Glass product film pasting device capable of preventing dust mixing

A glass product and film sticking device technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as affecting product appearance, lax fit, dust inclusion, etc., to improve overall work efficiency, tight fit, reduce The effect of dismantling and cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

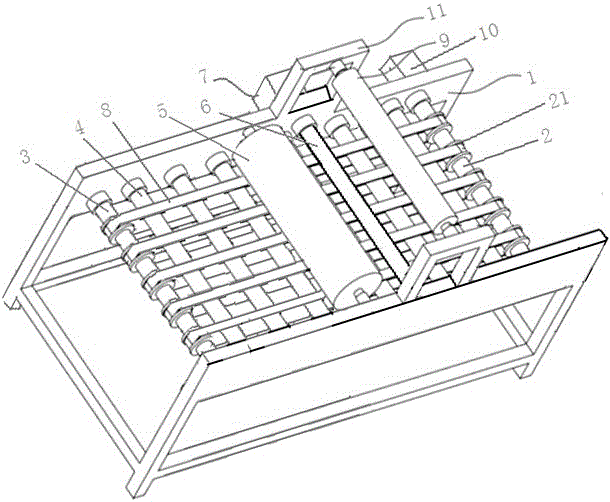

[0021] like figure 1 As shown, the supporting rod 4 is arranged parallel to the driving shaft 2 . The role of the support rod 4 is to assist the belt 8 to support the glass products during the transmission process, and at the same time prevent the glass products from moving downward with the elastic force of the belt 8 when the roller shaft 5 is rolling, and the support set perpendicular to the conveying channel The rod 4 can better realize the supporting function.

[0022] figure 1 In the embodiment, the dust removal wiper 6 is arranged parallel to the roller shaft 5. The operation interval between the roller shaft 5 and the dust removal wiper 6 is set to 10-20cm. The guided pasting of the film can be carried out manually.

[0023] The dust removal wiper 6 is a regular polyhedral cylinder, which is convenient to rotate and replace the dust removal surface, reduces the frequency of disassembly, cleaning and replacement of the dust removal cover, and improves work efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com