Patents

Literature

68 results about "Production analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production Analysis. Production analysis basically is concerned with the analysis in which the resources such as land, labor, and capital are employed to produce a firm’s final product. Variable Inputs. Inputs those change or are variable in the short run or long run are variable inputs.

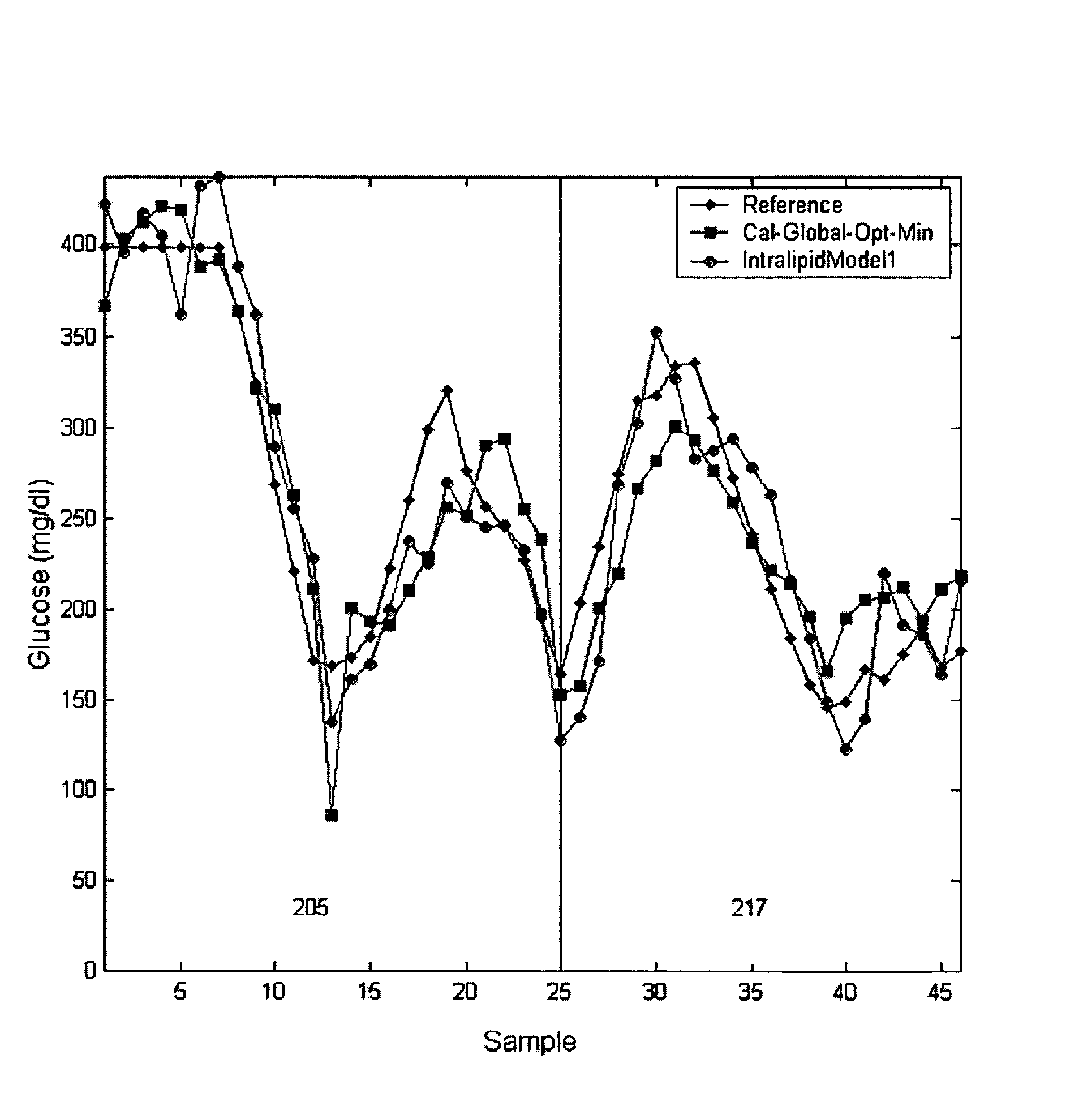

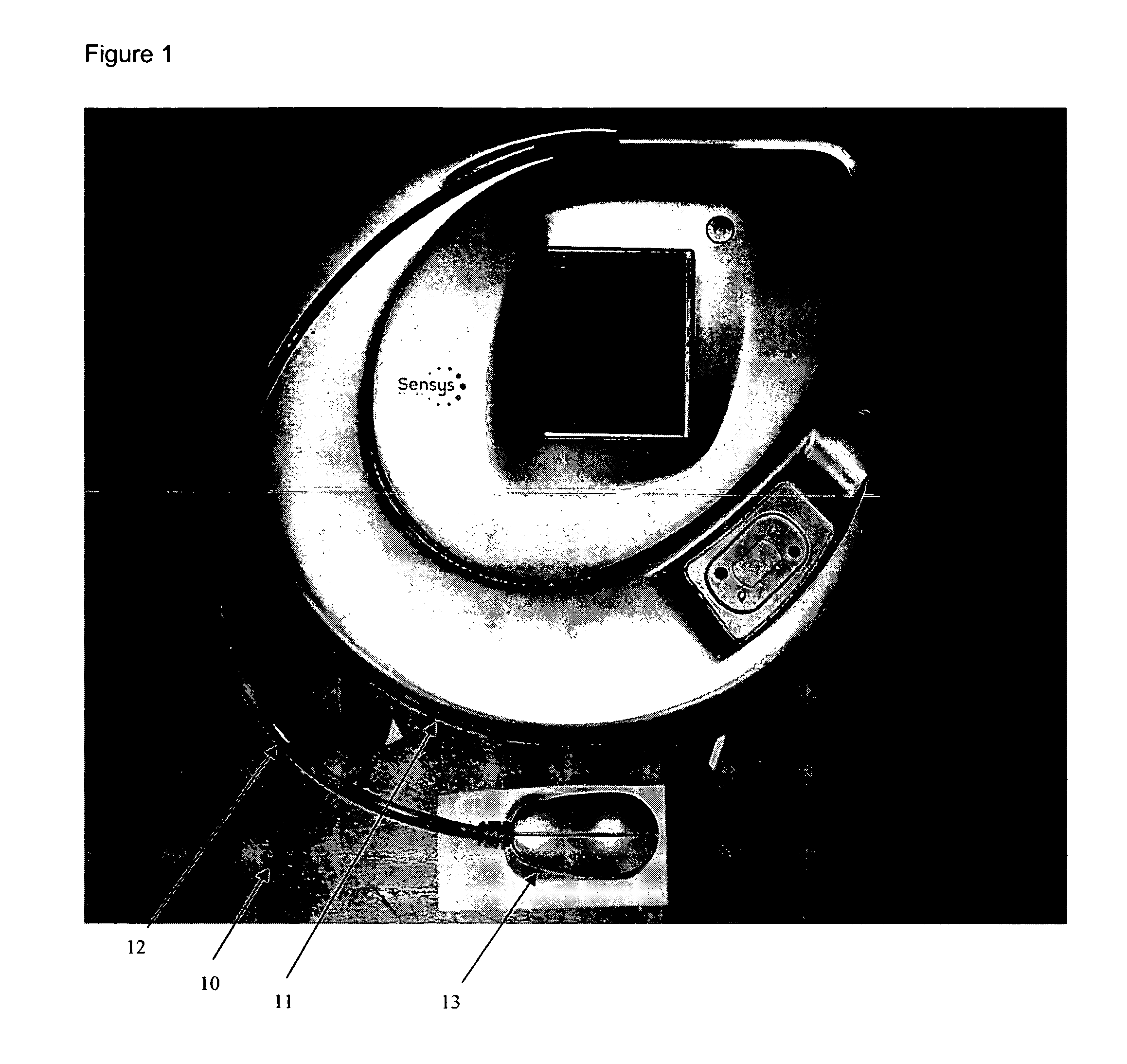

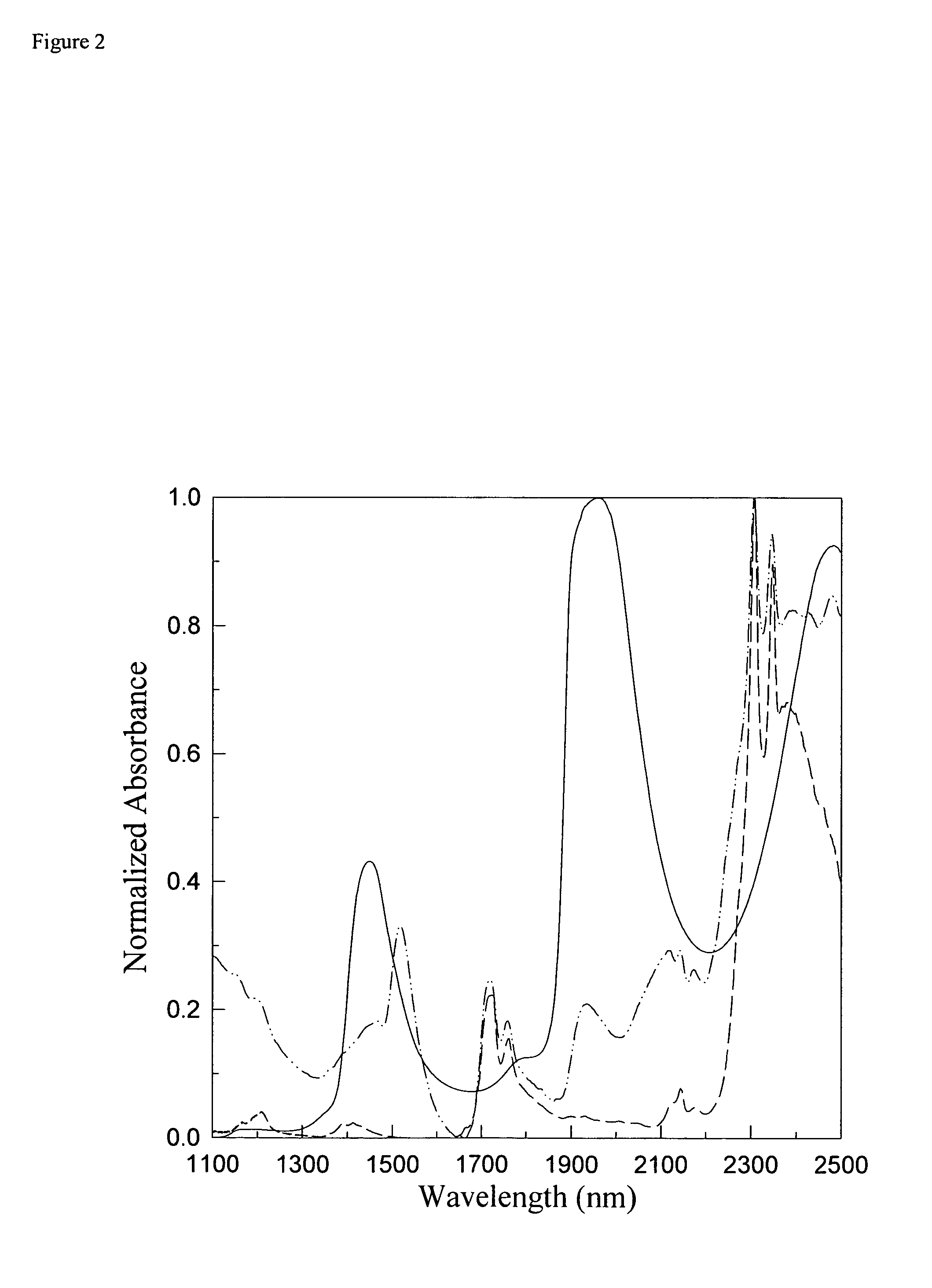

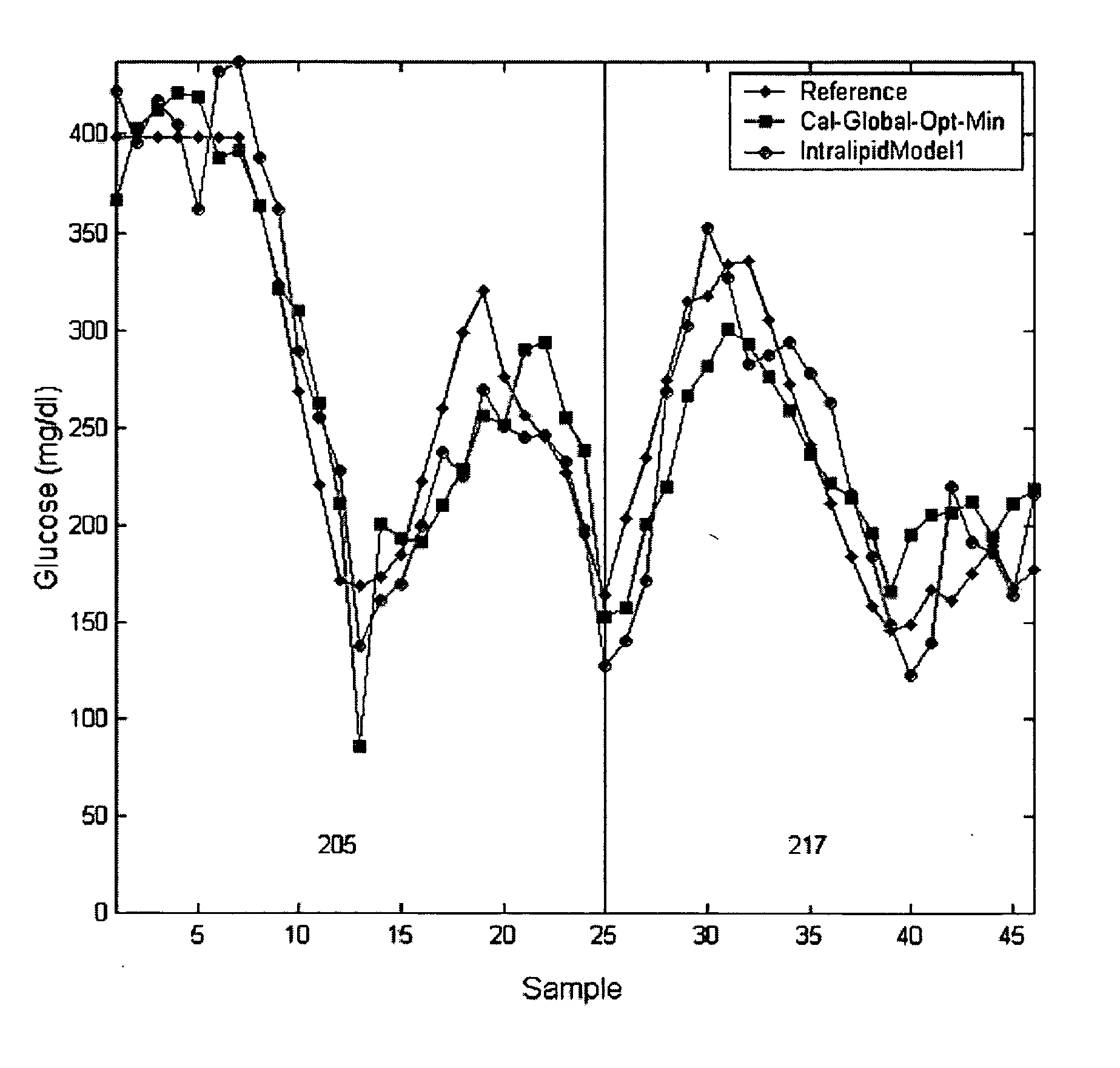

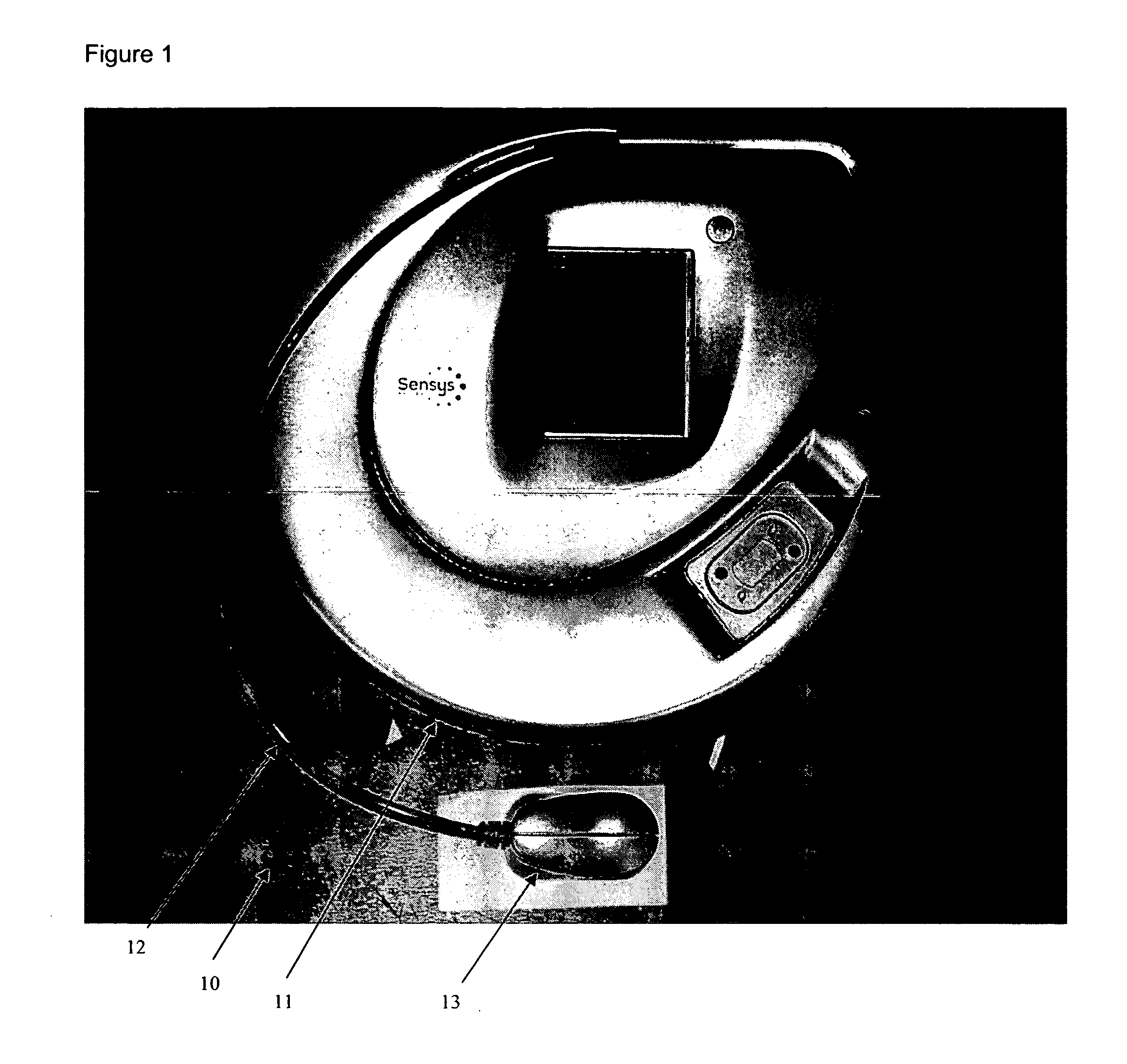

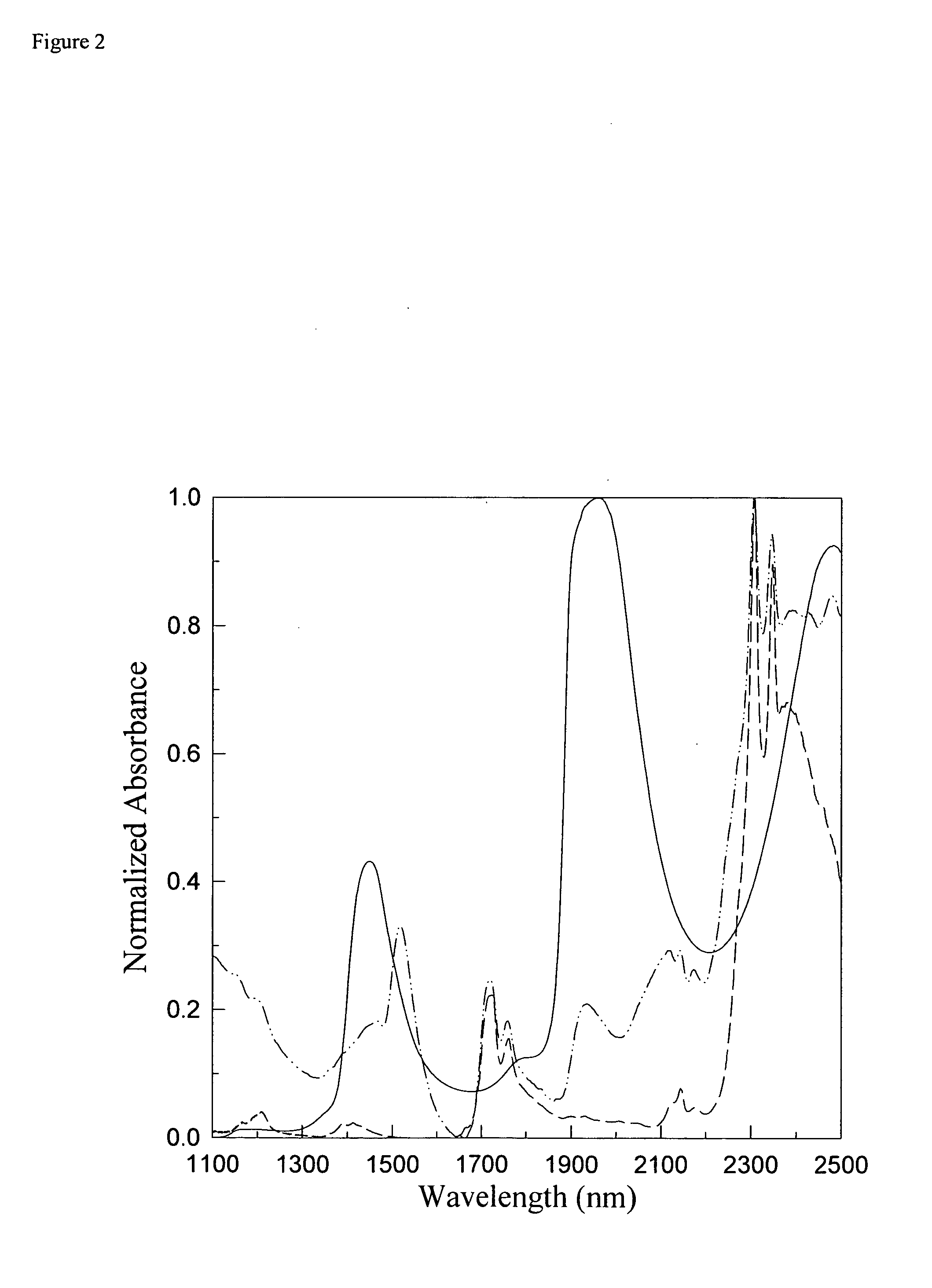

Method of adapting in-vitro models to aid in noninvasive glucose determination

InactiveUS7317938B2Easy to controlStrict controlDiagnostic recording/measuringSensorsConcentrations glucoseNon invasive

Owner:GLT ACQUISITION

Method of adapting in-vitro models to aid in noninvasive glucose determination

InactiveUS20050119541A1Easy to controlStrict controlDiagnostic recording/measuringSensorsConcentrations glucoseNon invasive

The invention relates to a noninvasive analyzer and a method of using information determined at least in part from in-vitro spectra of tissue phantoms or analyte solutions to aid in the development of a noninvasive glucose concentration analyzer and / or in the analysis of noninvasive spectra resulting in glucose concentration estimations in the body. The preferred apparatus is a spectrometer that includes a base module and a sample module that is semi-continuously in contact with a human subject and that collects spectral measurements which are used to determine a biological parameter in the sampled tissue, such as glucose concentration. Collection of in-vitro samples is, optionally, performed on a separate instrument from the production model allowing the measurement technology to be developed on a research grade instrument and used or transferred to a target product platform or production analyzer for noninvasive glucose concentration estimation.

