Coal ash bulk device

A bulk device, fly ash technology, applied in transportation and packaging, loading/unloading, etc., can solve problems such as excessive material, dust pollution, complicated operation, etc., to purify the working environment, solve the phenomenon of dust, and reduce operation and maintenance costs Effect

Inactive Publication Date: 2017-10-17

JIANGSU ZHONGNENG POWER EQUIP

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] When people transport some bulk dry powder and granular materials, they need to be loaded into vehicles. Most of the existing methods are to set up feeding pipes, dust suction fans and material switch doors. The structure of such equipment is too simple. , when used, it is mainly operated manually, the operation is complicated, and the feeding pipe is not closely matched with the loading port of the car. The material loading needs to be observed manually with the naked eye. If the control is not good, there may be too much material and the vehicle cannot be loaded. Need At the same time, it will also cause the problem of low vehicle loading efficiency and serious dust pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

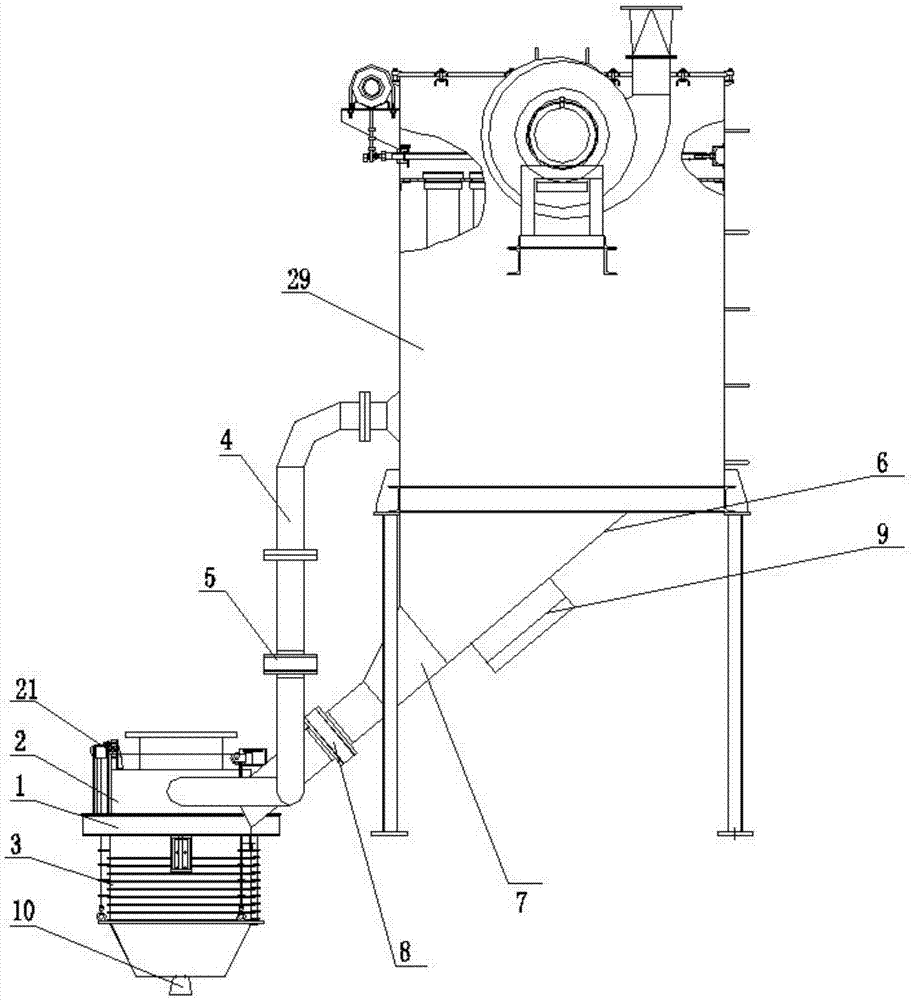

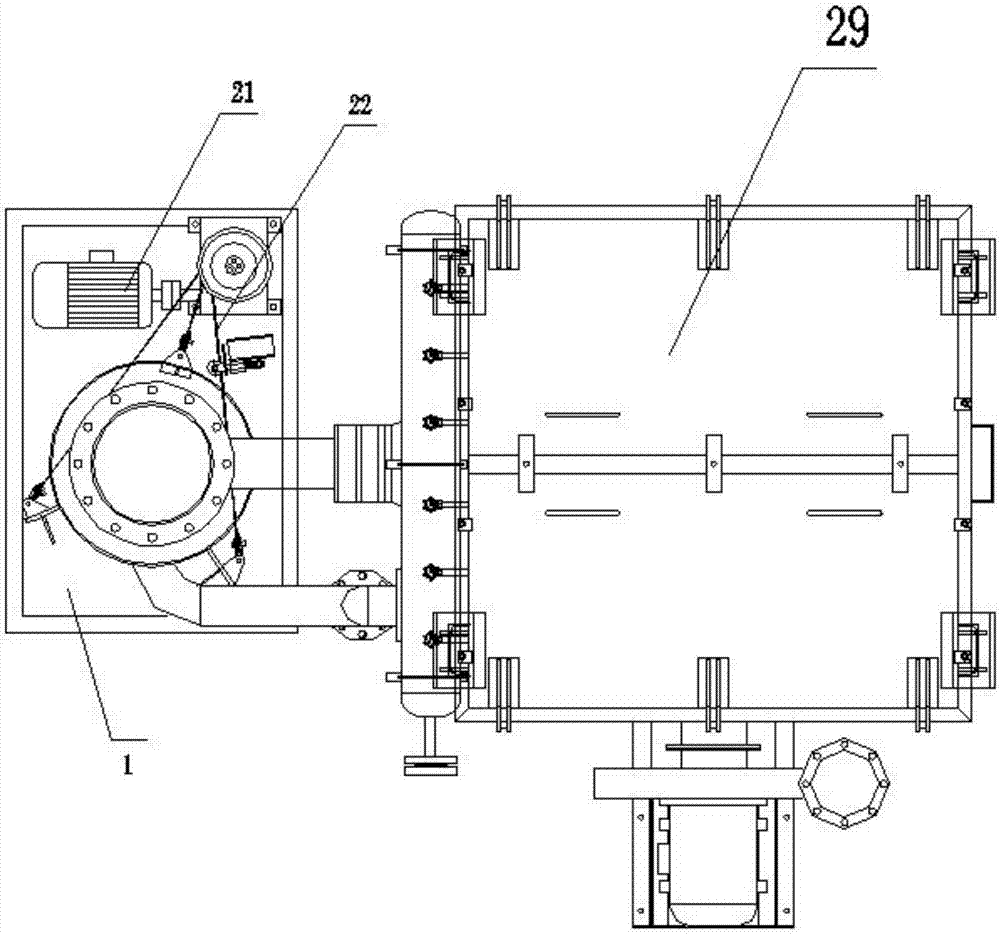

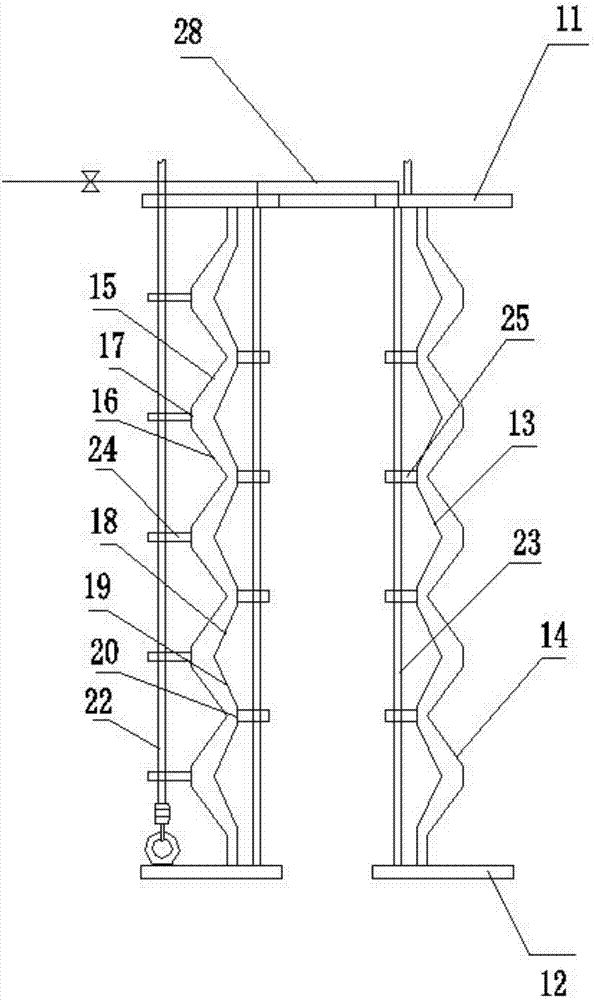

The invention relates to a coal ash bulk device. The coal ash bulk device comprises a base, a bulk machine body, a telescopic pipe and a cloth bag dust remover. The bulk machine body is fixed on the base, the telescopic pipe is arranged under the base and connected with the bulk machine body, and the bulk machine body is connected with the cloth bag dust remover through a first pipeline; a manual butterfly valve is arranged on the first pipeline, a lower