Patents

Literature

60results about How to "No dust phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust-depressor and preparation thereof

InactiveCN101412903AThe formula is scientific and reasonableSimple recipeOther chemical processesCarboxymethyl celluloseSocial benefits

The invention relates to a dust inhibitor, in particular to a dust inhibitor with remarkable dust inhibiting effect and a preparation method thereof, and belongs to the technical field of controlling environment pollution. The dust inhibitor comprises the following components in weight portion: 91.5 to 99.29 portions of water, 0.5 to 5 portions of polyvinyl alcohol re-dispersible gelatin powder, and 0.2 to 3 portions of carboxymethyl cellulose. The preparation method comprises the following steps: adding the polyvinyl alcohol re-dispersible gelatin powder and the carboxymethyl cellulose into a container according to the weight portion, fully stirring and mixing the mixture; and slowly adding the water into the mixed powder and stirring the mixture to dissolve fully, and obtaining the finished product of the dust inhibitor. The dust inhibitor has the advantages of no toxicity, no harm, no corrosiveness, scientific and reasonable formulation, simple preparation technology, low cost, safety, environmental protection and energy conservation; when the dust inhibitor is sprayed on the surface of a material, continuous hard shells can be formed on the surface and have certain strength, and the scattered material is sealed under the hard shells, so the dust inhibitor has dust-proof function; and the dust inhibitor has extensive economic and social benefits.

Owner:肖海燕

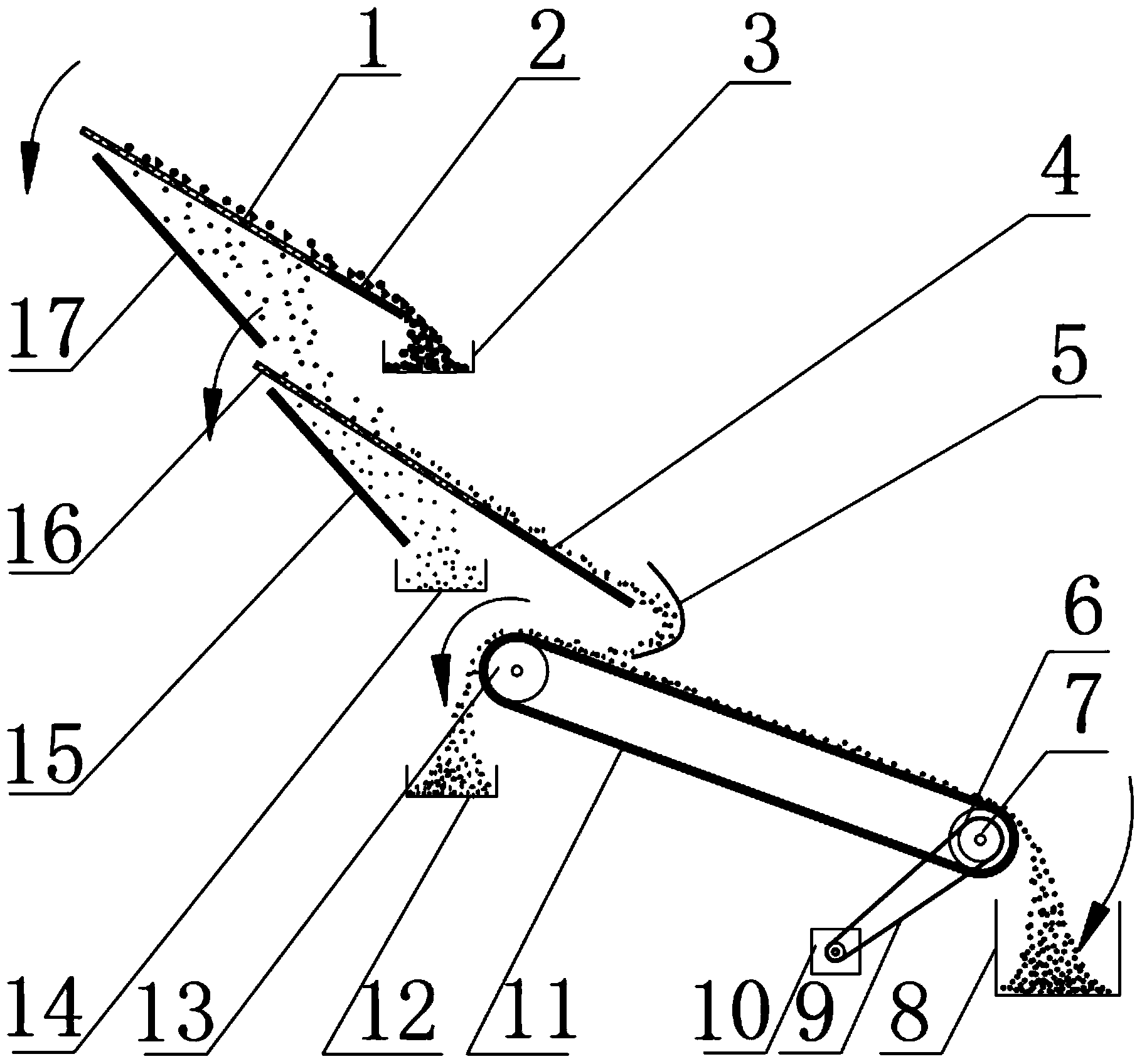

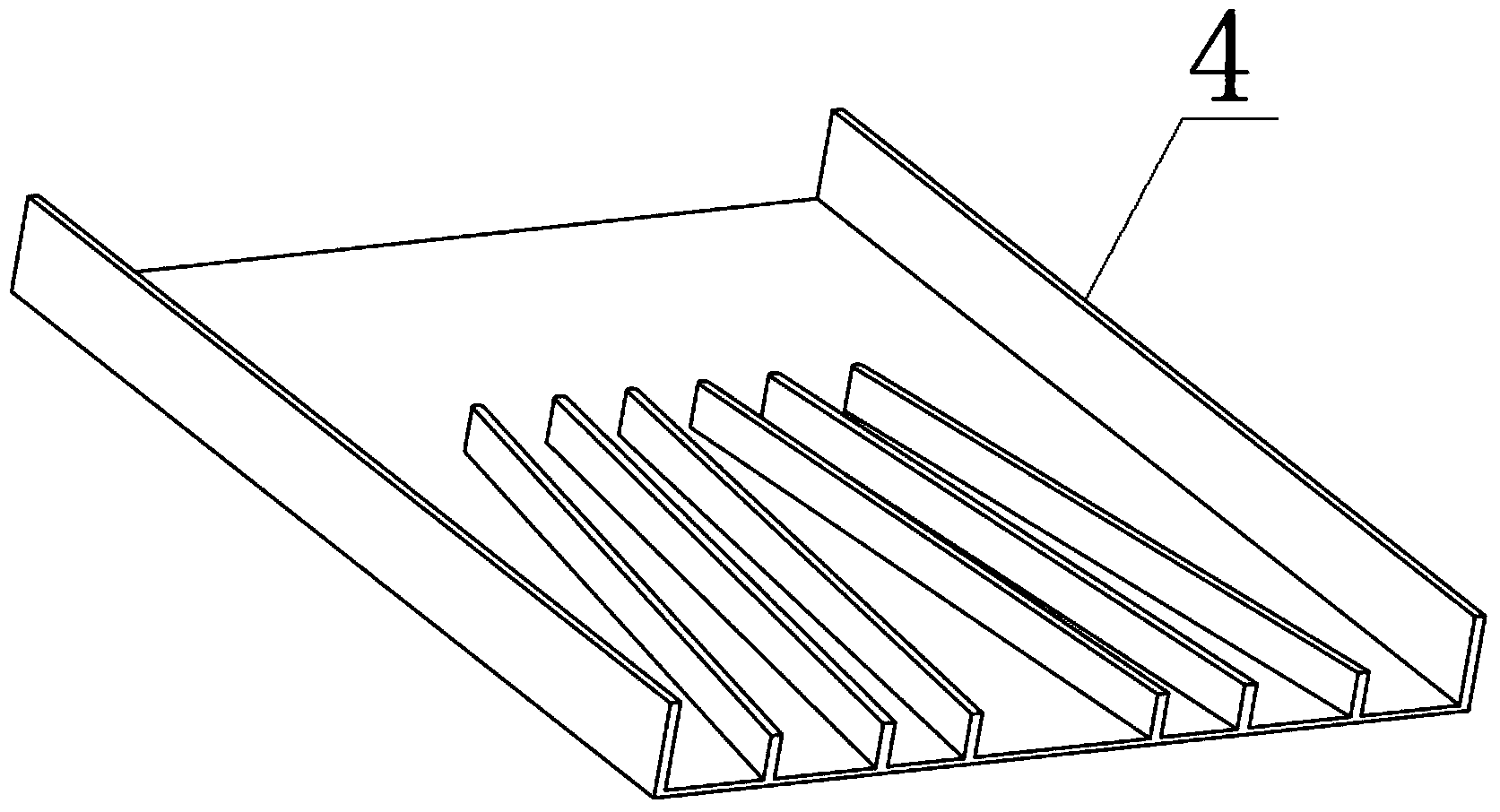

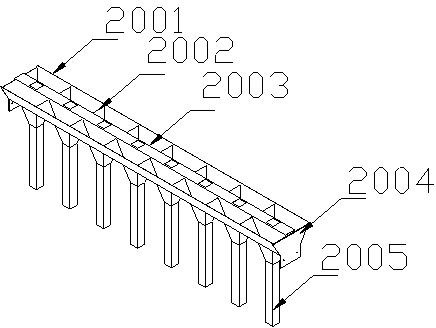

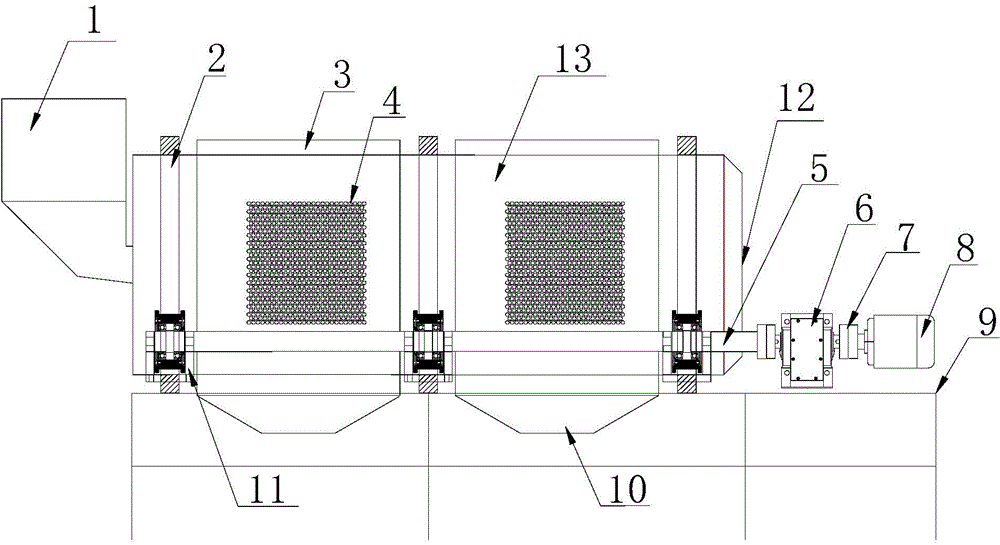

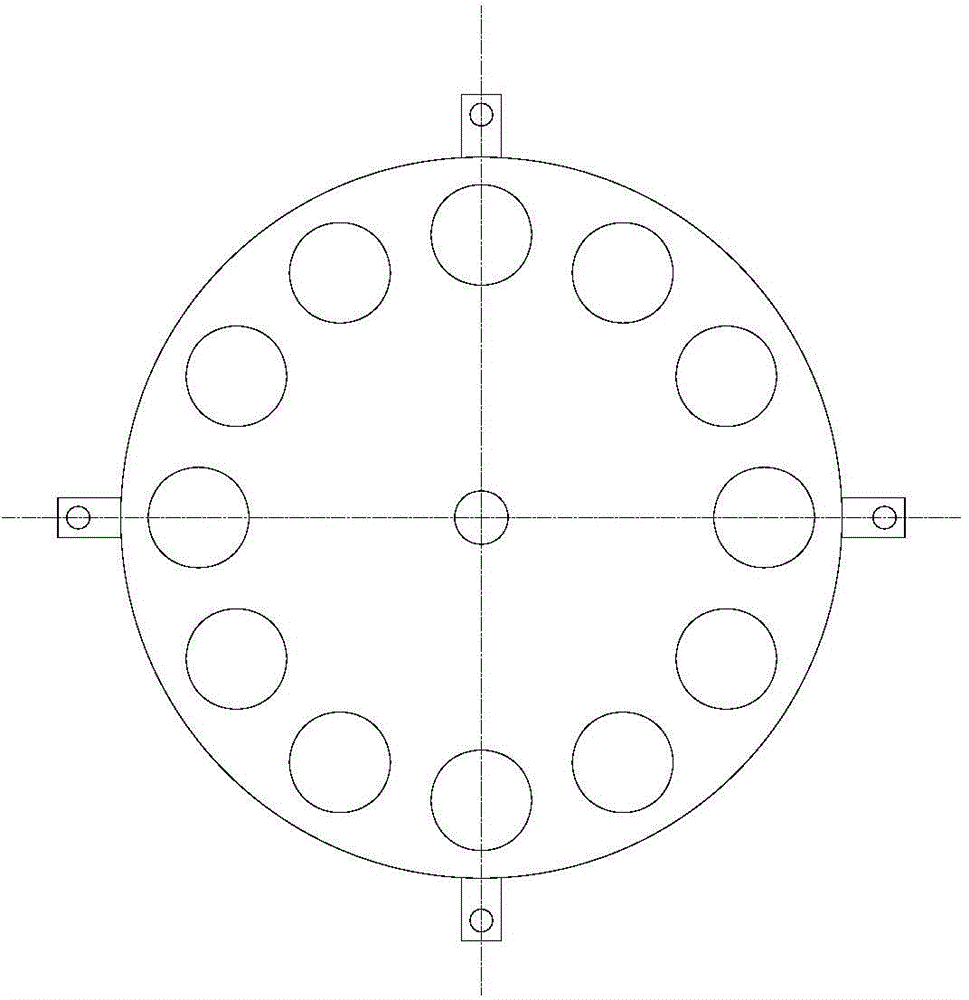

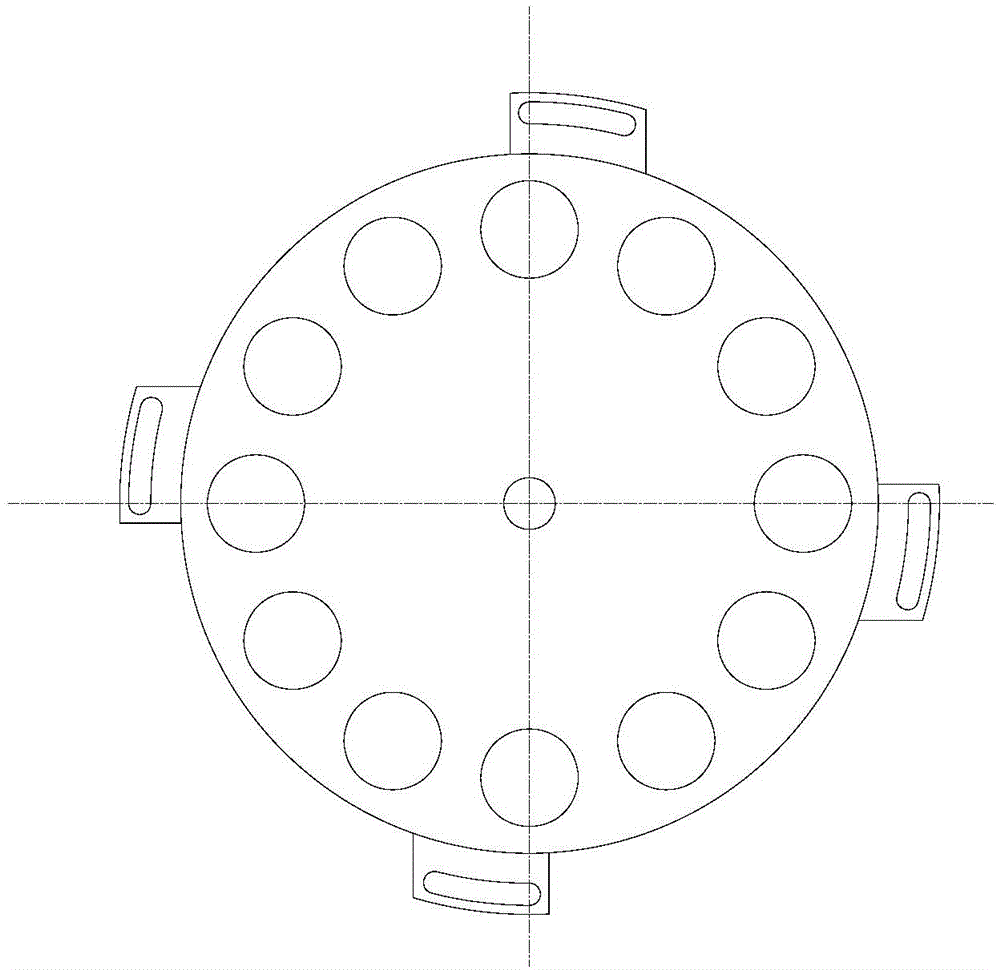

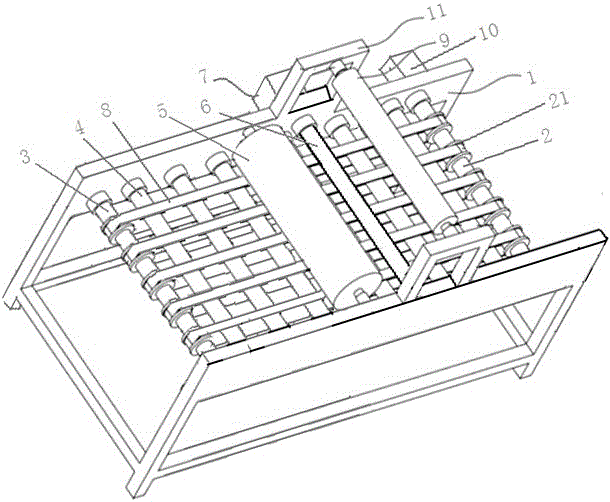

Abrasive screening machine allowing granularity to be adjustable

The invention provides an abrasive screening machine allowing the granularity to be adjustable, and belongs to the technical field of machinery. The abrasive screening machine is characterized in that a fine sieve is located below a coarse sieve, and a conveying belt is located at the tail end of the fine sieve. Abrasive grains are selected through the coarse sieve, and the abrasive grains with the sizes being larger than required sizes are removed; the abrasive grains are selected through the fine sieve, the abrasive grains with the sizes being smaller than the required sizes are removed, and the abrasive grains with the sizes meeting requirements are selected; the abrasive grains are screened through the reverse conveying belt, cracked abrasive grains with poor circularity are removed, and plump abrasive grains with good circularity are selected under the action of gravity. The mesh number of the coarse sieve and the mesh number of the fine sieve of the screening machine can be changed according to requirements, the inclined angle of the coarse sieve and the inclined angle of the fine sieve can be adjusted according to different abrasive grains, and the inclined angle and conveying speed of the conveying belt can be adjusted according to different selection requirements. The abrasive screening machine achieves selection of the abrasive grains with the sizes and circularity meeting requirements, and is convenient to use, reliable and beneficial for improving screening quality and efficiency of the abrasive grains.