Owner:GLT ACQUISITION

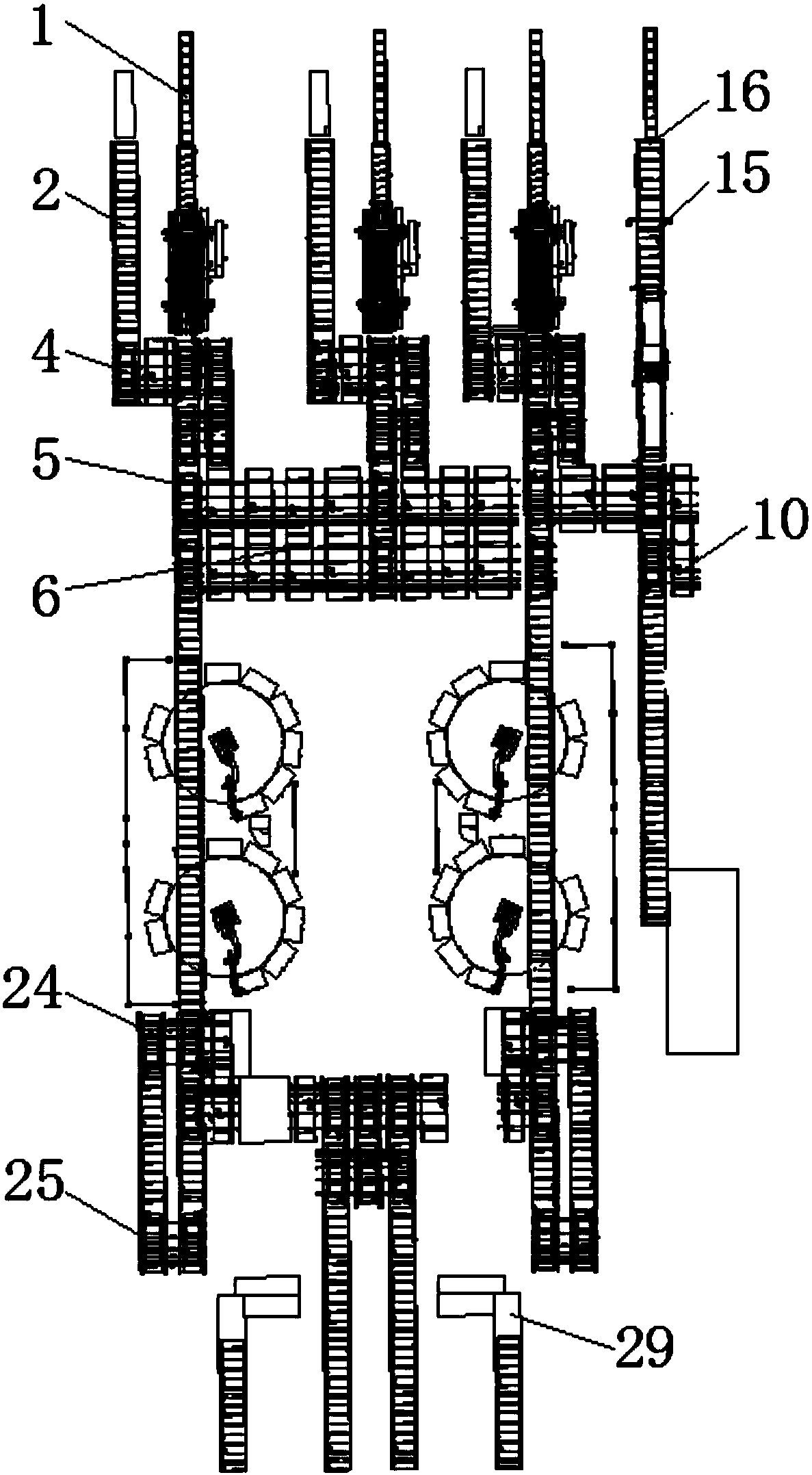

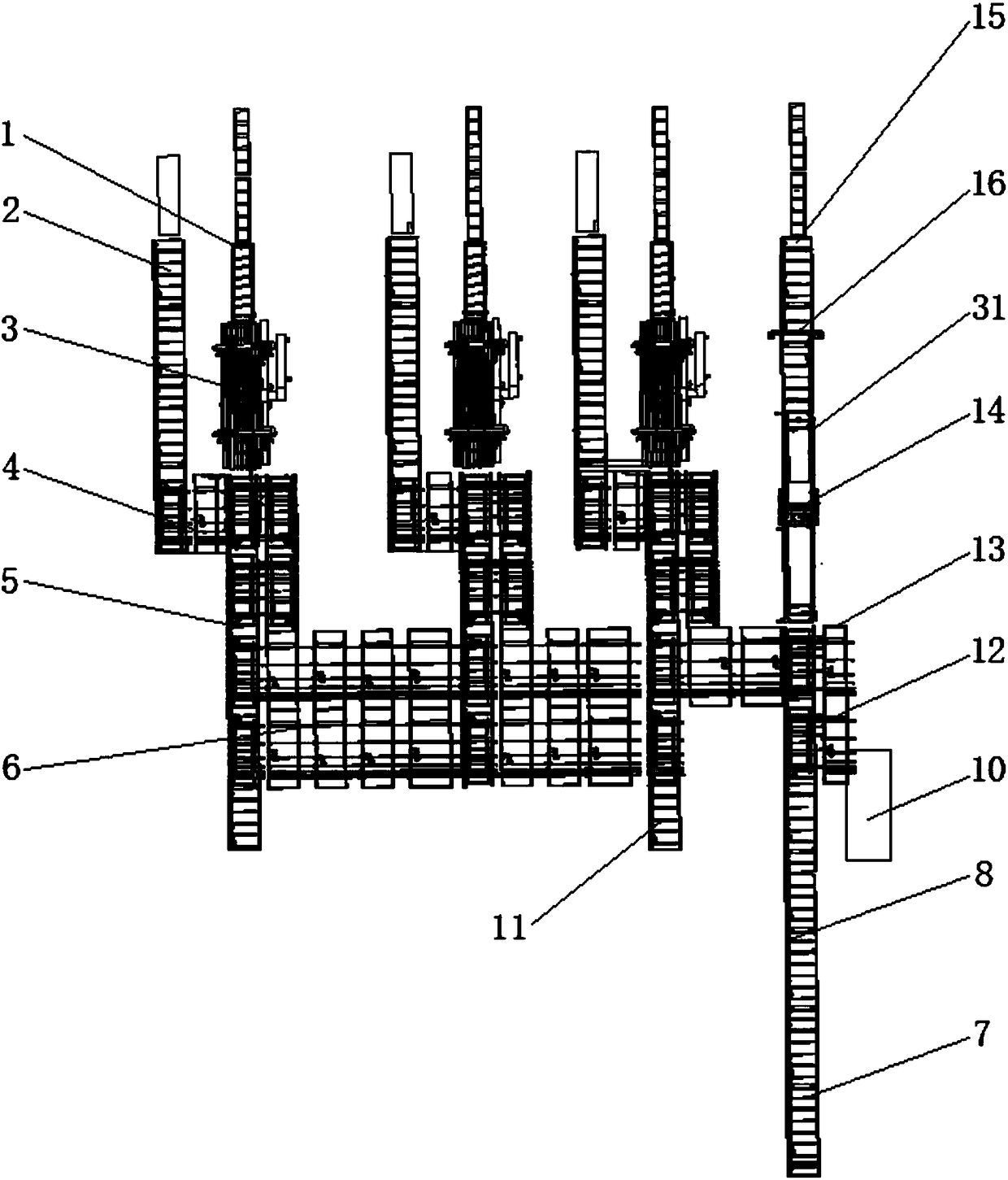

Intelligent board sorting system

ActiveCN108080288ASorting in real timeAccurate sortingDrilling machinesCleaning using toolsMaterial resourcesEngineering

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

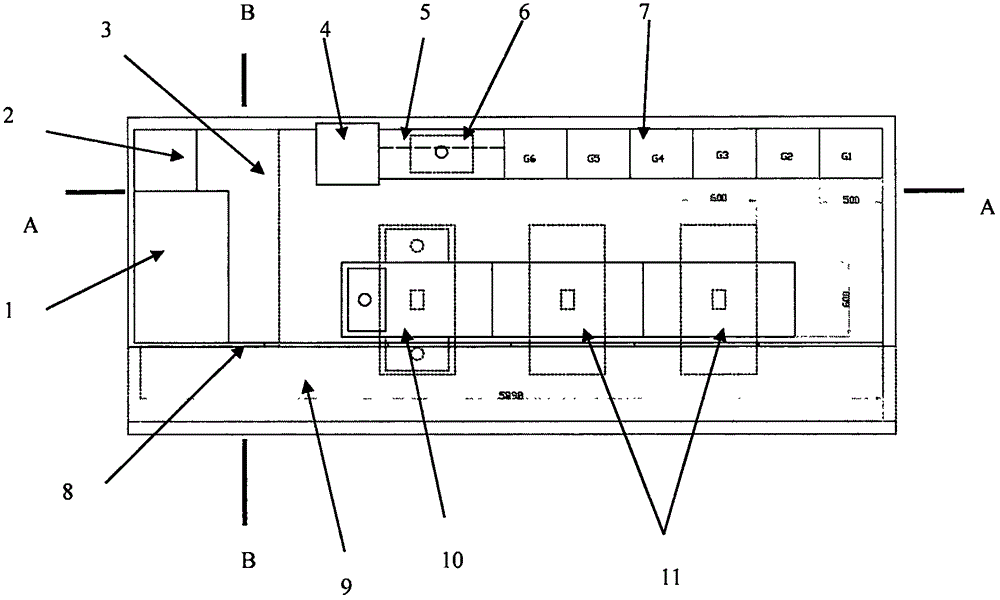

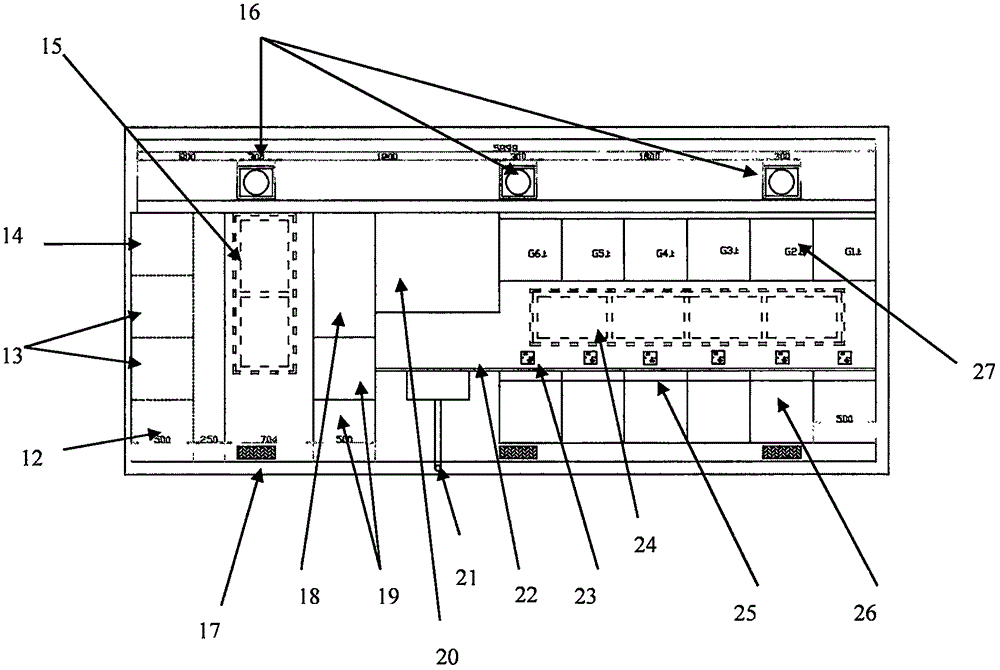

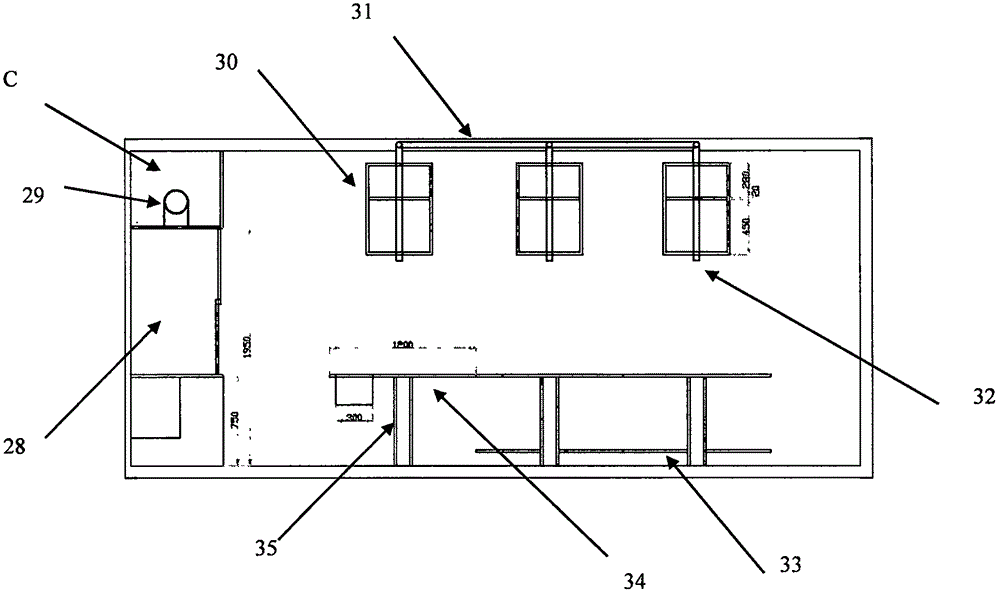

Analysis and detection basic-equipment laboratory building module and complete set design method thereof

The invention relates to the technical fields of basic equipment for analysis and detection and assembled and combined buildings (steel structure box assembled and combined buildings and container combined buildings) and provides an analysis and detection basic-equipment laboratory building module and a complete set design method thereof. Basic equipment of an analysis and detection laboratory is intensively designed in one integrated building module, completes building modules provided with the basic equipment of the analysis and detection laboratory form the semi-permanent and perpetual movable analysis and detection laboratory wide in application range, and the building module is widely applied to the fields of quality control analysis and detection, food safety analysis and detection, medicine quality analysis and detection, environmental protection analysis and detection, medical treatment analysis and detection, military science, agricultural production analysis and detection, industrial production analysis and detection and the like.

Owner:高海 +1

Aluminium-scandium alloy standard spectrum sample and preparation method thereof

InactiveCN1837785AAdd evenlyAdjust and control elemental chemical compositionPreparing sample for investigationColor/spectral properties measurementsScandiumProduction analysis

This invention relates to a aluminium-scandium alloy standard spectrum sample and preparation method, <0}wherein, the sample comprises: Si 0.045~0.27%, Fe 0.07~0.37%, Cu 0~0.11%, Mn 0.13~1.2%, Mg 4.3~7.8%, Cr 0~0.27%, Ni 0~0.11%, Zn 0~0.17%, Sc 0.03~0.54%, Ti 0~0.18%, Zr 0.025~0.22%, Be 0.00005~0.0035% and B 0.0005~0.010%. The preparation relates to smelting, casting, homogenizing, lathing surface, and extruding. This invention meets practical demand, and provides foundation for production of 5A70 and 5A71 series Al-alloy.

