Patents

Literature

126 results about "Design modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A design change is the modification conducted to the product. It can happen at any stage in the product development process. The design changes that happen early in the design process are less expensive when compared to those that take place after it is introduced into full-scale production.

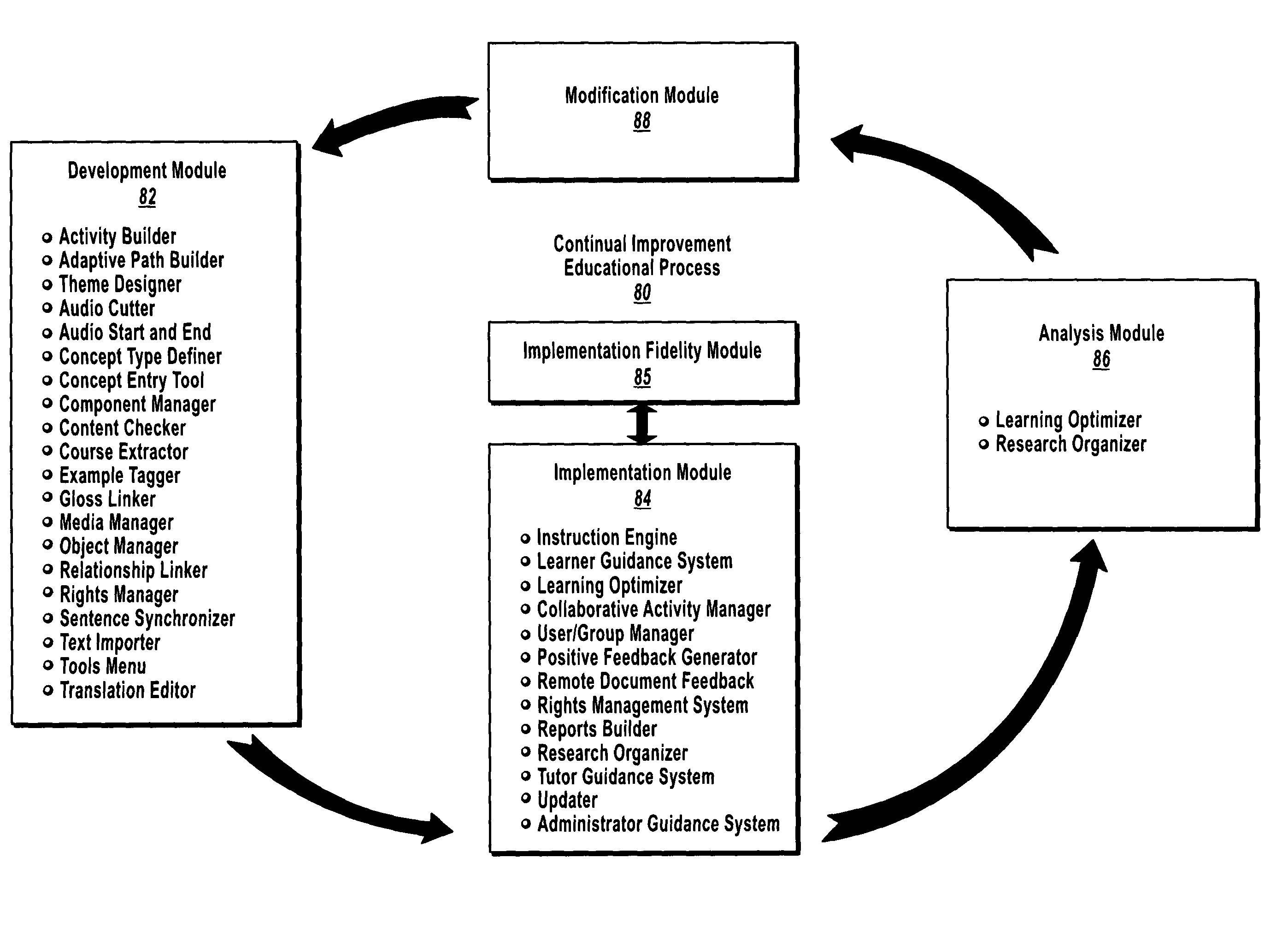

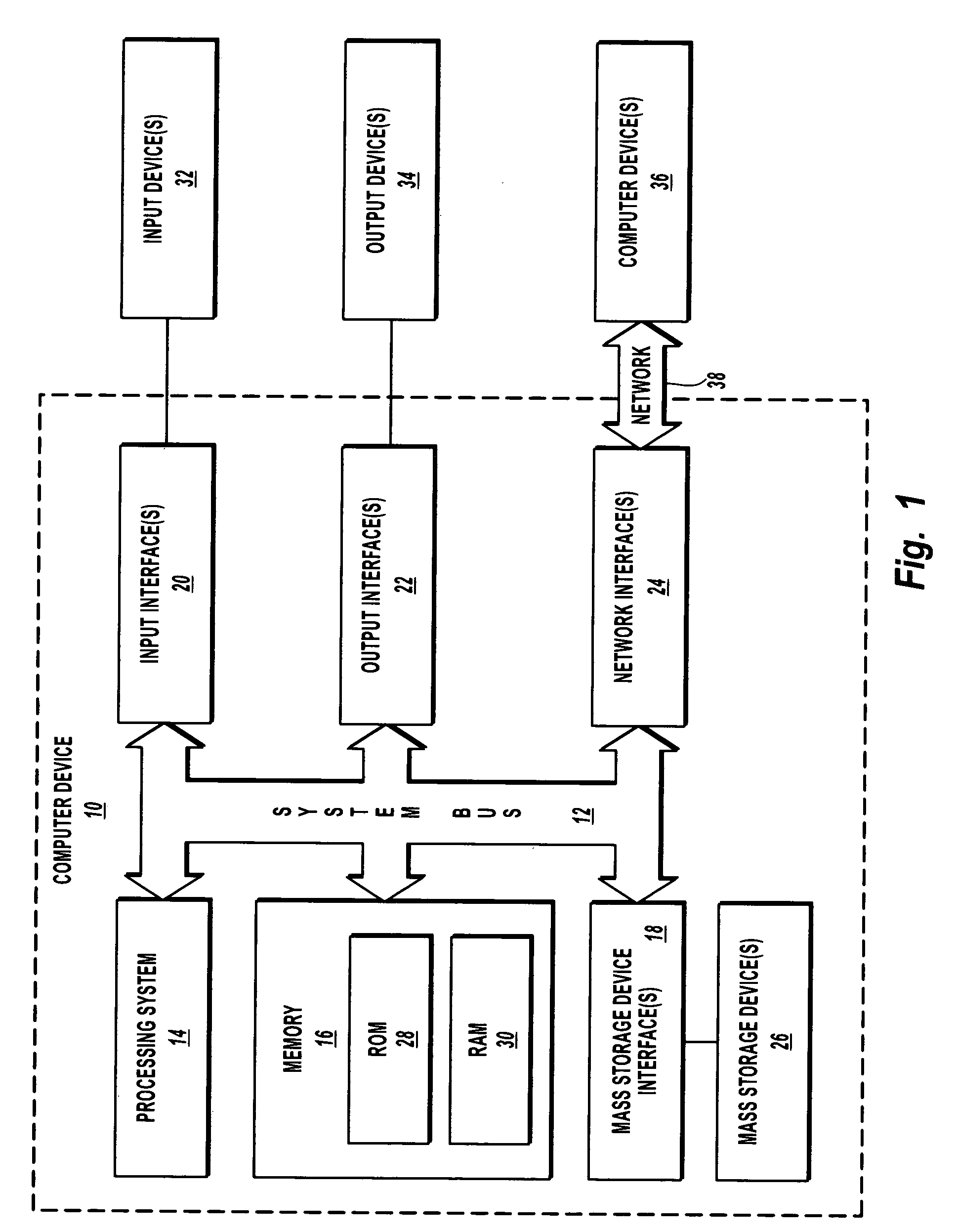

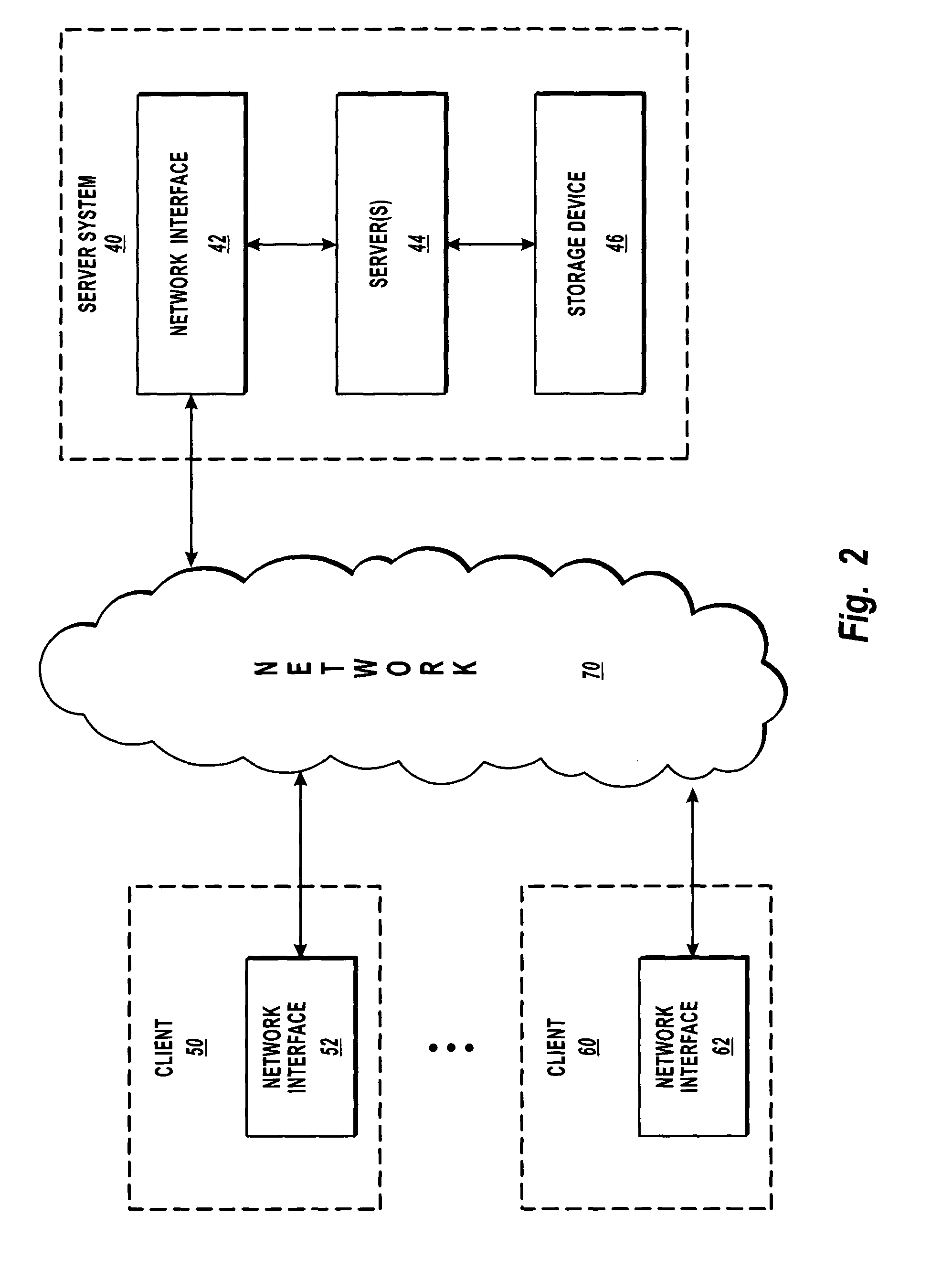

Systems and methods for providing a dynamic continual improvement educational environment

ActiveUS20050026131A1Quick modificationPrompt experienceEducational modelsElectrical appliancesAmbulatory systemLearning gain

Dynamic systems and methods for gathering / tracking data, automatically adapting to an individual's pace of learning, selectively determining the type and difficulty of content provided to an individual, selectively providing an exposure frequency for the content, and / or enabling rapid design modifications within the educational environment. Educational content is dynamically designed / developed and customizably presented to an individual learner. An analysis is performed on the data to optimize learning. Modifications are selectively or automatically made to the educational content. The process of designing, implementing, analyzing, and selectively modifying creates a cycle that optimizes the learning process and adapts to groups and individual learners with the goal of improving learning outcomes and efficiency. Furthermore, the educational content is dynamically provided to the learner on an iterative basis according to the need of that learner in the learning process.

Owner:INTELLECTUAL RESERVE

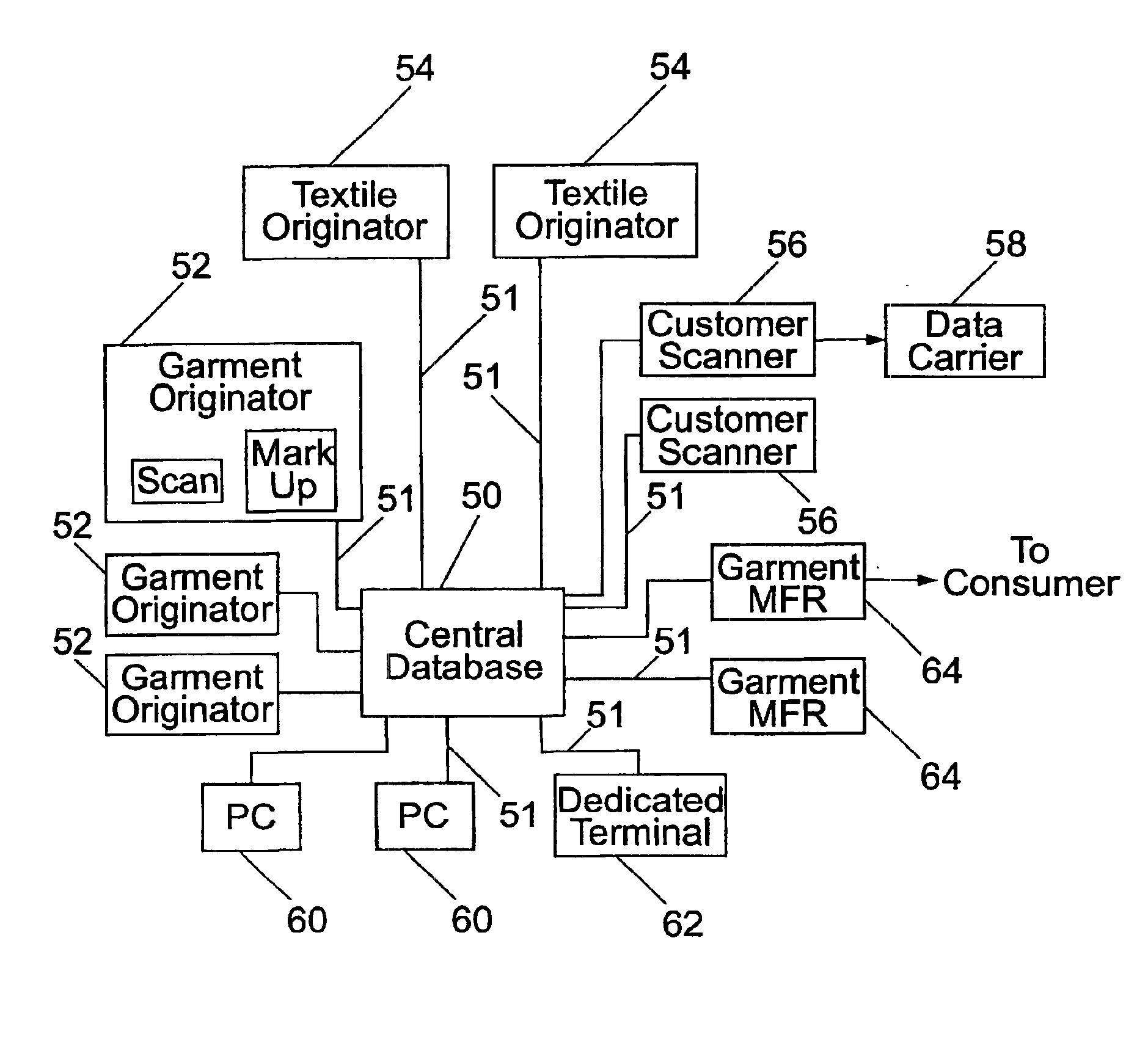

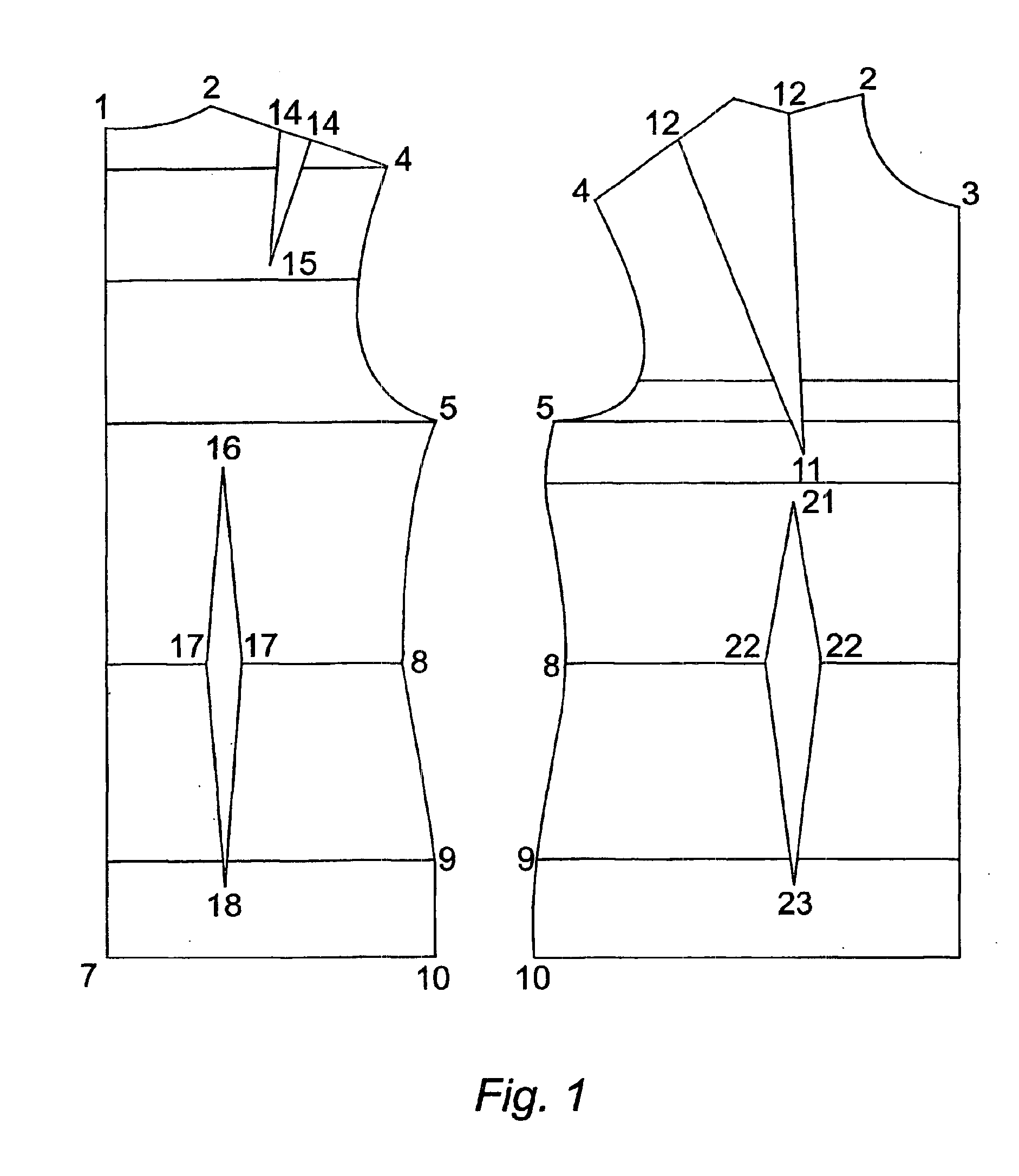

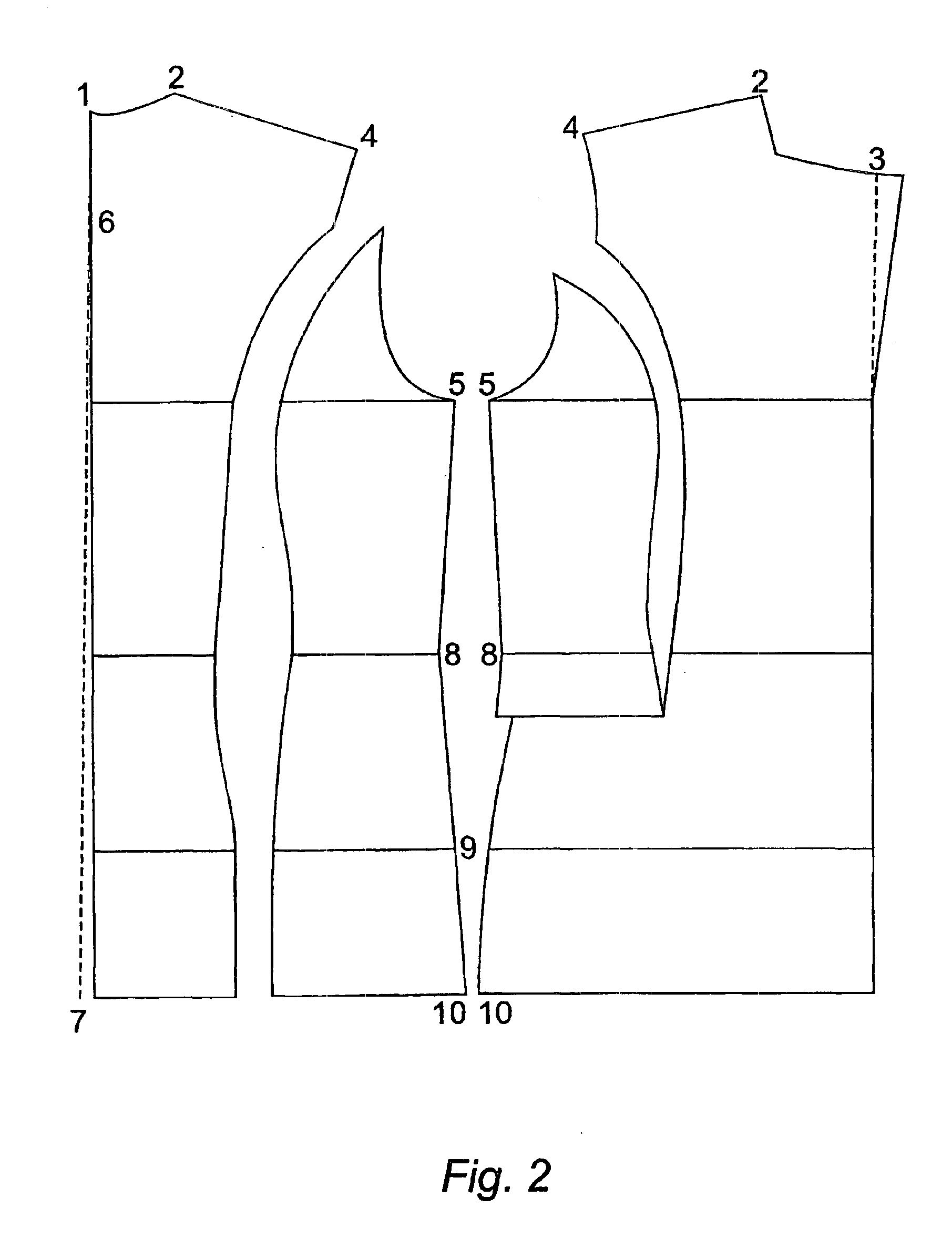

Production and visualization of garments

InactiveUS6907310B2Special data processing applicationsClothes making applicancesBody shapeEnergy minimization

Methods and systems for modelling and modifying garments, providing a basis for integrated “virtual tailoring” systems and processes. The garment models provided relate specific design points of the garment to specific body regions in terms of explicit 3D relationship rules, enabling garments to be modified holistically, by a constrained 3D warp process, to fit different body shapes / sizes, either in order to generate a range of graded sizes or made-to-measure garments, for the purposes of visualization and / or garment production. The methods described further facilitate the generation of 2D pattern pieces by flattening 3D representations of modified garments using a constrained internal energy minimization process, in a manner that ensures that the resulting pattern pieces can be assembled in substantially the same way as those of the base garment. The methods enable the visualisation and / or production of bespoke or graded garments, and garment design modifications, within an integrated virtual tailoring environment.

Owner:VIRTUAL MIRRORS

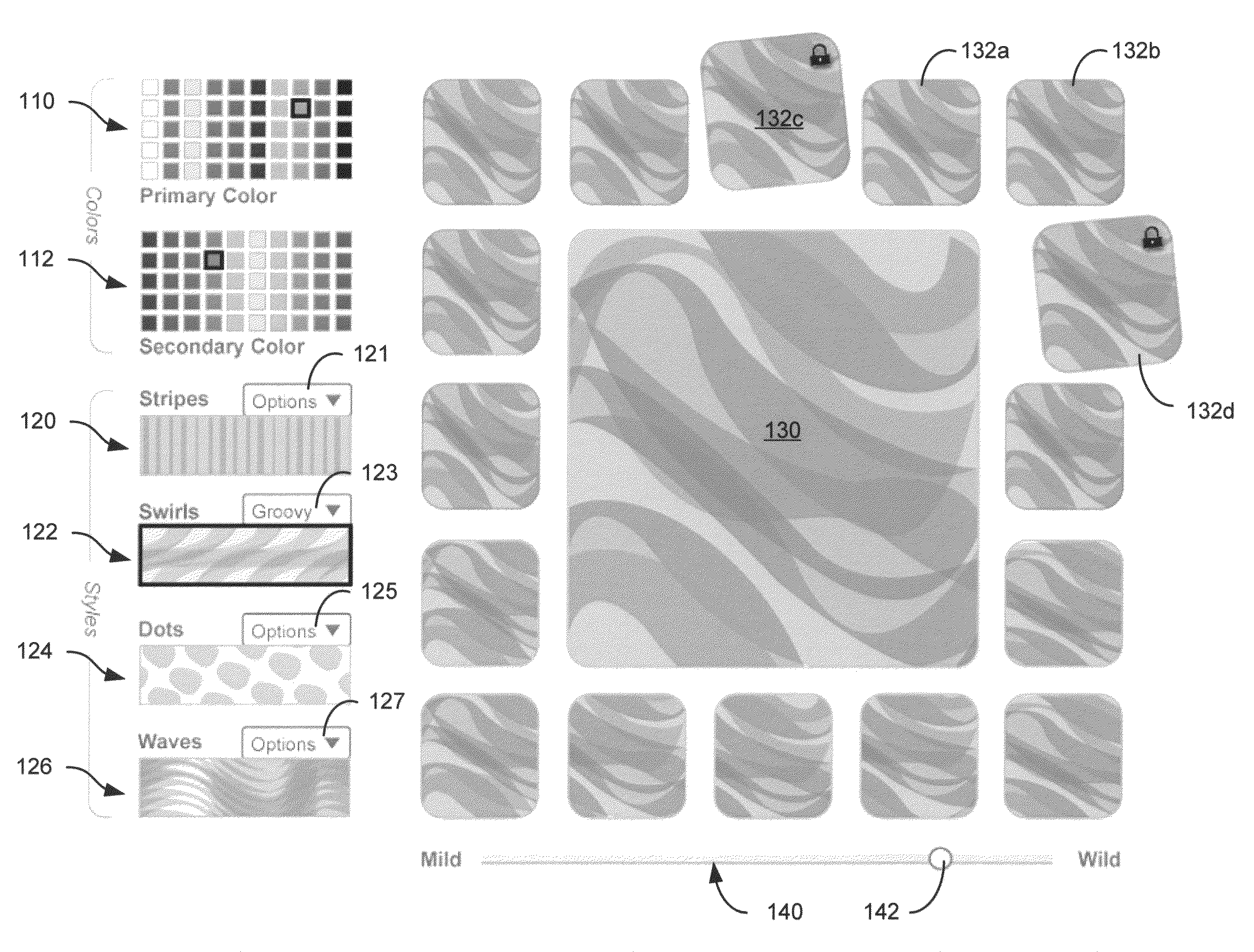

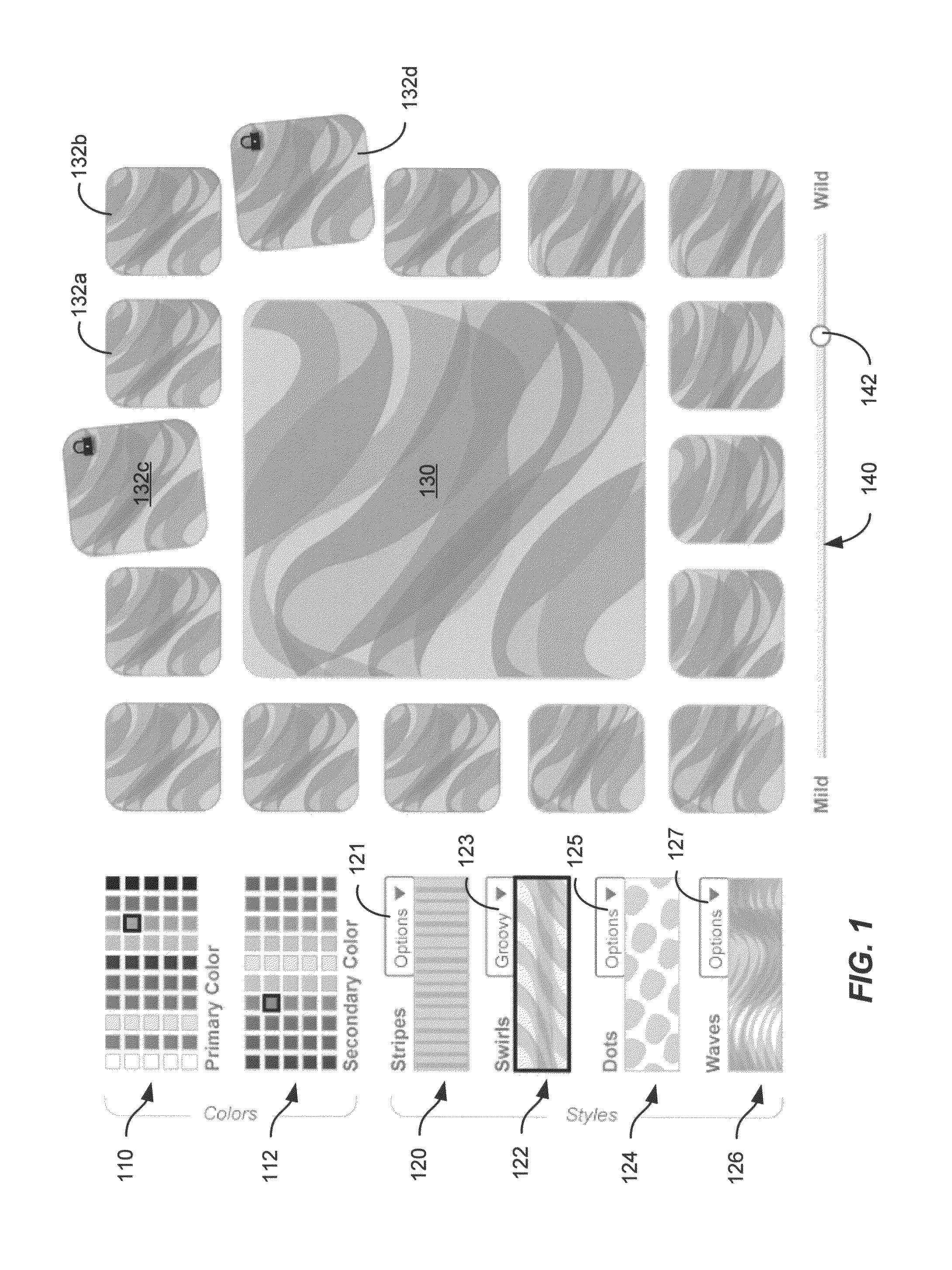

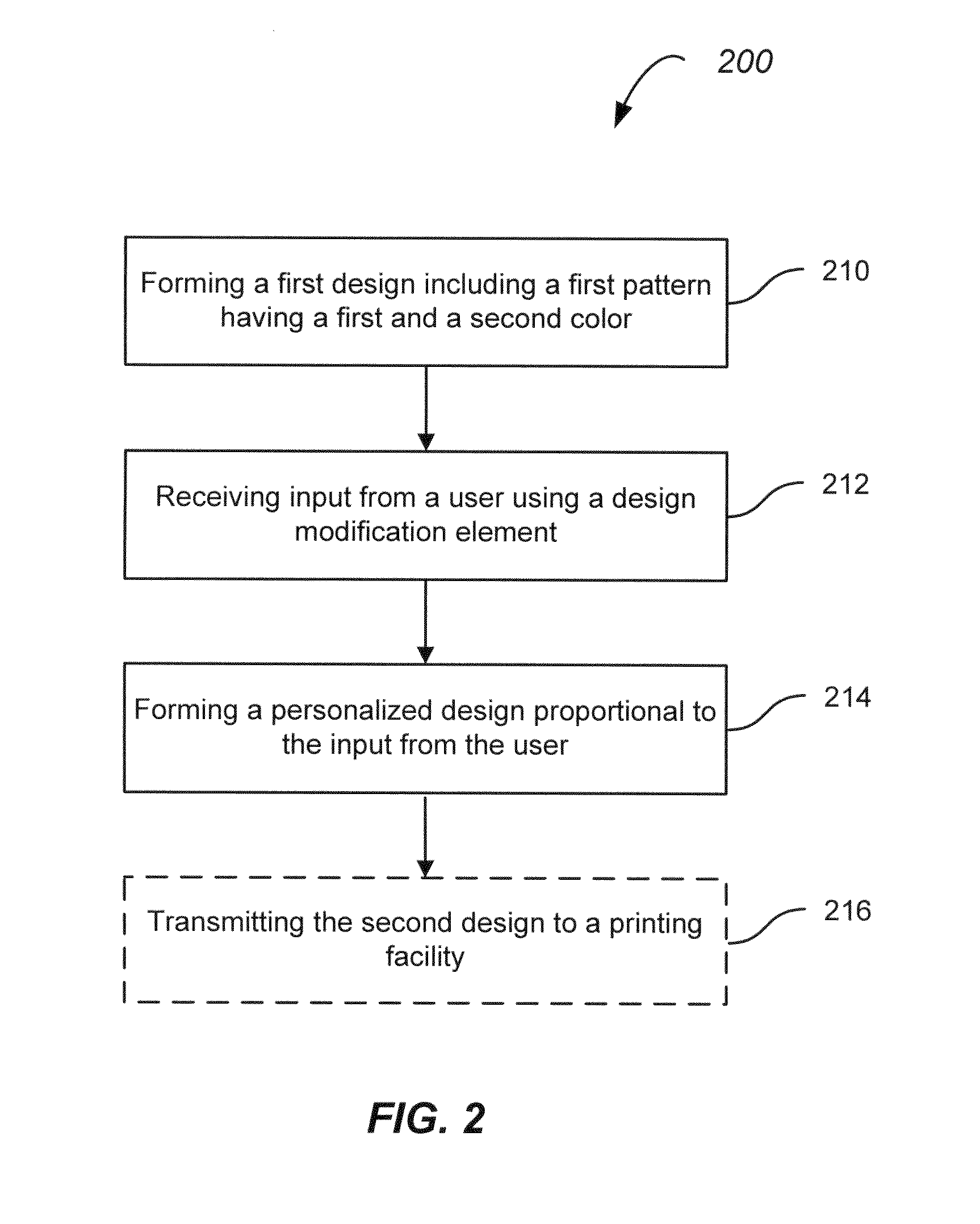

Method of operating a design generator for personalization of electronic devices

ActiveUS20100073380A1Easy to useColorful and interesting designTexturing/coloringCathode-ray tube indicatorsPersonalizationEngineering

A method of generating a customized image includes forming a first design including a first pattern having a first color and a second color. The method also includes receiving input from a user using a design modification element. The method further includes forming a second design including a second pattern including a third color and a fourth color. A change from the first design to the second design is proportional to the input received from the user using the design modification element.