Owner:DALIAN UNIV OF TECH

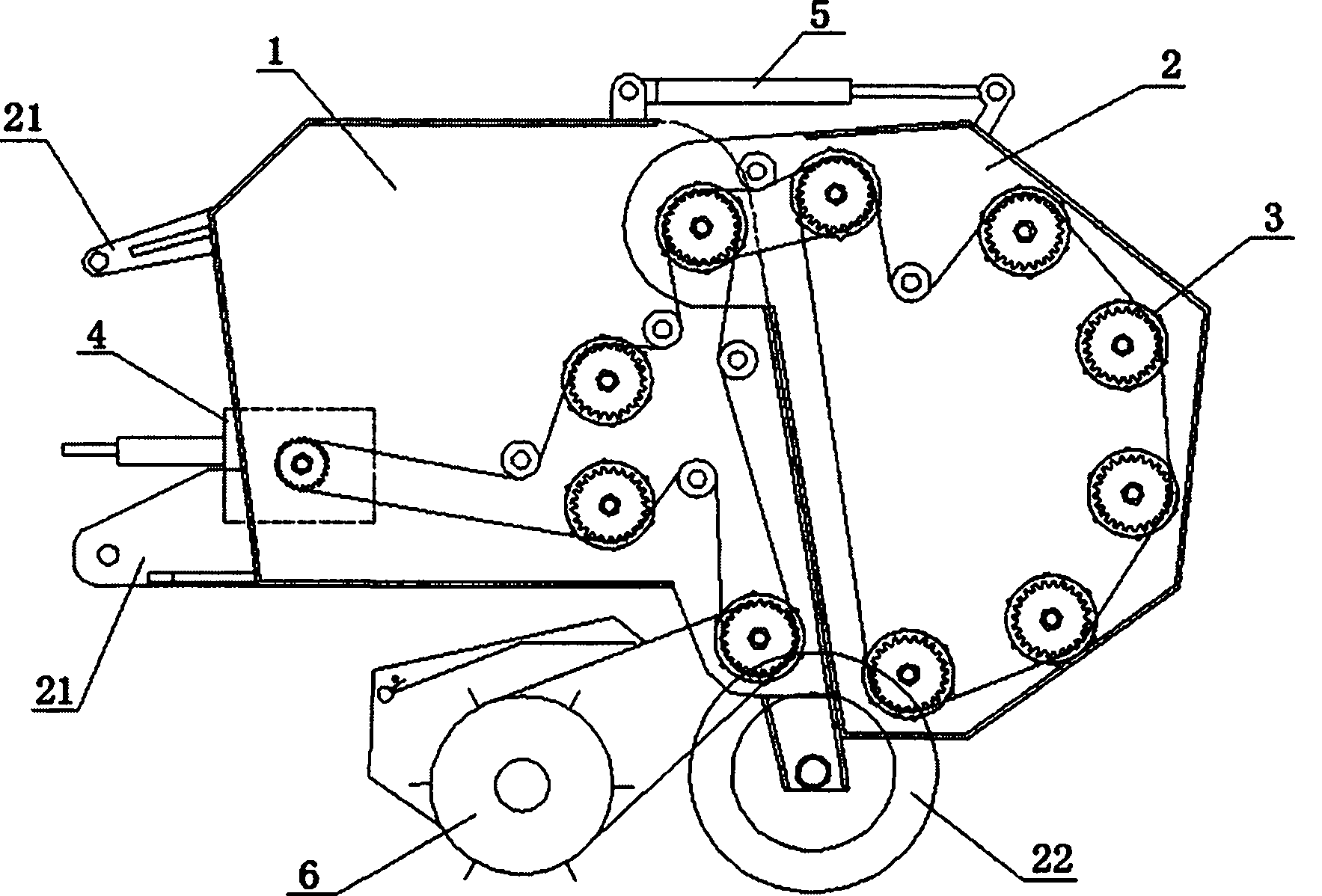

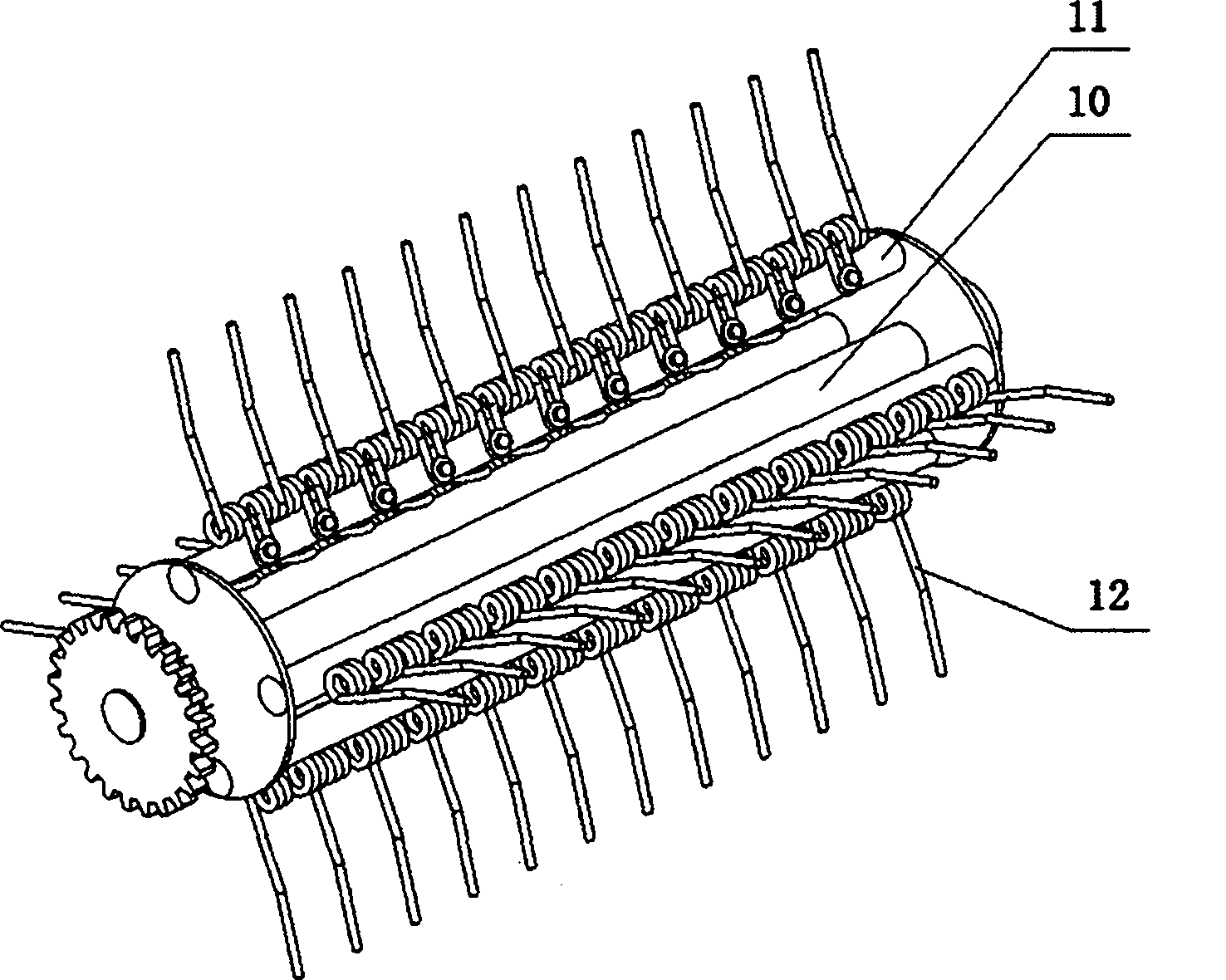

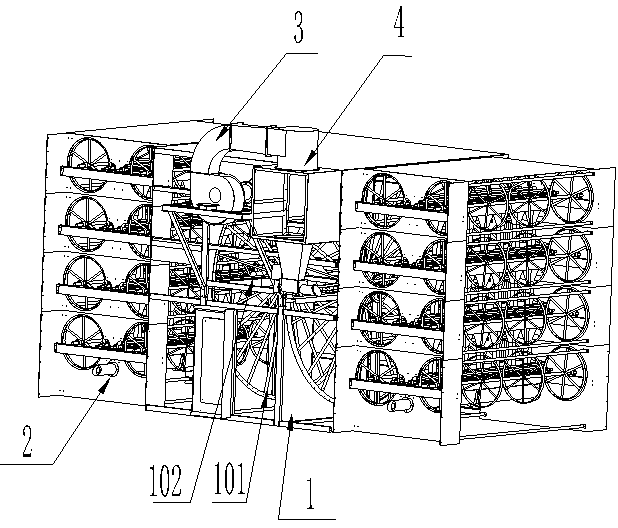

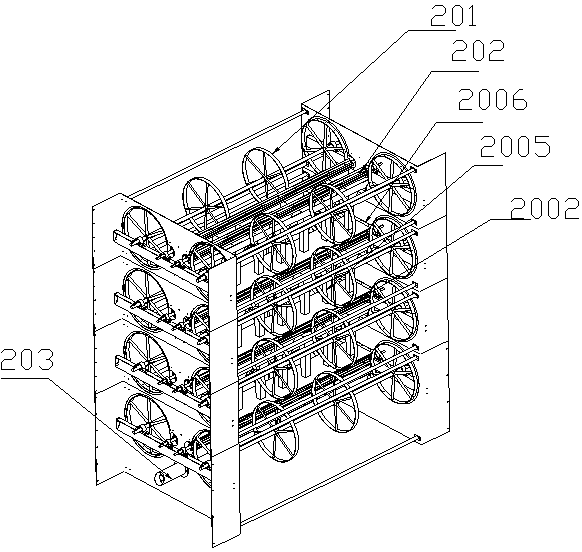

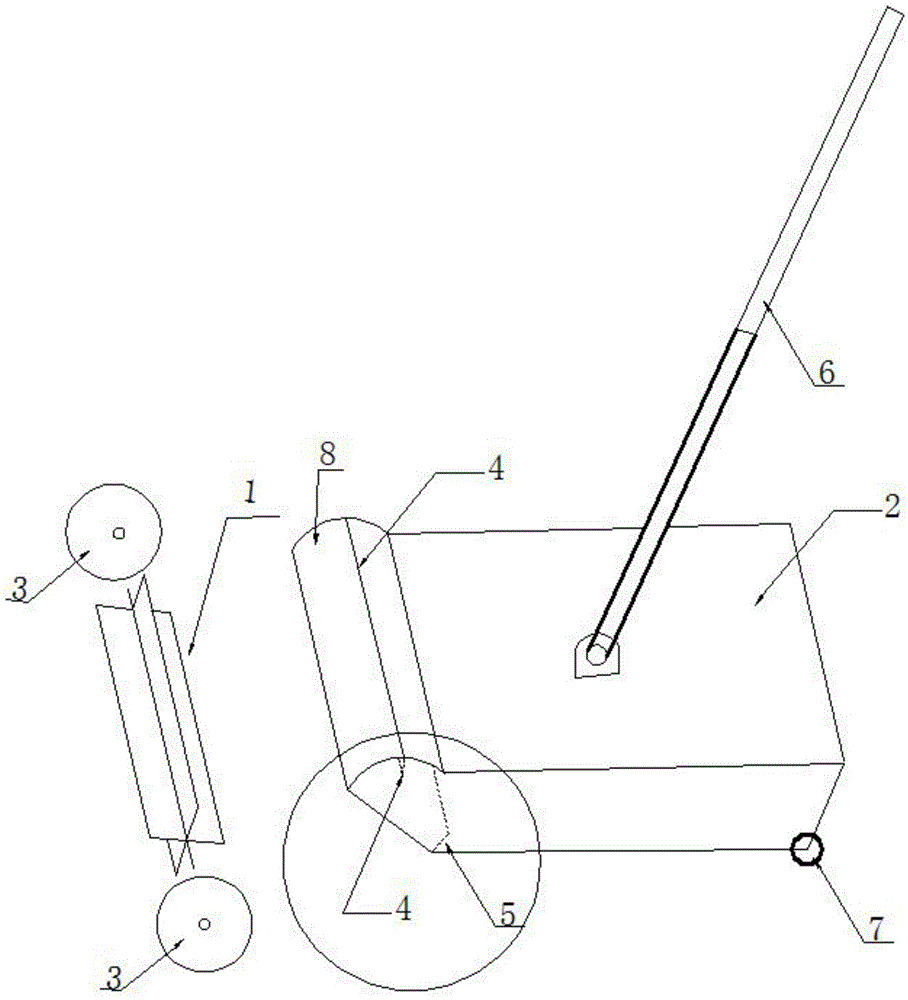

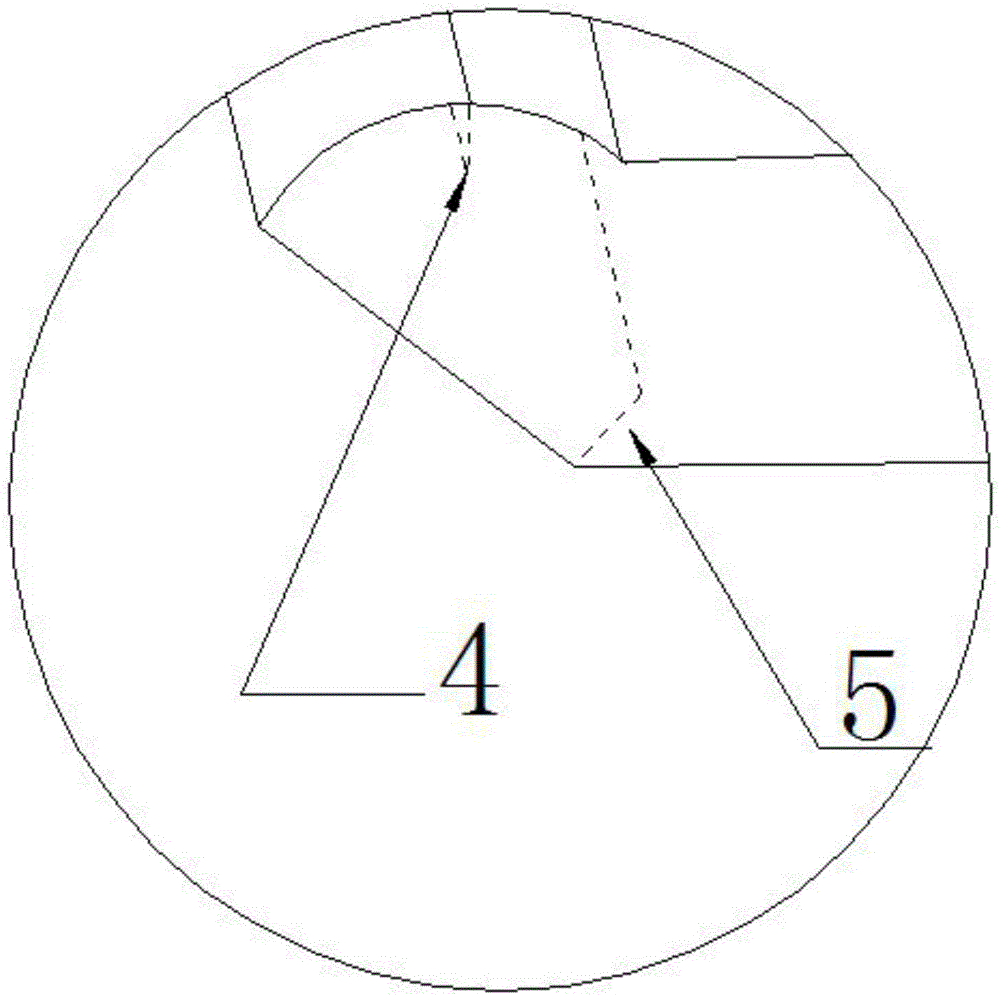

Bundling machine for picking up straws and plastic film residues

InactiveCN104137669ASmall density gradientEasy to useBalingGatherer machinesHydraulic cylinderEngineering

The invention discloses a bundling machine for picking up straws and plastic film residues. The bundling machine comprises a machine body, a picking-up device and a power transmission mechanism. The machine body is composed of a front machine body and a rear machine body, wherein the front machine body and the rear machine body are hinged together. A plurality of bundling roller wheels are annularly distributed on the front machine body and the rear machine body. A bundling chamber is defined by the bundling roller wheels. The power transmission mechanism comprises a gearbox driven by a haulage motor, and the gearbox drives the bundling roller wheels to rotate and drives the picking-up device to work through chains. A hydraulic cylinder driving the bundling chamber to be opened and closed is installed between the front machine body and the rear machine body. The picking-up device is installed on the lower portion of the front machine body and can replace an installed straw picking-up device and an installed plastic film residue picking-up device. The bundling machine is simple and reasonable in structure, low in manufacturing cost, multifunctional, capable of picking up and bundling the straws or the plastic film residues, small in needed power, and capable of being pulled by a small agricultural tractor to work.

Owner:柳志刚

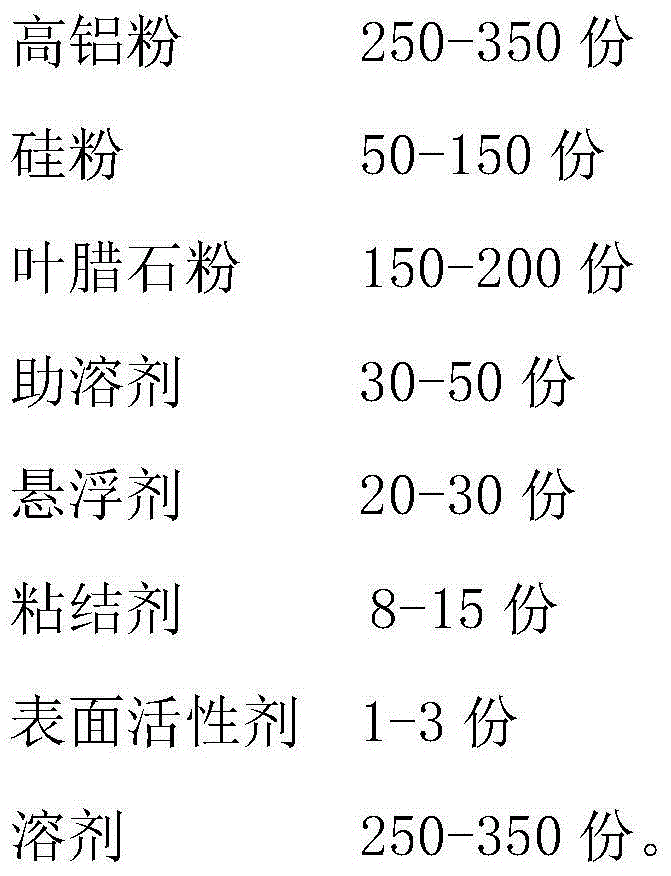

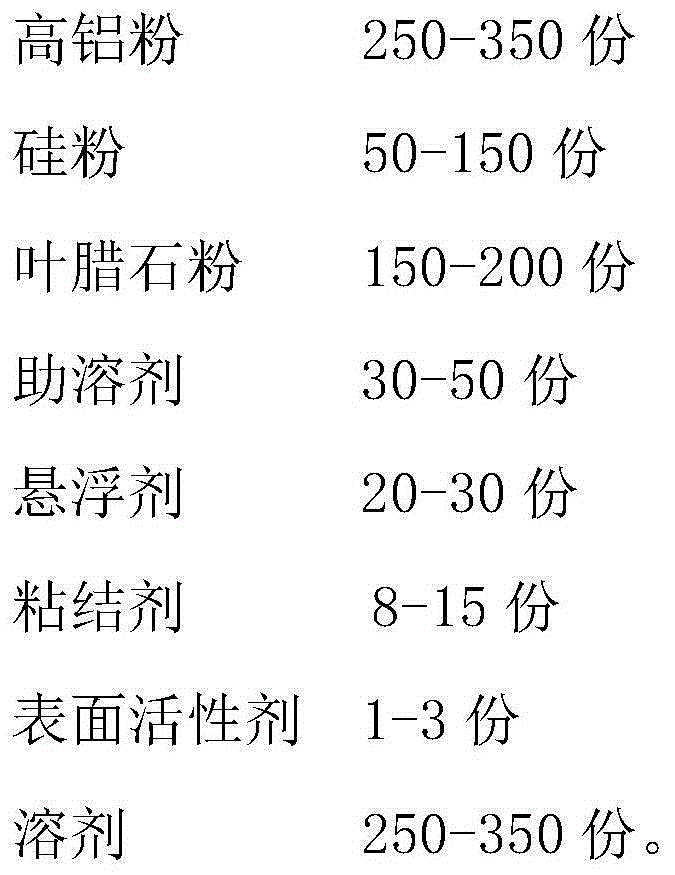

Environment-friendly alcohol group ceramic casting coating

ActiveCN104439049AGood sintering peeling propertiesImprove peeling effectFoundry mouldsFoundry coresSolventAluminium

The invention provides an environment-friendly alcohol group ceramic casting coating. The environment-friendly alcohol group ceramic casting coating comprises, by weight, 250-350 parts of high-alumina powder, 50-150 parts of silica powder, 150-200 parts of pyrophillite powder, 30-50 parts of cosolvent, 20-30 parts of suspending agents, 8-15 parts of binding agents, 1-3 parts of surfactant and 250-350 parts of solvent. The environment-friendly alcohol group ceramic casting coating overcomes the defects in the prior art and is high in refractoriness, good in sintering stripping effect, low in price and excellent in comprehensive performance.

Owner:TIANJIN NINGKANG TECH

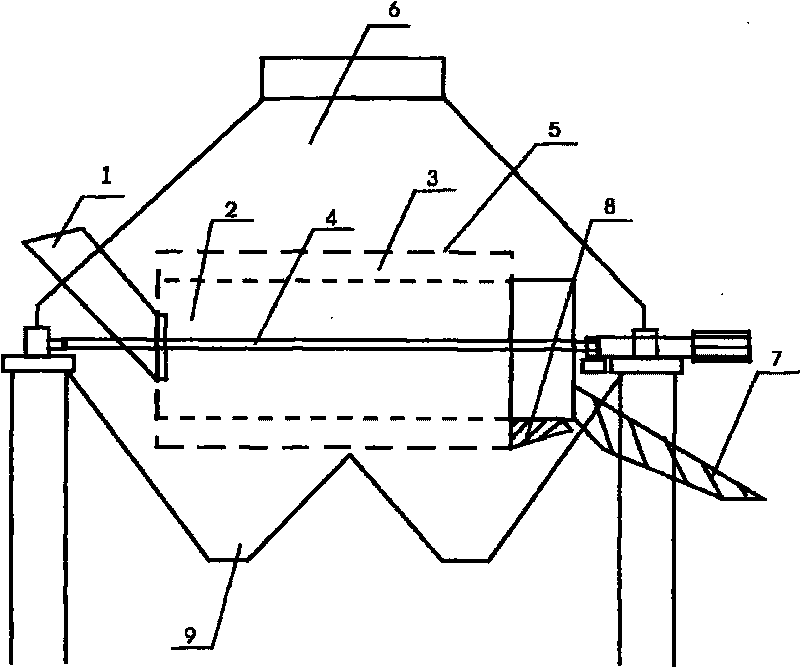

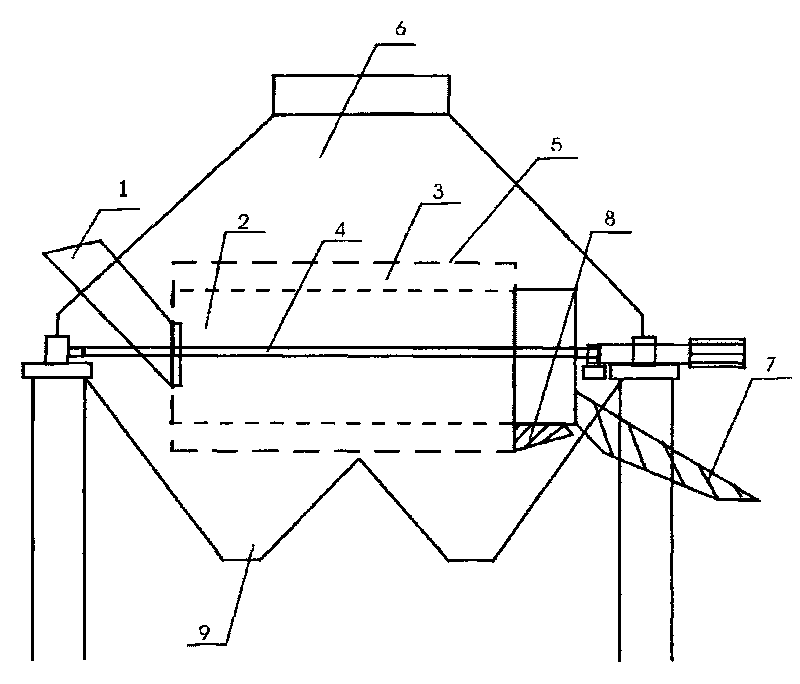

Screening and separating machine for granular materials

The invention relates to a screening and separating machine for granular materials, which comprises a feed hopper, an internal screen drum, an external screen drum, a rotating shaft, a tail discharge hopper, a lateral discharge hopper, a bottom discharge hopper and a dust hood, wherein the internal and external screen drums are provided with screen holes or screen cloth, and the feed hopper is communicated with the internal screen drum; the internal screen drum is positioned in the external screen drum and is connected to a rotating shaft together with the external screen drum; the tail discharge hopper is arranged below the tail part of the internal screen drum; the lateral discharge hopper is arranged below the tail part of the external screen drum; the bottom discharge hopper is positioned below the external screen drum and the internal screen drum; and the upper parts of the internal and external screen drums are positioned in the dust hood. The machine has the advantages that: mechanical operation is realized; various metal or non-metal materials with different particle sizes can be screened and separated at one time; the working efficiency is high; less workers are needed; the production cost is reduced; the design is reasonable; the noise is low; dust rise is avoided basically; and environmental-protection and production requirements are met.