box body of the cloth bag dust remover is connected with the bulk machine body through a second pipeline, and a pneumatic gate valve is arranged on the second pipeline; a vibrator is arranged on the lower box body, the telescopic pipe is a double sleeving pipe, and a material detaching head is arranged at the bottom of the telescopic pipe. According to the coal ash bulk device, a problem of dust raising generated during ash unloading of an ash bin is solved, working environment of a loading area is purified, and running and maintaining cost are reduced.

Description

technical field [0001] The invention relates to a bulk packing device, in particular to a fly ash bulk packing device. Background technique [0002] When people transport some bulk dry powder and granular materials, they need to be loaded into vehicles. Most of the existing methods are to set up feeding pipes, dust suction fans and material switch doors. The structure of such equipment is too simple. , when used, it is mainly operated manually, the operation is complicated, and the feeding pipe is not closely matched with the loading port of the car. The material loading needs to be observed manually with the naked eye. If the control is not good, there may be too much material and the vehicle cannot be loaded. Need At the same time, it will also cause the problems of low vehicle loading efficiency and serious dust pollution. Contents of the invention [0003] Aiming at the above problems, the present invention proposes a fly ash bulk packing device, which solves the dust...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G67/04B65G67/60B65G69/18

CPCB65G67/04B65G67/606B65G69/181

Inventor 丁为平陈太文高志翔

Owner JIANGSU ZHONGNENG POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com