Recovery technology of waste lithium batteries

A waste lithium battery and process technology, applied in the field of waste lithium battery recycling process, can solve problems such as air environment and noise impact, electrical short circuit, positive and negative electrode powder dust, etc., to reduce operating costs and investment costs, and improve the working environment , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

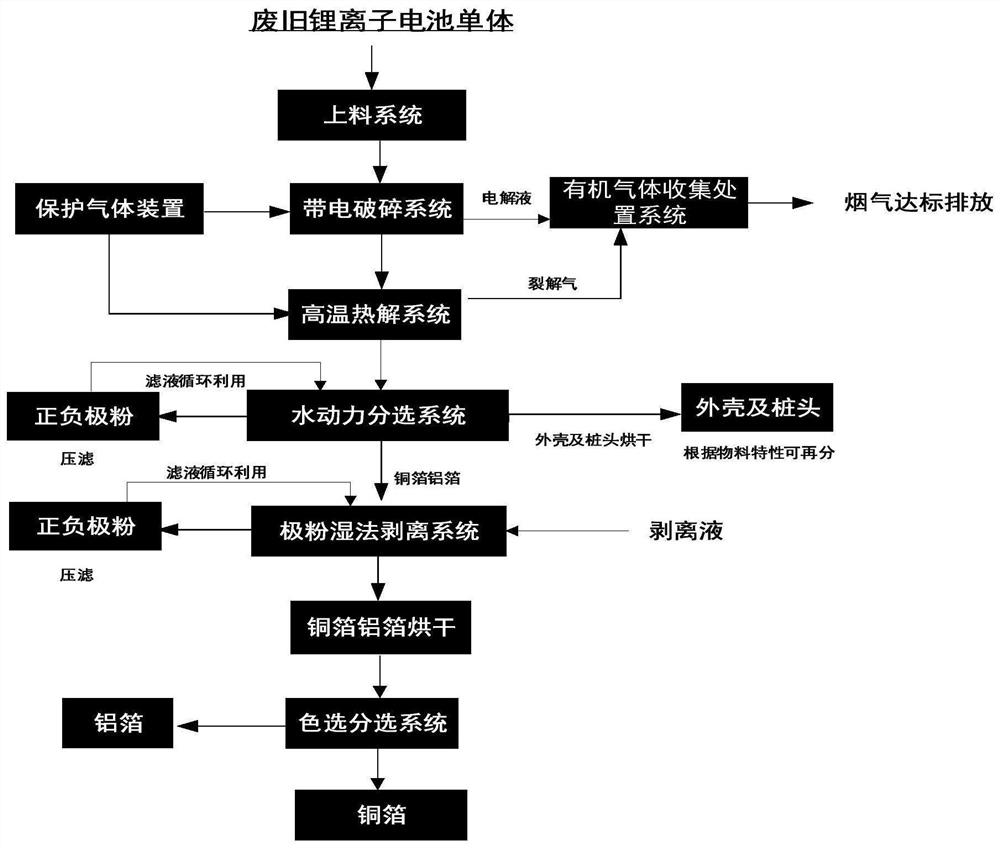

[0035] A recycling process for waste lithium batteries, comprising the steps of:

[0036] (1) Insulate the waste lithium battery and transfer it to the feeding system;

[0037] (2) The material falls to the crushing system through the feeding system, and the material is charged and sheared under the nitrogen protection state, and the fragments are transported to the high-temperature pyrolysis system by a screw;

[0038] (3) The crushed material enters the high-temperature pyrolysis system, and the PVDF glue and electrolyte on the waste lithium battery pole piece are pyrolyzed at 550°C for 1.5 hours under high-temperature and anaerobic conditions, and the pyrolysis gas is collected and disposed of through the exhaust port and organic gas The system docking realizes the discharge of flue gas up to the standard;

[0039] (4) The material from the pyrolysis system falls to the hydrodynamic sorting system. After meeting the flowing liquid from the bottom, the steel shell and coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com