Owner:胡永胜

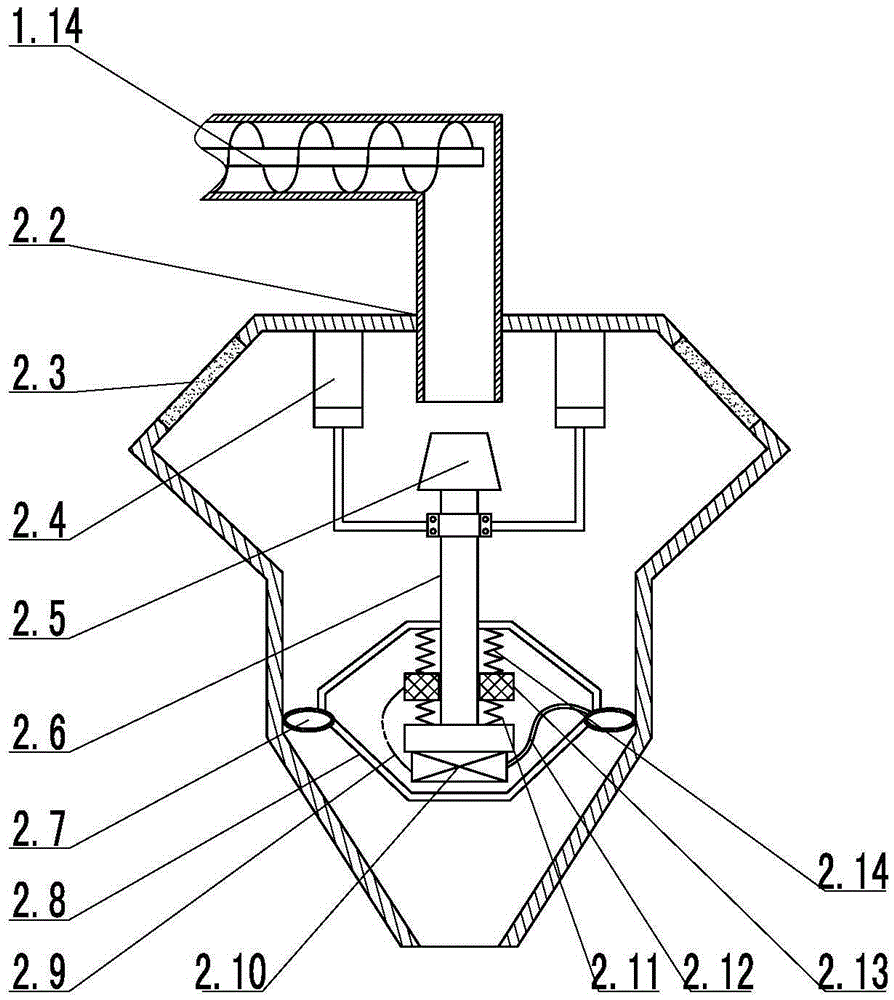

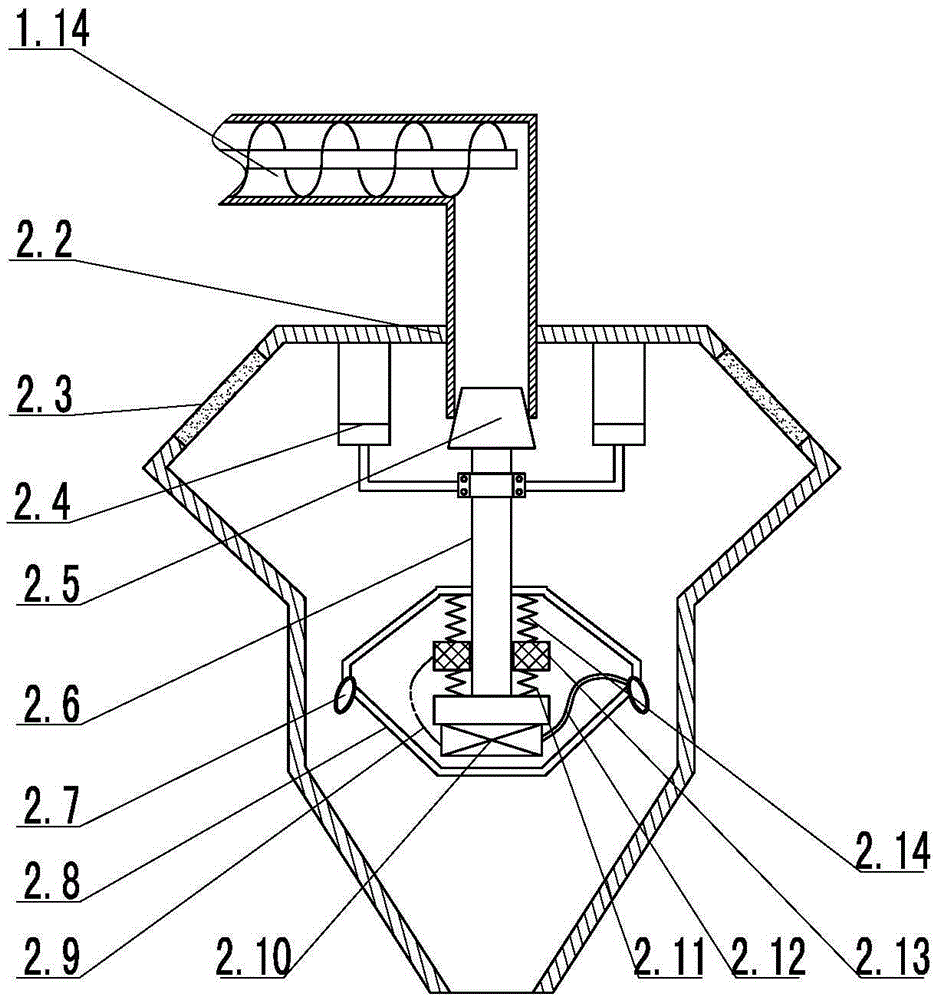

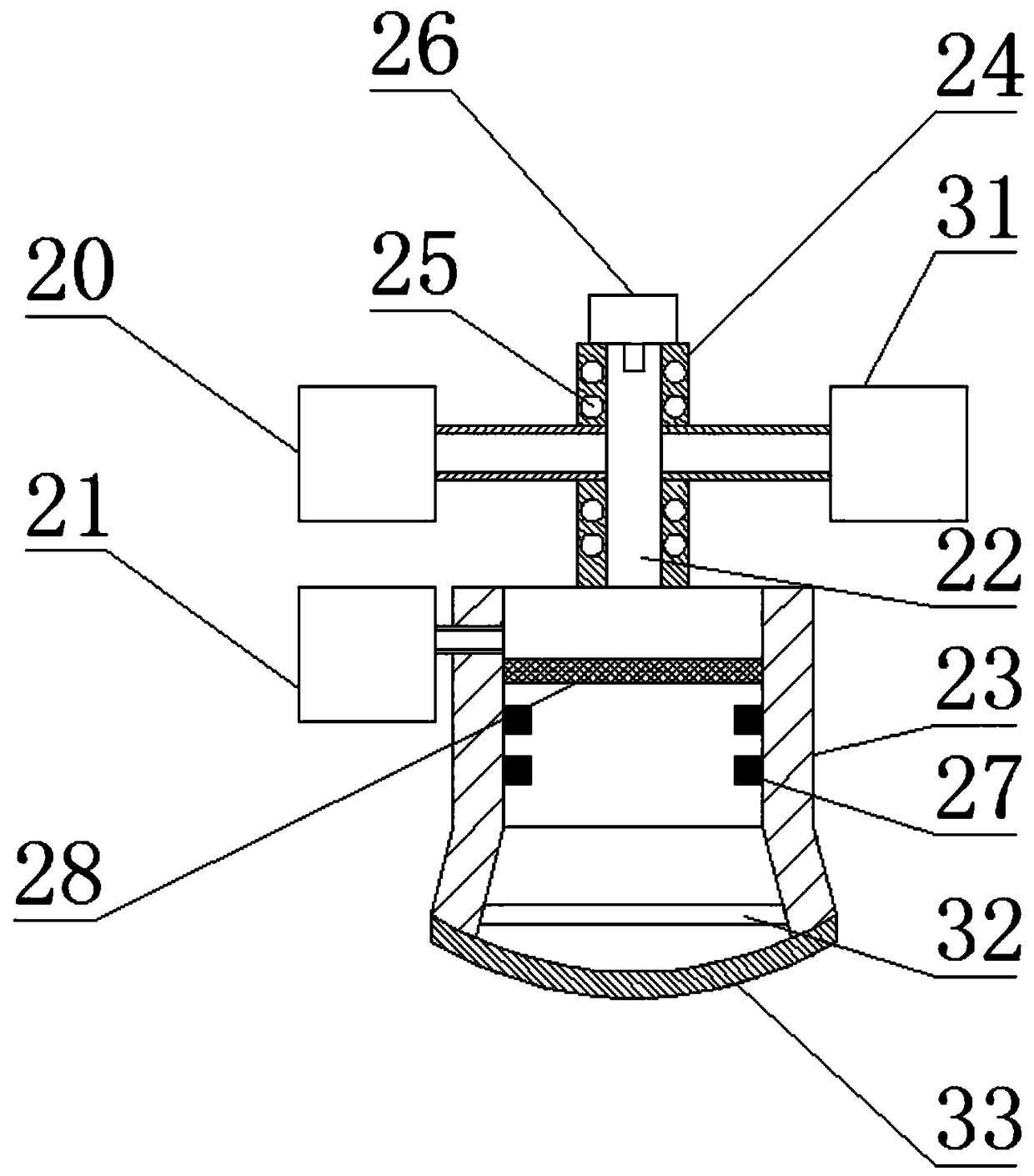

High efficient and environment-friendly pebble coal full-sealing discharge device

InactiveCN102942071ATimely dumpingEffectively judge the running status of dynamic and static ringsLarge containersLoading/unloadingElectricityWorking environment

The invention relates to equipment in a thermal power plant, and particularly relates to a high efficient and environment-friendly pebble coal full-sealing discharge device applied to a quick grinding pebble coal discharge system in a thermal power plant. The device comprises a transition pipeline, wherein the tail end of the transition pipeline is connected with a gas-tight silo; the gas-tight silo consists of a silo body and a sealing cover which is driven by a cylinder; a transferring box is arranged below the sealing cover; the top of the transferring box is provided with a feed port; a sealing ring is arranged between the edge of the feed port and the bottom surface of the sealing cover; the top of the sealing cover is provided with a lower shell; the lower opening of the silo body is provided with an upper shell; the upper shell and the lower shell are interlaced, sleeved and closed; the top of the sealing cover is also provided with a gas-tight cavity; the lower end of the joint gap between the upper shell and the lower shell is sealed in the gas-tight cavity; and the outer wall of the gas-tight cavity is provided with a sealed air inlet connected with a compressed air source. By adopting the high efficient and environment-friendly pebble coal full-sealing discharge device, dust pollution in a pebble coal working environment can be reduced, the labor intensity is lowered, and water and electricity consumption of auxiliary equipment are saved.

