Patents

Literature

428 results about "Transient temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

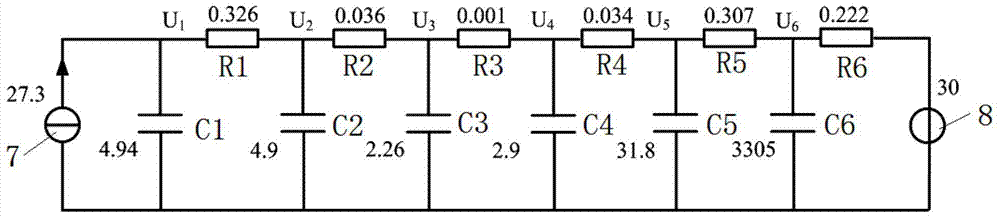

The transient temperature calculation is based on a dynamic thermal model of the raceway system, constructed mainly from thermal resistance, thermal capacitance, and heat sources. The thermal resistance is used to represent different thermal layers from the cable conductor to ambient soil.

Method and apparatus for analyzing a downhole fluid using a thermal detector

InactiveUS20060175547A1Material analysis by optical meansAbsorption/flicker/reflection spectroscopyElectricityPath length

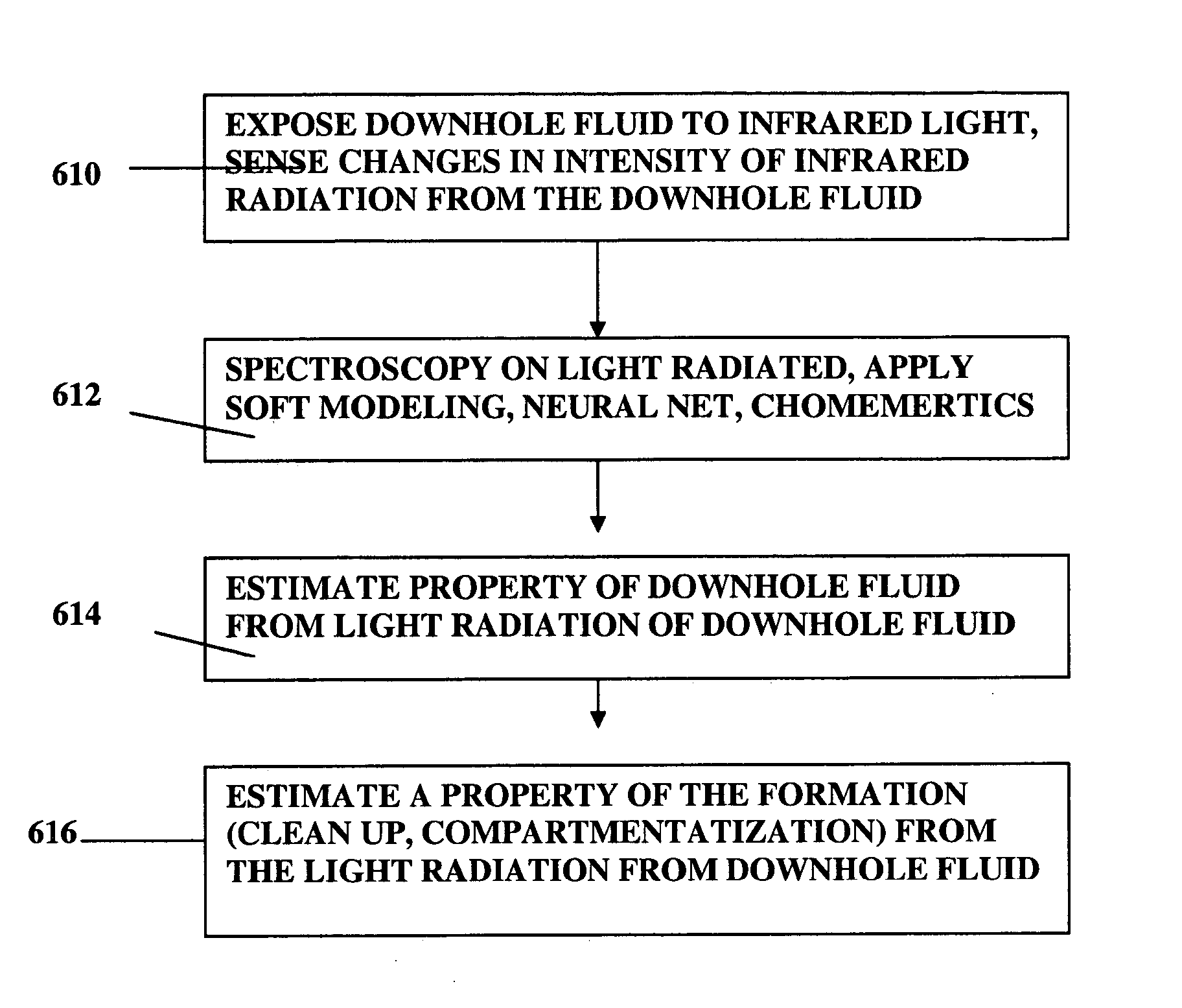

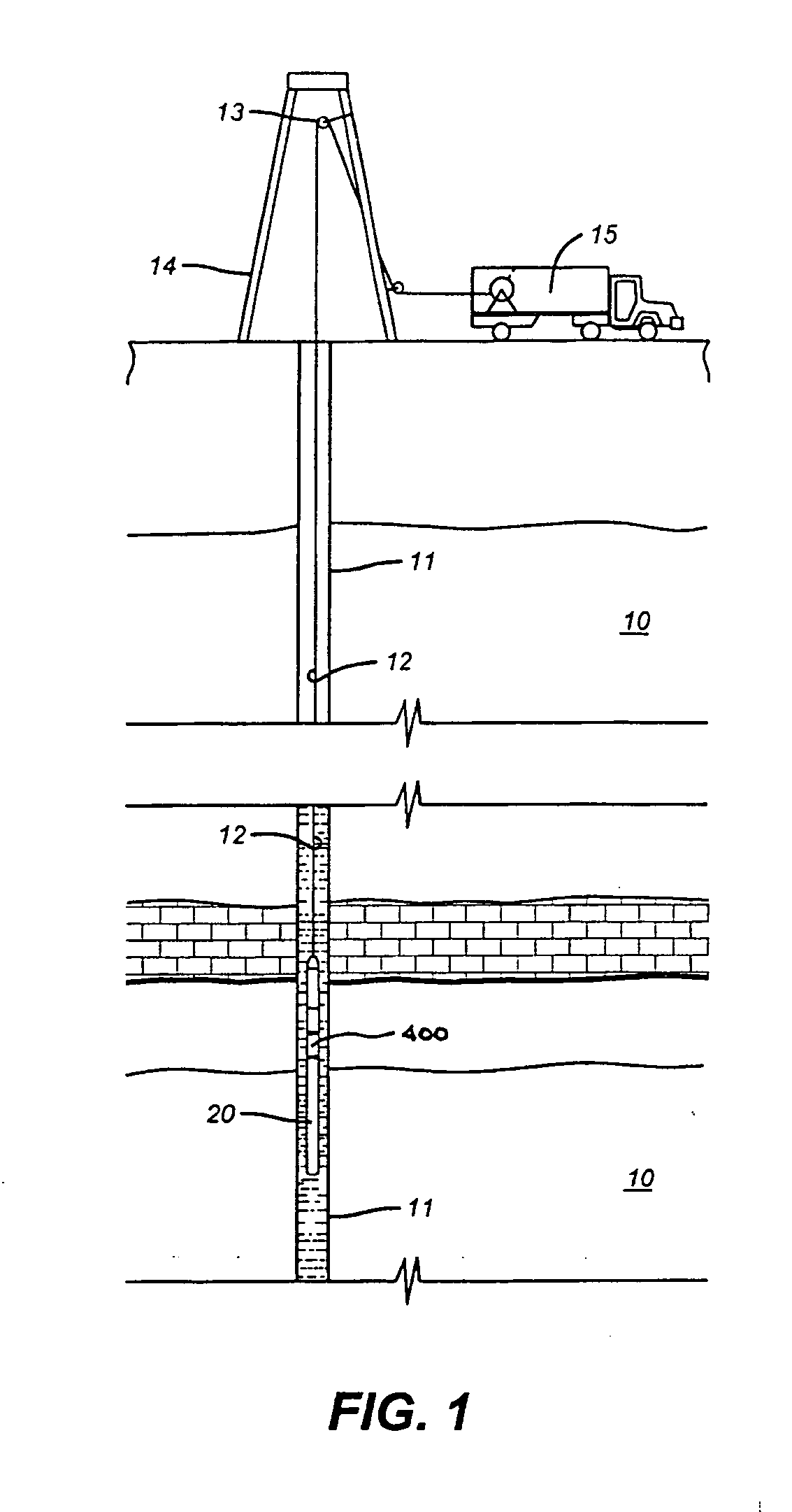

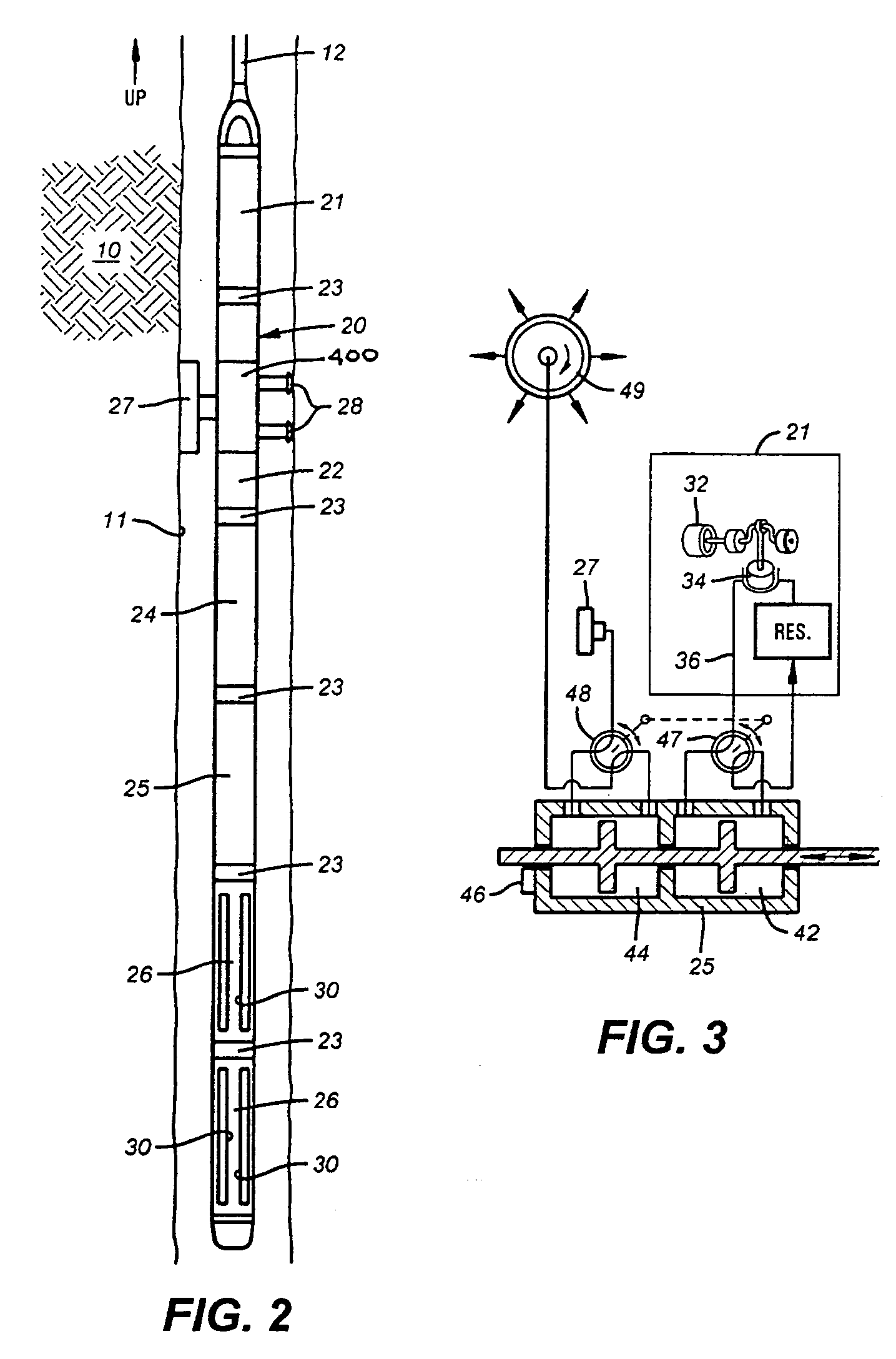

The present invention provides a method and apparatus for estimating a property of a fluid downhole by exposing the fluid to modulated light downhole and sensing changes in intensity of infrared radiation from the downhole fluid to estimate the property of the downhole fluid. The present invention senses changes in intensity of light by converting the changes to transient changes in temperature of a detector, such as a pyroelectric detector. The present invention performs spectroscopic analysis of fluids by optically filtering the light allowed to impinge on a pyroelectric detector, converting the changes in temperature of the pyroelectric detector to a signal and converting the signal to estimate the property of the downhole fluid. The light source is modulated by mechanically chopping the beam or by electrically pulsing the light source or by steering the beam between different path lengths of sample or between a reference cell (filled with a reference fluid or empty) and a sample-filled cell.