Owner:CISCO TECH INC

Systems and methods for providing a dynamic continual improvement educational environment

ActiveUS8182270B2Quick modificationPrompt experienceEducational modelsElectrical appliancesDesign modificationComputer science

Dynamic systems and methods for gathering / tracking data, automatically adapting to an individual's pace of learning, selectively determining the type and difficulty of content provided to an individual, selectively providing an exposure frequency for the content, and / or enabling rapid design modifications within the educational environment. Educational content is dynamically designed / developed and customizably presented to an individual learner. An analysis is performed on the data to optimize learning. Modifications are selectively or automatically made to the educational content. The process of designing, implementing, analyzing, and selectively modifying creates a cycle that optimizes the learning process and adapts to groups and individual learners with the goal of improving learning outcomes and efficiency. Furthermore, the educational content is dynamically provided to the learner on an iterative basis according to the need of that learner in the learning process.

Owner:INTELLECTUAL RESERVE

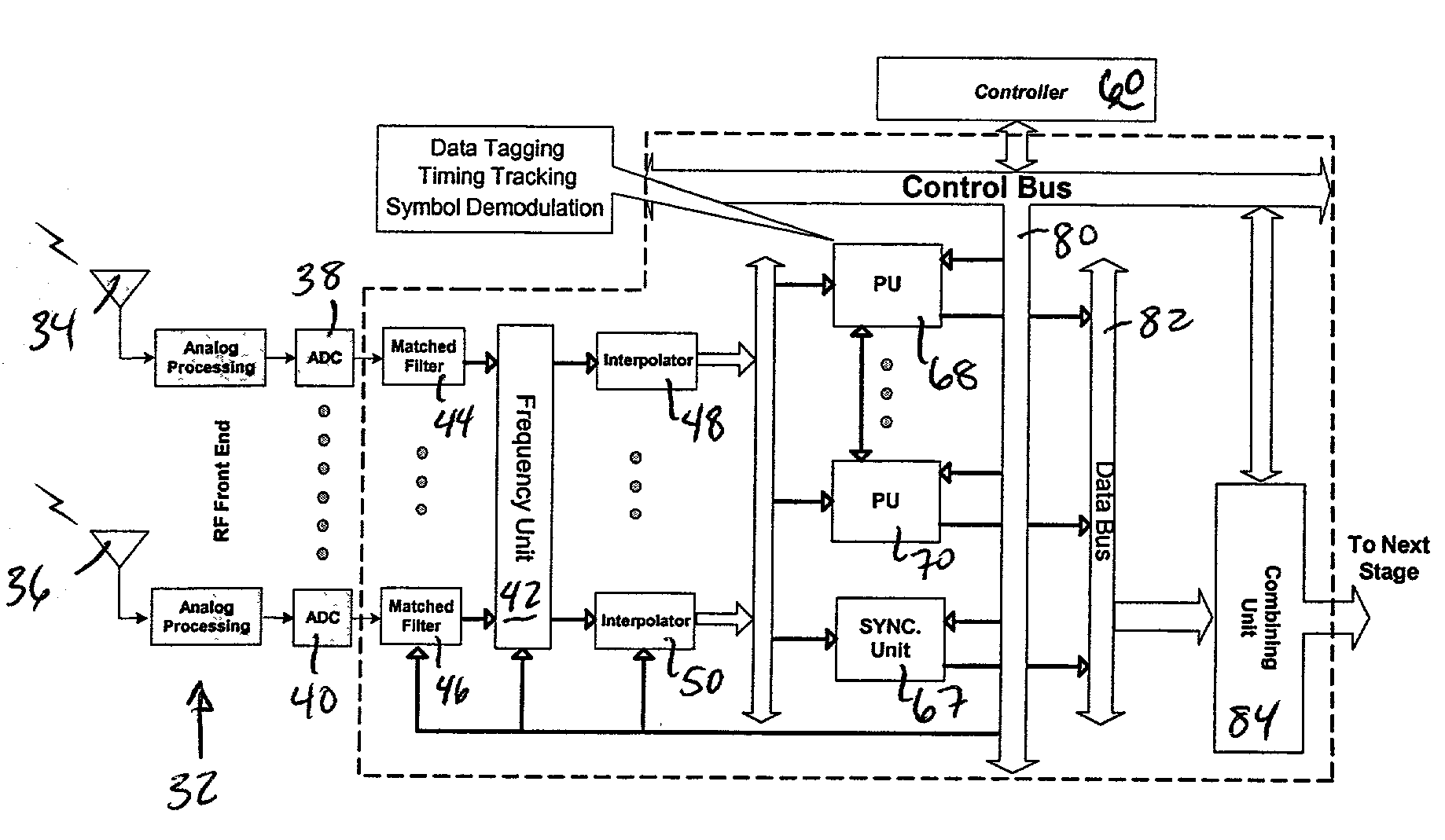

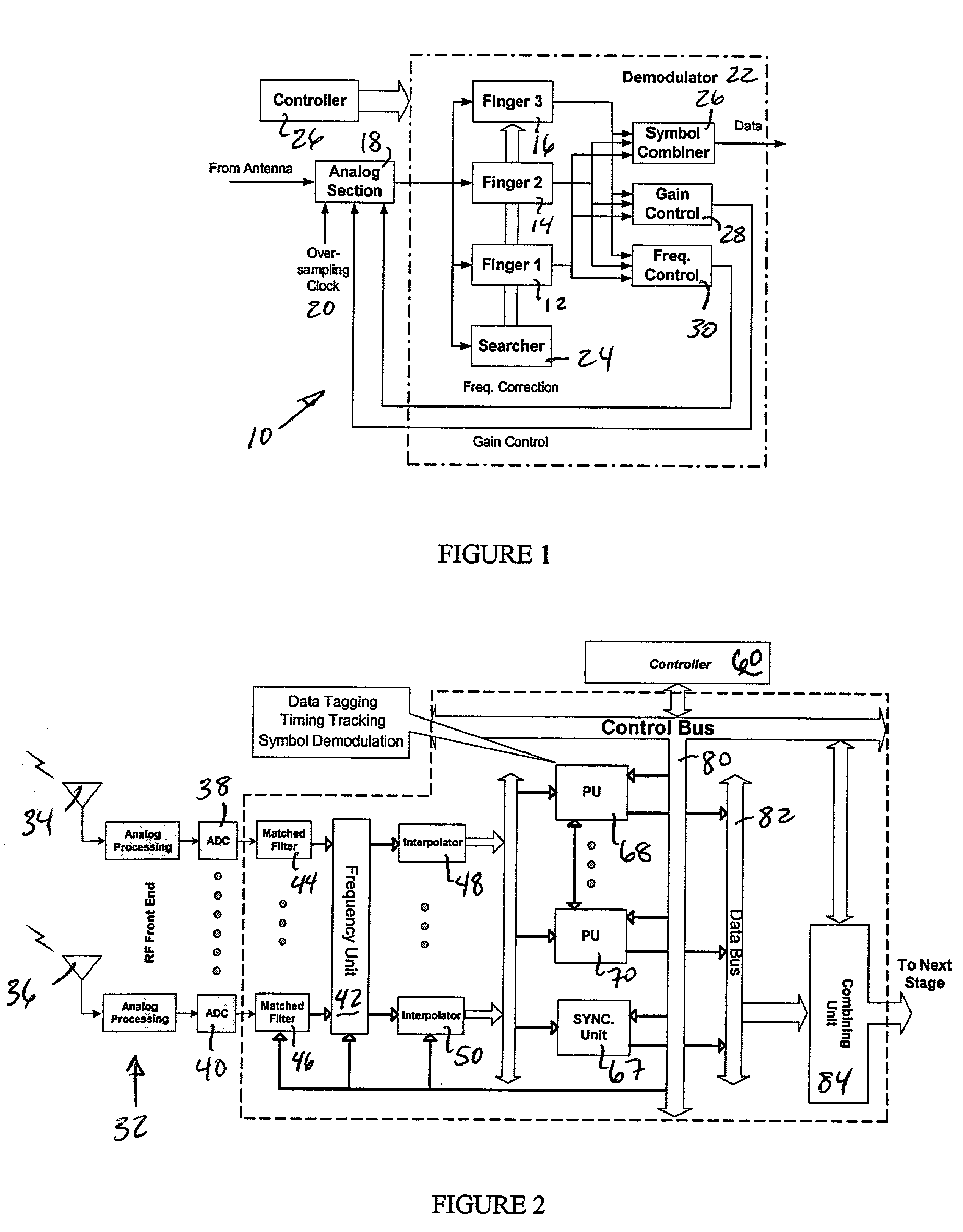

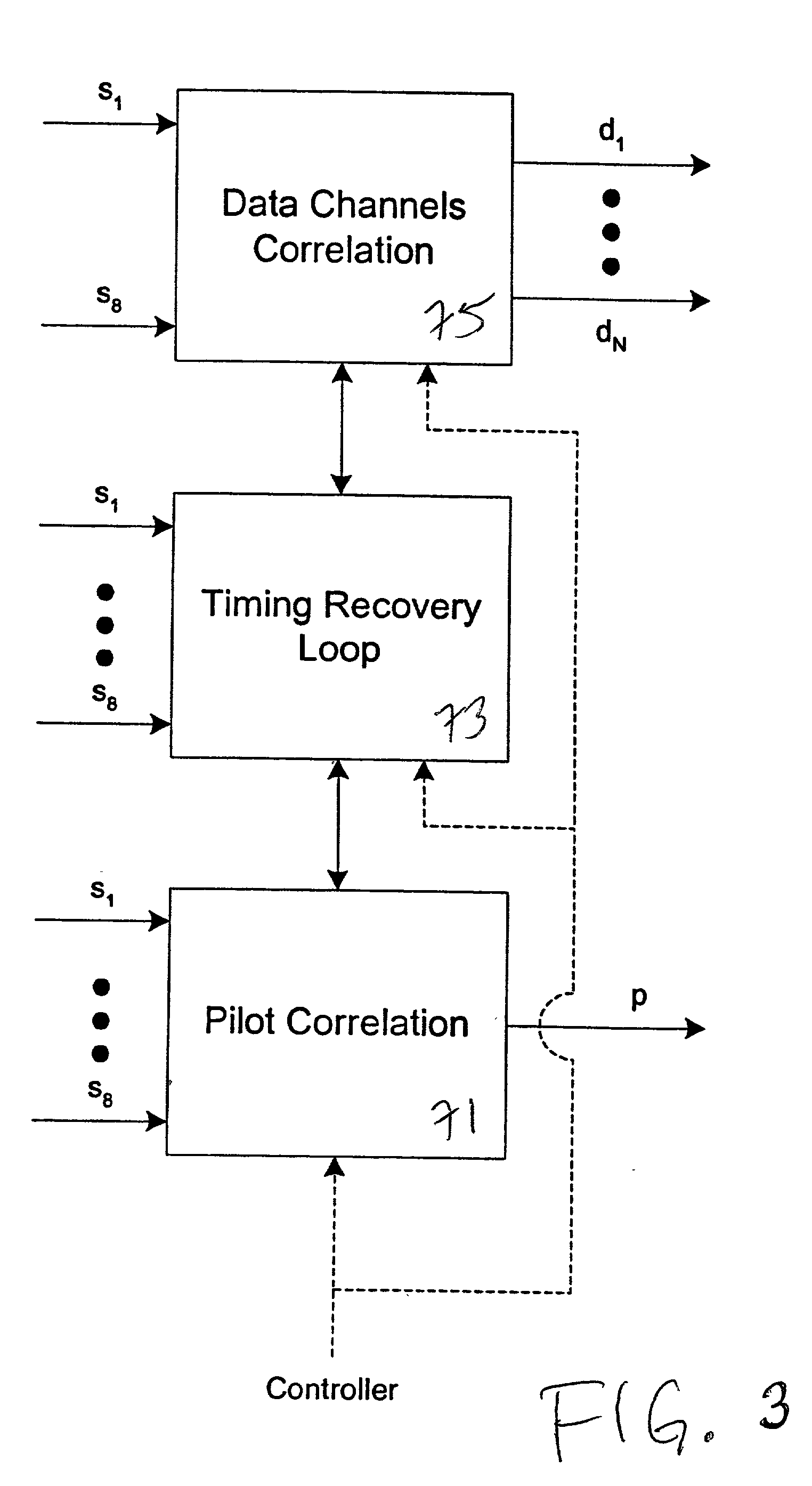

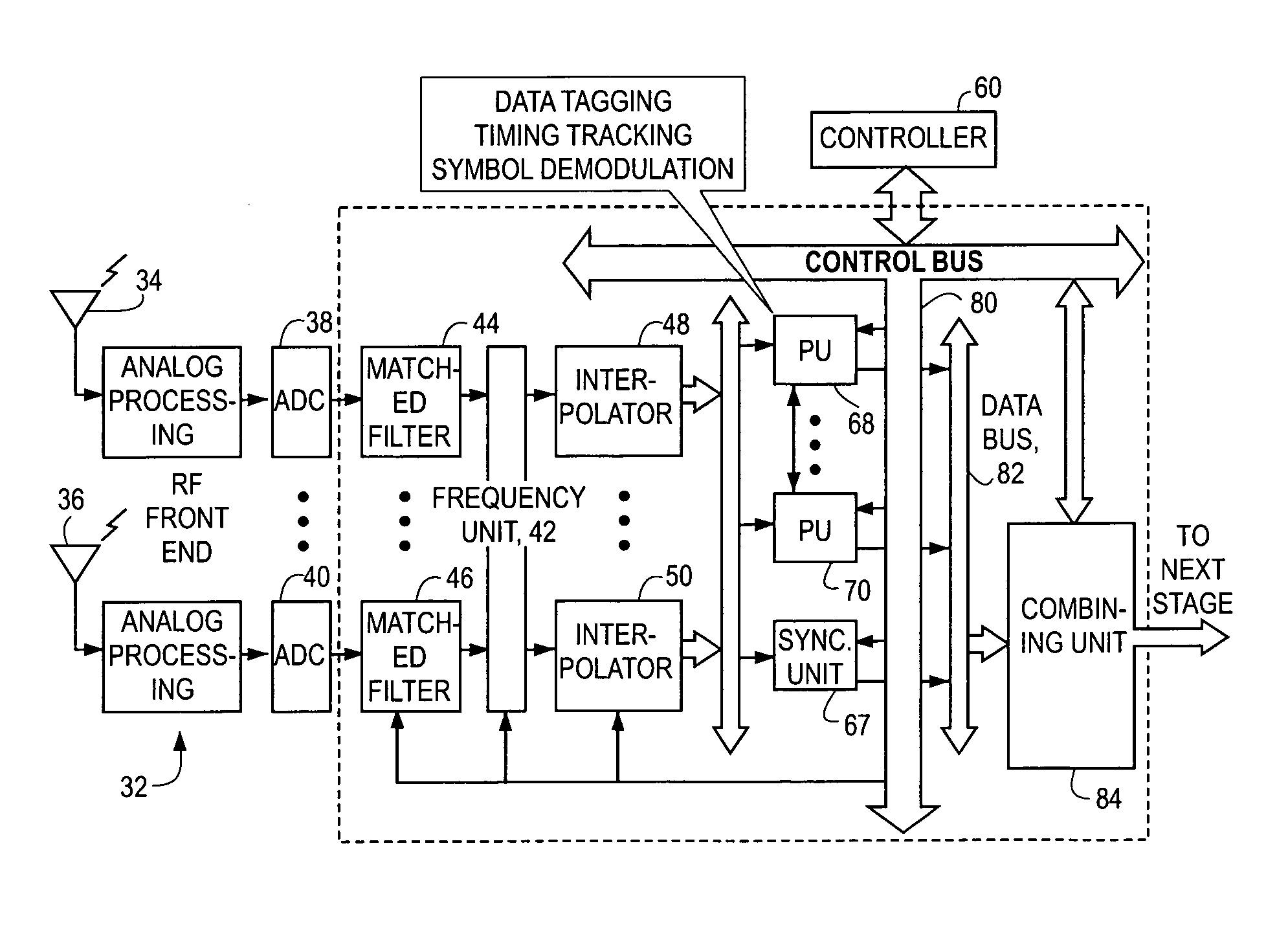

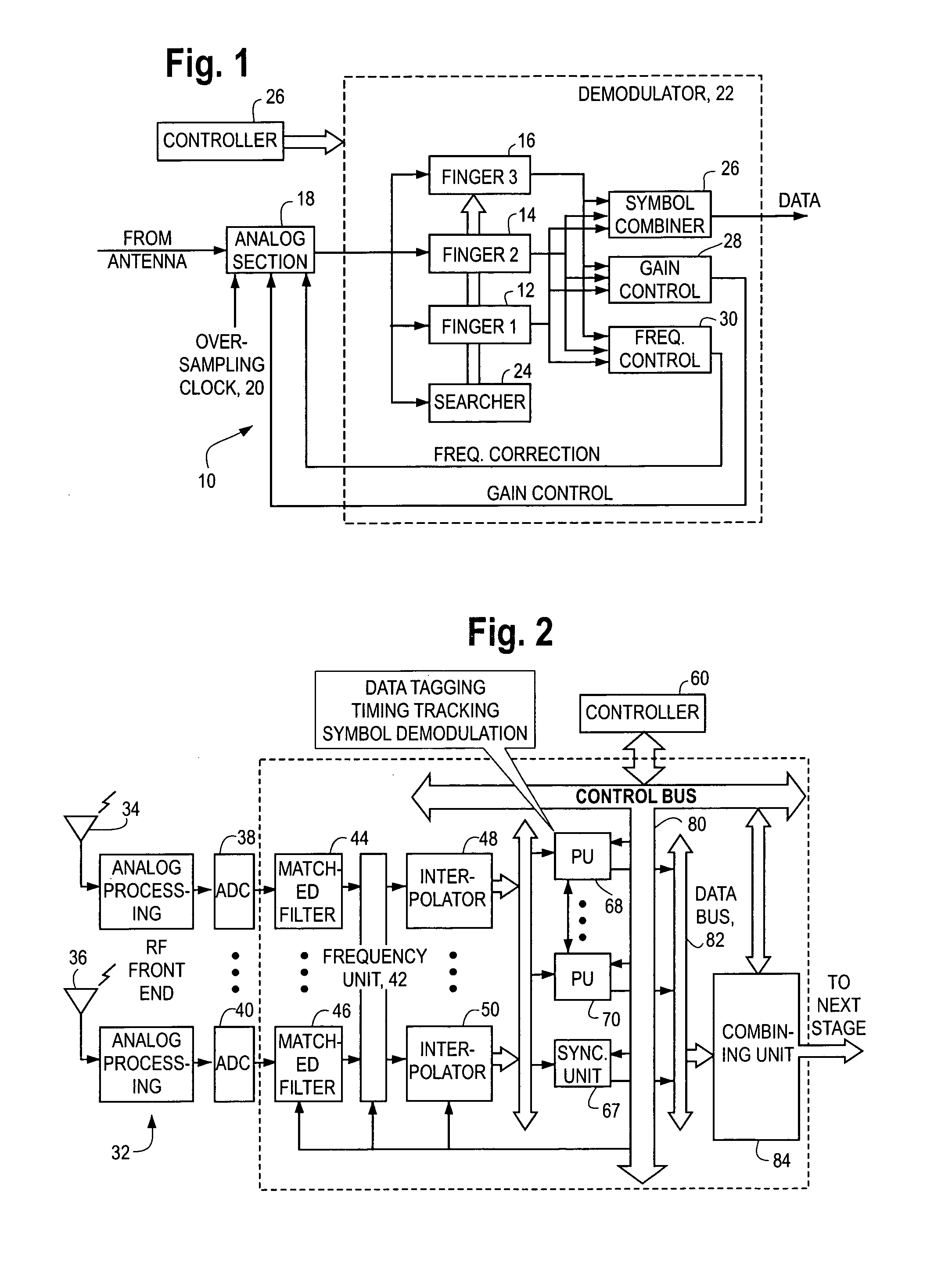

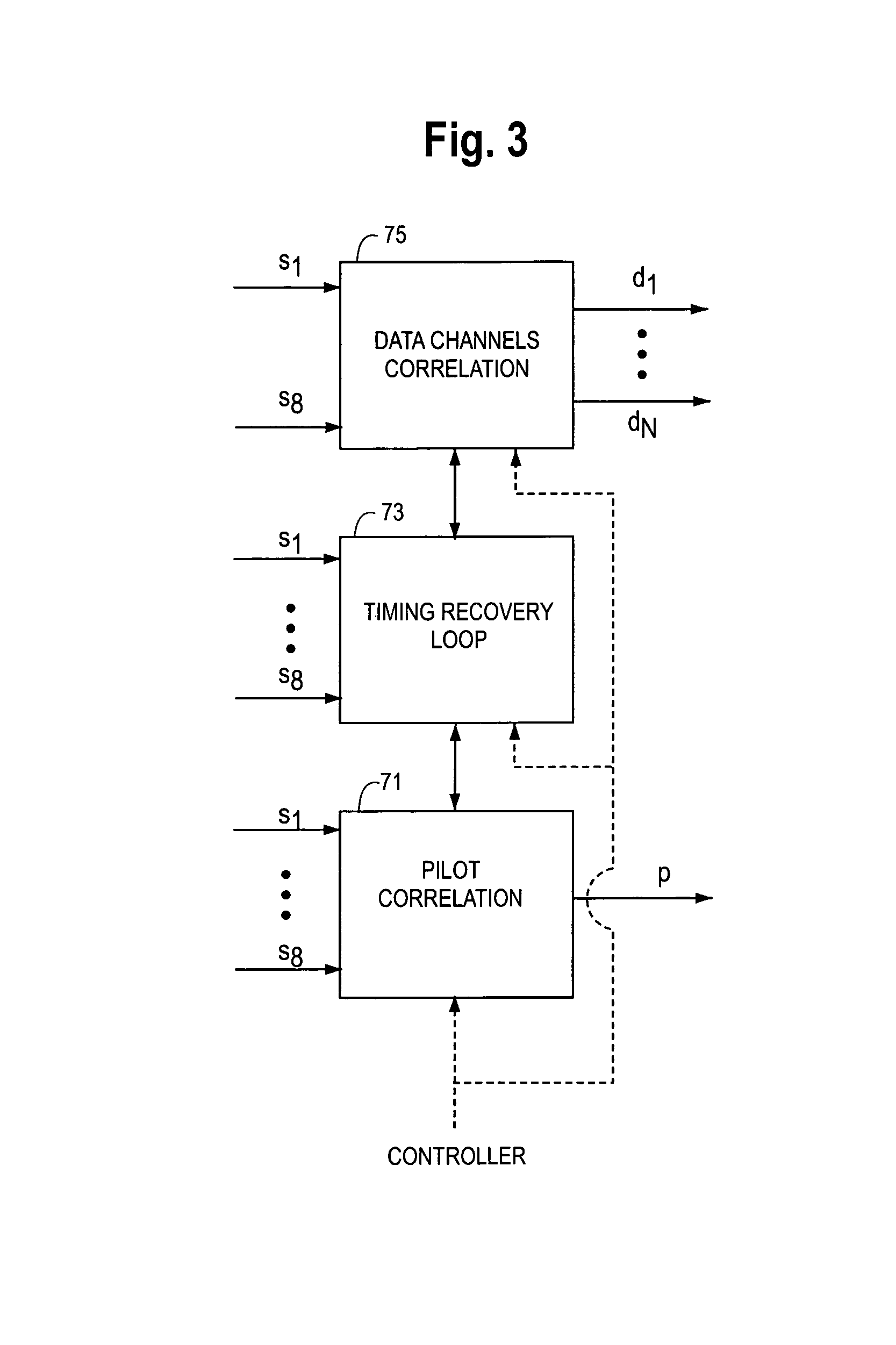

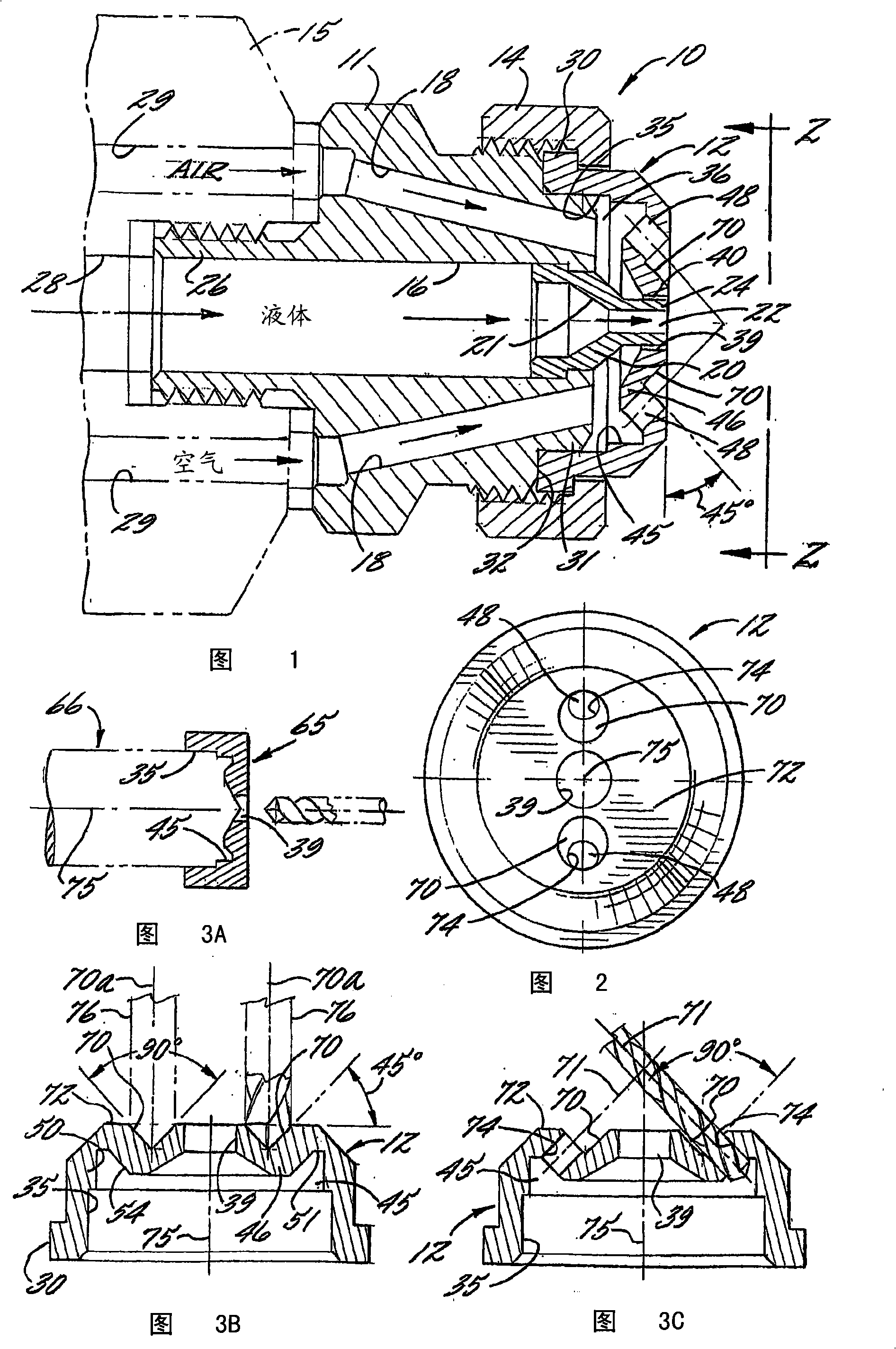

Universal rake receiver

InactiveUS20030142726A1Spatial transmit diversityFrequency/rate-modulated pulse demodulationModularityOperation mode

A universal rake receiver architecture includes modular independent processing units that can be flexibly programmed to support different modes of operation. The processing units are capable of performing the basic correlation calculations of DS-CDMA and each unit has an internal local memory and controller that controls its mode of operation. Each unit performs the required synchronization and demodulation operations for a multipath of a signal in the digital domain using all-digital frequency and timing correction techniques. Frequency feedback need not be supplied to the analog section of the receiver. Interpolation most preferably is used to find the optimum sampling position of each incoming chip. This independence allows the receiver to be used with one to several antennas without design modifications.

Owner:SASKEN COMMUNICATION TECHNOLOGIES

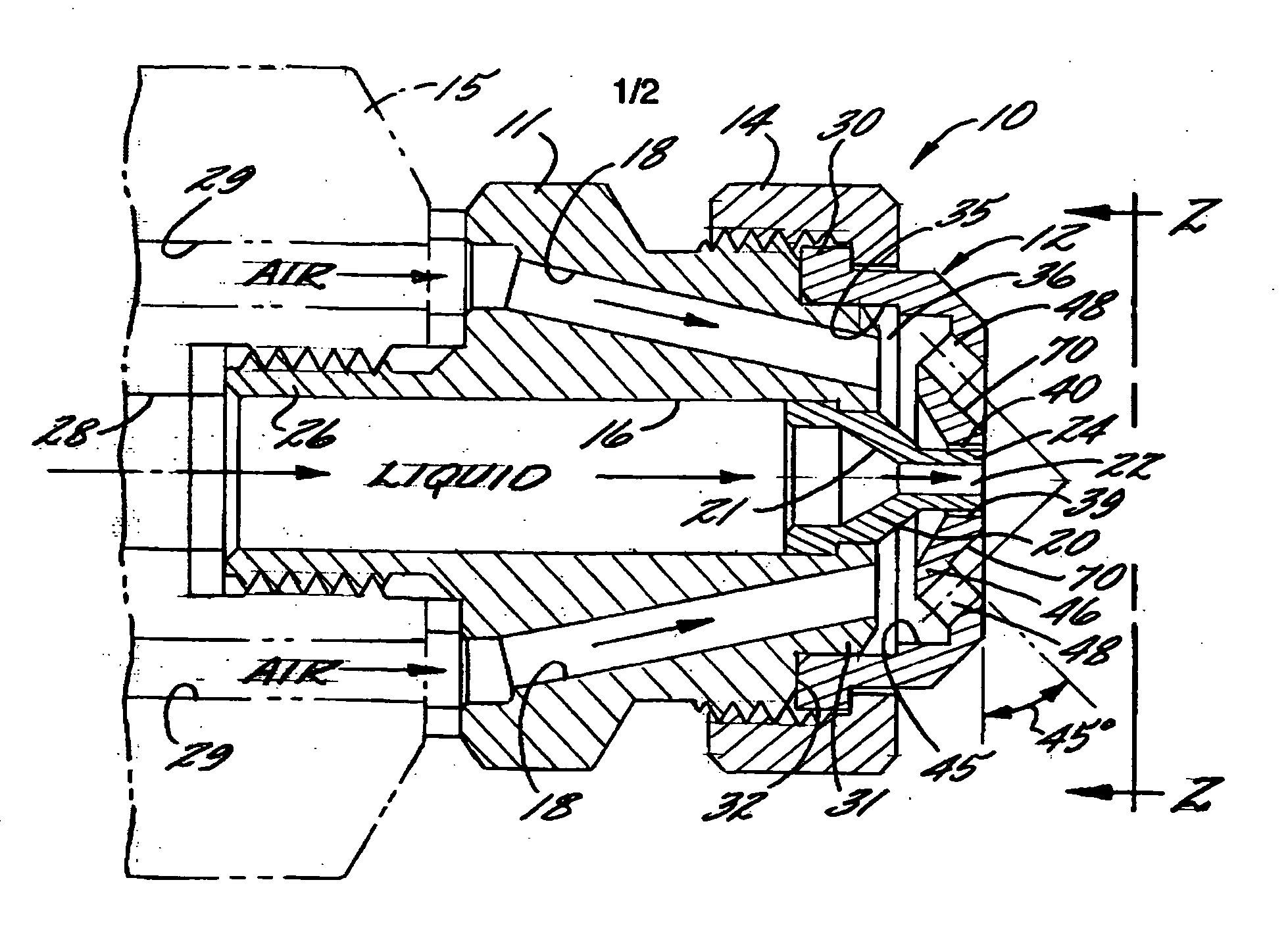

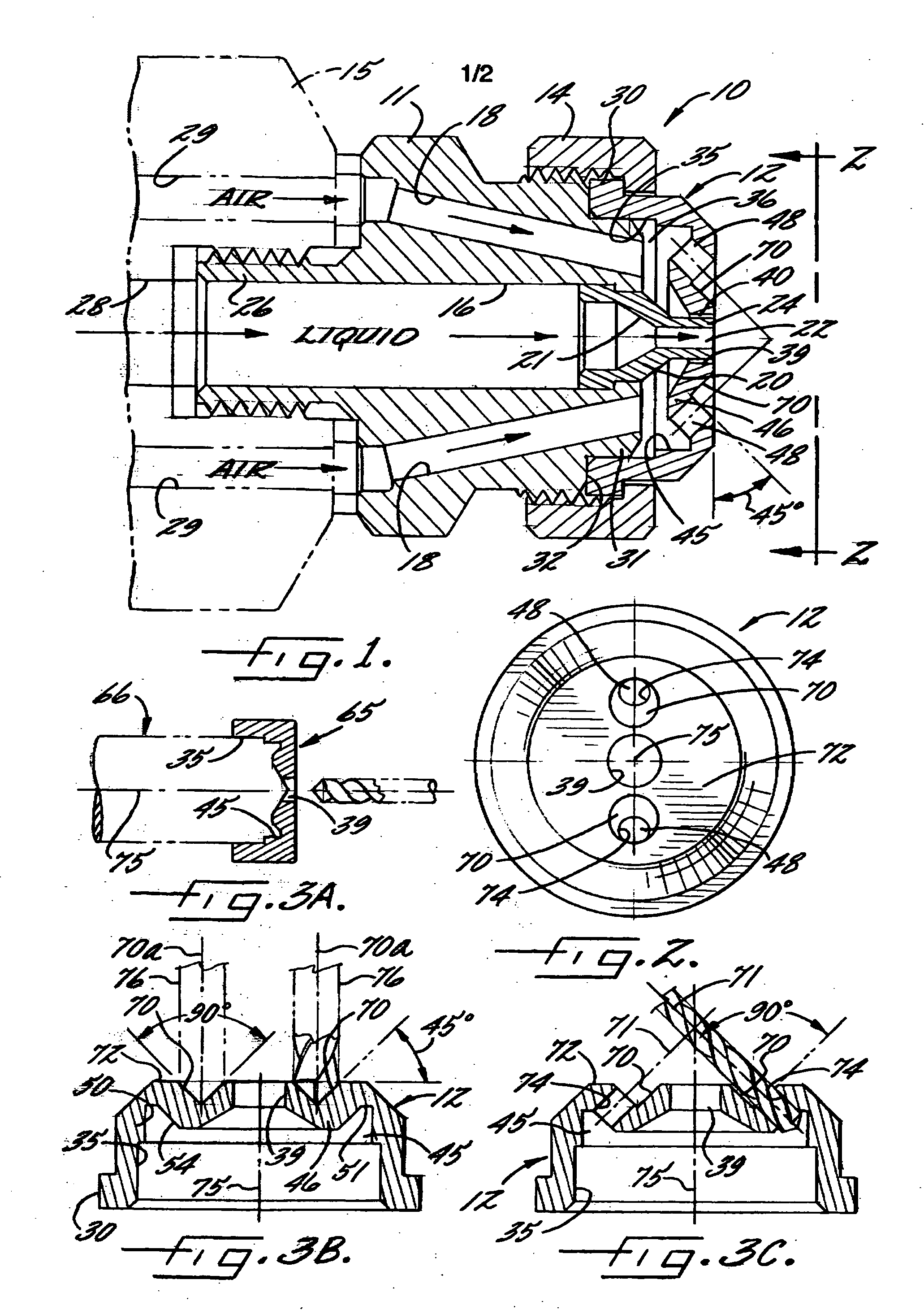

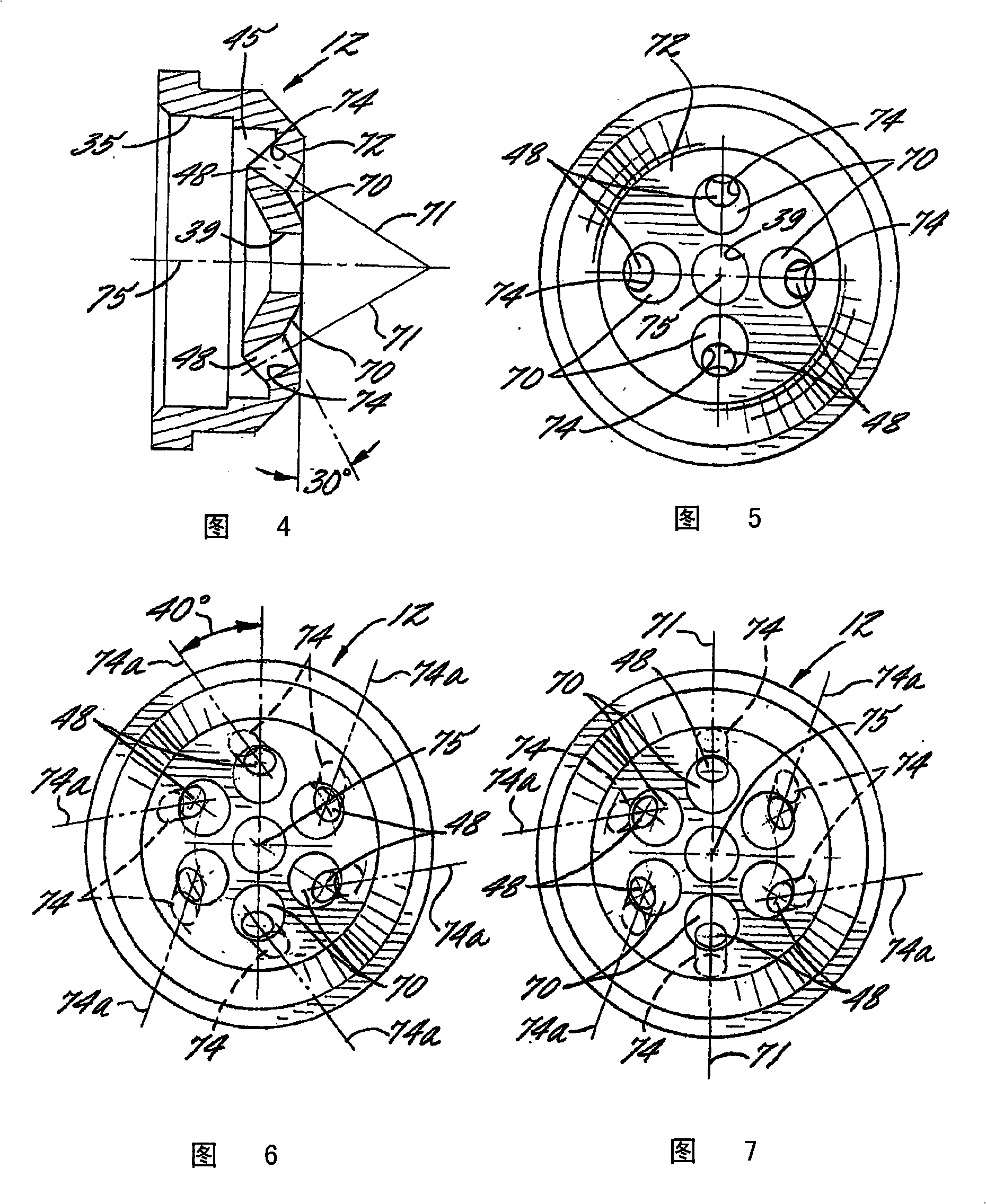

External mix air atomizing spray nozzle assembly

InactiveUS20050284957A1Guaranteed uptimeReduce necessitySpray nozzlesFire rescueEngineeringDesign modification

An external mix air atomizing spray nozzle assembly comprising a nozzle body having liquid and air flow passages, and an air cap formed with an air chamber communicating with said air passage and a plurality of angled pressurized air discharge passages communicating with said chamber at an angle to a central axis of said spray nozzle assembly for directing pressurized air onto a liquid flow stream discharging from said liquid passage. The angled air discharge passages each are defined by a conical indentation in a front face of the air cap and a cylindrical bore communicating in perpendicular relation to a side surface of the conical indentation. The design of the angled air discharge passages permits easy manufacture and design modification for particular spray applications.