Owner:JIANGSU ZHONGNENG POWER EQUIP

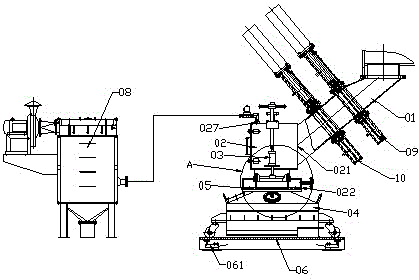

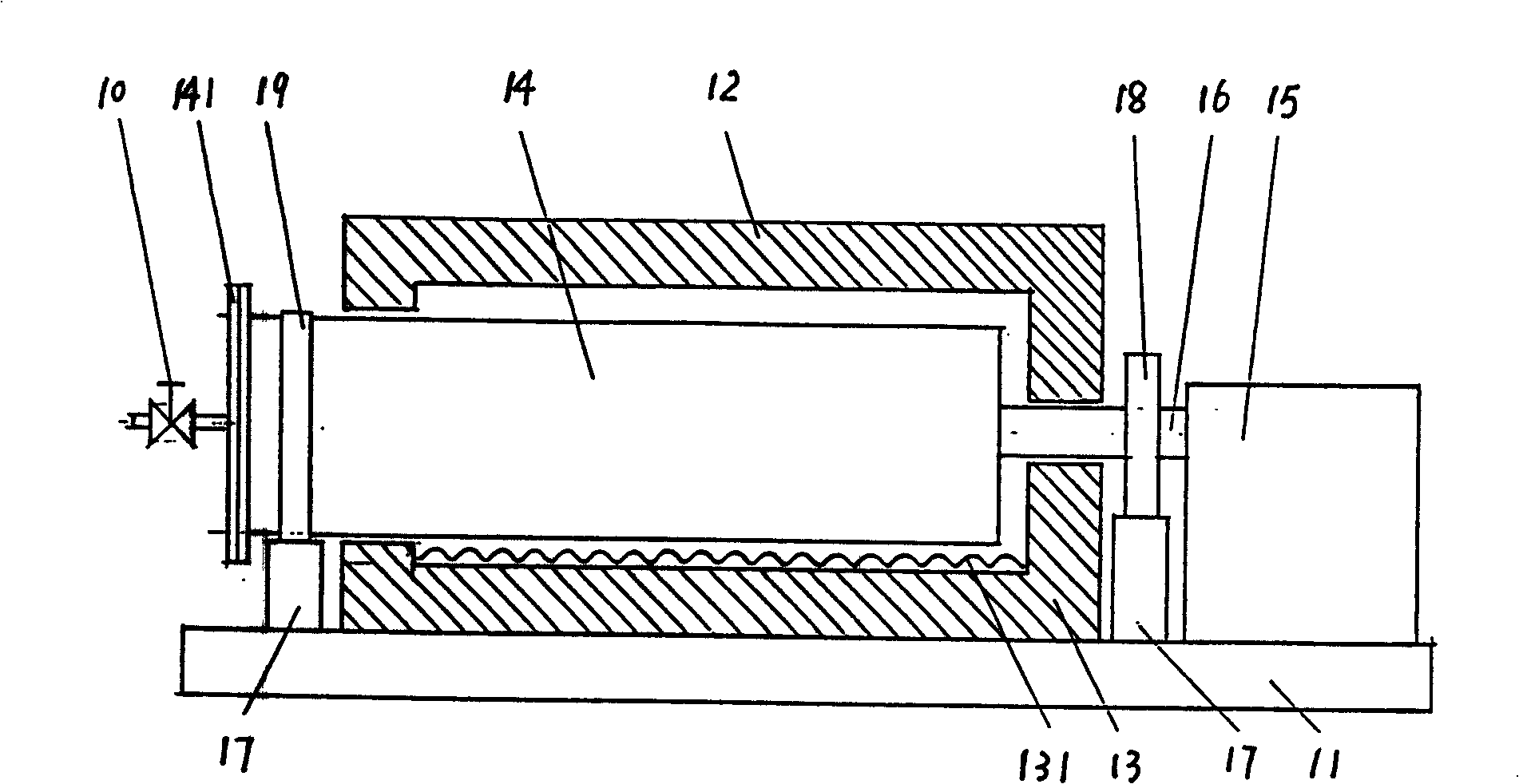

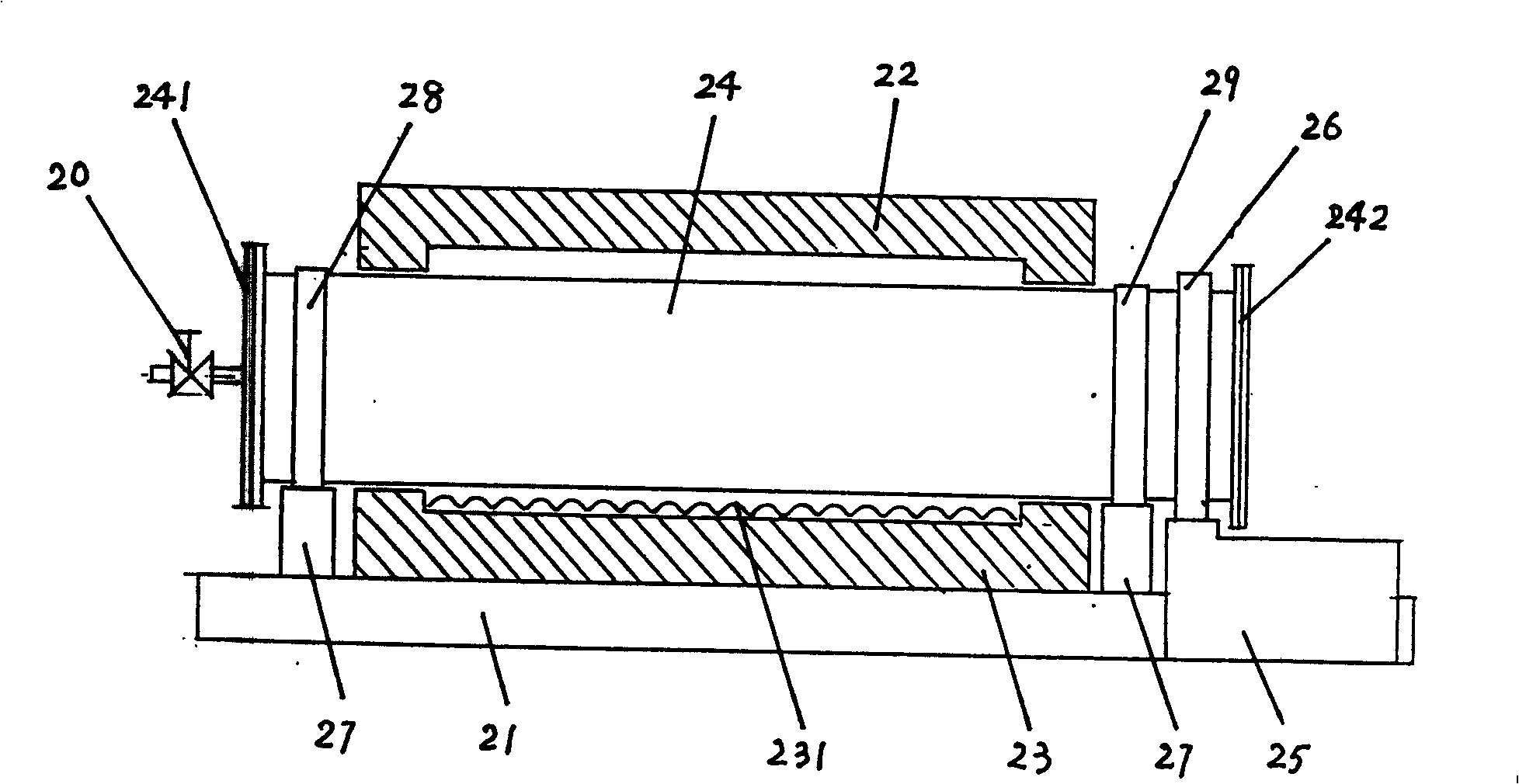

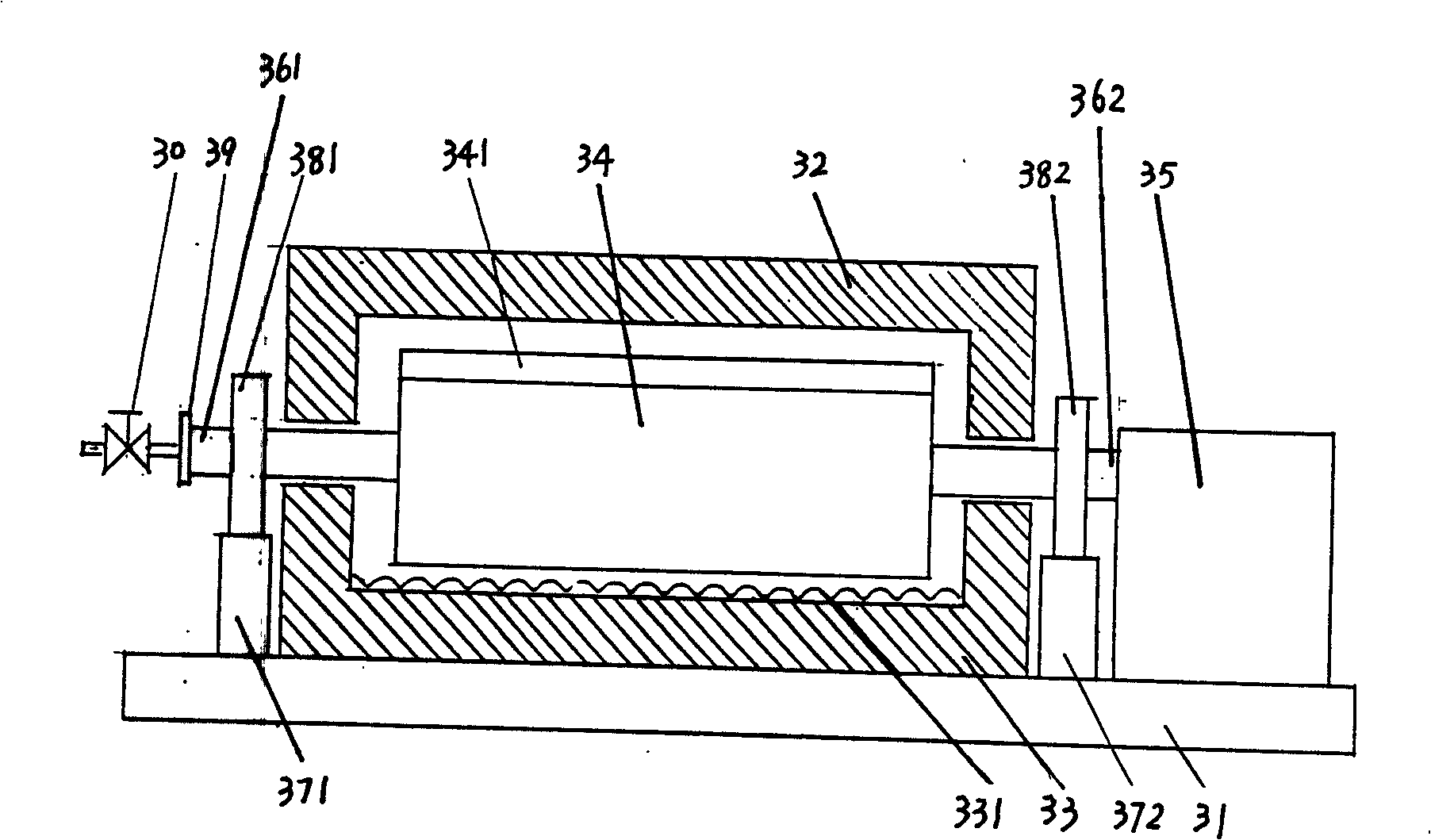

Full-automatic production device for refractory plastic material

ActiveCN105419817AExquisite designImprove mixing efficiencyFireproof paintsProcess engineeringManufacturing engineering

A full-automatic production device for refractory plastic materials belongs to the field of production devices for refractory materials and is characterized by comprising: a material preparing device, a material metering and dispensing device and a packaging device, wherein the three devices are connected successively to each other. The production device achieves full automation in production operation of the refractory plastic materials, reduces labor intensity of workers and improves production efficiency and quality. The production device is subjected to repeated design modification and test, is excellent in use effects and is suitable for being promoted in the field.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

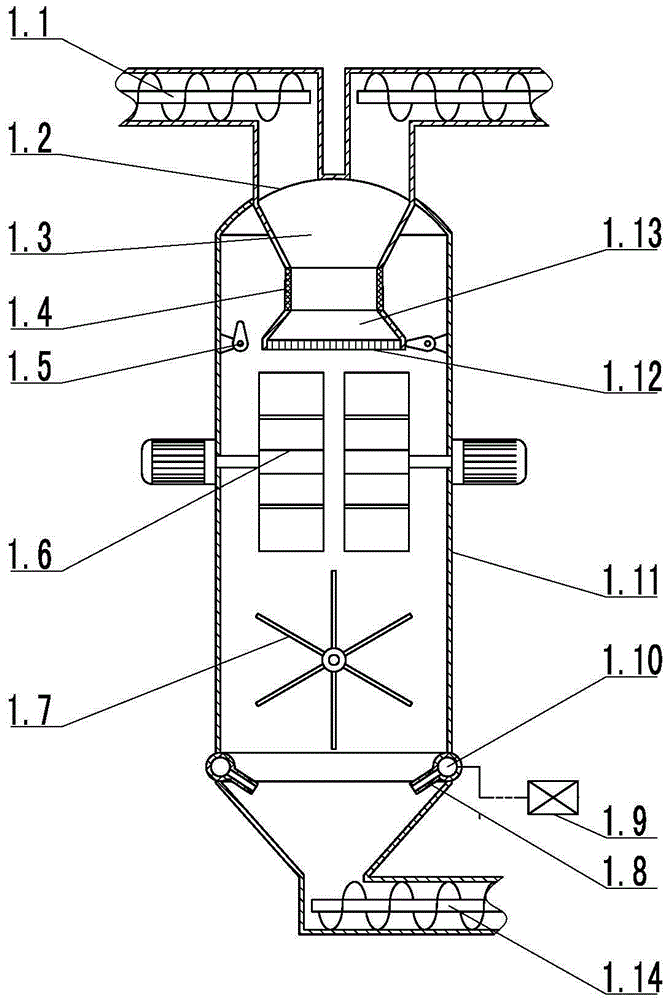

Disc rotary-net dust removing machine

InactiveCN103638752ATo achieve the purpose of purifying the airSimple structureDispersed particle filtrationFiberCircular disc

The invention discloses a disc rotary-net dust removing machine. The disc rotary-net dust removing machine comprises a dust removal chamber which is connected with a dust-source exhaust pipeline, wherein the dust removal chamber comprises an intermediate primary dust removal chamber and two secondary dust removal chambers which are symmetrically arranged on the left side and the right side of the primary dust removal chamber. The upper end of the primary dust removal chamber is connected with a compressing device through a dust removal fan and a pipeline, an air outlet of the dust removal fan is connected with the compressing device, and an air inlet is communicated with the inside of the primary dust removal chamber. The disc rotary-net dust removing machine adopts primary disc filter dust removal and secondary rotary-net filtering and adopts a symmetric two-stage dust removal way, so that the dust removal effect is more thorough; moreover, the fibers can be more effectively separated from the dust, the fibers can be recycled in a concentrating manner so as to reduce the resource waste, the disc rotary-net dust removing machine is more environment-friendly, and a dustless working environment can be provided for the employees.

Owner:JINAN RUNTONG ANJI MACHINERY

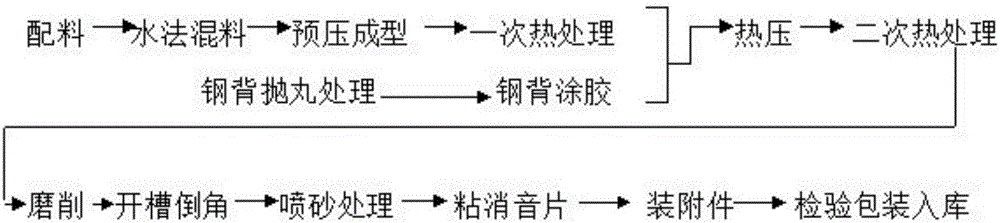

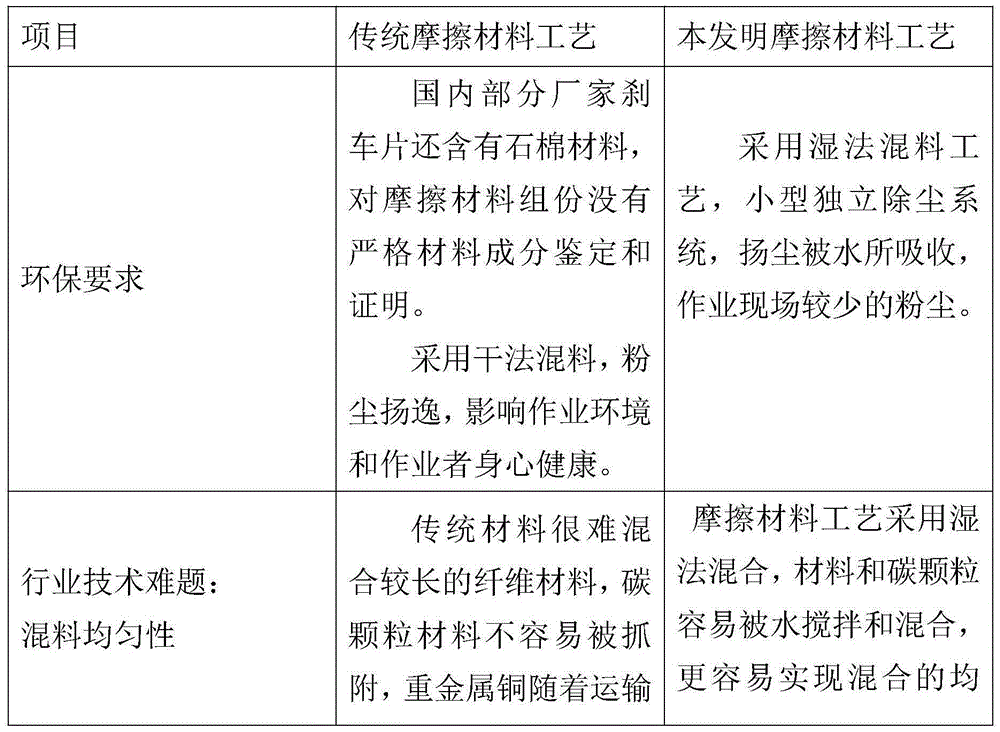

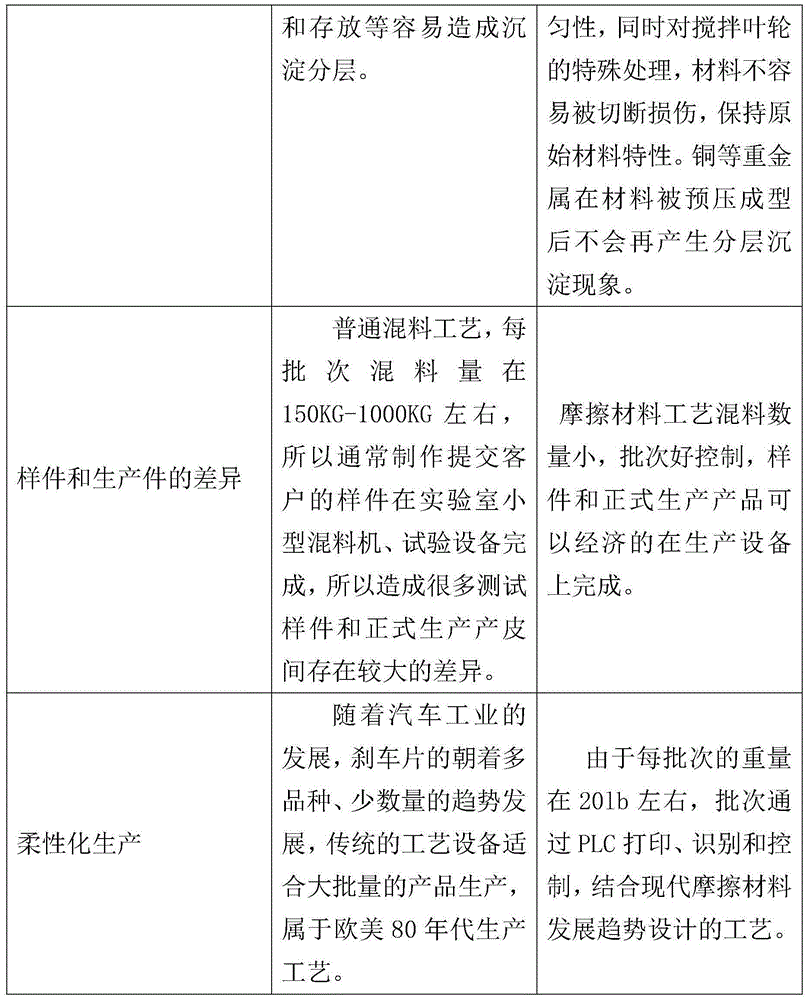

Novel brake pad and manufacturing method thereof

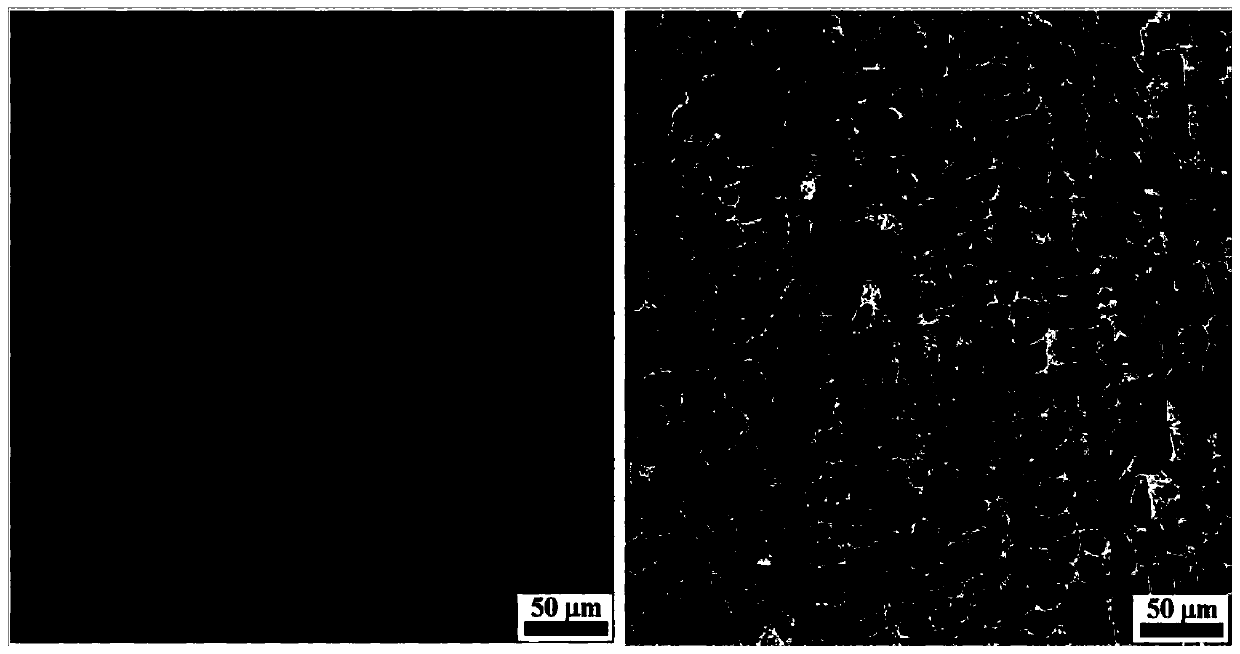

InactiveCN105154005AEasy to settleAvoid clumpingOther chemical processesFriction liningSand blastingThermal treatment

The invention discloses a novel brake pad and a manufacturing method thereof. The novel brake pad comprises a friction material and a steel backing. The friction material is prepared from, by weight, 5-12 parts of aramid pulp, 1-5 parts of aramid fibers, 5-20 parts of zirconia, 2-8 parts of graphite, 1-5 parts of petroleum coke, 0.5-4 parts of rubber powder, 2-10 parts of antimony sulfide, 5-15 parts of barite, 1-5 parts of friction powder, 5-15 parts of copper fibers, 2-10 parts of mineral fibers, 2-10 parts of mica, 5-10 parts of resin, 5-10 parts of potassium titanate and 1-8 parts of curing agent. The method includes the steps: (1) producing a friction material workblank by burdening, water mixing, prepressing for forming and primary thermal treatment; (2) subjecting the steel backing to shot blasting, and gluing the steel backing; (3) subjecting the friction material workblank and the steel backing to thermo-compression formation to obtain a brake pad workblank; (4) sequentially carrying out secondary thermal treatment, grinding, grooving, chamfering, sand blasting, silencer adhesion, accessory installation, checking, packaging and storing. High uniformity, high toughness, cleanness in production and transferring and high product uniformity are realized.

Owner:ANHUI GOOD TECH AUTO PARTS

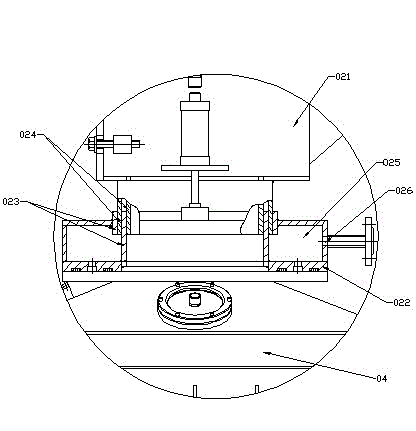

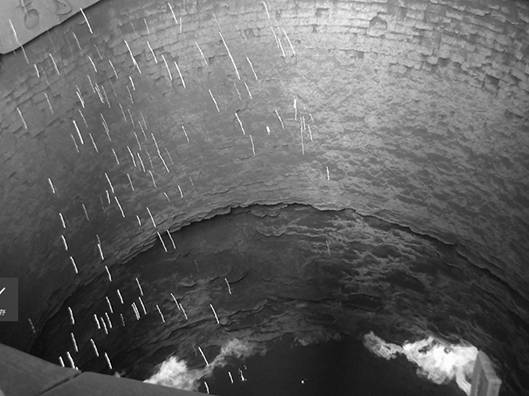

Remote-control thermal-state wet-process injection lining making method

PendingCN113604619AIncreased strength and wear resistanceStrong wear resistanceBlast furnace componentsBlast furnace detailsHot blastChemistry

The invention relates to a repairing and maintaining method for a blast furnace lining, in particular to a remote-control thermal-state wet-process injection lining making method. The remote-control thermal-state wet-process injection lining making method comprises the following steps that S1, equipment enters a site, specifically, a spraying manipulator is mounted in a blast furnace and is connected with an injection workstation outside the blast furnace in a matched manner; S2, banking fire is performed, specifically, the internal environment of the blast furnace is adjusted; S3, cleaning is performed, specifically, washing is performed on to-be-repaired positions of the inner wall of the blast furnace for multiple times so as to perform spraying, repairing and lining making; S4, injection is performed, specifically, the spraying manipulator is controlled to perform spraying repairing on the inner wall of the blast furnace; S5, the furnace is dried, specifically, hot air is supplied into the furnace to bake the interior of the blast furnace; and S6, the furnace is opened, specifically, the furnace is opened for normal production after the interior of the furnace reaches a specified state. By means of the remote-control thermal-state wet-process injection lining making method, the hot repair efficiency of the blast furnace can be rapidly improved and the service life of the blast furnace can be prolonged to the maximum extent during the damping-down time of the blast furnace, particularly gunning in a hot state.

Owner:HENAN HUAXI FURNACE REFRACTORY

Polyurethane foam for heat insulation and sound insulation of automobile engine

The invention relates to polyurethane foam for heat insulation and sound insulation of an automobile engine. The foam is prepared by foaming of a component A and a component B, and the density of the polyurethane foam is 17 plus or minus 3kg / m<3>, wherein the component A comprises 100 parts by weight of polyether polyol and 20 parts by weight of graphite; the hydroxyl value of the polyether polyol is 120 plus or minus 10mgKOH / g, and the viscosity below 25 DEG C is 700 plus or minus 100mPa s; and the component B comprises 100 parts by weight of polyisocyanate, the content of NCO is 31 plus or minus 1%, and the viscosity below 25 DEG C is 200 plus or minus 50 mPa s. The product has good size stability after forming, and the foam in the uniform honeycomb-like cellular structure in a foam block has good sound absorption and heat insulation effects; the product has excellent extensibility and can meet the requirements in various aspects and the radian in the design; and the product can prevent the dust phenomenon, prevent harming a human body and meet the standard of VOC (volatile organic compounds) in the automobile industry.

Owner:LIYANG SHANHU IND CO LTD

Multifunctional paste-shaped plaster and preparation method thereof

The invention discloses multifunctional paste-shaped plaster and a preparation method thereof. The multifunctional paste-shaped plaster is prepared from 30-45 parts of quartz sand, 25-35 parts of packing, 0.2-0.5 part of water retention thickening agent, 20-40 parts of emulsifying agent, 0.5-1 part of coalescing agent, 0.1-0.15 part of preservative, 0.2-0.3 part of defoaming agent and 1-2 parts of anti-cracking fibers. The preparation method includes the steps that the quartz sand, the packing, the water retention thickening agent and the wood fibers are weighed first, and then are evenly stirred after being mixed, so that a mixed material is obtained; afterwards, a certain quantity of silicone-acrylic emulsifying agent is weighed and added into a stirring machine to be stirred, the defoaming agent, the coalescing agent and the preservative are added while stirring is carried out, and the mixture is fully and evenly mixed; then the mixed material which is well mixed before is added to be fully mixed and evenly stirred. The plaster does not contain cement, and thus the efflorescence condition can be avoided when solidified plaster meets rainwater.