Owner:BAKER HUGHES INC

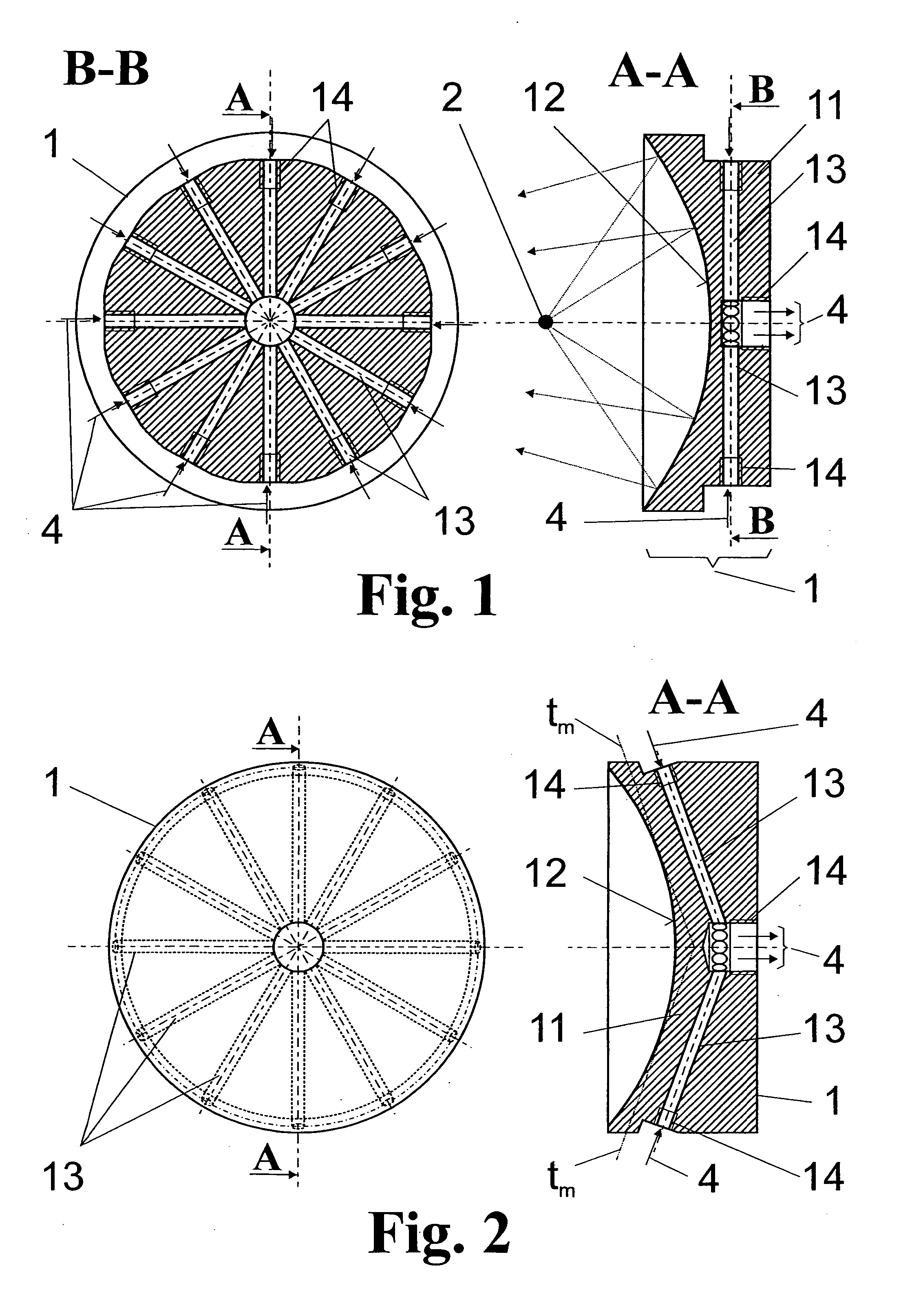

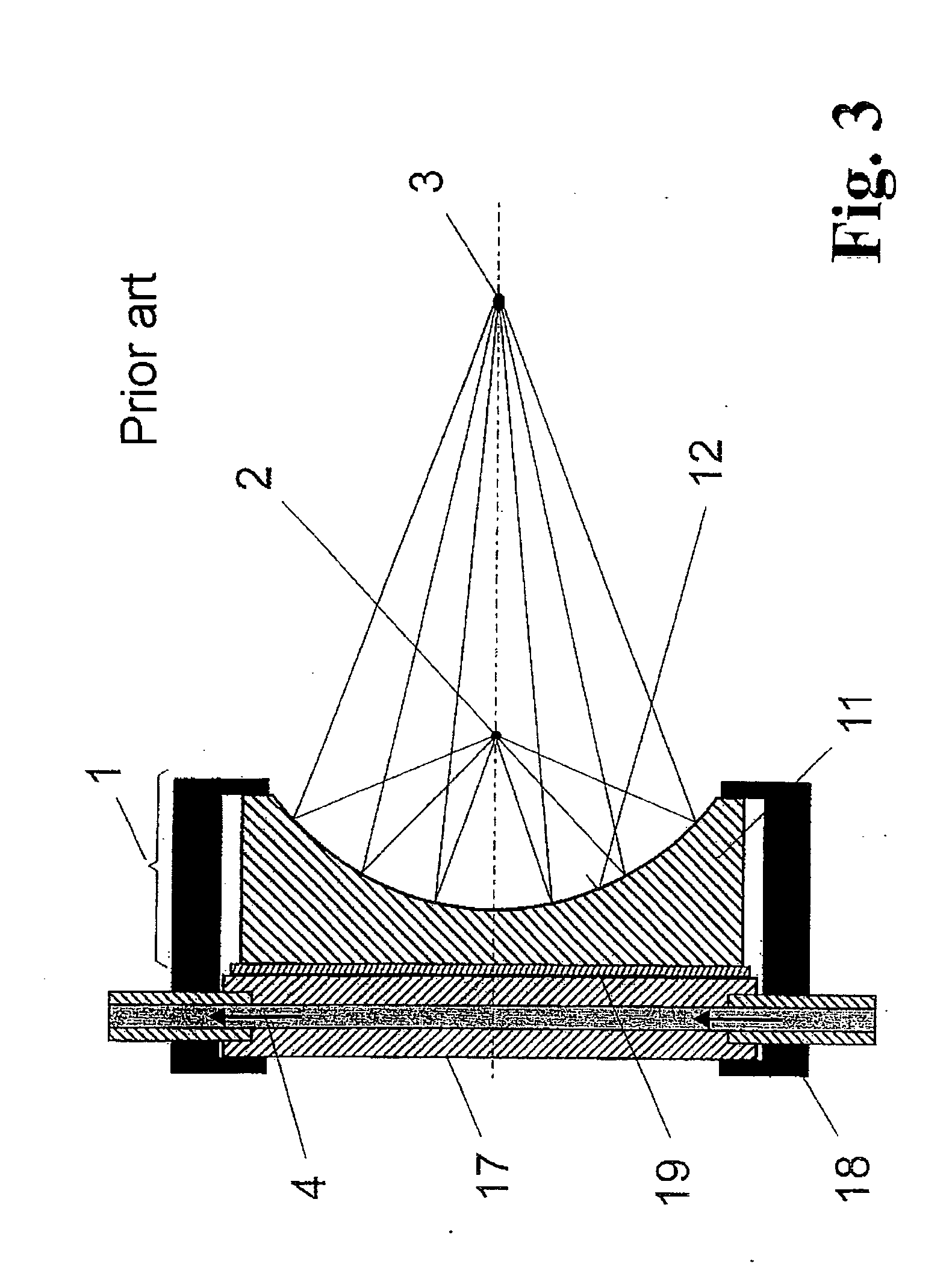

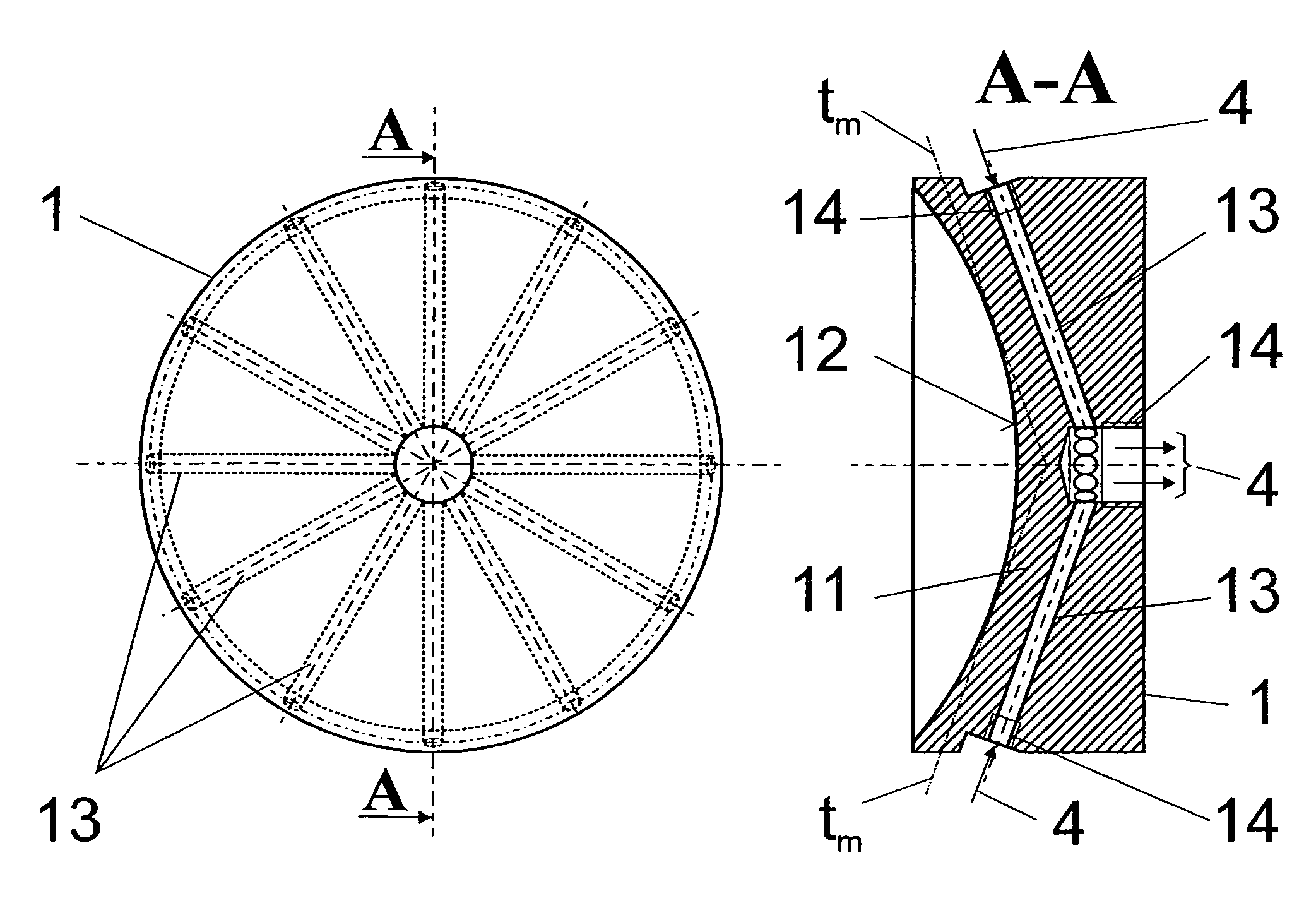

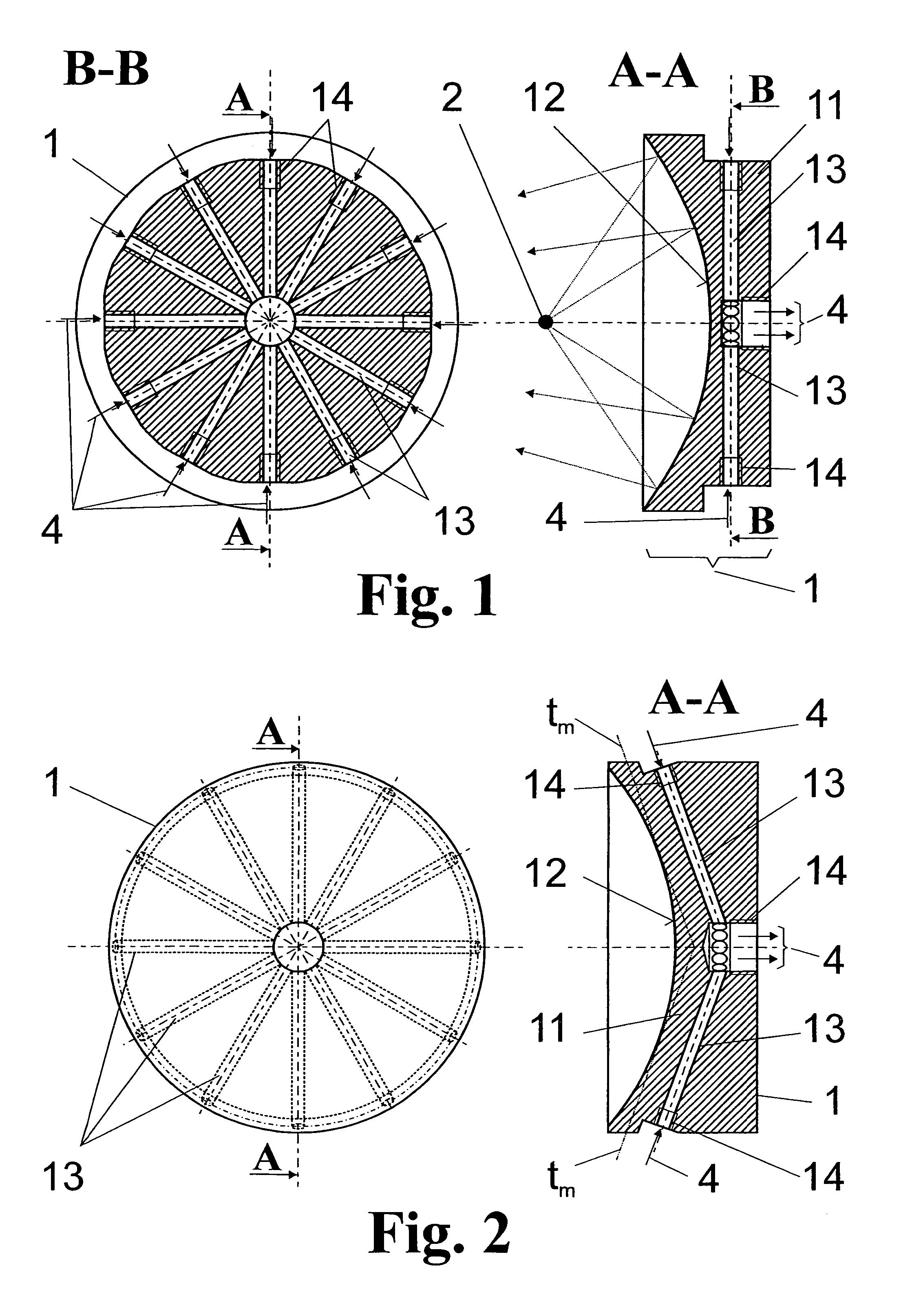

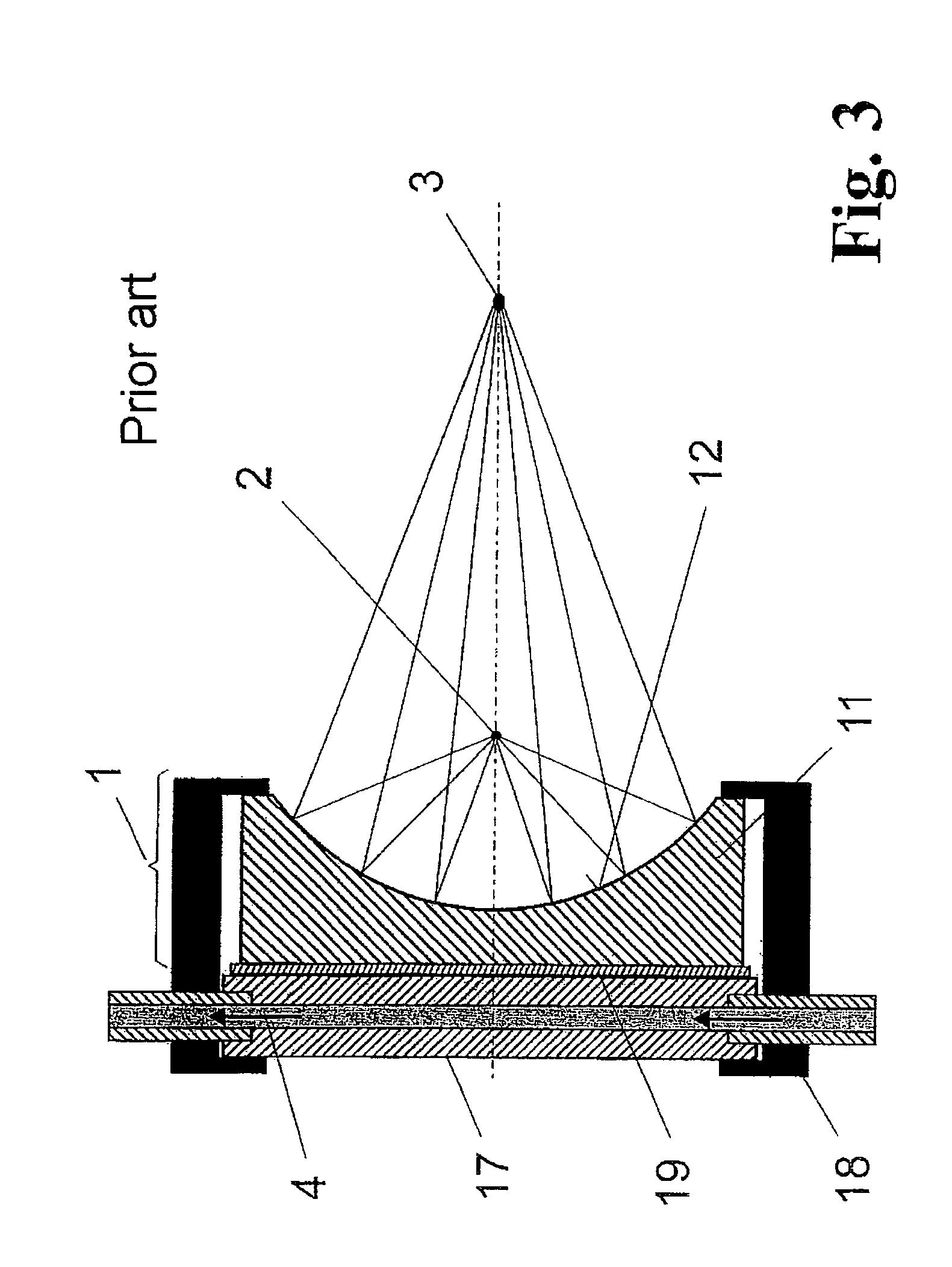

Collector mirror for plasma-based, short-wavelength radiation sources

ActiveUS20060227826A1High-performance thermal connectionGreat expenditureMirrorsRadiation/particle handlingTransport mediumThermostat

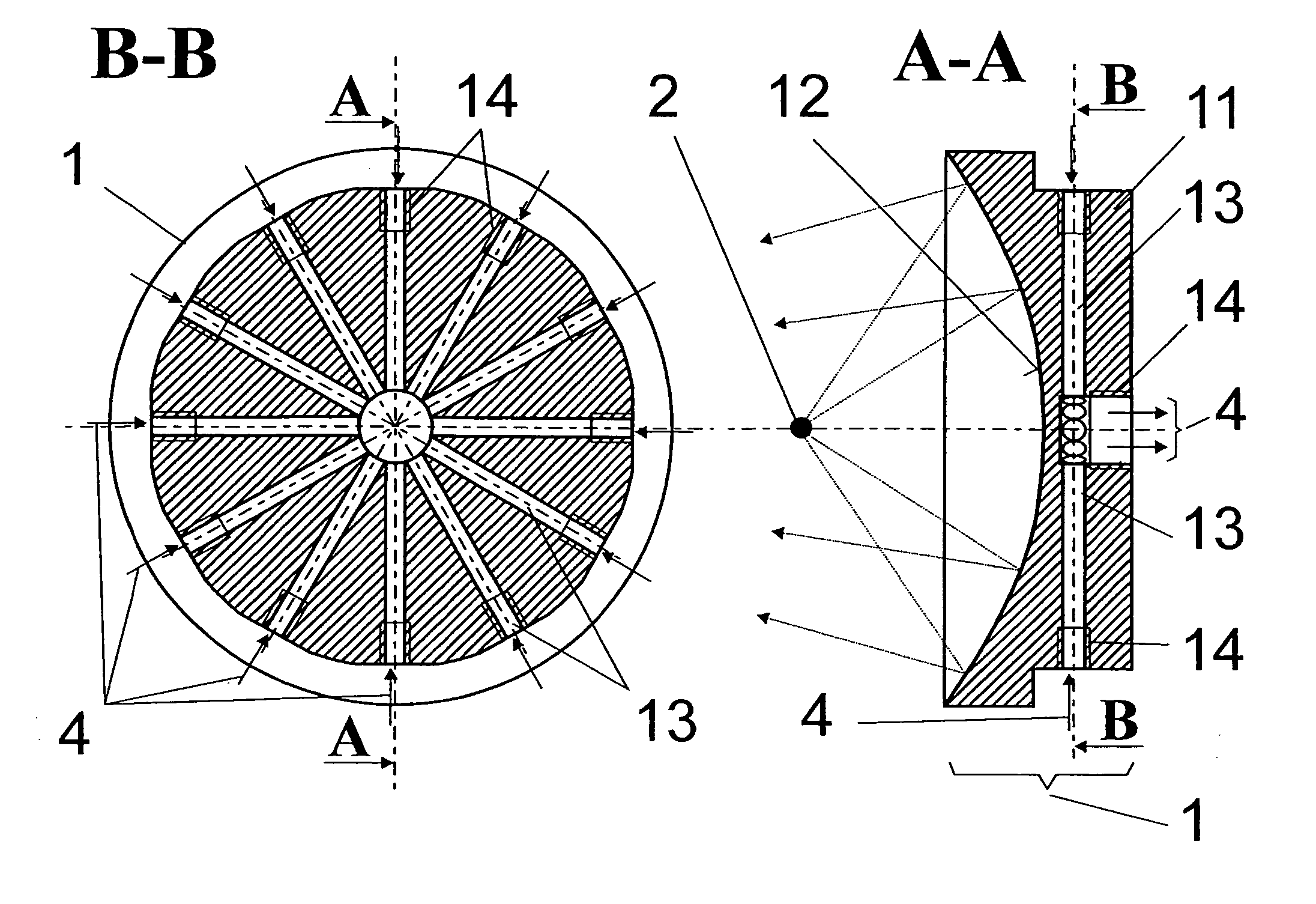

The invention is directed to a collector mirror for short-wavelength radiation based on a plasma. It is the object of the invention to find a novel possibility for managing the temperature of a collector mirror for focusing short-wavelength radiation generated from a plasma which allows an efficient thermal connection to be produced between the optically active mirror surface and a thermostat system without the disadvantages relating to space requirements or high-precision manufacture of the collector mirror. This object is met, according to the invention, in that the collector mirror has a solid, rotationally symmetric substrate which comprises a material with high thermal conductivity of more than 50 W / mK and in which channels for cooling and temperature management are incorporated in the substrate so that a heat transport medium can flow through directly and for rapidly stabilizing the temperature of the optically active mirror surface. Heat of transient temperature spikes which occur in pulsed operation for plasma generation at the mirror surface and which temporarily exceed the temperature average by a multiple is quickly dissipated.