Owner:SPRAYING SYST

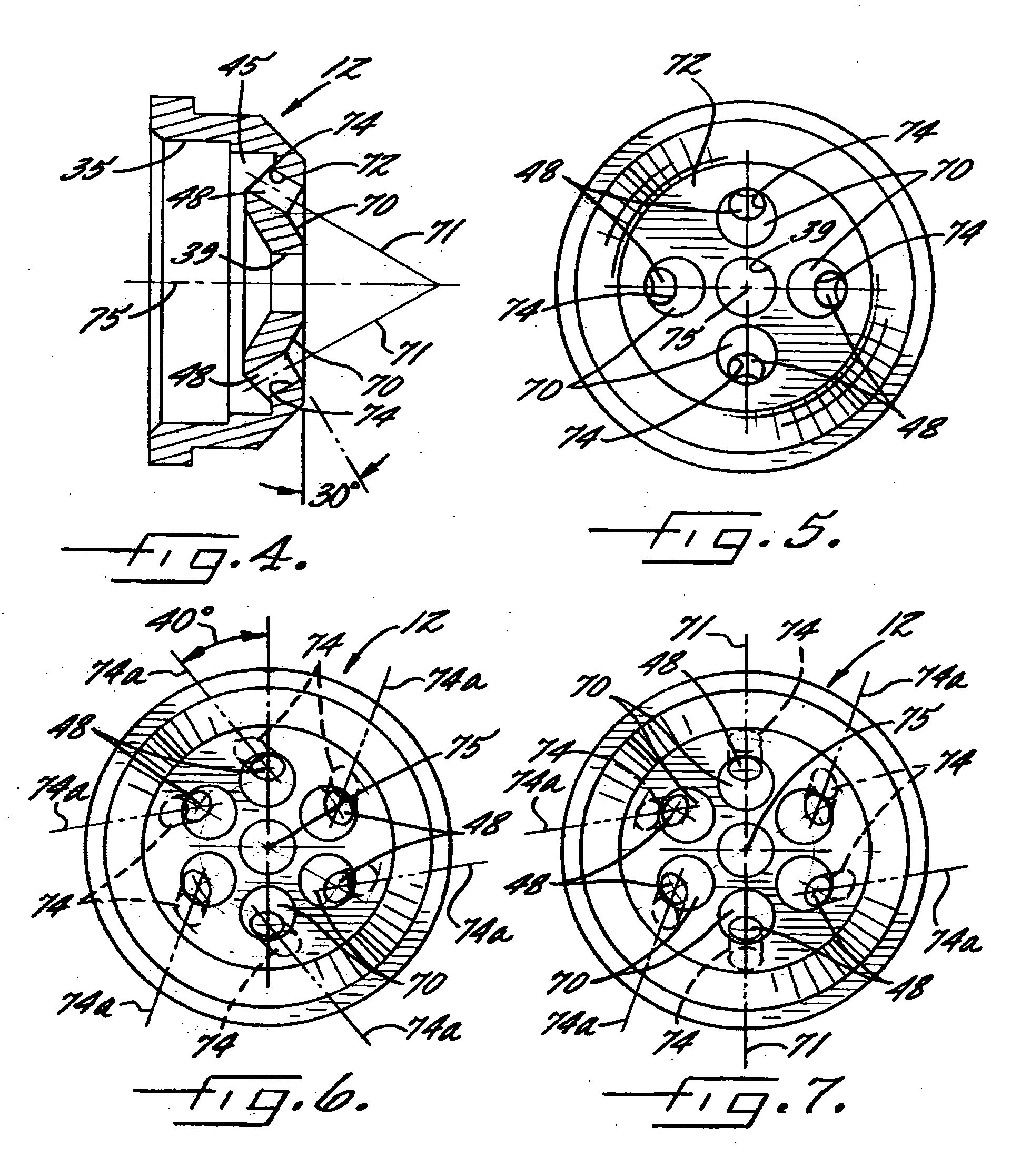

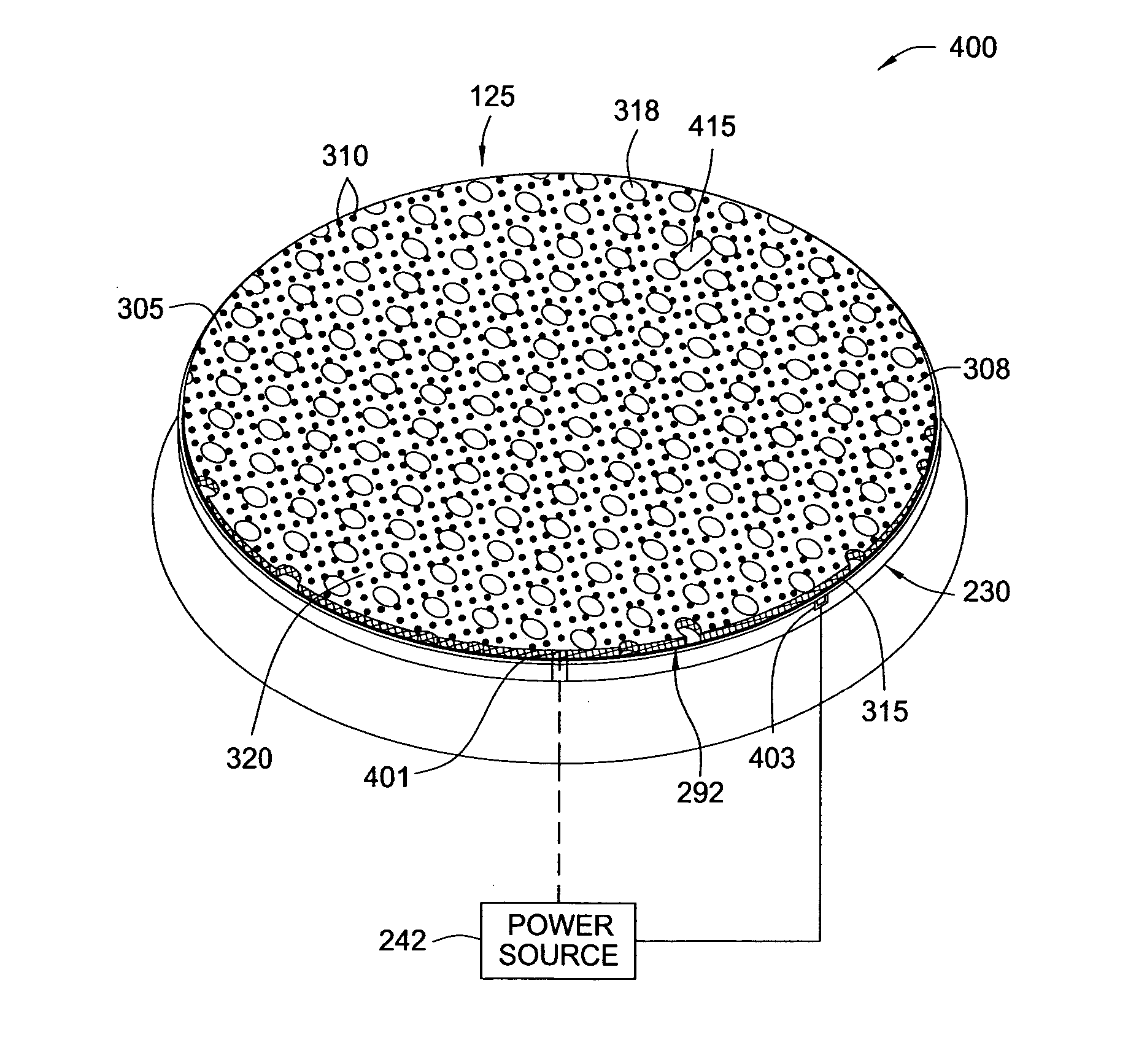

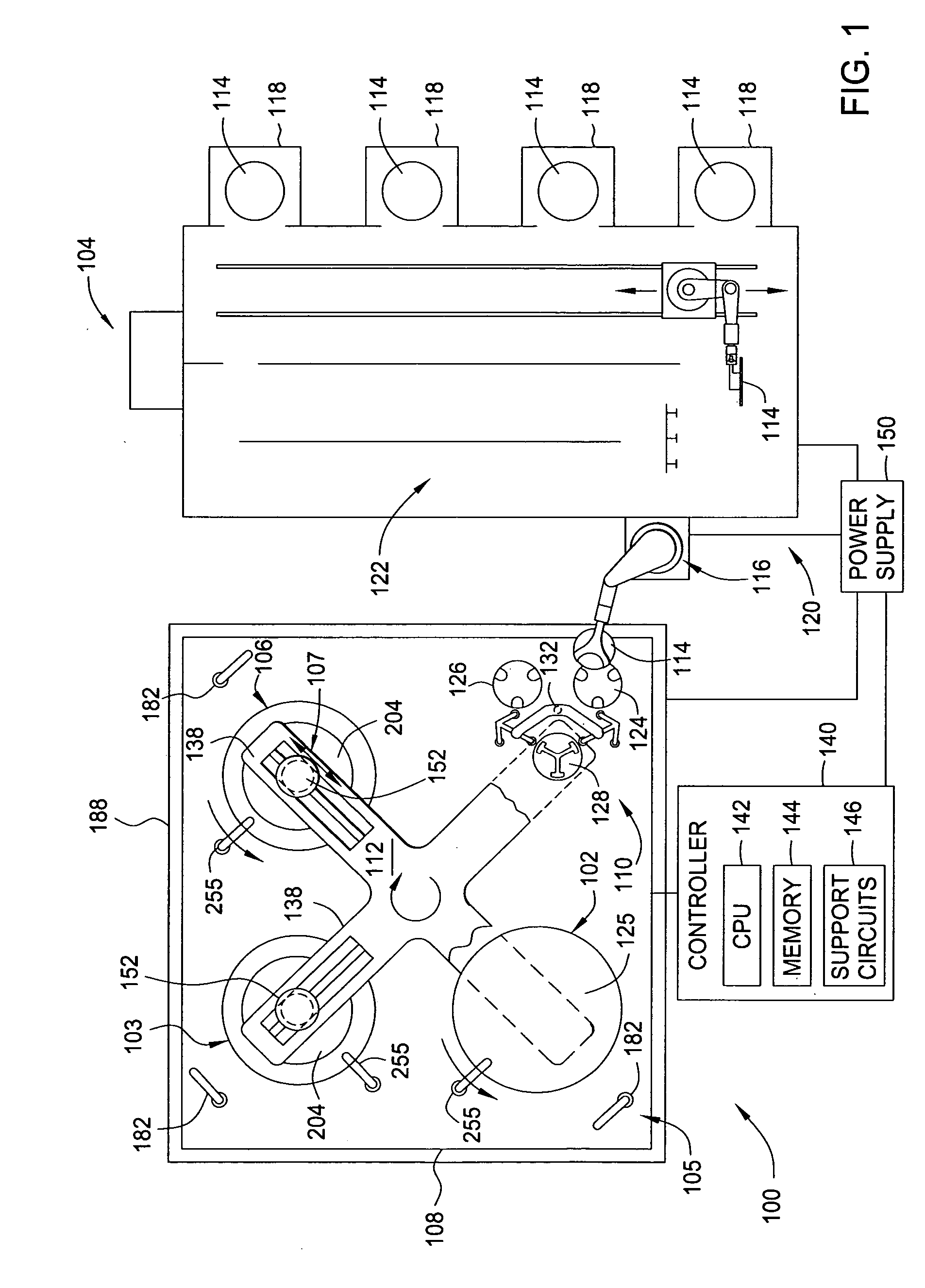

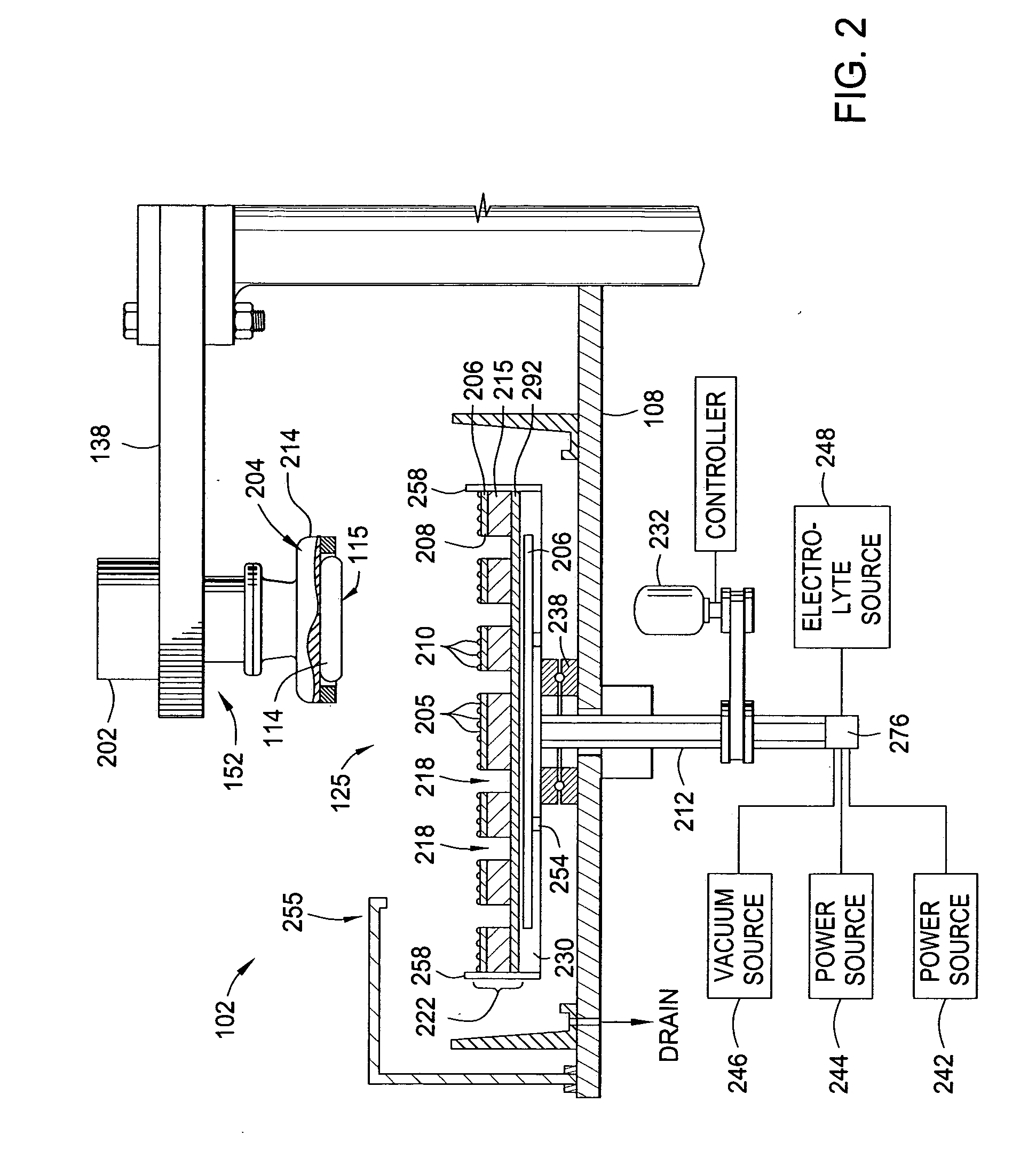

Conductive pad design modification for better wafer-pad contact

An apparatus and method for manufacturing and refurbishing a conductive polishing pad assembly for performing an electrochemical process on a substrate is disclosed. The conductive polishing pad assembly is formed using a contact surface as a foundation that is coated with a metallic coating to create a conductive contact surface. In one embodiment, the metallic coating is a high purity tin / zinc alloy that is sprayed on the contact surface. The contact surface contains abrasive particles while the metallic coating provides at least conductive qualities to the contact surface.

Owner:APPLIED MATERIALS INC

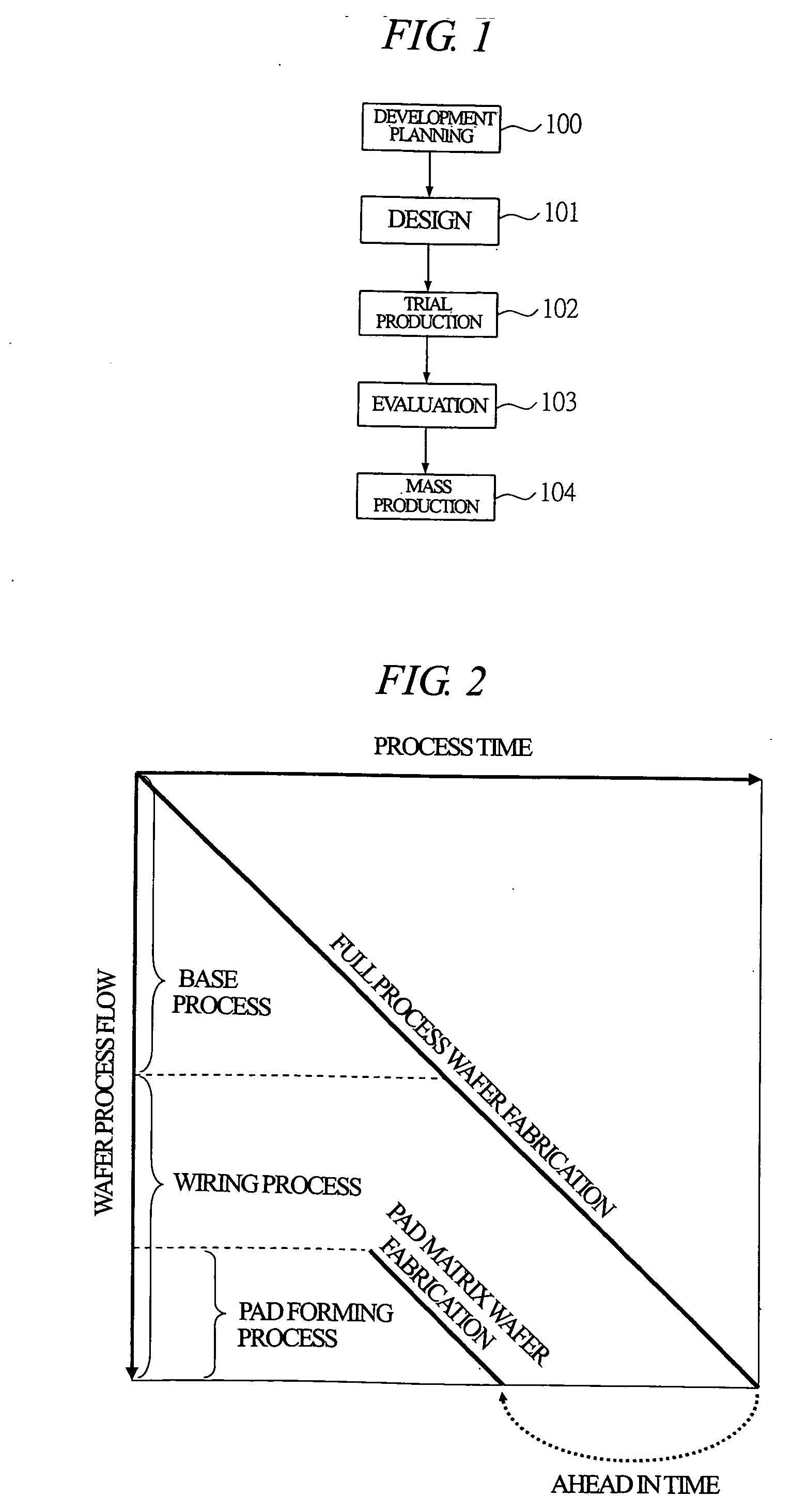

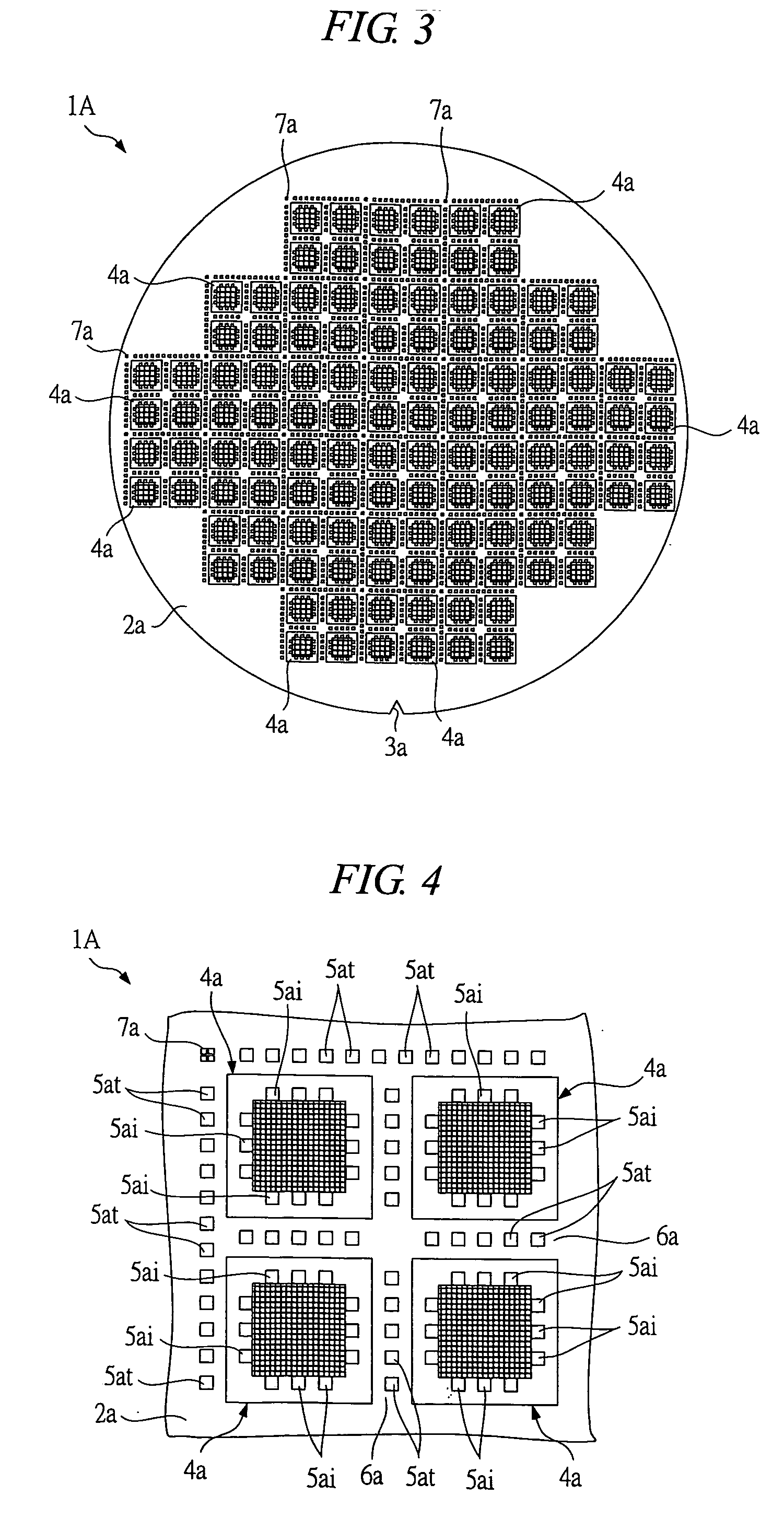

Manufacturing method of semiconductor device

InactiveUS20050208684A1Shorten the timeReduce deliverySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialPre treatment

In a trial production process from a design process to an actual manufacturing process of semiconductor devices, a pre-process of a pad matrix wafer with simpler configuration than a prototype wafer is completed before a pre-process of the prototype wafer is completed, and data of conditions and evaluations to be used in a test process and a post-process subsequent to the pre-process of the prototype wafer is created by using the pad matrix wafer. Therefore, the data of conditions and evaluations used in the process subsequent to the pre-process can be prepared and the design modifications of various devices used in the process subsequent to the pre-process can be finished before the post-process of the prototype wafer is started. Therefore, a smooth transition from the pre-process to the subsequent processes of the prototype can be achieved, and the delivery time of semiconductor devices can be shortened.

Owner:TRECENTI TECHNOLOGIES INC

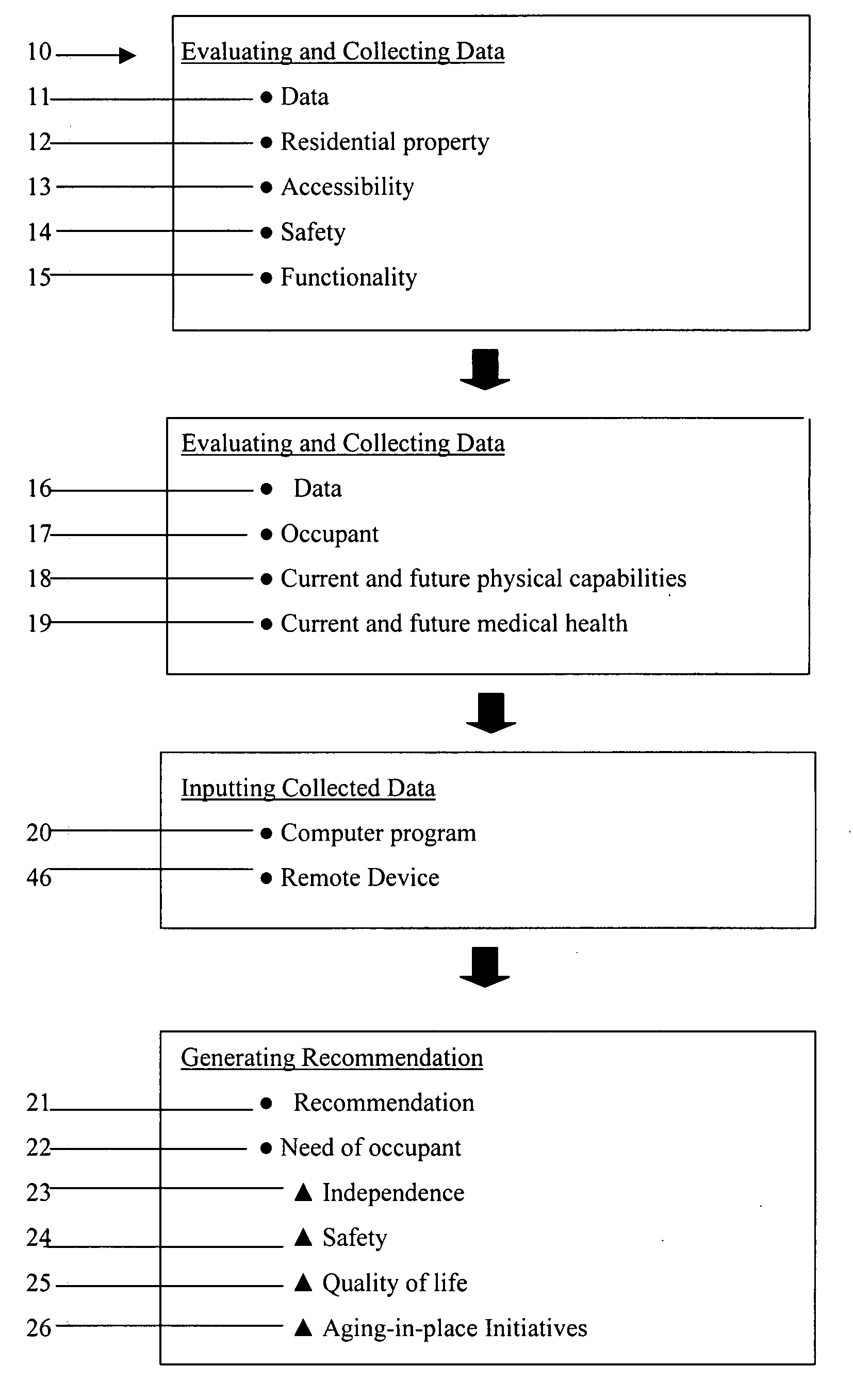

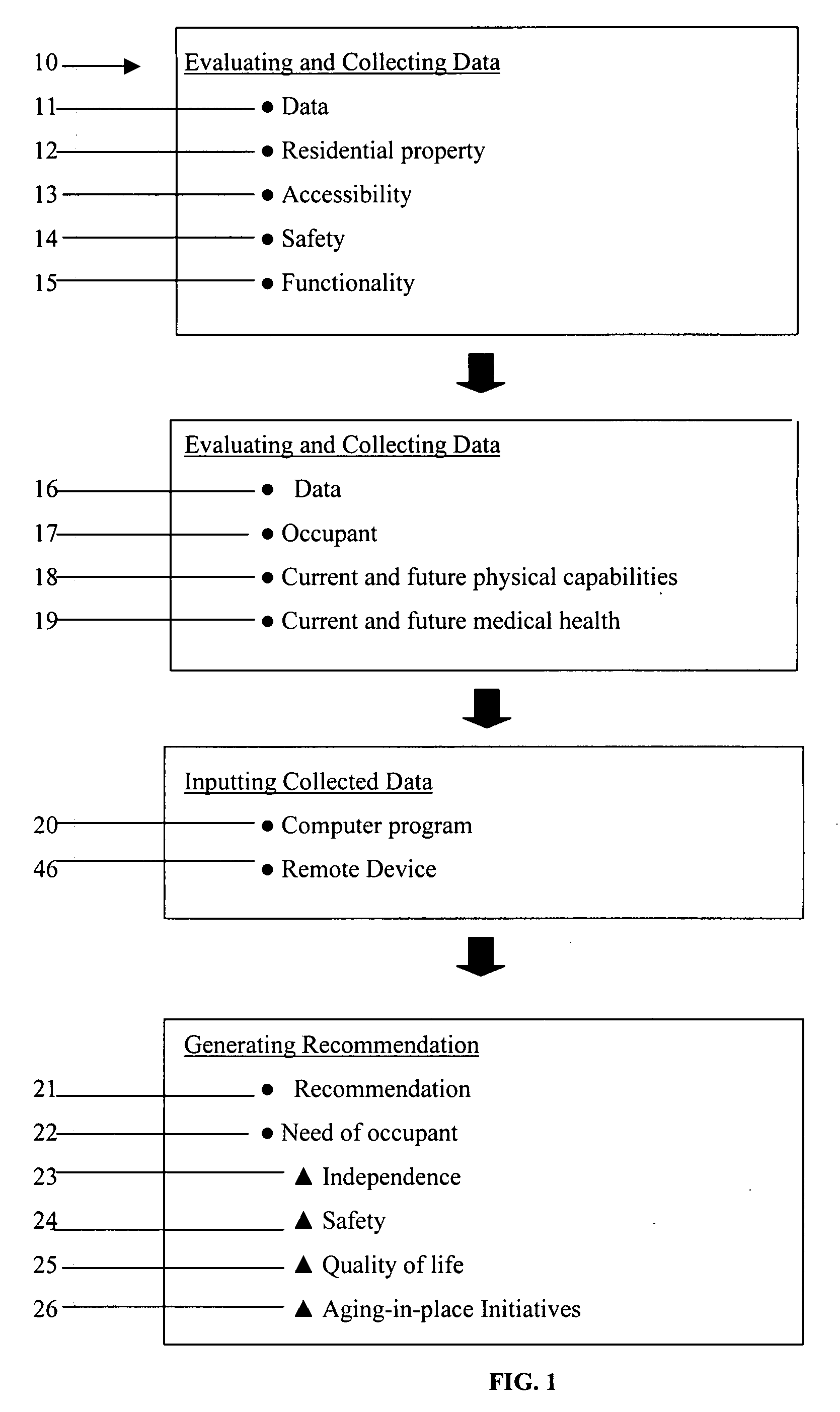

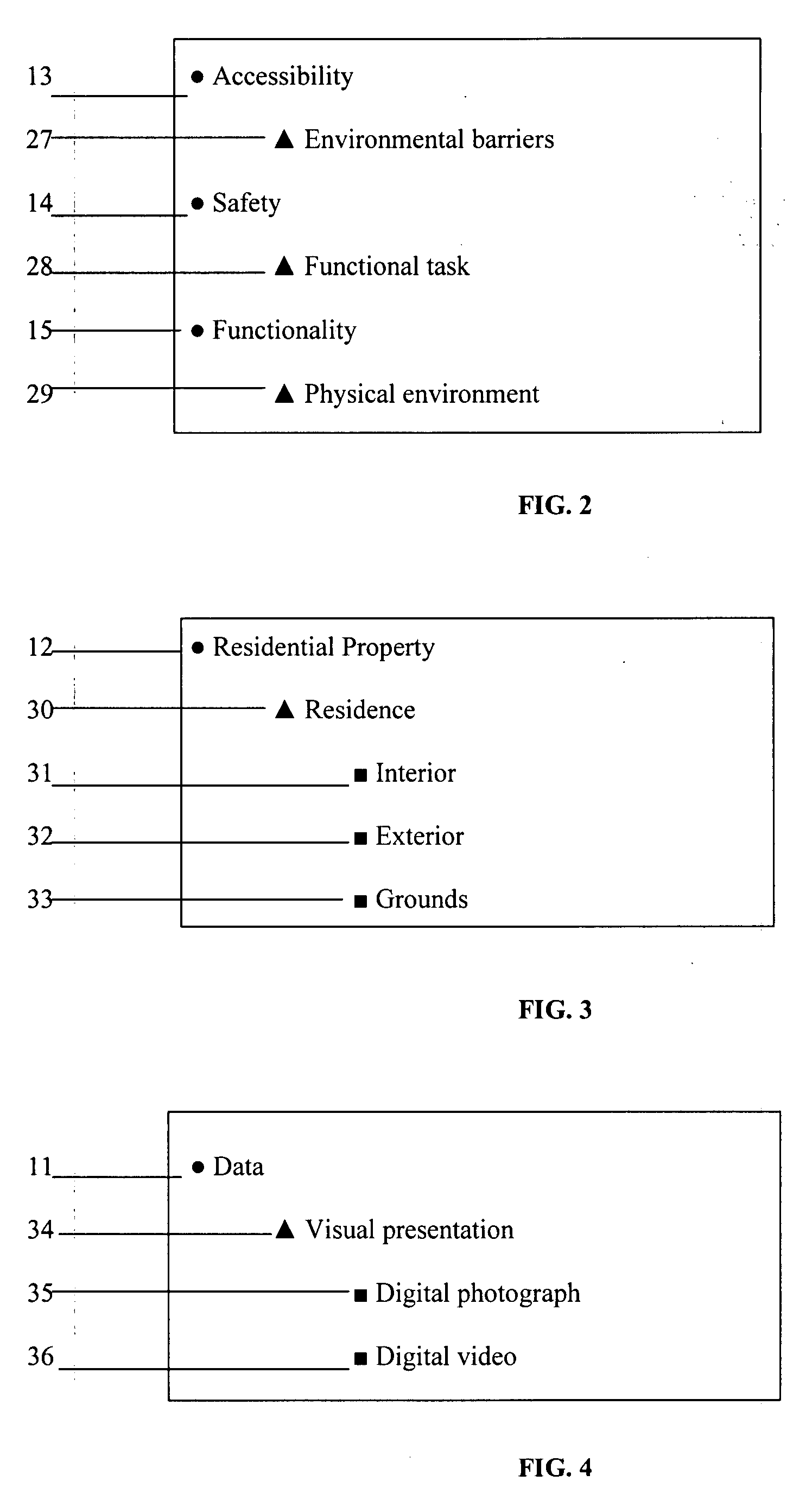

Computer-based method of recommending modifications to residential or commercial property

InactiveUS20080189166A1Easy to useNovel methodData processing applicationsSpecial data processing applicationsDiseaseTablet computer

A computer-based method used by certified aging-in-place specialists and / or licensed medical professionals to evaluate and recommend universal, accessibility, adaptability, visitability and / or aging-in-place design modifications to residential or commercial property to satisfy independence, safety, and / or quality of life needs of an occupant of the property. The occupant may be a resident, care giver, or owner. The computer-based method employs a computer program that recommends the design modifications in response to specific environmental, disease, disability, or aging impairments of the occupant. The computer program is part of a wide area network accessible by a remote device such as a laptop computer, a tablet computer, or a hand-held computer via a secured Internet connection.