Owner:SOUTHWEST ALUMINUM GRP

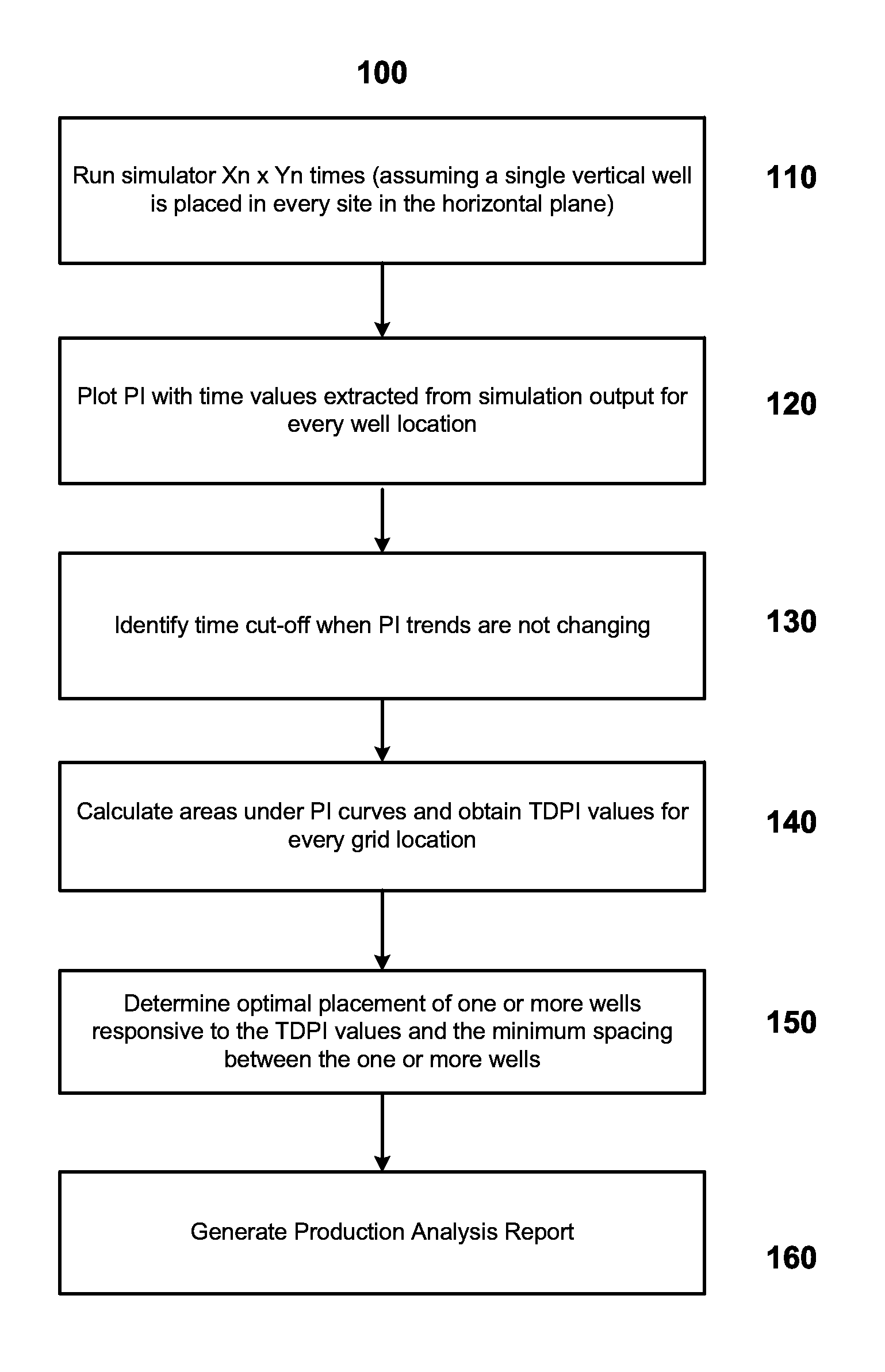

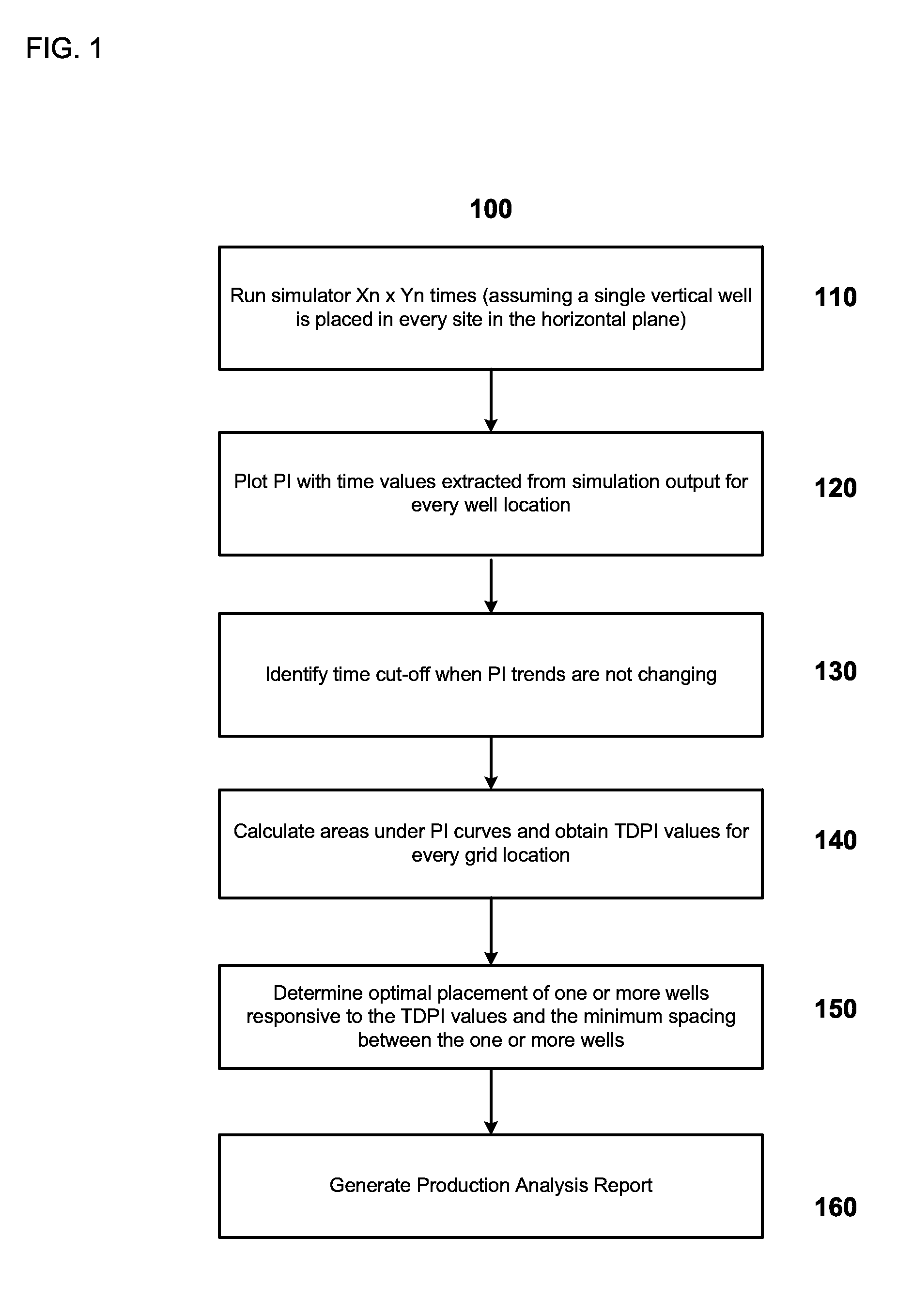

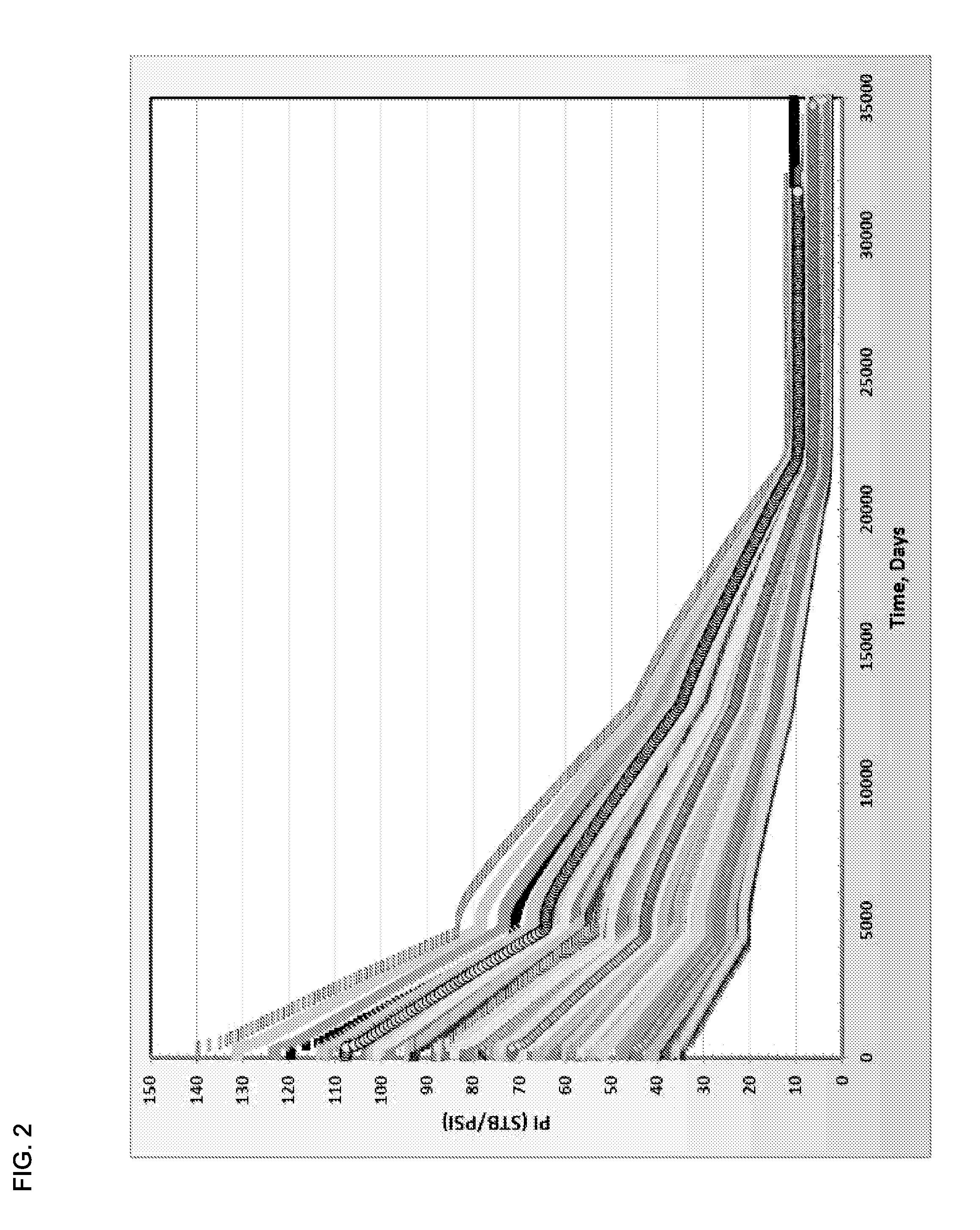

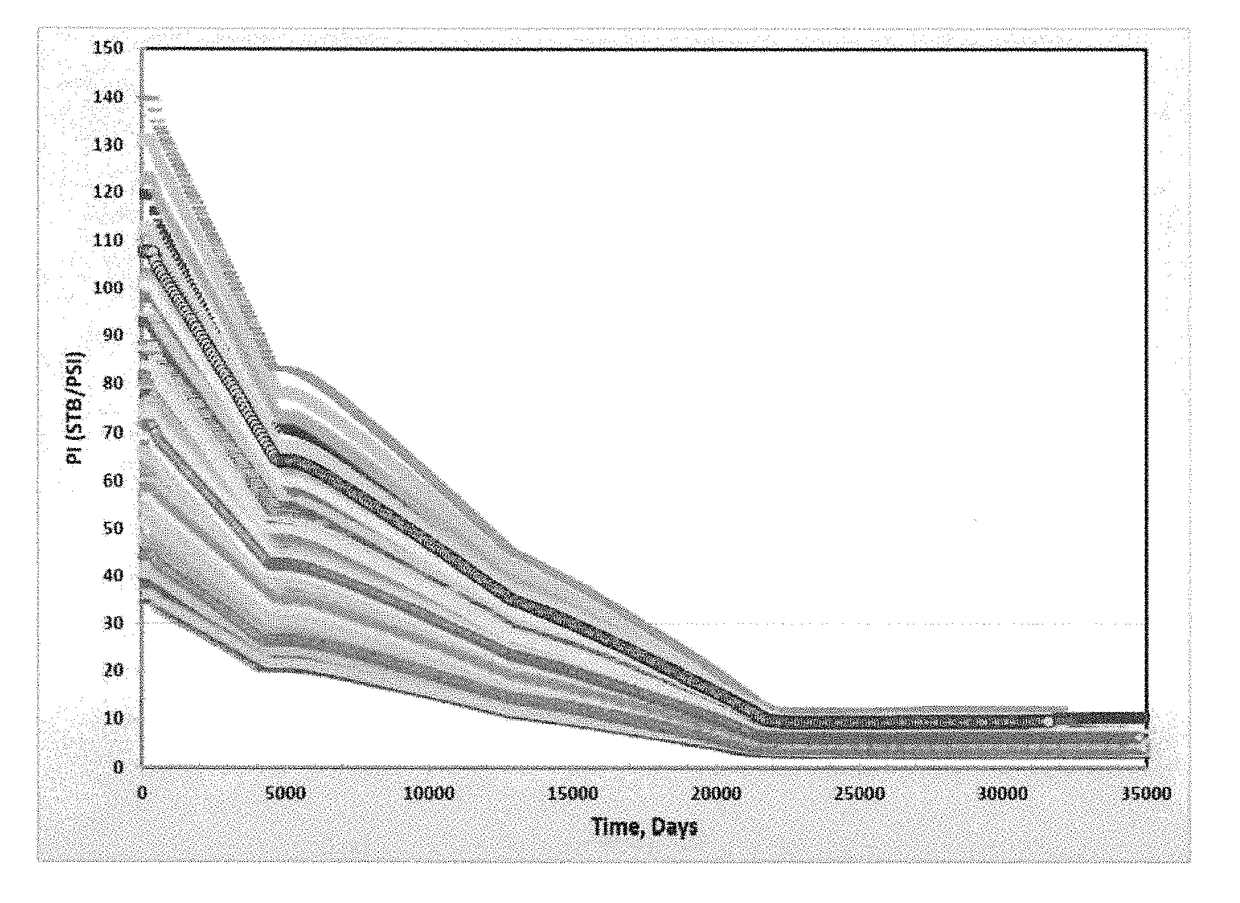

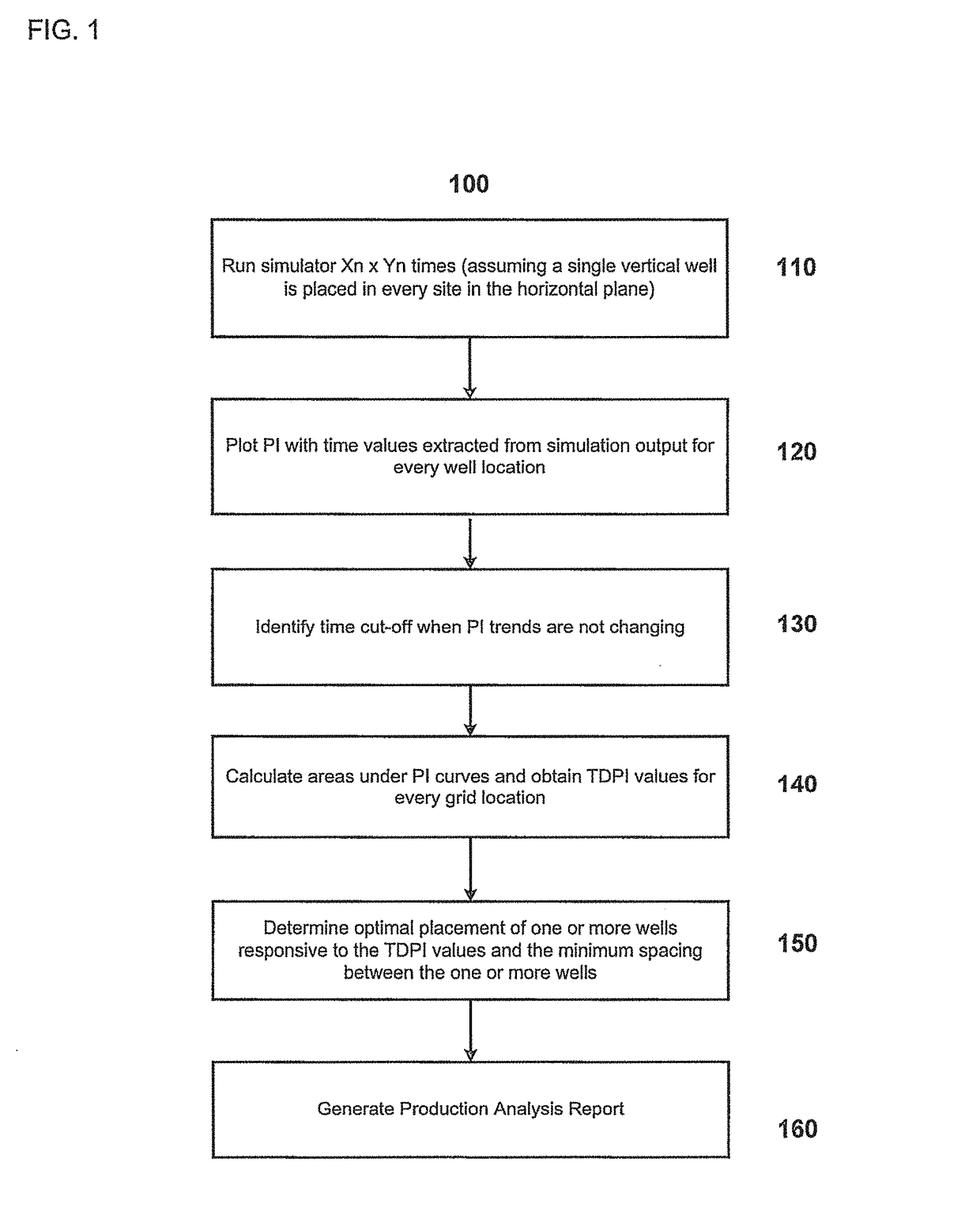

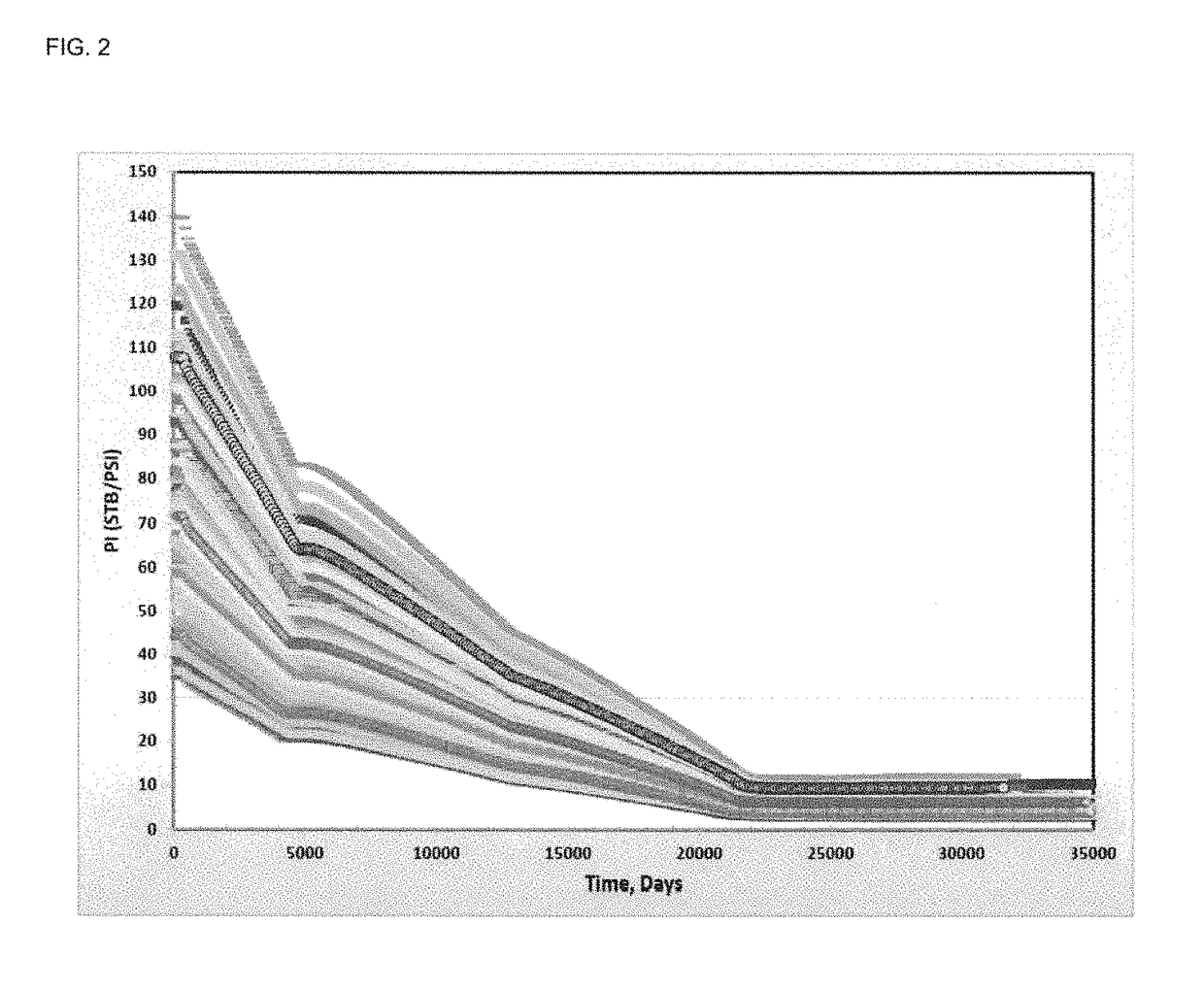

Methods, systems, and computer medium having computer programs stored thereon to optimize reservoir management decisions

ActiveUS20160010444A1The result is accurateEasy to placeForecastingFluid removalGrid patternWell placement

Embodiments of the invention include systems, methods, and computer-readable mediums for optimizing the placement of wells in a reservoir. Embodiments include, for example, determining for a reservoir a productivity index for each coordinate of a reservoir using reservoir metrics associated with the reservoir, generating a grid pattern of the reservoir using the productivity index with time values extracted for each coordinate, determining a total dynamic productivity index for each coordinate, and determining placement of one or more wells responsive to the total dynamic productivity index and minimum spacing between the one or more wells. Embodiments further include, for example, generating a production analysis report for the reservoir that includes an assessment of well placement and generating a wells placement map using one or more total dynamic productivity index indicators.

Owner:SAUDI ARABIAN OIL CO +1

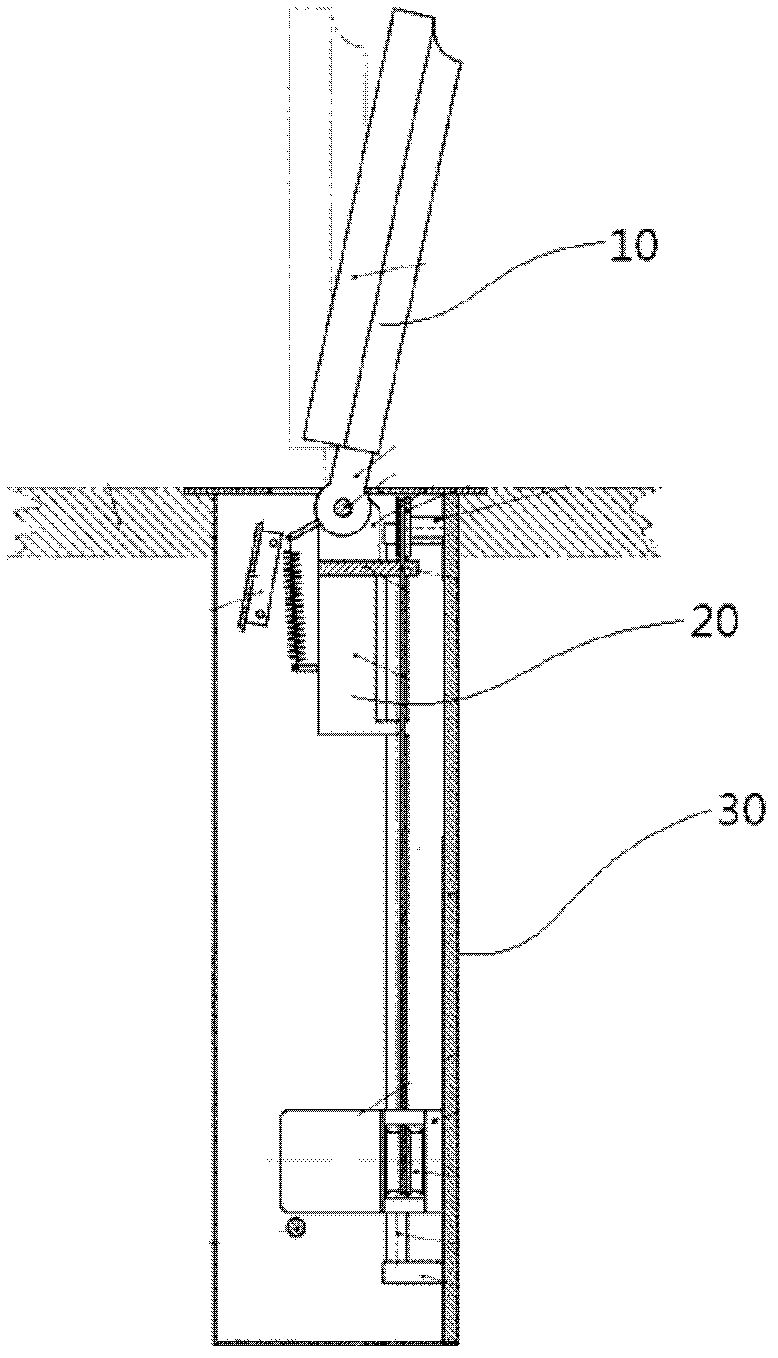

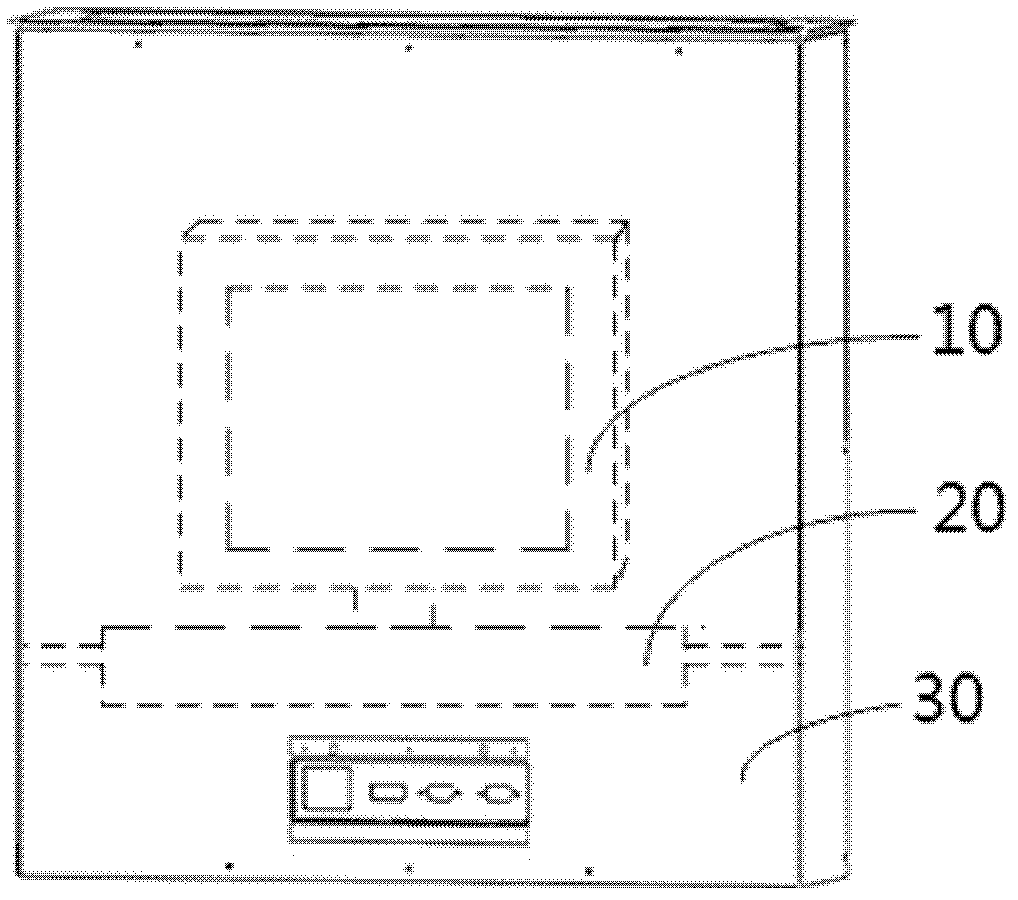

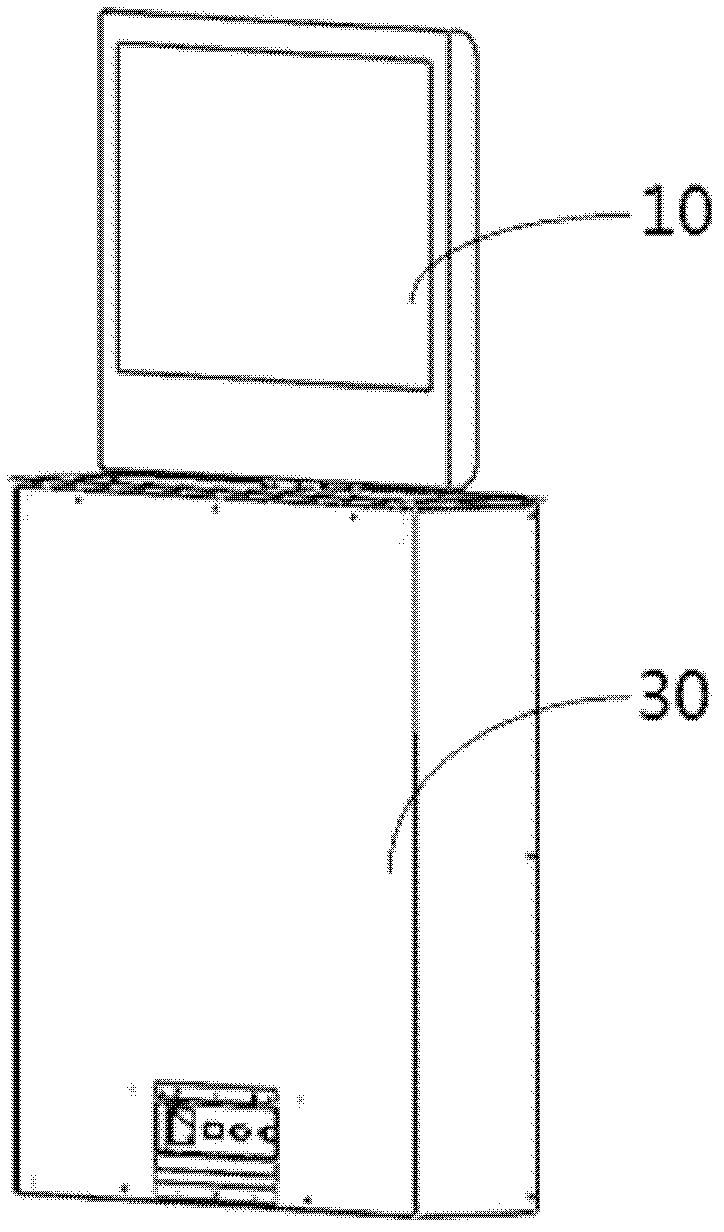

Fully automatic lifter with wide-angle display

The invention aims to provide a fully automatic lifter with a wide-angle display. The fully automatic lifter comprises a host machine shell, a displayer and a lift platform; the lift platform is arranged in the host machine shell through a vertical lifting mechanism; and the lift platform is connected with the back of the display through a wide-angle automatic overturning mechanism. Compared with the prior art, the wide-angle overturning of the display can be implemented with the minimum desktop damage, so that various demands for customers to use touch screens and the like can be met; and meanwhile, the problem that the opposite sight is blocked when the normal liquid crystal screen is used is solved. The fully automatic lifter provided by the invention is suitable for multimedia conference systems, TV conference systems, command and control systems, production analysis systems, financial analysis systems, large-scale conference systems, academic communication, information management, web office, various exhibition demos and the like.

Owner:SHANGHAI JOMARD INTELLIGENT TECH CO LTD

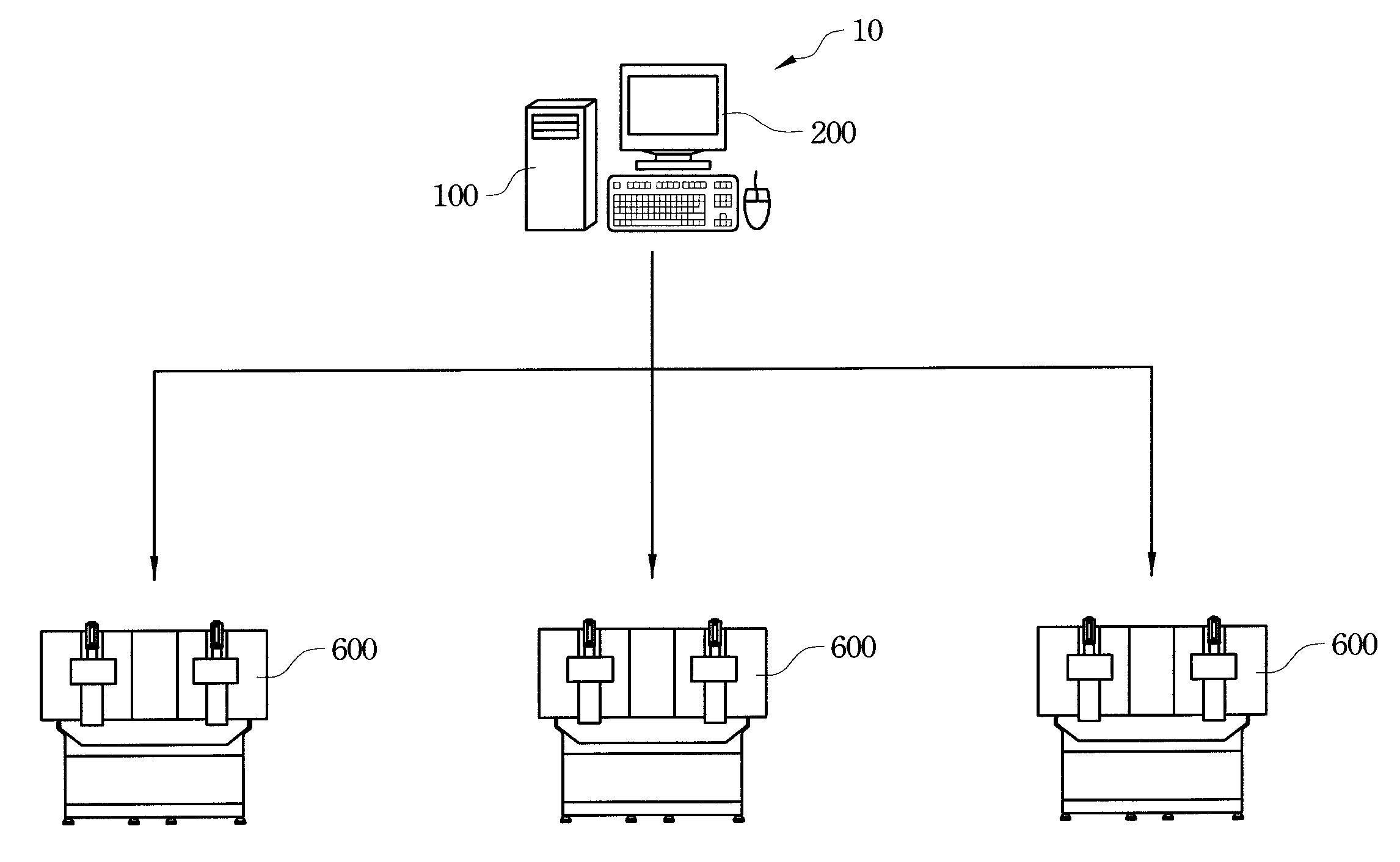

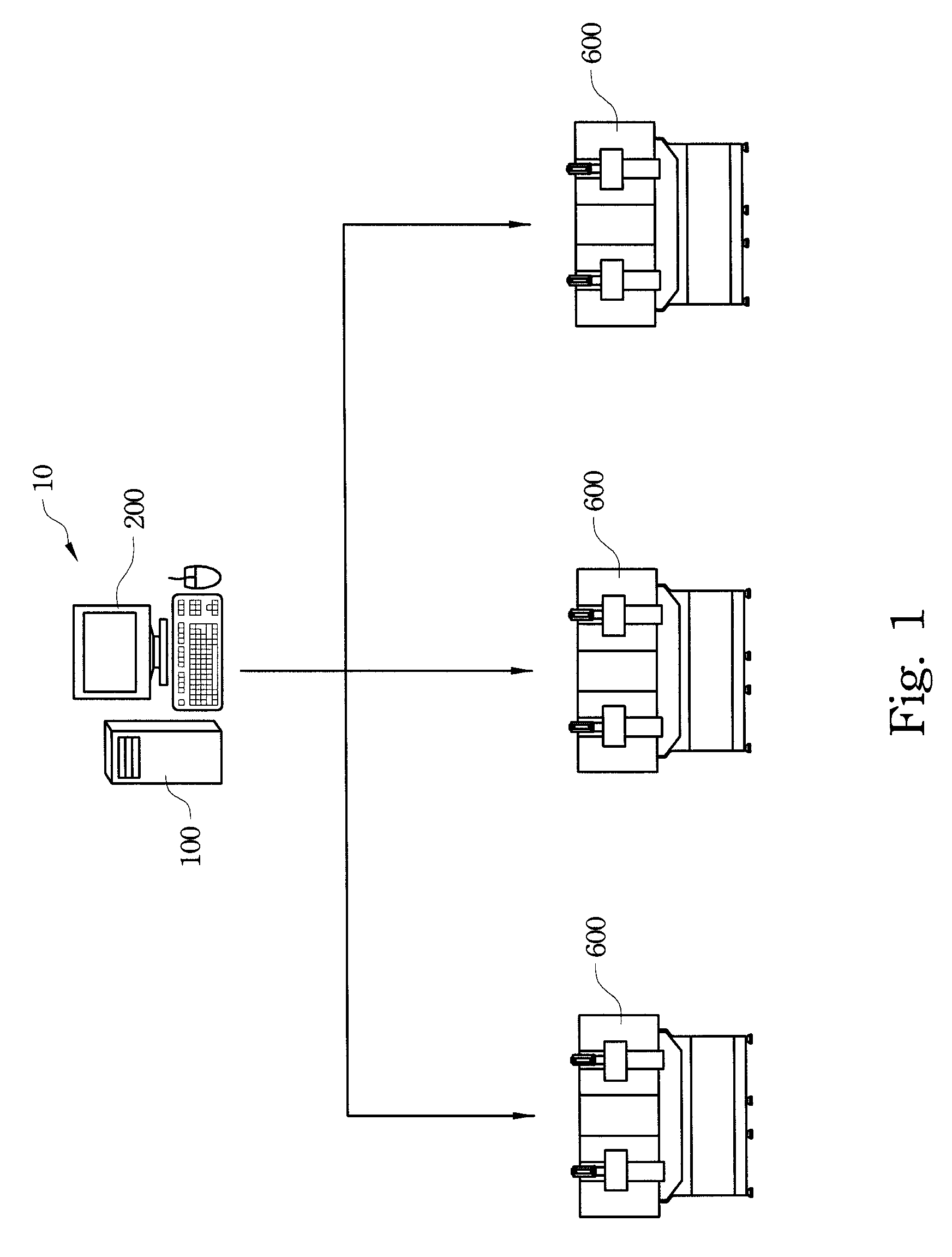

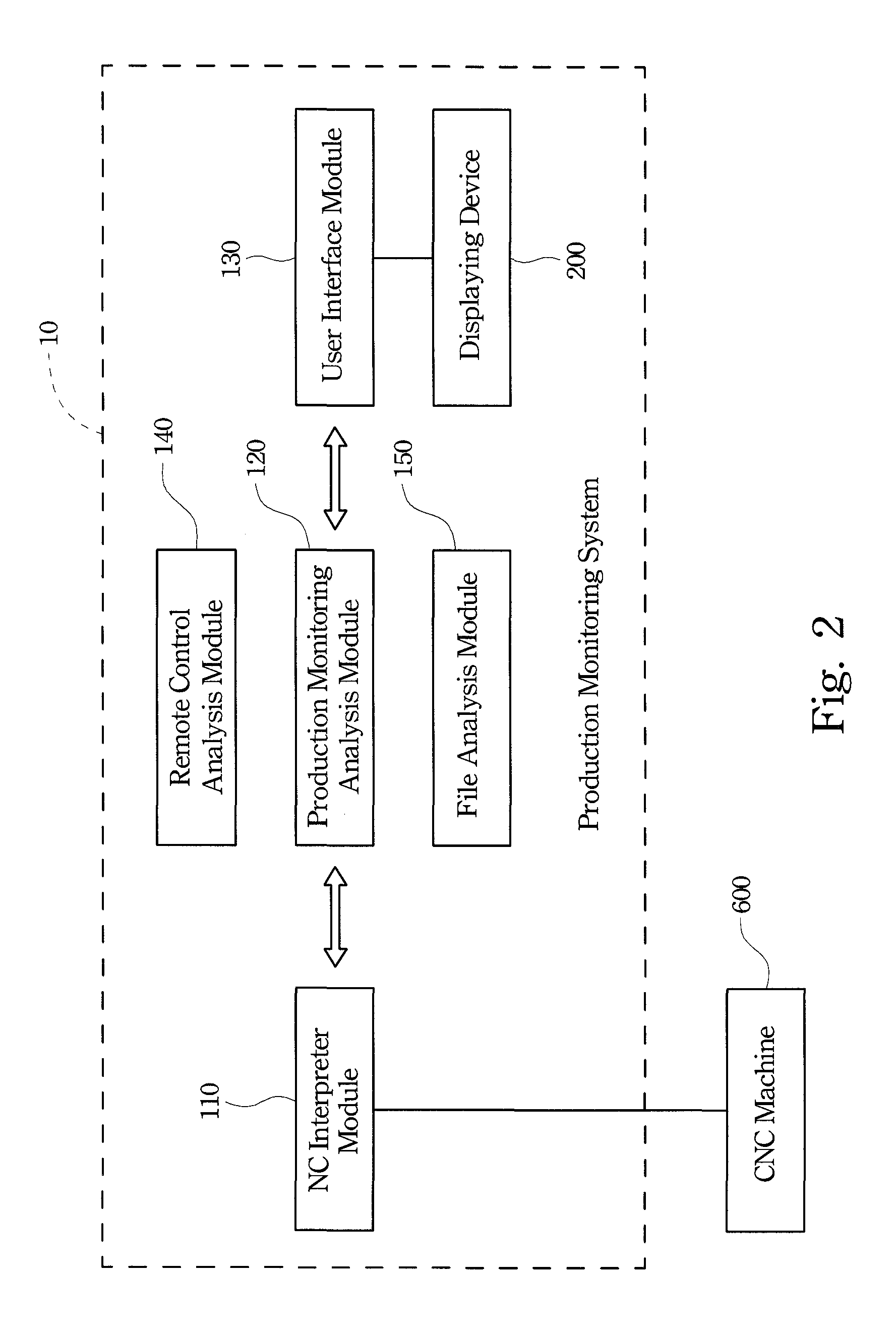

System and method for monitoring production of CNC machines

InactiveUS20090062950A1Easily and conveniently see informationProgramme controlTotal factory controlDisplay deviceUser Friendly

A system and method for monitoring production of CNC machines is provided. The system comprises a monitoring host and a displaying device. The monitoring host comprises an NC interpreter, a production analysis module, and a user interface module. The NC interpreter interprets first format data received from CNC machines into second format data saved within a temporary file. The production analysis module analyzes control codes and parameters of control codes contained in the temporary file to obtain current operation states and information of CNC machines connected to the monitoring host. The user interface module transforms the collected current operation states and information of CNC machines into a user-friendly interface that is displayed on the displaying device, such as a monitor.