Owner:USHIO DENKI KK

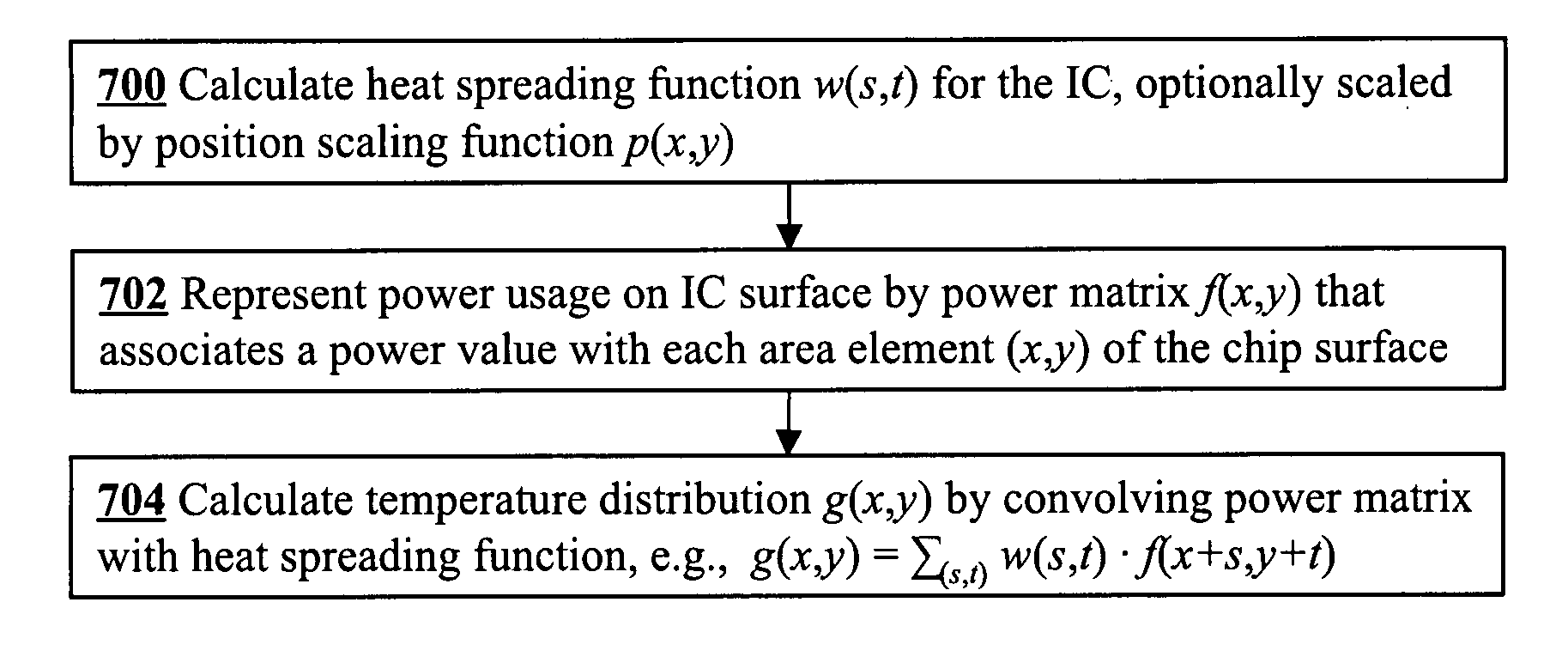

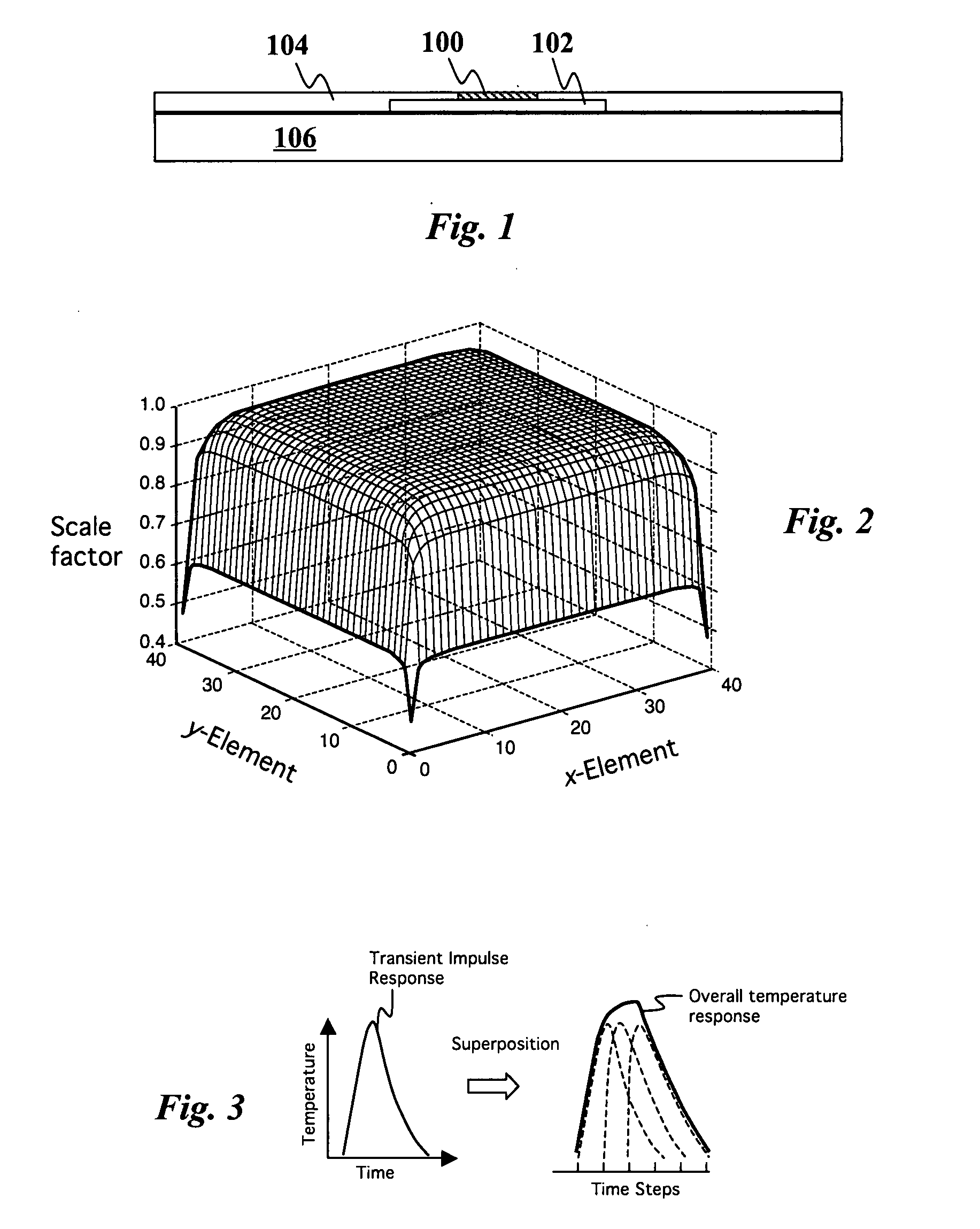

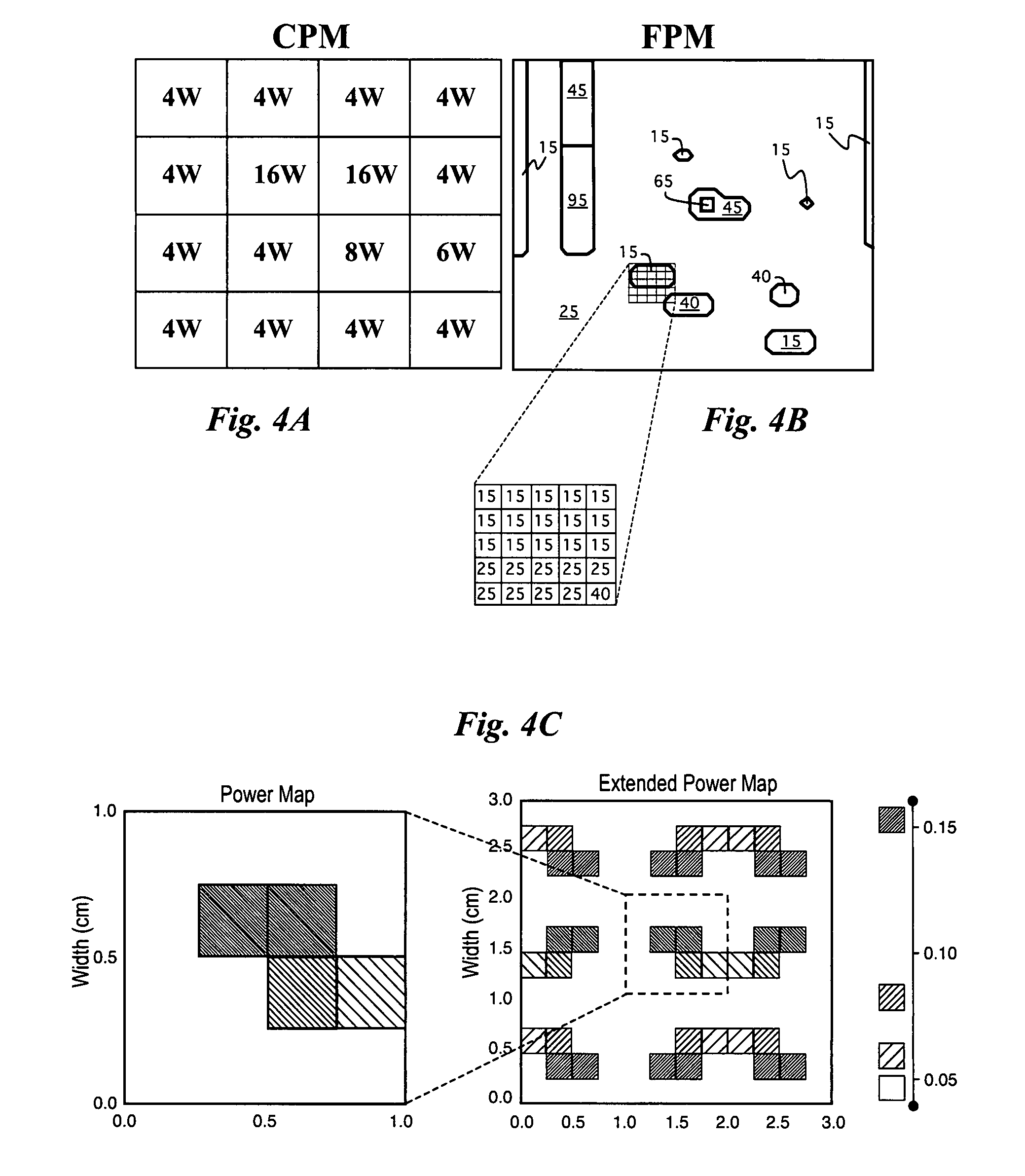

Efficient method to predict integrated circuit temperature and power maps

InactiveUS20080026493A1Fast and accurate methodMinimizes localized heatingSemiconductor/solid-state device testing/measurementDetecting faulty computer hardwareElement analysisDiffusion function

The temperature distribution associated with a design of an integrated circuit is calculated by convoluting a surface power usage represented by a power matrix with a heat spreading function. The heat spreading function may be calculated from a simulation of a point source on the integrated circuit using a finite element analysis model of the integrated circuit or other techniques. To account for spatial variations on the chip, the heat spreading function may be made dependent on position using a position scaling function. Steady-state or transient temperature distributions may be computed by using a steady-state or transient heat spreading function. A single heat spreading function may be convolved with various alternative power maps to efficiently calculate temperature distributions for different designs. In an inverse problem, one can calculate the power map from an empirically measured temperature distribution and a heat spreading function using various de-convolution techniques. While the forward problem is analogous to image blurring, the inverse problem is analogous to image restoration.