Owner:苏州大乘环保新材有限公司

High performance environment-friendly metal polishing agent and preparation method thereof

The invention discloses a high performance environment-friendly metal polishing agent which is prepared from the following raw materials in parts by weight: 10-14 parts of organic acid, 2-4 parts of inorganic acid, 0.7-0.9 part of a bright adjuvant, 5-7 parts of glycerinum, 8-12 parts of calcium carbonate, 3-5 parts of an antirust agent, 2-4 parts of acetyl monoethanolamine, 1-3 parts of stearate,10-12 parts of a wax emulsion, 5-10 parts of triethanolamine, 0.5-1.5 parts of a surfactant, 1-3 parts of sodium nitrite, 2-4 parts of a stabilizer, 1-3 parts of nano silicon dioxide, 5-7 parts of zinc sulfate, 0.1-0.3 part of a corrosion inhibitor and 35-45 parts of distilled water. The high performance environment-friendly metal polishing agent disclosed by the invention has the characteristicsof being good in polishing quality, convenient to use, high in efficiency and the like, the surface brightness of a metal can be enhanced, and in the polishing process, no corrosive gas, dust and chromic anhydride harmful substances are available. The demand on wastewater treatment condition is low, and the high performance environment-friendly metal polishing agent is good in abrasive dispersityand relatively good in stability of composition, and has a remarkable effect on surface evenness of the metal and micro-puncture phenomenon.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

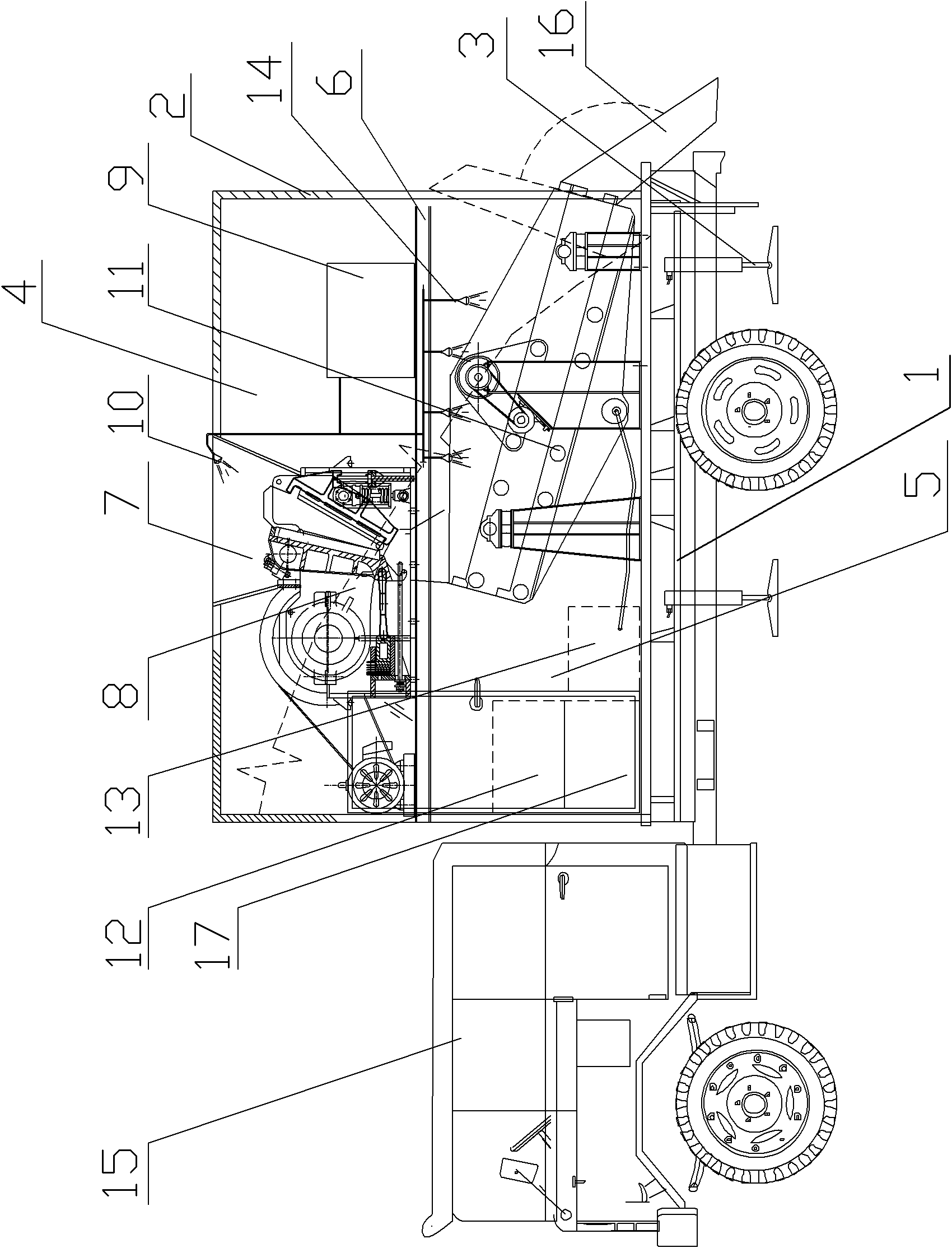

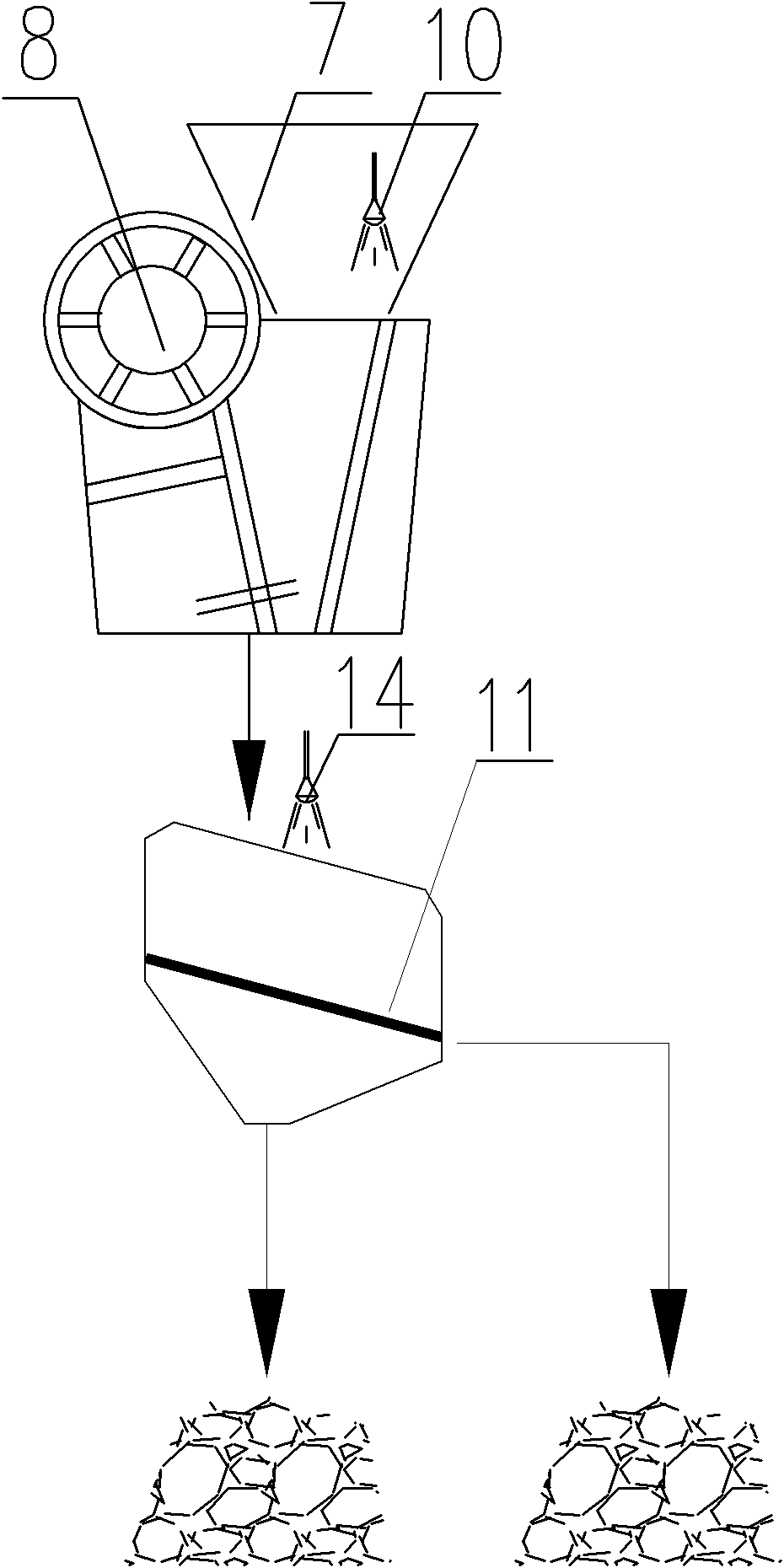

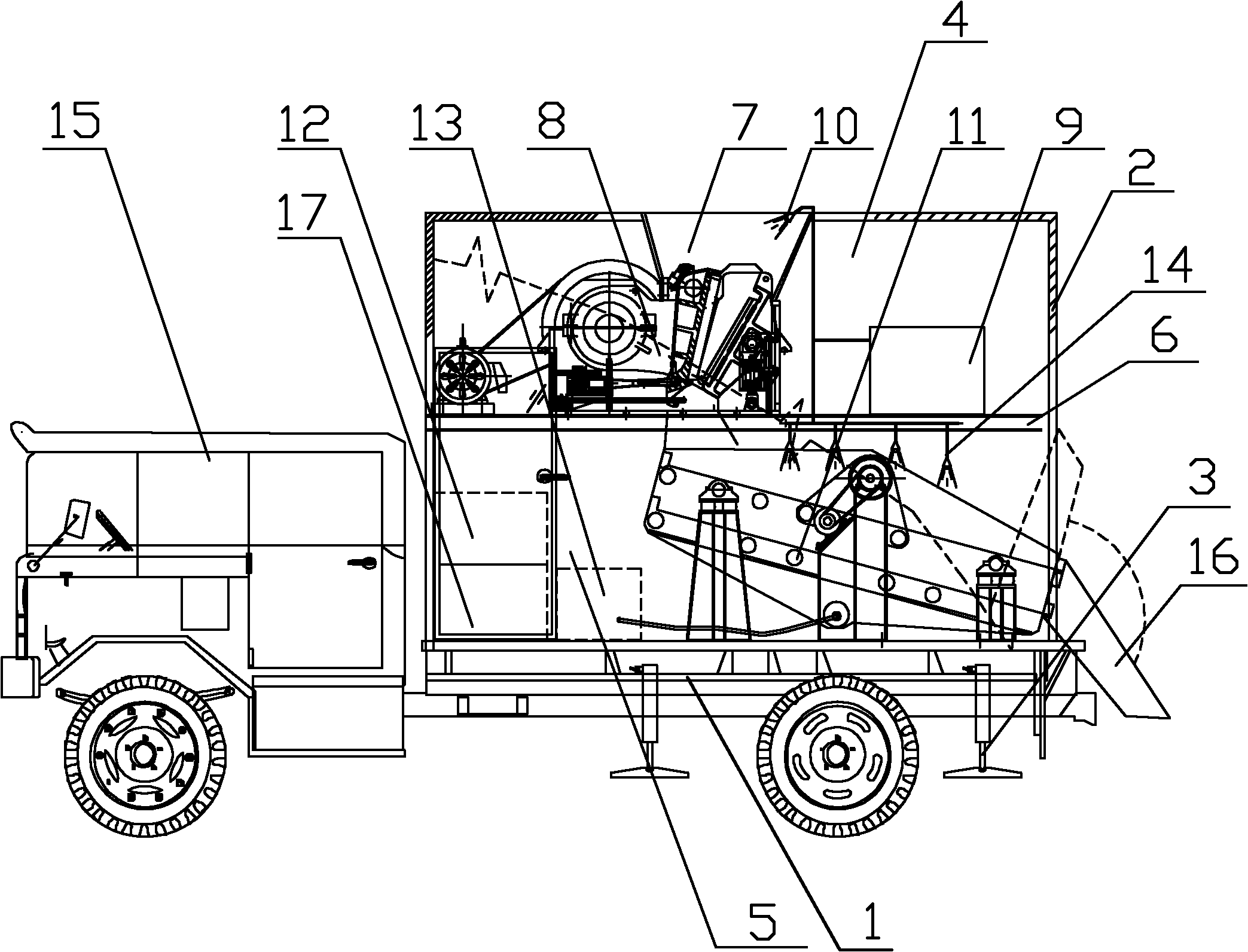

Wheel type sound-insulating dust-proof construction aggregate preparation vehicle

The invention relates to a wheel type sound-insulating dust-proof construction aggregate preparation vehicle which comprises a wheel type vehicle chassis, support legs and a box body type work chamber, wherein the support legs are arranged on both sides of the wheel type vehicle chassis; and the box body type work chamber is installed on the wheel type vehicle chassis and comprises an upper crushing chamber and a lower screening chamber, and the crushing chamber and the screening chamber are isolated by an operating platform. Construction wastes such as concrete, tiles, bricks and the like are crushed and screened referring to the sandstone aggregate production flow to realize on-site processing and on-site recovery by arranging medium and small crushing and screening devices and corresponding control devices on the wheel type vehicle chassis. The crushed and screened wastes can be used for manufacturing building blocks, bricks and wallboards, so that the construction wastes are effectively recycled. The wheel type vehicle chassis is lightweight, flexible and convenient to move and can be widely applied to the on-site preparation of engineering construction aggregates for roads, railways, old city reformation and the like.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Road cleaning equipment

The invention discloses road cleaning equipment. The road cleaning equipment comprises at least a cleaning equipment body; a rotary disc is arranged below the cleaning equipment body; the outer sidesof the rotary discs are wrapped with cleaning brushes; a water outlet is formed in each rotary disc; a rotary shaft is inserted in the center of each rotary disc; one end of each rotary shaft penetrates through a driven belt wheel and is fixed on a bearing; a driving belt wheel is arranged on one side of the driven belt wheel; an annular belt is arranged between the driven belt wheel and the driving belt wheel; a reduction motor is arranged on an input end of driving belt wheel; a water inlet passage is formed in the rotary shaft; one end of the water inlet passage communicates with a water inlet pipe; one end of the water inlet passage is connected to a water storage tank; a water inlet is formed in the top of the water storage tank; and a buckle cover which is matched with the water inlet covers the water inlet. The road cleaning equipment is simple in style and novel in structure, and road cleaning work can be finished on the premise of avoiding dust raising phenomena.

Owner:徐州荣腾机车有限公司

Crusher

InactiveCN104646165AMeet actual needsRealize continuous feeding and dischargingSievingScreeningMotor driveElectric machinery

The invention discloses a crusher. The crusher comprises a driving mechanism and further comprises a sieve barrel, wherein a plurality of sieve holes are formed in the side wall of the sieve barrel; the driving mechanism comprises a plurality of supporting rails fixedly connected with the outer side wall of the sieve barrel, a transmission mechanism, a motor and supporting wheels; the output end of the motor is connected with the transmission mechanism; the transmission mechanism is connected with the plurality of supporting wheels; the motor drives the supporting wheels to rotate; and the supporting rails drive the sieve barrel to rotate by the friction force between the supporting wheels and the supporting rails. The sieve holes are formed in the sieve barrel and the feeding speed is controlled; materials with uniform meshes can be sieved and the requirements of controlling materials respectively are met; the requirements of users can be met and continuous feeding and discharging can be realized; and the continuous production work is realized, the treatment amount is great, the working efficiency is high and the production efficiency is improved.

Owner:胡永胜

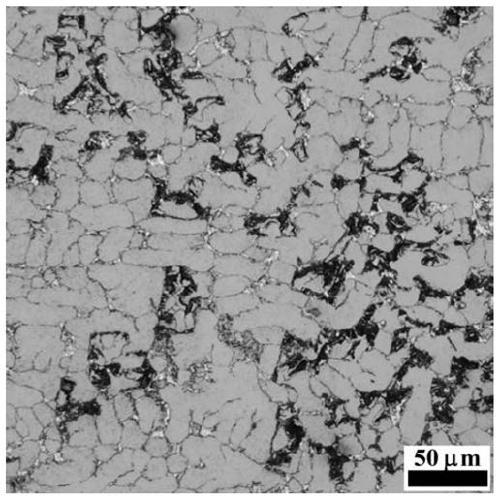

Special composite slag removing agent for beryllium aluminum alloy refining, preparation method and slag removing method

The invention discloses a special composite slag removing agent for beryllium aluminum alloy refining, a preparation method and a slag removing method. The slag removing agent comprises the followingcomponents in parts by weight: 30-50 parts of sodium tetraborate, 2-8 parts of AlB12 intermediate alloy, 2-5 parts of hexachloroethane, 7-10 parts of sodium hexafluorisilicate, 2-6 parts of sodium fluoroaluminate, 1-5 parts of sodium fluoride, 5-12 parts of potassium chloride, 6-13 parts of beryllium chloride, 2-5 parts of lithium chloride, 2-5 parts of sodium carbonate, and 1-3 parts of clay. Theslag removing agent achieves excellent high-temperature stability and reliability under the vacuum condition, and is excellent in adhesiveness after melting, high in spreadability, quick in slag collection, easy incrustation of slag skin and excellent in slag removing and refining effect. Through the synergistic effect of all the components, oxides in melts, magnesium-contained impurities and hydrogen achieve excellent slag removing and absorbing effects; and meanwhile, the slag skin can effectively cover the surfaces of the melts, so that the temperature loss can be effectively reduced, thesplashing of the melts is inhibited, and new melting slag and secondary oxidation are prevented.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

