Closure heating type metal leakage furnace

A metal infiltration and heating technology, applied in the field of metal infiltration on metal surface, can solve the problems of waste of rework, harsh production environment, complicated operation, etc., and achieve the effect of excellent infiltration layer quality, saving metal raw materials, and expanding application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

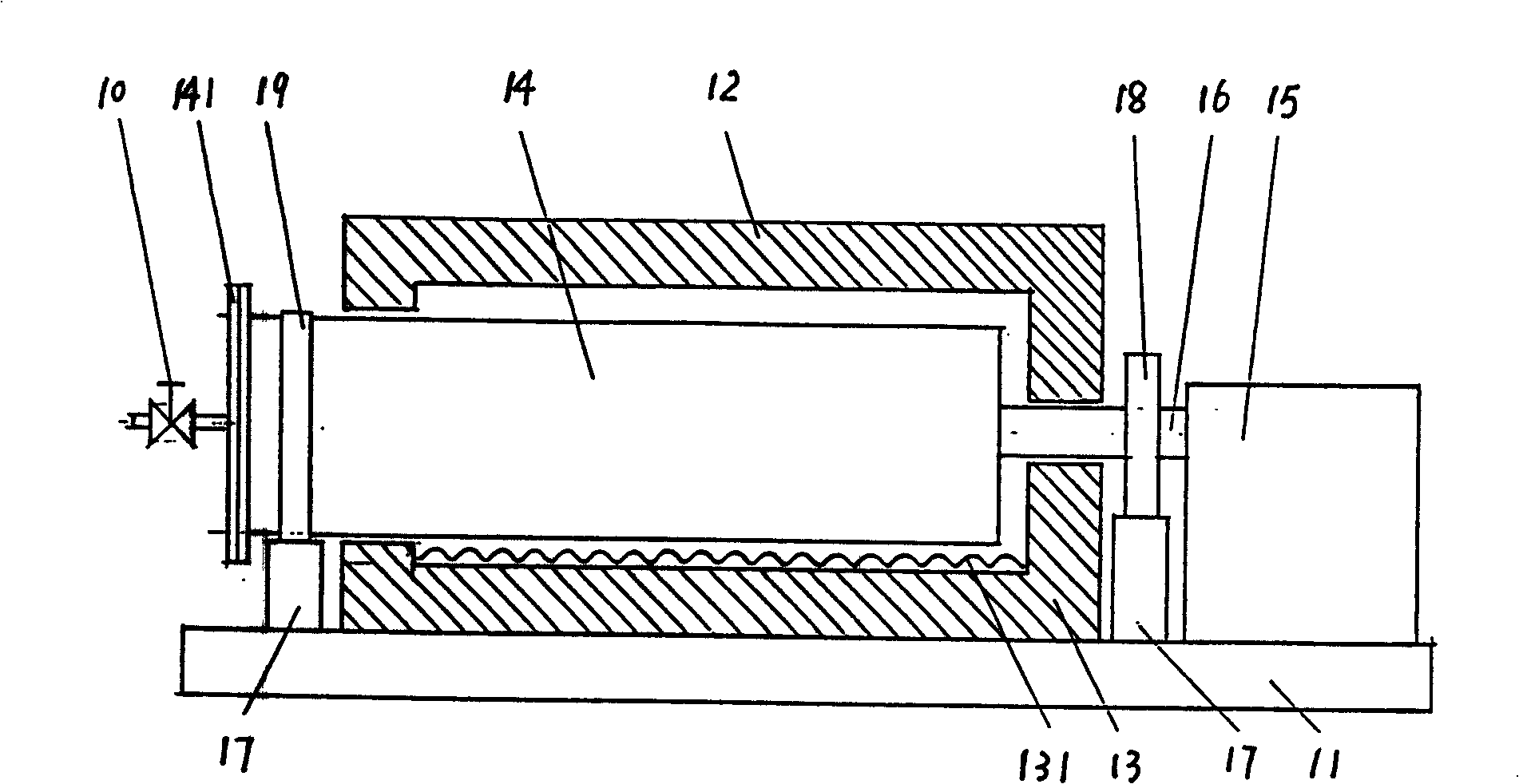

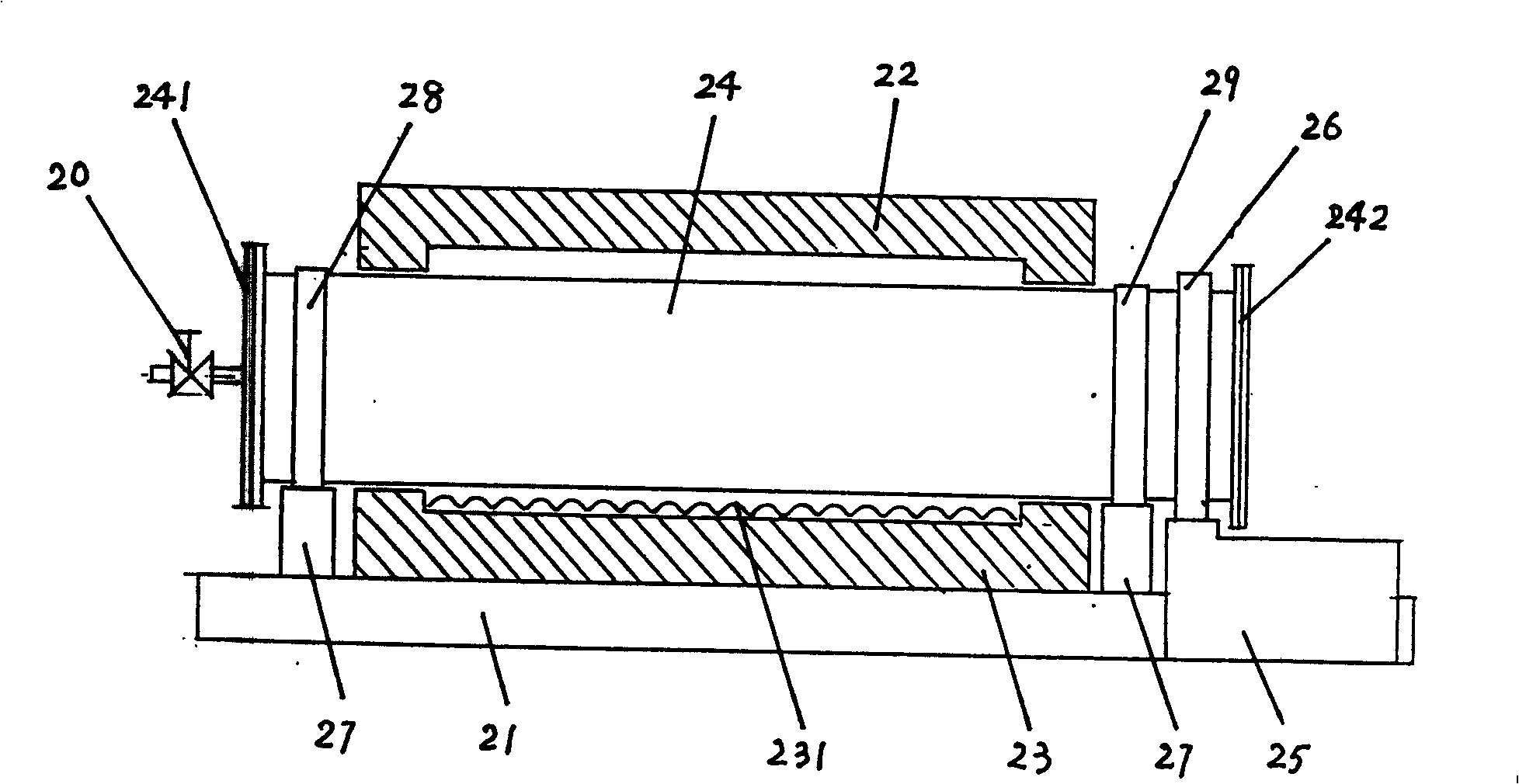