Owner:REN AN INFORMATION TECH CO LTD

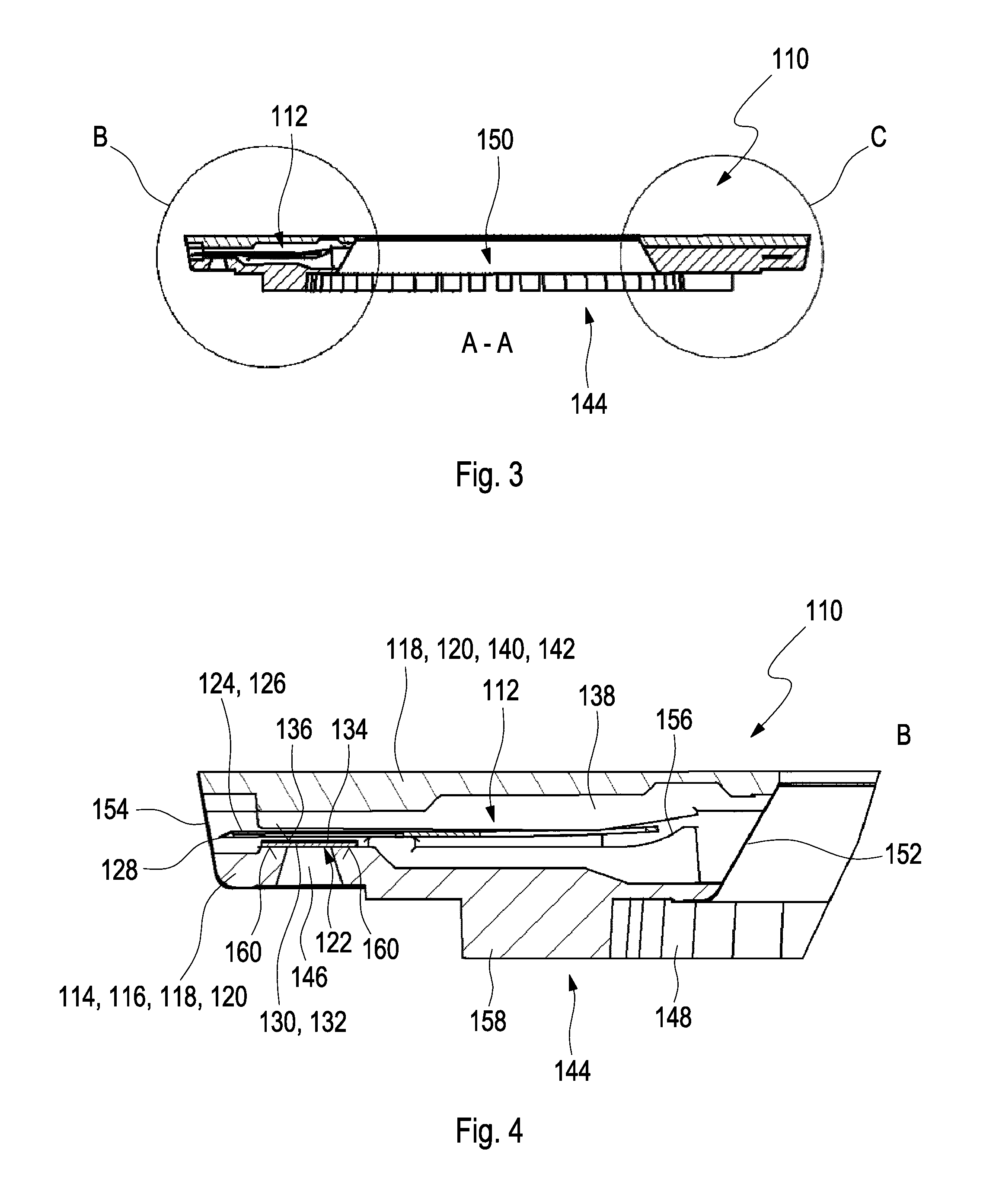

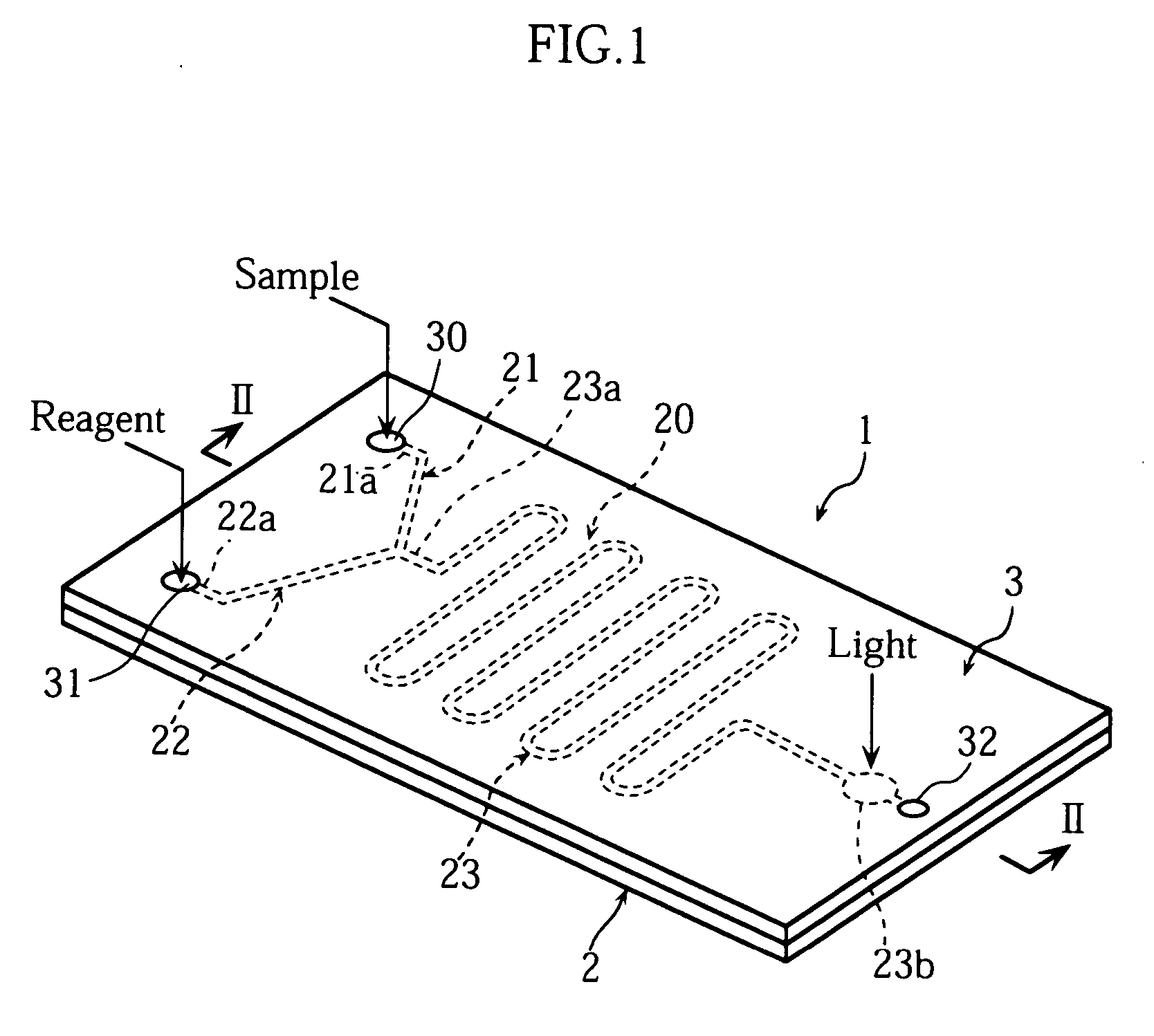

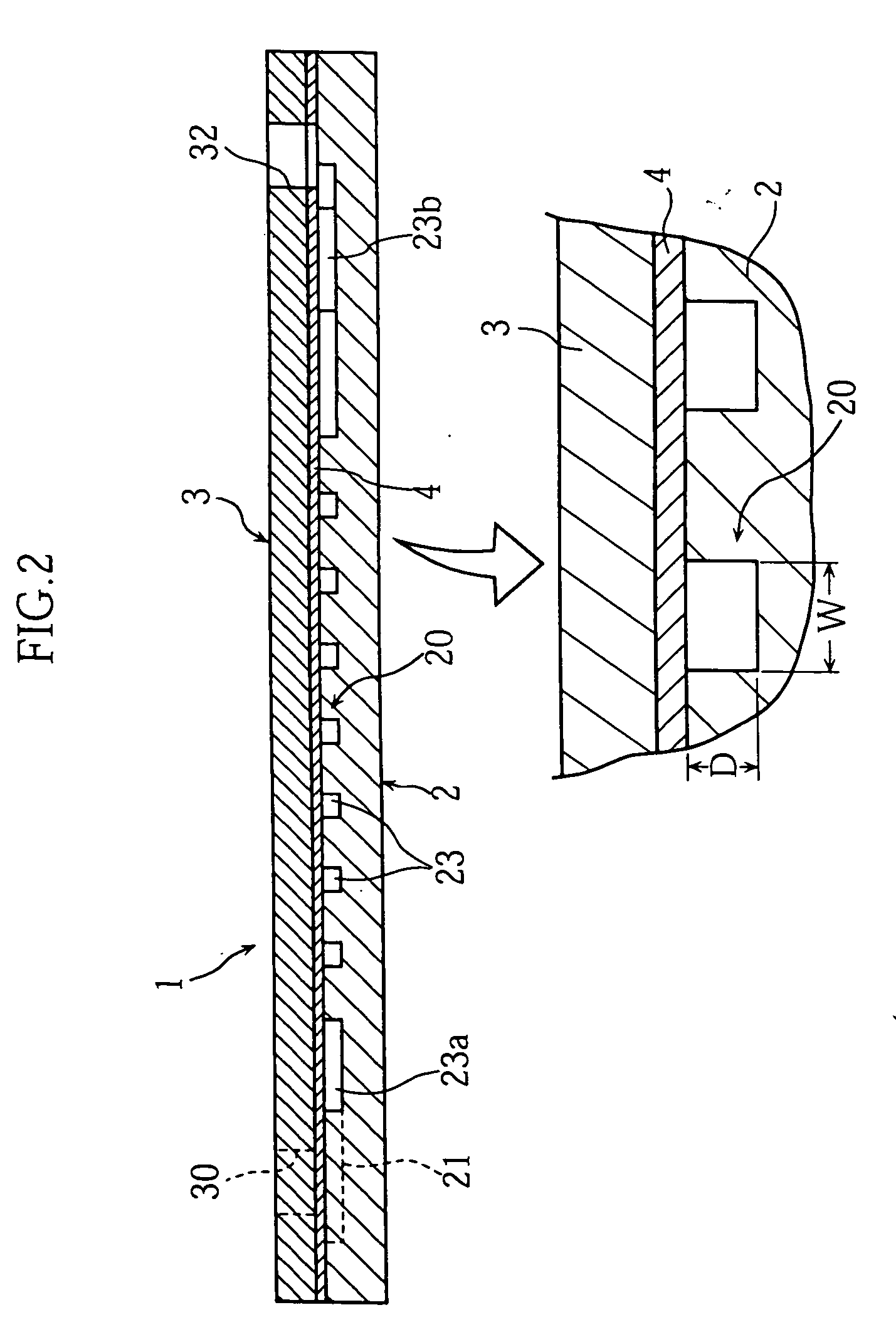

Analytical aid

InactiveUS9097679B2Test is very complexAvoid disadvantagesMaterial analysis by observing effect on chemical indicatorEnzymologyAnalyteEngineering

A process for producing an analytical aid for the detection of at least one analyte in a sample, such as a body fluid. The analytical aid includes at least one housing and at least one test element including at least one test chemistry. The process includes the following steps: providing the test element; and producing at least one housing part of the housing at least one shaping process, during which the test element is connected to the housing part.

Owner:ROCHE DIABETES CARE INC

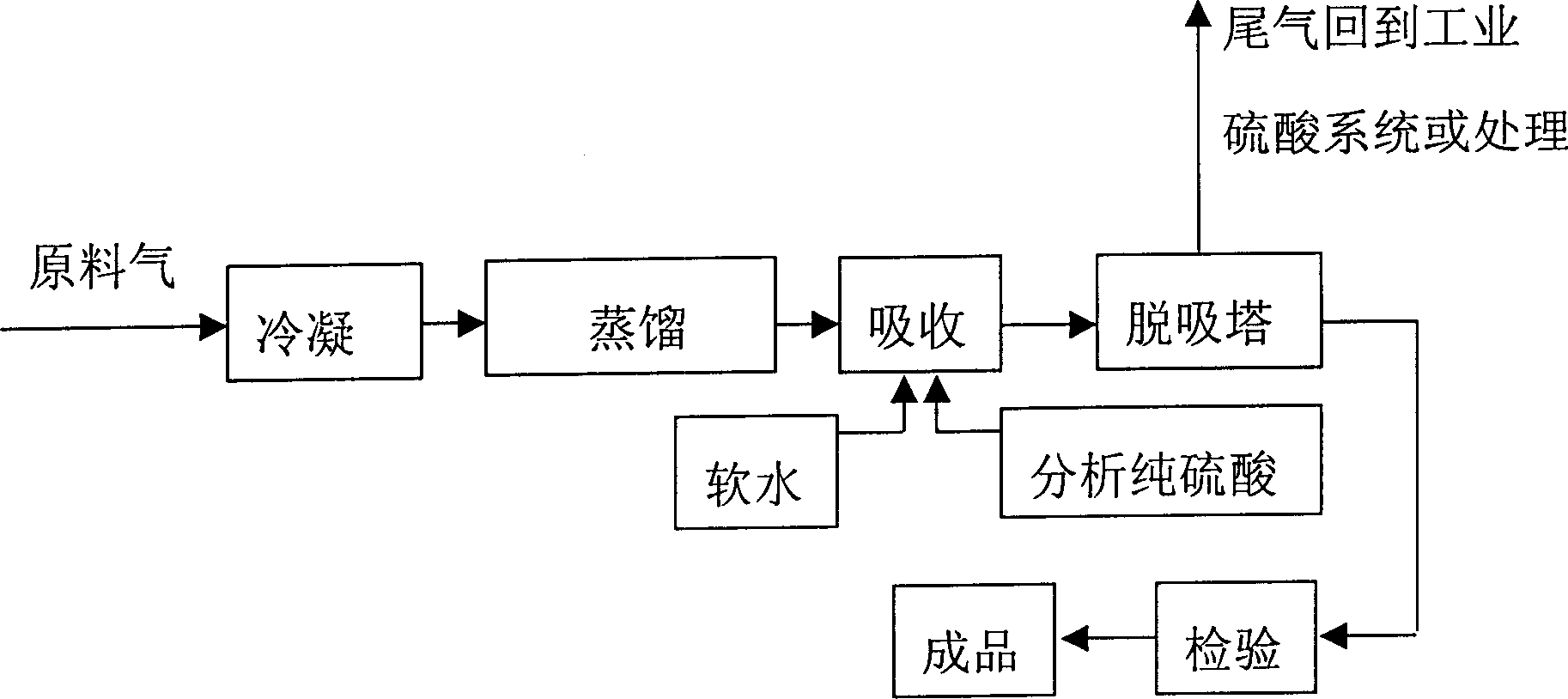

Analytical pure sulfuric acid production process

InactiveCN1699146AReduce energy consumptionReduce manufacturing costSulfur-trioxide/sulfuric-acidHigh concentrationAbsorption column

Disclosed is an analytical pure sulfuric acid production process which comprises using high concentration sulfur trioxide gas as raw material gas, passing through condenser for condensation, distilling sulfur trioxide in the form of condensed fluid into gas, loading into absorption column for absorption, wherein the absorption solution employs analytical pure sulfuric acid, soft water is utilized for adjusting acid concentration, then the product is subject to desorption with air in a desorption tower, thus removing the sulfur dioxide dissolved in the product, the examined specification product is then loaded into finished products warehouse.

Owner:WUHAN QINGJIANG CHEM IND

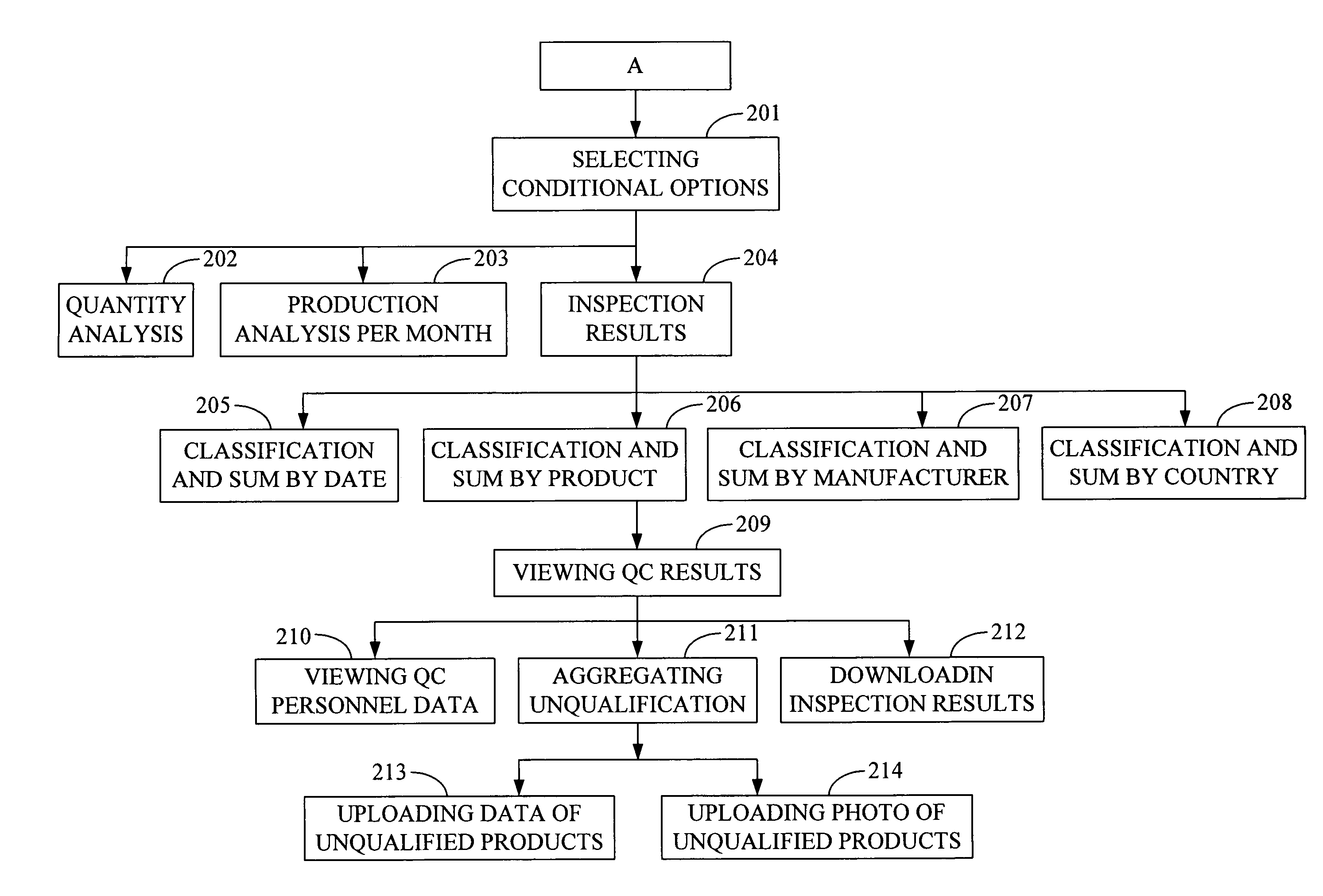

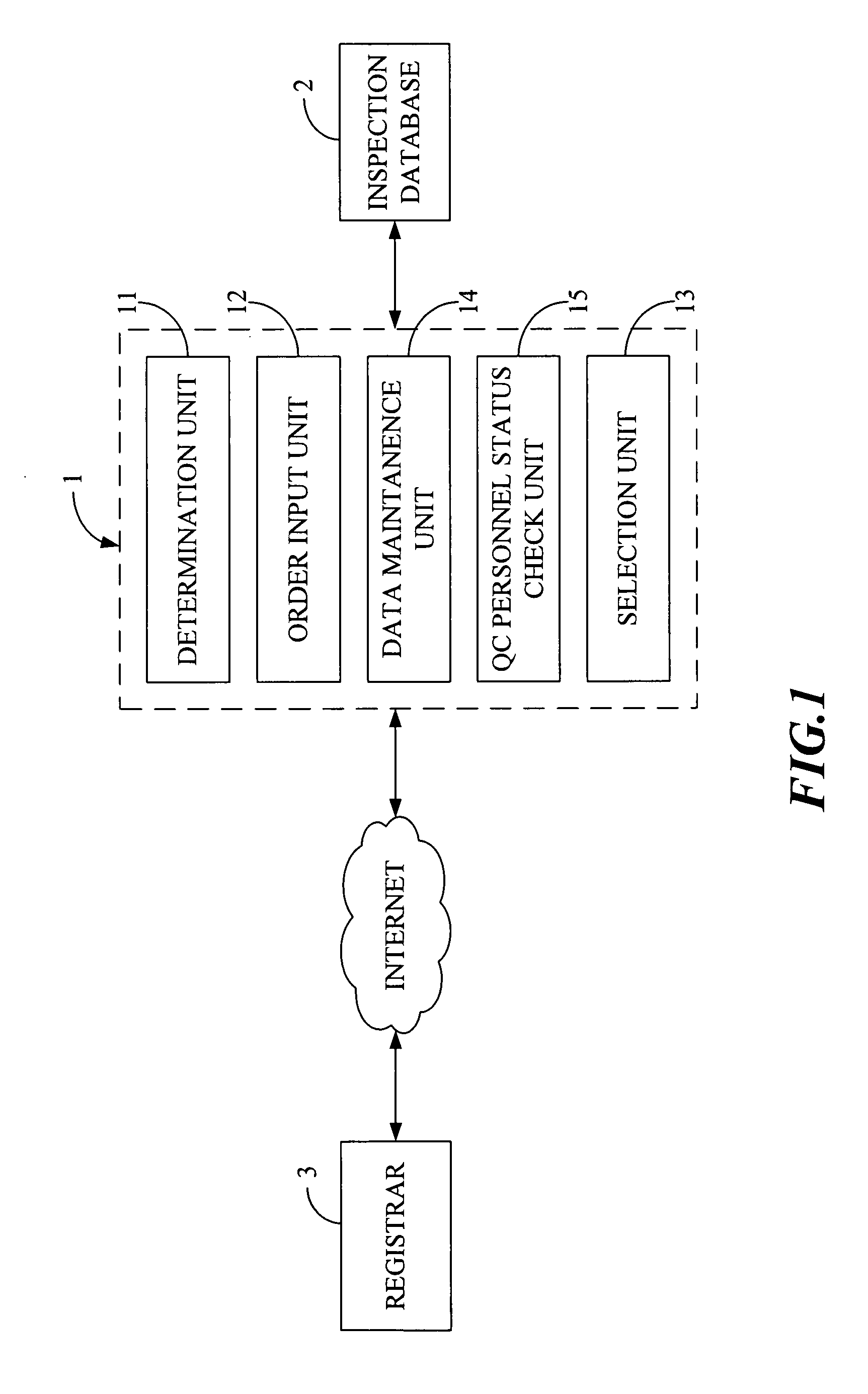

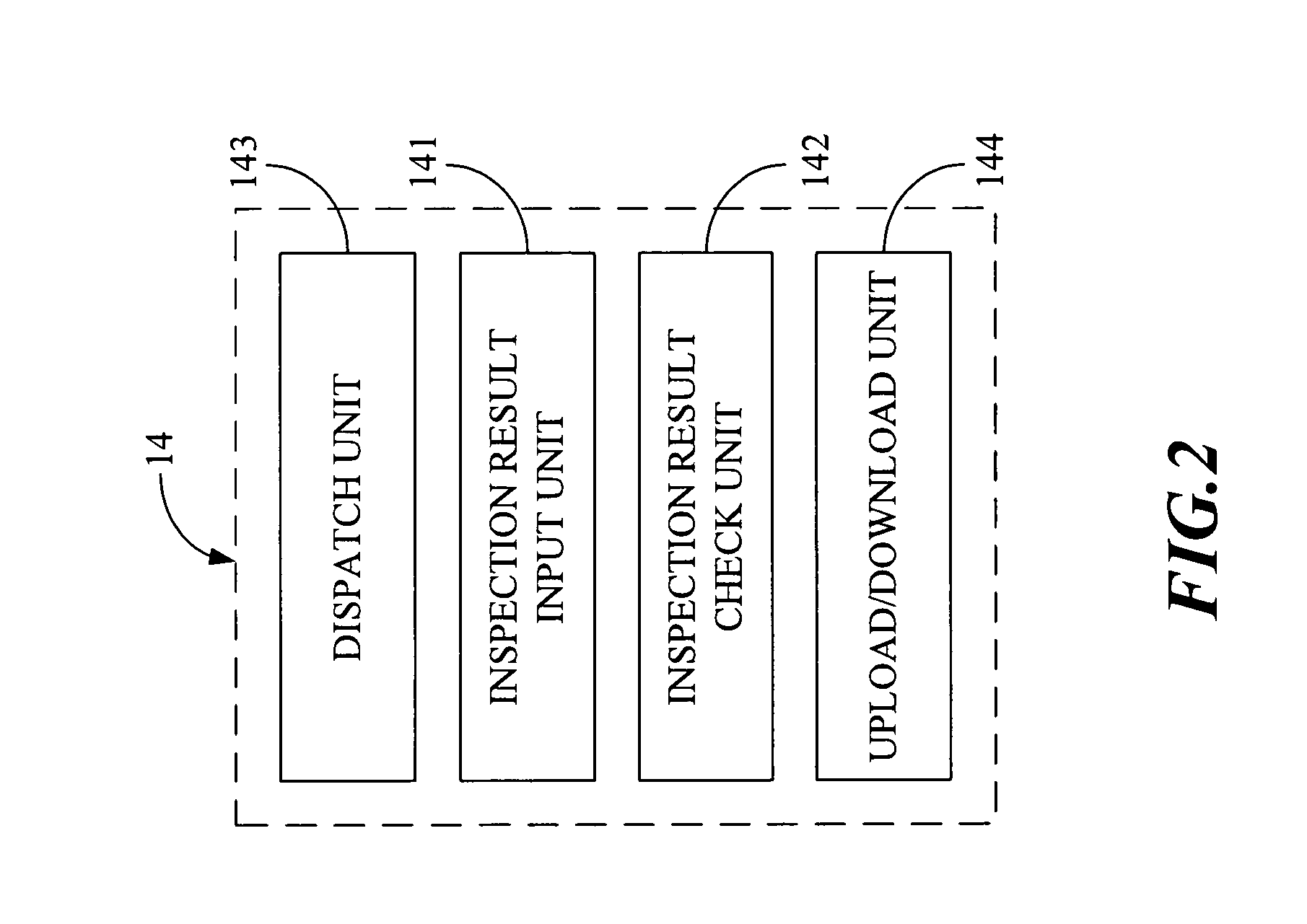

Quality Control Inspection and Maintenance Result Reporting System

A quality control (QC) inspection and maintenance result reporting system includes a web server, and an inspection database. The web server has various selection and analysis webpages built therein, and the inspection database has quantity analysis reports, production analysis reports, inspection result reports, QC personnel data, unqualified data and photographs for each type of product, and analysis reports for the rates of unqualified and qualified products stored therein. The registrar can be connected with the web server through the Internet. The web server can determine the registrar's privilege, according to the registering account and password, can display webpages for the registrar to select conditional options, according to the registrar's privilege, and can retrieve the requested reports from the inspection database for the registrar to view, according the selection made by the registrar, so that the registrar can know of QC inspection and maintenance results and the relevant QC personnel data in real time.