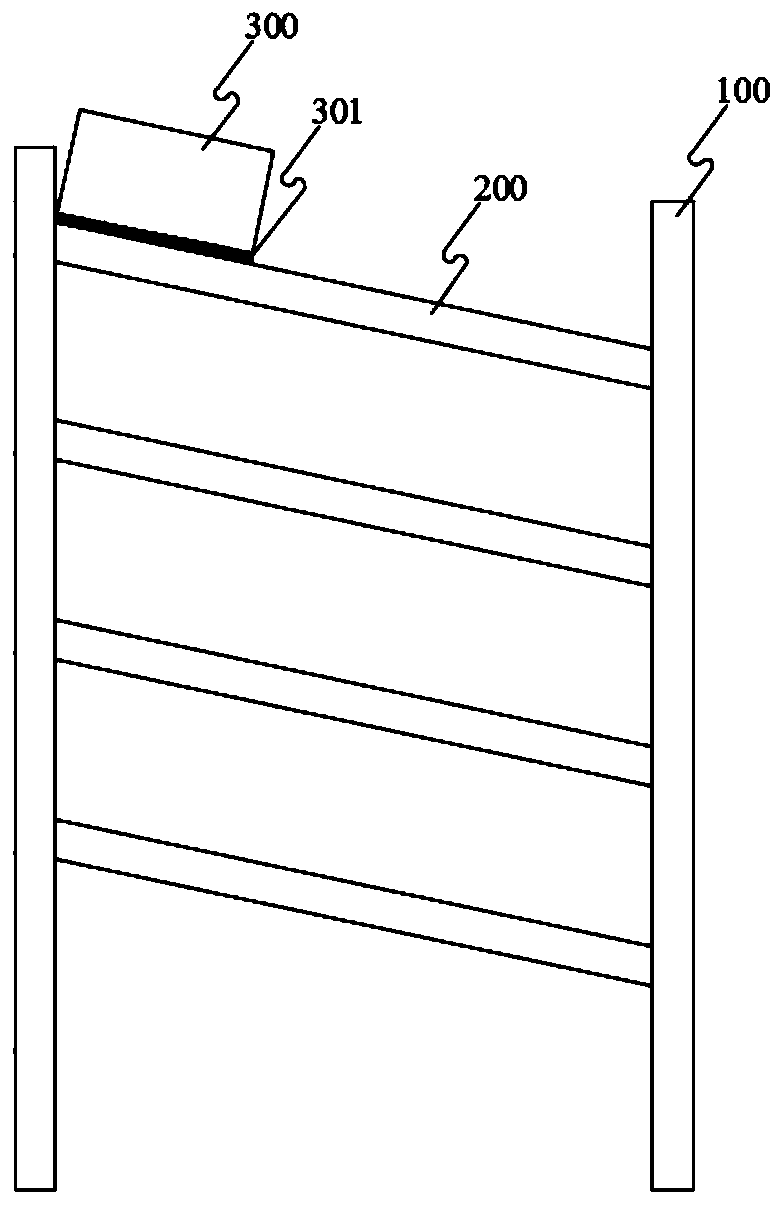

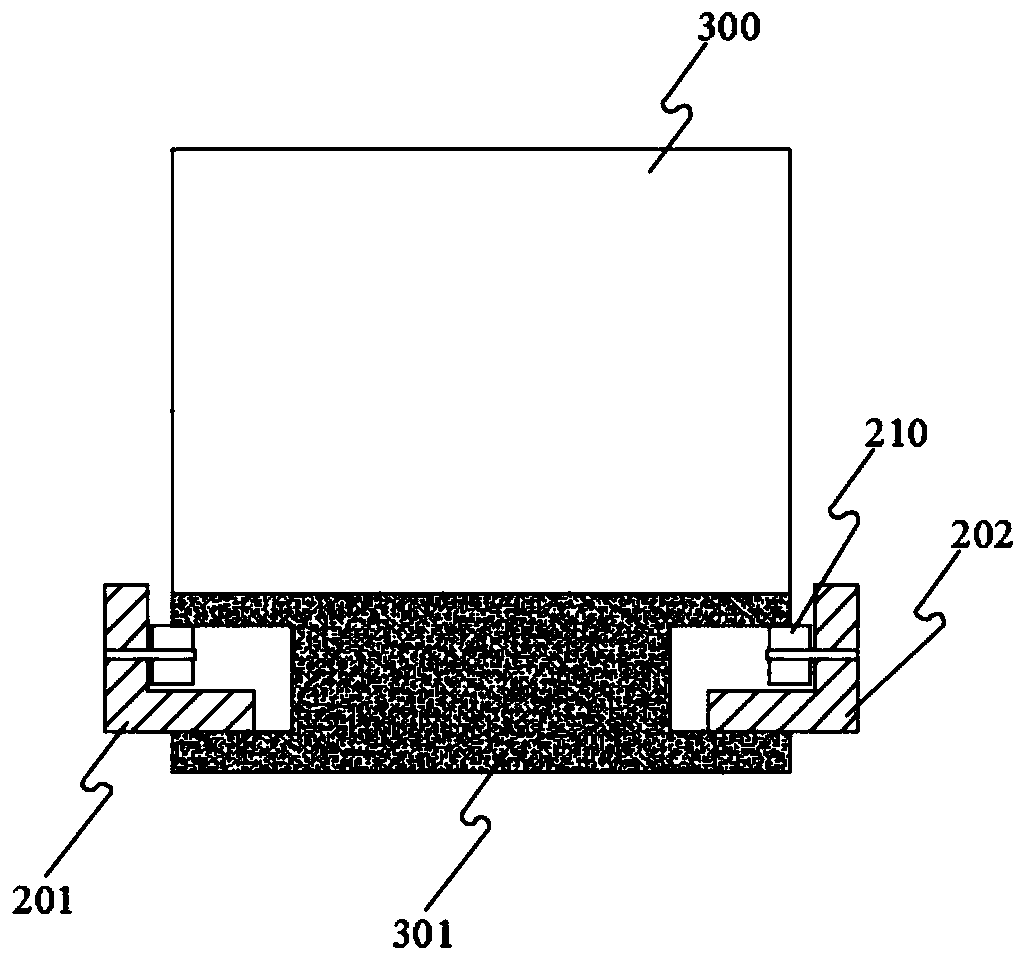

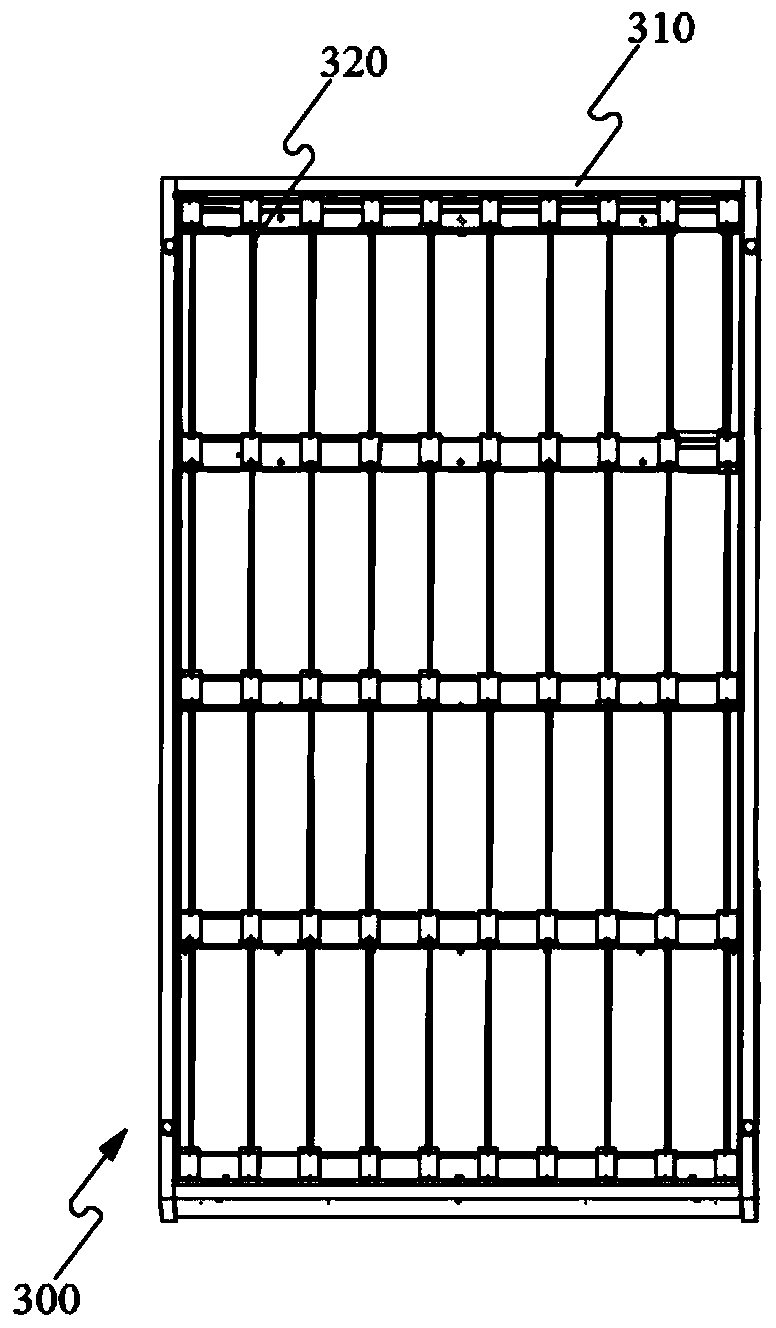

Dust-free transmission rail and battery transmission device

InactiveCN110182559AReduce consumptionNo dust phenomenonSemiconductor/solid-state device manufacturingPackaging under vacuum/special atmosphereElectrical batteryWear resistant

The invention discloses a dust-free transmission rail and a battery transmission device, wherein the dust-free transmission rail comprises a support, a guide rail arranged on the support and a conveying box used for loading materials; the guide rail comprises a first end part and a second end part in its length direction, and the distance between the first end part and the ground is larger than the distance between the second end part and the ground; a wear-resistant layer is arranged at the bottom of a transport box, and a wear-resistant block is slidably embedded on the guide rail. The dust-free transmission rail and the battery transmission device aim to solve the technical problems that the transmission device in the prior art easily generates dust and influences product quality, and that energy consumption in the transmission process is large. During transportation and operation, dust generated by friction is avoided, so that the device is suitable for production processes with high requirements for environment cleaning degree; product quality is improved; the device can be applied in production processes of lithium batteries, such as transferring process of the lithium batteries in a vacuum drying box.

Owner:SHENZHEN TIME HIGH TECH EQUIP

Convenient manual cleaning device

InactiveCN105534414AEasy to cleanClean up and save effortCarpet cleanersFloor cleanersBristleEngineering

The invention provides a convenient manual cleaning device. The convenient manual cleaning device comprises a brush, a box, a handle, two front wheels, two rear wheels, and an arc-shaped panel positioned on the end part of an opening end and covering the brush upwards, wherein the left end of the box is provided with an opening, the left end of a bottom panel of the box contacts the ground and is close to the brush, two ends of the brush pass through a front side panel and a rear side panel on the left end of the box through two short axles and then are fixedly connected with the two front wheels, the outer edge part, parallel to the ground, of the brush, is provided with bristles, the other part of the brush is a plastic plate, when the front wheels rotate, the bristles on the brush contact the ground, the plastic board on the brush does not contact the ground, the handle is hinged to the center of an upper panel of the box, the two rear wheels are mounted on a front side panel and a rear side panel on the right end of the box through two short axles, and a row of comb teeth for combing the bristles on the brush is arranged on the inner side of the arc-shaped panel. According to the convenient manual cleaning device, hair or thread residues attaching to the brush can be removed in time, so that the work efficiency is improved; in addition, the dust raise phenomenon in the use process of the device is avoided.

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

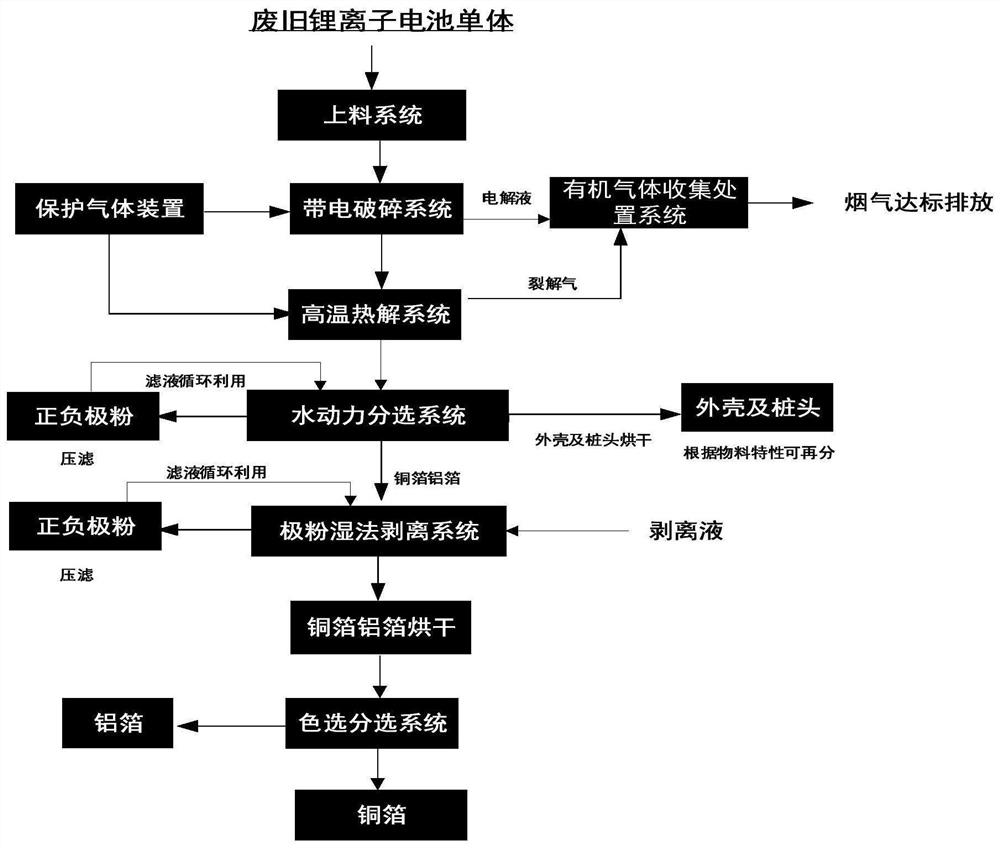

Recovery technology of waste lithium batteries

PendingCN113908977AReduce investment and operating costsReduce noiseSolid separationWaste accumulators reclaimingLithium compoundChemistry

The invention discloses a recovery technology of waste lithium batteries. According to the technology, the waste lithium ion batteries are disassembled through shearing and crushing and then enter a pyrolyzing furnace for high-temperature pyrolysis, PVDF glue and electrolyte on pole pieces of the waste lithium batteries are pyrolyzed in a high-temperature anaerobic state, the pyrolyzed materials directly enter a hydrodynamic sorting system for sorting, shell pile heads in the waste batteries can be separated from copper-aluminum foil pole powder, and the pole powder attached to the surface of copper-aluminum foil is further stripped through a wet-method stripping system. The battery powder discharged from the pyrolysis system does not need to be subjected to the processes of dry-method screening, wind separation and the like, and the battery powder is directly subjected to hydrodynamic separation, so that pole powder dust raising can be avoided; lithium-containing compounds and graphite powder in the batteries are electric conductors and combustible materials, in the sorting process, if powder dust is raised and is attached to an electric switch for a long time, electric short circuit and ignition spontaneous combustion are easily caused, and potential safety hazards exist.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

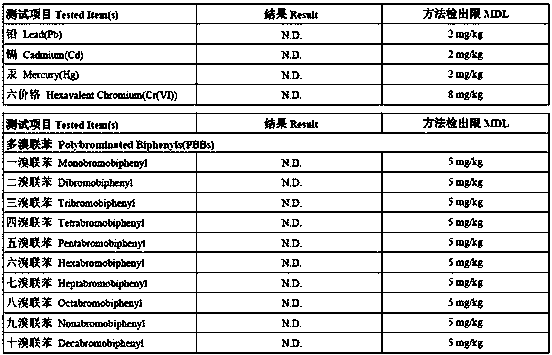

Special flame-retardant masterbatch for low carrier PBT and preparation method thereof

The invention discloses a special flame-retardant masterbatch for low carrier PBT and a preparation method thereof. A novel flame-retardant formula system is adopted, deep research and development iscarried out on PBT high-performance flame-retardant masterbatch, and the special flame-retardant masterbatch with low carrier, high GWIT and high CTI for PBT is researched and developed. Brominated polystyrene is taken as a main material, a phosphorus and nitrogen system flame retardant, antimony phosphate, pretreated PBT powder and a dispersing agent are added for preparation, wherein the dispersing agent consists of a lubricating agent PETS-T and esterified E wax, low-temperature liquid nitrogen grinding fabrication processing is carried out on PBT, the fusion with the component of the flame-retardant is more thorough, PBT powder is taken as the compound of the flame-retardant masterbatch, the special flame-retardant masterbatch for PBT can be rapidly fused with subsequent PBT resin, andan excellent flame-retardant effect is reached.

Owner:JIANGYIN LONGSHAN SYNTHETIC MATERIAL

Glass product film pasting device capable of preventing dust mixing

The invention discloses a glass product film pasting device capable of preventing dust mixing. The glass product film pasting device comprises a frame body. A conveying channel is arranged on the frame body. A drive rotating shaft and a driven rotating shaft which are parallel are arranged at the two ends of the conveying channel. Multiple bearing rods are arranged between the drive rotating shaft and the driven rotating shaft. The drive rotating shaft is sleeved with multiple annular rotating seats in the axial direction of the drive rotating shaft, and the driven rotating shaft is sleeved with multiple annular rotating seats in the axial direction of the driven rotating shaft, wherein the annular rotating seats on the drive rotating shaft correspond to the annular rotating seats on the driven rotating shaft in position, and multiple rotating seat pairs are formed. A conveying belt is wound around each rotating seat pair. The end portion of the drive rotating shaft is connected with a drive motor. A roller shaft, a dust removing wiper and a film pasting roller are rotationally erected above the conveying channel. The axial direction of the roller shaft is parallel to the drive rotating shaft. An operation interval exists between the dust removing wiper and the roller shaft. The dust removing wiper comprises a core body and a dust removing sleeve. The core body can be detachably sleeved with the dust removing sleeve. In the process that a glass product moves along with the conveying channel, the dust removing wiper is located between the glass product and a pasting film to be used for pasting, a glass surface to be pasted can be subjected to dust removing, and the purpose of preventing dust mixing is prevented.

Owner:苏州市灵通玻璃制品有限公司

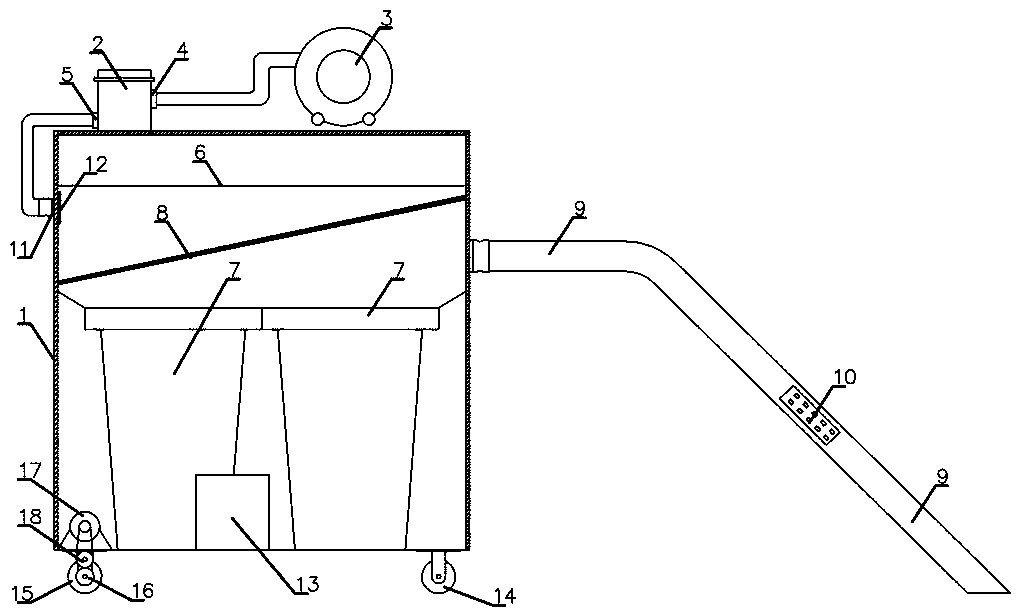

Outdoor ground suction garbage truck

The invention relates to the field of garbage cleaning environment-friendly equipment, in particular to an outdoor ground suction garbage truck. A filtering barrel and an air exhauster are arranged atthe top of a truck body. A garbage filtering cavity is formed in the truck body. Garbage collecting barrels are arranged below the garbage filtering cavity. A garbage filtering sieve is obliquely arranged in the garbage filtering cavity. A dust collector hose is outwards installed on the cavity wall of one side of the garbage filtering cavity. An air outlet is formed in the cavity wall of the other side of the garbage filtering cavity and communicated with the filtering barrel through a pipeline. A mobile power supply device for supplying power to the air exhauster is further installed in thetruck body, and a rolling device is installed at the bottom of the truck body. Garbage is swept in a negative pressure mode through a dust collector, the design is novel, operation is convenient andfast, meanwhile, corners difficult to sweep by a traditional garbage truck can be thoroughly swept through the dust collector hose, the sweeping efficiency is higher, the labor amount is small, the dust raising phenomenon hardly occurs in the sweeping process, and good application prospects are achieved.

