Process design method and system based on system packaging technology, medium and apparatus

A technology of process design and system packaging, applied in computer-aided design, calculation, comprehensive factory control, etc., can solve the problems of cumbersome and error-prone manufacturing process, and achieve the effect of reducing manufacturing risk, work difficulty and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

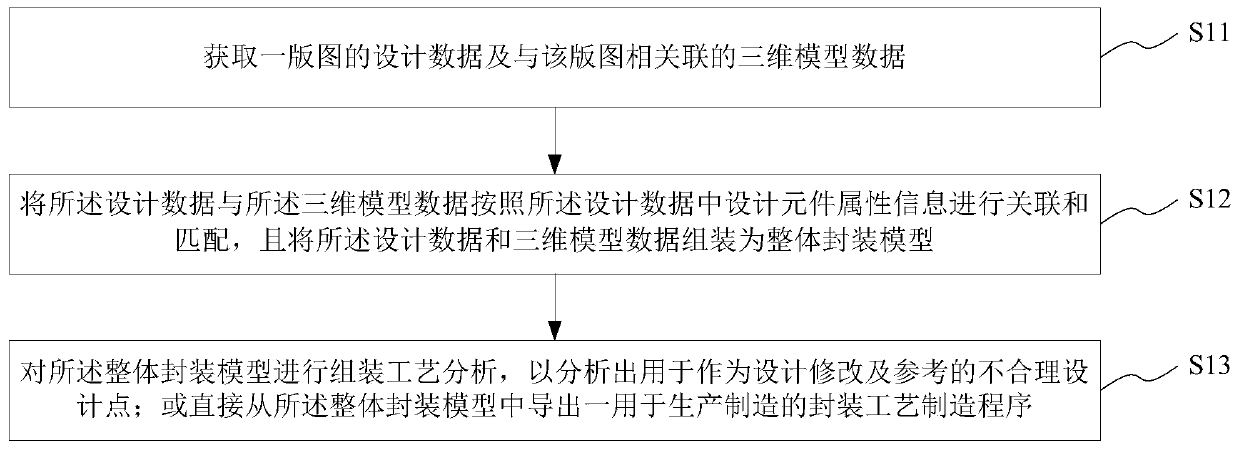

[0040] This embodiment provides a process design method based on system packaging technology. The process design method based on system packaging technology includes:

