Environment-friendly dust-free vibration screen

A vibrating sieve, environmental protection technology, applied in the direction of filter screen, grille, separating solids from solids with air flow, etc., can solve the problems of small workload, inability to drop grain, complex structure, etc., achieve good effect and solve dust Phenomenon, the effect of improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

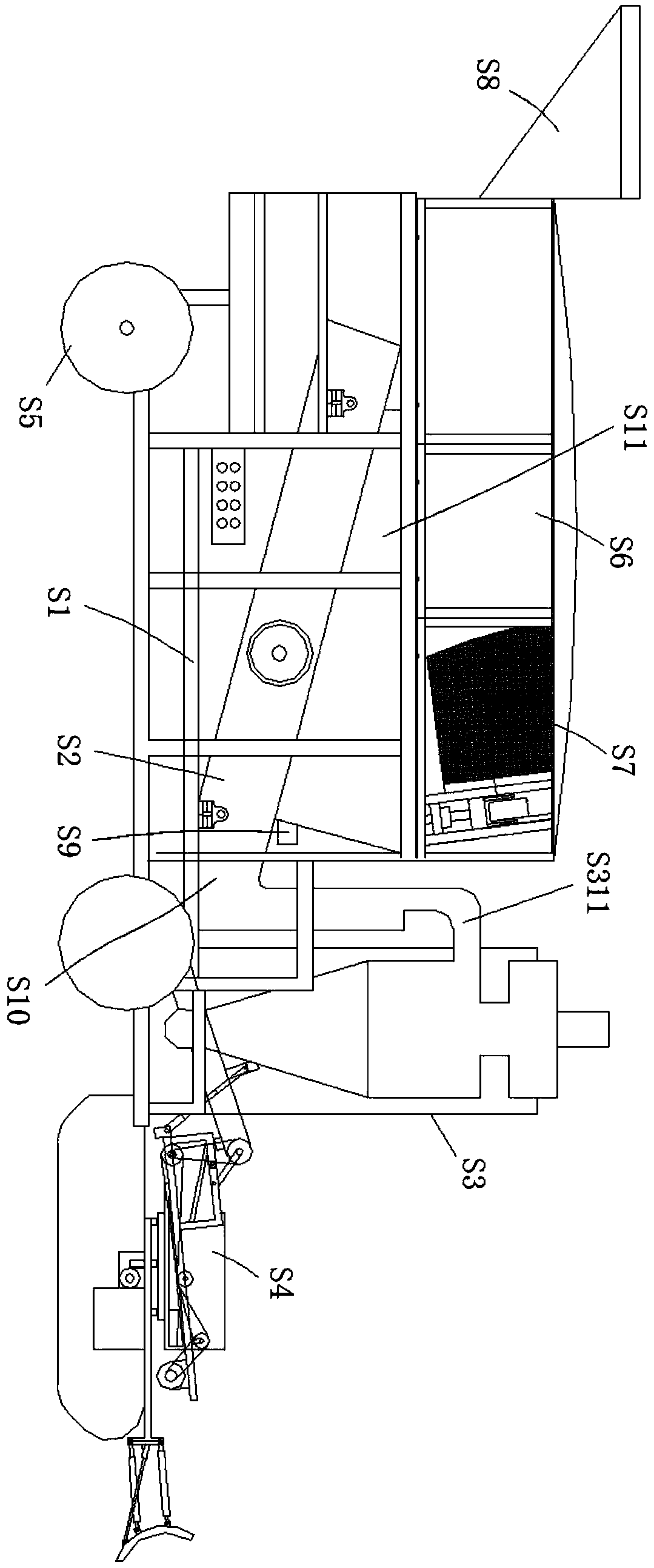

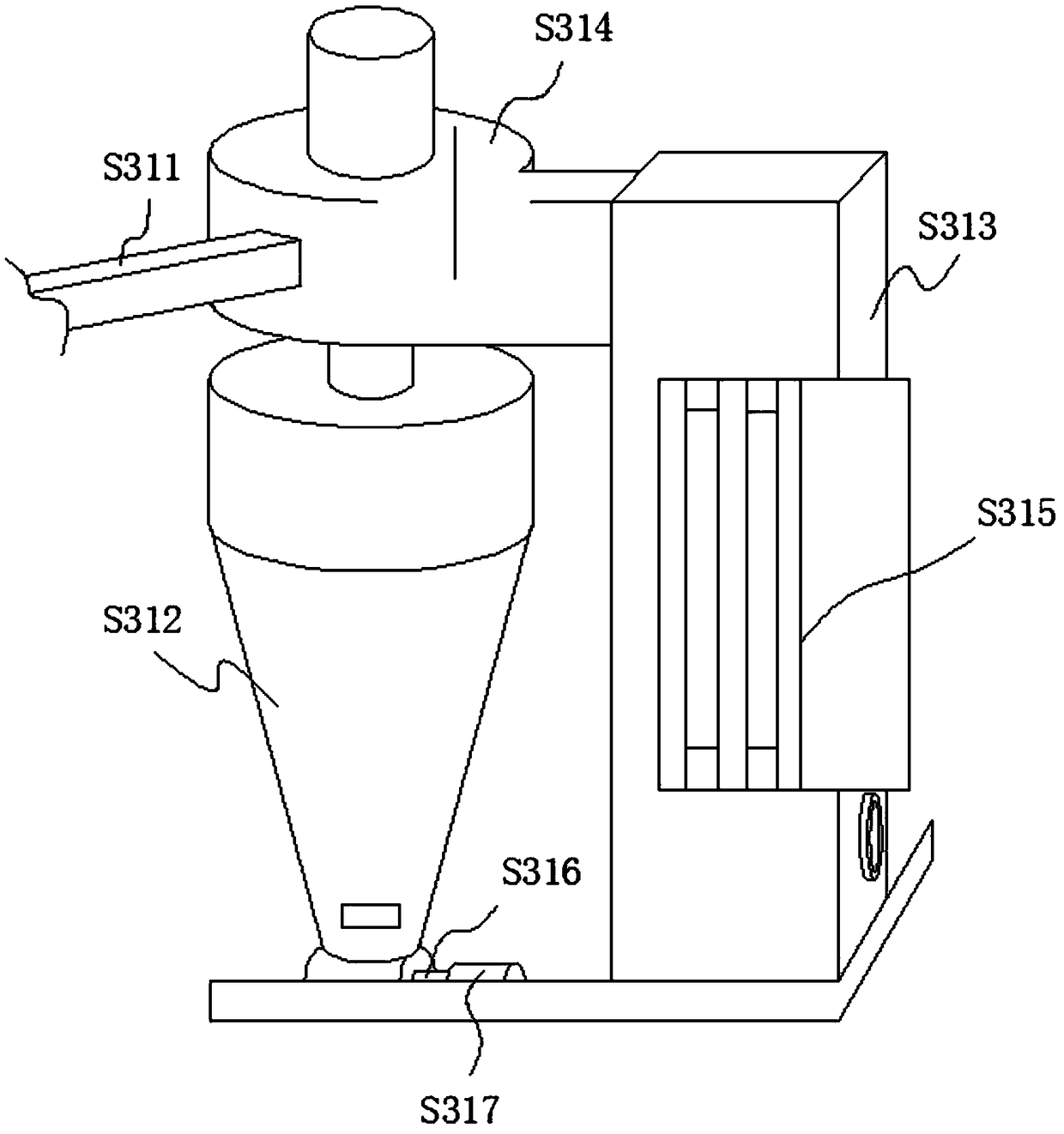

[0041] see figure 1 , an environment-friendly dust-free vibrating screen, comprising: a frame S1, a vibrating screen S2, a dust removal assembly S3 and a grain transportation assembly S4, the bottom of the frame S1 is equipped with a walking wheel S5, and the upper part of the frame S1 is provided with Outer shell S6, a spiral screen S7 is horizontally installed in the outer shell S6, a rotating shaft is installed in the spiral screen S7, a driving motor is connected to one end of the rotating shaft, and the driving motor drives the rotating shaft to rotate, thereby driving The spiral screen S7 rotates, and one end of the spiral screen S7 is connected with a grain feeding hopper S8, the vibrating screen S2 is arranged under the outer shell S6, and the grain feeding end surface of the vibrating screen S2 passes through the grain feeding channel S11 and the outer shell. The spiral screen S7 in the body S6 is connected, so that the clean grain falling from the spiral screen S7 ca...

