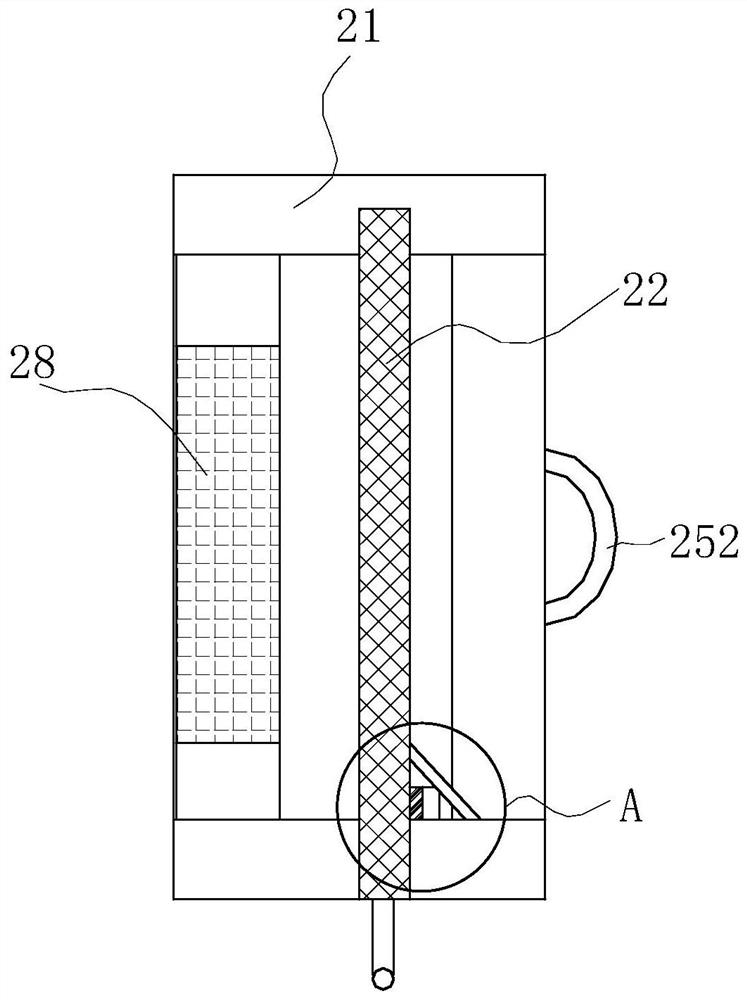

Multi-station numerical control lathe

PendingCN113352138AEasy to cleanAvoid dust phenomenonMaintainance and safety accessoriesNumerical controlStructural engineering

The invention relates to the technical field of numerical control lathes, in particular to a multi-station numerical control lathe which comprises a numerical control lathe body, a dustproof mechanism is arranged at the front end of the numerical control lathe body and comprises an extension frame, a filter layer is movably connected into one end of the extension frame, and a sliding groove is formed in the outer side of the filter layer in the extension frame. A first handle is fixedly connected to one end of the filter layer, a collecting mechanism is arranged on the lower side of the front end of the extension frame and comprises a collecting drawer, a second handle is fixedly connected to the front end of the collecting drawer, and a containing cavity is formed in the lower side of the front end of the extension frame and located outside the collecting drawer. According to the multi-station numerical control lathe, dust on the surface of the filter layer can be quickly cleared cleanly through a scraper and a hair brush, scrap iron adsorbed to the filter layer is adsorbed out through soft mud, the dust can be collected together through the collecting drawer, and the dust in the collecting drawer is poured into a collecting bag, thus the dust raising phenomenon can be avoided, and the lathe is practical.

Owner:梁聪

Environment-friendly dust-free vibration screen

InactiveCN108188027AImprove air qualityAvoid dust phenomenonCombination devicesSievingRotational axisInlet channel

An environment-friendly dust-free vibration screen comprises a machine frame, a vibration screen body, a dedusting assembly and a grain conveying assembly. Travelling wheels are mounted at the bottomof the machine frame. An outer shell is arranged on the upper portion of the machine frame. A spiral screen cloth is horizontally mounted in the outer shell. A rotary shaft is mounted in the spiral screen cloth. One end of the rotary shaft is connected with a driving motor. The rotary shaft is driven by the driving motor to rotate, and thus the spiral screen cloth is driven to rotate. A grain feeding hopper is connected with one end of the spiral screen cloth. The vibration screen body is arranged on the lower portion of the outer shell. The grain feeding inlet end face of the vibration screenbody communicates with the spiral screen cloth in the outer shell through a grain inlet channel, and thus pure grain falling down from the spiral screen cloth can fall onto the vibration screen body.A big impurity channel is arranged at the front end of the spiral screen cloth. The vibration screen body is obliquely arranged. A grain outlet channel is arranged at the lower end of the vibration screen body. The dedusting assembly is connected to the upper portion of the grain outlet channel. The grain conveying assembly is arranged on the lower portion of the grain outlet channel. The screened pure grain can be sent to assigned places through the grain conveying assembly.

Owner:界首市金龙机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com