Owner:KUO COOPER S K

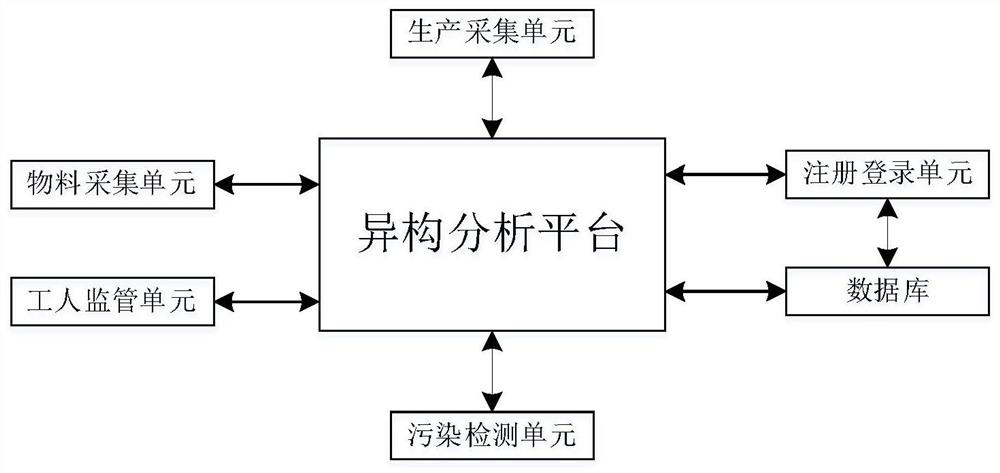

Intelligent heterogeneous industrial data analysis system based on user driving

ActiveCN113077128AImprove work efficiencyImprove accuracyOffice automationResourcesCollection analysisCollection system

The invention discloses an intelligent heterogeneous industrial data analysis system based on user driving, relates to the technical field of intelligent heterogeneous industrial data analysis, and solves the technical problem that the working efficiency of industrial production is reduced due to the fact that industrial production data cannot be collected and analyzed in the prior art, the industrial production information is analyzed through the production acquisition unit, the ratio of high-quality products to low-quality products produced by the industrial production equipment, the total number of times of whole-month maintenance of the industrial production equipment and the dust content of the surrounding environment of the industrial production equipment are obtained, and the production analysis coefficient Xi of the industrial production equipment is obtained through a formula, if the production analysis coefficient Xi of the industrial production equipment is larger than or equal to the production analysis coefficient threshold value of the industrial production equipment, it is judged that production of the industrial production equipment is abnormal, and the production equipment is detected, so that industrial production data are collected and analyzed, the working efficiency of industrial production is improved, and meanwhile the working efficiency of a collection system is improved.

Owner:贵州航天云网科技有限公司

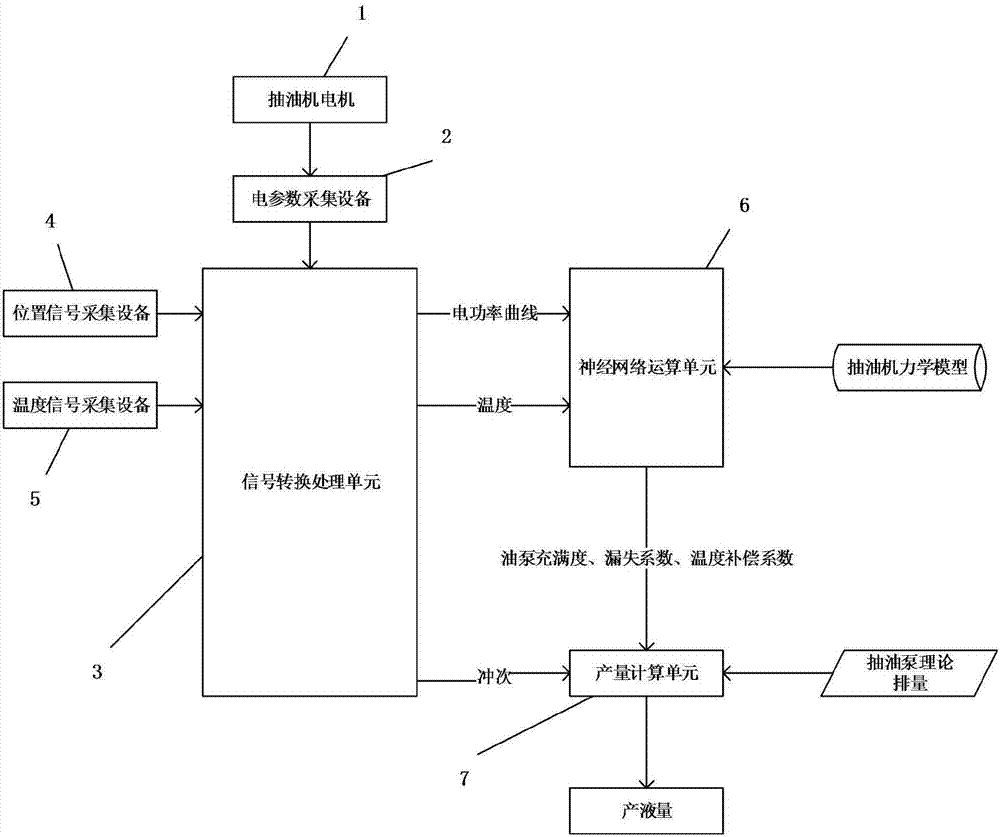

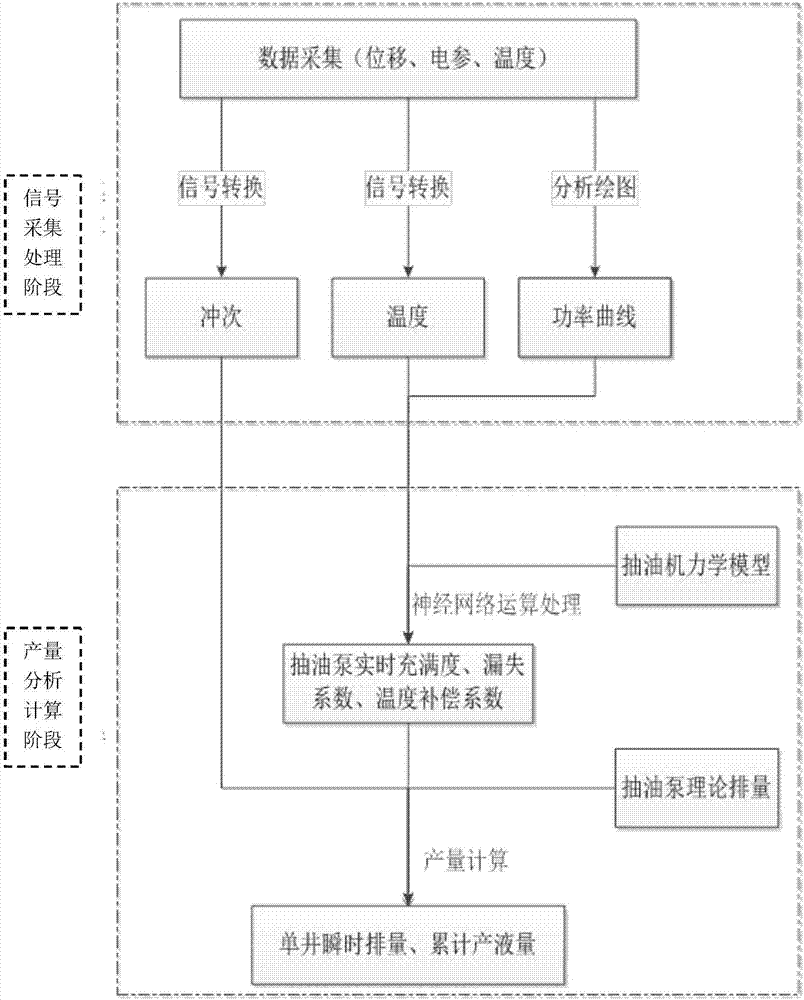

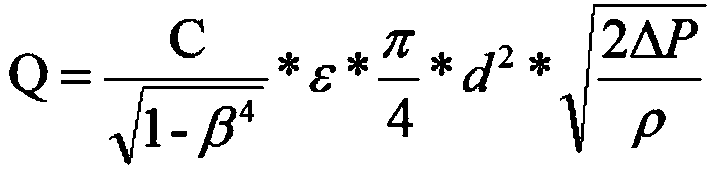

Device for measuring fluid production of single well with electrical parameters and method

ActiveCN107143322AReduce the influence of human factorsReduce measurement errorSurveyConstructionsElectricityMechanical models

The invention provides a device for measuring fluid production of a single well with electrical parameters and a method and relates to a device applicable to single well measuring of an oil well and the method. According to the device and the method, the electrical operating parameters of an oil-pumping unit motor of the oil well are used as a basis, an oil-pumping unit mechanical model and a neural network algorithm are combined to judge the fullness degree of an oil pump below the well and a leakage coefficient, the theoretical displacement of the oil pump is combined to calculate the real-time fluid production, and accordingly the daily fluid production of the single well is accumulated and obtained. The device for measuring the fluid production of the single well with the electrical parameters comprises an electrical parameter collecting device (2), a position signal collecting device (4), a temperature signal collecting device (5), a signal conversion processing unit (3), a neural network calculating unit (6) and a production calculating unit (7). The method for calculating the fluid production of the single well by using the device comprises the steps of (1) a signal collecting and processing stage and (2) a production analysis and calculation stage.

Owner:XINJIANG DUNHUA PETROLEUM TECH CO LTD

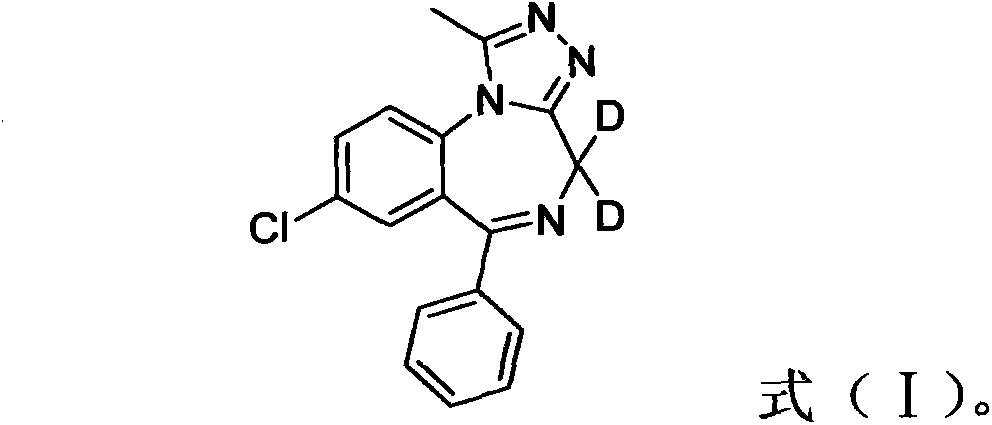

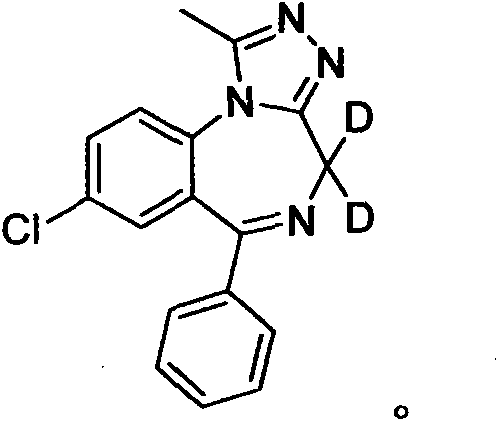

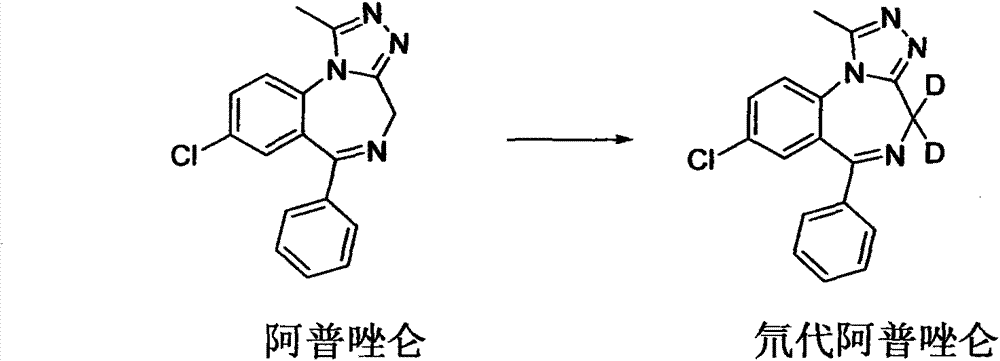

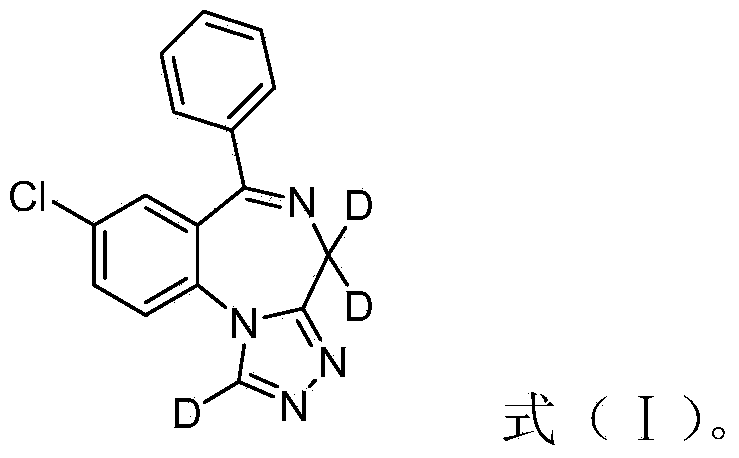

Deuterated alprazolam and preparation method thereof

InactiveCN103204856ASimple reaction conditionsEasy to purifyOrganic chemistryDeuterated chloroformPotassium carbonate

The invention discloses deuterated alprazolam and a preparation method thereof. The preparation method of deuterated alprazolam comprises the following steps of: (1) mixing commercially available non-deuterated alprazolam and N,N-dimethyl formamide, and stirring; (2) adding potassium carbonate and deuterated chloroform, heating the mixture to more than 40 DEG C and stirring; and (3) carrying out separation to obtain the deuterated alprazolam. The preparation method provided by the invention is short, simple and convenient to operate, low in cost and easy to purify. The commercially available non-deuterated alprazolam uses a small amount of deuterated reagents as deuterium sources in a non-deuterated solvent atmosphere, so that deuterated alprazolam is obtained in a relatively short period of time, and through simple column chromatography purification, a purified product is purified. The deuterated alprazolam standard product prepared according to the invention is high in purity and stable in chemical property; and the preparation of the standard product for analysis is convenient. The preparation method provided by the invention can be used for producing deuterated internal standard substance used for analyzing and detecting alprazolam.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

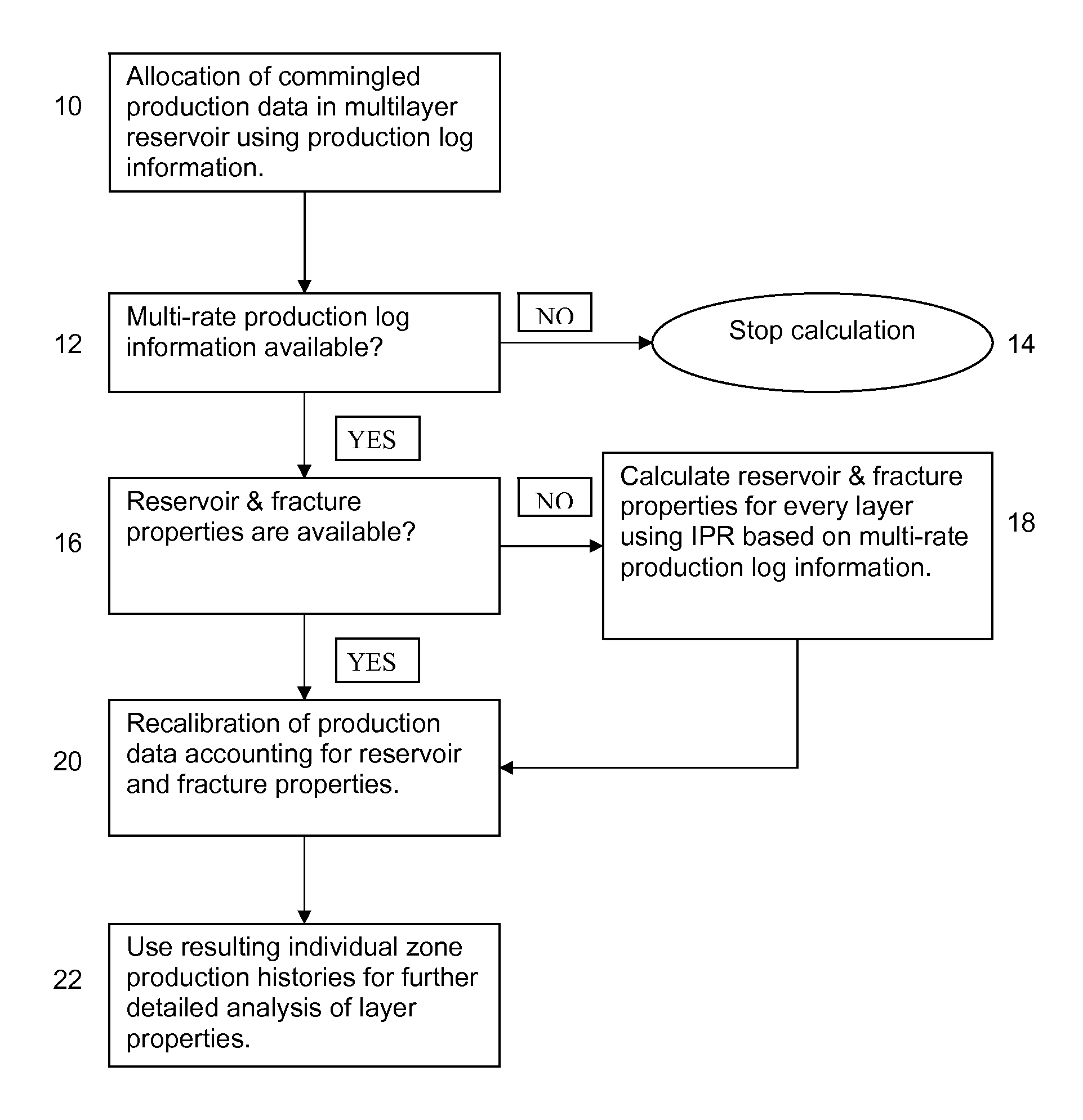

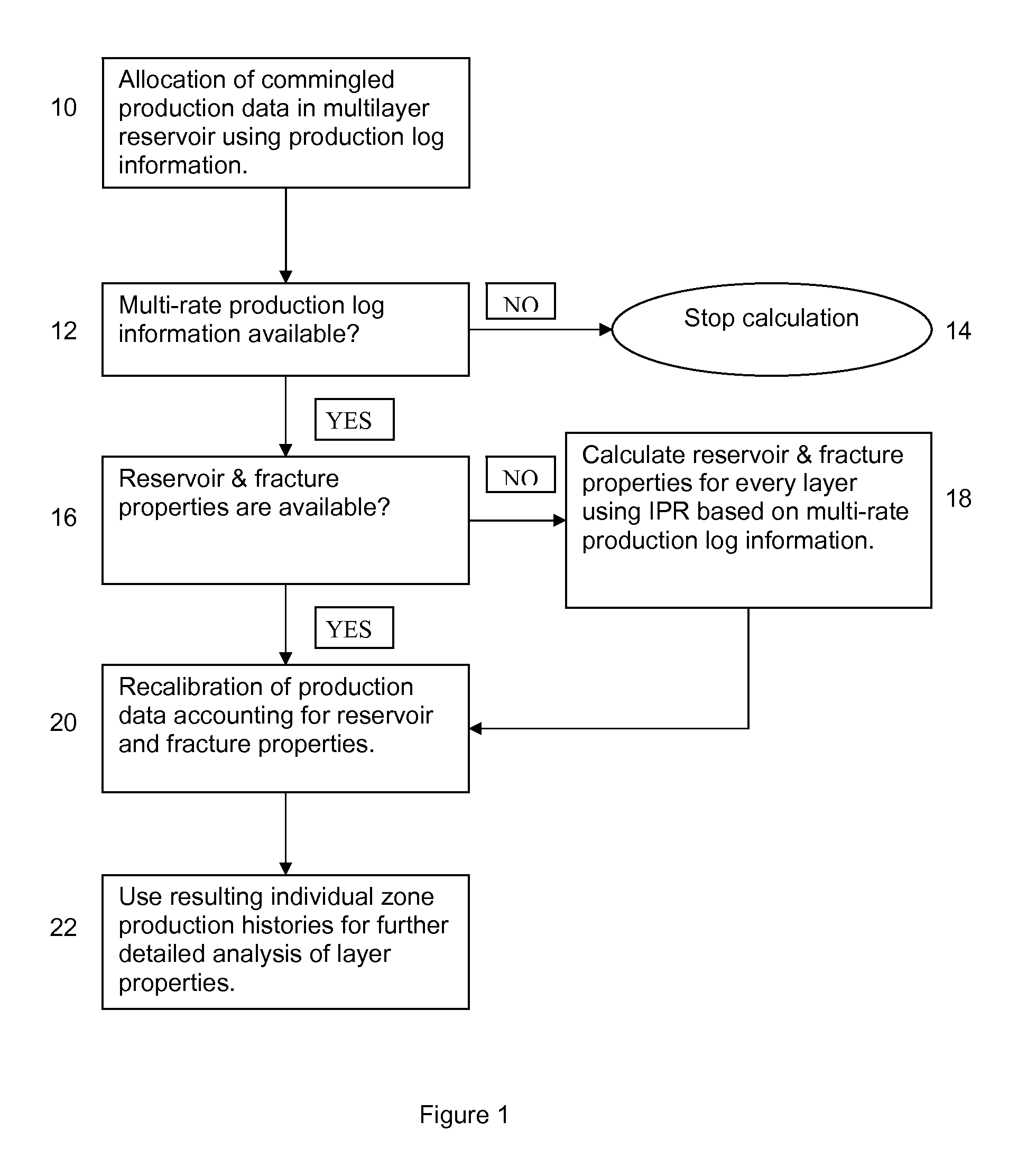

Method for optimizing reservoir production analysis

Optimizing reservoir production in a commingled hydraulically fractured reservoir by allocating commingled system production data to each of the individual completed intervals in the system, calculating the reservoir and fracture properties for each completed reservoir layer, and recalibrating the commingled and individual layer production data by accounting for the individual completed interval reservoir and fracture properties.