Owner:BROOKS JAY M

Universal rake receiver

InactiveUS7106784B2Spatial transmit diversityFrequency/rate-modulated pulse demodulationModularityEngineering

A universal rake receiver architecture includes modular independent processing units that can be flexibly programmed to support different modes of operation. The processing units are capable of performing the basic correlation calculations of DS-CDMA and each unit has an internal local memory and controller that controls its mode of operation. Each unit performs the required synchronization and demodulation operations for a multipath of a signal in the digital domain using all-digital frequency and timing correction techniques. Frequency feedback need not be supplied to the analog section of the receiver. Interpolation most preferably is used to find the optimum sampling position of each incoming chip. This independence allows the receiver to be used with one to several antennas without design modifications.

Owner:SASKEN COMMUNICATION TECHNOLOGIES

Improved external mix air atomizing spray nozzle assembly

An external mix air atomizing spray nozzle assembly comprising a nozzle body having liquid and air flow passages, and an air cap formed with an air chamber communicating with said air passage and a plurality of angled pressurized air discharge passages communicating with said chamber at an angle to a central axis of said spray nozzle assembly for directing pressurized air onto a liquid flow stream discharging from said liquid passage. The angled air discharge passages each are defined by a conical indentation in a front face of the air cap and a cylindrical bore communicating in perpendicular relation to a side surface of the conical indentation. The design of the angled air discharge passages permits easy manufacture and design modification for particular spray applications.

Owner:SPRAYING SYST

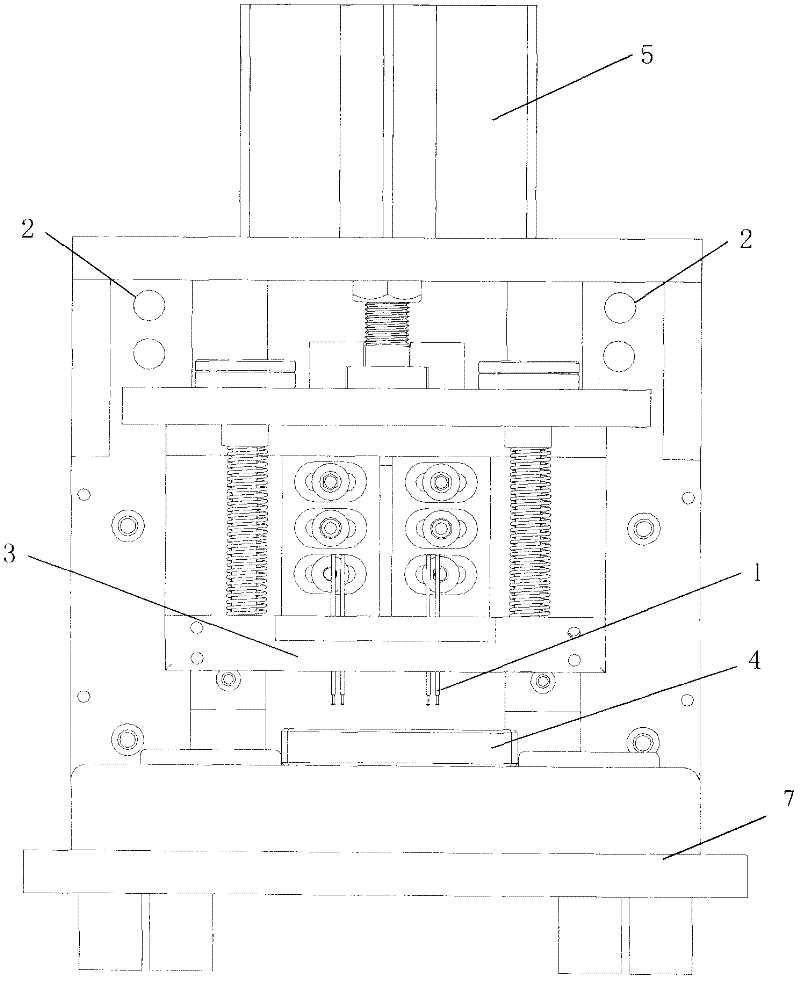

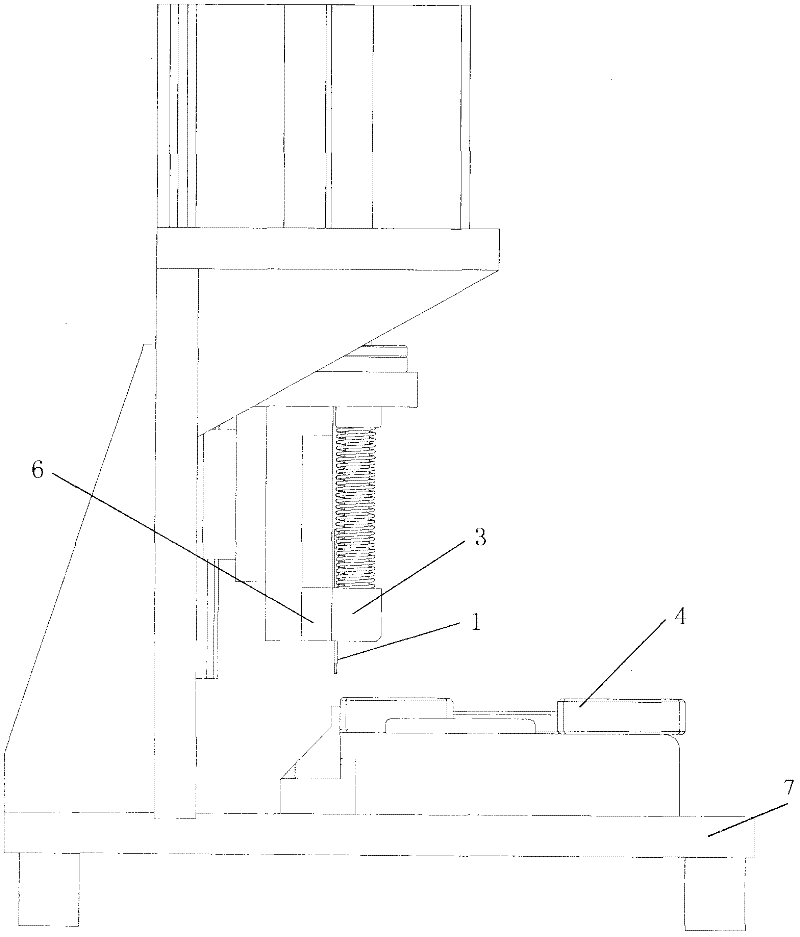

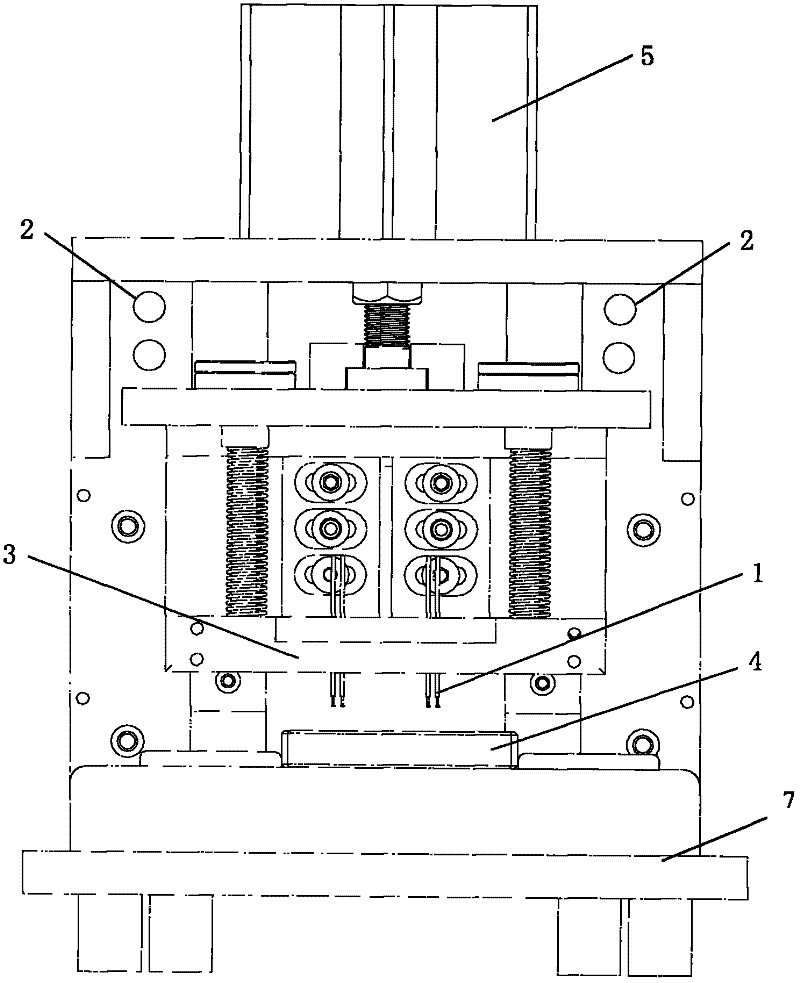

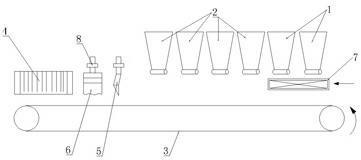

Integrated device for testing lithium ion battery and shaping and cutting battery lug

ActiveCN102544590ADamage controlImprove production efficiencyCell electrodesFinal product manufactureTest batteryElectrical battery

The invention discloses an integrated device for testing voltage and internal resistance of batteries and shaping and cutting battery lugs. Two groups of positive and negative probes are added on a strip-shaped press block which shapes the battery lugs, and the two groups of positive and negative probes are respectively connected to slots for an external test pen at the periphery of the device through leads; two positive slots and two negative slots are connected to positive test pens and negative test pens of an internal resistance tester; the shaping press block can be a Teflon component; the interval of the probes embedded in the shaping press block can be correspondingly adjusted according to different intervals of battery core lugs; before the battery lugs are cut, the shaping press blocks flatten the lugs, the positive and negative test probes are also pressed on the positive and negative lugs, and the voltage and internal resistance of the battery can be tested simultaneously; and scanning gun holding racks are respectively disposed at right side and left side of the device. According to the device, by designed modification, the divided operations of testing the voltage and internal resistance of the battery and shaping and cutting battery lugs can be combined; the production efficiency is improved; and the labor intensity is reduced.

Owner:DONGGUAN NVT TECH

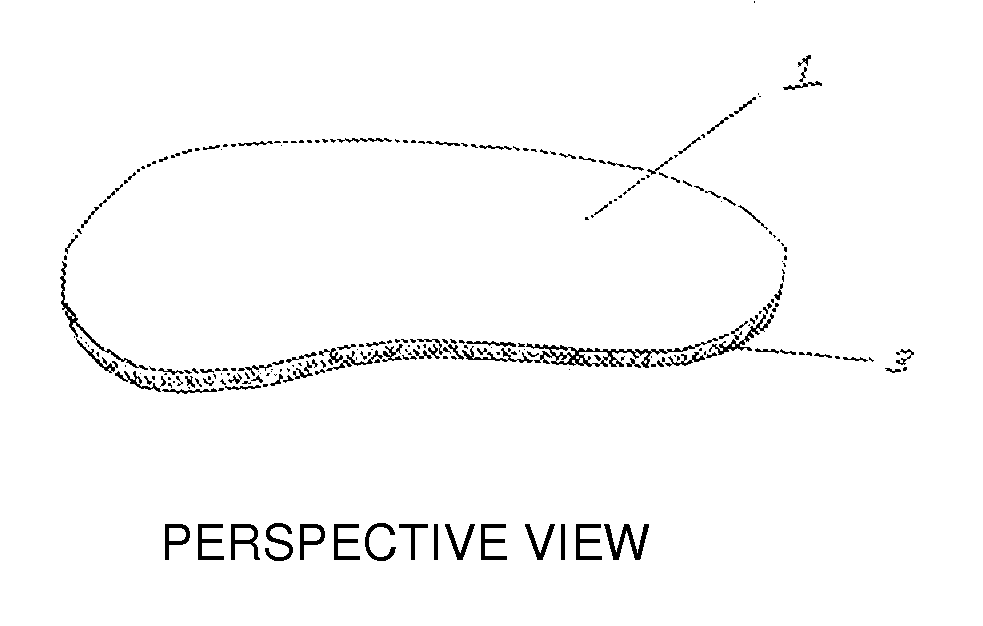

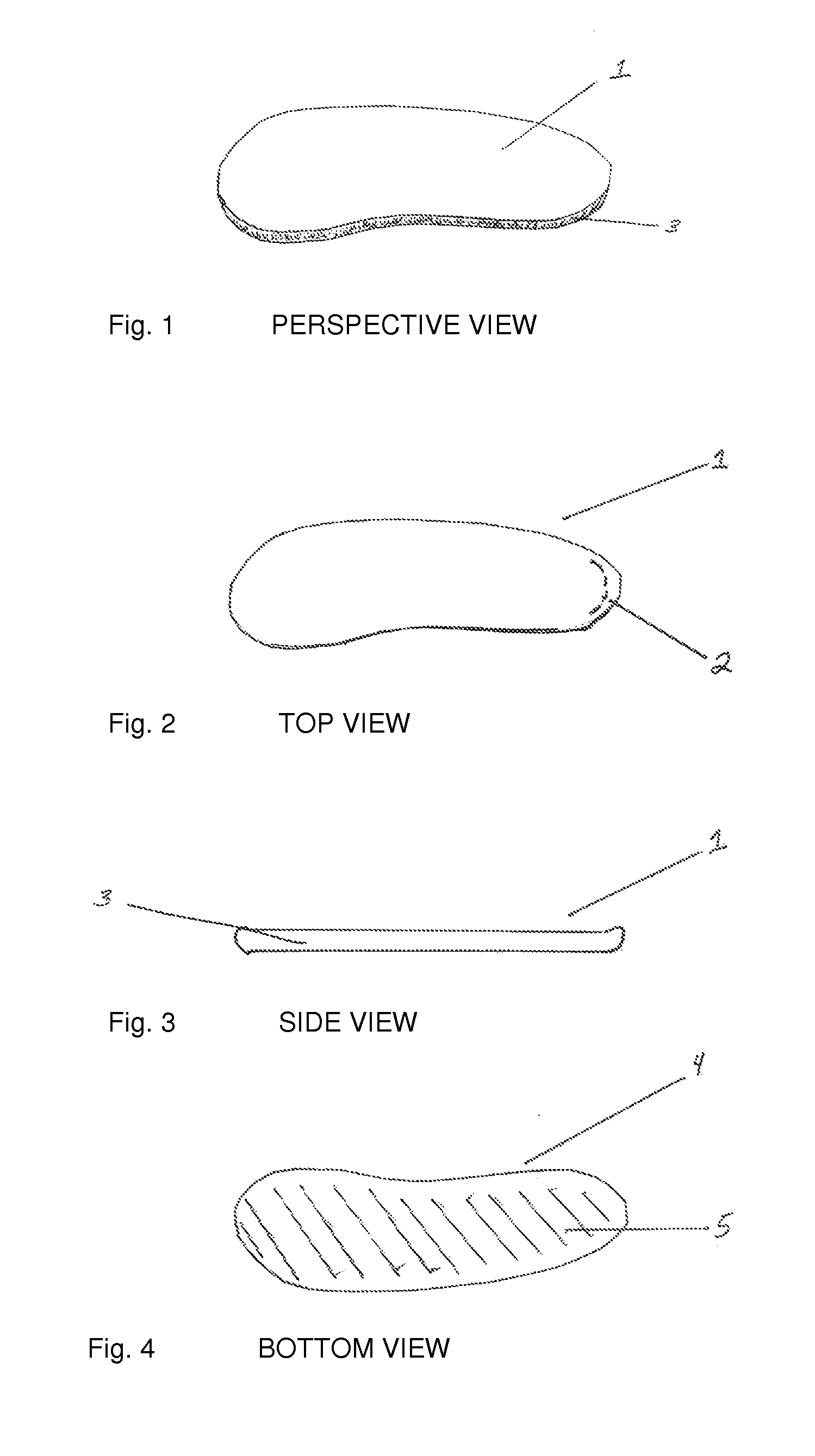

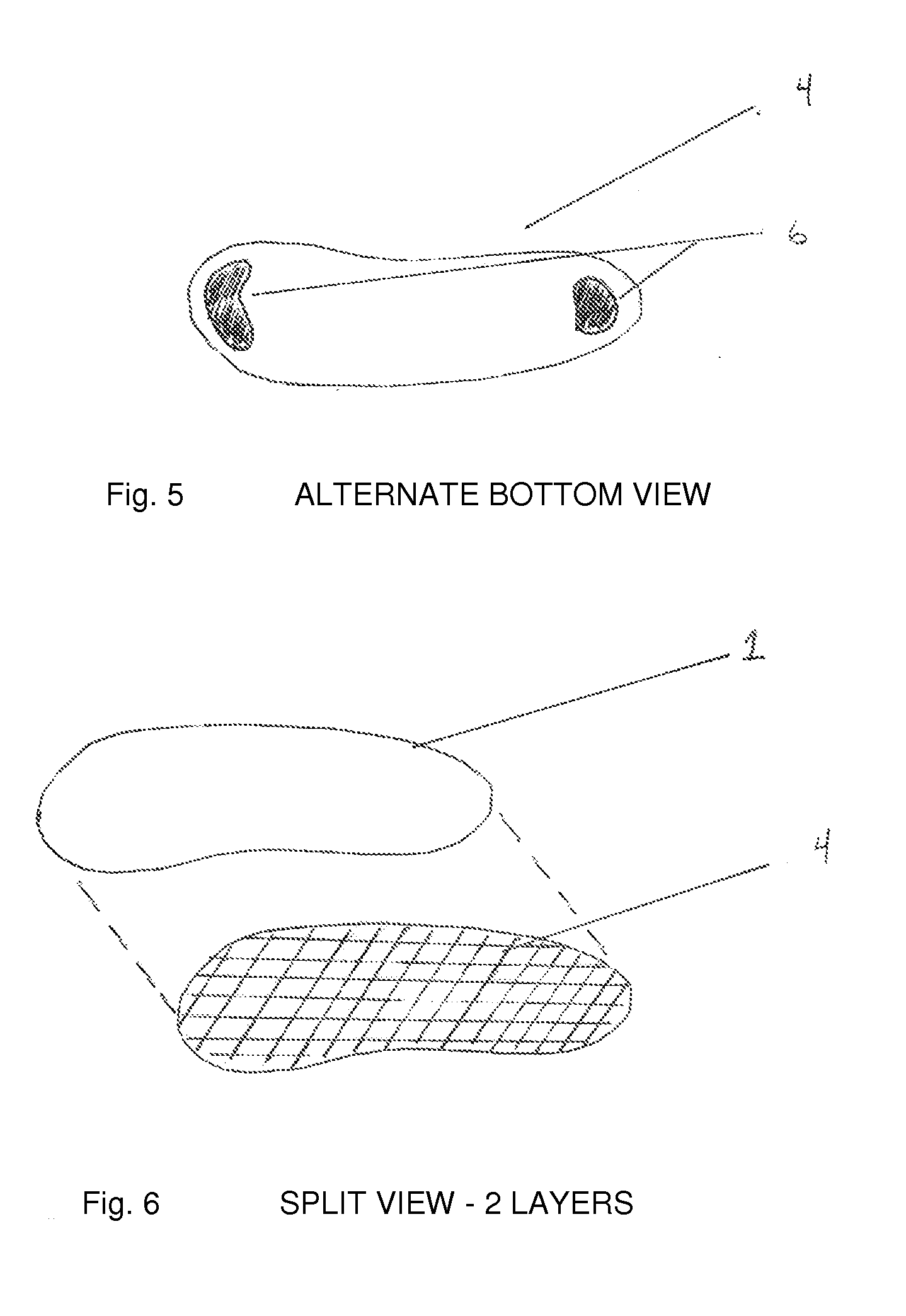

Flat, topless socks

The flat, topless sock is are re-usable, machine washable / dryable, sock / stocking alternative that is inserted into a shoe or sandal, adhering to the shoe's insole so it can be worn in place of traditional socks to give the wearer the “no-sock” look while providing the benefits of wearing a sock. The preferred embodiment of the flat, topless sock consists of a soft, durable, absorbent surface in contact with the skin on the bottom of the foot and an adhesive / anti-slip surface on the opposite side which is in contact with / adheres to the insole of the shoe or sandal. Optional features may include but are not limited to: the addition of extra layer(s) for added comfort, shock and / or sweat absorption; the addition of an anti-microbial agent; a design modification to allow for use in a thong sandal; and an unlimited variety of decorative material designs, colors, textures, stitching patterns or appliqués.

