High efficient and environment-friendly pebble coal full-sealing discharge device

A technology of discharge device and pebble coal, which is applied in the field of thermal power plant equipment, can solve the problems of internal leakage and external leakage of slag discharge doors, air leakage, difficulty in processing and conveying pebble coal, etc., and achieves the effect of reducing fugitive dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

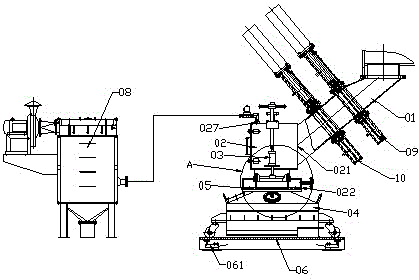

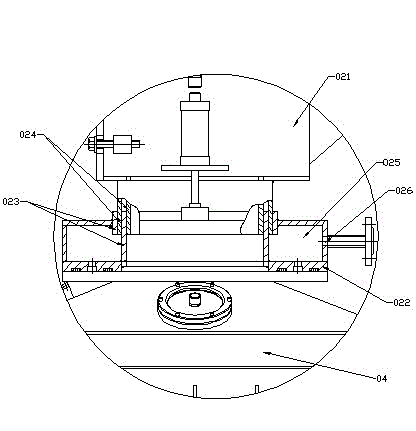

[0014] As shown in the figure, the high-efficiency and environmentally friendly pebble coal fully sealed discharge device includes a transition pipe 01 connected to the pebble coal outlet of the coal mill. The end of the transition pipe is connected to a sealed chamber 02. It consists of a liftable annular cover 022 under the bin body, and the cover 022 is driven by the cylinder 03 installed on the warehouse body 021; a removable transfer box 04 is arranged under the cover 022, and a removable transfer box 04 is arranged on the top of the transfer box. The feed port 041 at the bottom of the cover is fitted, and a sealing ring 05 is provided between the edge of the feed port 041 and the bottom surface of the cover 022; several coaxial lower cylinders 023 with different diameters are provided on the top of the cover 022, and at the same time in the warehouse The lower opening of the body 021 is provided with several coaxial upper cylinders 024 with different diameters, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com