Owner:湖北骏马环保科技有限公司

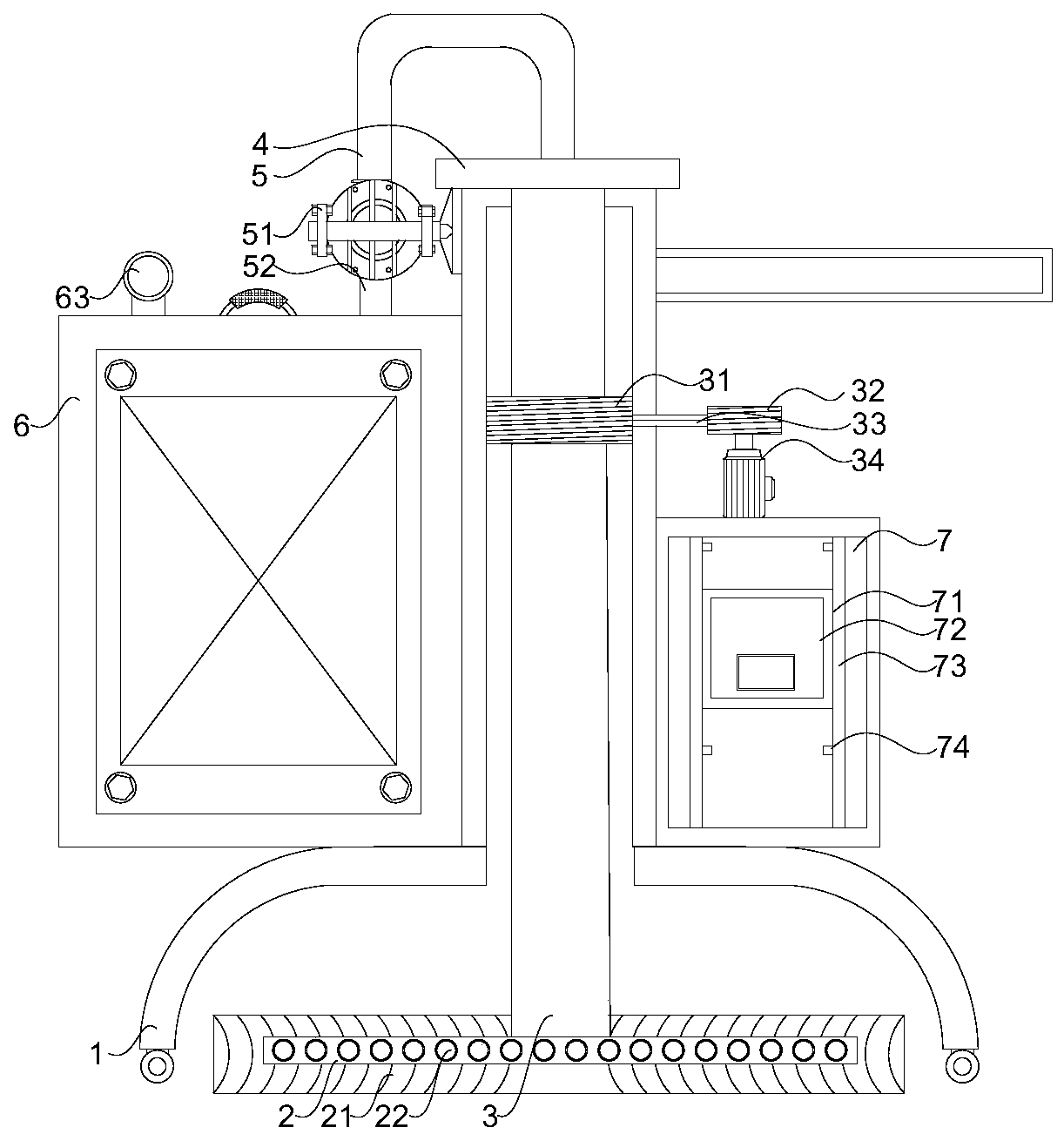

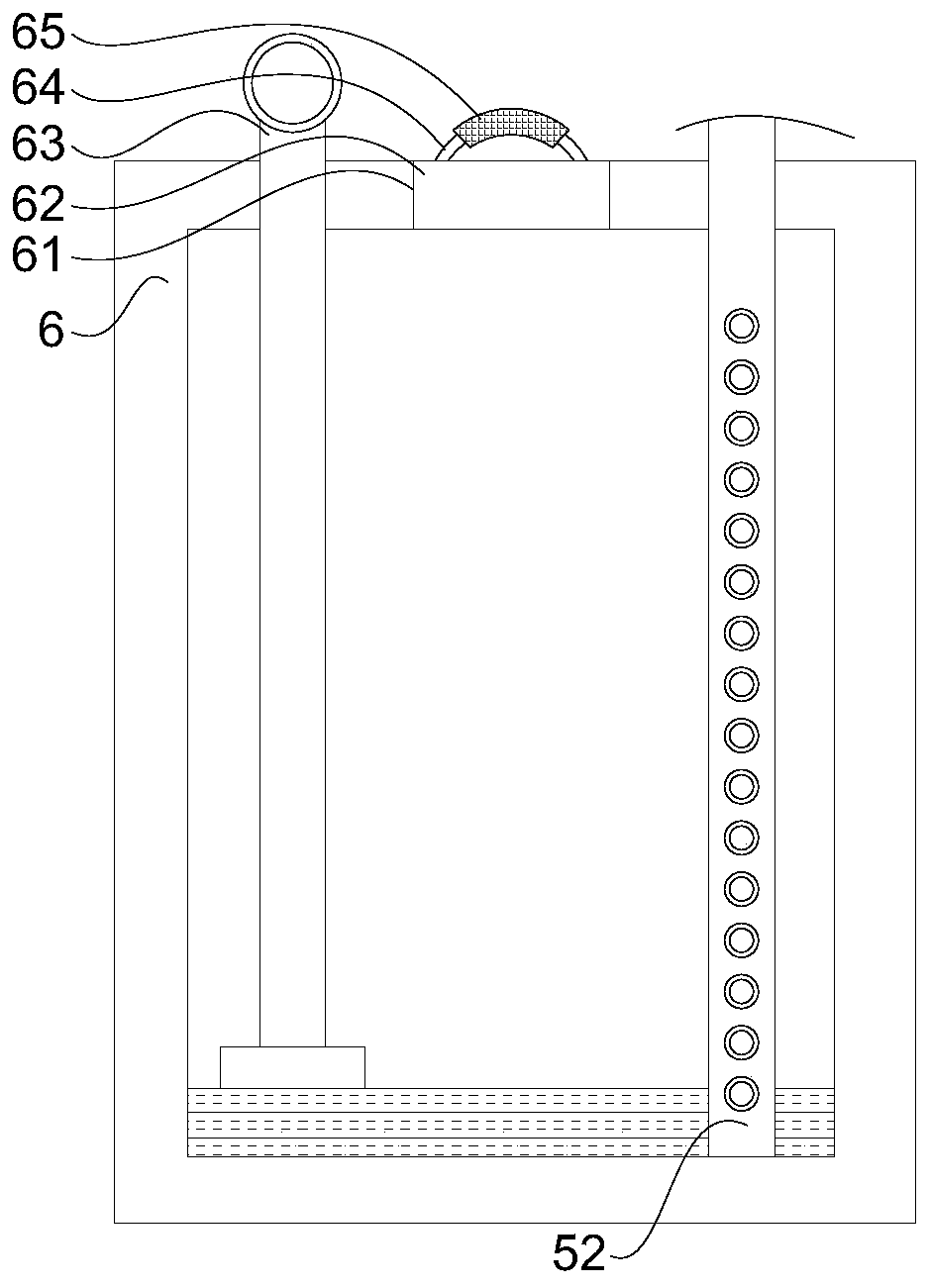

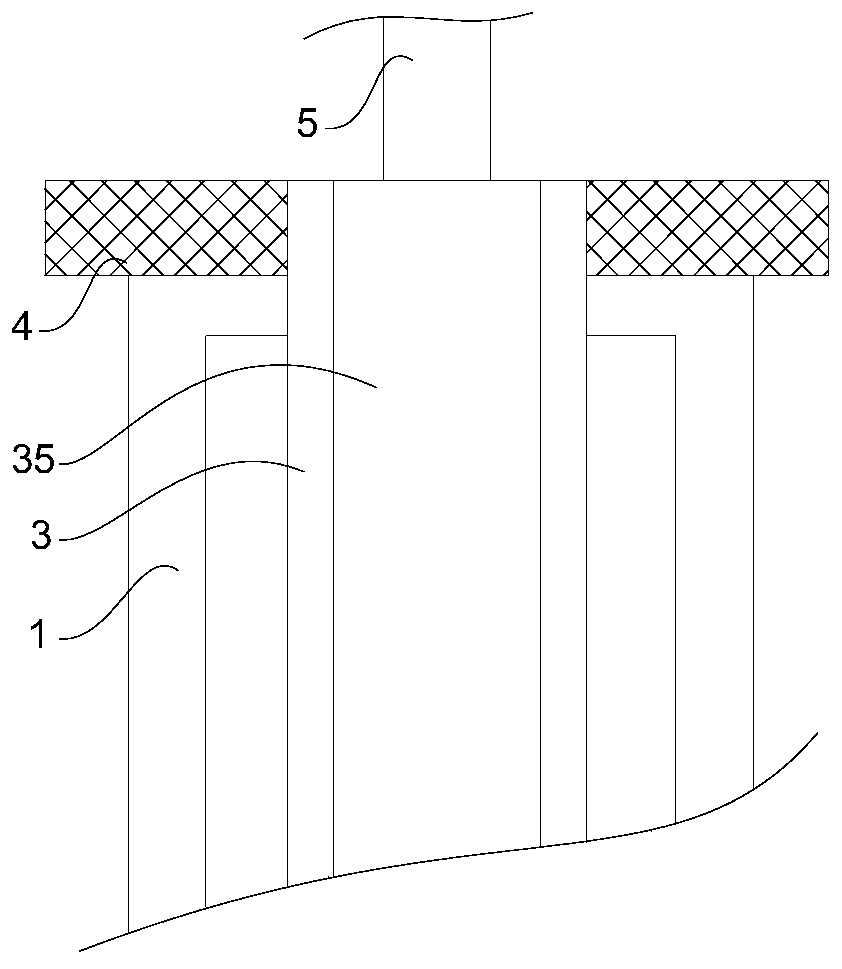

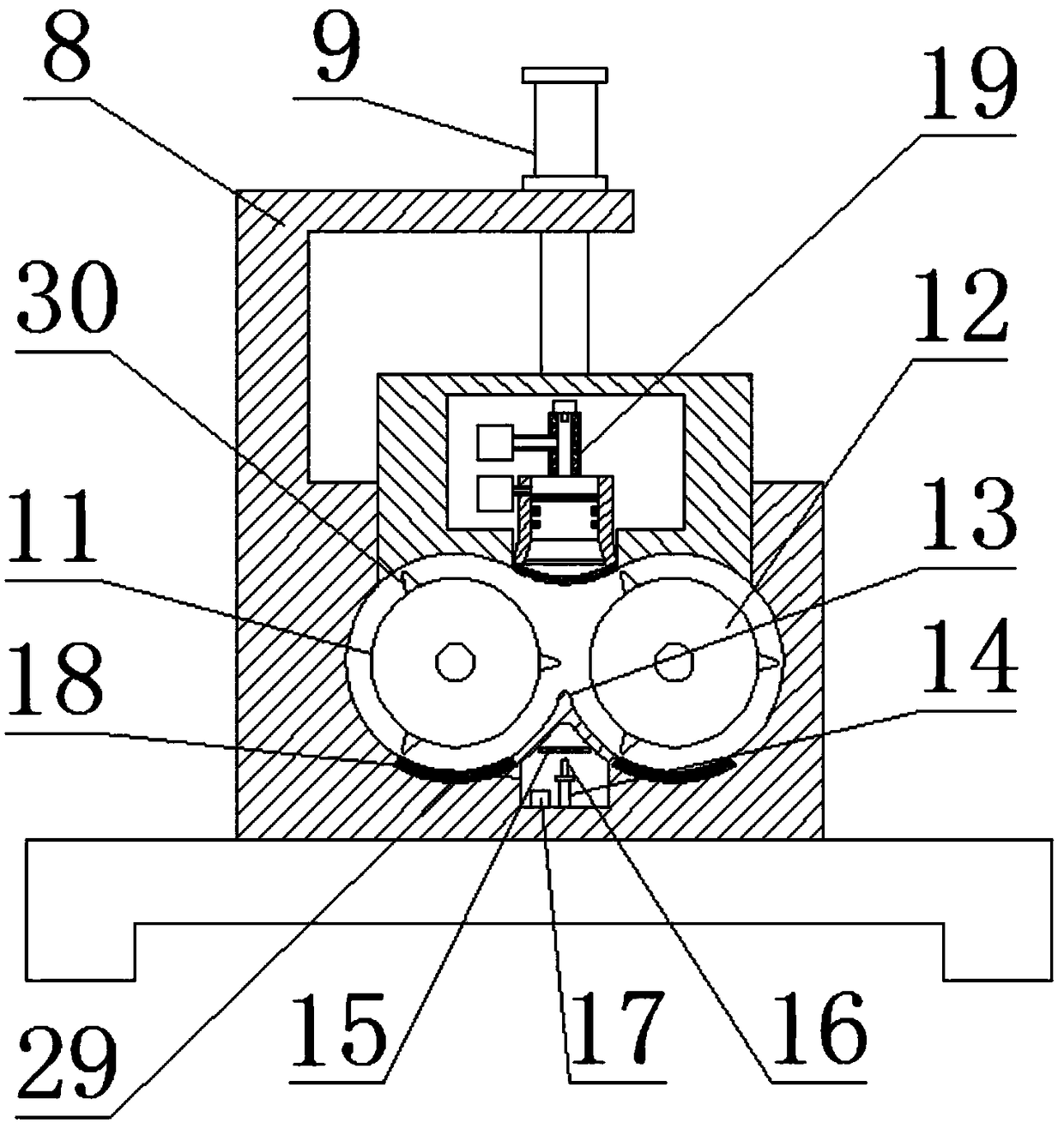

Ionic internal mixer

The invention relates to the technical field of raw rubber mixing, an ionic internal mixer comprises a bottom frame, a mixing chamber, a pressure block, a hydraulic system, a first motor unit, a second motor unit and a control box, wherein the mixing chamber is disposed on the bottom frame; a support frame is provided on one side of the mixing chamber; the hydraulic system comprises a hydraulic cylinder disposed on the support frame, a hydraulic motor group and a hydraulic oil tank; one end of the pressure block is connected to a hydraulic cylinder, and the other end of the pressure block is sleeved in a mixing chamber; an extrusion wheel I, an extrusion wheel II, a shearing block and a cathode arc plate are arranged in the mixing chamber; the first motor unit is disposed on one side of the mixing chamber and connected to one end of the extrusion wheel I, and the second motor unit is disposed on one side of the mixing chamber and connected to one end of the extrusion wheel II; a cooling chamber is arranged at the bottom of the shearing block. The equipment is low in energy consumption, high in efficiency, environmentally friendly and beneficial to popularization.

Owner:兰溪市旺兴塑胶制品有限公司

Mechanical equipment stainless steel material polishing agent and preparation method thereof

The invention discloses a mechanical equipment stainless steel material polishing agent. The mechanical equipment stainless steel material polishing agent comprises, by weight, 5-10 parts of triethanolamine, 0.5-1.5 parts of surfactant, 7-11 parts of inorganic acid, 1-3 parts of sodium nitrite, 3-5 parts of hydrogen peroxide, 2-4 parts of a stabilizing agent, 5-9 parts of compound additives, 1-3 parts of nanometer silicon dioxide, 1-2 parts of nanometer zinc oxide, 0.1-0.3 part of a corrosion inhibiting agent and 40-50 parts of distilled water. The polishing agent has the beneficial effects of being good in polishing quality, convenient to use, high in efficiency and the like, is free of the powder dust phenomenon and is free of chromic anhydride type toxic substances in the polishing process, the requirement for the waste water treatment condition is lowered, the abrasive dispersity of the polishing agent is good, the composition stability is good, and the surface evenness and the micro spine phenomenon effect of polishing on a mechanical equipment stainless steel material are remarkable; and meanwhile the preparation method of the mechanical equipment stainless steel material polishing agent is low in material cost, raw materials are easy to obtain, the process is concise, and high practical value and good application prospects are achieved.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

Closure heating type metal leakage furnace

InactiveCN101260506AImprove thermal efficiencySave electricitySolid state diffusion coatingMetallurgyElectric energy

Owner:黄留沪

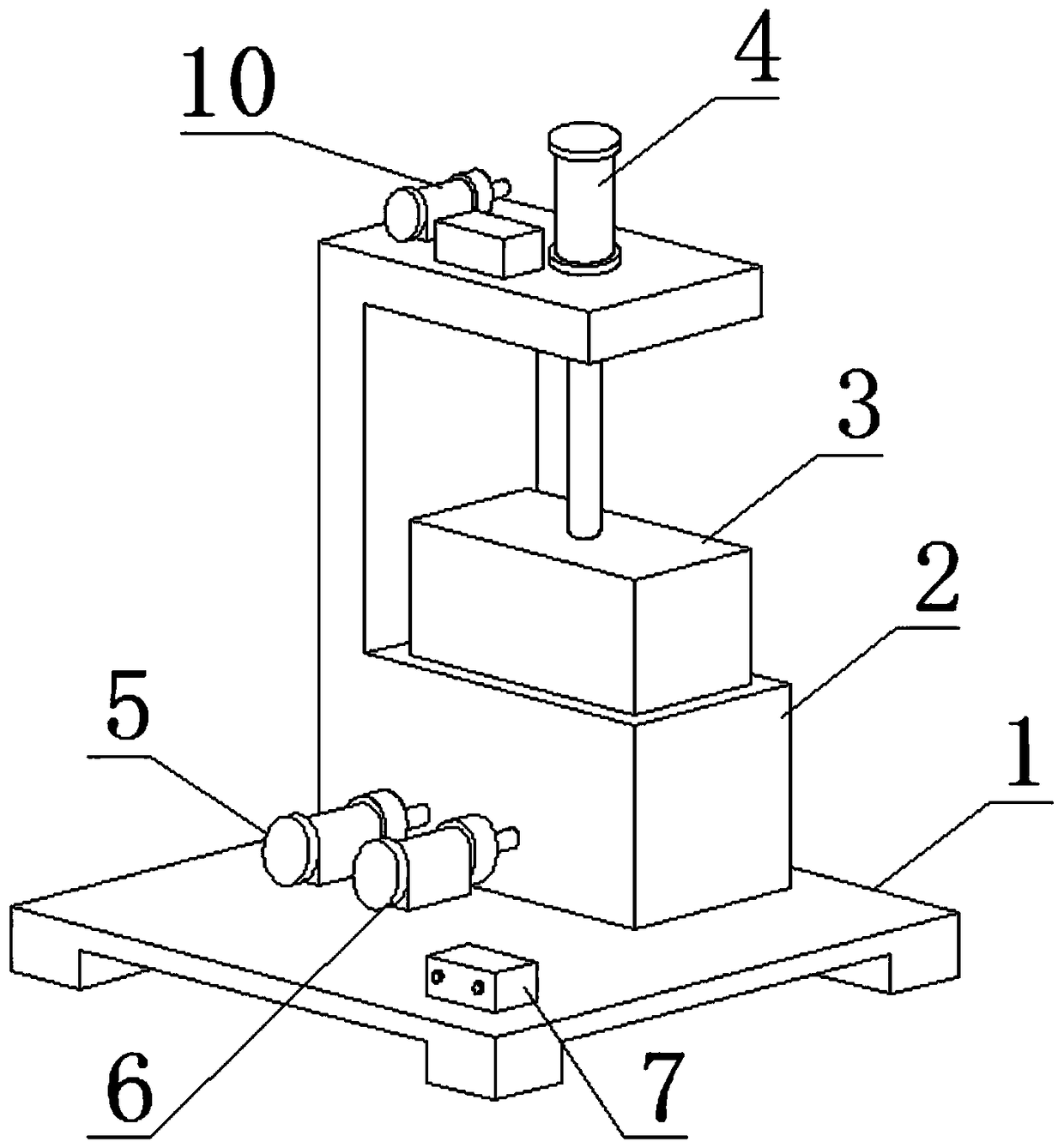

Device for preparing soil sample with specific water content as well as application thereof

ActiveCN108106904AUniform moisture contentSolve clumpingPreparing sample for investigationReal-time Control SystemWater storage

The invention provides a device for preparing a soil sample with specific water content as well as application thereof, and belongs to the technical field of geotechnical engineering. The device comprises a soil sample preparation device, a water storage device, a data acquisition and storage processor and a real-time control system, wherein the soil sample preparation device comprises a water spraying controller, a dry soil sprayer, a gravity sensor and a soil sample accommodating device. The device achieves the effect that the water content of the soil body is uniform and constant by combining layered spraying pavement of the soil layers and layered water spraying. As an example not limited and compared with the prior art, the device has the following beneficial effects that the uniformdegree of the water content of the soil body can be controlled well, in particular the problems that in the preparation process of the soil sample with the specific water content, the soil sample is agglomerated, the water content is non-uniform and the human factor has huge influence can be solved. The device is suitable for preparation of loess, sandy soil, expansive soil, in particular the sticky soil sample liable to agglomerate.

