A kind of composite slag remover specially used for beryllium aluminum alloy refining and its preparation method and method of slag removal

A technology of beryllium aluminum alloy and slag agent, which is applied to the special compound slag remover for beryllium aluminum alloy refining and the field of preparation method and slag removal, can solve the problem that the slag remover cannot be applied, and achieves the increase of slag removal and degassing effect, and the inhibition of slag removal. Dust phenomenon, good coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

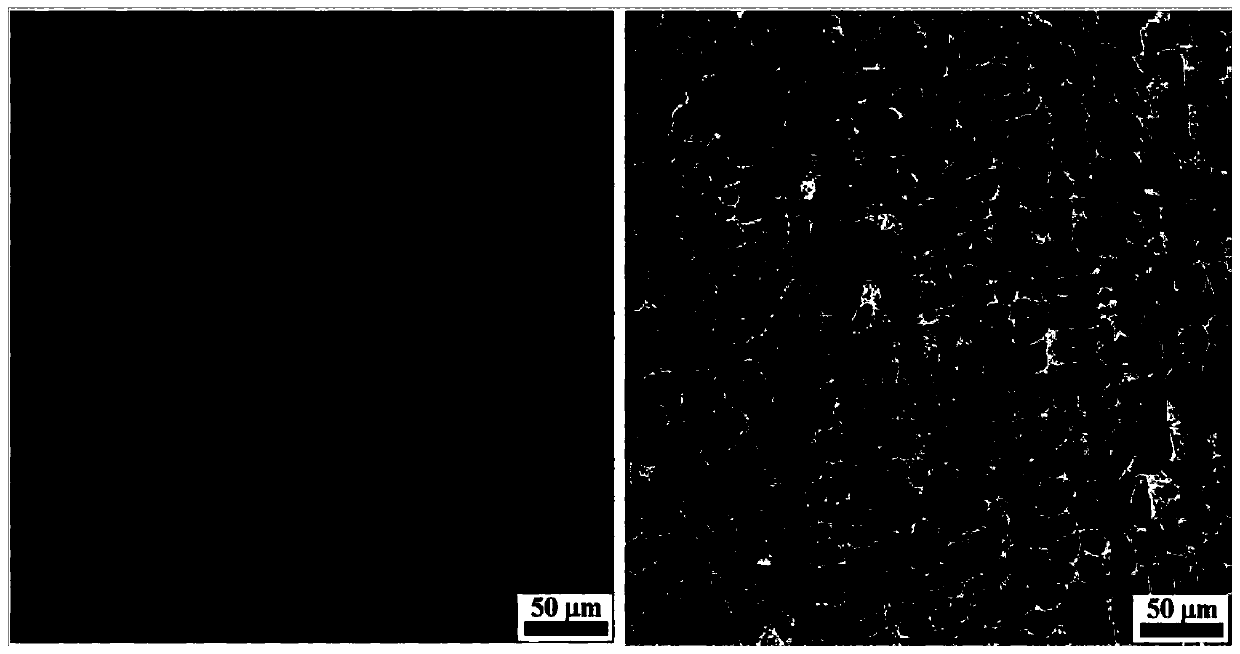

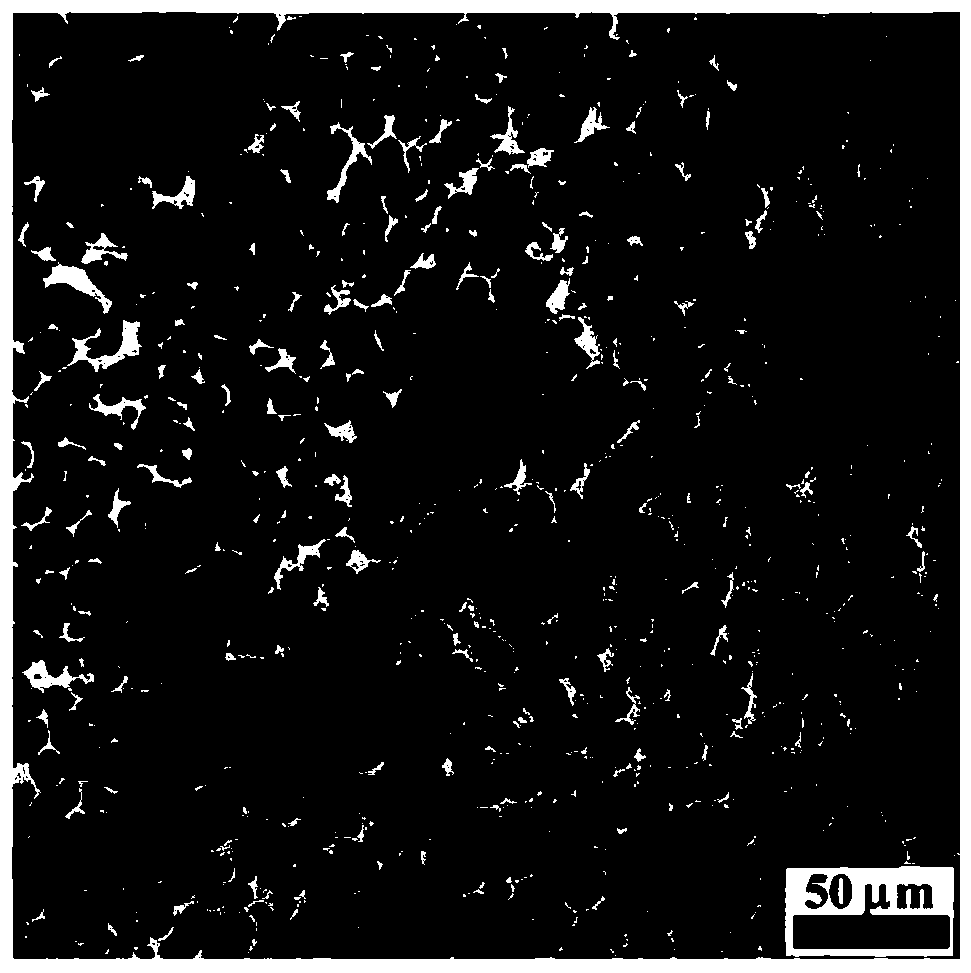

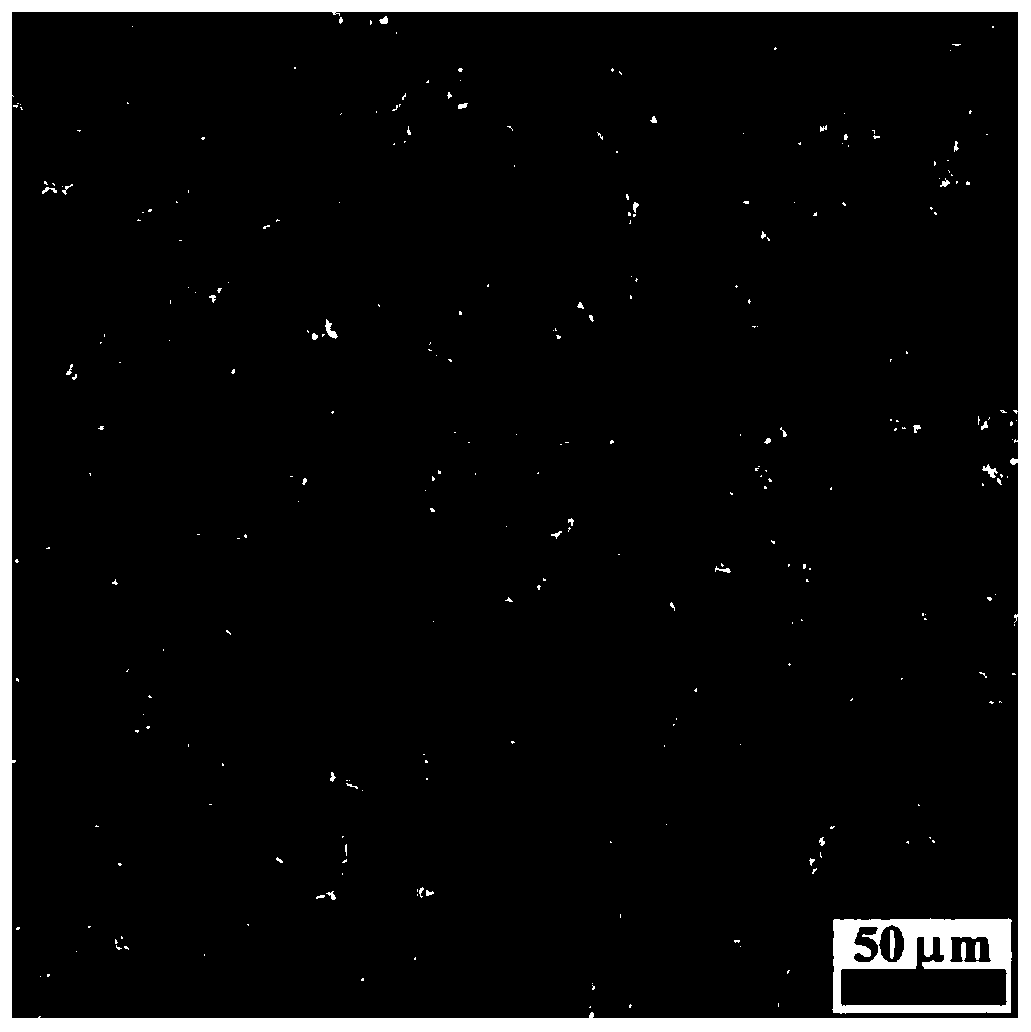

Image

Examples

Embodiment 1

[0058] This embodiment discloses the preparation method and application of the special composite slag remover for beryllium aluminum alloy refining of the present invention.

[0059] The composite deslagging agent of the present embodiment contains the following components by weight: sodium tetraborate (Na 2 B 4 o 7 ) 40 parts, AlB 12 6 parts of master alloy, hexachloroethane (C 2 Cl 6 ) 5 parts, sodium hexafluorosilicate (Na 2 SiF 6 ) 10 parts, sodium hexafluoroaluminate (Na 3 AlF 6 ) 6 parts, sodium fluoride (NaF) 2 parts, potassium chloride (KCl) 10 parts, beryllium chloride (BeCl 2 ) 12 parts, lithium chloride (LiCl) 3 parts, sodium carbonate (Na 2 CO 3 ) 3 parts, clay 3 parts.

