Hydrocarbon Well Production Analysis System

a well and production analysis technology, applied in the field of on-site analysis of fluids, can solve the problems of insufficient gravity alone, difficult to determine relative percentages of emulsions, and high cost of separation devices, so as to facilitate maintenance and repair, and efficiently sweep the cylinder clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

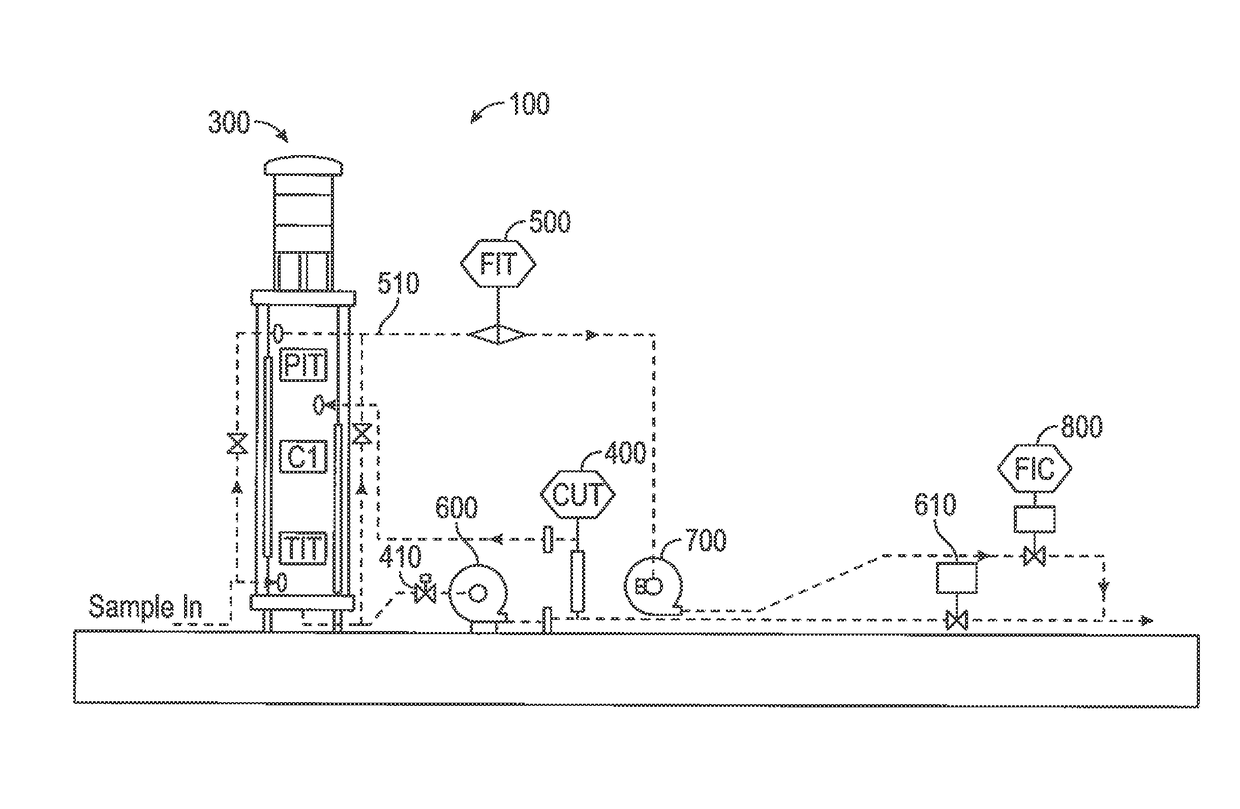

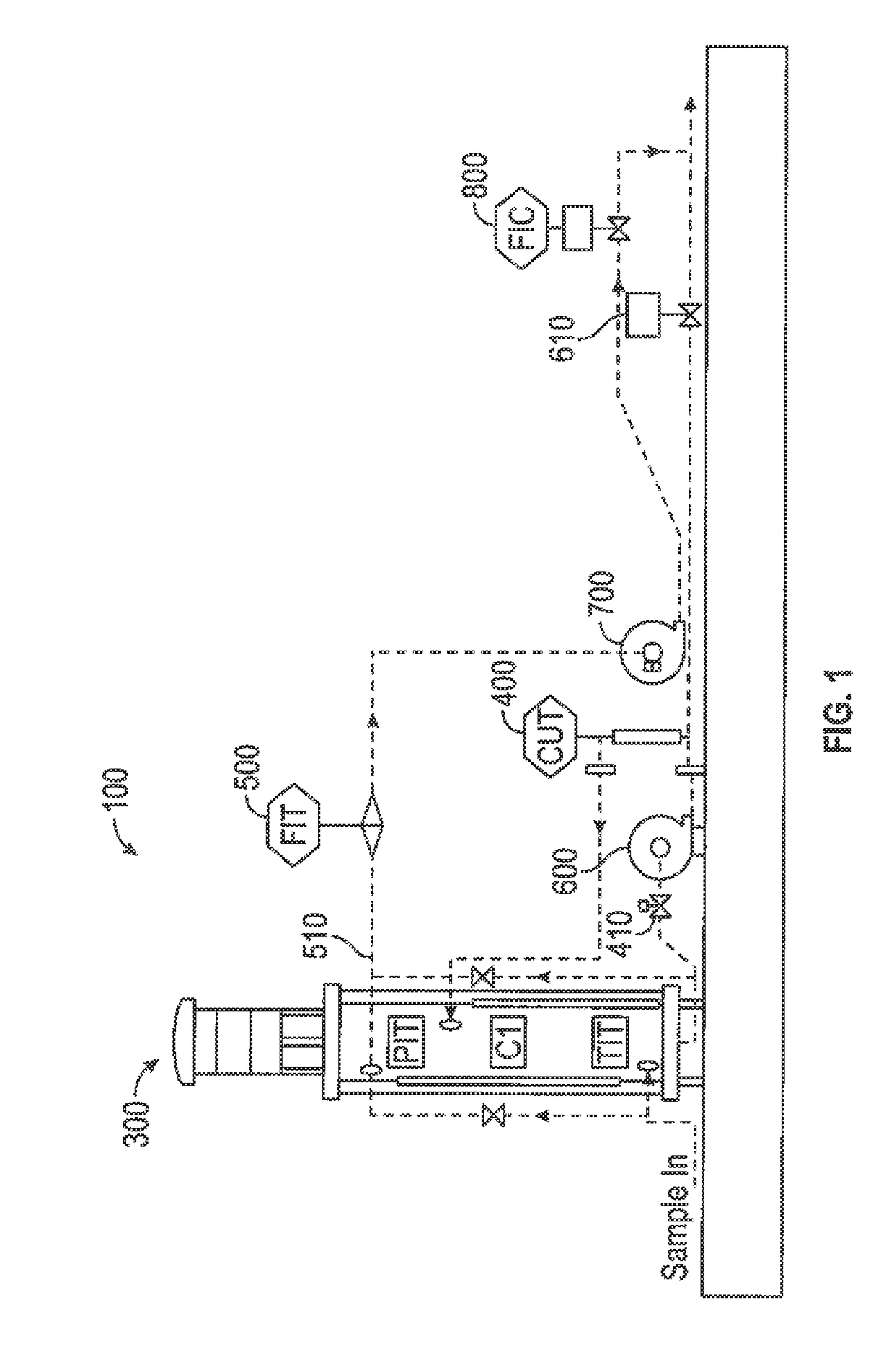

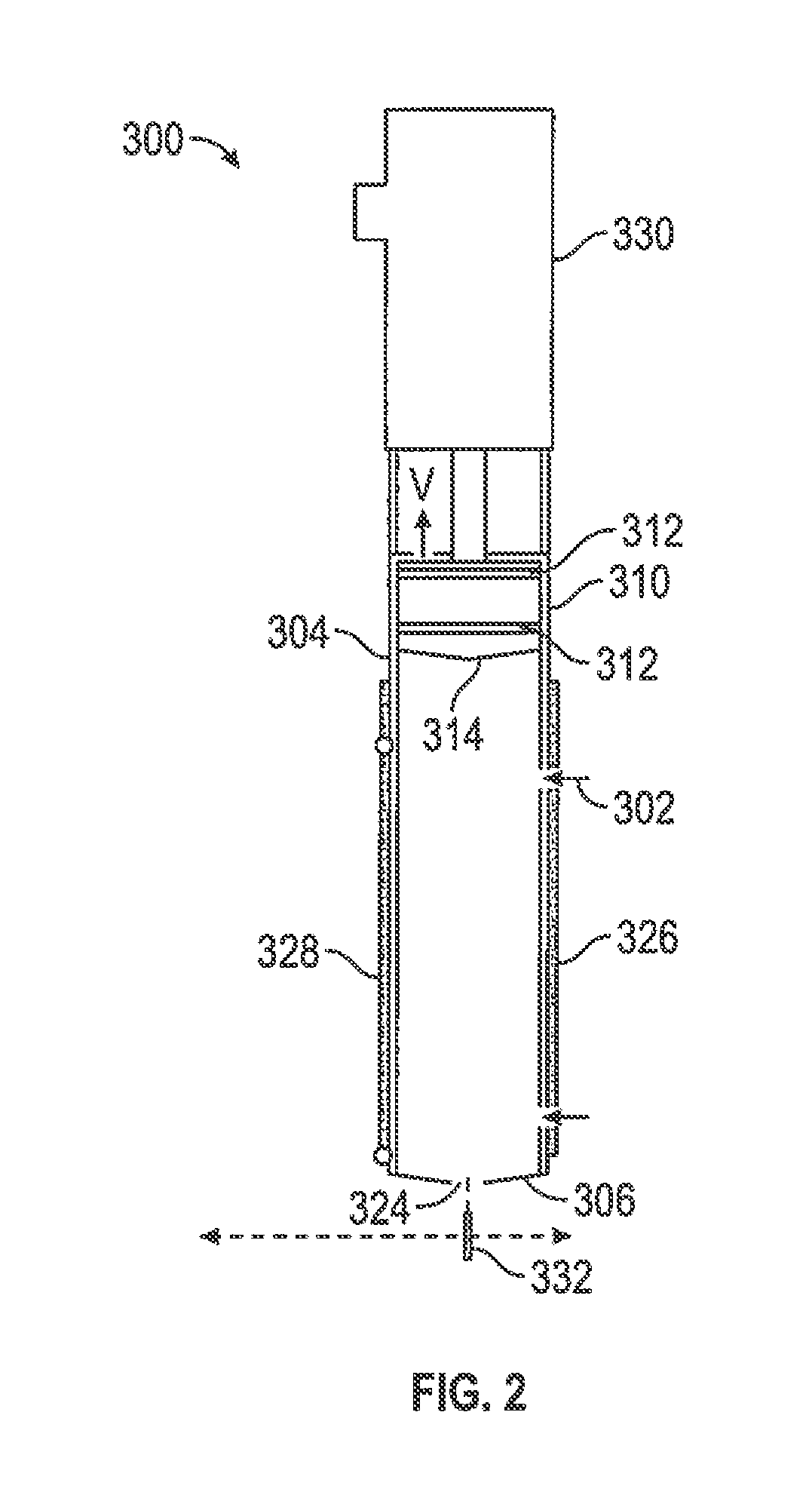

[0038]FIG. 1 schematically depicts an embodiment of the presently disclosed hydrocarbon well production analysis system 100 according to the present invention. A fluid sampling system 200 for obtaining a representative fluid sample from pipeline 10 is described in further detail below. With respect to the hydrocarbon analysis system depicted in FIG. 1, the major components of this embodiment include cylindrical vessel 300, water cut analyzer 400, gas flow meter 500, circulating pump 600, gas compressor 700, and flow control valve 800. A digital processor 1000, not shown in FIG. 1, provides, among other things, control of the process flow of the analysis system and reporting of the analysis results. It is to be appreciated that the components of the production analysis system 100 may be relatively small, fitting within an instrument cabinet or mounted on a transportable skid for easy movement between locations. Flow volumes may be relatively small and interconnecting piping may be ½ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com