Owner:TONGJI UNIV

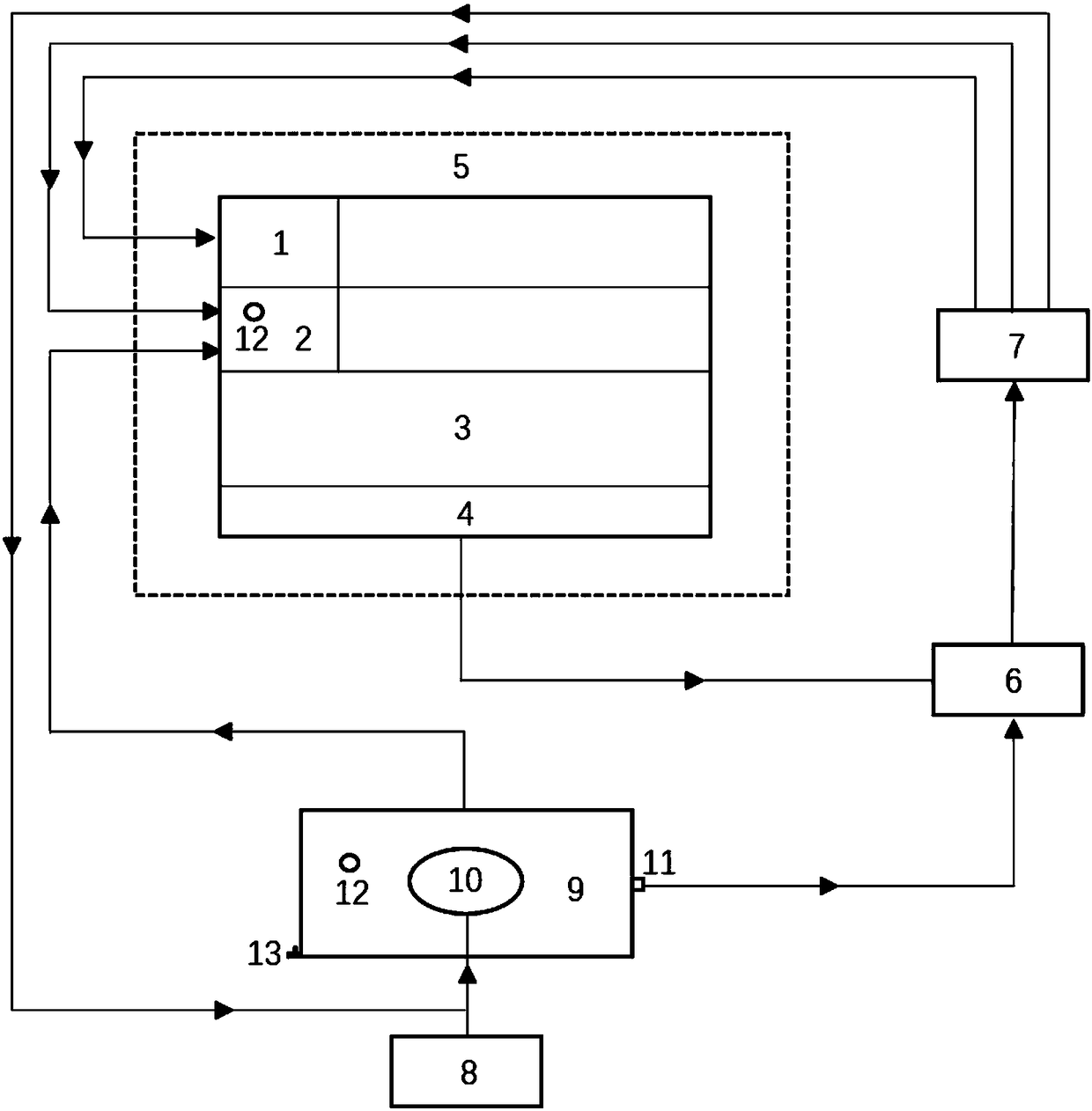

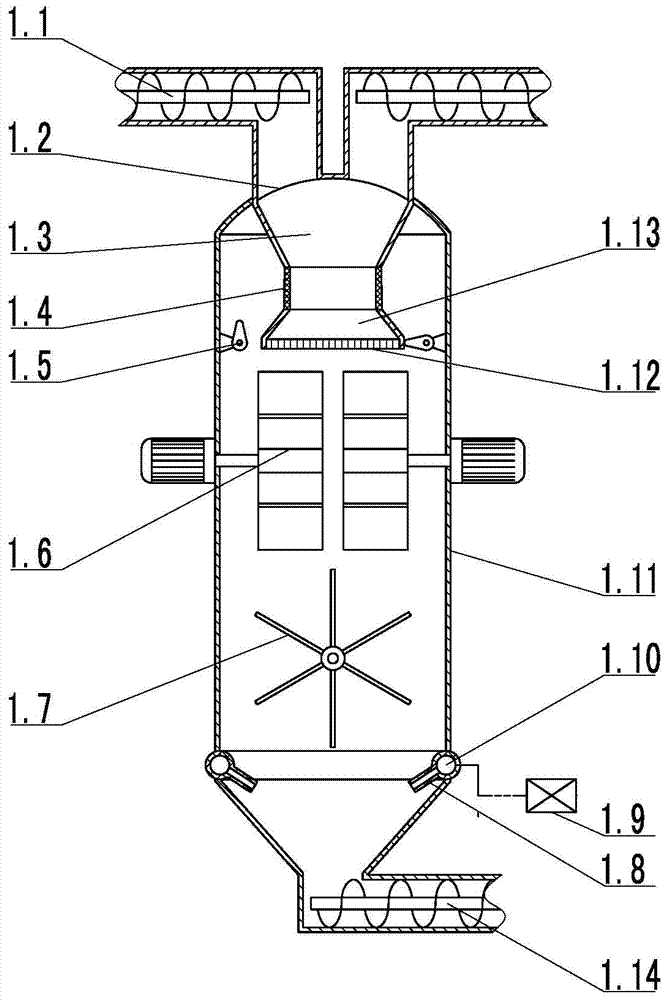

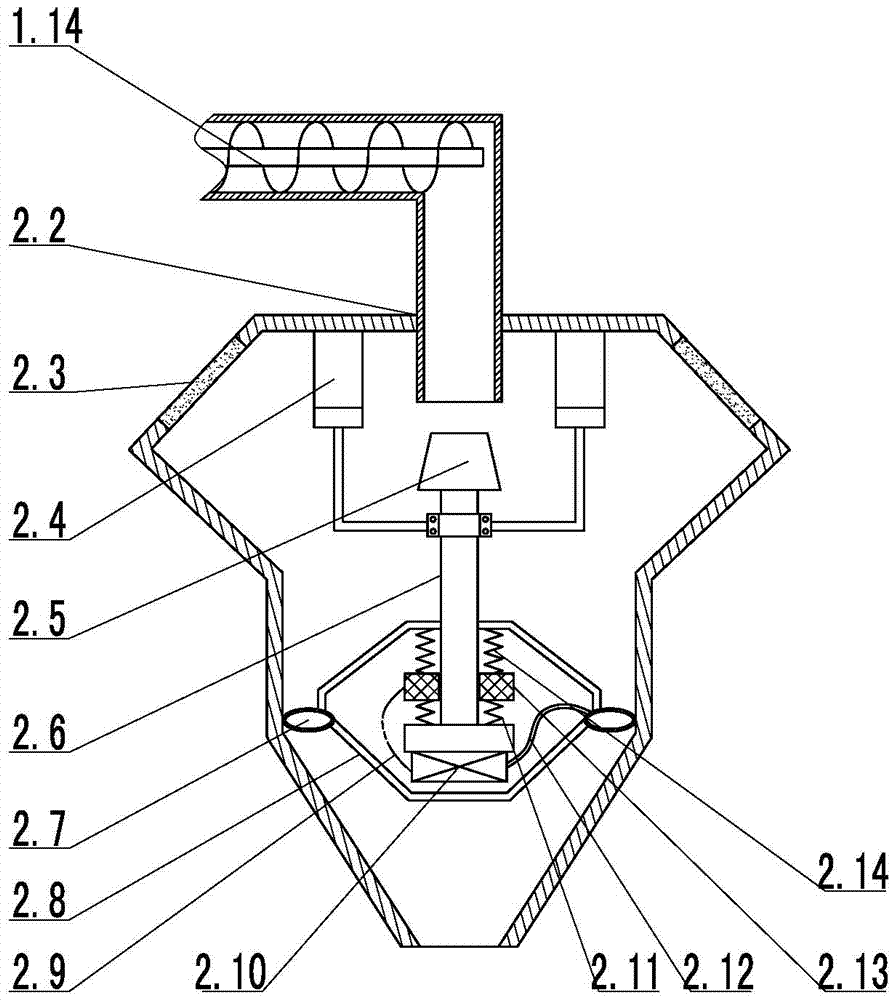

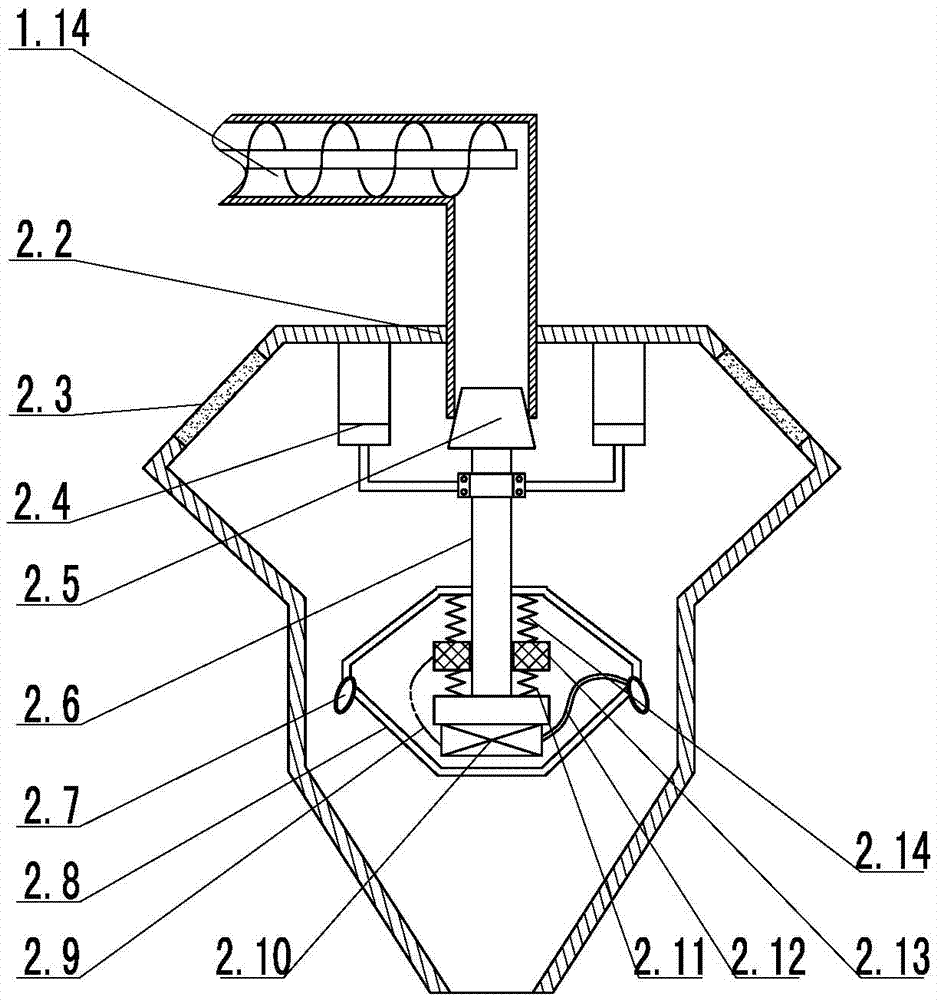

A fully automatic refractory plastic production equipment

ActiveCN105419817BAvoid clumpingAvoid uneven distribution of specific gravityFireproof paintsPlastic materialsRefractory

A full-automatic production device for refractory plastic materials belongs to the field of production devices for refractory materials and is characterized by comprising: a material preparing device, a material metering and dispensing device and a packaging device, wherein the three devices are connected successively to each other. The production device achieves full automation in production operation of the refractory plastic materials, reduces labor intensity of workers and improves production efficiency and quality. The production device is subjected to repeated design modification and test, is excellent in use effects and is suitable for being promoted in the field.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

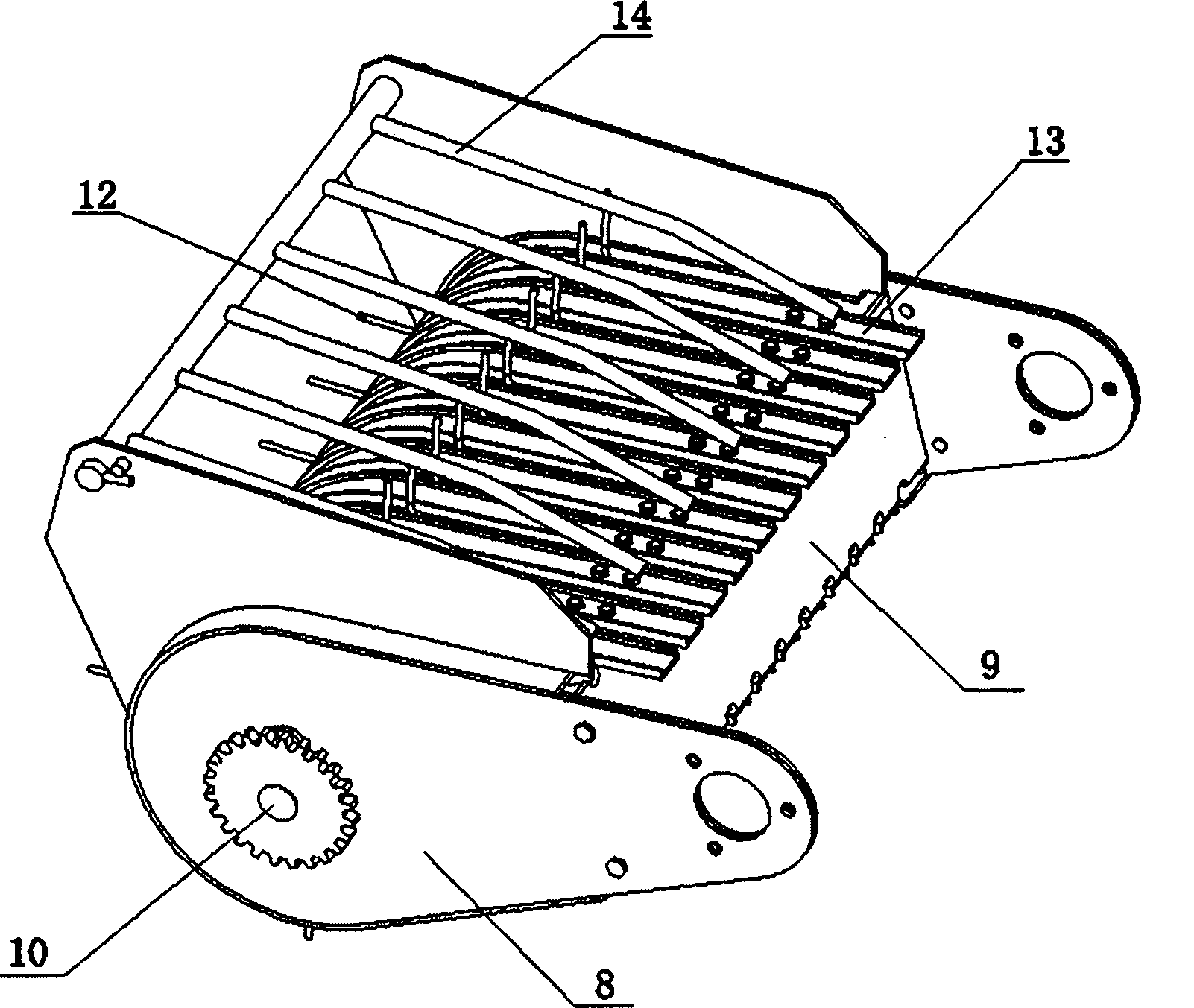

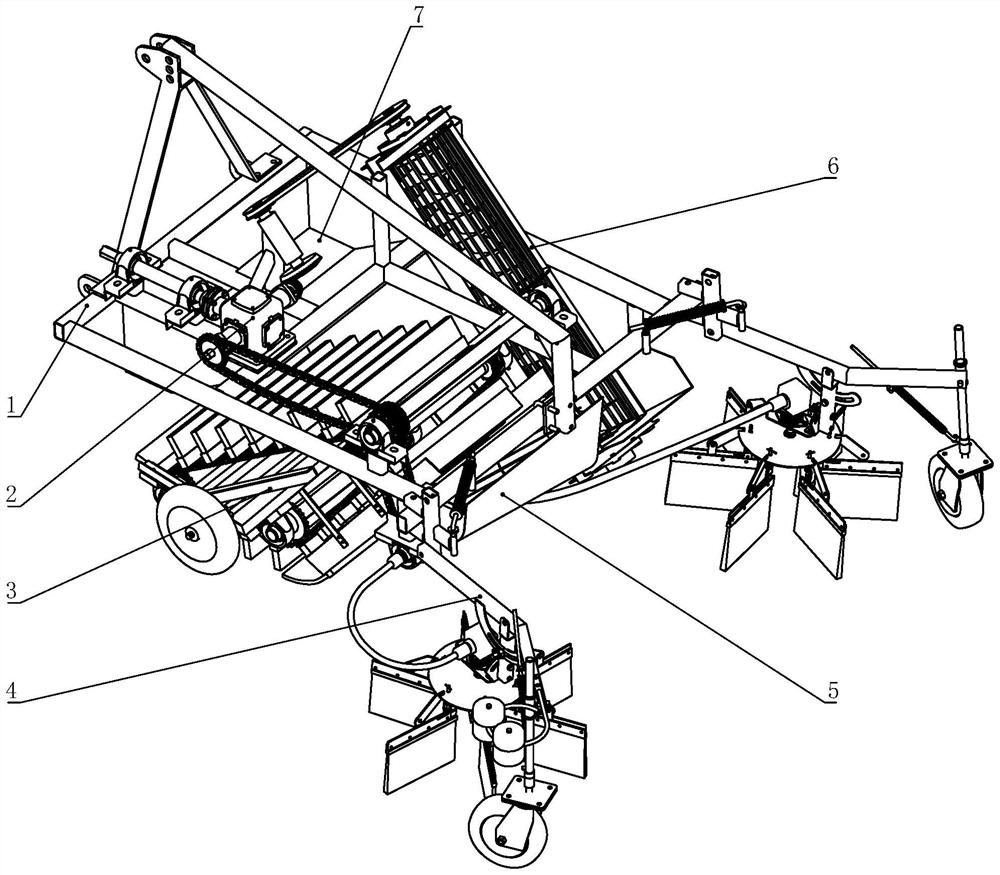

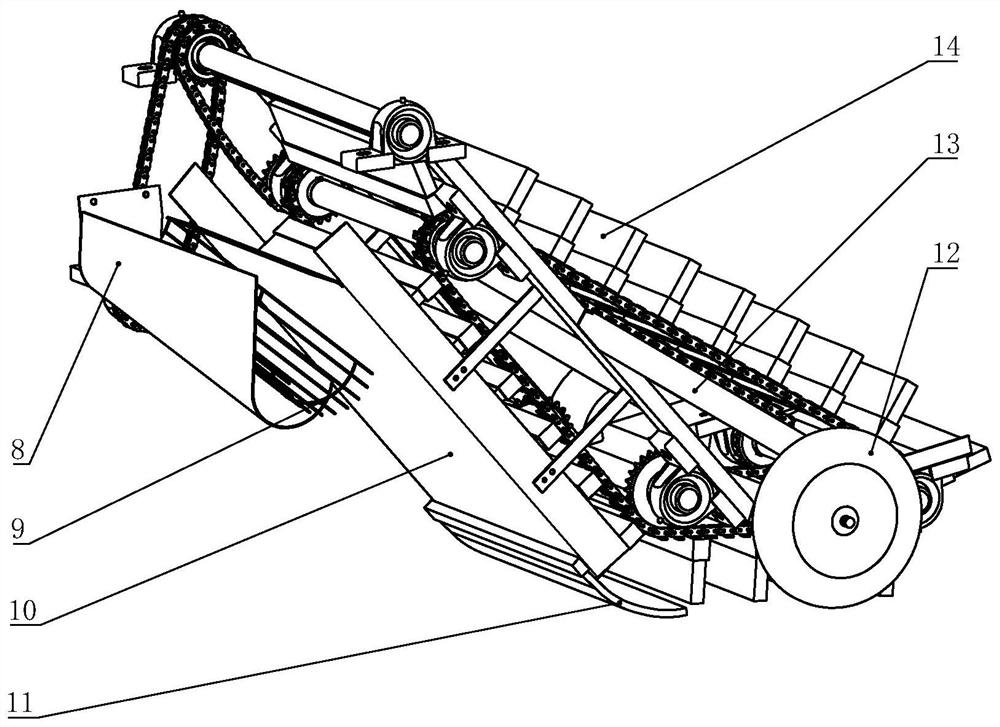

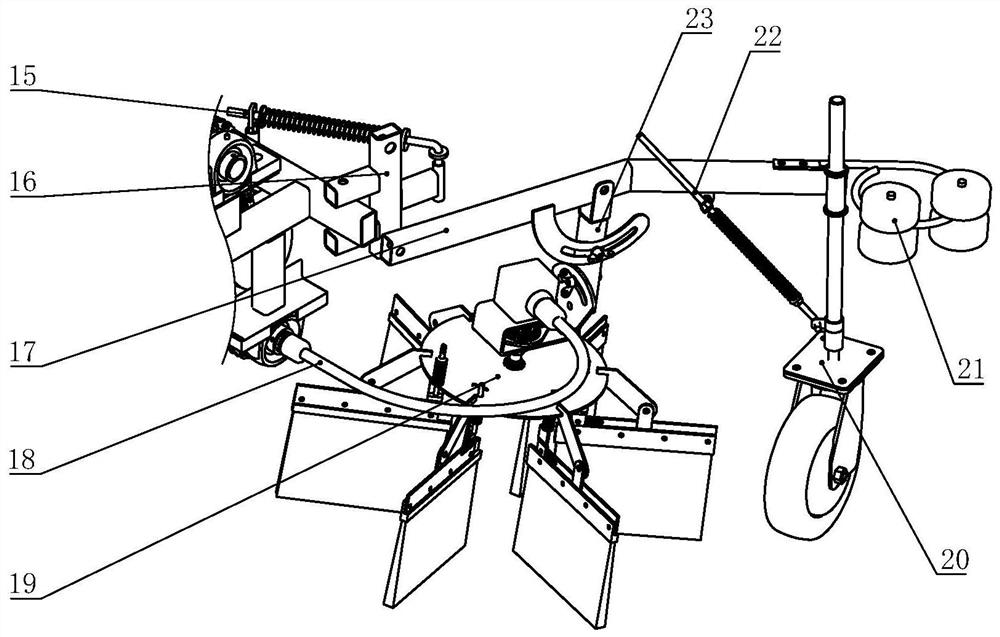

Harvester for red dates falling on ground

ActiveCN113748849ASimple structureReduce use costSievingScreeningAgricultural engineeringAgricultural science

The invention discloses a harvester for red dates falling on the ground, and belongs to the field of agricultural machinery. The harvester is composed of a suspension rack, sweeping devices, a picking device, an impurity removing device, a collecting net cage and a transmission system, wherein the sweeping devices are installed in front of the two sides of the front portion of the suspension rack respectively, the picking device is installed on the lower portion of the suspension rack, a soil removing device is installed below the suspension rack and connected with the front end of the upper portion of the picking device, the impurity removing device is installed in the suspension rack, the lower portion of the impurity removing device is connected with the tail end of a soil removing device, and the collecting net cage is located below the suspension rack and below the rear end of the impurity removing device. The harvester is suitable for picking and harvesting red dates falling to the ground and can complete the functions of sweeping and gathering, picking, impurity removing and collecting.

Owner:XINJIANG AGRI UNIV

A kind of composite slag remover specially used for beryllium aluminum alloy refining and its preparation method and method of slag removal

ActiveCN109735733BImprove adsorption capacitySuppress splashLithium chlorideSodium hexafluoroaluminate

The invention discloses a special composite slag removing agent for beryllium aluminum alloy refining, a preparation method and a slag removing method. The slag removing agent comprises the followingcomponents in parts by weight: 30-50 parts of sodium tetraborate, 2-8 parts of AlB12 intermediate alloy, 2-5 parts of hexachloroethane, 7-10 parts of sodium hexafluorisilicate, 2-6 parts of sodium fluoroaluminate, 1-5 parts of sodium fluoride, 5-12 parts of potassium chloride, 6-13 parts of beryllium chloride, 2-5 parts of lithium chloride, 2-5 parts of sodium carbonate, and 1-3 parts of clay. Theslag removing agent achieves excellent high-temperature stability and reliability under the vacuum condition, and is excellent in adhesiveness after melting, high in spreadability, quick in slag collection, easy incrustation of slag skin and excellent in slag removing and refining effect. Through the synergistic effect of all the components, oxides in melts, magnesium-contained impurities and hydrogen achieve excellent slag removing and absorbing effects; and meanwhile, the slag skin can effectively cover the surfaces of the melts, so that the temperature loss can be effectively reduced, thesplashing of the melts is inhibited, and new melting slag and secondary oxidation are prevented.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com