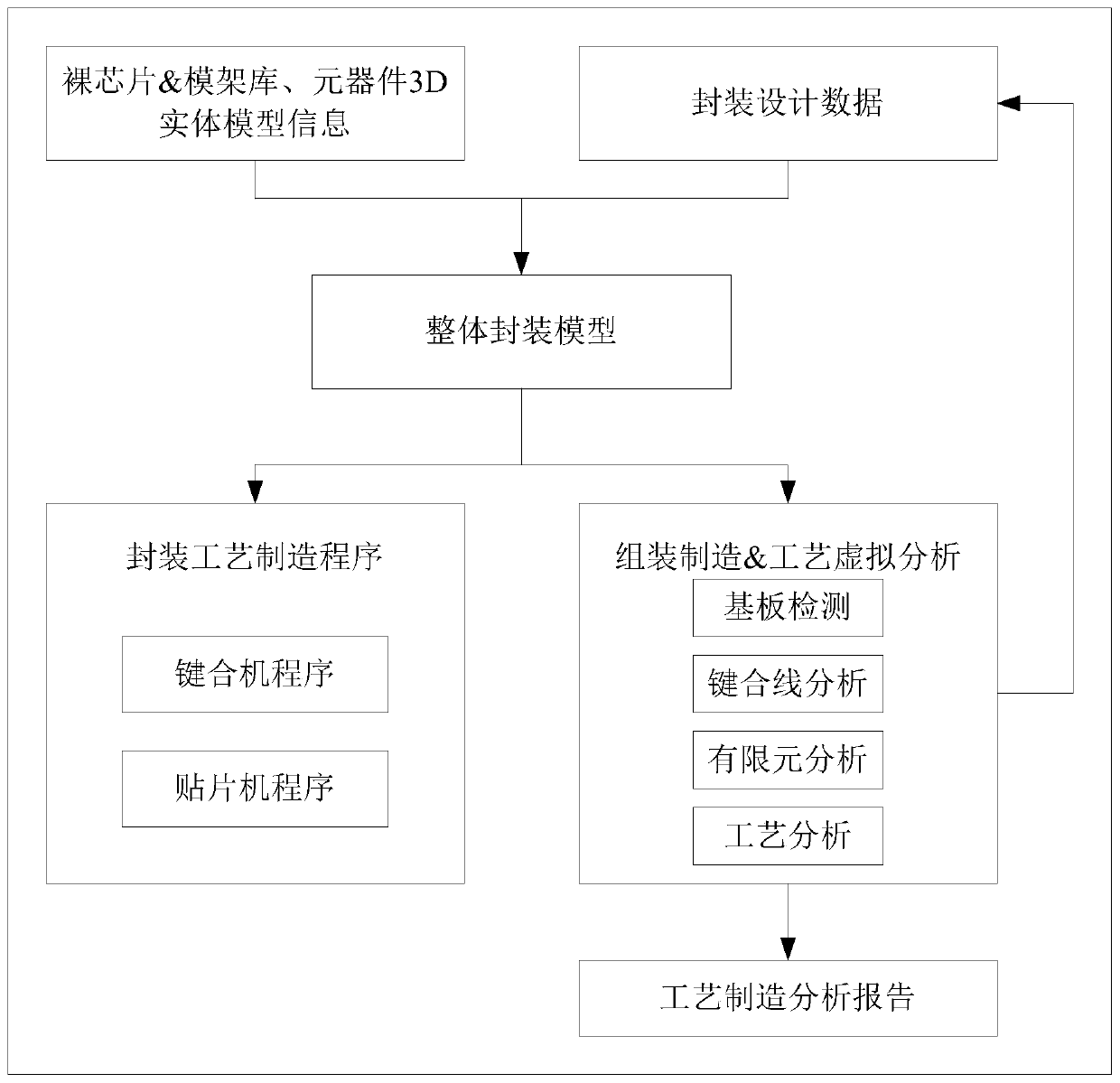

[0041] Obtaining design data of a layout and 3D model data associated with the layout;

[0042] Associating and matching the design data and the three-dimensional model data according to the design component attribute information in the design data, and assembling the design data and the three-dimensional model data into an overall packaging model;

[0043] Performing assembly process analysis on the overall packaging model to analyze unreasonable design points used as design modifications and references, the assembly process analysis is to perform design specifications and system performance detection on the overall packaging model; or

[0044] A packaging process manufacturing program for manufacturing is directly derived from the overall packaging model.

[0045] The following will combine Figure 1A and ...

Embodiment 2

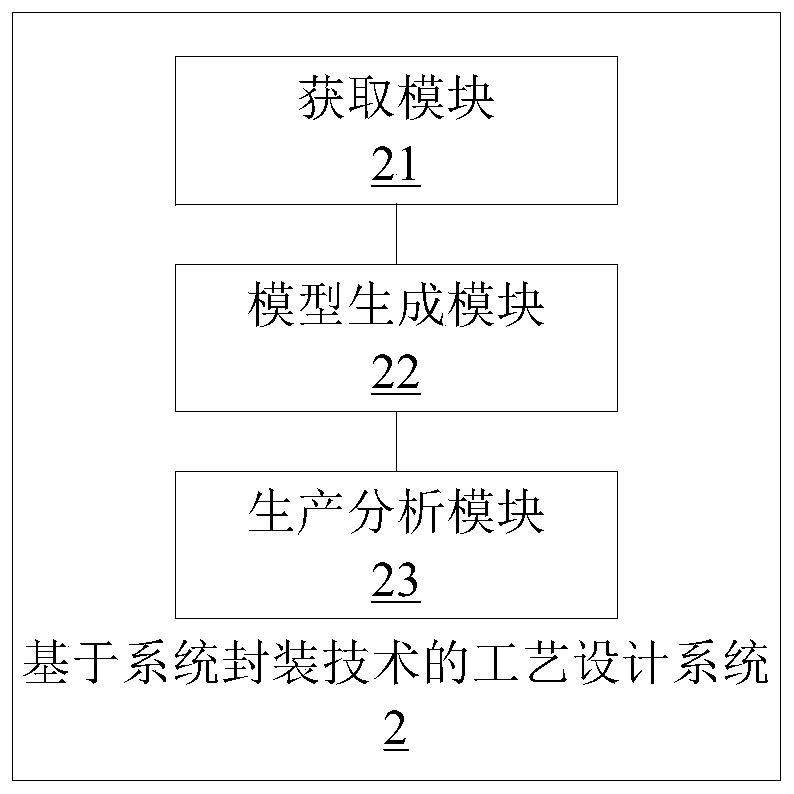

[0074] This embodiment provides a process design system based on system packaging technology. The process design system based on system packaging technology includes:

[0075] An acquisition module, configured to acquire design data of a layout and 3D model data associated with the layout;

[0076] A model generation module, configured to associate and match the design data and the three-dimensional model data according to the design element attribute information in the design data, and assemble the design data and the three-dimensional model data into an overall packaging model;

[0077] The production analysis module is used to analyze the assembly process of the overall package model to analyze unreasonable design points used as design modification and reference; or directly derive a package for manufacturing from the overall package model Craft manufacturing procedure.

[0078] The process design system based on the system packaging technology provided by this embodiment ...

Embodiment 3

[0089] This embodiment provides a device, including: a processor and a memory; the memory is used to store a computer program, and the processor is used to execute the computer program stored in the memory, so that the device executes the system-based encapsulation Technological process design methods.

[0090] see image 3 , which is a device connection diagram in an embodiment of the process design method based on the system packaging technology of the present invention. Described equipment comprises: processor 31, memory 32, transceiver 33, communication interface 34 or / and system bus 35; Memory 32 and communication interface 34 are connected with processor 31 and transceiver 33 by system bus 35 and complete mutual communication Communication, the memory 32 is used to store computer programs, the communication interface 34 is used to communicate with other devices, the processor 31 and the transceiver 33 are used to run computer programs, so that the devices execute the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com