Owner:UNIV OF CALIFORNIA SANTA CRUZ

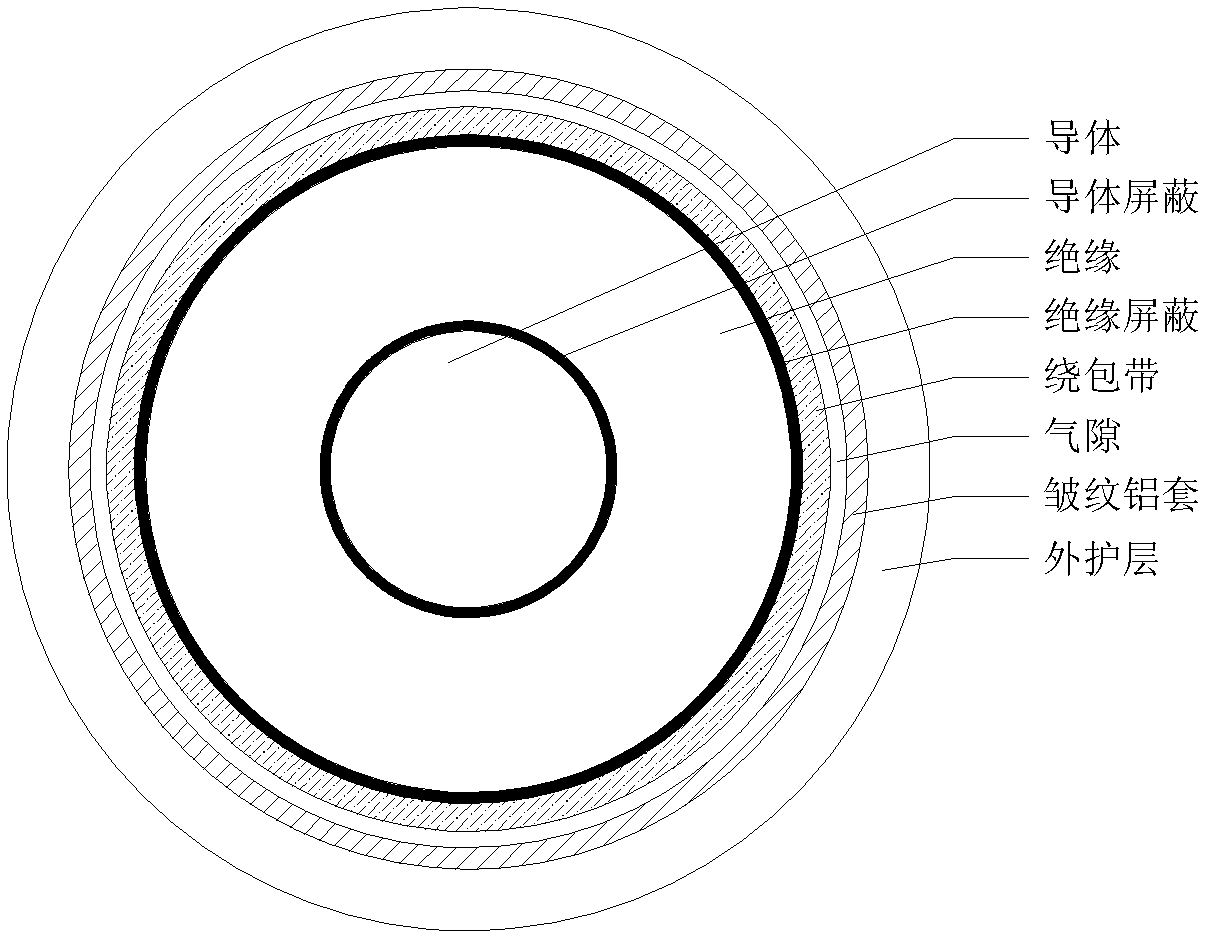

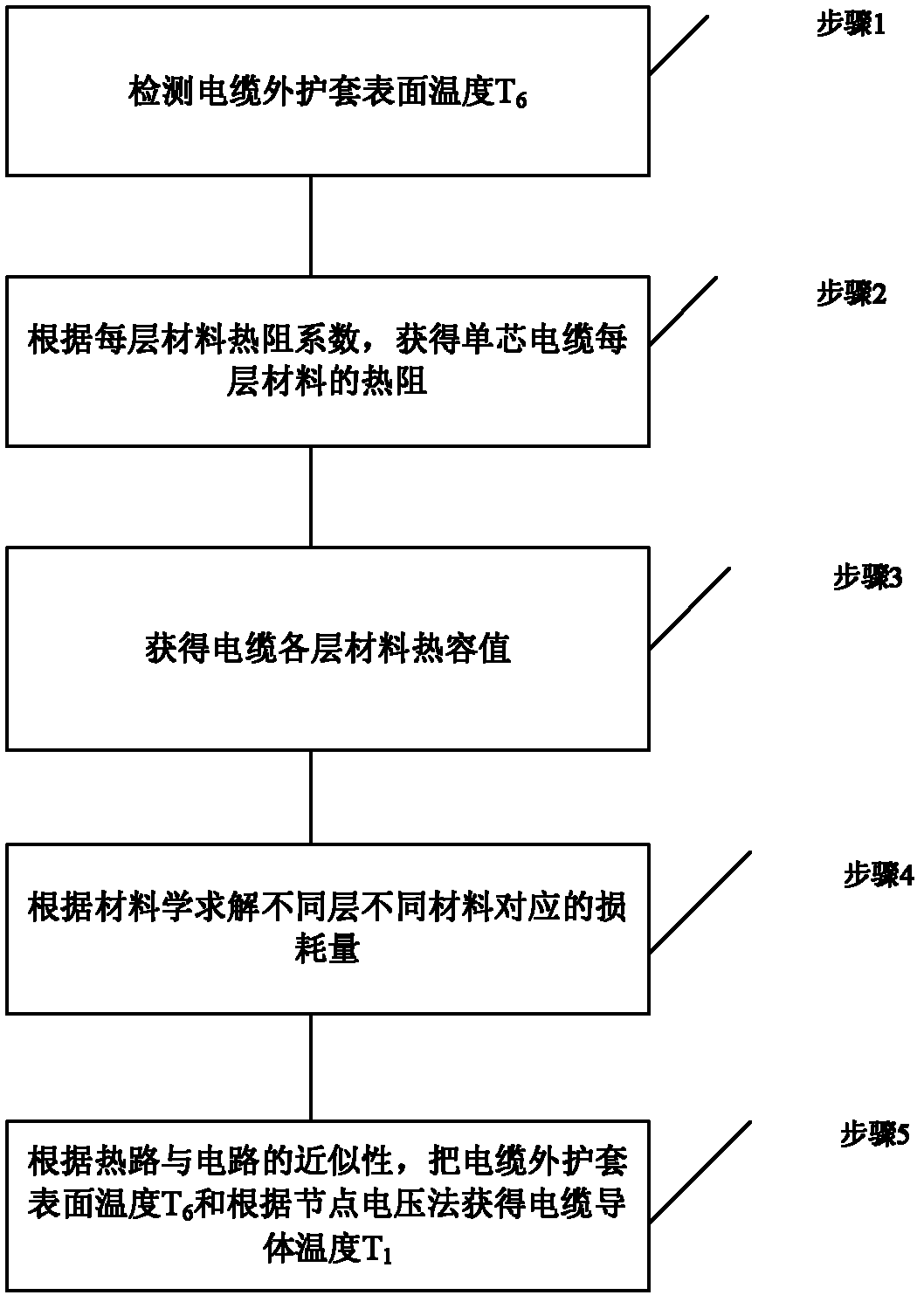

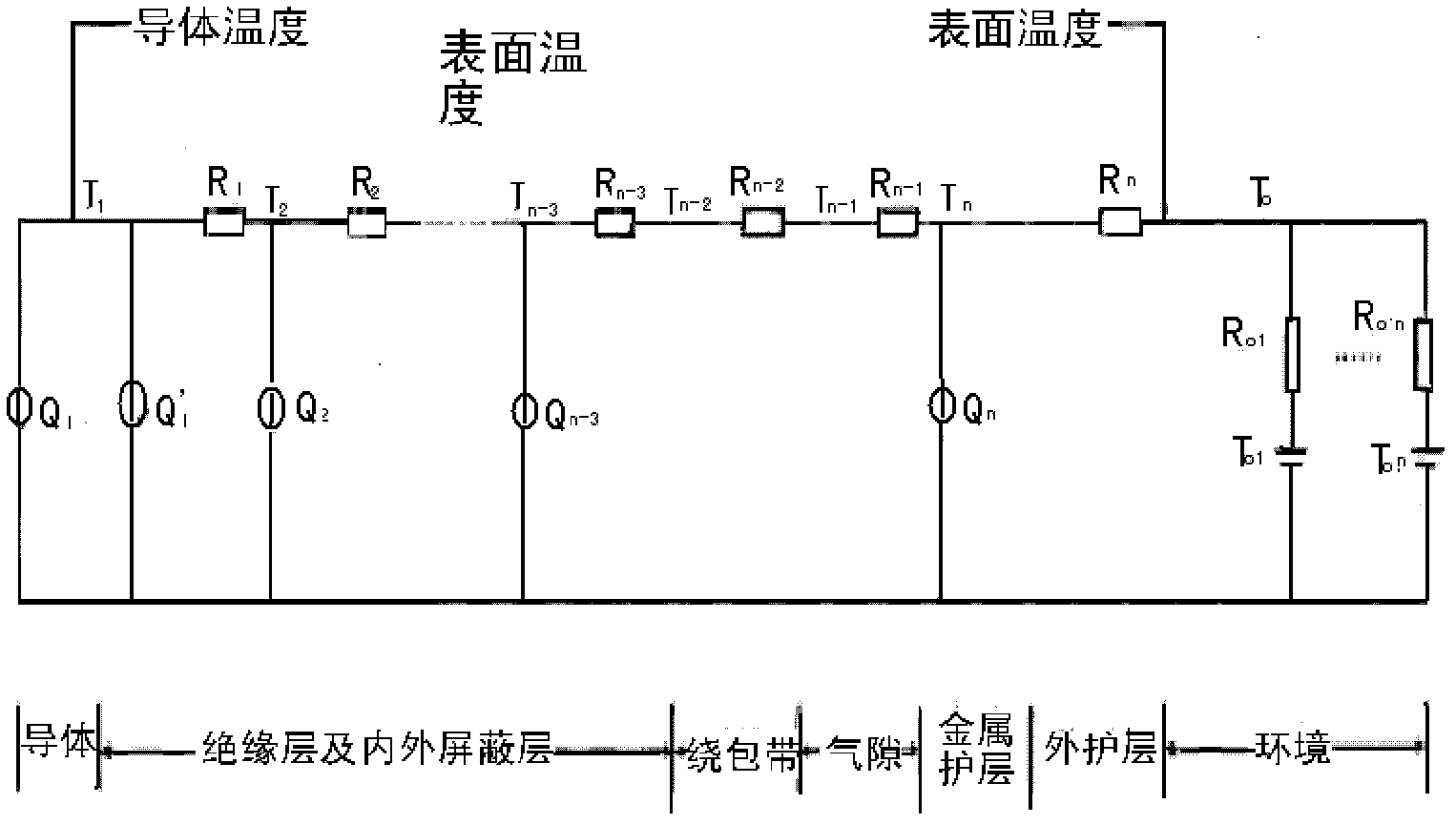

System for monitoring current-carrying capacity of cable conductor and method

InactiveCN102323496AIncrease margin spaceAccurate assessmentElectrical testingThermometer applicationsCarrying capacityElectrical conductor

The invention provides a method for monitoring the current-carrying capacity of a cable conductor, which comprises the following steps of: firstly, monitoring the temperature of an outer sheath layer of the cable conductor and current of a cable core of the cable conductor; deducting the cable conductor into a conductor layer, a conductor shielding layer, an insulating layer, an insulated shielding layer, a cushion layer, an air gap layer, an aluminum sheath shielding layer and an outer sheath layer in advance according to the heat transfer characteristic of the cable conductor; acquiring the heat resistance of each layer for the cable conductor and the loss generated by each layer for the cable conductor according to the heat conducting performance of each layer of material of the cable; acquiring the temperature of the cable conductor by using a node method according to the heat resistance, the loss, the outer sheath layer temperature of the cable conductor and the current of the cable cote of the cable conductor, wherein the temperature of the cable conductor comprises the steady temperature and the transient temperature of the cable conductor; and monitoring the current-carrying capacity of the cable conductor according to the temperature of the conductor cable. The invention further provides a device for monitoring the current-carrying capacity of the cable conductor. According to the method and the device, disclosed by the invention, the temperature of the cable conductor can be monitored in a real time.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD +1