Owner:SCHLUMBERGER TECH CORP

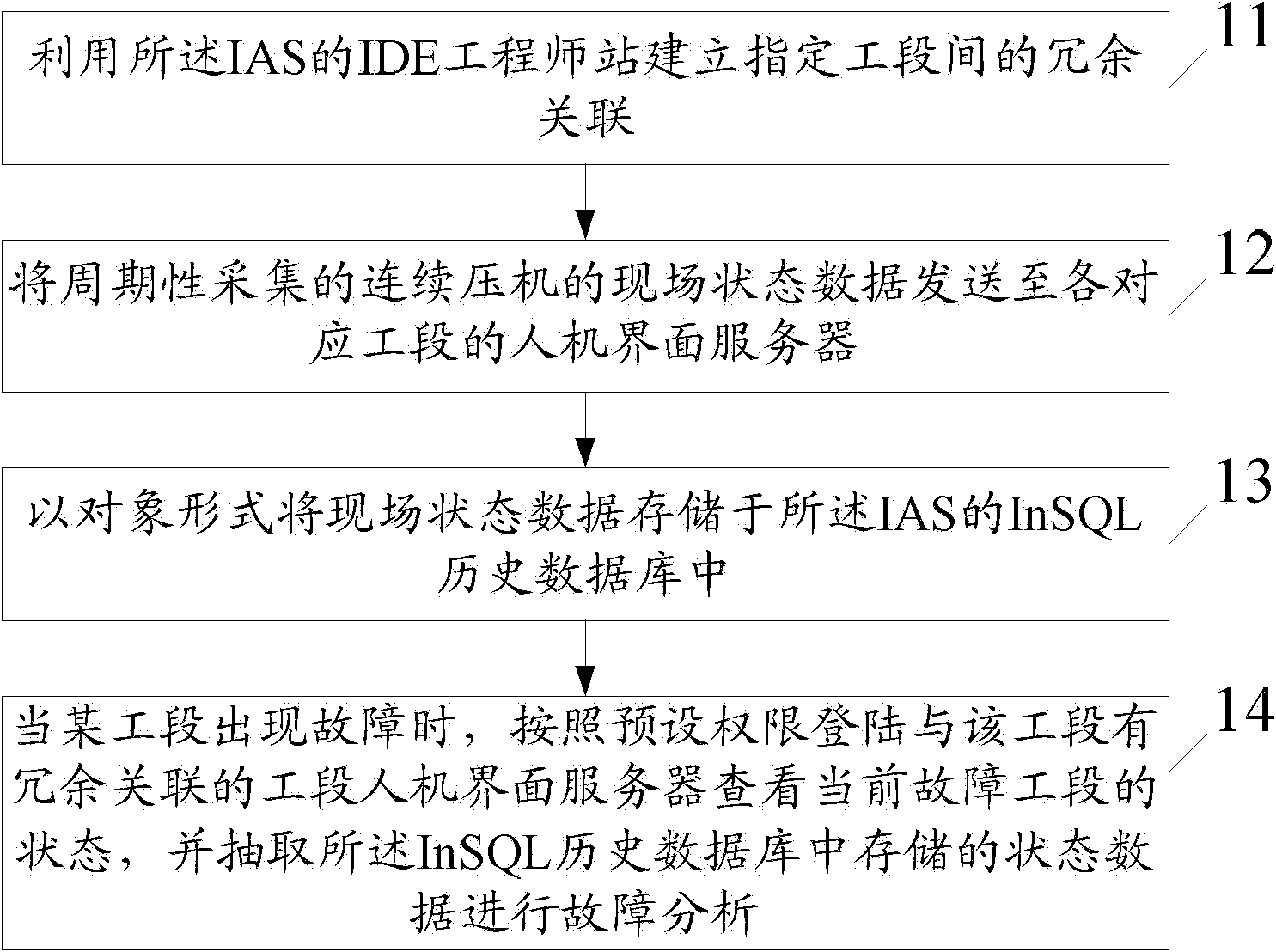

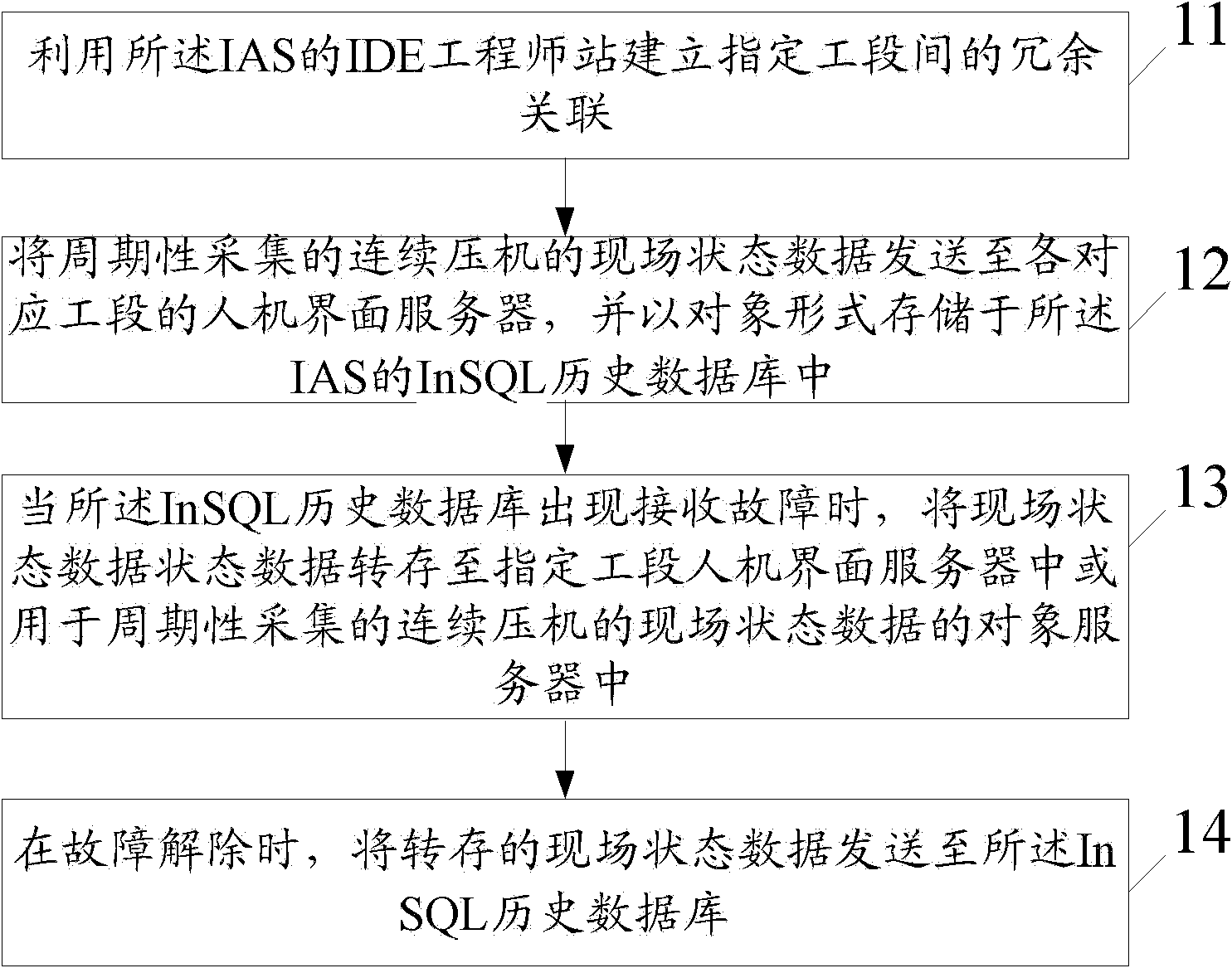

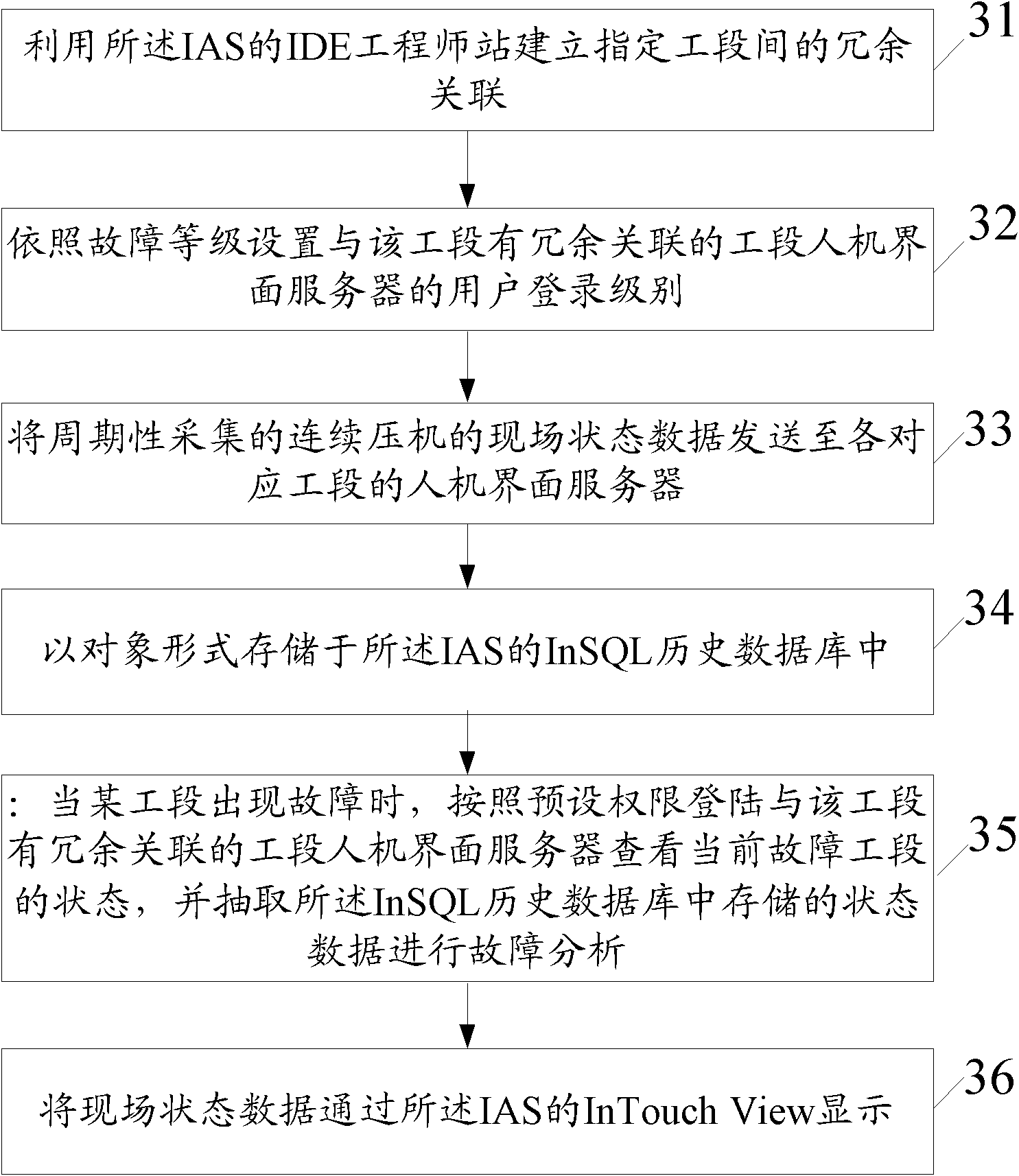

Continuous press machine man-machine interface data interaction method based on IAS and system thereof

InactiveCN102736571AAvoid lossTimely detection and timely eliminationTotal factory controlProgramme total factory controlProduction lineHuman–machine interface

The embodiment of the invention discloses a continuous press machine man-machine interface data interaction method based on IAS and a system thereof. The method is based on an IAS application platform, redundant association between working sections is set by using an IDE engineer station in the platform, data sharing can be carried out to avoid data loss in the event of a failure, field state data of the working sections is stored at a history database in an object form for being used by retrieval and production analysis, a purpose of timely discovery and timely elimination of a working section fault on a huge production line is realized, and disadvantages that the fault can not be timely discovered and history data is lost caused by a point-to-point HMI data interaction form in the prior art are overcome. The embodiment of the invention also discloses the system corresponding to the method, and the system is constructed with an object server as a core and with the working section redundant association as a base.

Owner:上海板机电气制造有限公司

Methods, systems, and computer medium having computer programs stored thereon to optimize reservoir management decisions

Embodiments of the invention include systems, methods, and computer-readable mediums for optimizing the placement of wells in a reservoir. Embodiments include, for example, determining for a reservoir a productivity index for each coordinate of a reservoir using reservoir metrics associated with the reservoir, generating a grid pattern of the reservoir using the productivity index with time values extracted for each coordinate, determining a total dynamic productivity index for each coordinate, and determining placement of one or more wells responsive to the total dynamic productivity index and minimum spacing between the one or more wells. Embodiments further include, for example, generating a production analysis report for the reservoir that includes an assessment of well placement and generating a wells placement map using one or more total dynamic productivity index indicators.

Owner:SAUDI ARABIAN OIL CO +1

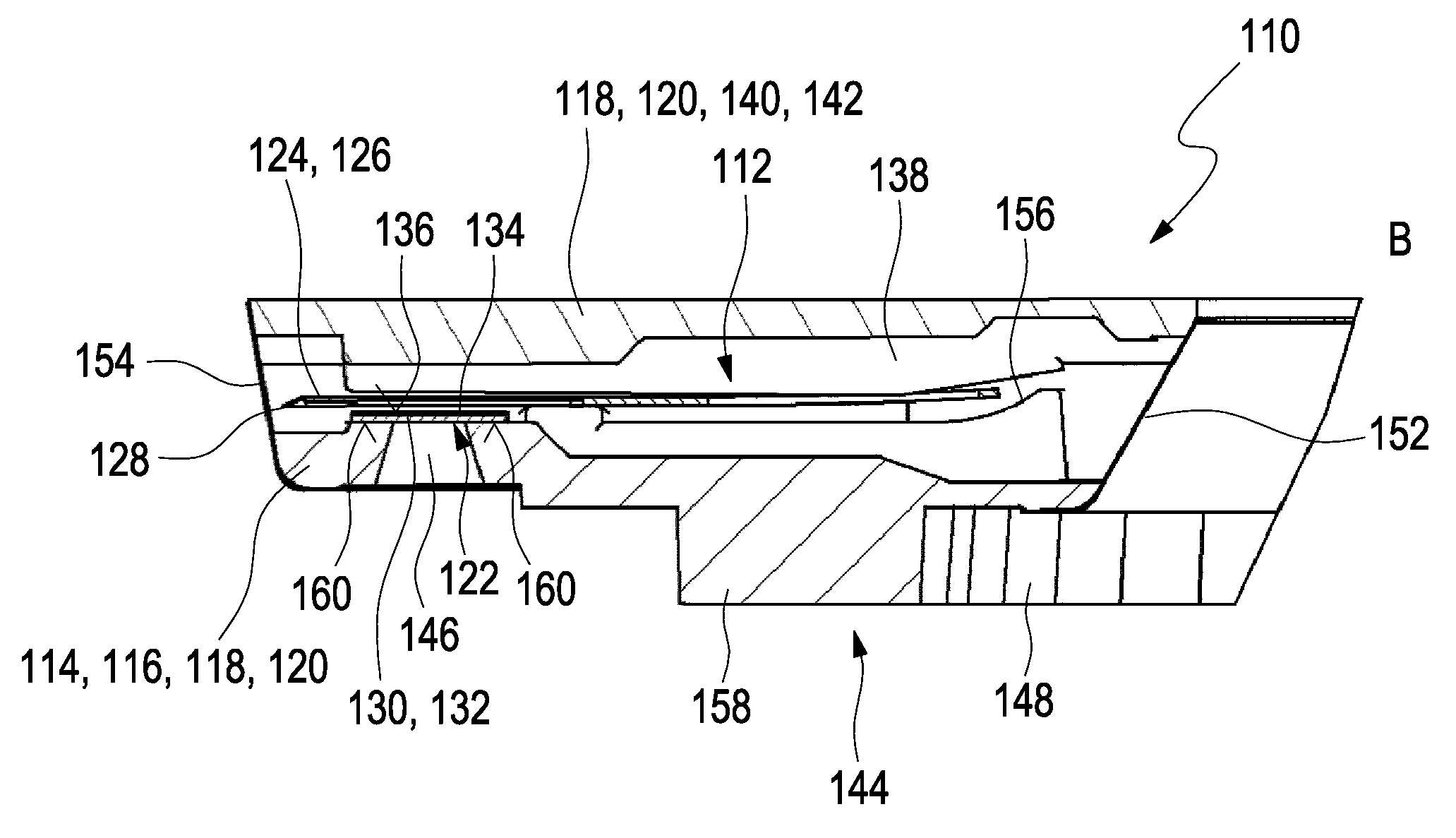

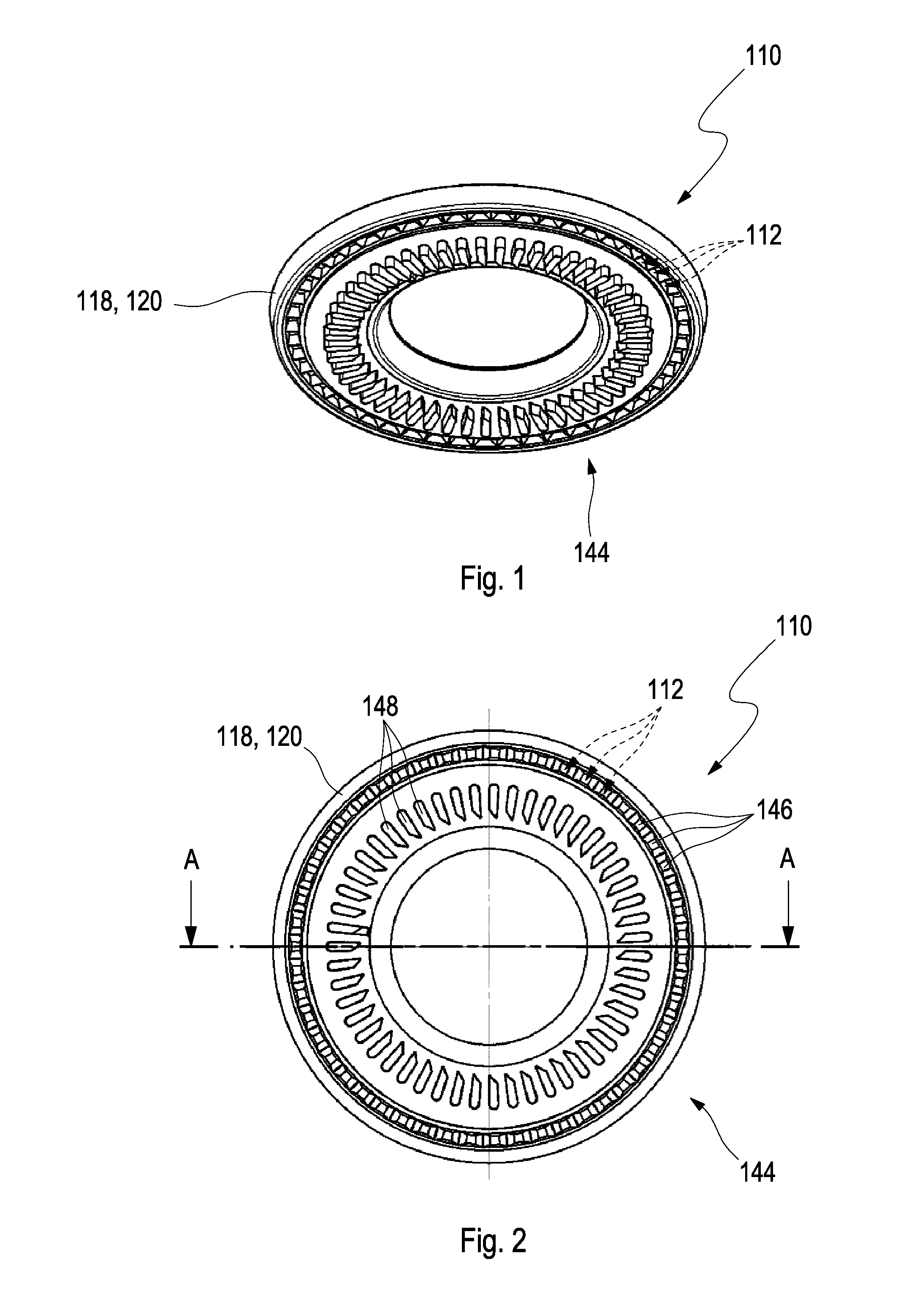

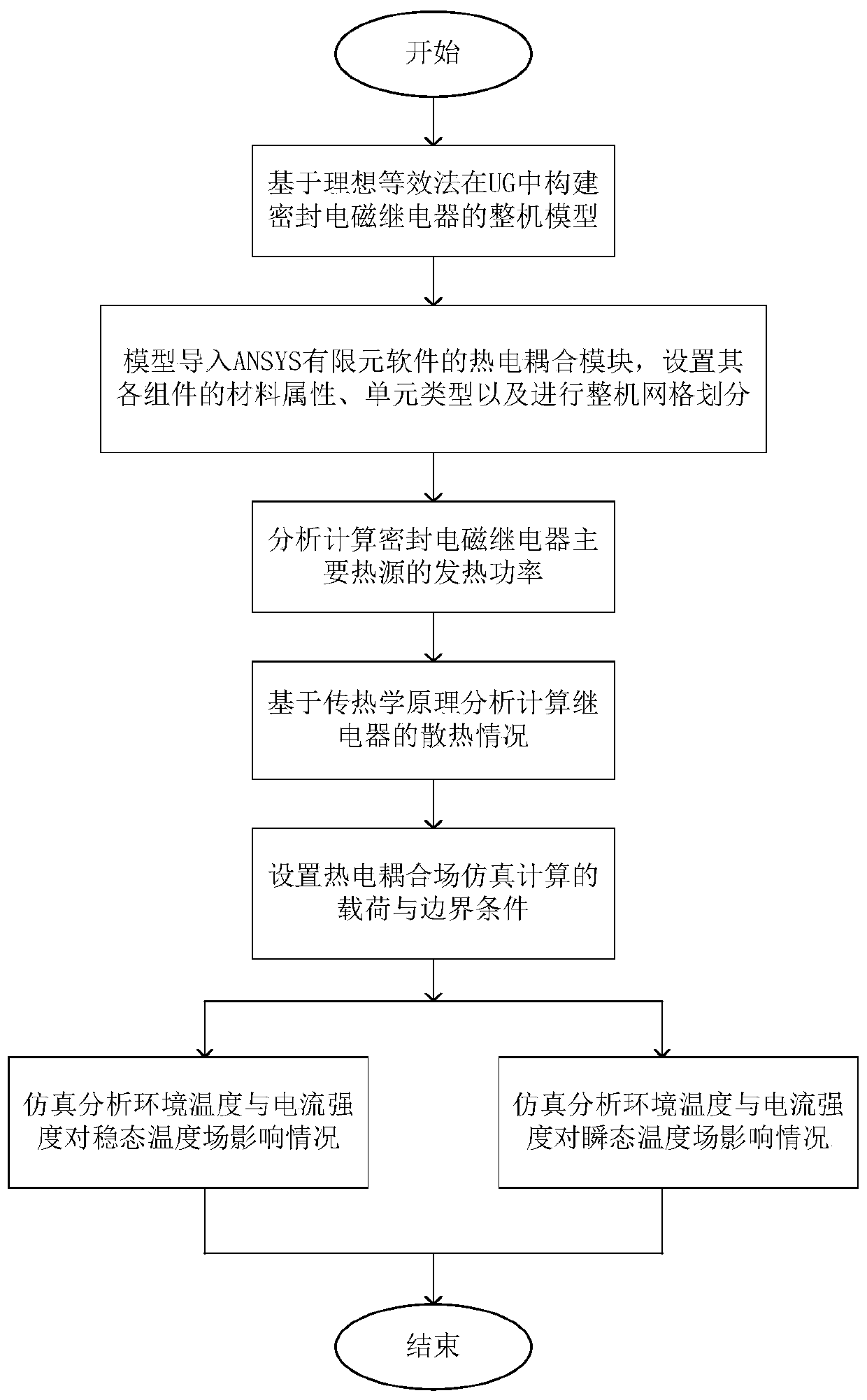

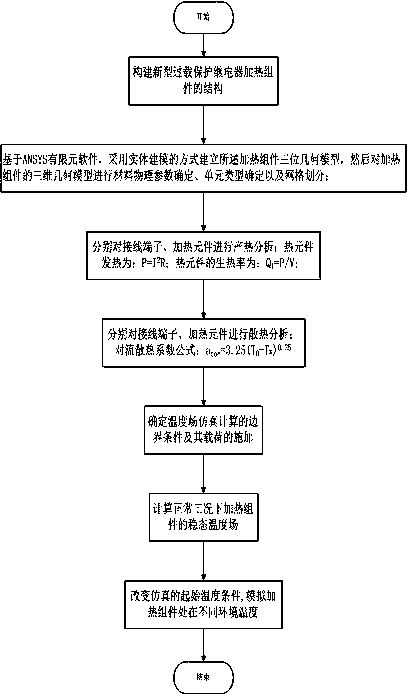

Sealed electromagnetic relay temperature field analysis method based on multi-field finite element simulation

ActiveCN110390172AImprove computing efficiencyImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsSteady state temperatureMulti field

The invention relates to a sealed electromagnetic relay temperature field analysis method based on multi-field finite element simulation, and the method comprises the following steps: constructing a sealed electromagnetic relay complete machine entity model through UG modeling software based on an ideal equivalent method; importing the model into a thermoelectric coupling simulation module of ANSYS finite element analysis software, and establishing an ideal equivalent simulation model of the sealed electromagnetic relay by setting physical parameters of each component material, unit types during simulation calculation and a mesh division method; and respectively carrying out heat production analysis and calculation on a main heat source assembly control coil and a contact system of the sealed electromagnetic relay, carrying out heat dissipation analysis on the sealed electromagnetic relay based on a heat transfer theory, and completing application of load and boundary conditions duringthermoelectric coupling simulation calculation. Based on the ideal equivalent simulation model with the set load and boundary conditions, the influence condition of the environment temperature and the current intensity is acquired by calculation on the steady-state temperature field under the long-term working system of the relay and the transient temperature field under the short-term working system of the relay.