Owner:PIZZO CARL M

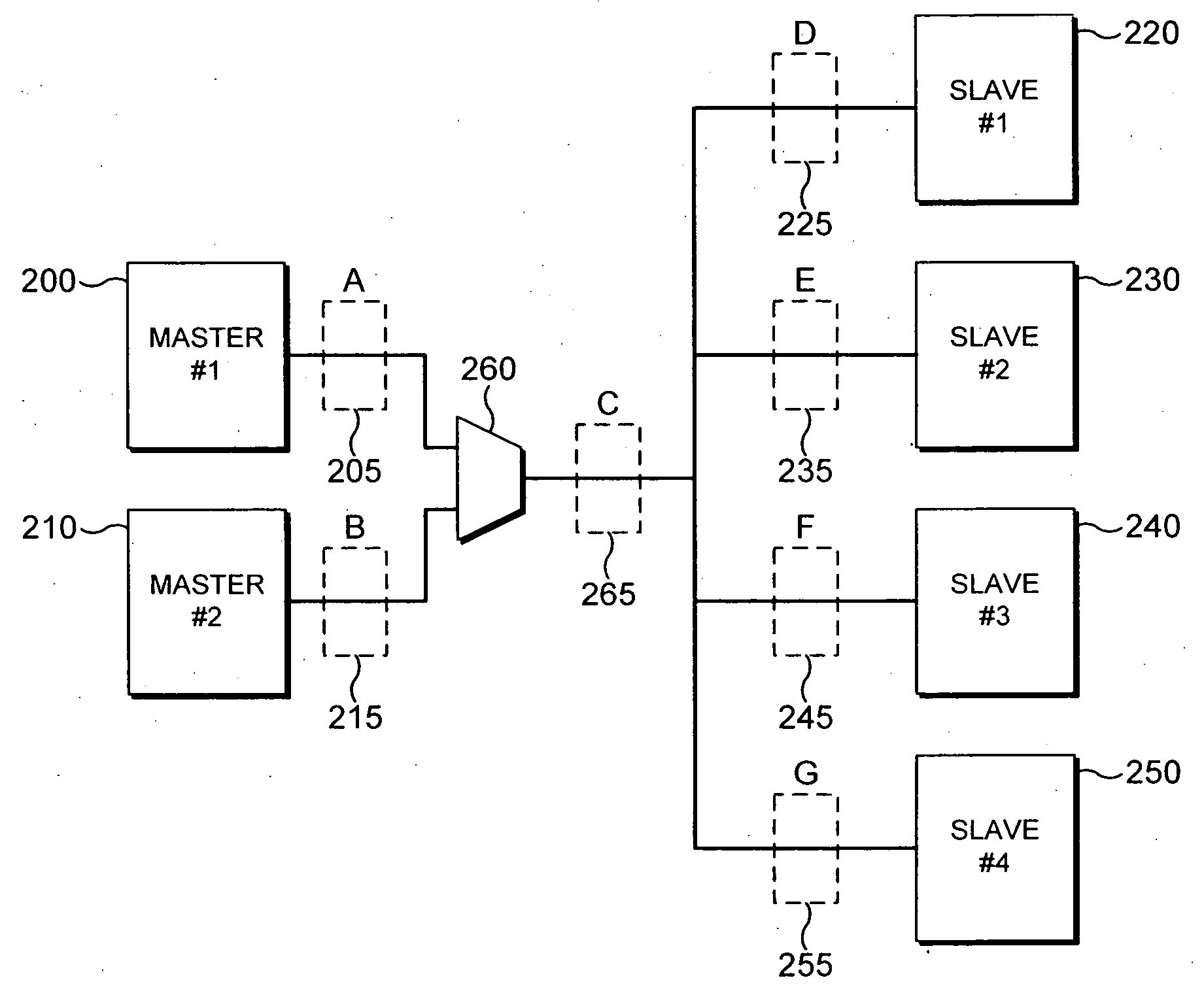

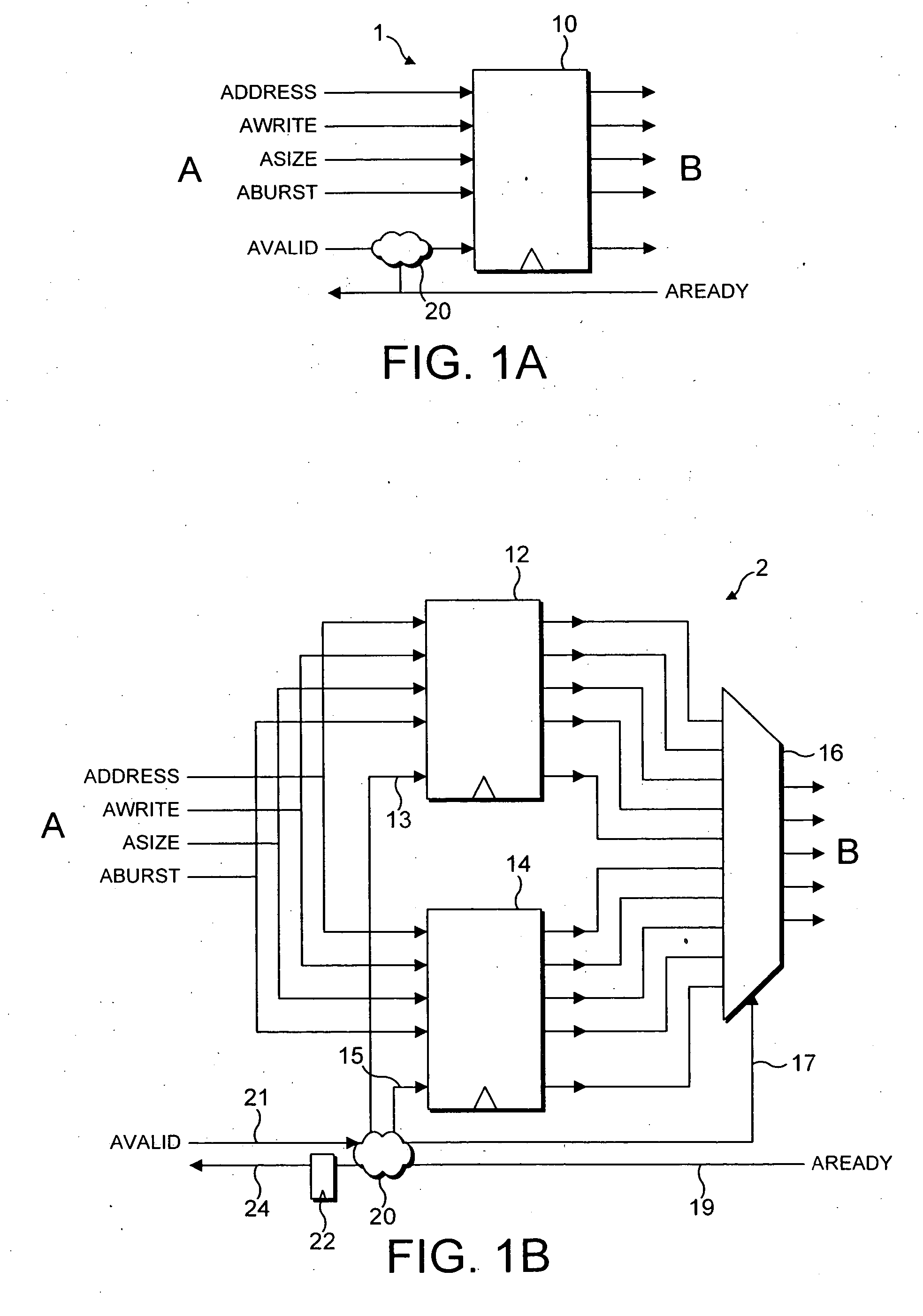

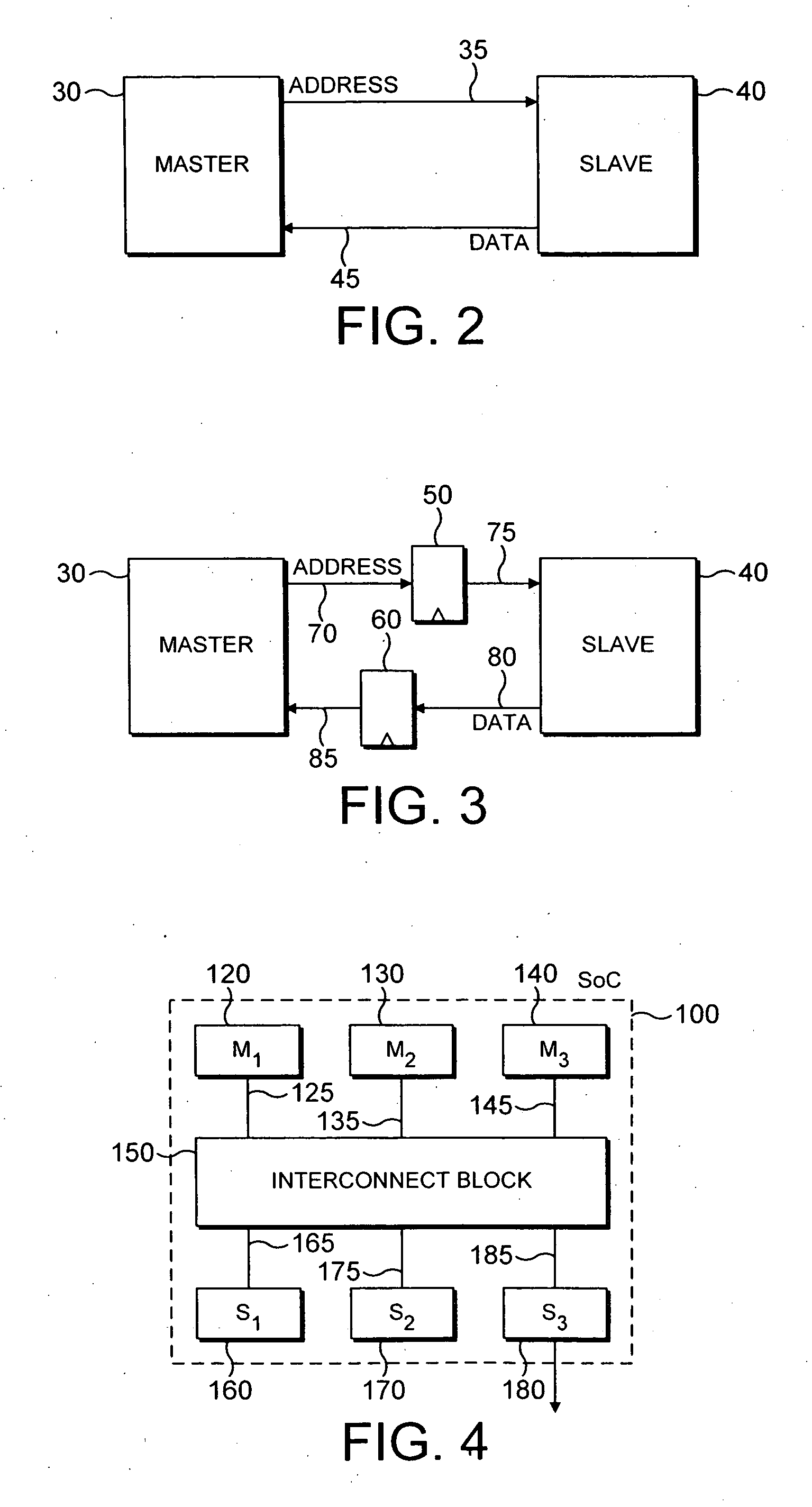

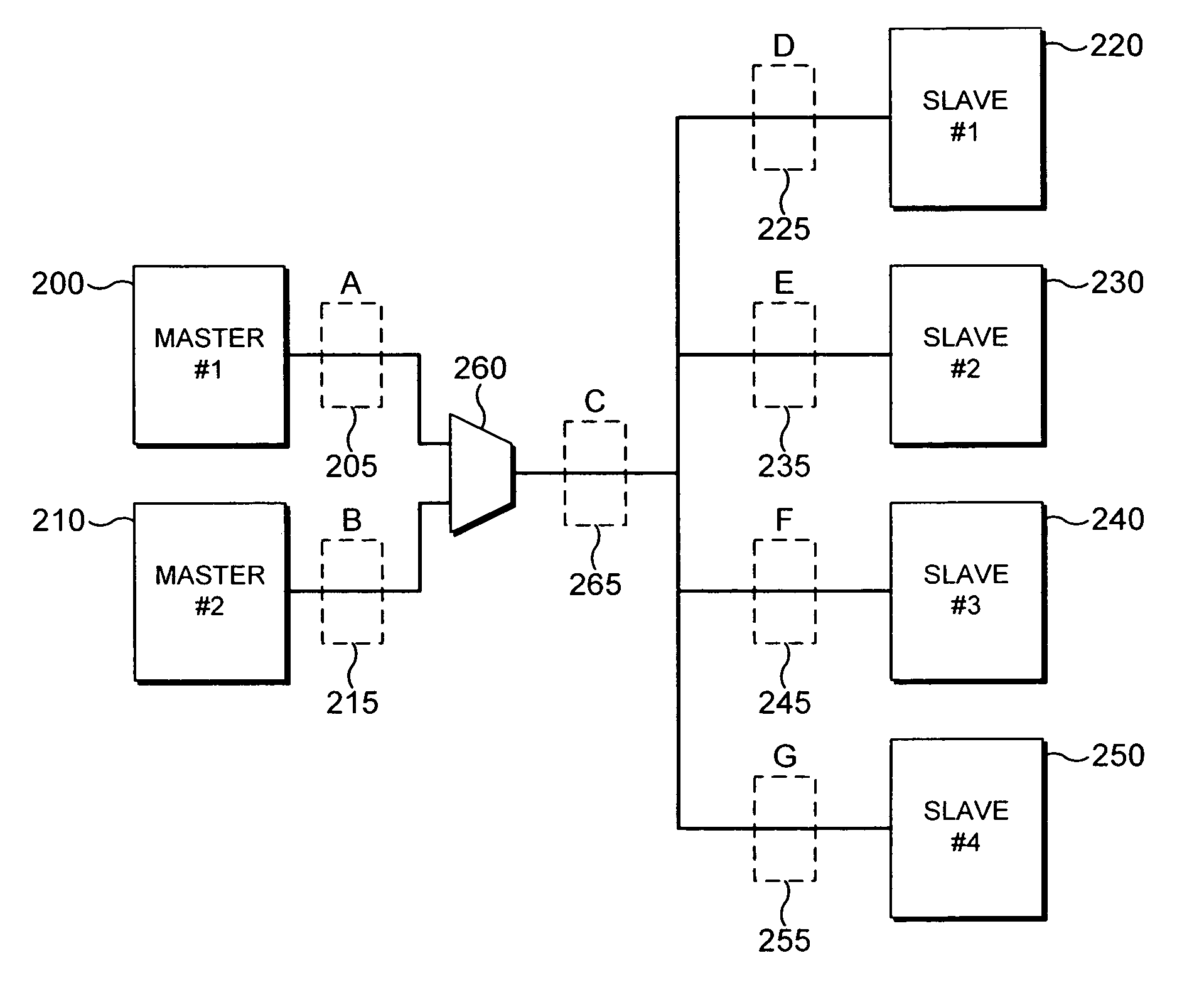

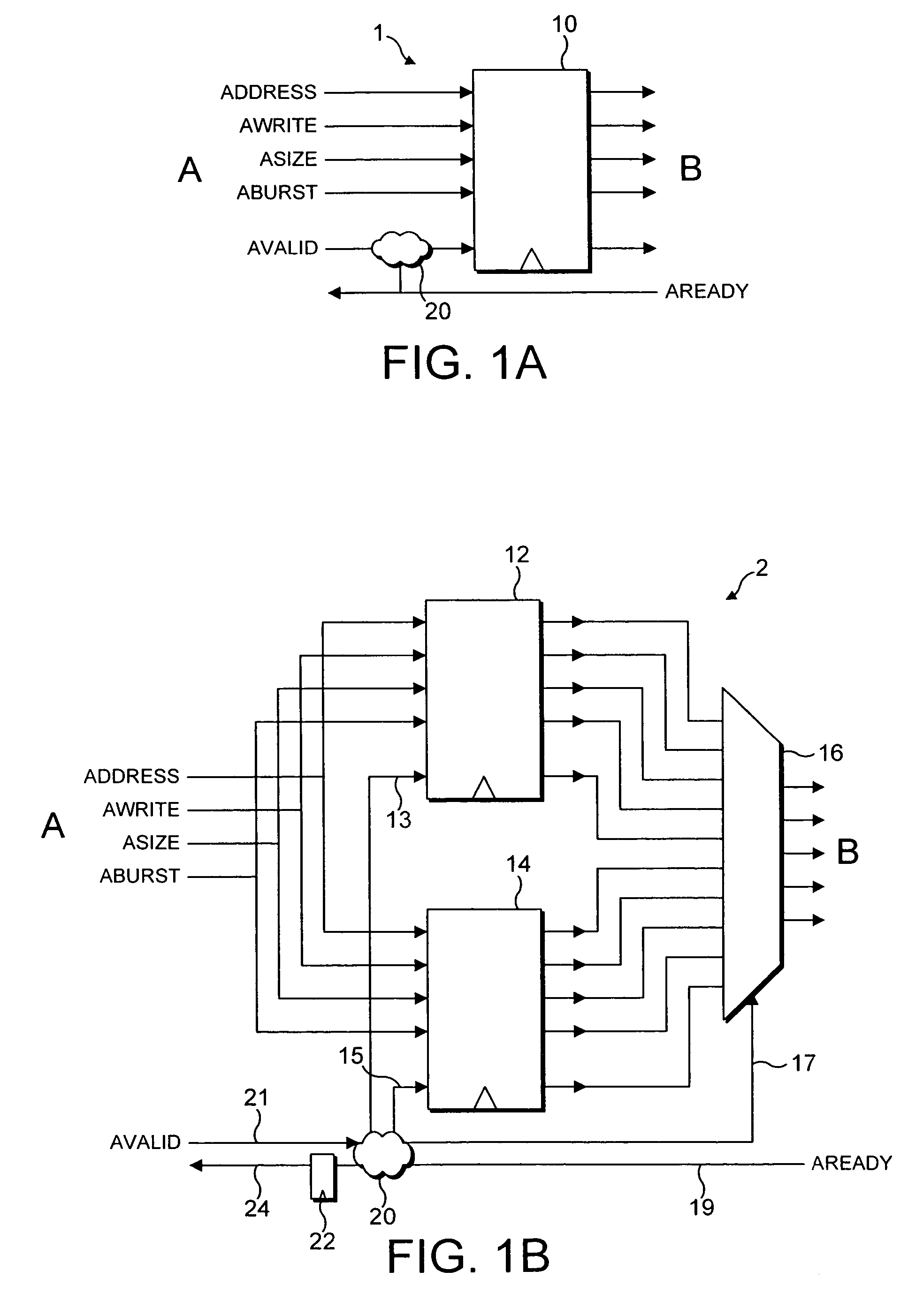

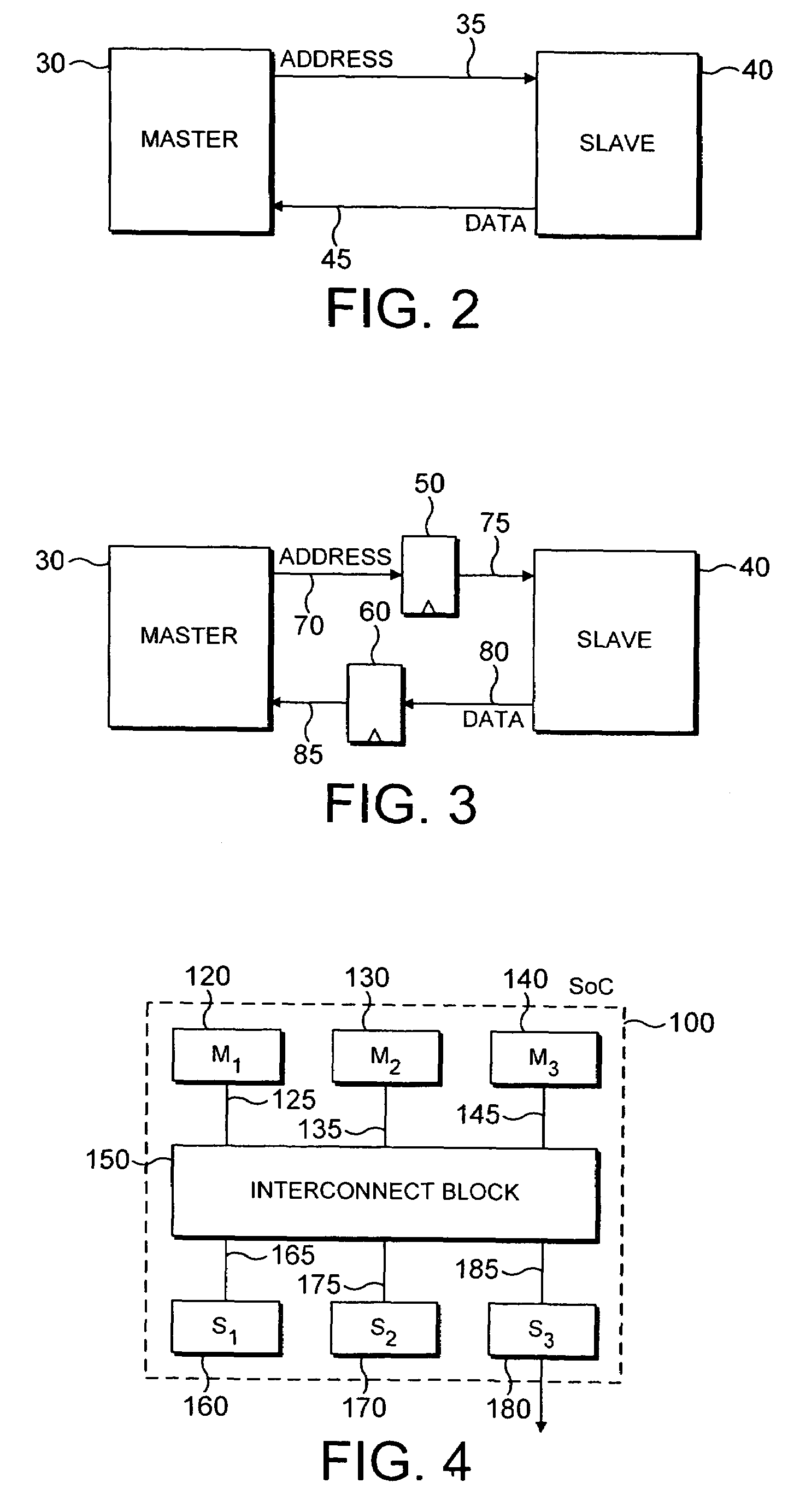

Flexibility of design of a bus interconnect block for a data processing apparatus

ActiveUS20040267994A1Extension of timeReduce power consumptionElectronic switchingArchitecture with single central processing unitEngineeringDesign modification

A method and design tool are provided for modifying a design of a bus interconnect block for a data processing apparatus in order to meet a requirement for a chosen characteristic of the bus interconnect block. The bus interconnect block provides a plurality of connections via which one or more master devices may access one or more slave devices, each connection comprising one or more paths, and each path having one or more path portions separated by storage elements. The method comprises the steps of: (a) selecting one or more candidate paths from said paths; (b) for each candidate path, applying predetermined criteria to determine whether modification of the number of storage elements in said path will assist in meeting the requirement for said chosen characteristic; and (c) modifying the number of storage elements in each candidate path for which it is determined at said step (b) that modification will assist in meeting the requirement for said chosen characteristic. Such an approach allows design modifications to be made iteratively with limited impact on previously made decisions, and allows design modifications to be considered and implemented on a connection-by-connection basis.

Owner:ARM LTD

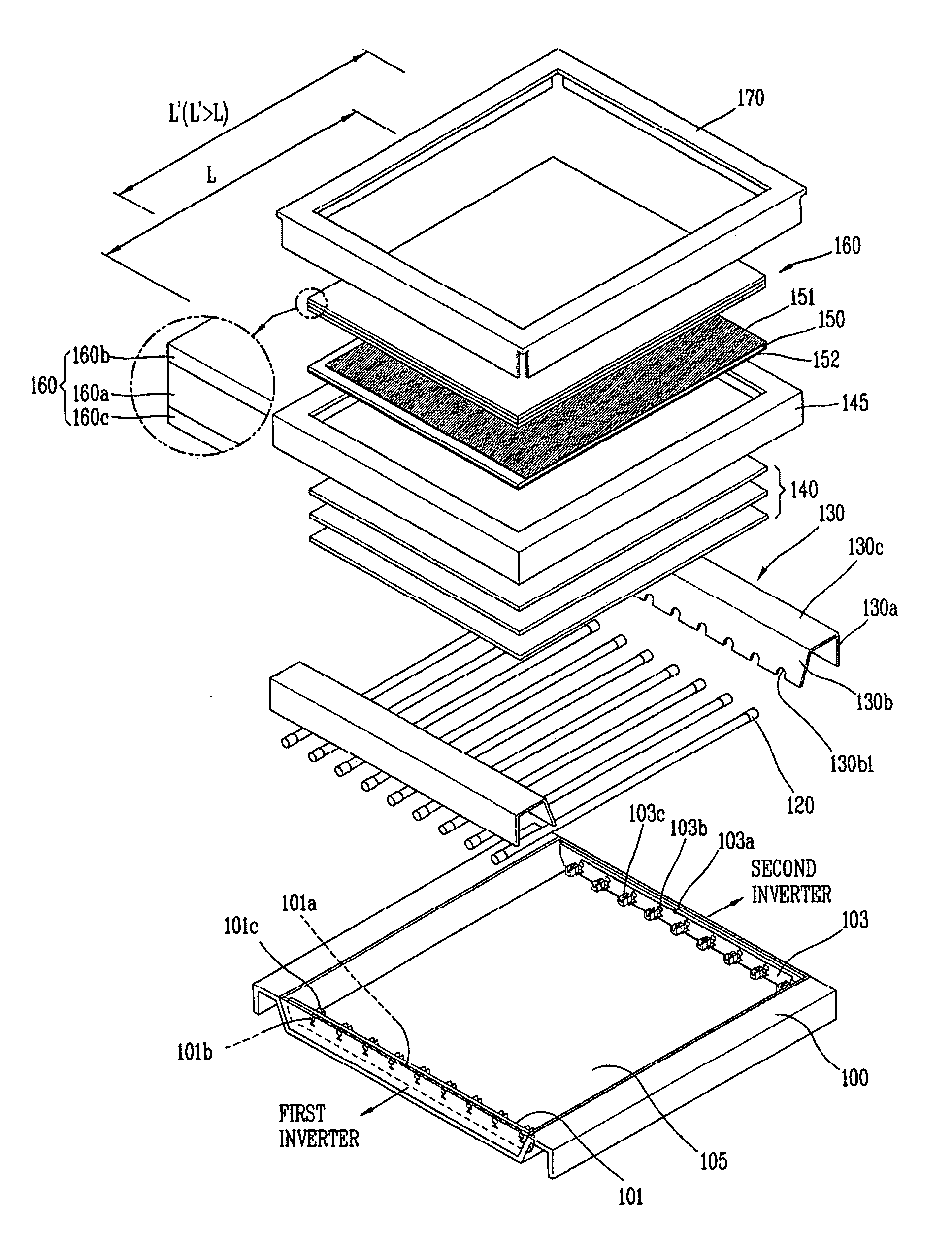

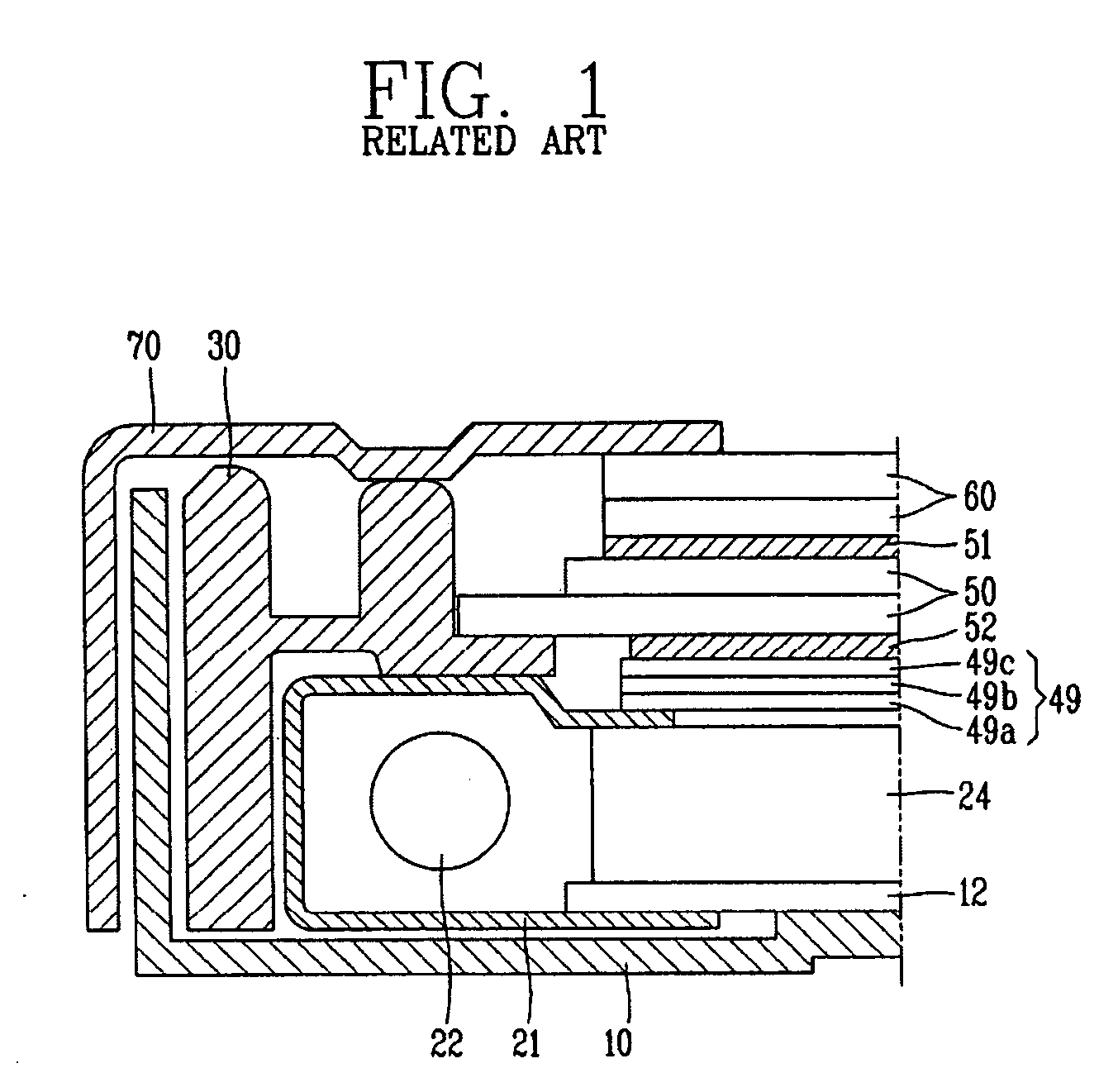

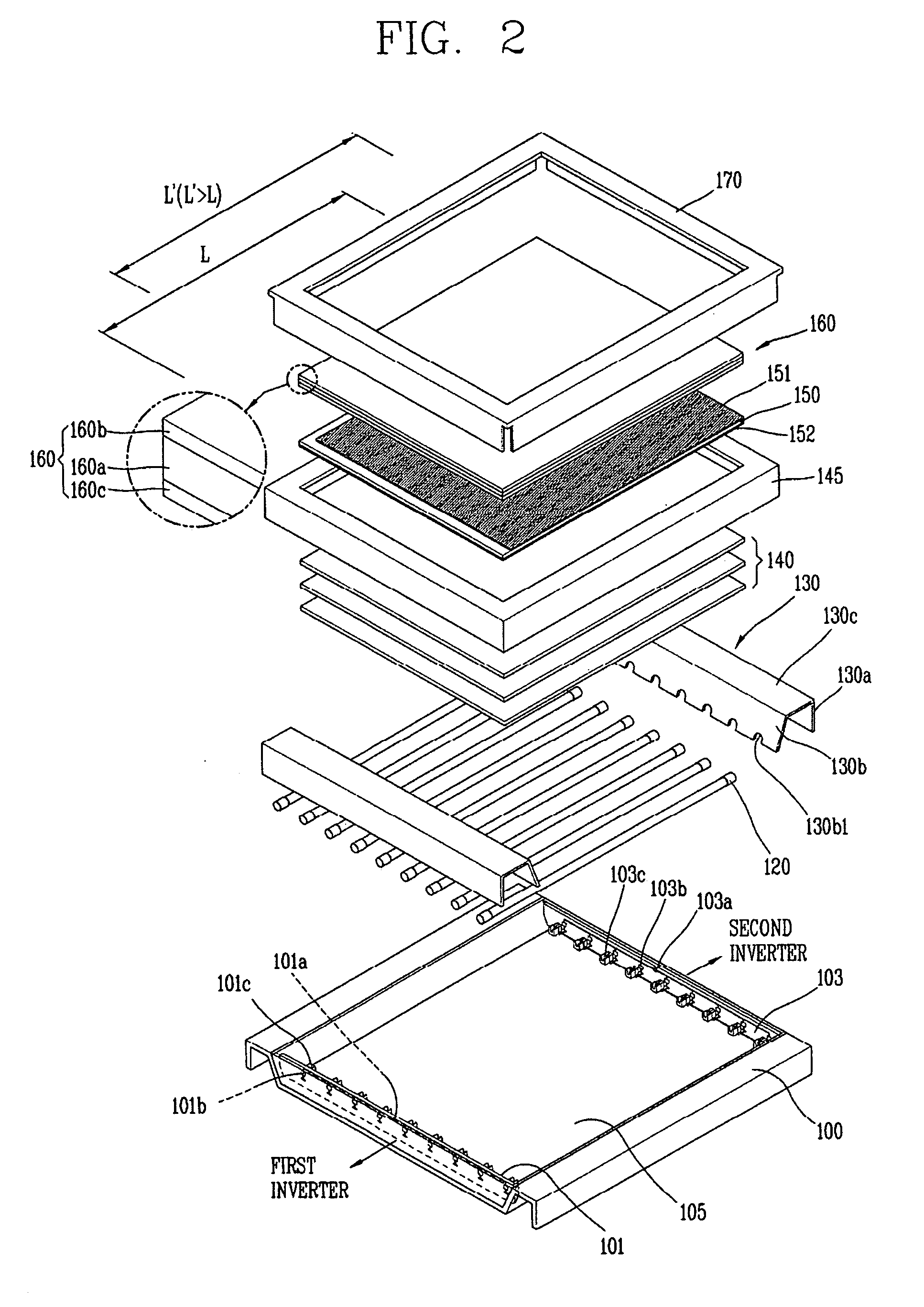

Liquid crystal display device

An LCD device capable of preventing damage of an LC panel by an impact damping member or through a design modification of a functional member when a functional plate such as a touch panel or the functional member is attached onto the LC panel. The LCD device comprises an LC panel, a backlight unit disposed below the LC panel for providing light, a functional member disposed on the LC panel within a size range of the LC panel, and an impact damping member disposed to be spacing from one or more sides of the functional member for absorbing an impact of the functional member when the LC panel moves.

Owner:LG DISPLAY CO LTD

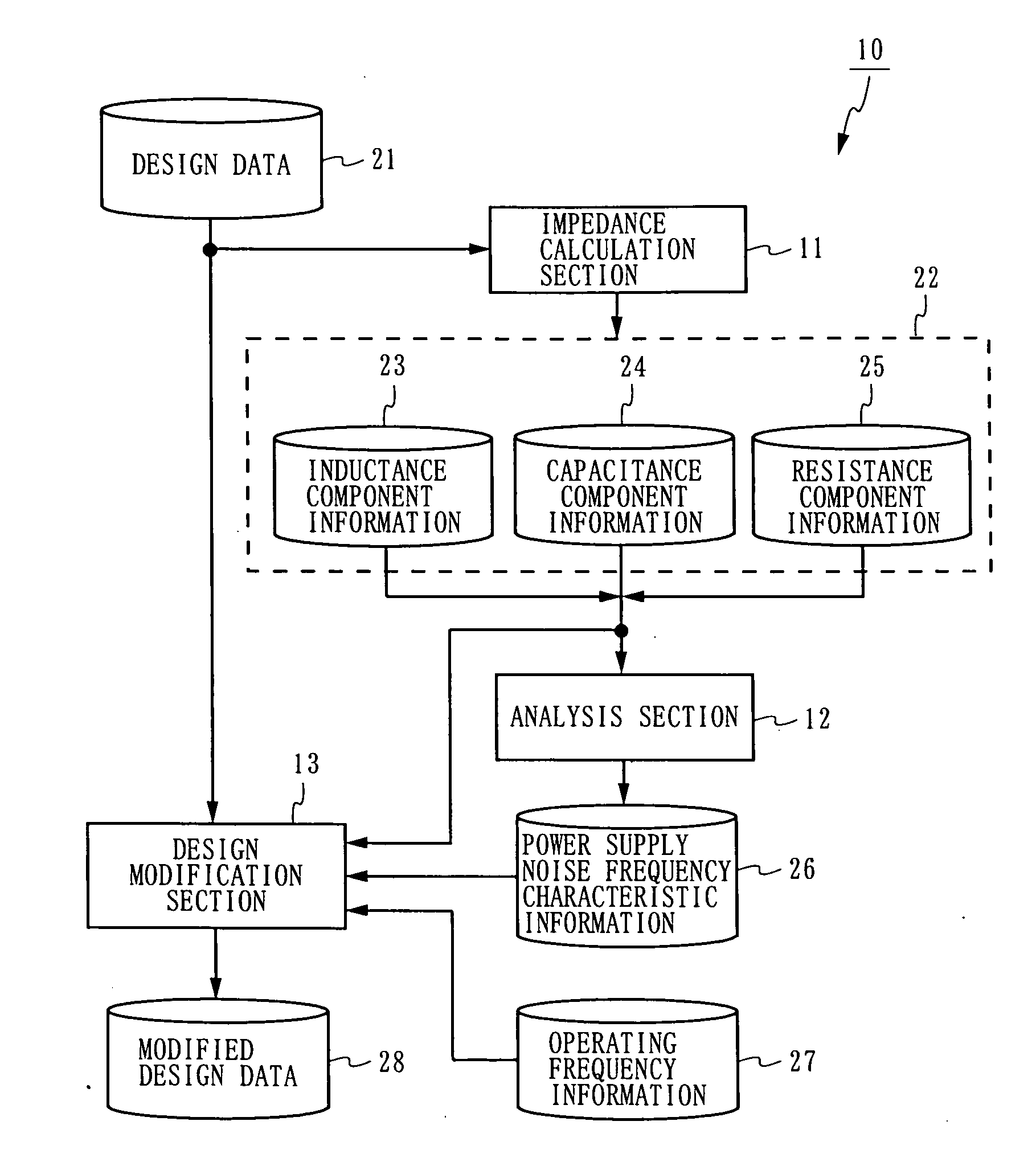

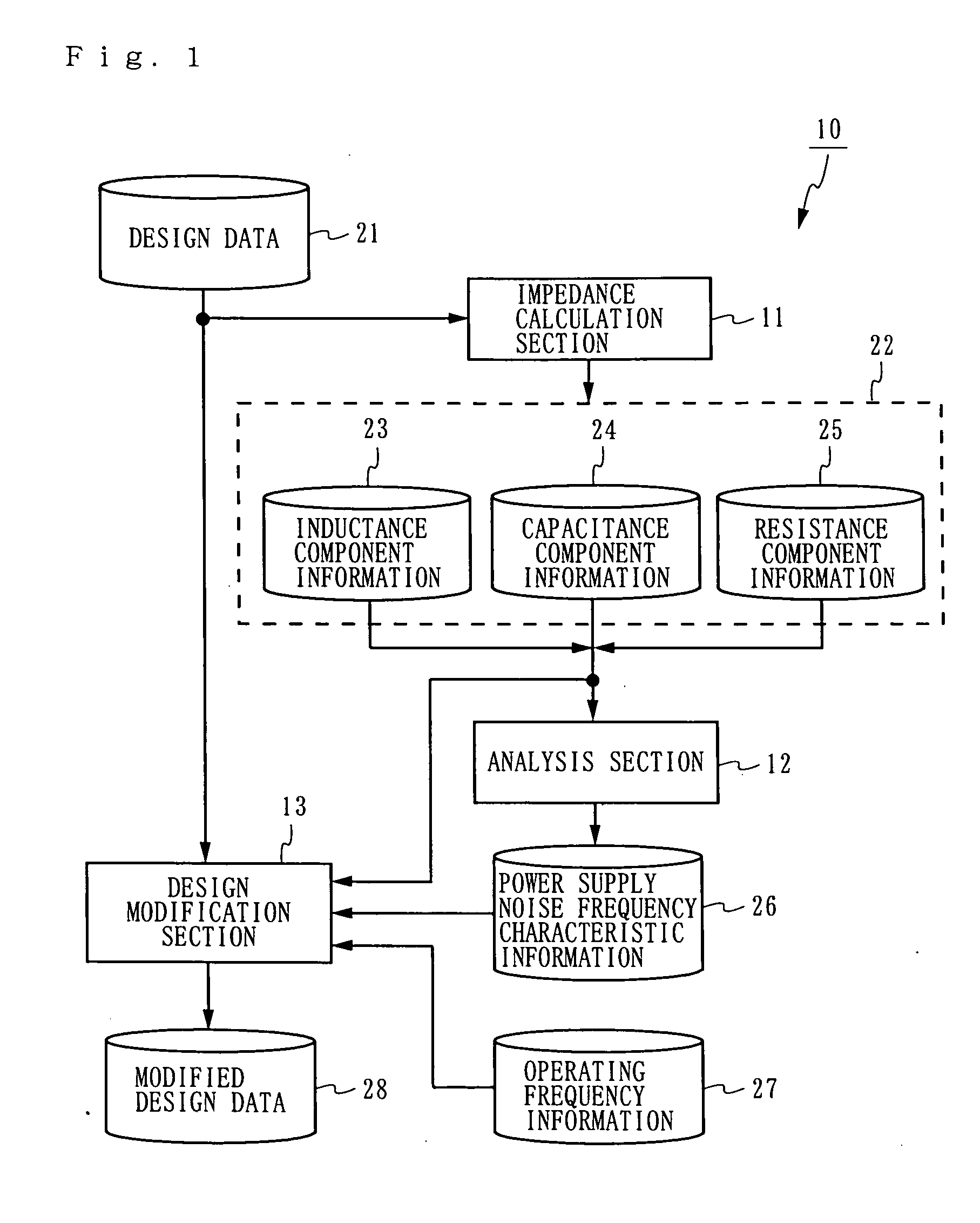

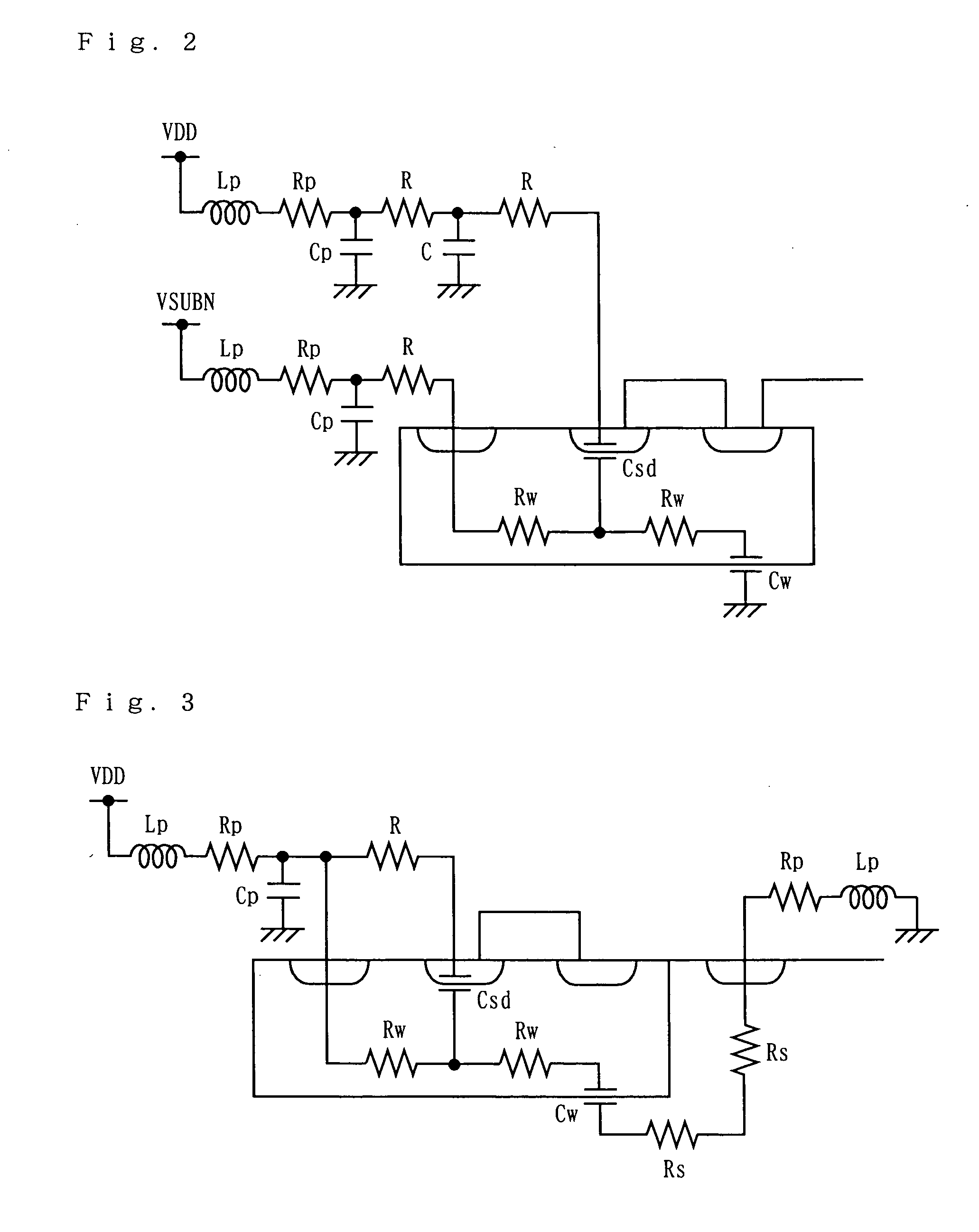

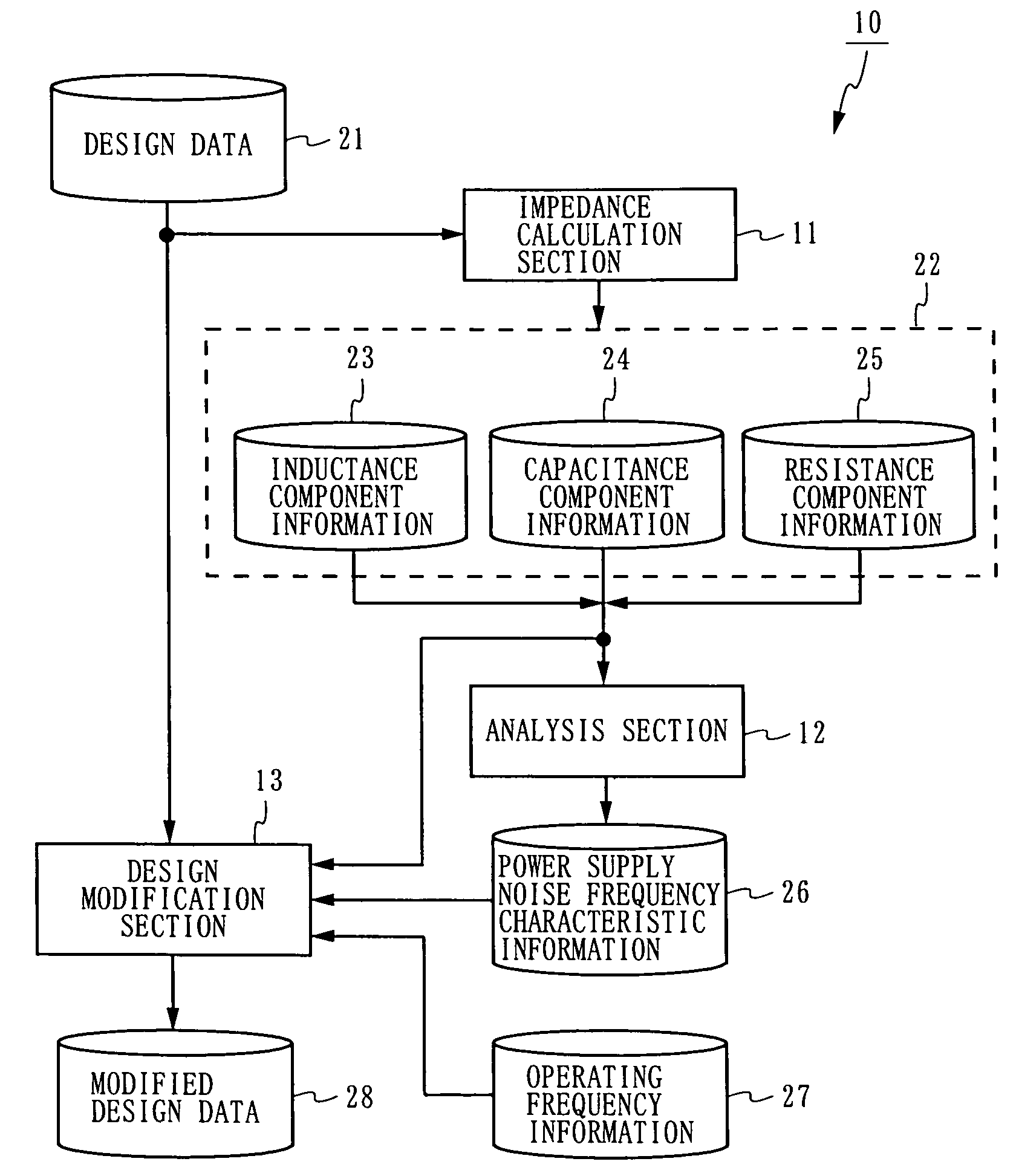

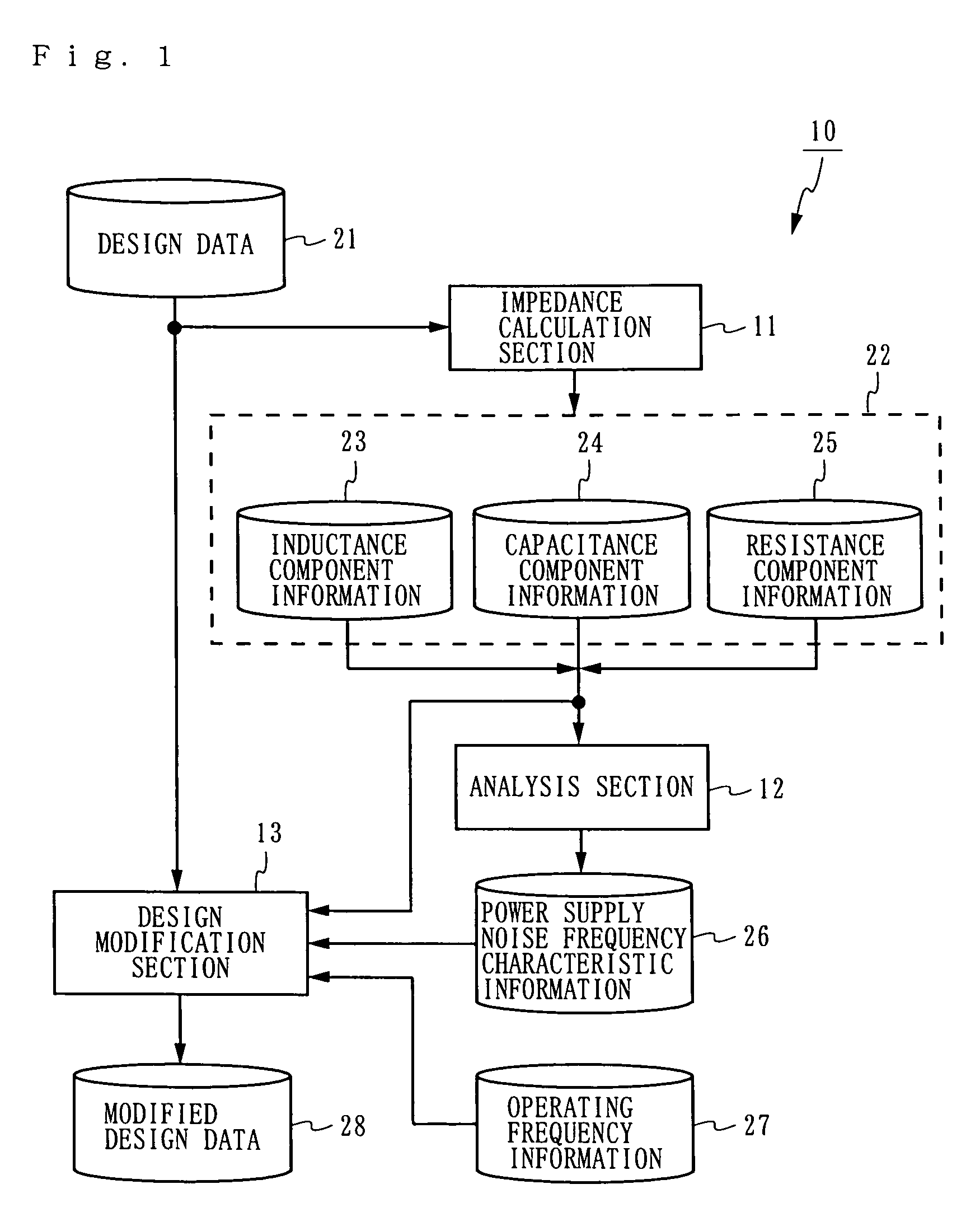

Design method for semiconductor integrated circuit suppressing power supply noise

InactiveUS20050149894A1Suppressing power supply noiseSuppress noiseSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceElectrical impedance

An impedance of a power supply wire is calculated based on design data of a semiconductor integrated circuit, a frequency characteristic of the calculated impedance is obtained, and a design of the semiconductor integrated circuit is changed based on the obtained frequency characteristic. As the above-described impedance, an impedance between power supplies that are different in potential such as a power supply and a ground may be calculated, or an impedance between power supplies that are substantially the same in potential such as a power supply and an N-well power supply may be calculated. By a design modification, a wiring method, the number of pads, separation of power supplies, a type of package, a characteristic of an inductance element, a substrate structure, a distance between wires, a decoupling capacitance, a length of a wire, and a characteristic of a resistance element, for example, are changed.