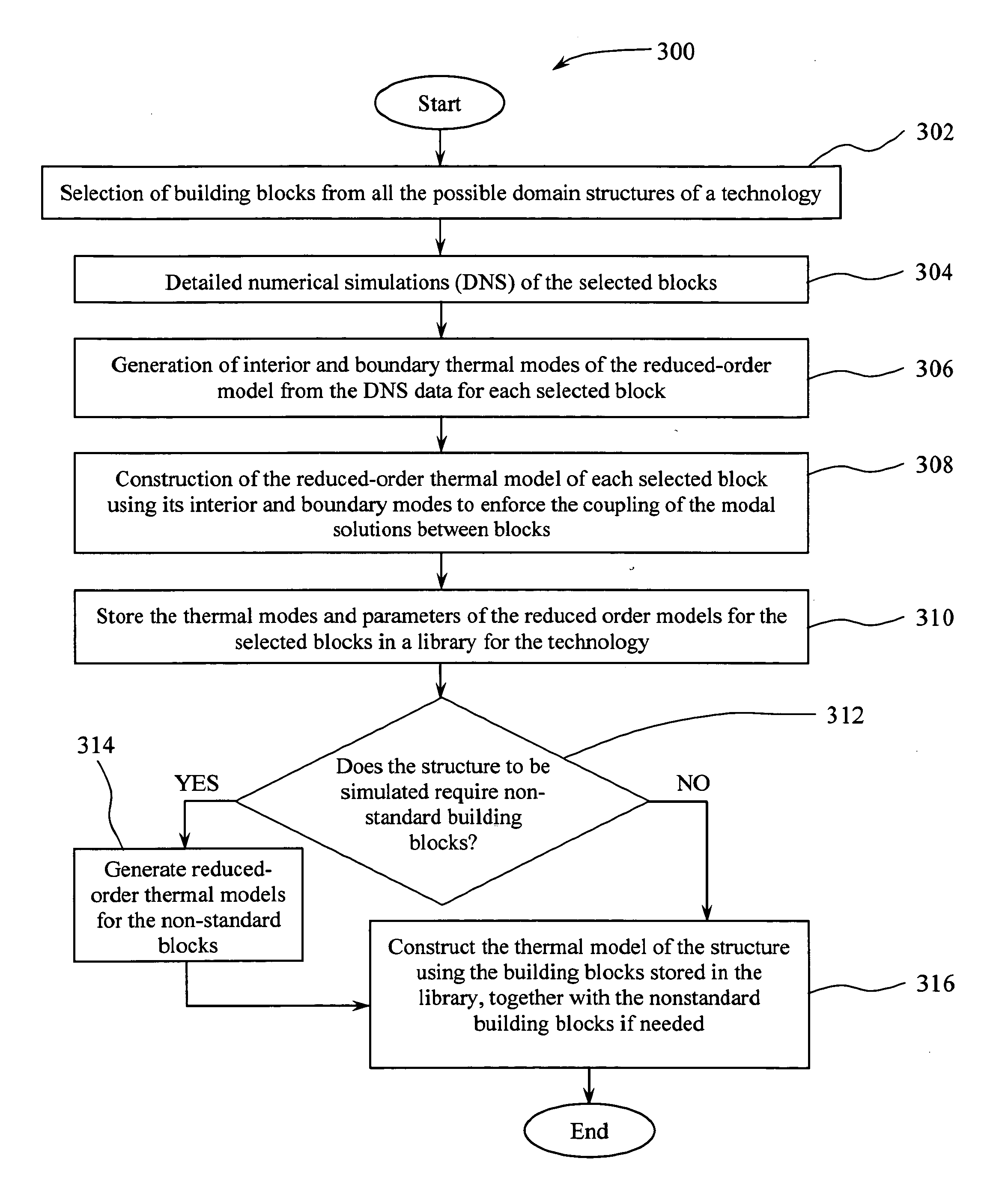

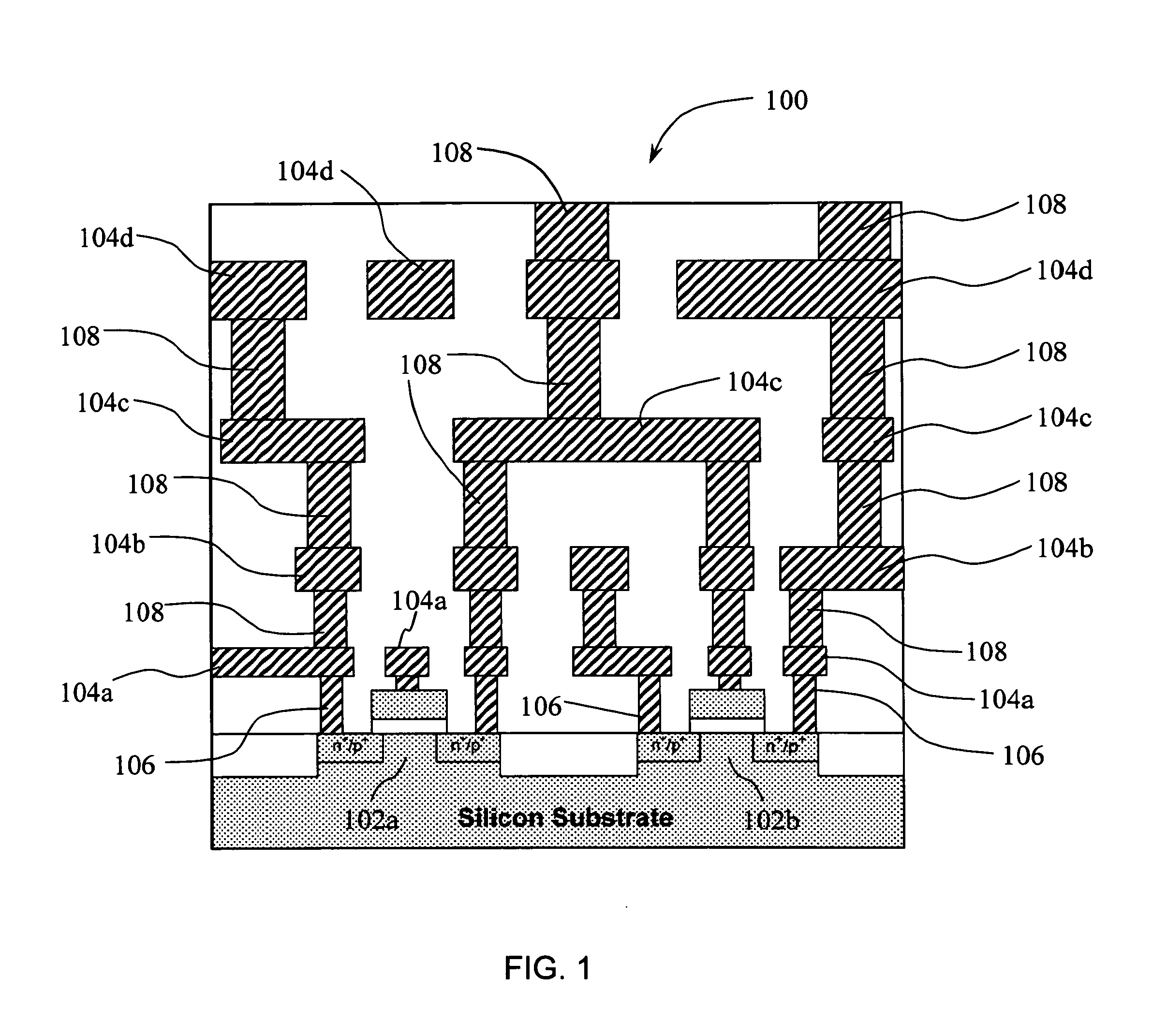

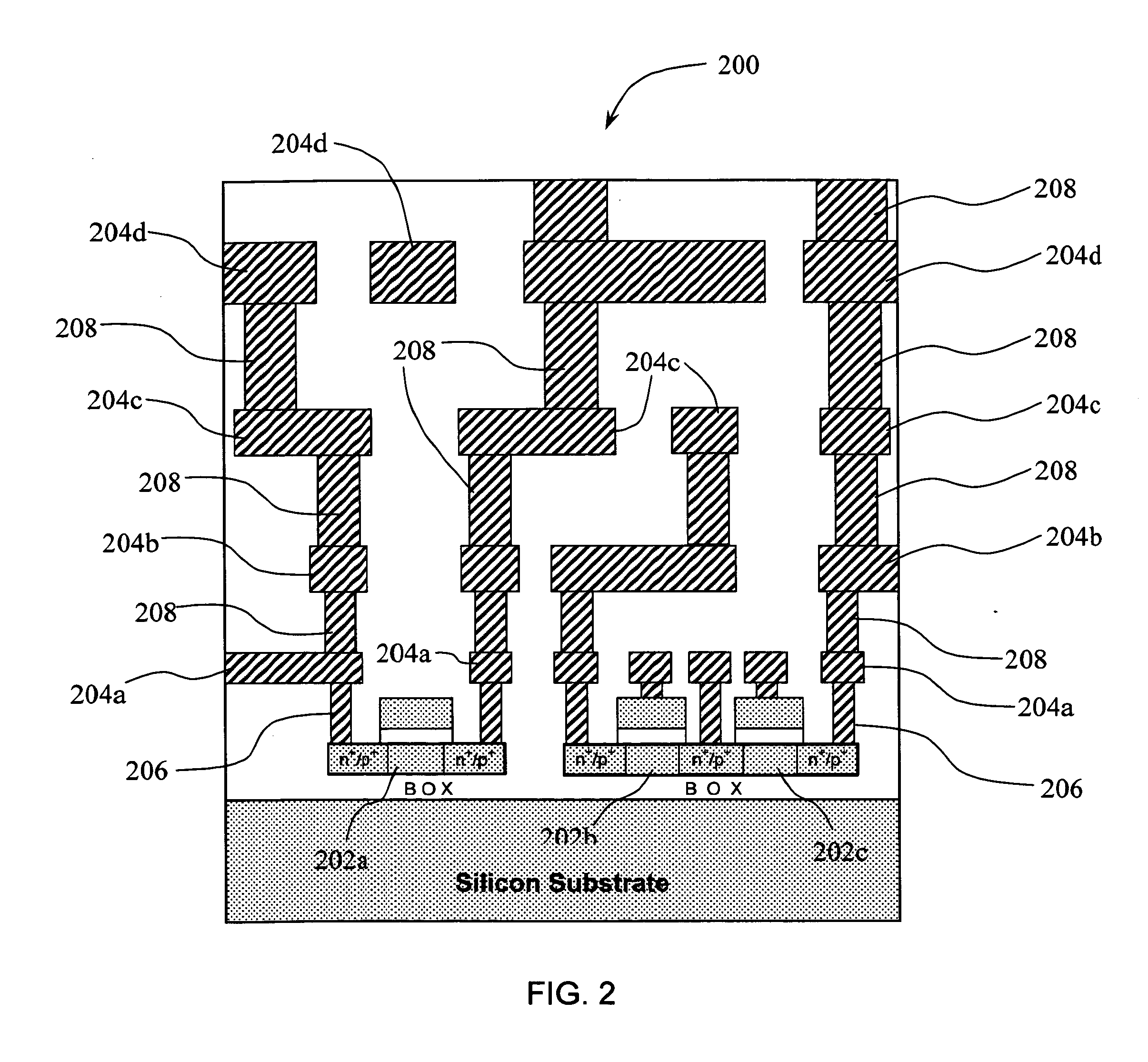

Method for thermal simulation

InactiveUS8539408B1Reduce computing timeWork efficiently and accuratelyComputer aided designSoftware simulation/interpretation/emulationPhysical spaceSemiconductor chip

The invention of novel methods is described for efficient and accurate thermal simulation of a structure that can be primarily constructed using building blocks. These structures may include, but not limited to, semiconductor chips, photovoltaic / solar panels, battery packs, etc. The methods are formulated in hierarchical function spaces, rather than the physical space and provide three-dimensional (3D) steady-state and transient temperature profiles of the structure, which are as detailed as full-scale numerical simulation, using substantially less computational degrees-of-freedom (DOF). The number of DOF required is comparable to that of lumped thermal models, yet no ad-hoc modeling assumptions related to geometry, dimensions, temperature profiles, or heat flow paths are required. The methods can be applied to evaluate temperature profiles at different levels of granularity. The methods can also be implemented in various computer-aided-design (CAD) or electronic-design-automation (EDA) tools for different technologies to perform electro-thermal simulations.