Owner:XIAN TECHNOLOGICAL UNIV

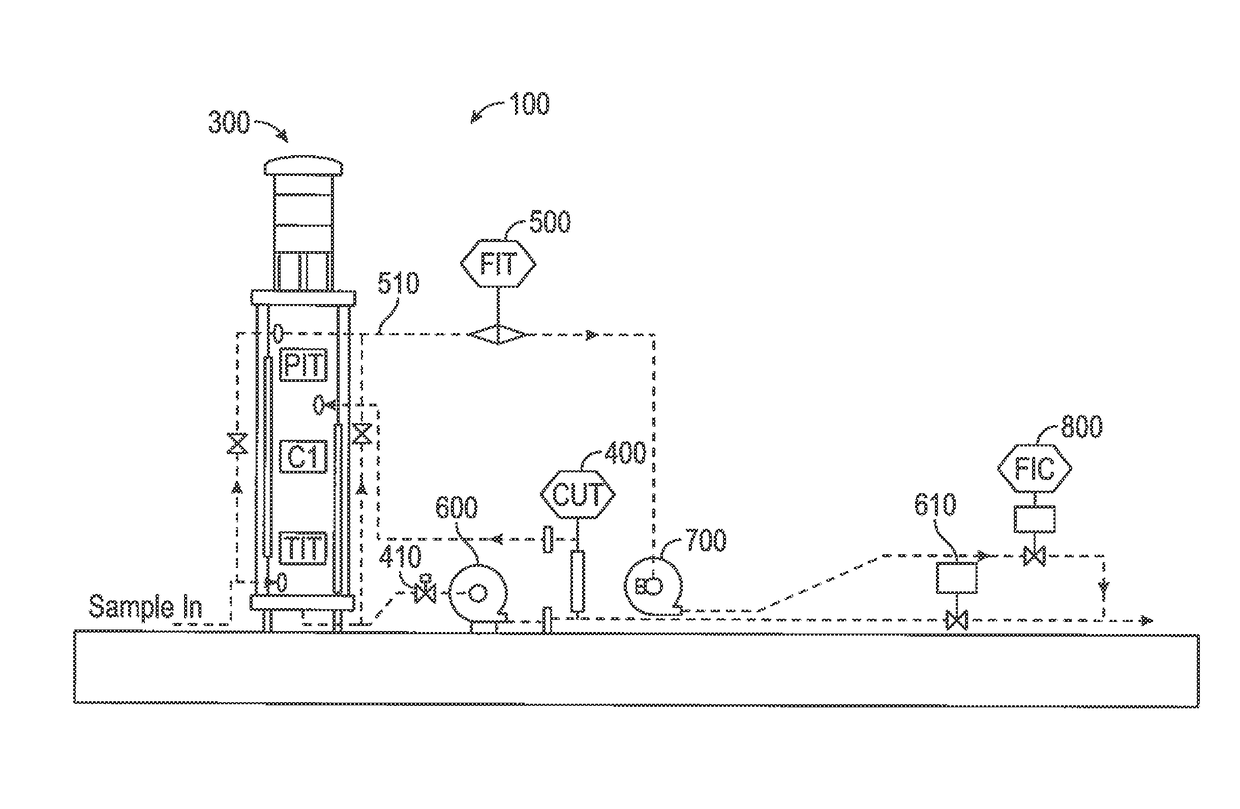

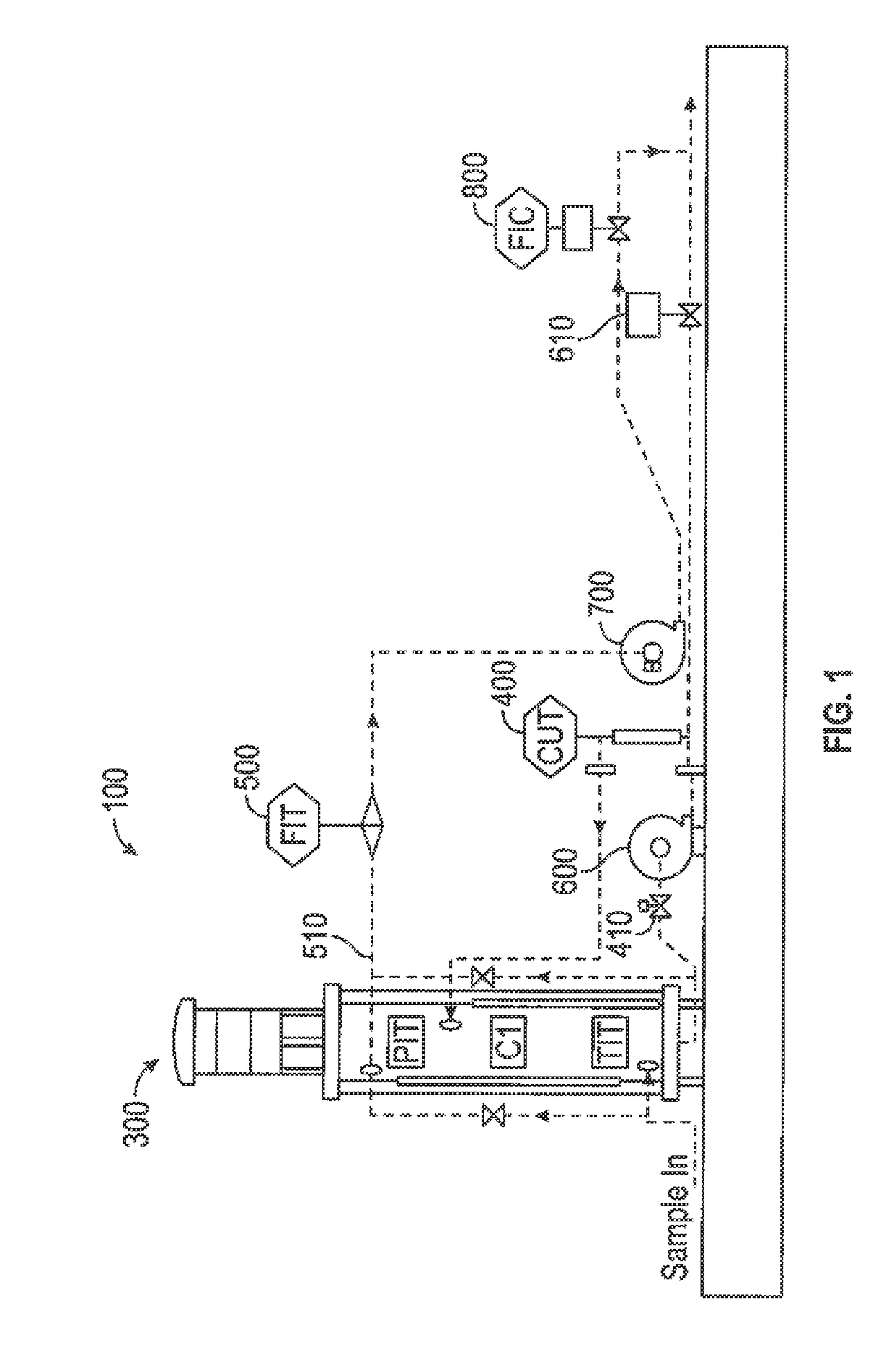

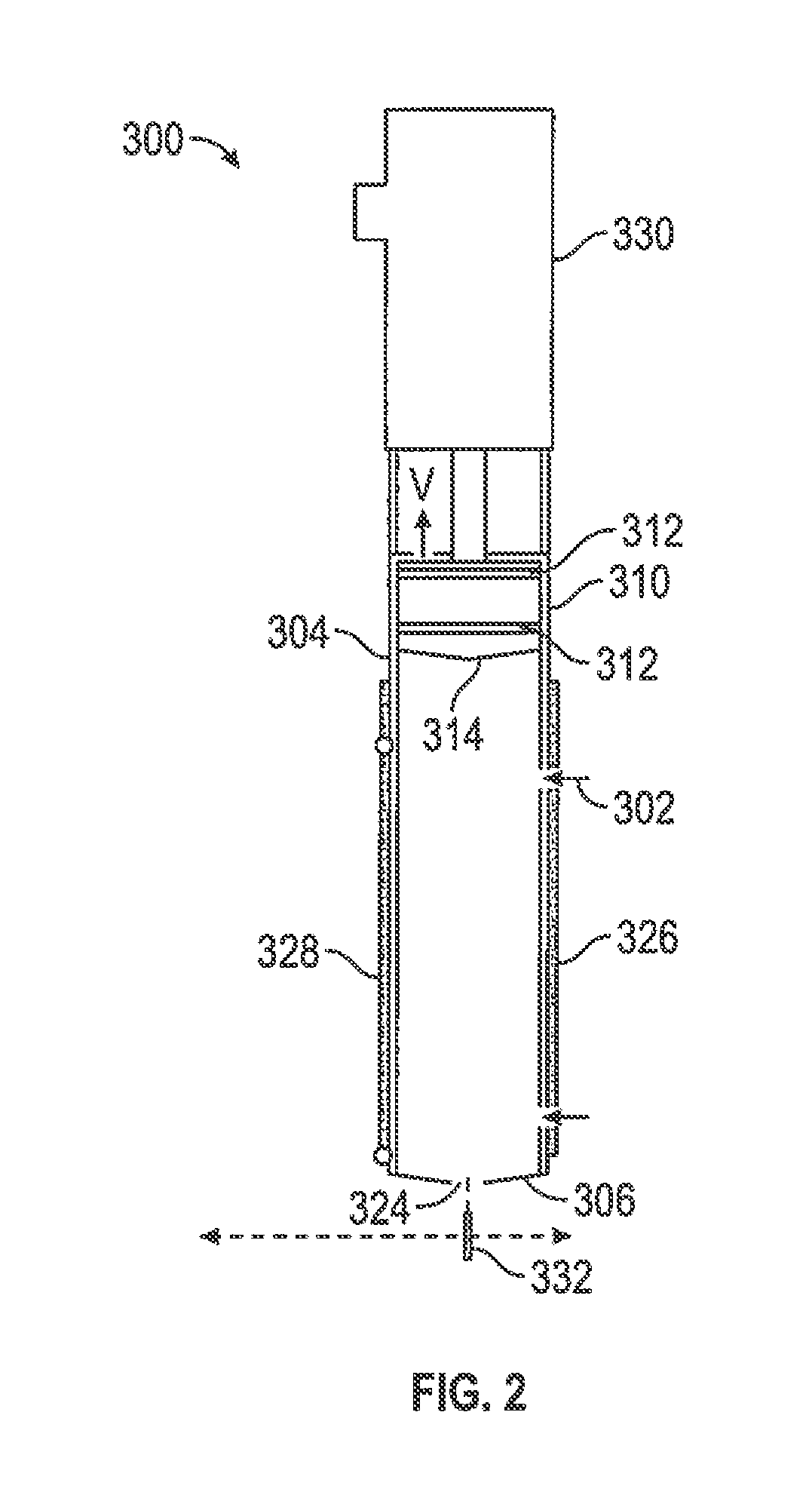

Hydrocarbon Well Production Analysis System

InactiveUS20170342824A1Improve accuracyEfficient cleaningSurveyWithdrawing sample devicesCirculating pumpOil well

An oil well production analyzing system receives production fluid samples from the oil well according to an automated sampling schedule. The fluid samples are taken from a pipeline through a sampling apparatus to obtain a representative sample. The representative sample flows into a circulation loop having a circulating pump, a water cut analyzer, and a cylindrical vessel, with interconnecting piping and actuated valves there between, with the actuated valves and the circulating pump controlled by a digital processor. Once a determination of the percentage of water and oil in the sample has been determined, the processor stops the circulating pump and activates a piston in the cylindrical vessel which sweeps the cylindrical vessel of any fluid contained in the vessel in preparation of receiving a subsequent fluid sample from the oil well.

Owner:DWT SOLUTIONS

Simulation method for researching influence of environment temperature on novel overload protection relay temperature

The invention belongs to the thermal overload protection field of a motor and especially relates to a simulation method for researching an influence of an environment temperature on a novel overload protection relay temperature. The method comprises the following steps of S1, constructing the structure of a novel overload protection relay heating component; S2, based on ANSYS finite element software, using a solid modeling mode to establish a heating-component three-dimensional geometric model, and then carrying out material physical parameter determination, unit type determination and grid division on the heating-component three-dimensional geometric model; S3, carrying out heat production analysis on a terminal and a heating component, wherein heat component heating satisfies the following formula: P=I<2>R, and the heat generation rate of a heat component satisfies the following formula: Q1=P / V; S4, carrying out heat dissipation analysis on the terminal and the heating component, wherein a convection heat dissipation coefficient formula is acon=3.25(T0-TF)<0.25>; S5, determining the boundary condition of temperature field simulation calculating and load applying; S6, calculatingthe stable state temperature field of the heating component under a normal condition; and S7, changing the initial temperature condition of simulation and simulating the temperatures of the heating component in different environments.

Owner:株洲市智汇知识产权运营服务有限责任公司

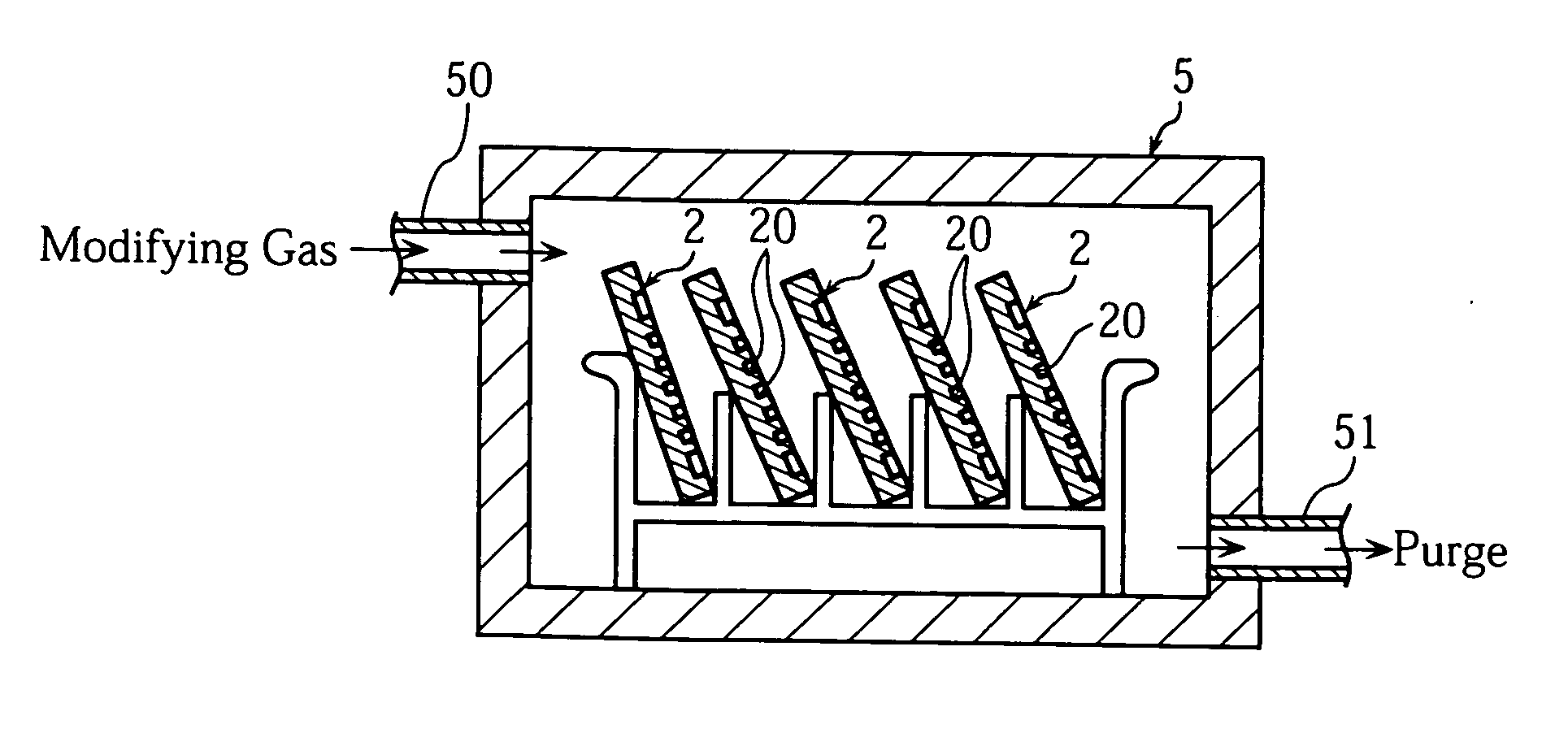

Method of producing analytical tool

InactiveUS20060118403A1Simple structureReduce manufacturing costOther chemical processesComponent separationEngineeringAnalysis tools

Owner:ARKRAY INC

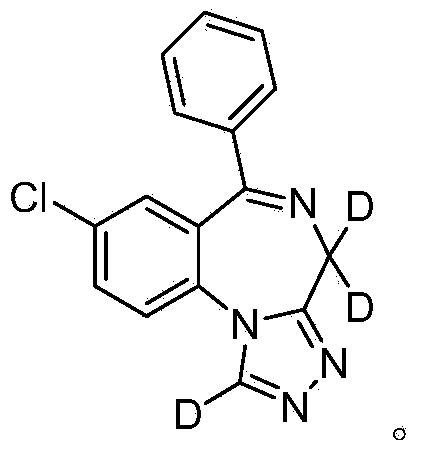

Deuterated estazolam and preparation method thereof

InactiveCN103864798AEasy to prepareSimple and fast operationOrganic chemistryDeuterated chloroformEstazolam

The invention discloses deuterated estazolam and a preparation method thereof. The preparation method comprises following steps of (1) adding 6-phenyl-8-chlorine-4H-[1,2,4] triazole-[4,3-a][1,4] benzo-diazepine into dimethyl sulfoxide or N,N-dimethylformamide, mixing and stirring; (2) adding a catalyst cesium carbonate or potassium carbonate as well as deuterated chloroform, stirring and heating up to over 40DEG C; and (3) separating so as to obtain deuterated estazolam. The preparation method is concise, is simple and convenient to operate, has low cost, and is easy for purification. Commercially available non-deuterated estazolam can be converted into deuterated estazolam by a little deuterated reagent used as a deuterium source in the non-deuterated solvent atmosphere in shorter time, and a pure product can be obtained through simple purification by column chromatography. The standard deuterated estazolam prepared by the method has high purity and stable chemical property, and is convenient for preparing standard substances for analysis. The preparation method can be used for producing, analyzing and detecting the deuterated internal standard substance used by estazolam.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

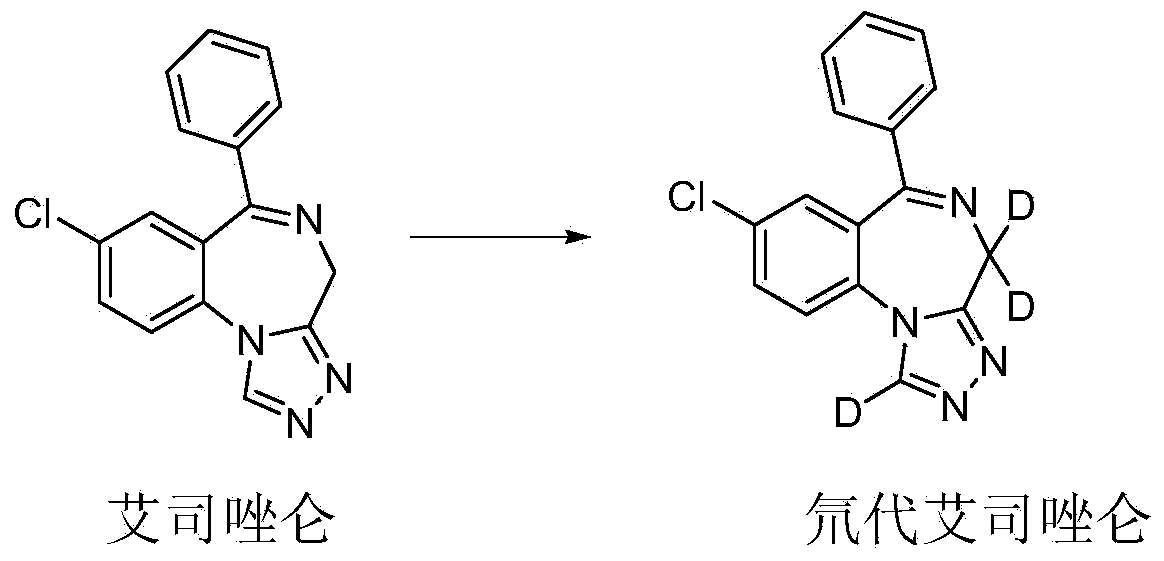

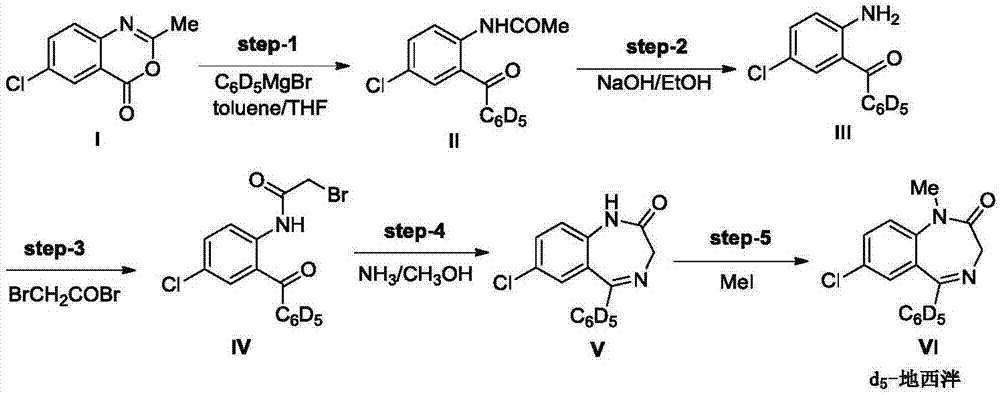

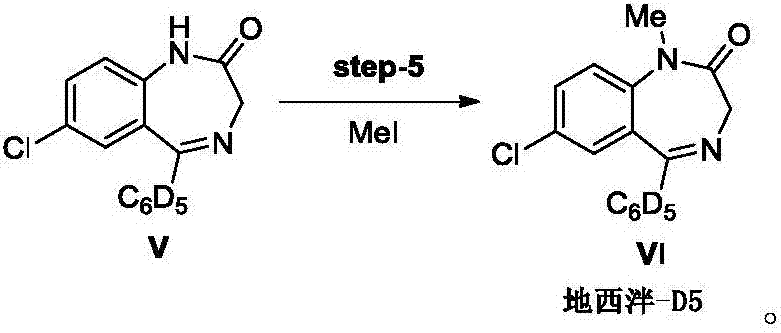

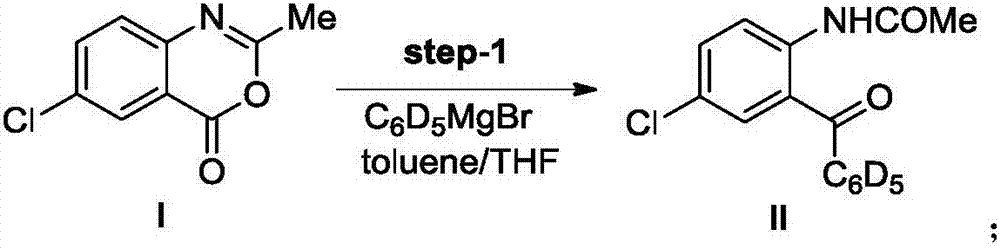

Diazepam-D5 preparation method

ActiveCN107365276AImprove product qualityImprove stabilityIsotope introduction to heterocyclic compoundsDiazepamInternal standard

The invention discloses a diazepam-D5 preparation method. According to the method, 6-chlorine-2-methyl-4H-3, 1-benzoxazine-4-ketone (a compound as shown in a formula) serves as a raw material, and the 6-chlorine-2-methyl-4H-3, 1-benzoxazine-4-ketone and deuterated bromobenzene reagents are reacted, hydrolyzed, acylated, cyclized, methylated, separated and purified to obtain diazepam-D5. The preparation method has the advantages of mild reaction condition, simple in operation and the like, and a diazepam-D5 standard product prepared by the method is high in chemical purity and good in quality and stability and can be conveniently used for analyzing preparation of standard products. The preparation method can be used for producing deuterated internal standard substances when the diazepam-D5 is analyzed and detected.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

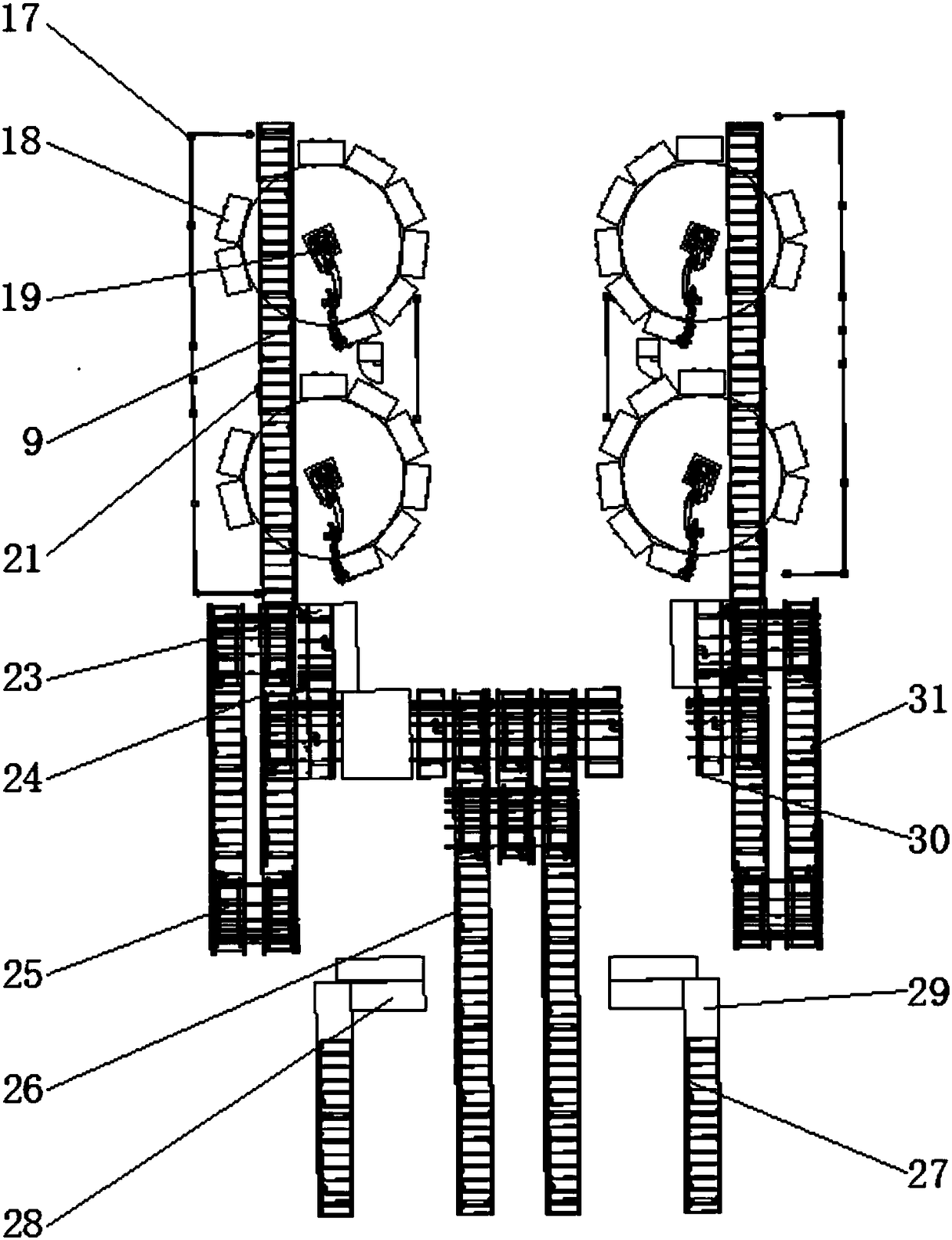

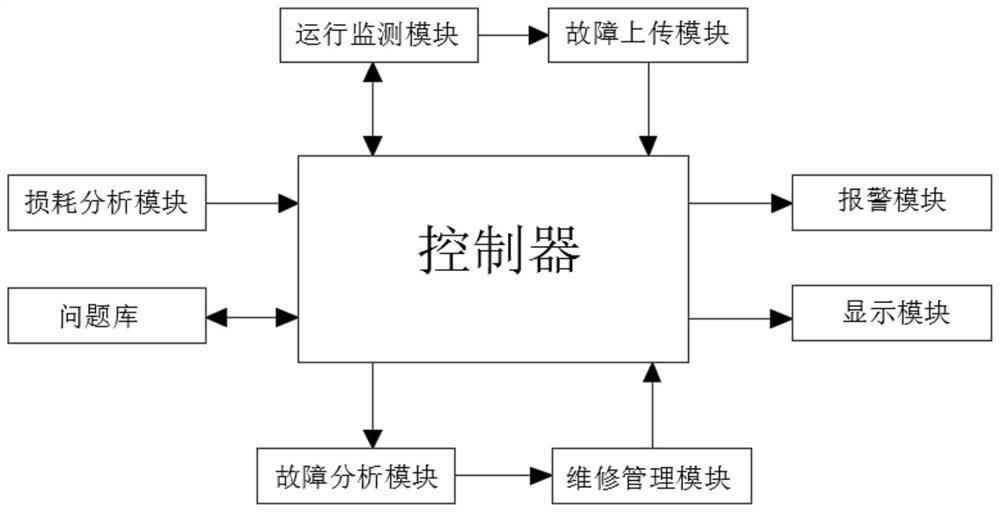

Control system of double-station magnetic sheet arrangement machine

ActiveCN114035466AAvoid affecting work efficiencyIncrease productivityProgramme controlComputer controlControl systemControl engineering

The invention discloses a control system of a double-station magnetic sheet arrangement machine, relates to the technical field of double-station magnetic sheet arrangement machines, and solves the problems that the working efficiency of the double-station magnetic sheet arrangement machine is affected due to long-time continuous work, remote monitoring is inconvenient, and early warning cannot be made in advance. The control system includes a loss analysis module, a controller, an operation monitoring module and a fault analysis module. The loss analysis module is used for carrying out loss coefficient analysis according to historical operation records of the double-station magnetic sheet arrangement machine; in response to the received production analysis signal, the operation monitoring module is used for collecting and analyzing operation parameter data of the double-station magnetic sheet arrangement machine according to a preset interval, judging whether the double-station magnetic sheet arrangement machine operates normally or not, and performing early warning in time; the fault analysis module is used for carrying out fault coefficient evaluation on the fault part to obtain a corresponding part maintenance table; maintenance personnel can conveniently and sequentially detect the parts according to the corresponding part maintenance tables, and the maintenance efficiency is effectively improved.