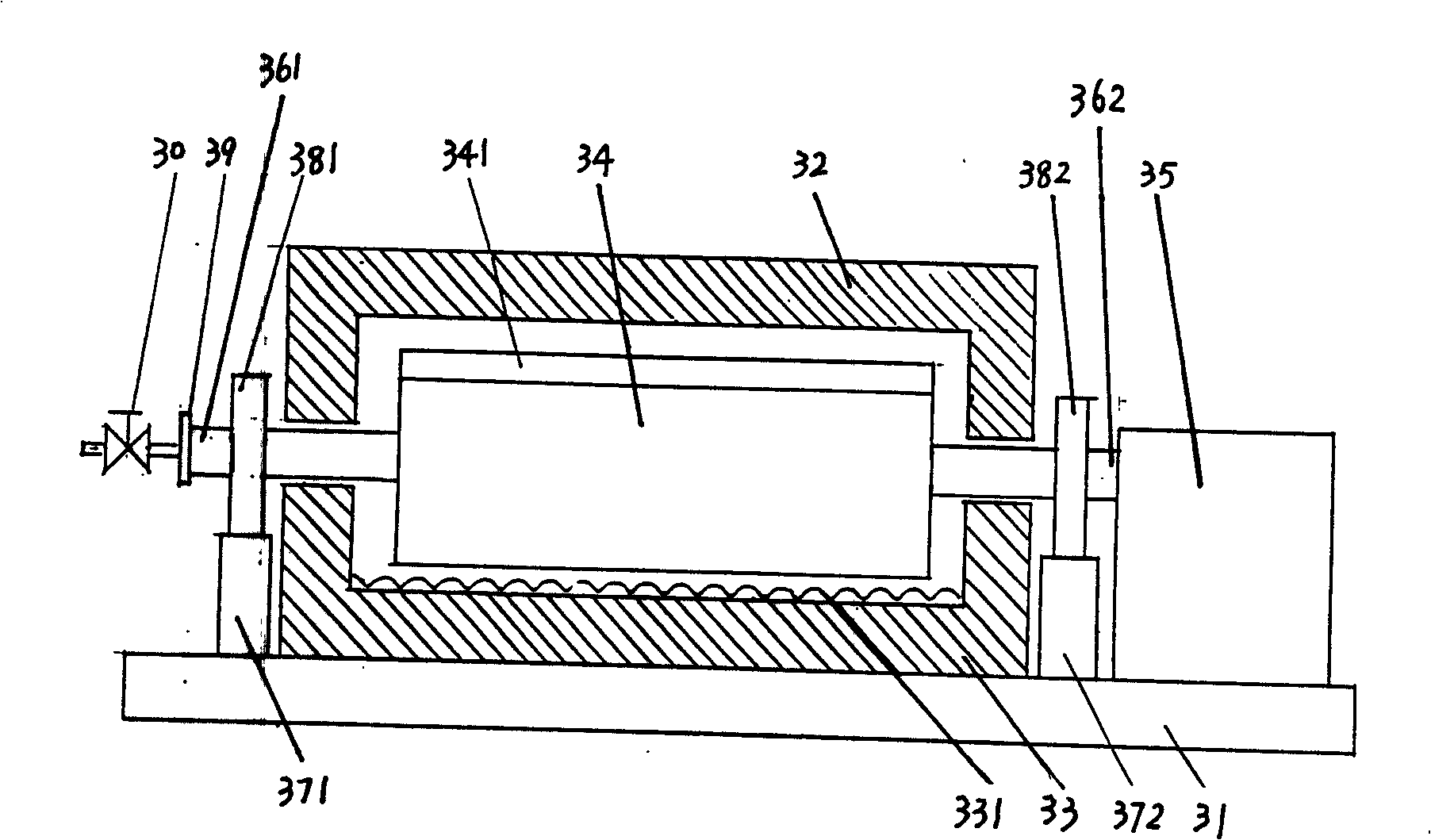

[0028] see image 3 , Figure 4 , the closed heating type metal infiltrating furnace of the present invention comprises a furnace body seat 31, an upper furnace body 32, a lower furnace body 33, a furnace gall 34, a power mechanism 35, front and rear axles 361, 362, front and rear support wheel groups 371, 372, front and rear Roller 381,382, axle end cover 39 and pressure regulating assembly 30. The upper furnace body 32 and the lower furnace body 33 are combined into a split type furnace body and erected on the furnace body base 31 , and a heating element 331 is installed in the lower furnace body 33 . Furnace 34 is all arranged in the inner cavity of the furnace to form an inner container, and a furnace door 341 is provided on the side wall of furnace 34 . The two ends of the furnace 34 are respectively connected with a front wheel shaft 361 and a rear wheel shaft 362, and the two wheel shafts pass through the two ends of the furnace body respectively and are erected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com