Owner:CLARKSON UNIVERSITY

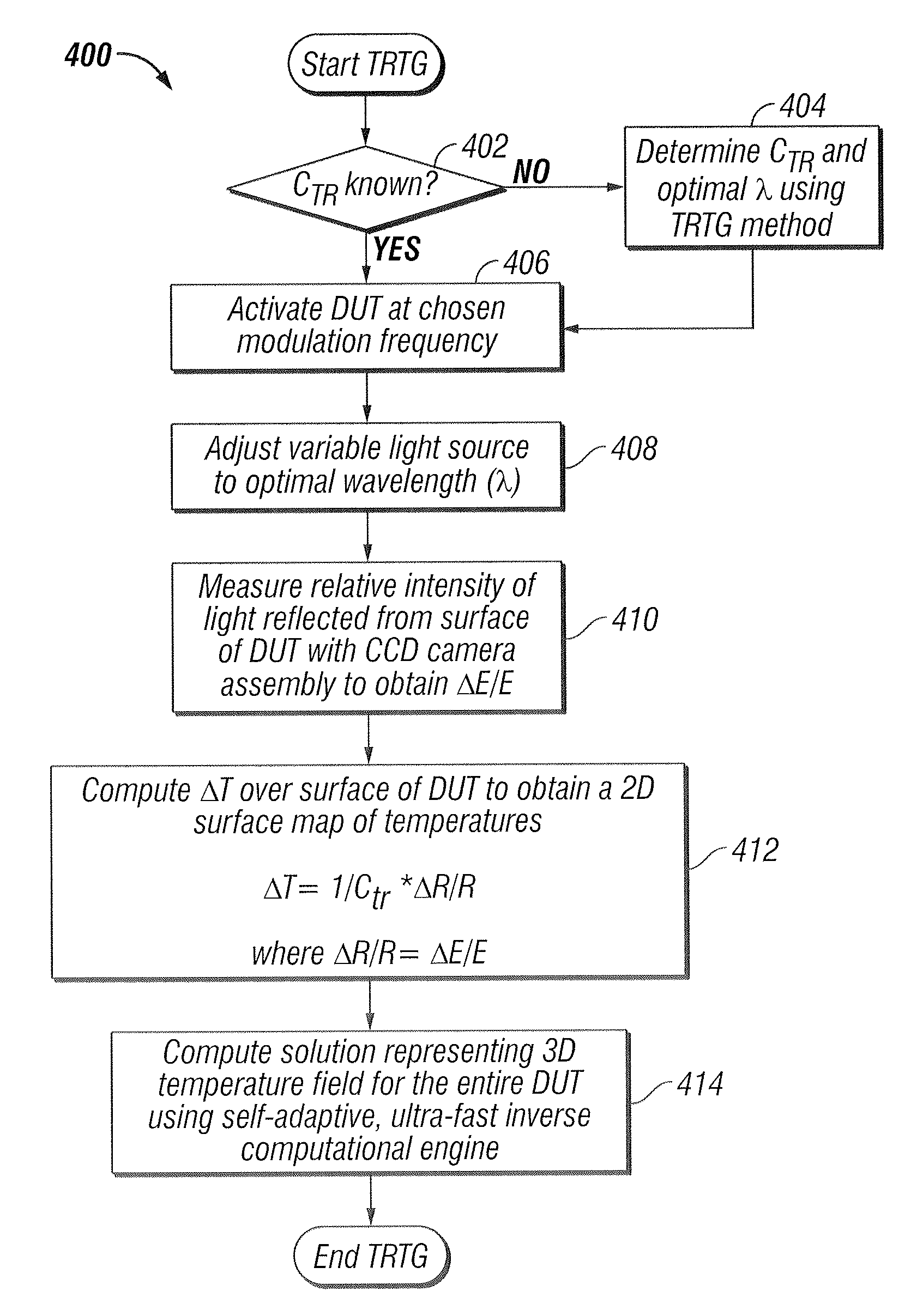

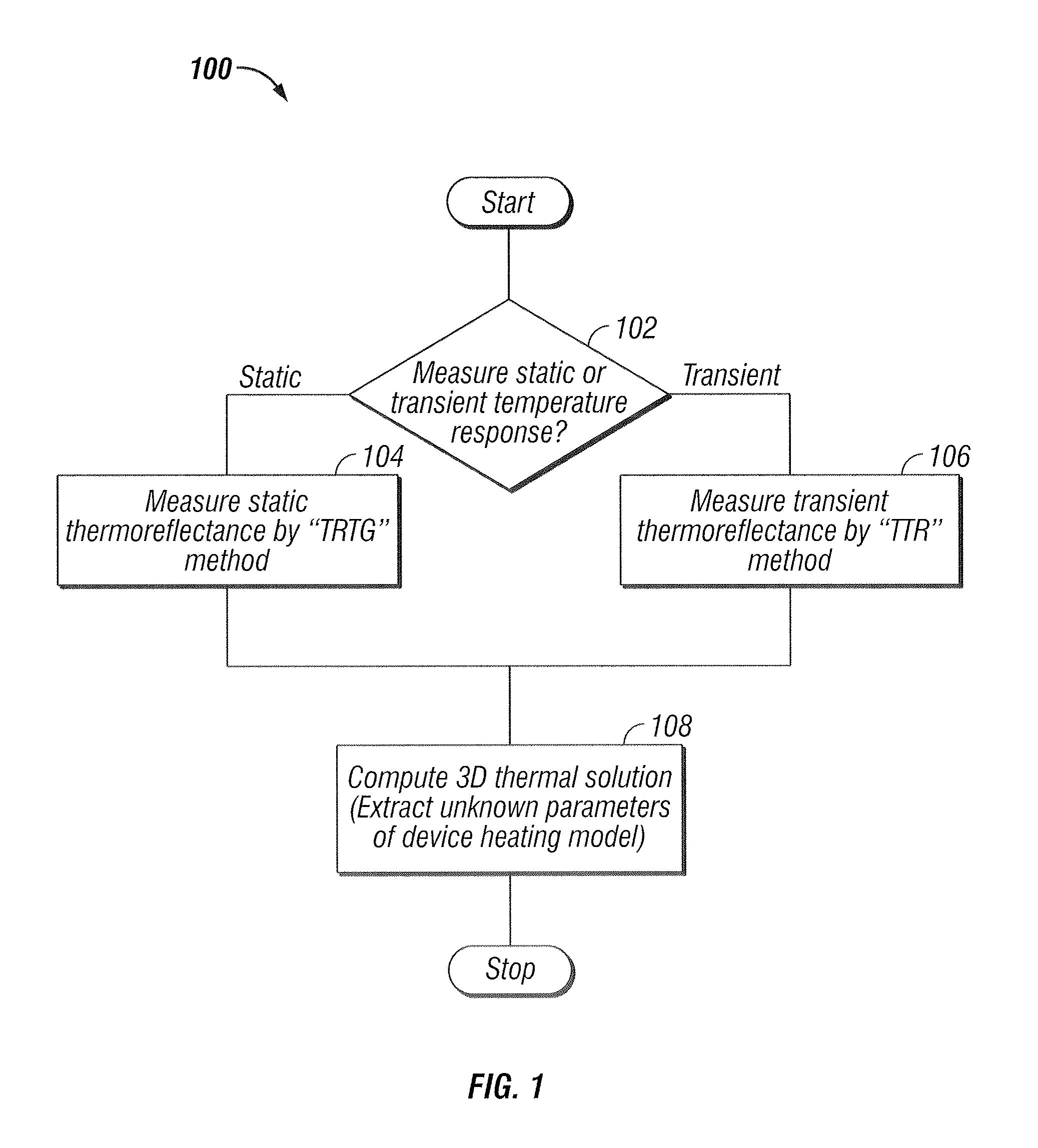

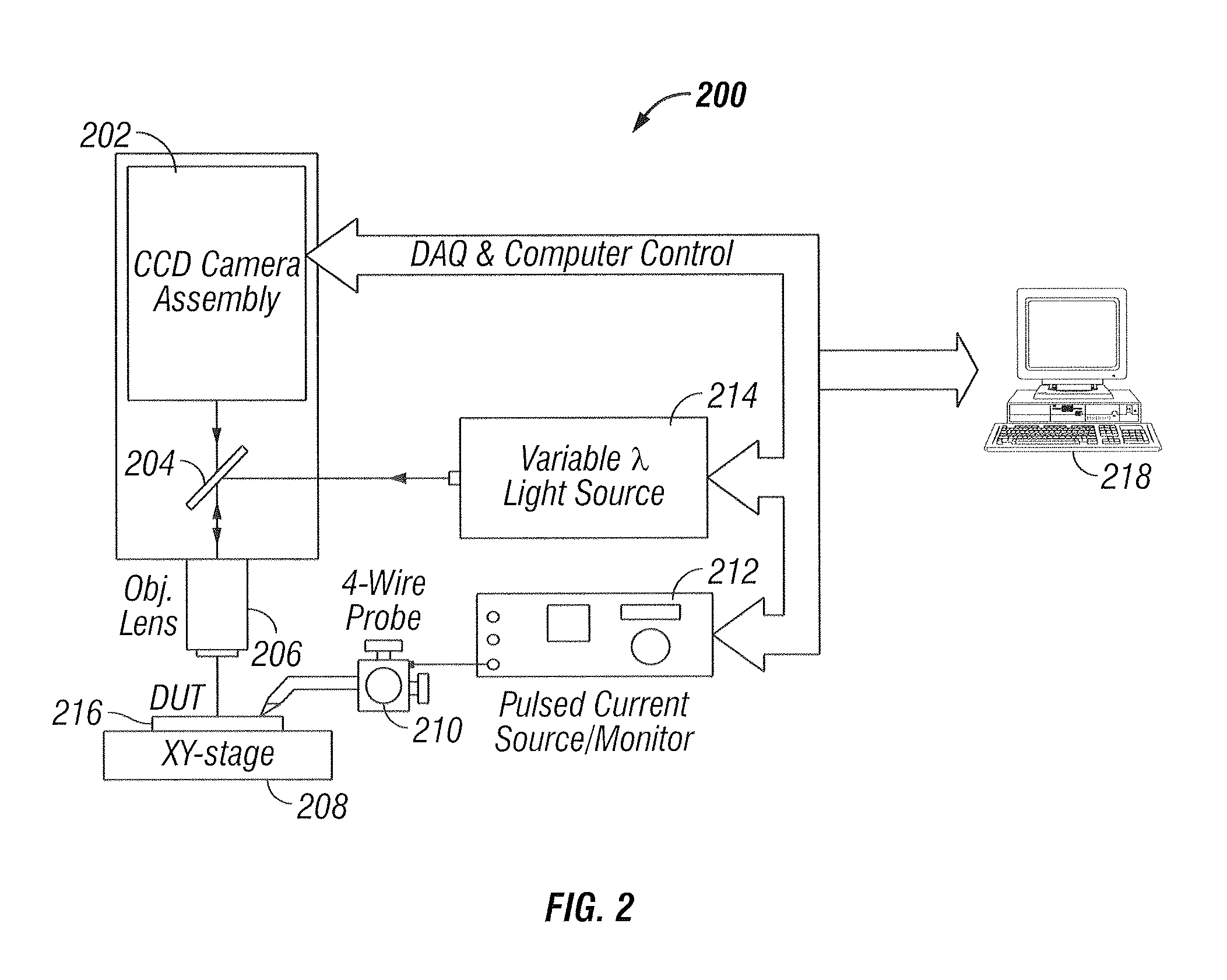

Thermography measurement system for conducting thermal characterization of integrated circuits

ActiveUS20080082288A1High spatialHigh temporal accuracyCounting objects with random distributionSpecial data processing applicationsLight energyPhotodetector

A system and method to fully characterize the thermal behavior of complex 3D submicron electronic devices. The system replaces and / or supplements laser-based surface temperature scanning with a CCD camera-based approach. A CCD camera records multiple points of light energy reflected from an integrated circuit to obtain a static temperature measurement. The system is used to non-invasively measure with submicron resolution the 2D surface temperature field of an activated device. A CW laser illuminates a single point on the surface of an active device and a photodetector records the reflected light energy to obtain a transient temperature measurement. The measured 2D temperature field is used as input for an ultra-fast inverse computational solution to fully characterize the thermal behavior of the complex 3D device. The system extracts geometric features of a known device, assessing the system's ability to combine measured results and computations to fully characterize complex 3D electronic devices.

Owner:RAAD PETER E

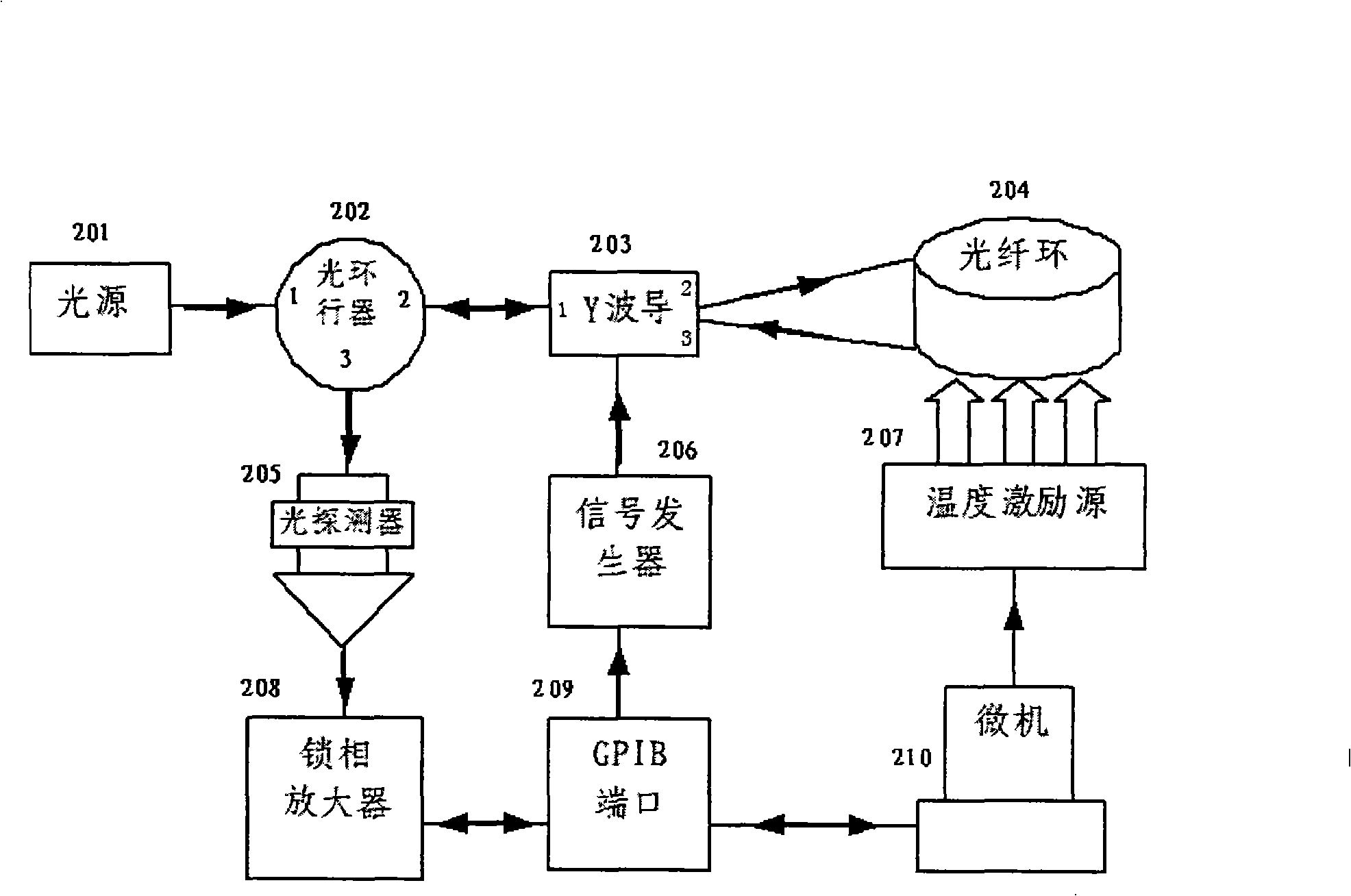

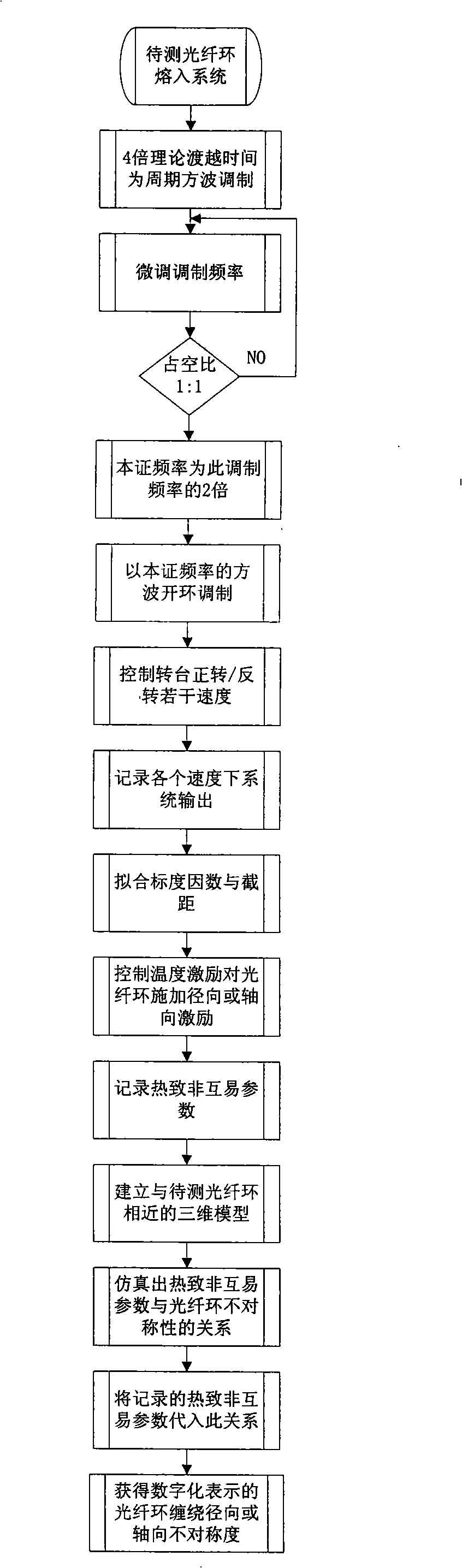

Optical fiber ring quality measurement method and its device for optical fibre gyroscope

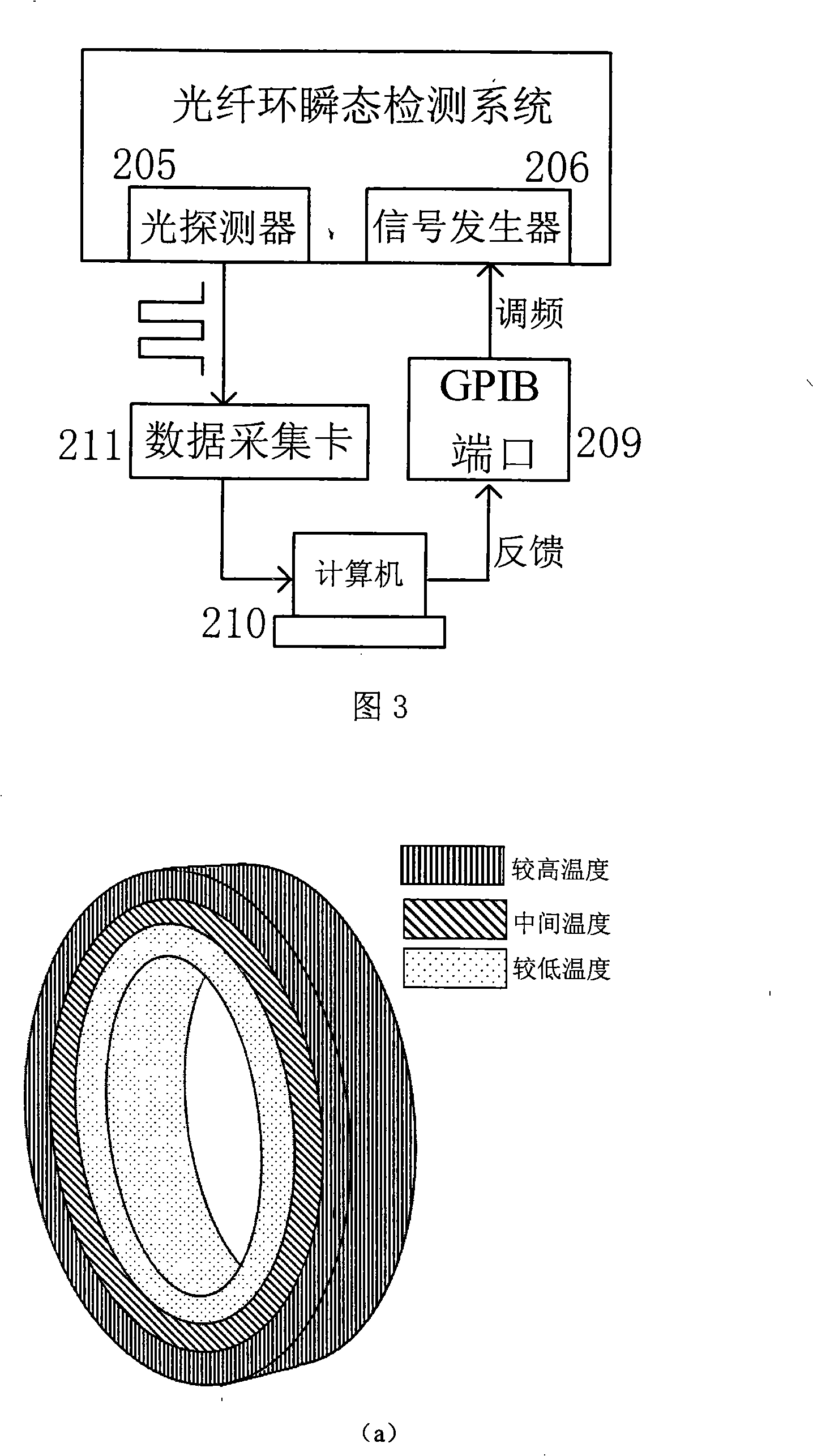

ActiveCN101339093AConvenient and accurateThe detection process is fastTesting optical propertiesConstant powerGyroscope

The invention relates to a measuring method of the quality of optical fiber ring, used in an optical fiber gyroscope, and a and measuring device thereof; the measuring method and the measuring device belong to the technological field of optical measurement and optical fiber sensing. The method includes the following steps: exerting radial and axial temperature excitation on the optical fiber ring (constant power heating, periodic power heating or non-periodic power heating); measuring the characteristics of the transient temperature of the optical fiber ring; acquiring the test signals of the characteristics of the transient temperature of the optical fiber ring; analyzing and processing the collected data according to the numerical value simulation result of three-dimensional mathematical model of the optical fiber ring; and acquiring the equivalent but asymmetric information of the quantized optical fiber ring which is wound in the radial and axial directions. The device comprises a measuring light source, an optical device which has three ports, a Y wave guide, an optical detector, a signal generator, an electric signal amplification circuit, a controllable heating device, a control circuit and a set of controlling and calculating software. The measuring method can accurately, conveniently and rapidly measure the quality of temperature symmetry of the optical fiber ring, but also can determine the dynamic characteristics of the optical fiber ring without installing the finished product of the optical fiber gyroscope. Thus the measuring method is conducive to the mass production and measurement of the optical fiber ring.

