Method for desorbing acidic gas by oxidization process

A technology of acid gas and oxidation method, which is applied in the direction of chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as low efficiency, achieve the effects of reducing load, improving removal efficiency, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

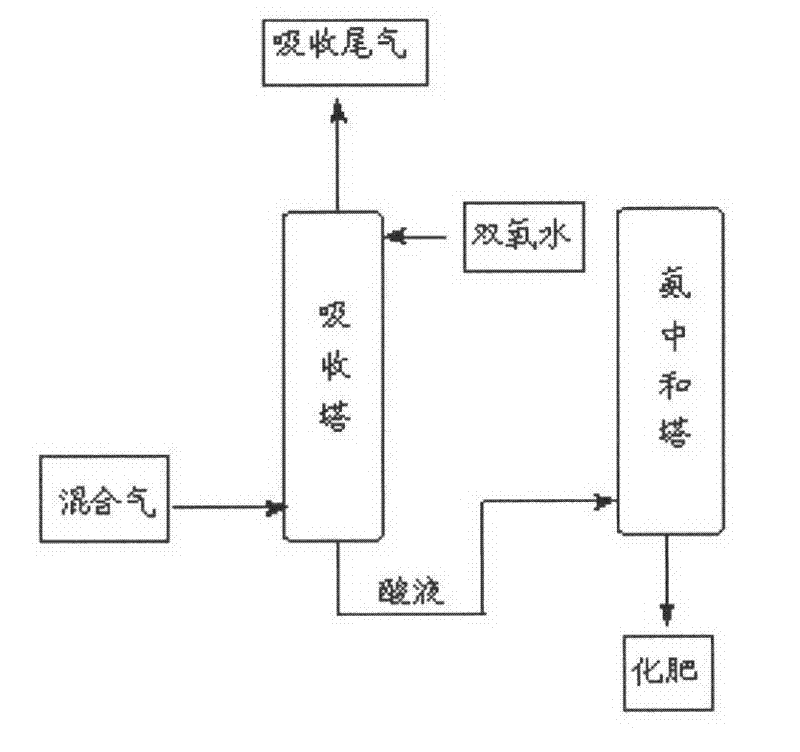

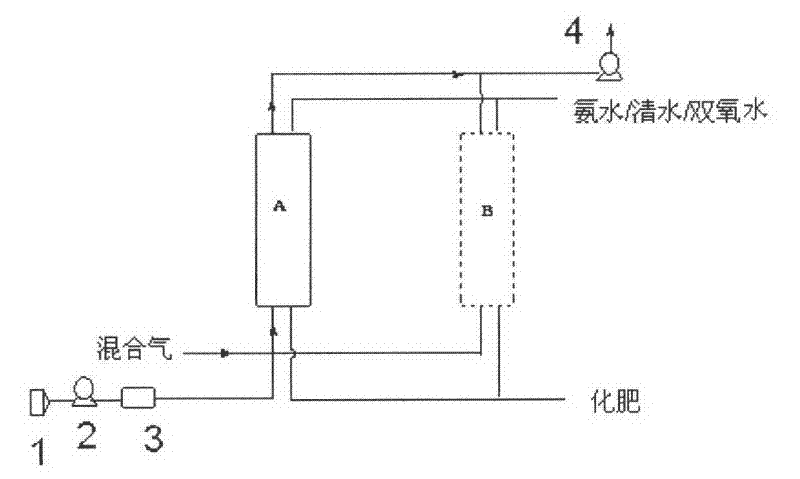

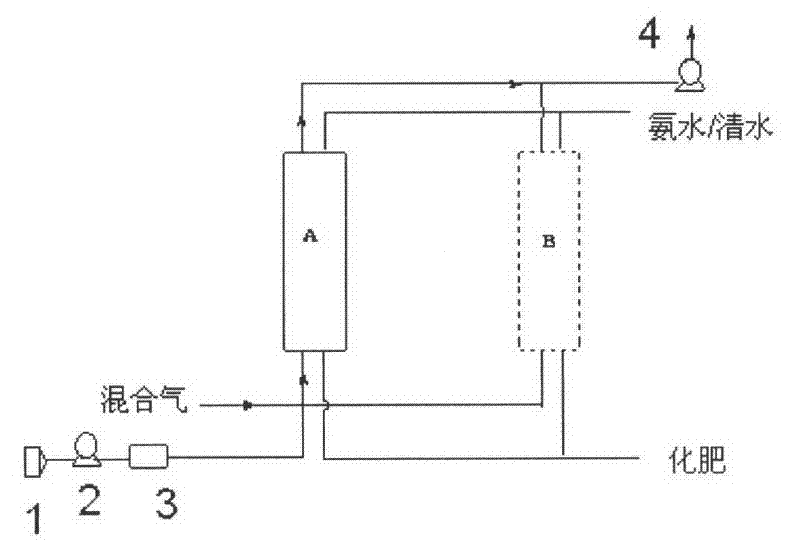

[0026] The present invention is described in detail as follows with reference to accompanying drawing:

[0027] As shown in the figure, A is the first adsorption tower, and B is the second adsorption tower. 1 is an air filter, 2 is a blower, 3 is a heater, and 4 is an induced draft fan.

[0028] absorb

[0029] After the mixed gas to be treated is washed with water to remove dust and cooled, it enters the absorption tower from the bottom under the condition of normal pressure and not higher than 60°C (normal temperature to 60°C), and the hydrogen peroxide is sprayed from the top of the tower to combine with the SO in the mixed gas 2 / NO x The reaction occurs, and the generated acid liquid is discharged from the bottom of the tower into the neutralization tower, and the tail gas after absorption is discharged from the top of the tower.

[0030] neutralize

[0031] The acid liquid discharged from the absorption tower reacts with ammonia water in the neutralization tower to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com