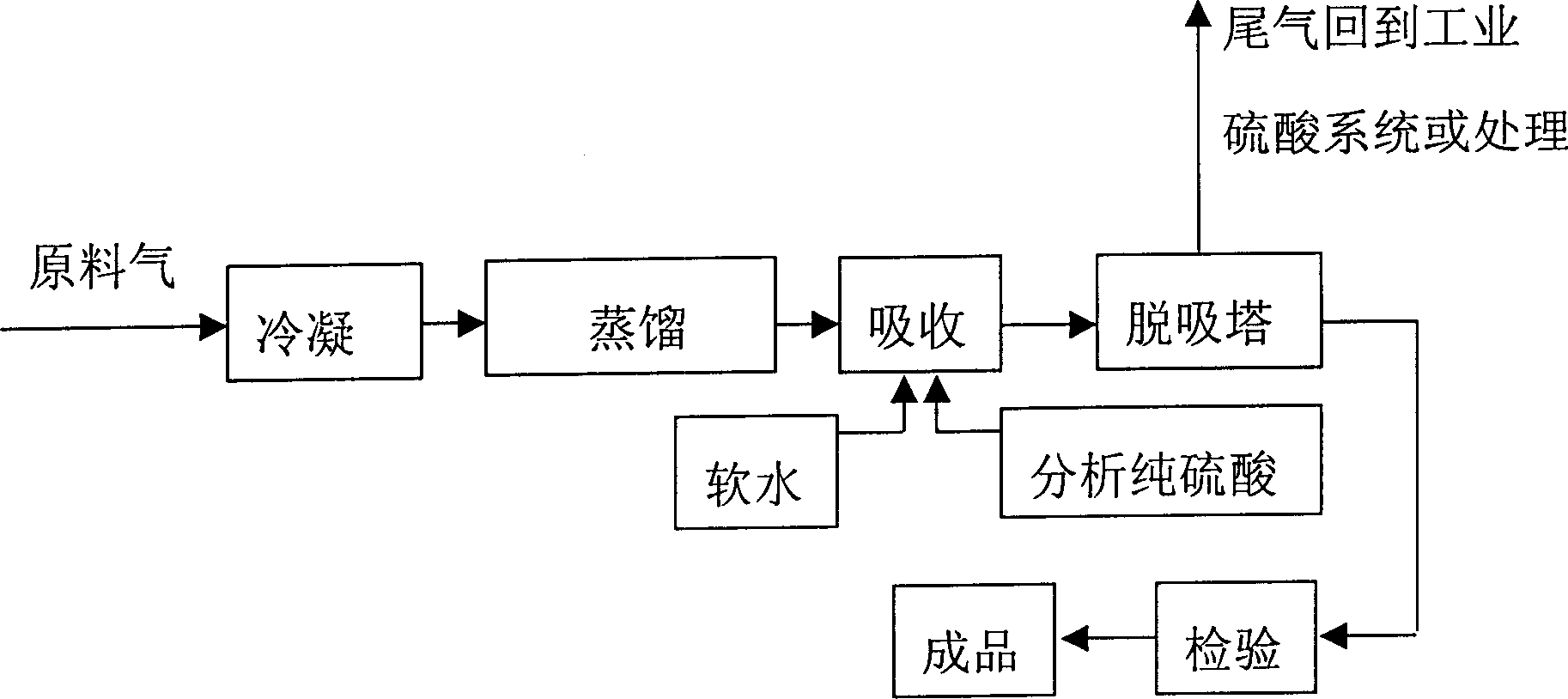

Analytical pure sulfuric acid production process

A sulfuric acid production and process technology, applied in the field of analytical pure sulfuric acid, can solve problems such as increased operation, equipment management, damage, accelerated equipment corrosion, etc., and achieves the effects of easy device maintenance and management, reduced production costs, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Embodiment: Get 800kg of high-concentration sulfur trioxide gas as raw material gas and condense it into a liquid at a temperature of 30-40°C through a condenser, and distill the sulfur trioxide condensed into a liquid at a temperature of 60-80°C with a glass-lined reactor to become The gas is sent to the absorption tower for absorption, the absorption liquid is qualified analytical pure sulfuric acid, the concentration of analytical pure sulfuric acid is adjusted with soft water, and then the product is desorbed in the desorption tower by the negative pressure generated by the vacuum pump to make the dissolved The sulfur dioxide in the product is deabsorbed and removed (returned to the industrial sulfuric acid production system or treated separately), and the qualified product is sent to the finished product warehouse to obtain about 1000kg of analytically pure sulfuric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com