Owner:SOCIONEXT INC

Flexibility of design of a bus interconnect block for a data processing apparatus

ActiveUS7117277B2Extension of timeReduce power consumptionElectronic switchingArchitecture with single central processing unitDesign modificationEmbedded system

A method and design tool are provided for modifying a design of a bus interconnect block for a data processing apparatus in order to meet a requirement for a chosen characteristic of the bus interconnect block. The bus interconnect block provides a plurality of connections via which one or more master devices may access one or more slave devices, each connection comprising one or more paths, and each path having one or more path portions separated by storage elements. The method comprises the steps of: (a) selecting one or more candidate paths from said paths; (b) for each candidate path, applying predetermined criteria to determine whether modification of the number of storage elements in said path will assist in meeting the requirement for said chosen characteristic; and (c) modifying the number of storage elements in each candidate path for which it is determined at said step (b) that modification will assist in meeting the requirement for said chosen characteristic. Such an approach allows design modifications to be made iteratively with limited impact on previously made decisions, and allows design modifications to be considered and implemented on a connection-by-connection basis.

Owner:ARM LTD

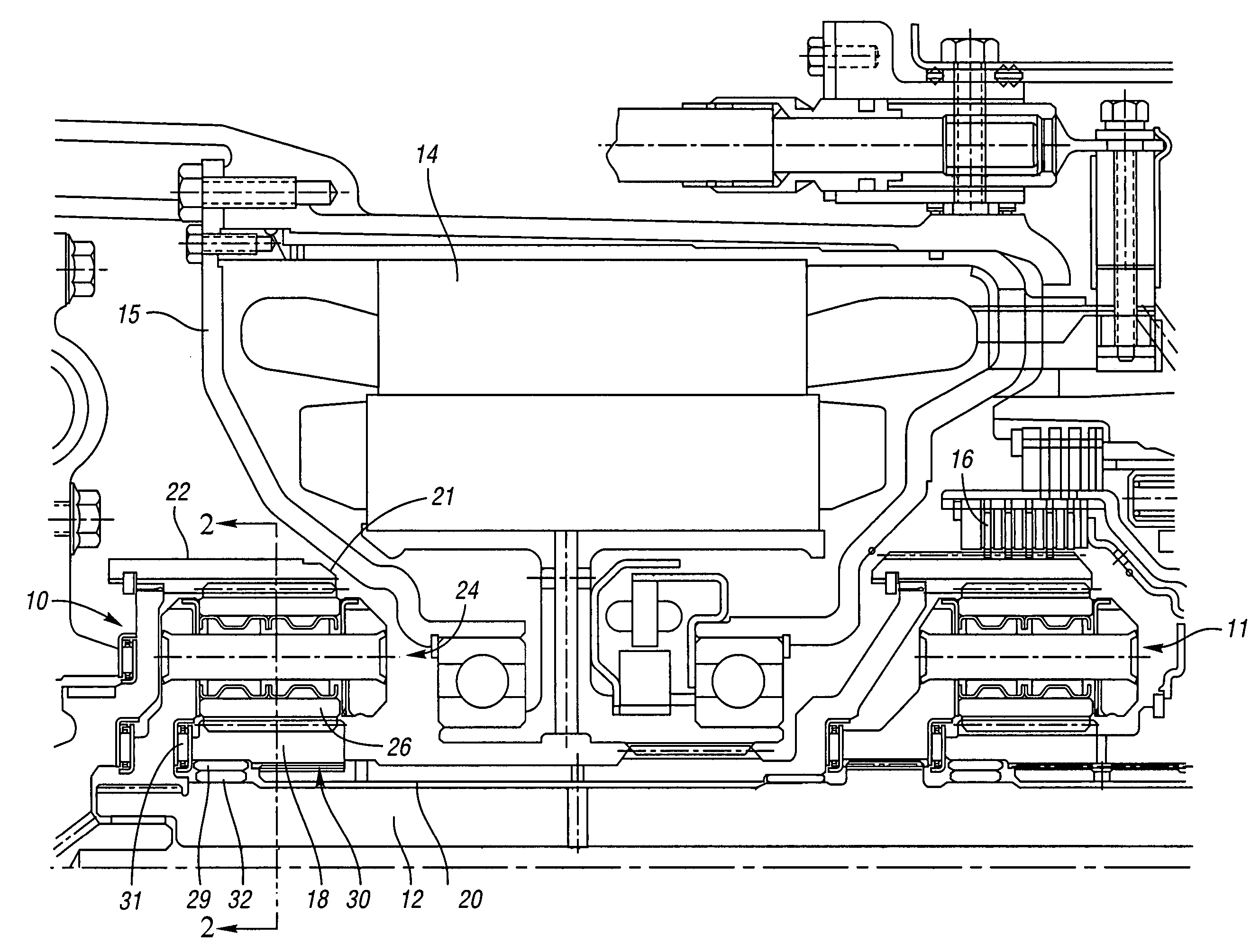

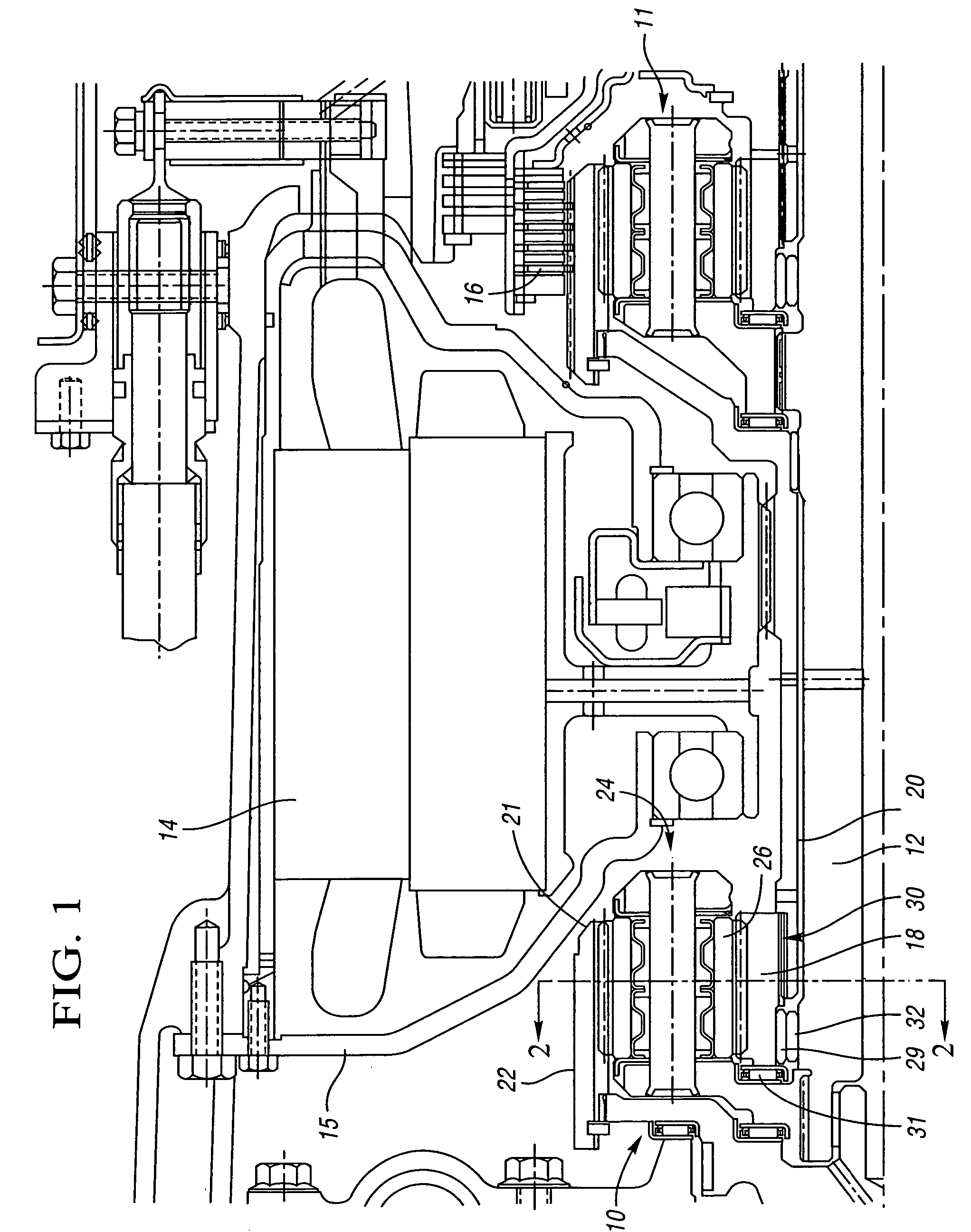

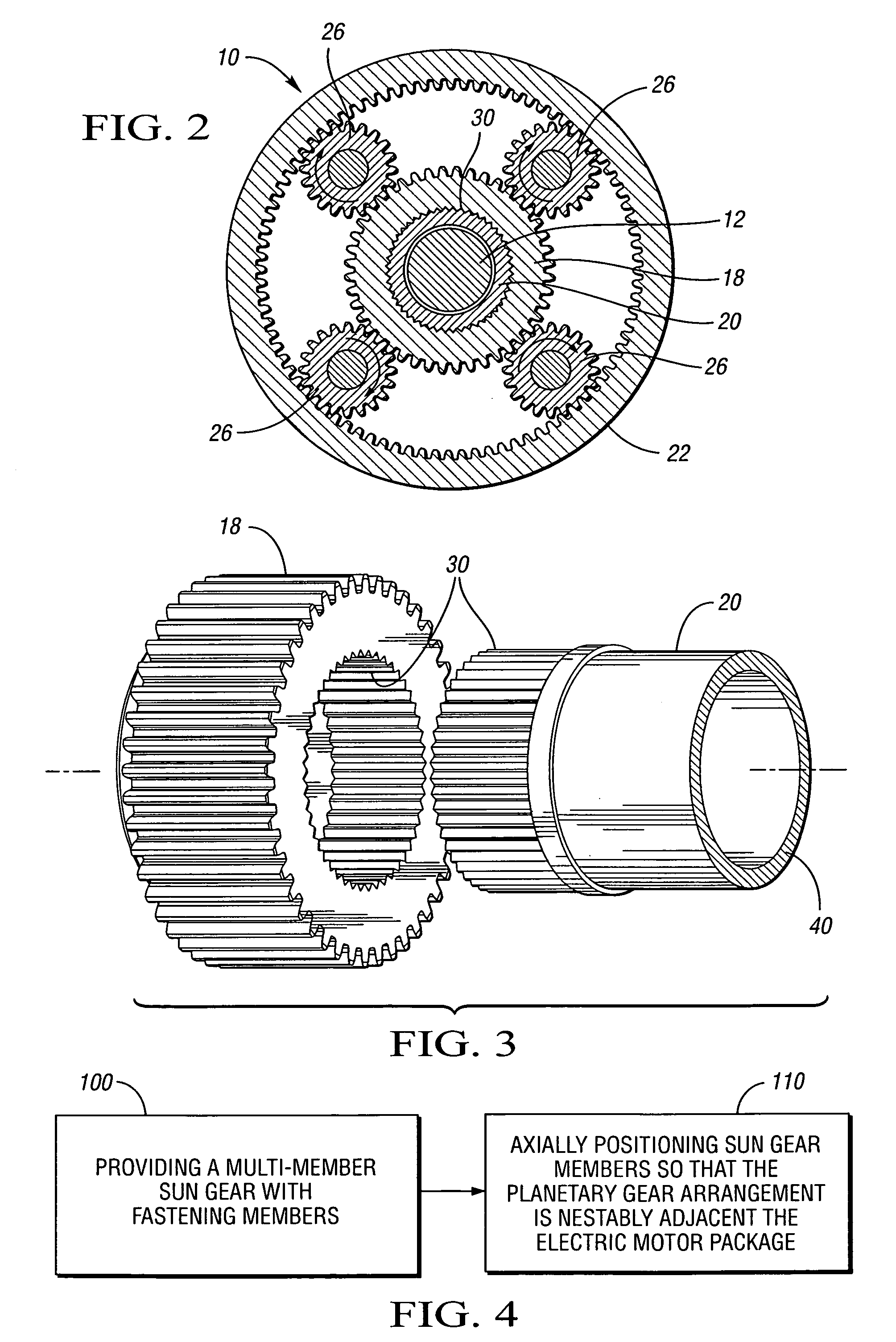

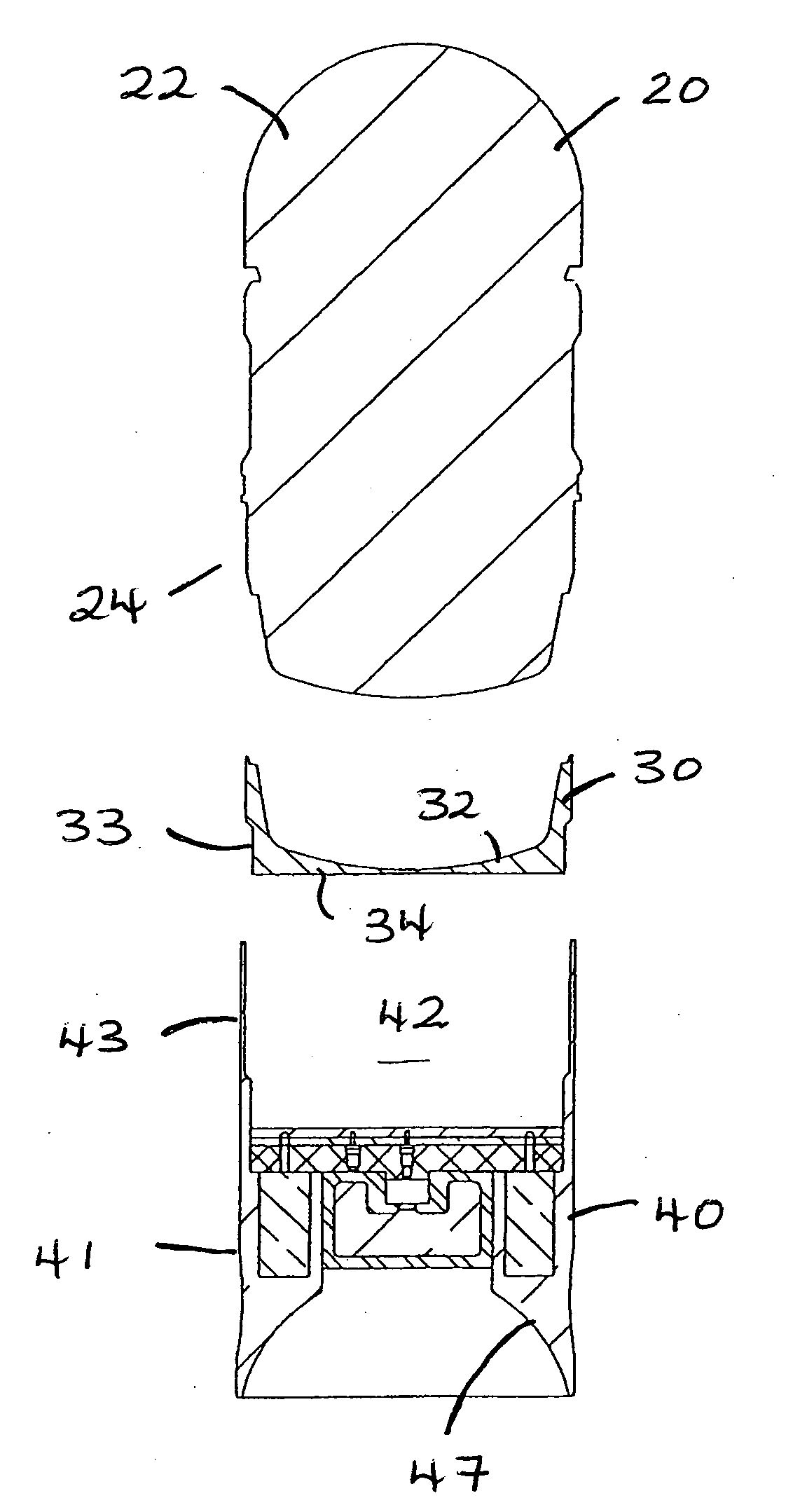

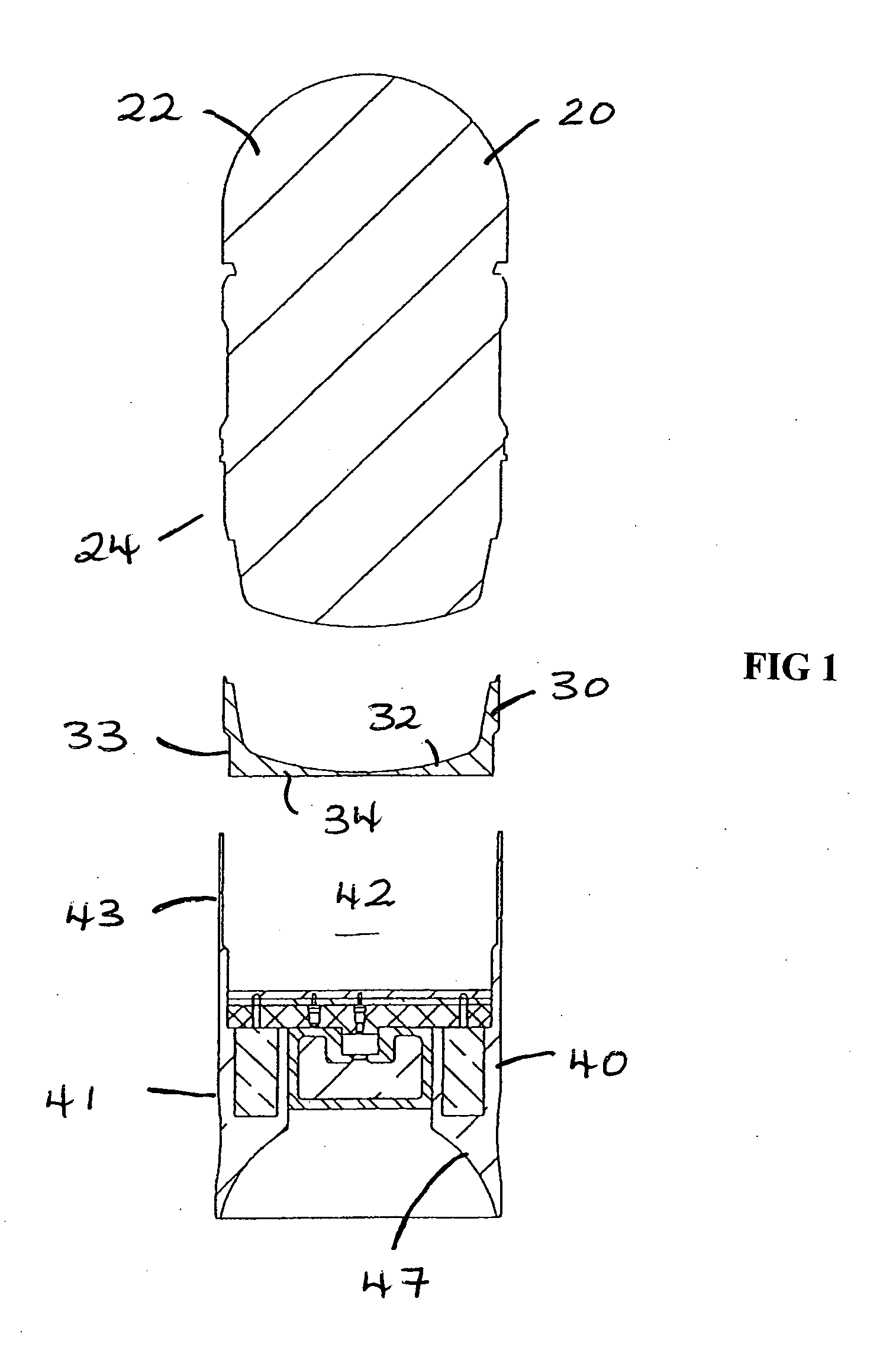

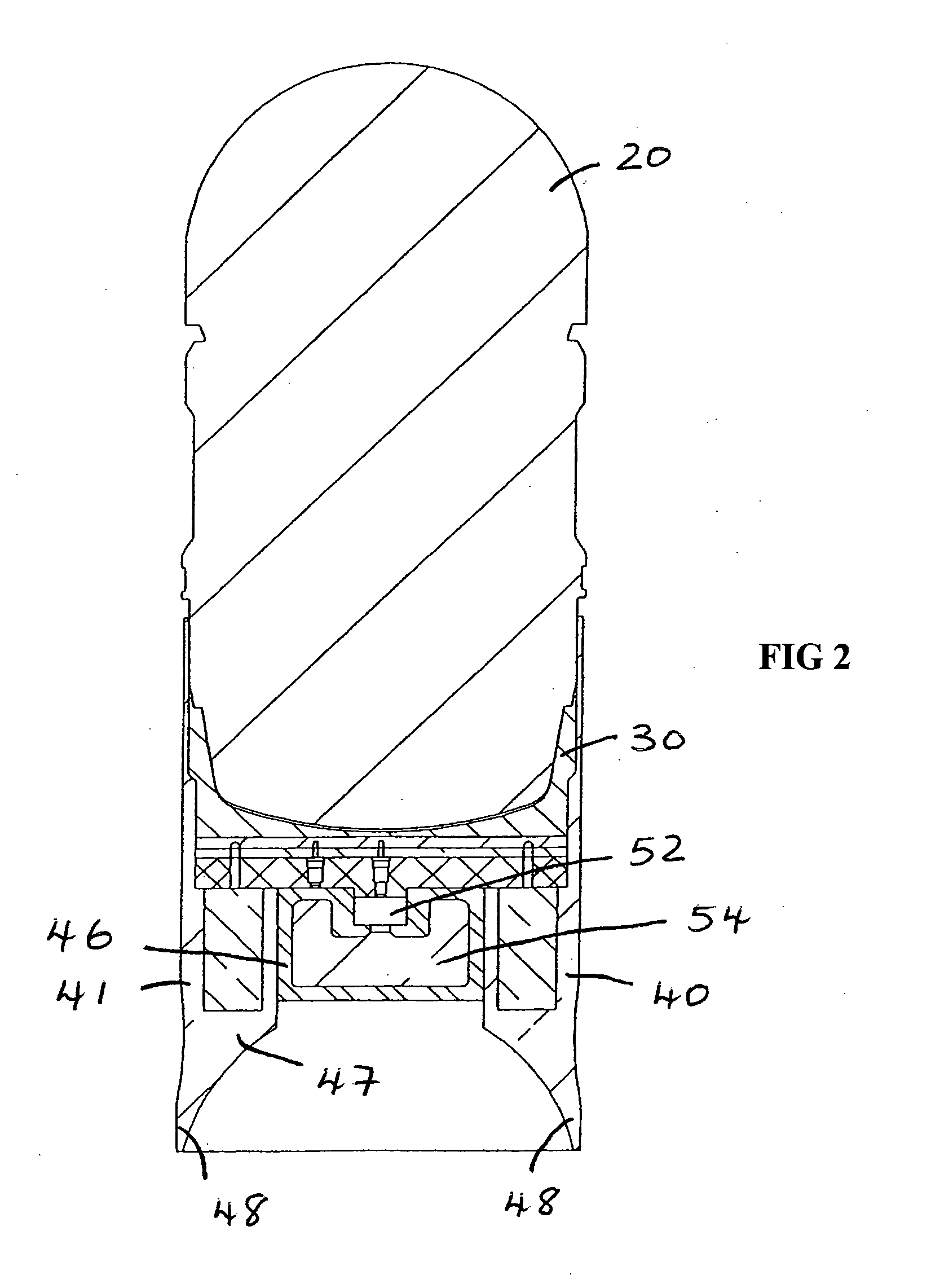

Splined sun gear and method for compact electro-mechanical transmission

ActiveUS7195575B2Reduce the overall diameterImprove manufacturabilityPortable liftingToothed gearingsGear wheelEngineering

This invention relates to a sun gear member and sun gear shaft providing improved manufacturing time and material cost savings. This invention further relates to the packaging of a compact electro-mechanical transmission specifically as it pertains to the redesign of the planetary gear arrangement to compensate for the new design of the sun gear member and sun gear shaft. Several design modifications are disclosed in order to reduce the diameter of the planetary gear arrangement and its inclusive members. For example, the ring gear is chamfered to allow for additional clearance so that the planetary gear arrangement and the electronic motor package can be more compact when sun gear has separable sun gear members. In addition to packaging considerations, material costs, fatigue life requirements, and manufacturability of relevant transmission components were governing concerns in the redesign of the sun gear member and sun gear shaft.

Owner:GM GLOBAL TECH OPERATIONS LLC

Adaptor for stackable projectile

ActiveUS20100101443A1Enhanced couplingIncrease propulsionAmmunition projectilesShotgun ammunitionDesign modificationProjectile

The present invention relates to stackable projectiles having a warhead and a propulsion unit. An adaptor enables the warhead to be coupled to propulsion units made of different materials. Furthermore, an adaptor couples different profiles of warheads and propulsion units and allows projectiles to be stacked without need for design modifications. The assembled projectile can be fired electrically or mechanically.

Owner:DEFENDTEX

Design method for semiconductor integrated circuit suppressing power supply noise

InactiveUS7278124B2Suppress noiseSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

An impedance of a power supply wire is calculated based on design data of a semiconductor integrated circuit, a frequency characteristic of the calculated impedance is obtained, and a design of the semiconductor integrated circuit is changed based on the obtained frequency characteristic. As the above-described impedance, an impedance between power supplies that are different in potential such as a power supply and a ground may be calculated, or an impedance between power supplies that are substantially the same in potential such as a power supply and an N-well power supply may be calculated. By a design modification, a wiring method, the number of pads, separation of power supplies, a type of package, a characteristic of an inductance element, a substrate structure, a distance between wires, a decoupling capacitance, a length of a wire, and a characteristic of a resistance element, for example, are changed.