Owner:肇庆高峰机械科技有限公司

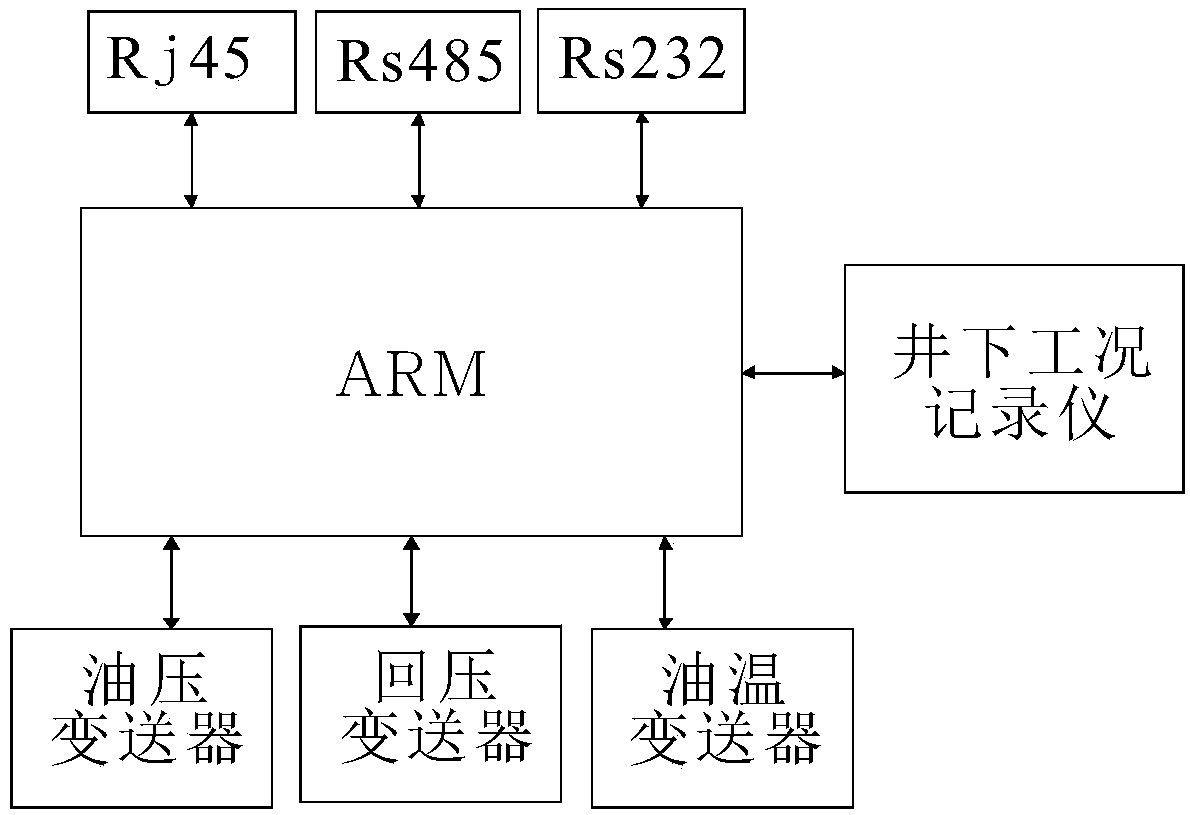

Electric submersible pump well production IOT system

PendingCN108333990ARealize remote controlLow input costProgramme controlComputer controlData interfaceRemote data transmission

The invention provides an electric ground pump well production IOT system, relating to the technical field of petroleum development. The system includes: a remote terminal controller, an oil pressuretransmitter, a back pressure transmitter, an oil temperature transmitter and downhole condition recorder; the oil pressure transmitter, the back pressure transmitter and the oil temperature transmitter are connected to the electric submersible pump well and connected to the remote terminal controller through the RS232 data interface; the downhole working condition recorder is connected to the electric submersible pump and connected to the remote terminal controller through the RS485 data interface; the oil pressure transmitter, the back pressure transmitter, the oil temperature transmitter andthe downhole condition recorder send the collected downhole data to the ARM processor of the remote terminal controller; the remote terminal controller accesses the IOT system to report downhole datathrough the RJ45 network interface. The system can realize oil quantity monitoring without deploying equipment such as metering separator, and realizes remote data transmission and storage by using IOT technology, providing big data and providing scientific basis for production analysis.

Owner:天津仪控科技有限公司

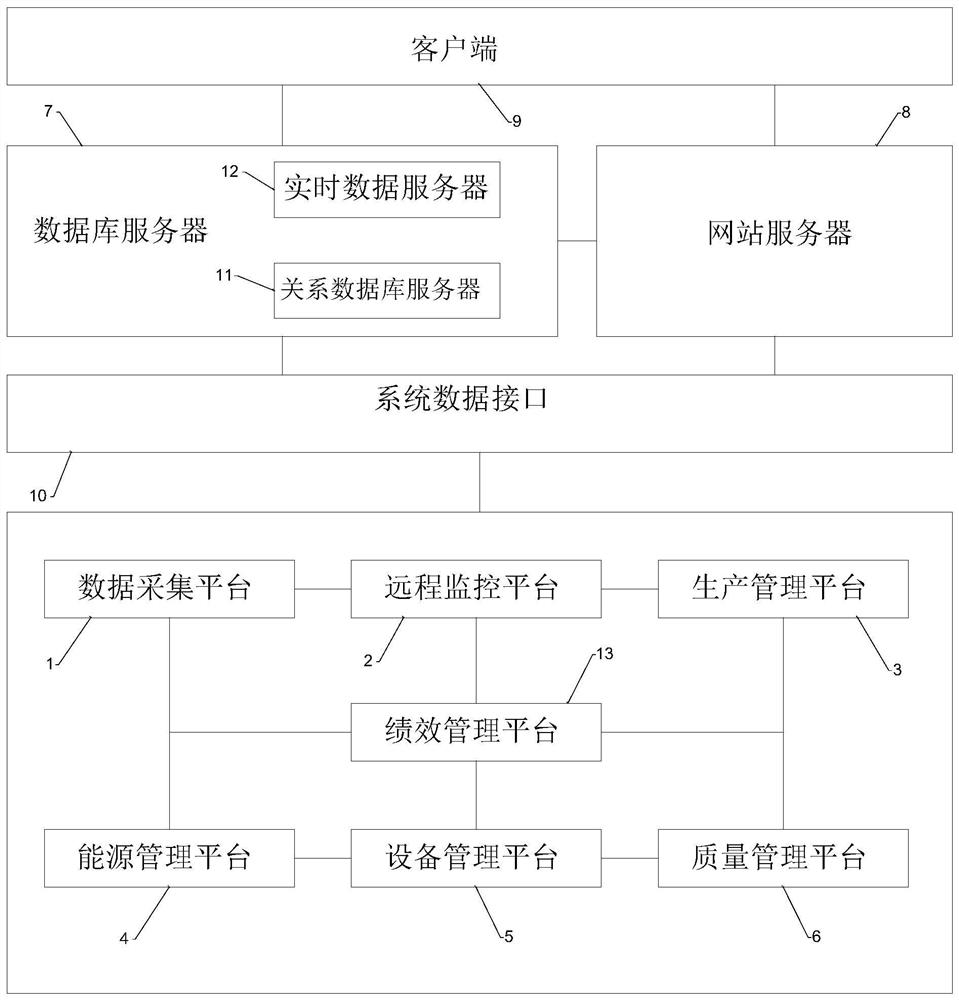

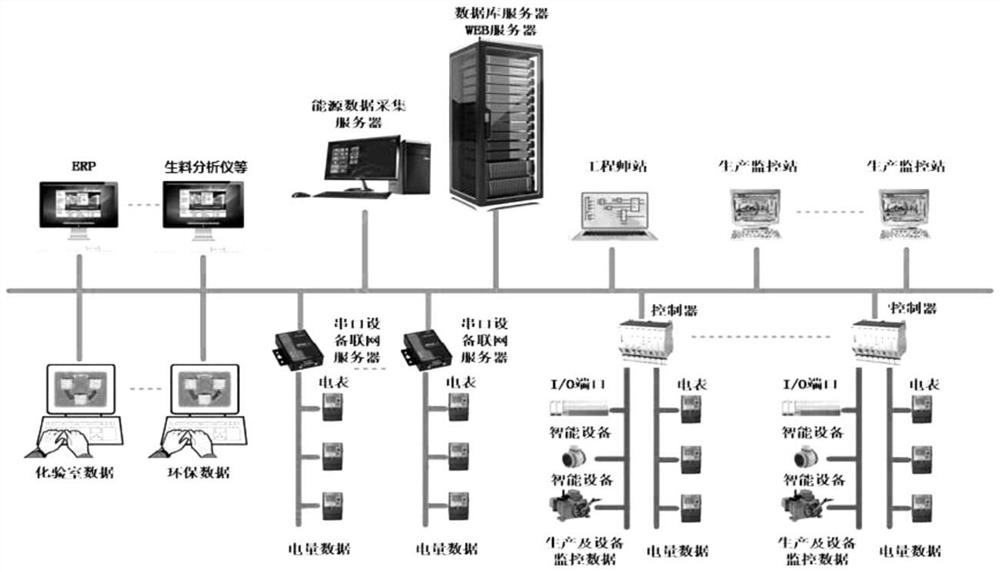

Intelligent unattended factory system for cement production line

InactiveCN111650901ASatisfy the balanceMeet Scheduling ManagementEnergy industryTotal factory controlInformation repositoryData acquisition

The invention discloses an intelligent unattended factory system for a cement production line. A data acquisition platform acquires and reflects equipment operation conditions and process parameter data; the remote monitoring platform monitors parameters of energy metering and carries out energy data real-time alarm by setting an alarm threshold value, and remote monitoring, data analysis, automatic report and system fault alarm and analysis of operation equipment in the cement generation process are carried out through the remote monitoring platform. The production management platform managesa cement production plan, production scheduling, material balance, production analysis and a production report; the energy management platform monitors the energy material consumption in real time and diagnoses and evaluates the energy utilization state; the equipment management platform establishes an equipment archive information base; and the quality management platform collects and integratesthe product quality data to form a quality information database of the whole process from raw material factory entering to product factory leaving, and performs quality analysis management accordingto the quality information database. According to the invention, efficient operation of cement production and effective control of cost are achieved.

Owner:北京坚构创新科技有限公司

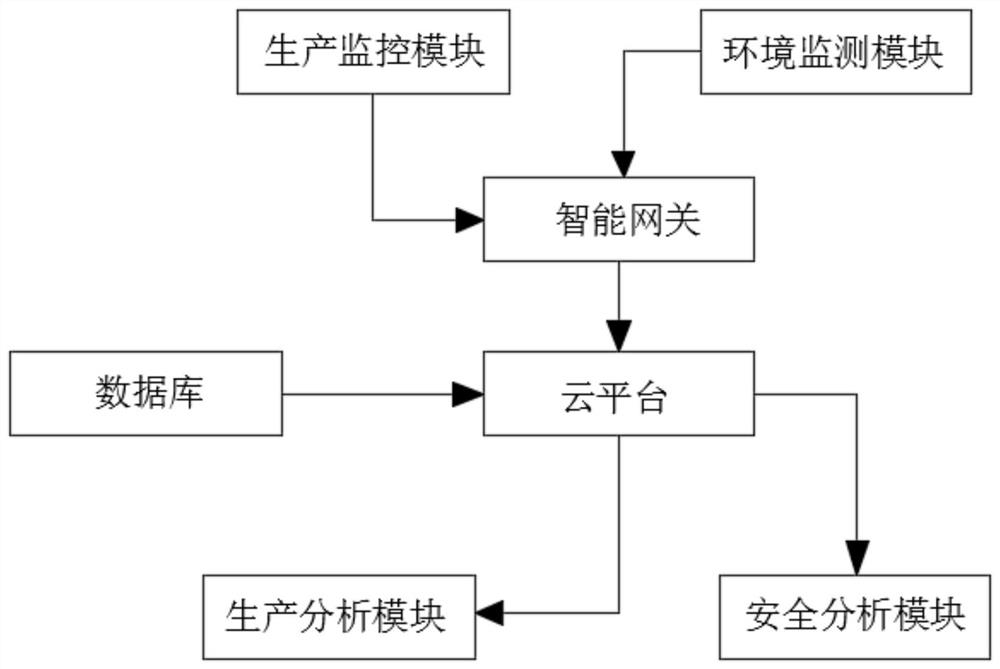

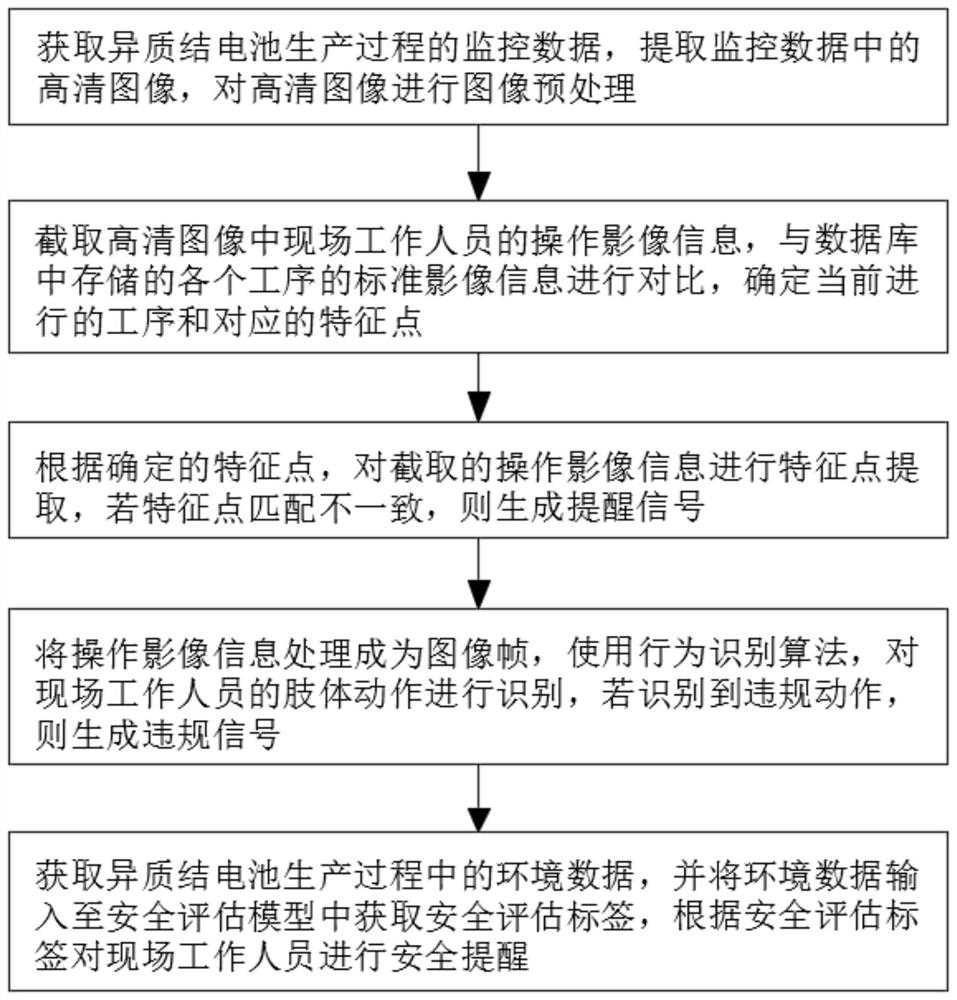

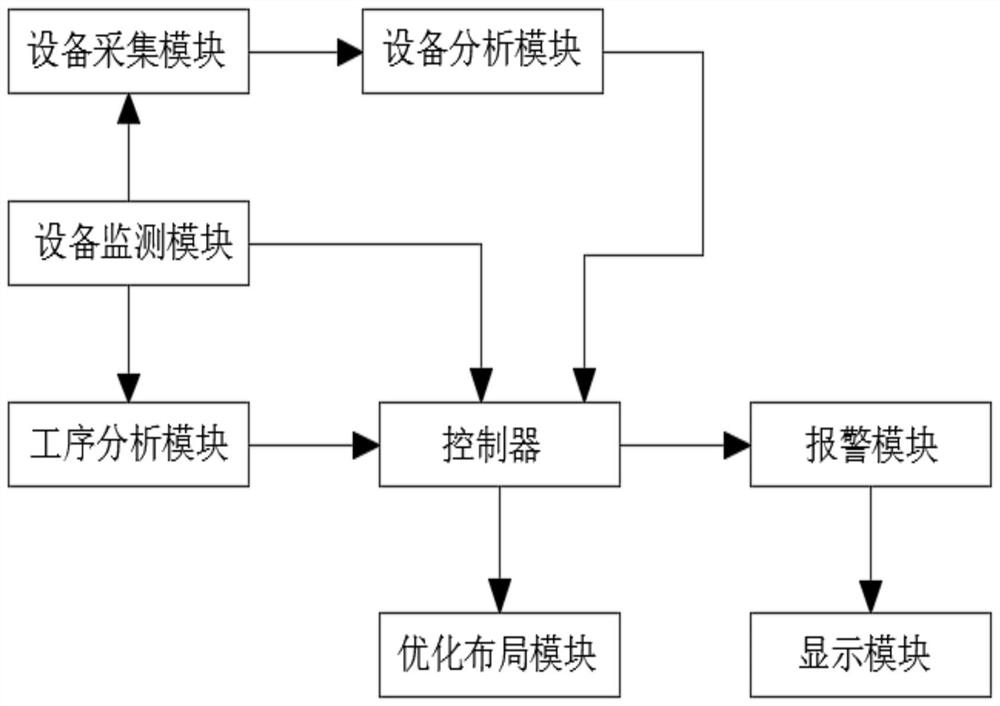

Heterojunction cell production monitoring system and method

PendingCN114358242AIncrease productivityImprove production safetyCharacter and pattern recognitionAlarmsHeterojunctionElectrical battery

The invention discloses a heterojunction cell production monitoring system and method, and relates to the technical field of solar cells, and the system comprises a production monitoring module, a production analysis module, a safety analysis module, an environment monitoring module and a cloud platform. The production analysis module is used for acquiring and analyzing monitoring data of a production field, intercepting operation image information of field workers to perform feature point extraction, and judging whether the operation of the field workers is standard or not; meanwhile, a behavior recognition algorithm is used for recognizing limb actions of field workers, and when the field workers do not operate in a standard or rule-breaking mode, an alarm is given in time to remind the field workers to correct in time, so that production monitoring is automatic, and the production efficiency is improved; and the safety analysis module is used for receiving the environment data collected by the environment monitoring module, inputting the environment data into a safety evaluation model to obtain a safety evaluation label, and then carrying out safety reminding on field staff according to the safety evaluation label, so that the production safety is improved.

Owner:CHINALAND SOLAR ENERGY

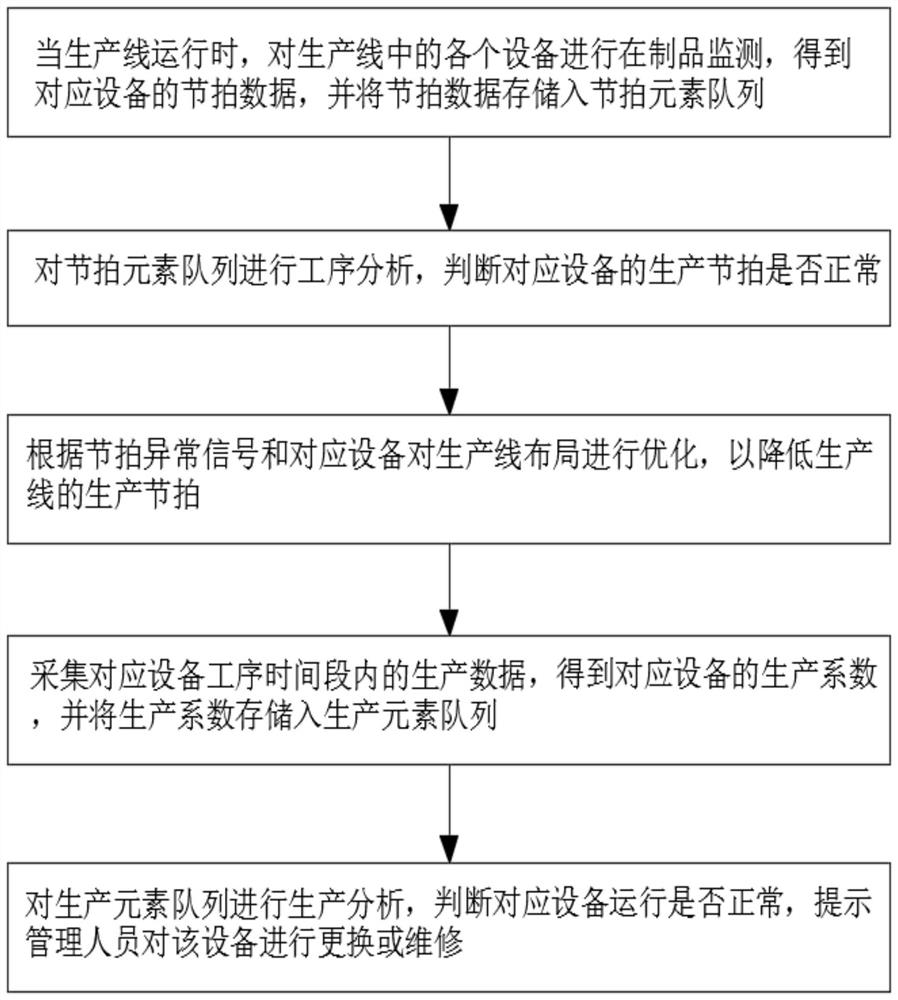

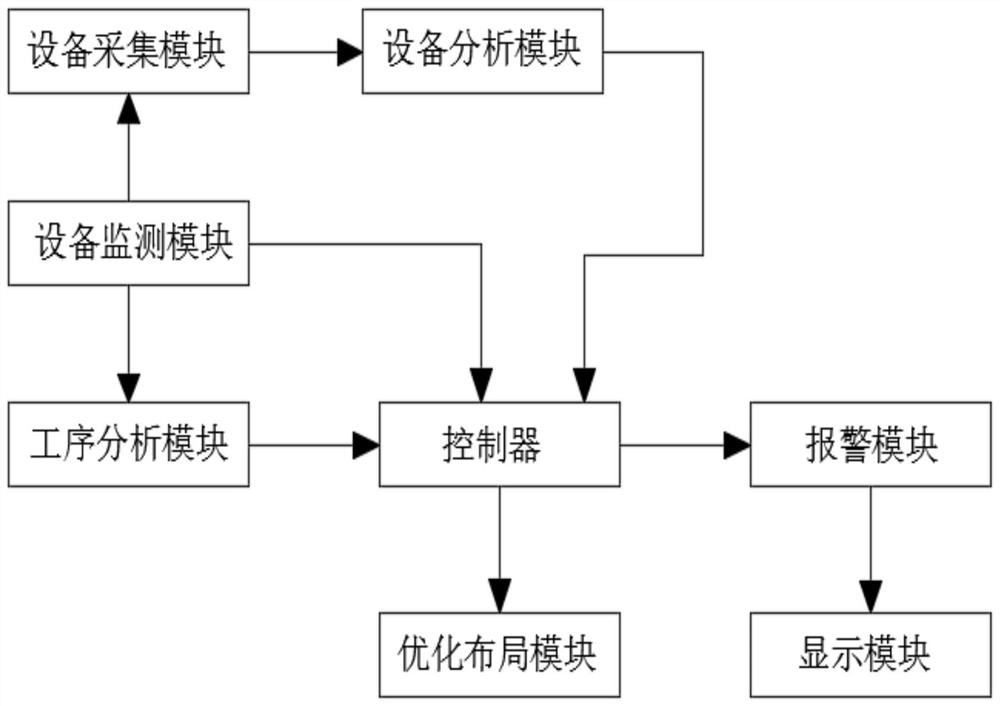

Cloud platform data management system based on industrial big data and construction method thereof

PendingCN113962439AShorten the takt timeIncrease production capacityForecastingManufacturing computing systemsThe InternetIndustrial Internet

The invention discloses a cloud platform data management system based on industrial big data and a construction method thereof, and relates to the technical field of industrial Internet. The system comprises an equipment monitoring module, a controller, a process analysis module, an optimization layout module, an equipment collection module and an equipment analysis module. When a production line runs, an equipment monitoring module performs in-process monitoring on each piece of equipment in the production line to obtain beat data of the corresponding equipment, and stores the beat data into a beat element queue; the procedure analysis module analyzes the rhythm element queue and judges whether the production rhythm of the corresponding equipment is normal or not; the layout optimization module optimizes the layout of the production line according to the rhythm abnormal signal and the corresponding equipment so as to reduce the production rhythm of the production line and improve the productivity of the production line; and the equipment analysis module is used for carrying out production analysis on the production element queue, judging whether the corresponding equipment runs normally or not, and prompting management personnel to replace or maintain the equipment, so that the production efficiency is improved, and the energy consumption is reduced.

Owner:郭志良

Aluminium-scandium alloy standard spectrum sample and preparation method thereof

InactiveCN100417930CAdd evenlyAdjust and control elemental chemical compositionPreparing sample for investigationColor/spectral properties measurementsScandiumProduction analysis

This invention relates to a aluminium-scandium alloy standard spectrum sample and preparation method, <0}wherein, the sample comprises: Si 0.045~0.27%, Fe 0.07~0.37%, Cu 0~0.11%, Mn 0.13~1.2%, Mg 4.3~7.8%, Cr 0~0.27%, Ni 0~0.11%, Zn 0~0.17%, Sc 0.03~0.54%, Ti 0~0.18%, Zr 0.025~0.22%, Be 0.00005~0.0035% and B 0.0005~0.010%. The preparation relates to smelting, casting, homogenizing, lathing surface, and extruding. This invention meets practical demand, and provides foundation for production of 5A70 and 5A71 series Al-alloy.

Owner:SOUTHWEST ALUMINUM GRP

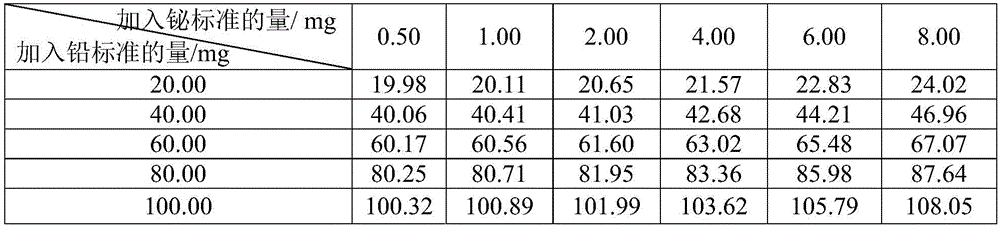

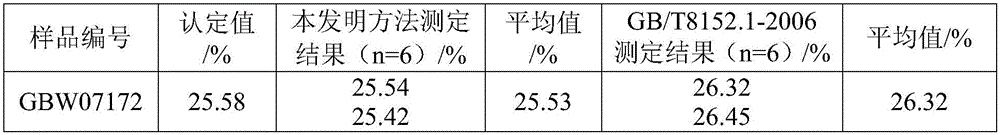

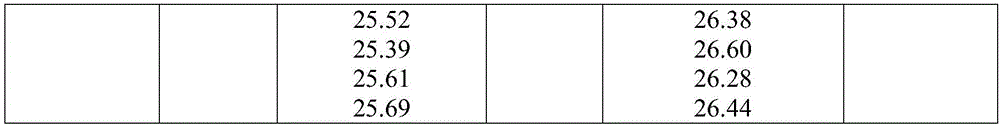

Method for eliminating bismuth interference in determination of lead content of mineral by EDTA (ethylenediaminetetraacetic acid) volumetric method

InactiveCN105784919AEliminate distractionsSimple methodChemical analysis using titrationAcetic acidLead acetate

The invention discloses a method for eliminating bismuth interference in the determination of lead content of a mineral by EDTA (ethylenediaminetetraacetic acid) volumetric method. The method using the mineral as a specimen includes the steps of specimen digesting, acid driving, lead sulfate precipitate forming, lead sulfate precipitate dissolving, and titrating. The method is differed from the prior art in that before titrating lead acetate solution obtained in the step of lead sulfate precipitate dissolving, 2,3-dimercaprol is added; the 2,3-dimercaprol is used to react with bismuth to generate a substance with a stability constant higher than that of Bi-EDTA, the interference due to the presence of bismuth in the determination of lead content of the mineral by EDTA volumetric method is effectively eliminated accordingly, and the method is simple and quick, has reliable results and can meet the production analytical requirement.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com