Fuel-resistant anti-static oil delivery pipe

An antistatic and fuel-resistant technology, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of difficult handling of pipe joints, complex production process, high mold requirements, etc., and achieve low cost and simplified manufacturing process , good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

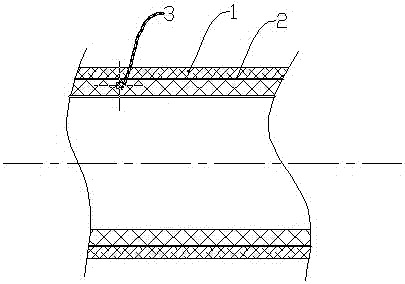

[0034] Embodiment 1: a fuel-resistant antistatic pipeline, the pipeline has three layers from the outside to the inside in the radial direction, which are a reinforcement layer, an adhesive layer, and an oil-resistant antistatic layer in turn; the reinforcement layer is a polyethylene material; the oil-resistant antistatic layer is an oil-resistant antistatic layer. Antistatic polymer composites.

[0035] The polymer composite material of the oil-resistant and antistatic layer is mainly composed of a mixture of 65 parts by weight of ethylene-vinyl alcohol copolymer, 30 parts of carbon black and carbon nanotubes (mass ratio of 1:1), 5 parts of polyurethane. The preparation method of the material is as follows: first, the graphene and carbon nanotube conductive powder materials are mixed uniformly in proportion; second, the conductive powder mixture is chemically modified with sulfuric acid and polyhydric alcohol to form hydroxyl functional groups on the surface thereof. 3. Mix...

Embodiment 2

[0036] Embodiment 2: a fuel-resistant antistatic pipeline, the pipeline has three layers from the outside to the inside in the radial direction, which are a reinforcement layer, an adhesive layer, and an oil-resistant antistatic layer in turn; the reinforcement layer is a polyethylene material; the oil-resistant antistatic layer is an oil-resistant antistatic layer. Antistatic polymer composites.

[0037]The polymer composite material of the oil-resistant antistatic layer is mainly composed of 65 parts by weight of ethylene-vinyl alcohol copolymer and polyphenylene sulfide (mass ratio is 4:1); 22 parts of carbon powder, carbon nano A mixture of tubes, graphite, graphene and Ketjen black (mass ratio 1:1:0.5:1:0.5); 8 parts of polyurethane. The preparation method of the material is as follows: 1. Mix carbon powder, carbon nanotubes, graphite, graphene and Ketjen black conductive powder materials evenly according to the ratio of parts by weight; 2. Mix the conductive powder mixtu...

Embodiment 3

[0038] Embodiment 3: A fuel-resistant antistatic pipeline, the pipeline has three layers radially from outside to inside, followed by a reinforcement layer, an adhesive layer, and an oil-resistant and antistatic layer; wherein the reinforcement layer is made of polyvinyl chloride; the oil-resistant and antistatic layer is Oil resistant and antistatic polymer composite material.

[0039] The polymer composite material of the oil-resistant antistatic layer is mainly composed of 75 parts by weight of ethylene-vinyl alcohol copolymer, polyether ether ketone, polyphenylene sulfide, polytetrafluoroethylene (mass ratio is 2:0.5 :0.5:0.2); 25 parts of a mixture of carbon powder, carbon nanotubes and Ketjen black (mass ratio is 1:0.8:0.2); 8 parts of carbodiimide polymer (such as N,N'-di isopropylcarbodiimide). The preparation method of the material is as follows: 1. Mix carbon powder, carbon nanotubes and ketjen black conductive powder materials evenly according to the ratio of parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com