Owner:SOCIONEXT INC

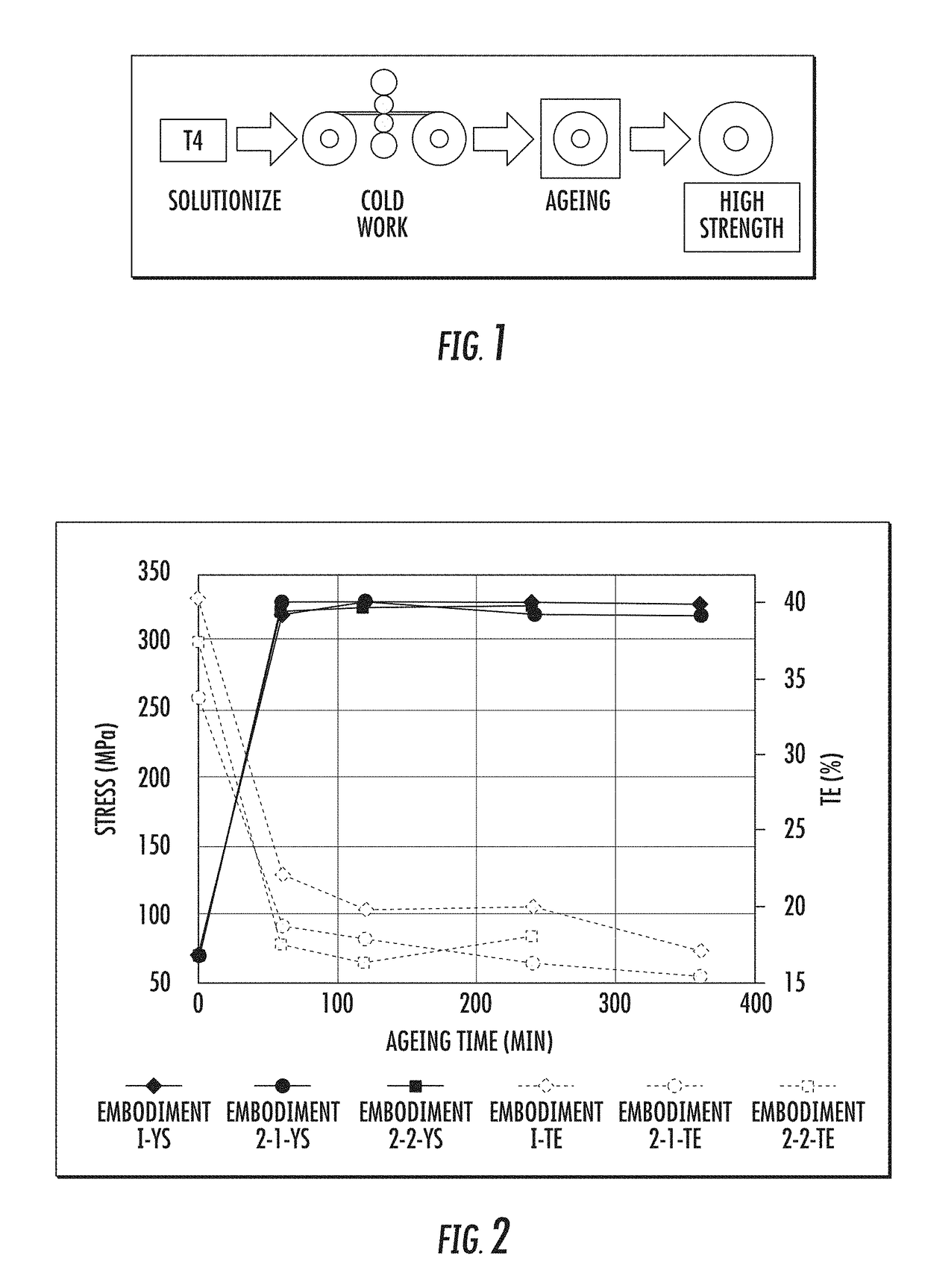

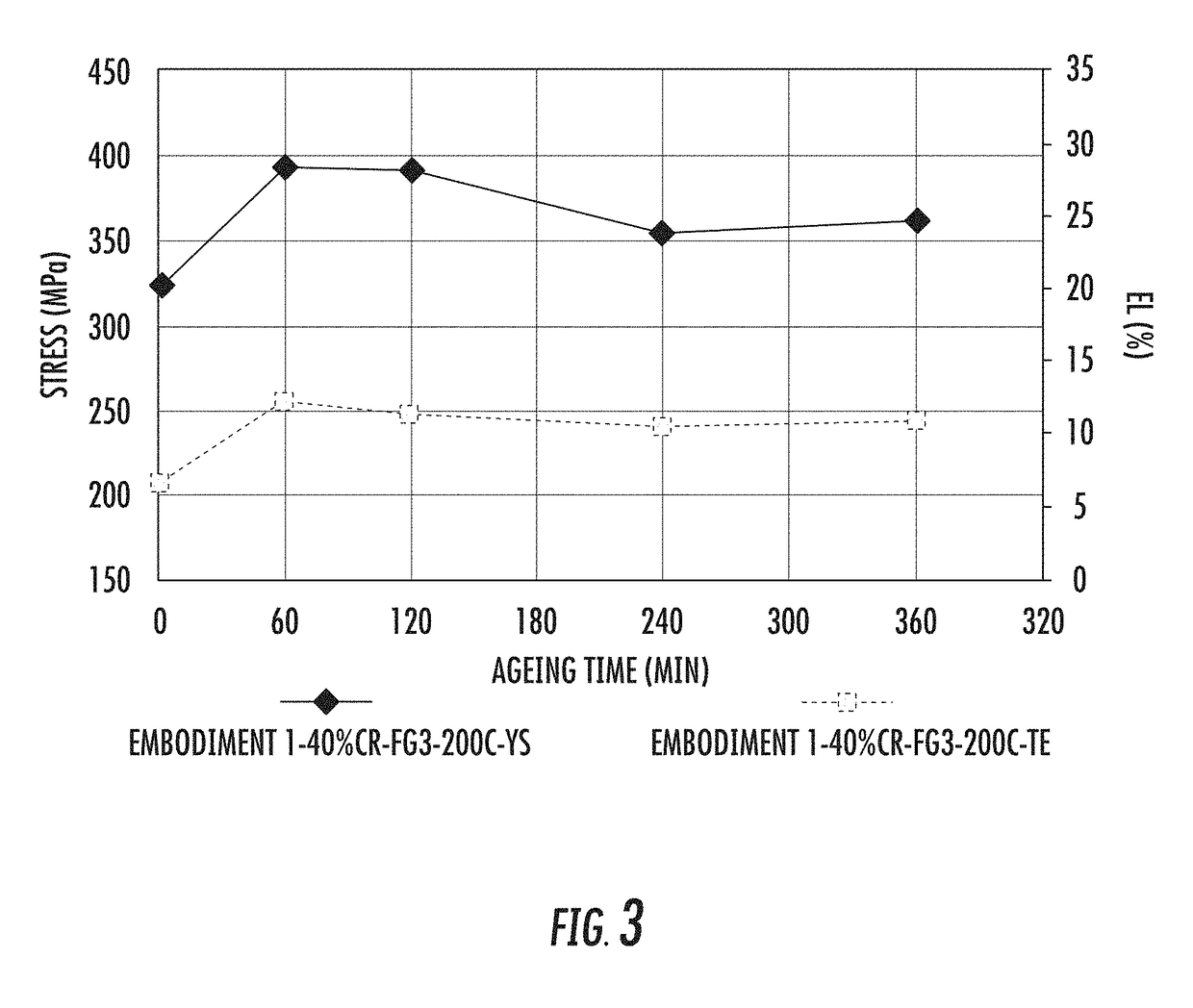

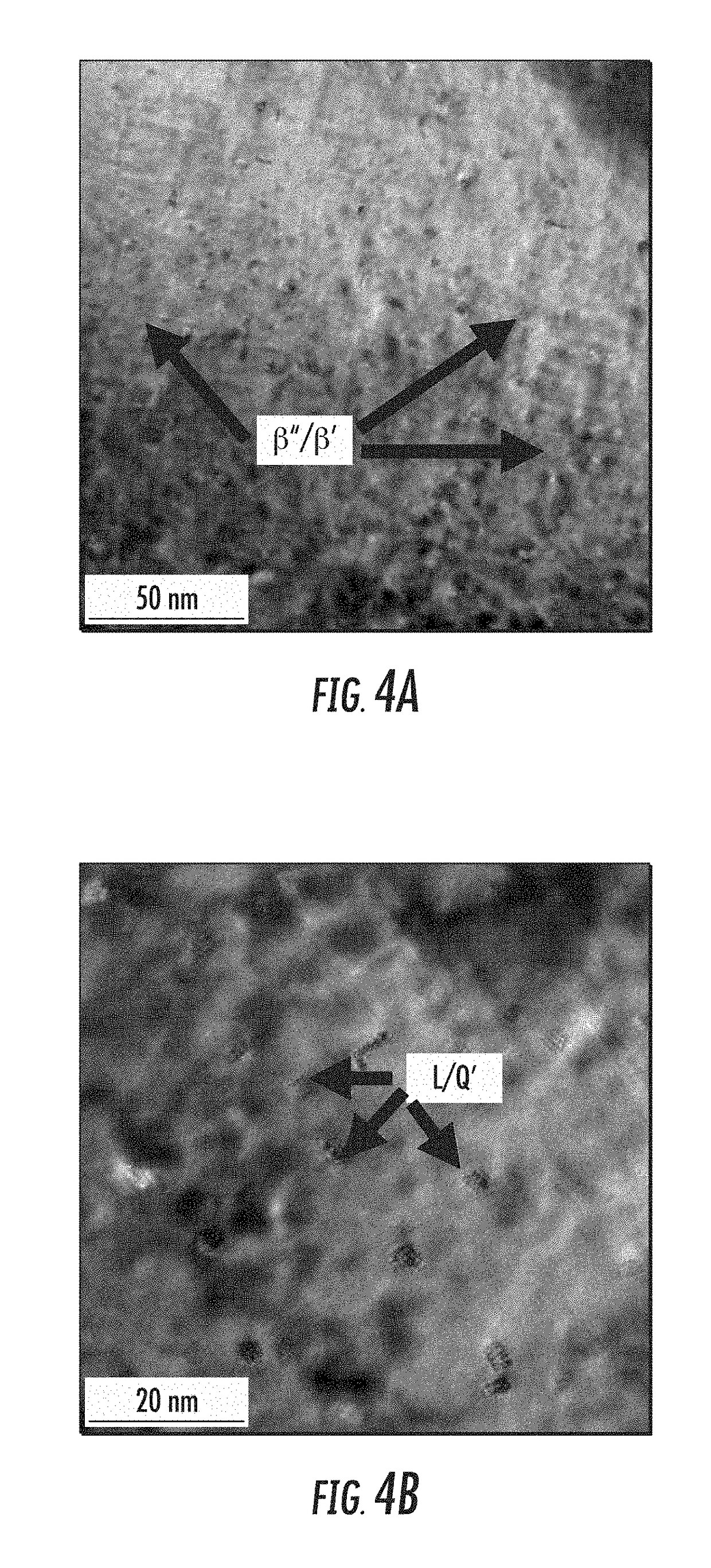

High strength 6xxx aluminum alloys and methods of making the same

ActiveUS20170175239A1High yield strengthFurnace typesHeat treatment furnacesHigh intensityDesign modification

Provided are new high strength 6xxx aluminum alloys and methods of making aluminum sheets thereof. These aluminum sheets may be used to fabricate components which may replace steel in a variety of applications including the transportation industry. In some examples, the disclosed high strength 6xxx alloys can replace high strength steels with aluminum. In one example, steels having a yield strength below 340 MPa may be replaced with the disclosed 6xxx aluminum alloys without the need for major design modifications.

Owner:NOVELIS INC

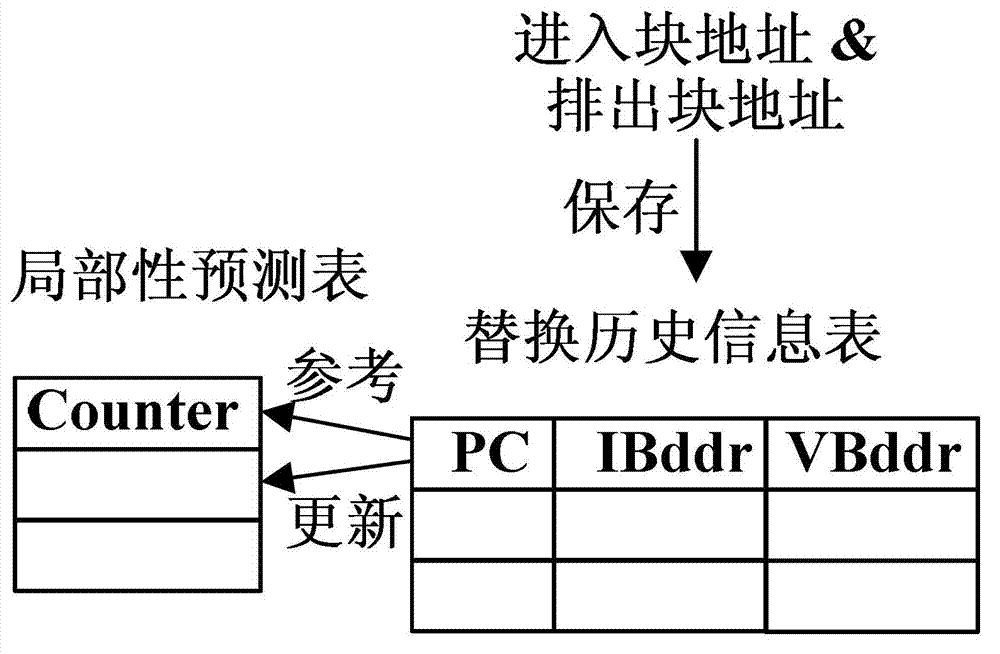

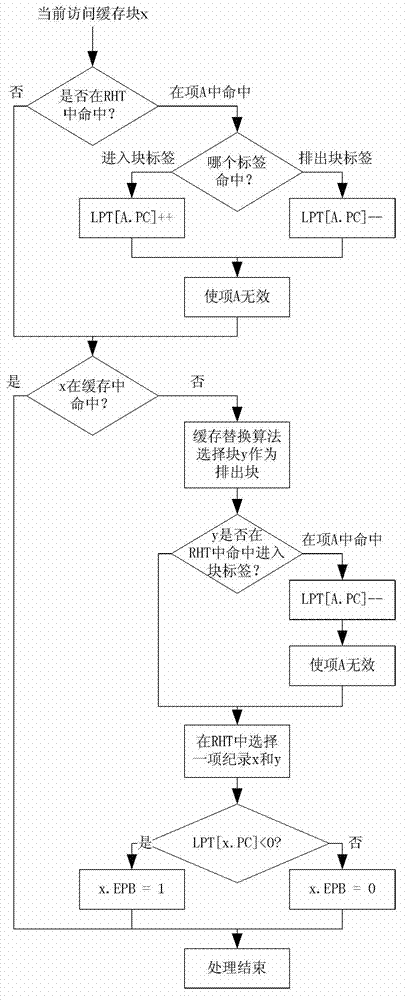

Substitution method for inclusive final stage cache

InactiveCN103049399AShort lifeLess overheadMemory adressing/allocation/relocationParallel computingSubstitution method

The invention provides a substitution method for inclusive final-stage cache and relates to a substitution method for inclusive final-stage cache in a processor. In the case of not sacrificing simplicity of a consistency protocol of the inclusive final-stage cache, the substitution method is capable of improving performances of the inclusive final-stage cache and includes the steps of predicting the locality of the entering block when a cache block enters a final-stage cache; putting the cache block into a high discharge priority list if the locality prediction of the cache block is poor; otherwise, putting the cache block into a low discharge priority list; determining cache blocks in the high discharge priority list in substitution; and substituting a cache block which is in a high discharge priority list outside an inner cache as a victim for the final-stage cache. The substitution method for the inclusive final-stage cache has the advantages of improving performances of the inclusive final stage cache and requiring minimal hardware overhead and design modifications.

Owner:北京北大众志微系统科技有限责任公司

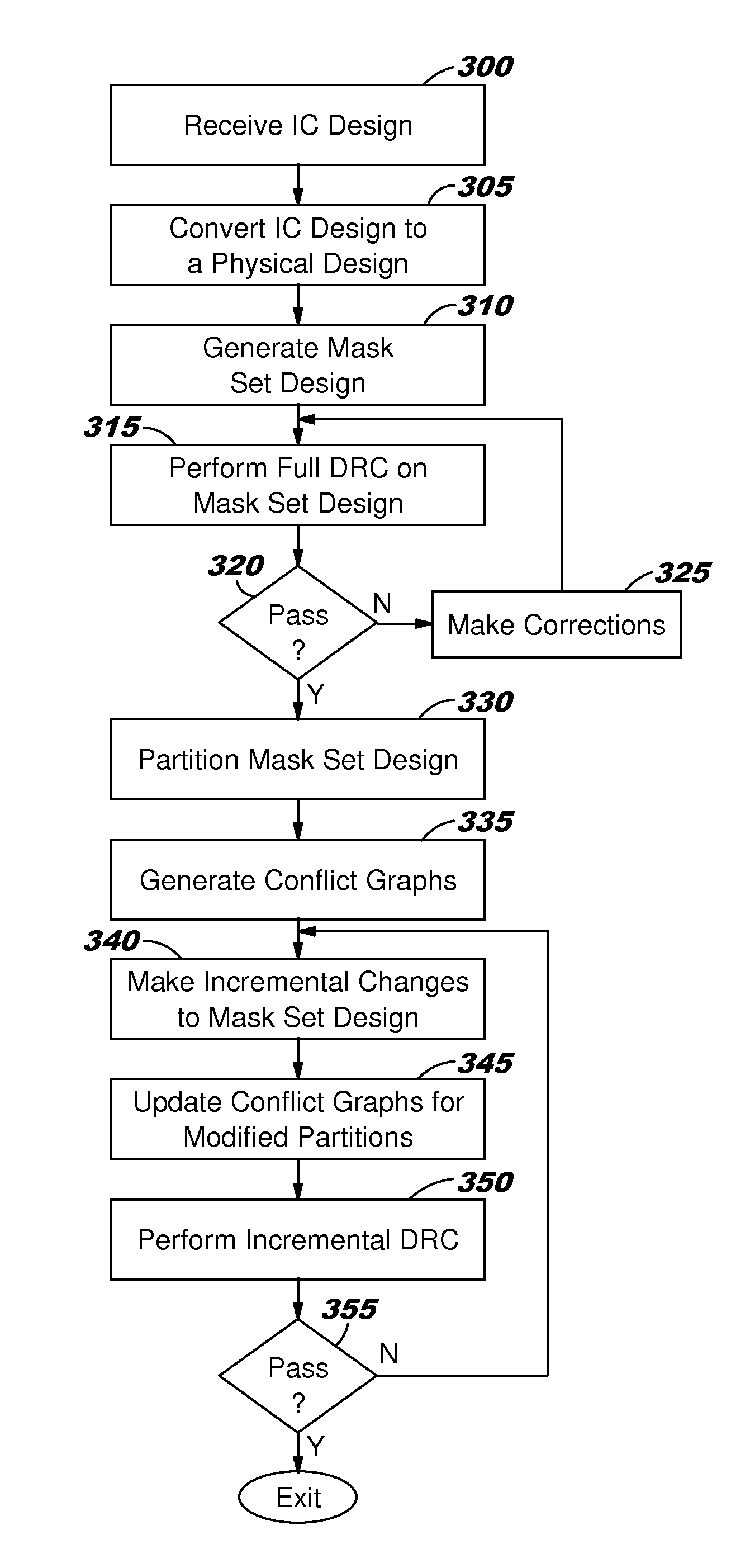

Preventing double patterning odd cycles

ActiveUS9298084B2Originals for photomechanical treatmentSpecial data processing applicationsEngineeringDesign modification

A method, system or computer usable program product for preventing odd cycles caused by design modifications to a double patterning layout including utilizing a processor to identify a set of double patterning cycles in the layout for storage in a memory; receiving a set of design modifications to the layout; utilizing the processor to identify from the set of double patterning cycles a subset of double patterning cycles affected by the set of design modifications; utilizing the processor to identify from the set of design modifications a subset of design modifications which may cause odd cycles in the subset of double patterning cycles; and providing a notification of the subset of design modifications.

Owner:SYNOPSYS INC

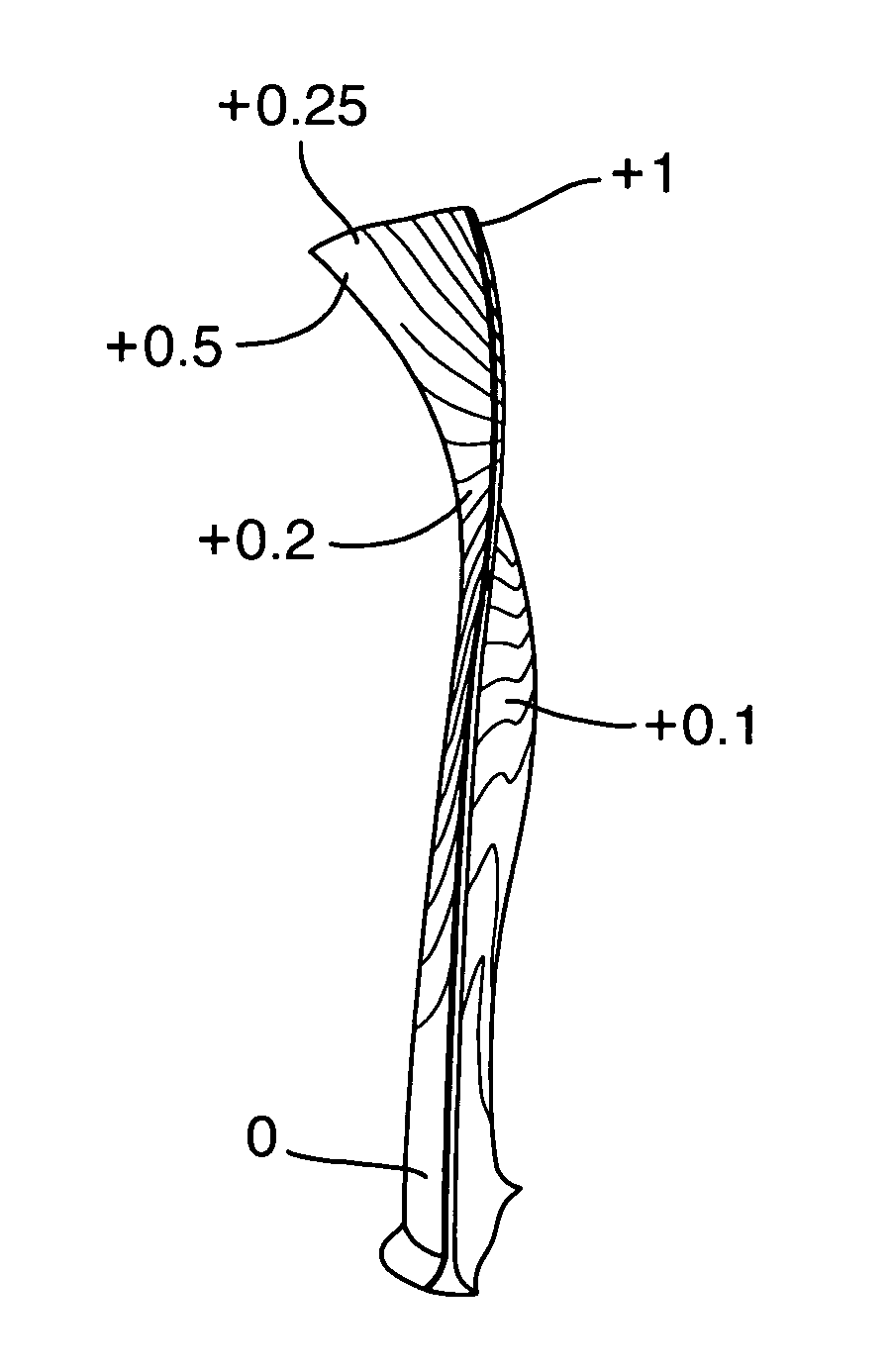

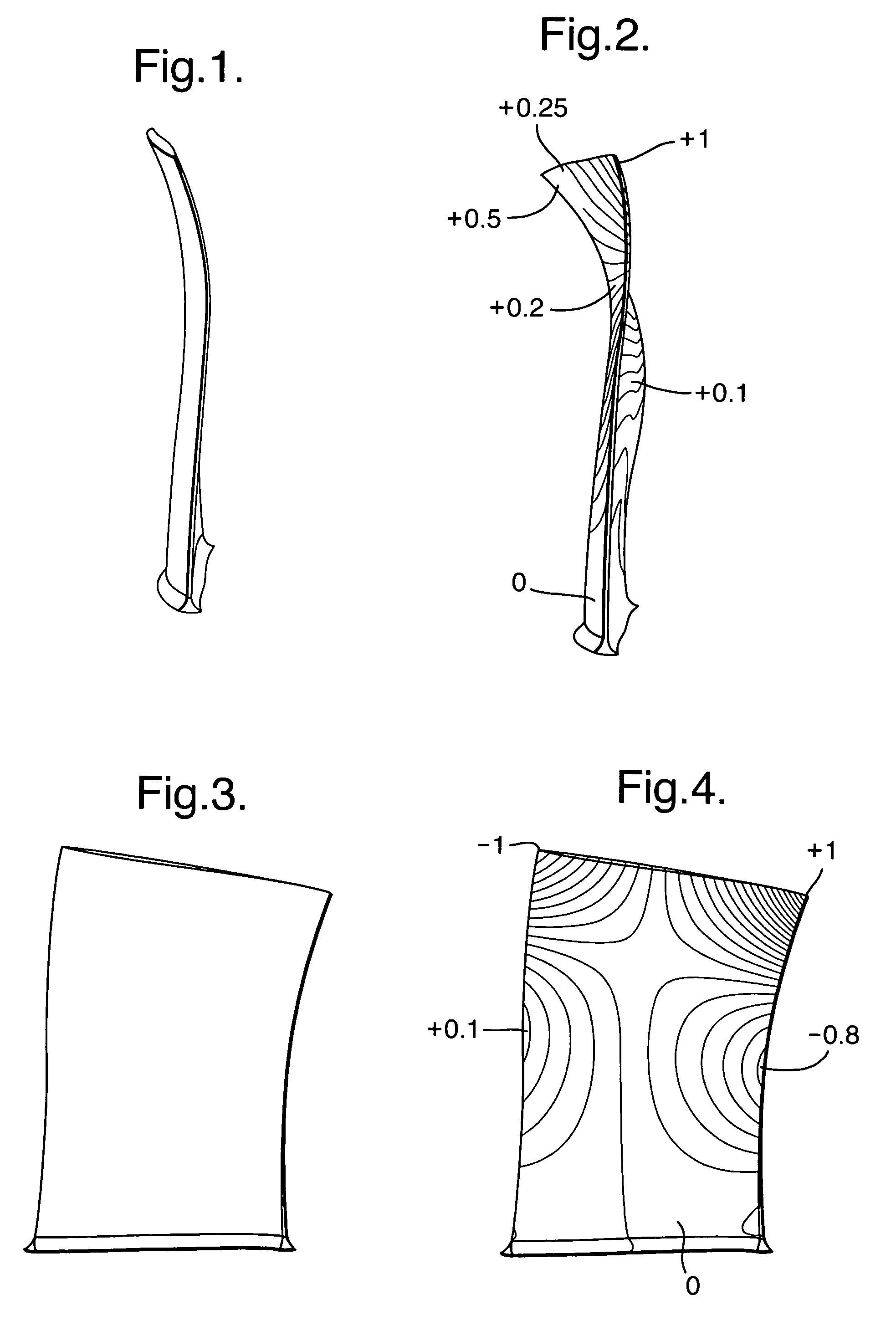

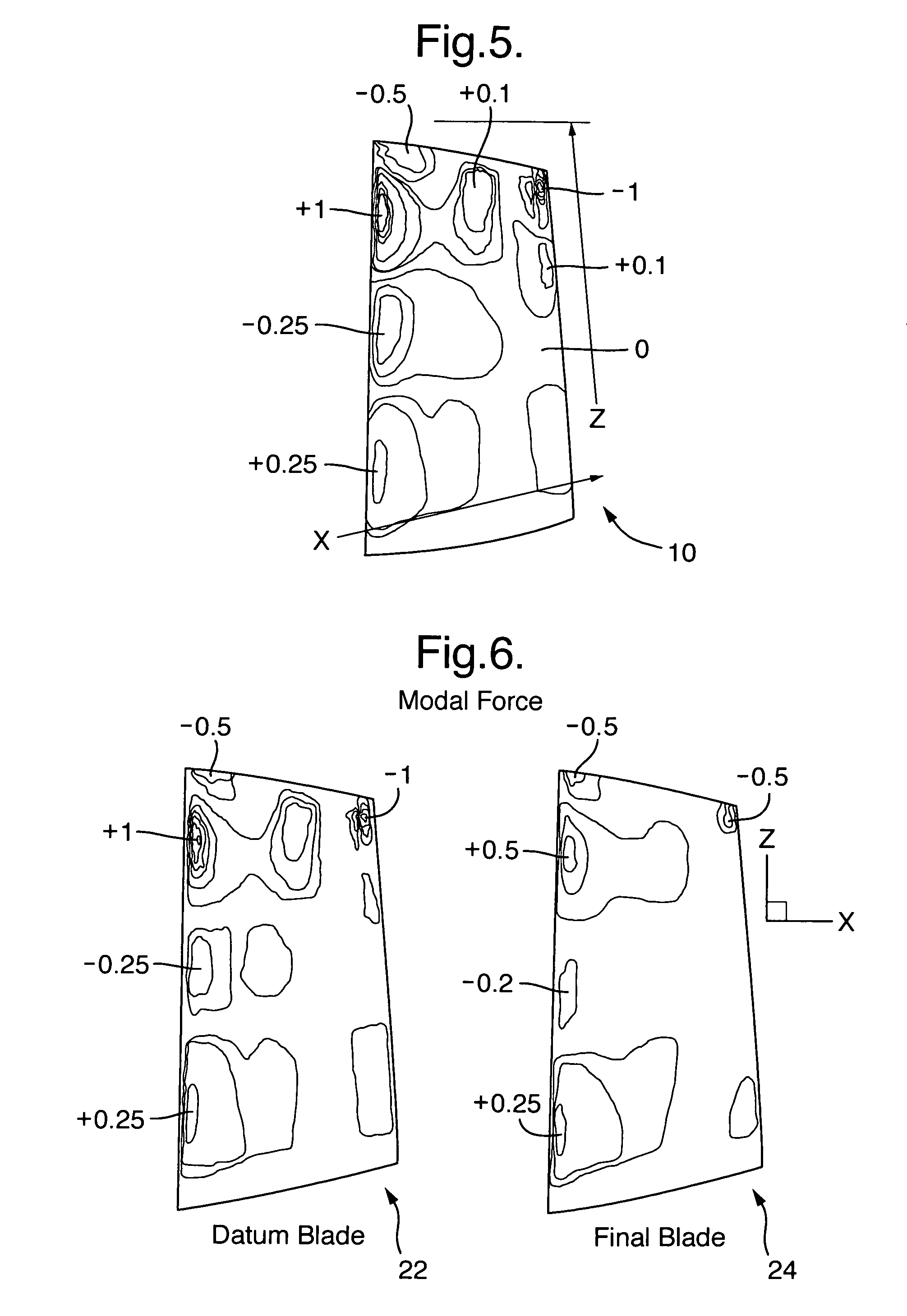

Vanes for exposure to vibratory loading

InactiveUS7909580B2Minimize correlationAvoid the needPropellersPump componentsEngineeringResponse level

Disclosed are methods for designing vanes that, in use, are expected to be exposed to vibratory loading, in particular rotor or stator vanes for aero engines or turbomachinery. A quantitative characteristic (modeshape) is used which is a measure of correlation between the excitation force to which the vane is to be subjected in use and a vibrational mode of the vane, corresponding to a characteristic frequency of the excitation. The modeshape of the first design is determined. Then the first design is modified to give a second design, by one or more of leaning, sweeping or twisting the blade design, or by altering the local shape of the design, or by altering the material of the design. Then the modeshape of the second design is determined. The design modification gives rise to a reduction in the forced response levels.

Owner:ROLLS ROYCE PLC

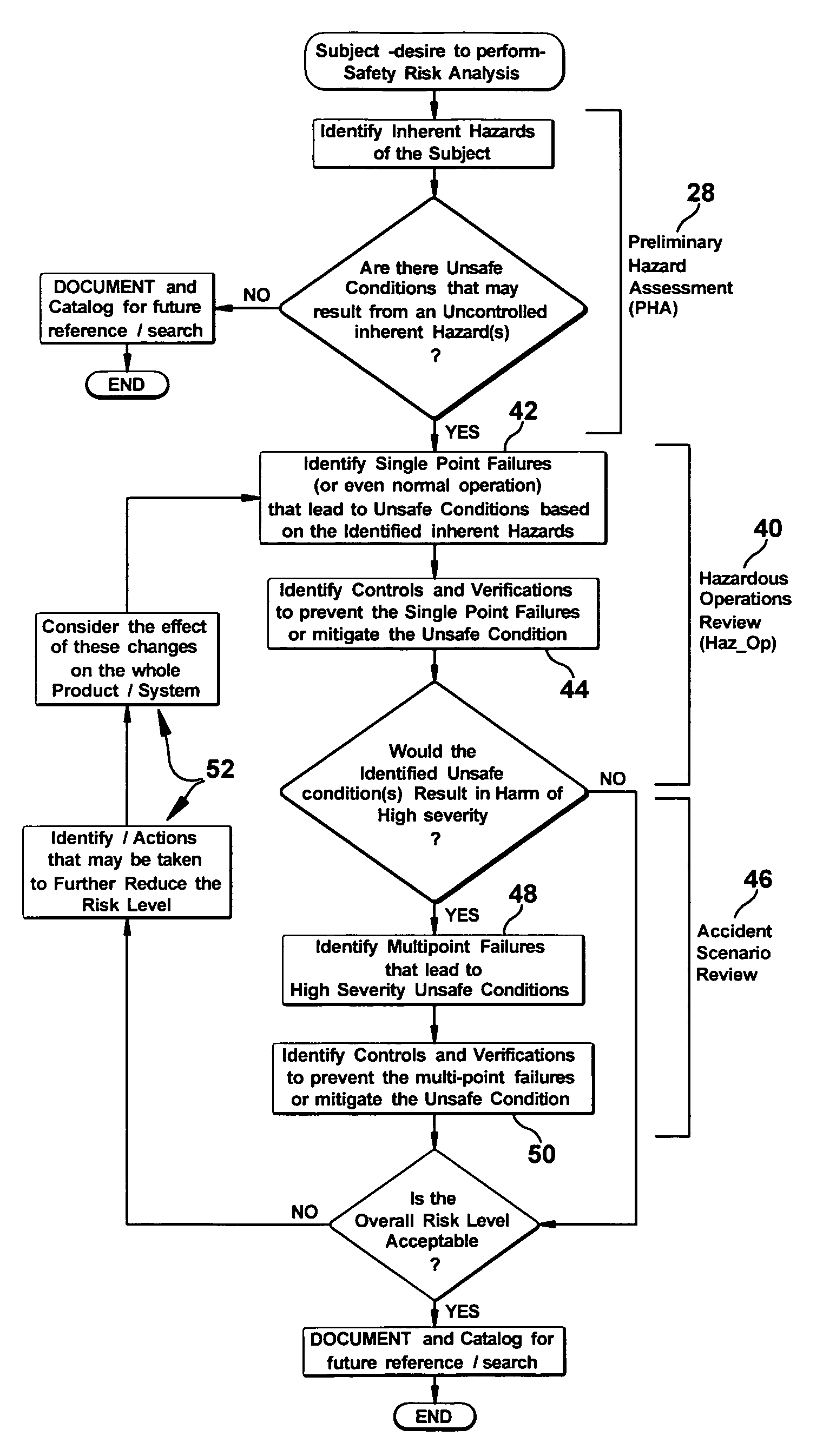

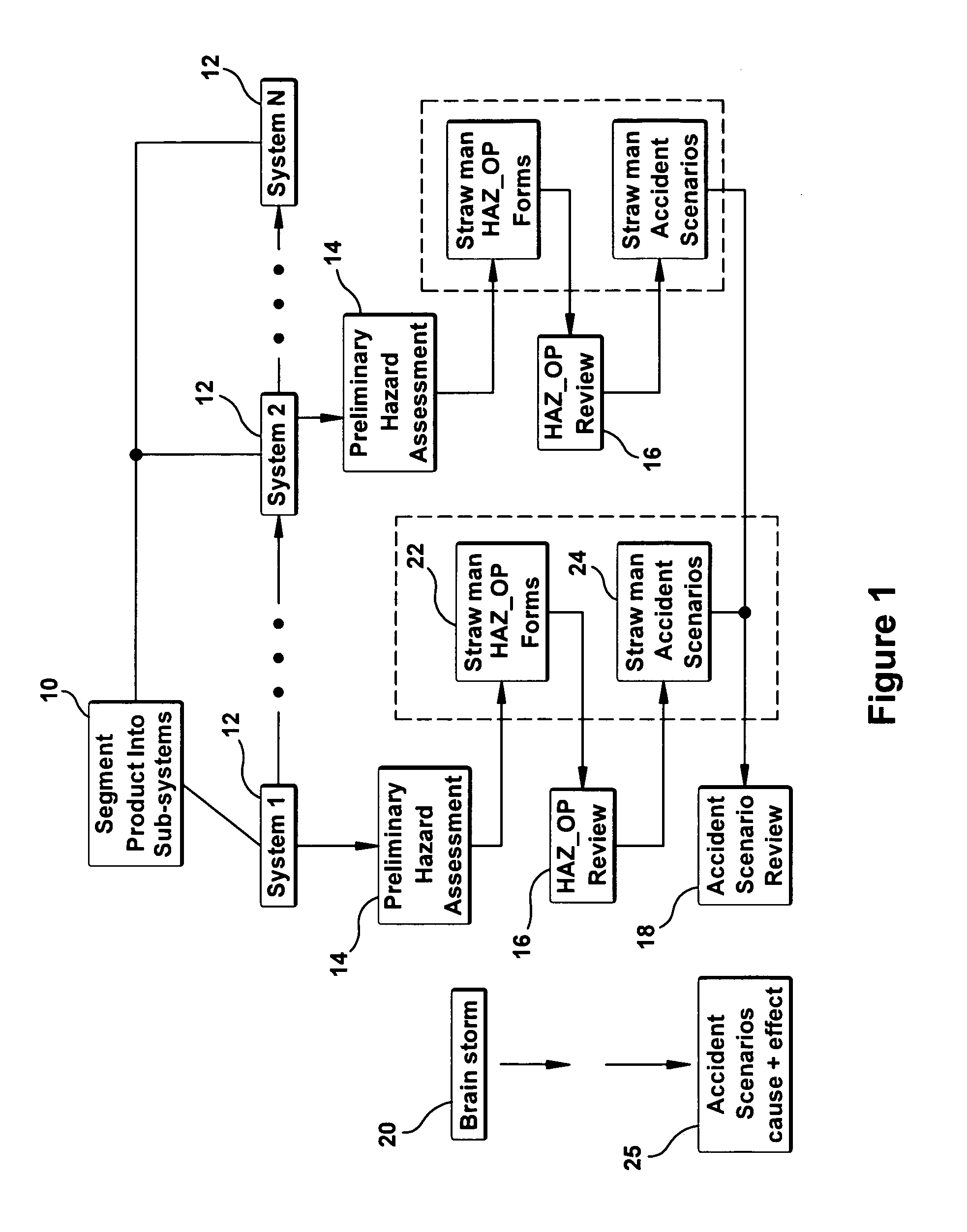

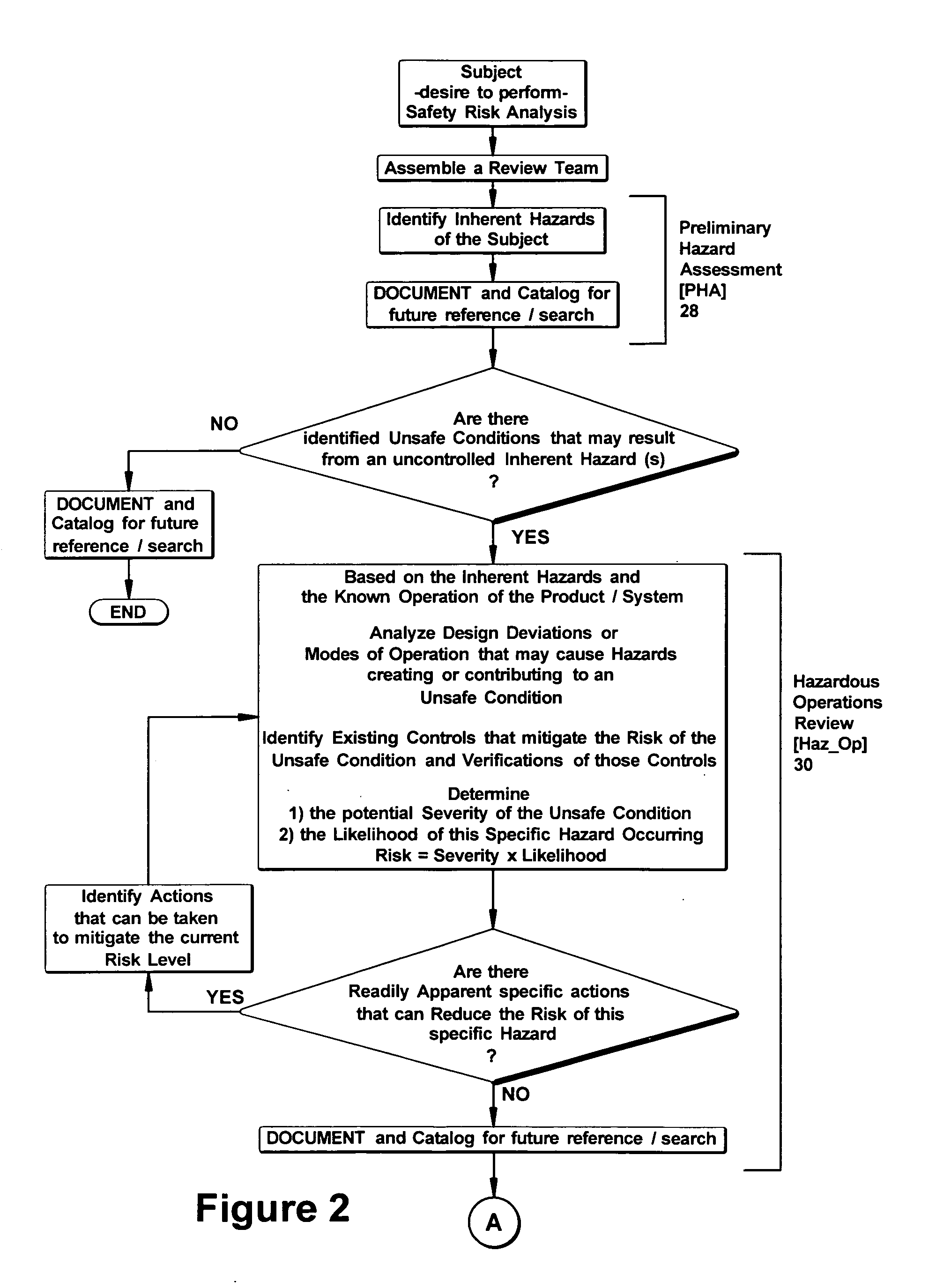

Method for assessing reliability requirements of a safety instrumented control function

InactiveUS20080126150A1Reduce residual riskReduce riskFrequency-division multiplex detailsTemperatue controlUnsafe conditionSafety status

A method for analyzing a system for safety to personnel is disclosed comprising: identifying at least one operating parameter of a first subcomponent of said product; identifying an inherent hazard of said first subcomponents based on an analysis of the at least one operating parameter; identifying features of the structure or operation of the subcomponent corresponding to the inherent hazard; identifying design modifications for the identified features that would mitigate the inherent hazard; identifying safety instrumented control functions and their probability of failure requirements that would mitigate the inherent hazard; prioritizing the identified features with respect to the effect that each of said features has on safety of the product; and determining whether an unsafe condition could result from the inherent hazard.