Embodiment 2

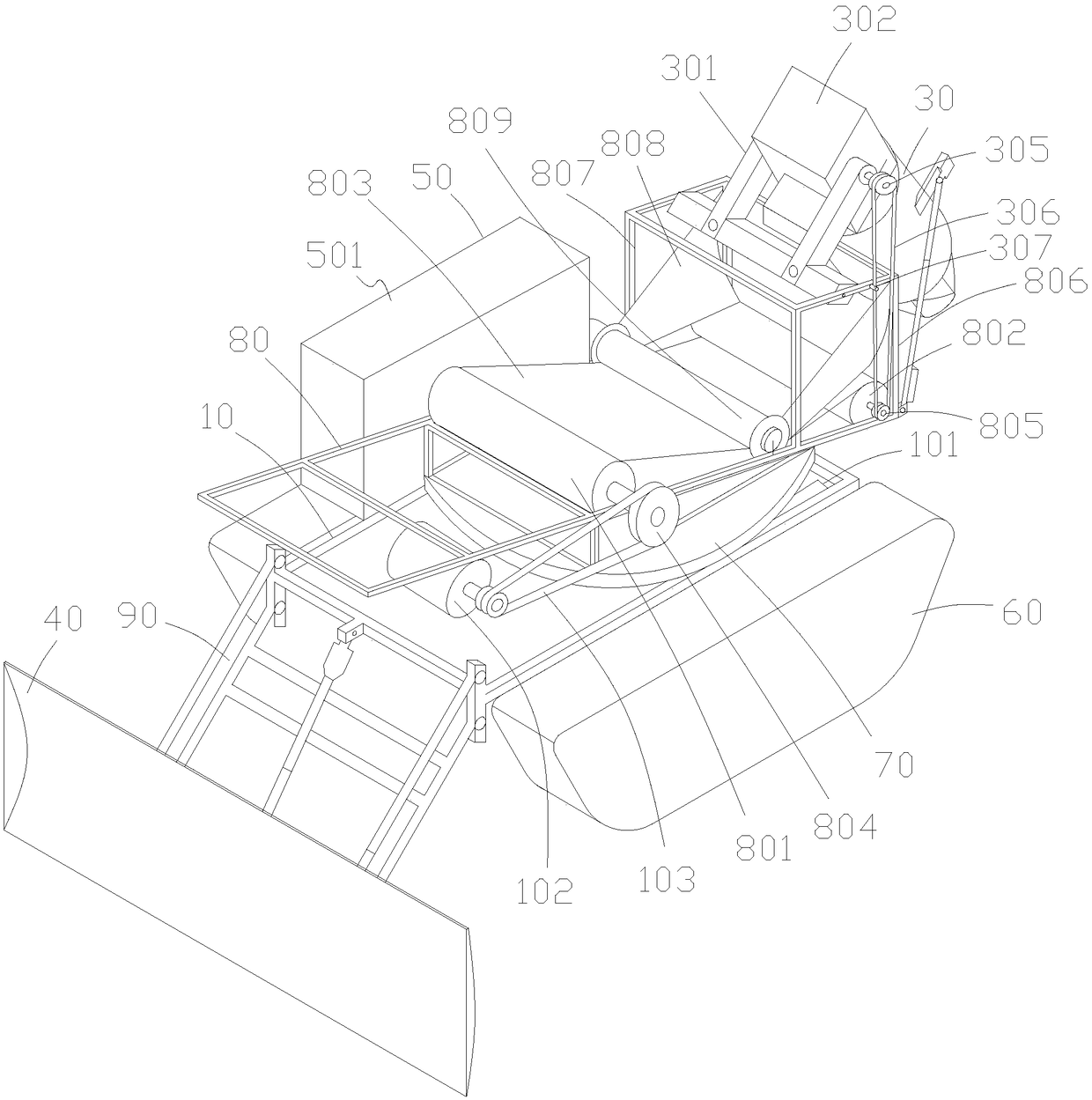

[0044] see Figure 3-7 , on the basis of Embodiment 1, the grain transport assembly is improved, wherein the grain transport assembly includes: an underframe assembly 10, a first drive motor 101, a grain transport auger 30, a grain push shovel 40, a control system 50 and the driving wheel 60, the control system 50 is installed in a box body 501, and the box body 501 is fixed on the upper position of one side of the chassis assembly 10, and the chassis assembly 10 is made of aluminum alloy and has a square structure; the first The driving motor 101 is installed at the bottom of the chassis assembly 10, and the driving wheels 60 are installed on both sides of the chassis assembly 10, and the driving wheels 60 are powered by the first driving motor 101. The driving wheels 60 adopt a crawler structure, and the power is strong. The driving is barrier-free, and the track is a rubber track, which will not crush the grain. A turntable 70 is installed on the chassis assembly 10, and a...

Embodiment 3

[0057] On the basis of embodiment 2, the control system is designed as a remote control type, the control system includes a remote controller, an infrared receiver and a processor, the infrared receiver and the processor are installed in the box, the infrared emitter in the remote controller and the infrared The receiver communicates through infrared rays, the infrared receiver is connected to the processor, and the processor is connected to the first drive motor, the second drive motor, the first push rod motor and the second push rod motor to realize remote control operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com