[0060] AlB in this embodiment 12 The mass fraction of boron in the master alloy is 3.83%.

[0061] The preparation method of the composite slag remover in this embodiment is as follows: accurately weigh each raw material according to the parts by weight of the above-mentioned componen...

Embodiment 2

[0067] This embodiment discloses the preparation method of the special composite slag remover for beryllium aluminum alloy refining of the present invention.

[0068] The composite deslagging agent of the present embodiment contains the following components by weight: sodium tetraborate (Na 2 B 4 o 7 )45 parts, AlB 12 Master alloy 4 parts, hexachloroethane (C 2 Cl 6 ) 2 parts, sodium hexafluorosilicate (Na 2 SiF 6 ) 8 parts, sodium hexafluoroaluminate (Na 3 AlF 6 ) 2 parts, sodium fluoride (NaF) 5 parts, potassium chloride (KCl) 12 parts, beryllium chloride (BeCl 2 ) 10 parts, lithium chloride (LiCl) 5 parts, sodium carbonate (Na 2 CO 3 ) 5 parts, clay 2 parts.

[0069] AlB in this embodiment 12 The mass fraction of boron in the master alloy is 4.89%.

[0070] The preparation method of the composite deslagging agent in this embodiment is as follows: accurately weigh each raw material according to the weight fraction of the above-mentioned components, and the purity ...

Embodiment 3

[0075] This embodiment discloses the preparation method of the special composite slag remover for beryllium aluminum alloy refining of the present invention.

[0076] The composite deslagging agent of the present embodiment contains the following components by weight: sodium tetraborate (Na 2 B 4 o 7 )32 parts, AlB 12 8 parts master alloy, hexachloroethane (C 2 Cl 6 ) 5 parts, sodium hexafluorosilicate (Na 2 SiF 6 ) 9 parts, sodium hexafluoroaluminate (Na 3 AlF 6 ) 5 parts, sodium fluoride (NaF) 4 parts, potassium chloride (KCl) 12 parts, beryllium chloride (BeCl 2 ) 13 parts, lithium chloride (LiCl) 4 parts, sodium carbonate (Na 2 CO 3 ) 5 parts, clay 3 parts.

[0077] AlB in this embodiment 12 The mass fraction of boron in the master alloy is 3.11%.

[0078] The preparation method of the composite deslagging agent in this embodiment is as follows: accurately weigh each raw material according to the weight fraction of the above-mentioned components, and the purit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com