Owner:GENERAL ELECTRIC CO

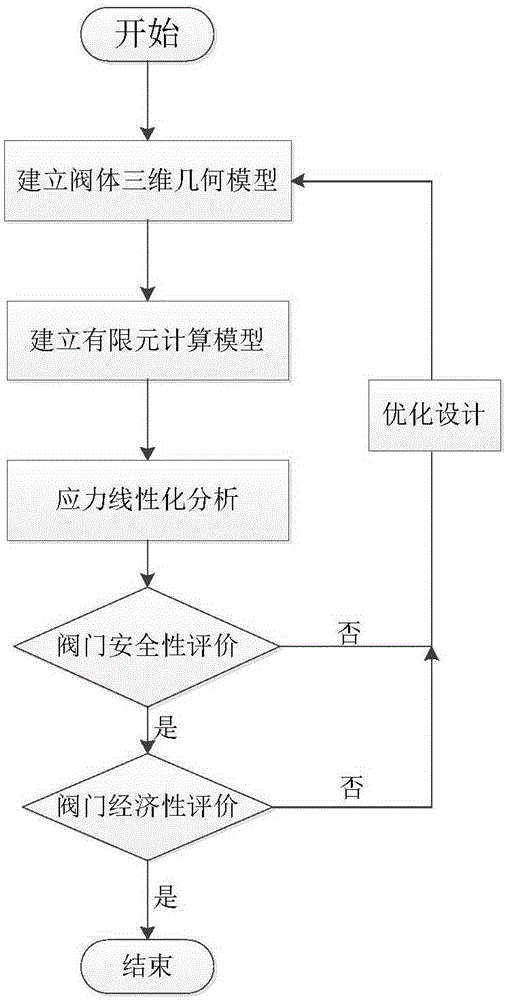

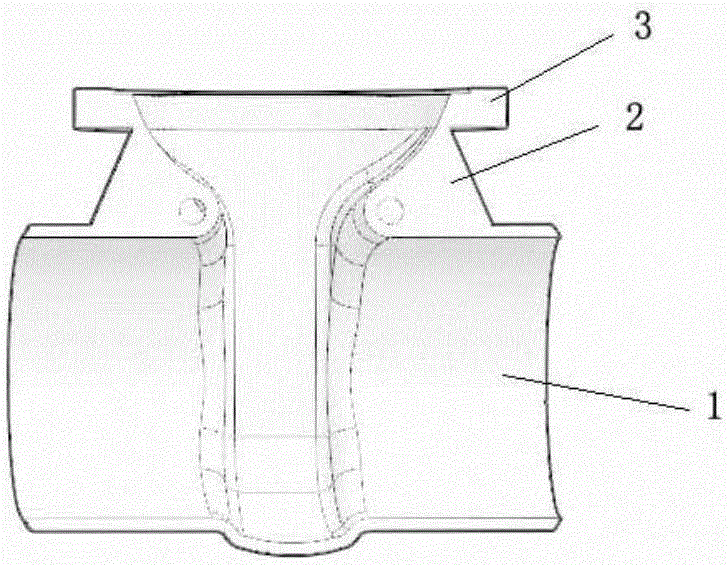

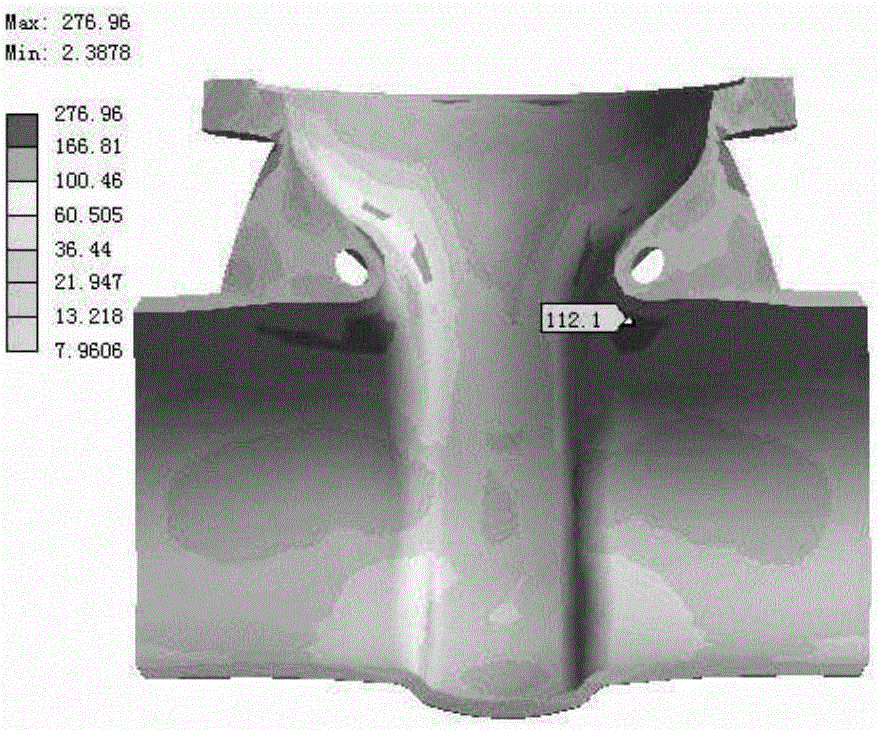

Valve body optimization design method

InactiveCN105183926ASatisfy securityEnsure safetySpecial data processing applicationsStress evaluationUltimate tensile strength

The invention provides a valve body optimization design method. A three-dimensional geometrical model is established through a parameter method, thereby facilitating optimization design and greatly shortening design modification time. Through an established stress evaluation rule, various types of stresses which generate different failures are considered. A plurality of evaluation conditions are used for evaluating the stress. Whether the structural strength of the valve body satisfies a safety requirement can be comprehensively and integrally evaluated. Furthermore the economical performance of the structure is evaluated through a stress result. According to an economical performance evaluation standard, contributions of different types of stresses to the structural strength are sufficiently considered, and furthermore a difference between design and reality is considered. When the structure of the valve body satisfies safety evaluation and furthermore satisfies economical performance evaluation, not only is high safety of the valve ensured, but also the material can be saved maximally and the bearing potential of the structure is sufficiently exerted, thereby reducing weight of the valve body, saving material, reducing cost, and making the designed structure more reasonable and more economical.

Owner:NEWAY VALVE SUZHOU

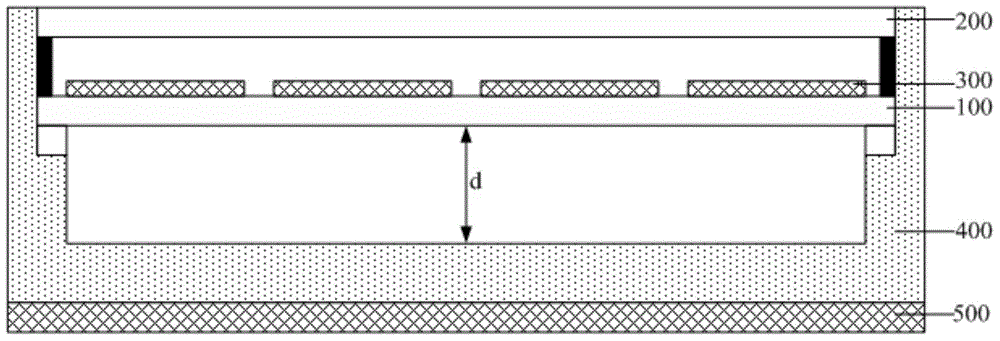

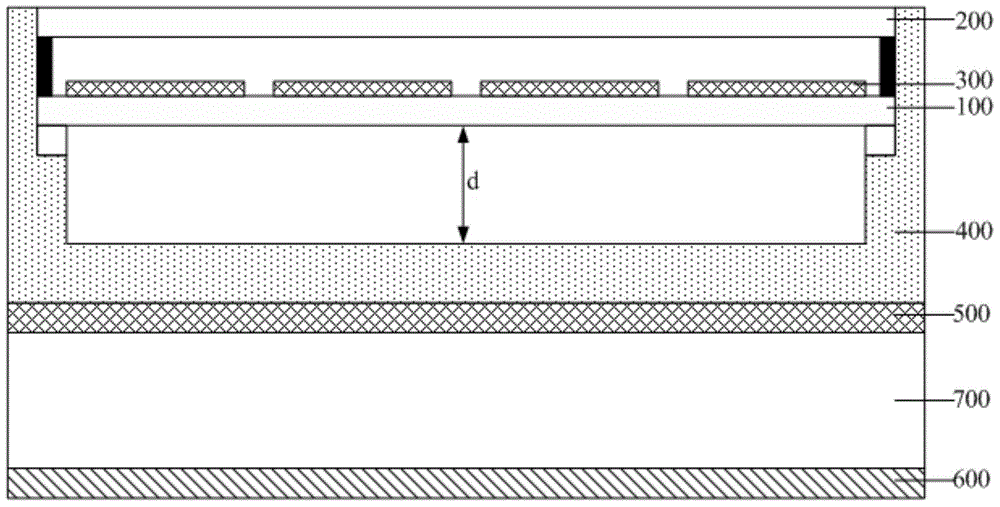

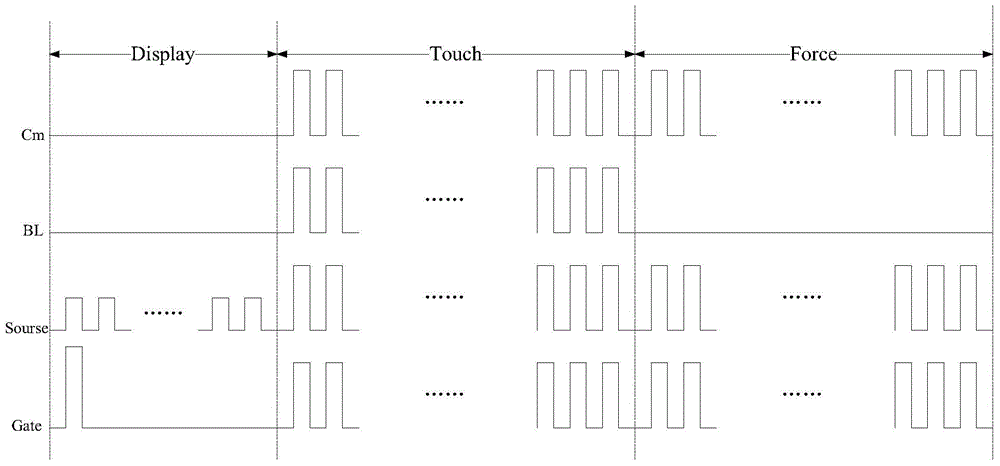

Display device and driving method thereof

ActiveCN106708338AMinor structural design changesRealize the touch detection functionNon-linear opticsInput/output processes for data processingCapacitanceDisplay device

The invention discloses a display device and a driving method thereof; force sensing function is achieved via a capacitance structure formed between self-capacitance electrodes and backlight metal of a touch screen; in the period of touch detection, a touch detection signal is loaded to both the self-capacitance electrodes and the backlight metal, a touch position is judged by detecting changes in capacitances of the self-capacitance electrodes so as to achieve the touch detection function; in the period of force detection, a touch detection signal is loaded to the self-capacitance electrodes or the backlight metal, a change in the distance between the self-capacitance electrodes and the backlight metal due to force touch may lead to charge and discharge of the capacitance structure formed between the self-capacitance electrodes and the backlight metal, and therefore the magnitude of force at the touch position can be judged by detecting changes in the capacitances of the self-capacitance electrodes so as to achieve the force sensing function. The display device provided by the embodiment of the invention experiences few structural design modifications not limited to assembly allowance, better detection precision is benefited, and manufacture cost can be saved.

Owner:BOE TECH GRP CO LTD +1

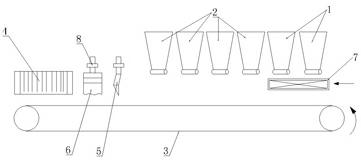

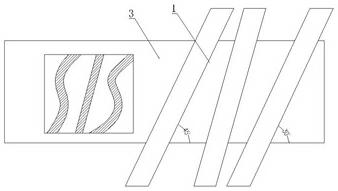

Material distributing method and equipment of polished tiles

ActiveCN102248595AEasy to replaceNatural texture decorative effectCeramic shaping apparatusBand shapeLamellar Pattern

The invention discloses a material distributing method and equipment of polished tiles. The method is characterized by comprising the following steps of: a. preparing materials: respectively distributing line materials and plus materials into a line material feeding hopper and a plus material feeding hopper which are arranged in the moving direction of a main conveyor belt; b. after the line materials are sieved by a vibration sieve, distributing the sieved line materials on the main conveyor belt to form a banded thin-layered line material, and distributing the plus materials on the main conveyor belt by virtue of the intermittent opening and closing of the plus material feeding hopper to form a banded thick-layered plus material; c. enabling the banded thick-layered plus material to be formed into linear lamellar patterns with lines by virtue of the intermittent blocking action of a linear baffle, and warping the linear material layer into a wavy material layer by virtue of the intermittent blocking action of a wavy baffle; and d. transferring the effect of the wavy material layer into a press mould by virtue of a texture fidelity feeding grate. In the invention, natural and delicate texture effects with rich layers in imitation of natural stones are formed by virtue of the combination of the formula and process provided by the invention; the equipment is easy to modify, so the equipment can be flexibly suitable for design modification requirements of products; and the product conversion cycle is shortened, and the loss and production cost are reduced.

Owner:FOSHAN DONGPENG CERAMIC +2

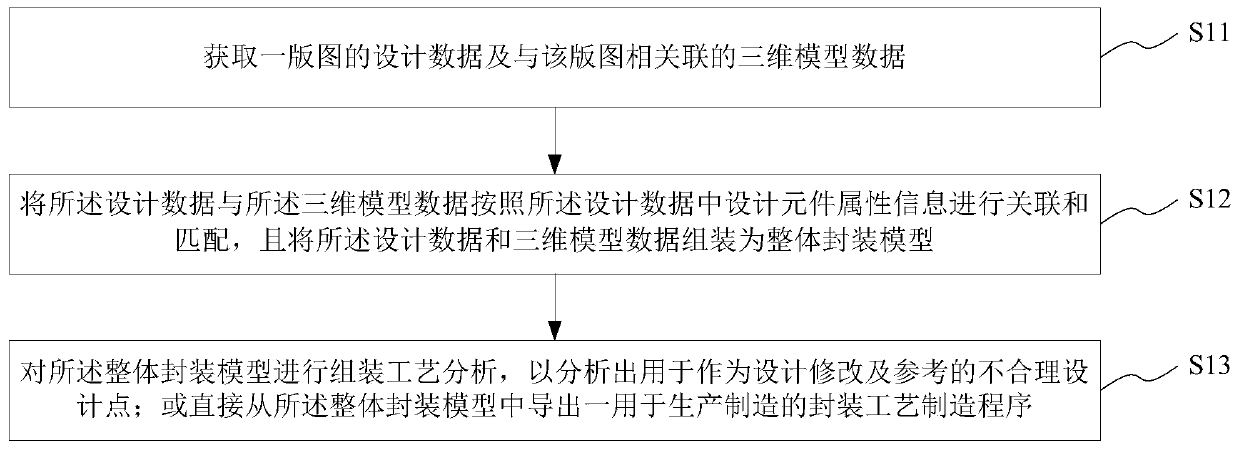

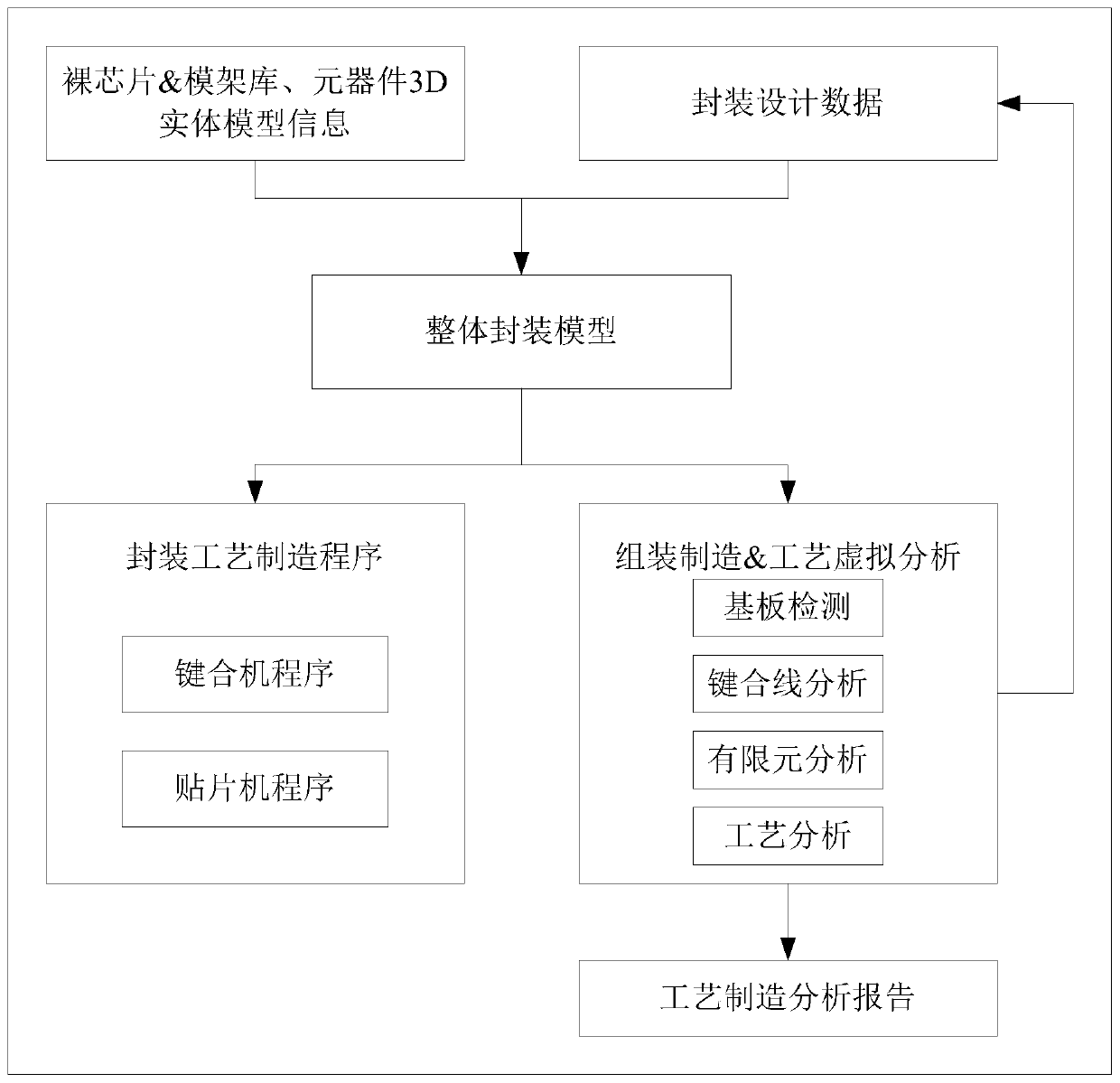

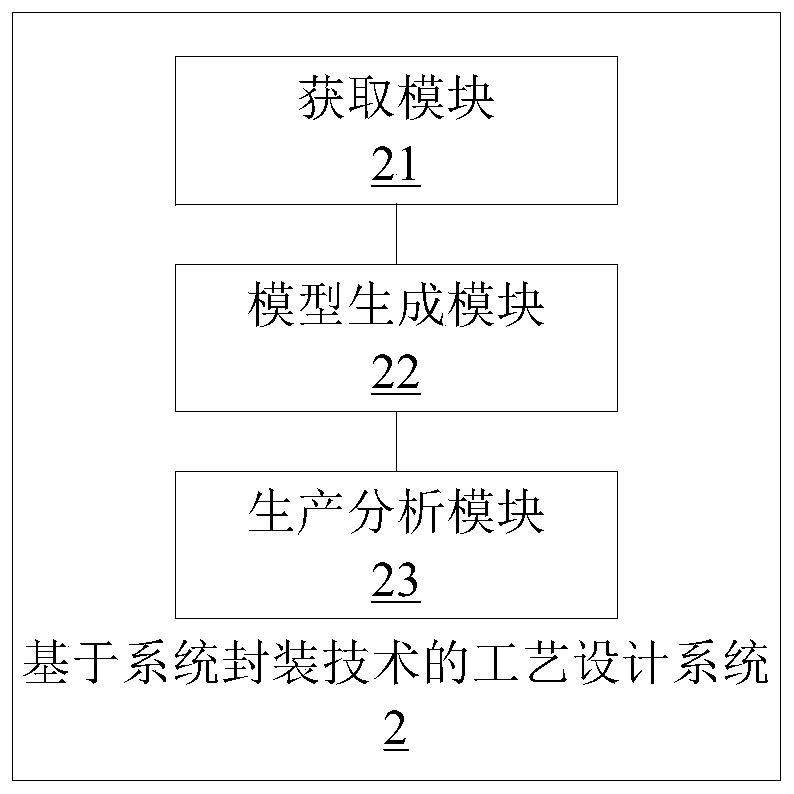

Process design method and system based on system packaging technology, medium and apparatus

ActiveCN110197019AShorten the timeEase of workConfiguration CADSpecial data processing applicationsProcess manufacturingProcess design

The invention provides a process design method and system based on a system packaging technology, a medium and an apparatus. The process design method based on the system packaging technology comprises the following steps of acquiring the design data of a layout and the three-dimensional model data associated with the layout; associating and matching the design data and the three-dimensional modeldata according to the design element attribute information in the design data, and assembling the design data and the three-dimensional model data into an integral packaging model; performing assembly process analysis on the integral packaging model to analyze unreasonable design points used as design modification and reference; or directly exporting a packaging process manufacturing procedure for production and manufacturing from the integral packaging model. According to the method, more repeated work can be removed, the manual work is replaced with automation, and compared with an originalmethod, the method saves 60%-80% of the time, and meanwhile, the working difficulty is reduced, and the process from design to simulation and production manufacturing is simplified, so that the competitiveness of an electronic product is greatly improved.

Owner:VAYO SHANGHAI TECH

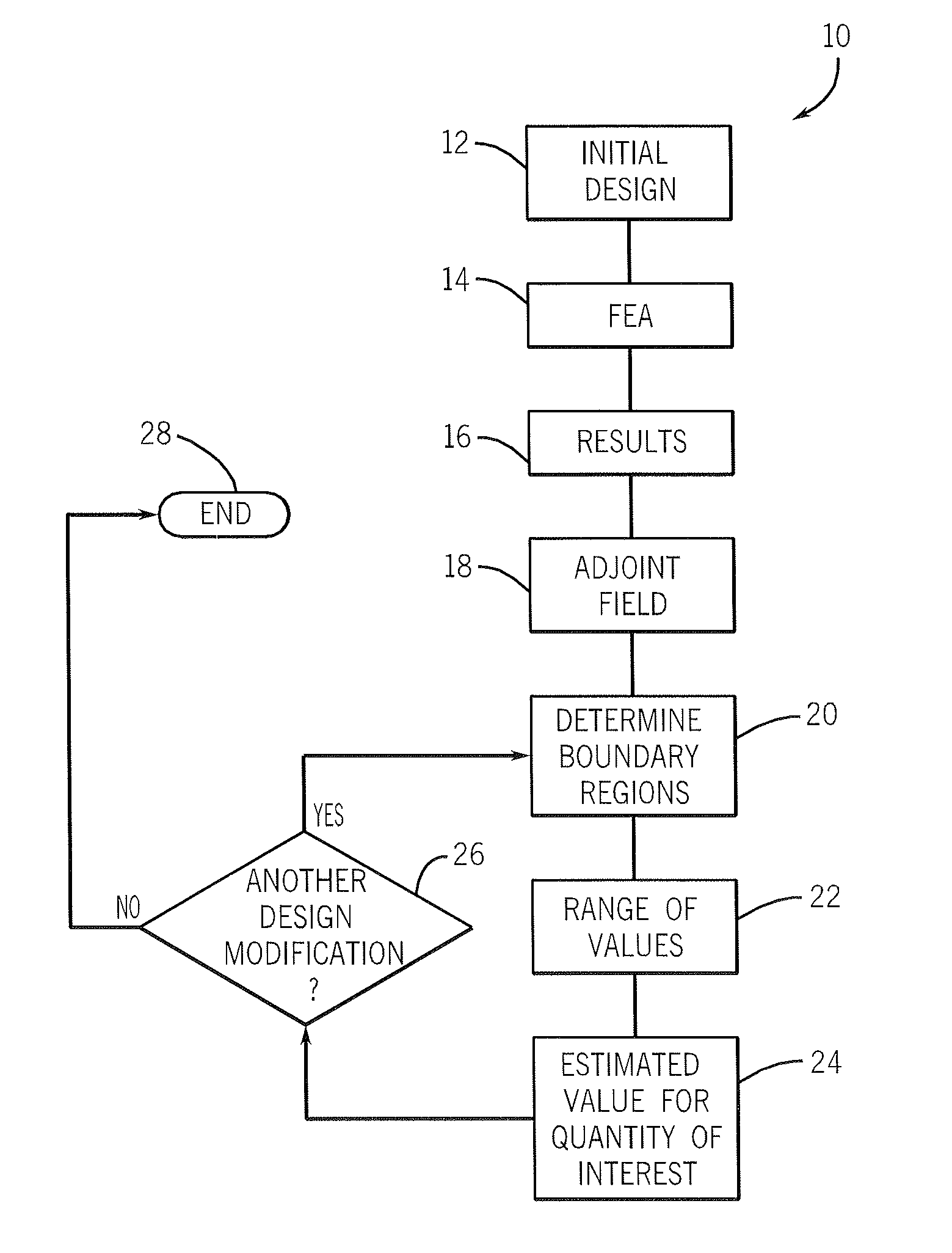

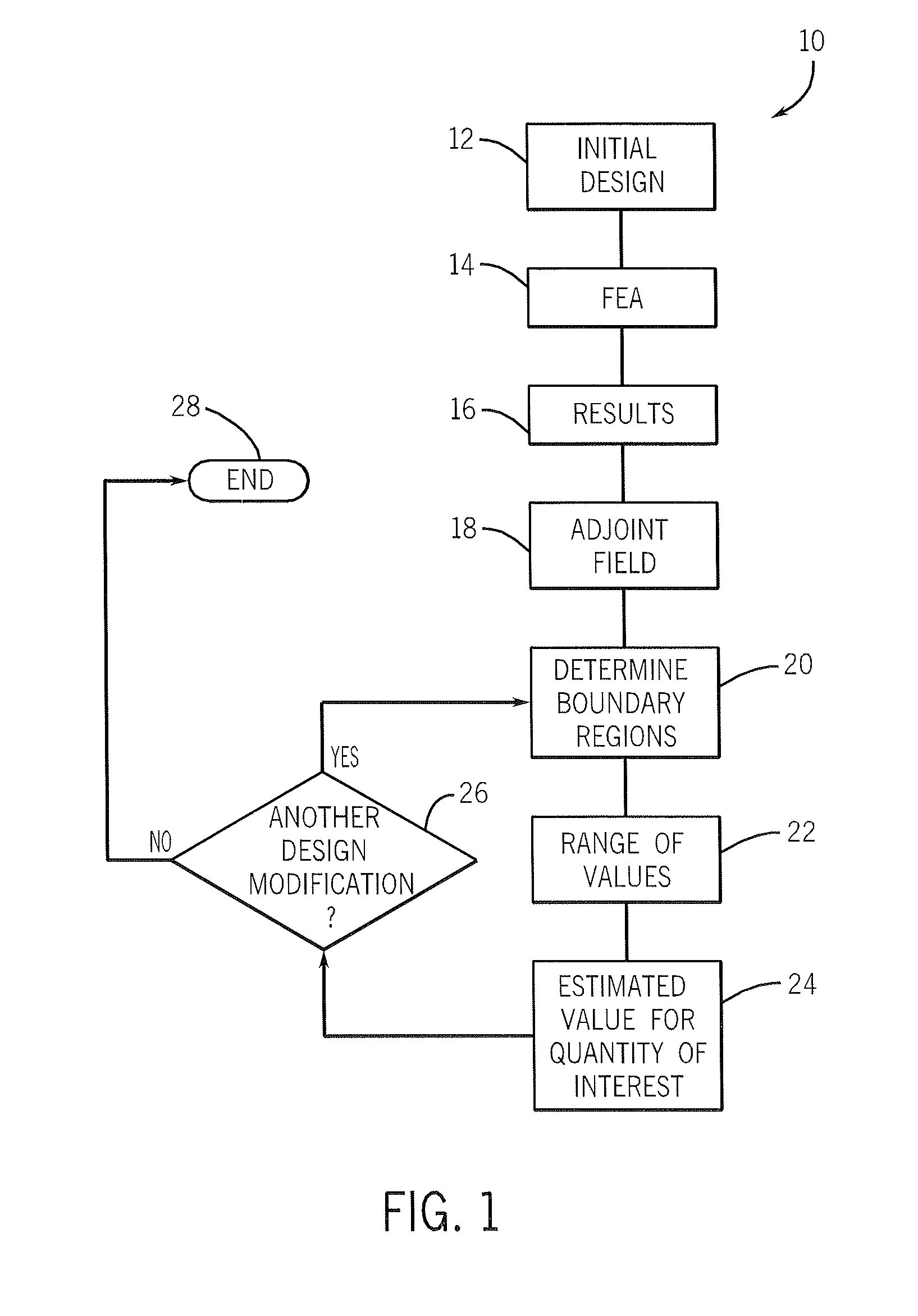

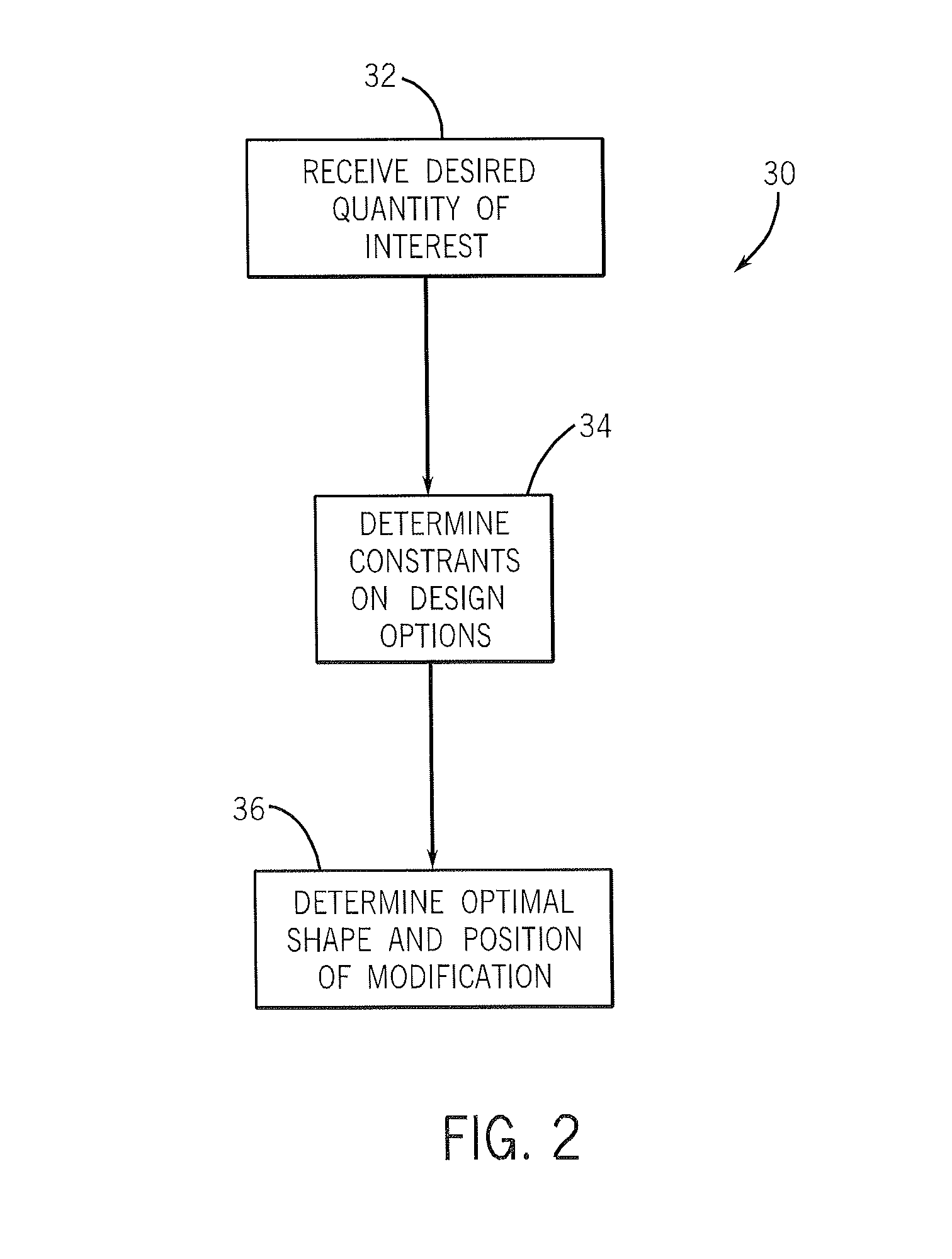

Method and apparatus for determining design modification effects on a computerized engineering model

ActiveUS20080183524A1Low costShorten the timeData processing applicationsDesign optimisation/simulationFinite element methodEngineering

An engineering simulation tool uses boundary regions of proposed design modifications to a finite design element to assess the impact of those proposed design modifications. This tool allows a designer to incorporate a new design feature into a proposed model and generate simulated performance results for the proposed design without re-execution of finite element method.

Owner:WISCONSIN ALUMNI RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com