Owner:苏州光环科技有限公司

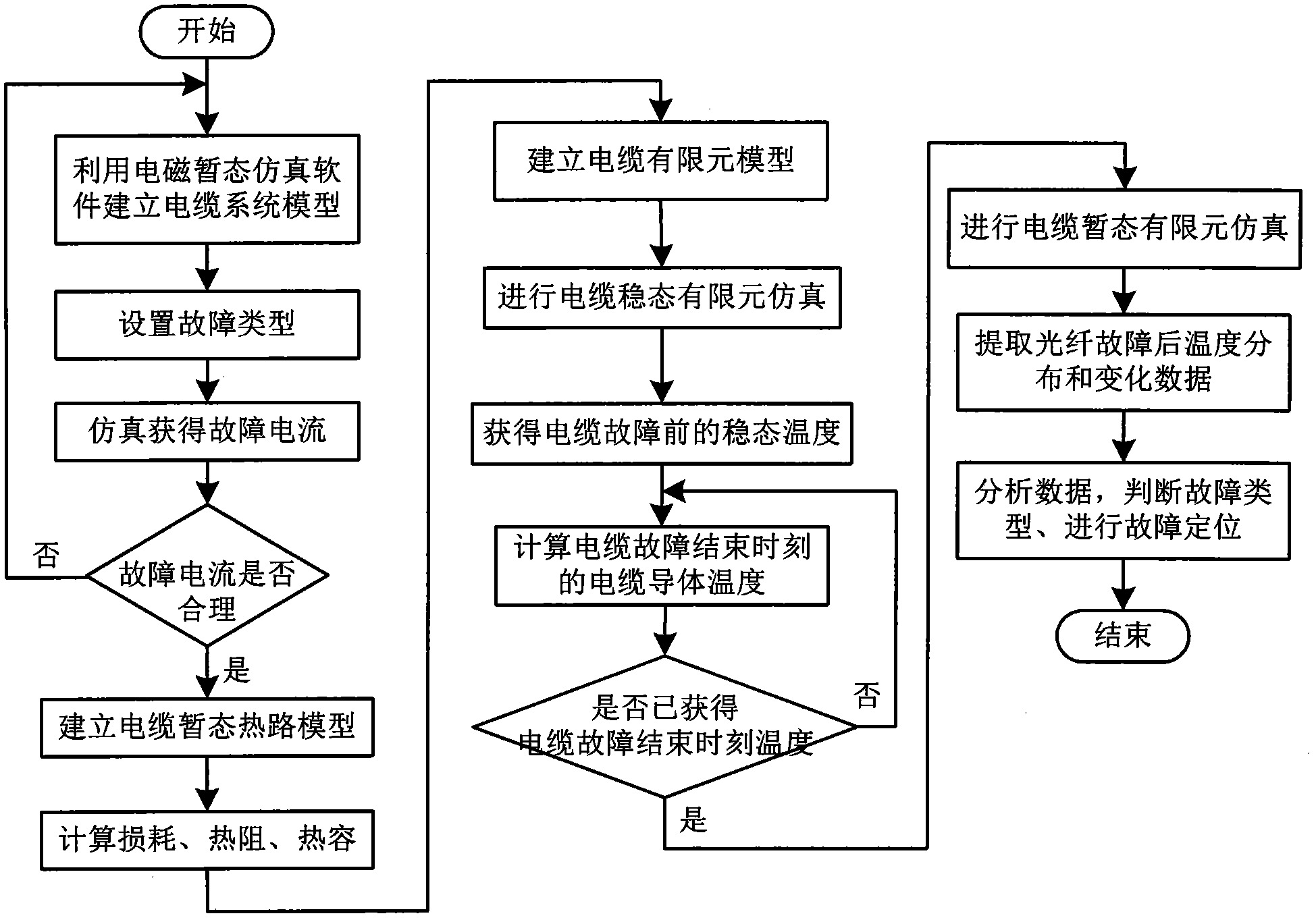

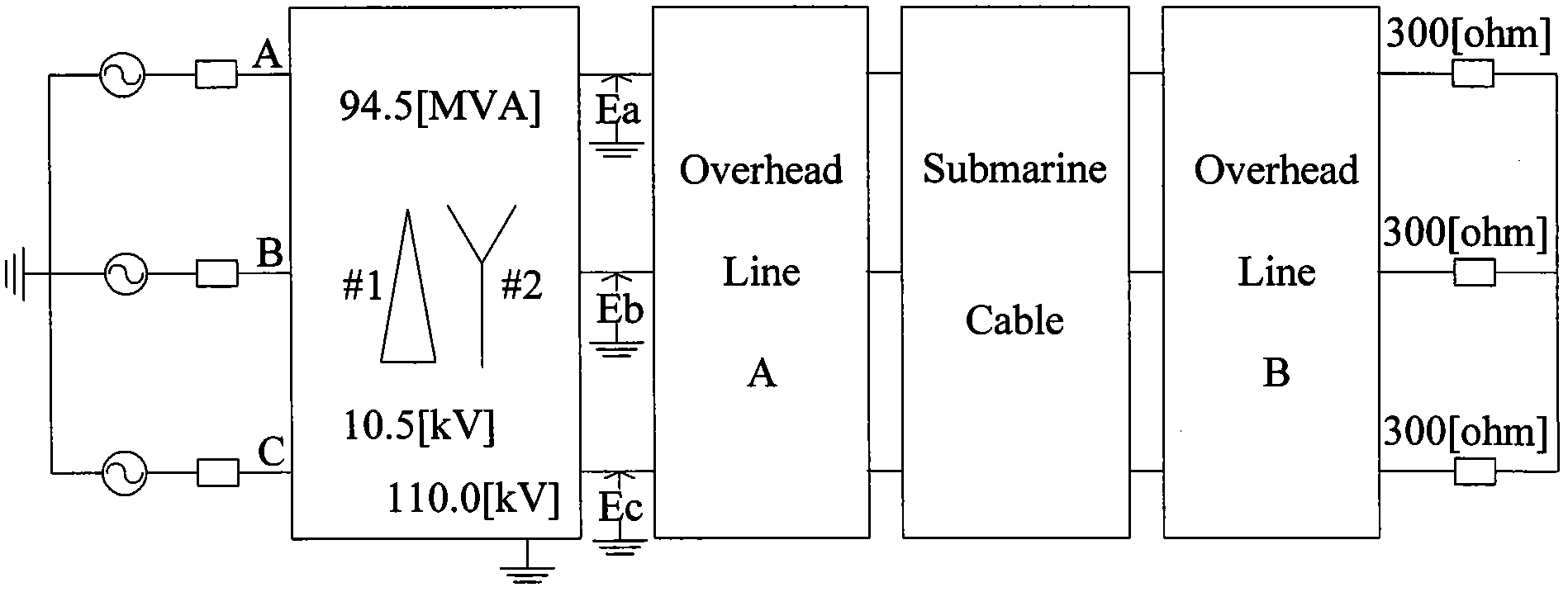

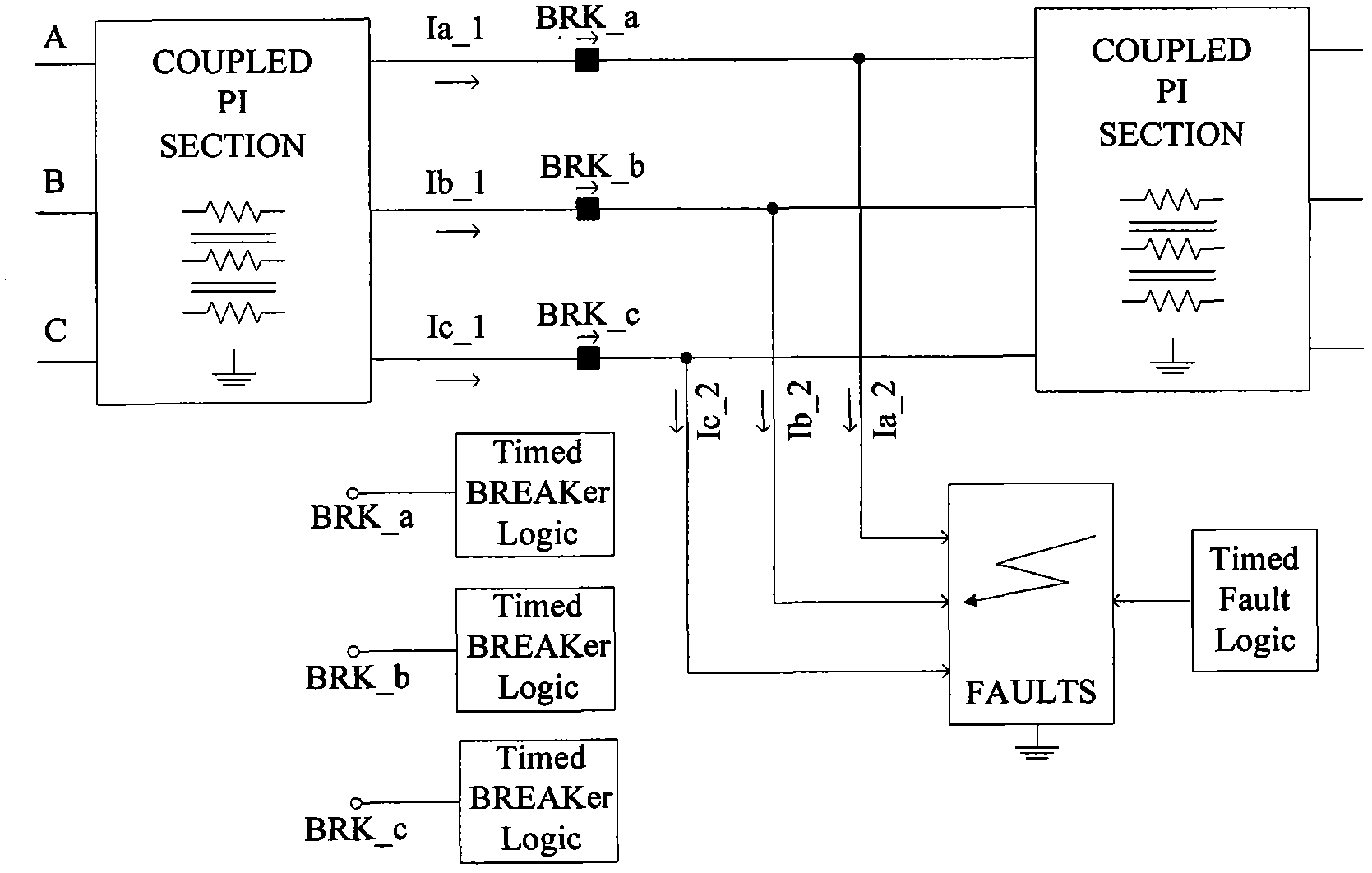

Distributive optical fiber temperature measurement based cable electrical failure simulation analysis method

ActiveCN103728539AFull failure dataComprehensive Failure DataFault locationTransient stateElement model

The invention belongs to the field of cable electrical failure simulation analysis and particularly relates to a distributive optical fiber temperature measurement based cable electrical failure simulation analysis method. The method comprises building a cable failure model, setting line parameters, determining failure types, performing failure simulation and obtaining the current value during the failure through electromagnetic transient simulation software; building a cable transient thermal path model according to IEC 60287 standards, and calculating the cable transient temperature during the failure; building a cable and temperature measurement optical fiber thermodynamic finite element model through finite element simulation software, and simulating the steady temperature field distribution before the failure and the transient temperature field distribution and changes after the failure of the cable and the temperature measurement optical fiber; obtaining cable electrical failure recognition and location criteria according to the temperature distribution and change rule of the temperature measurement optical fiber in simulation results. According to the method, the problems of poor accuracy, difficulties in experiment and the like during cable electrical failure analysis through temperature measurement optical fiber temperature distribution data are solved. The method has the advantages of being flexible in failure setting, high in work efficiency and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for estimating temperature at a critical point

ActiveUS20100094582A1Reduce the temperatureThermometer detailsThermometers using material expansion/contactionData processing systemSteady state temperature

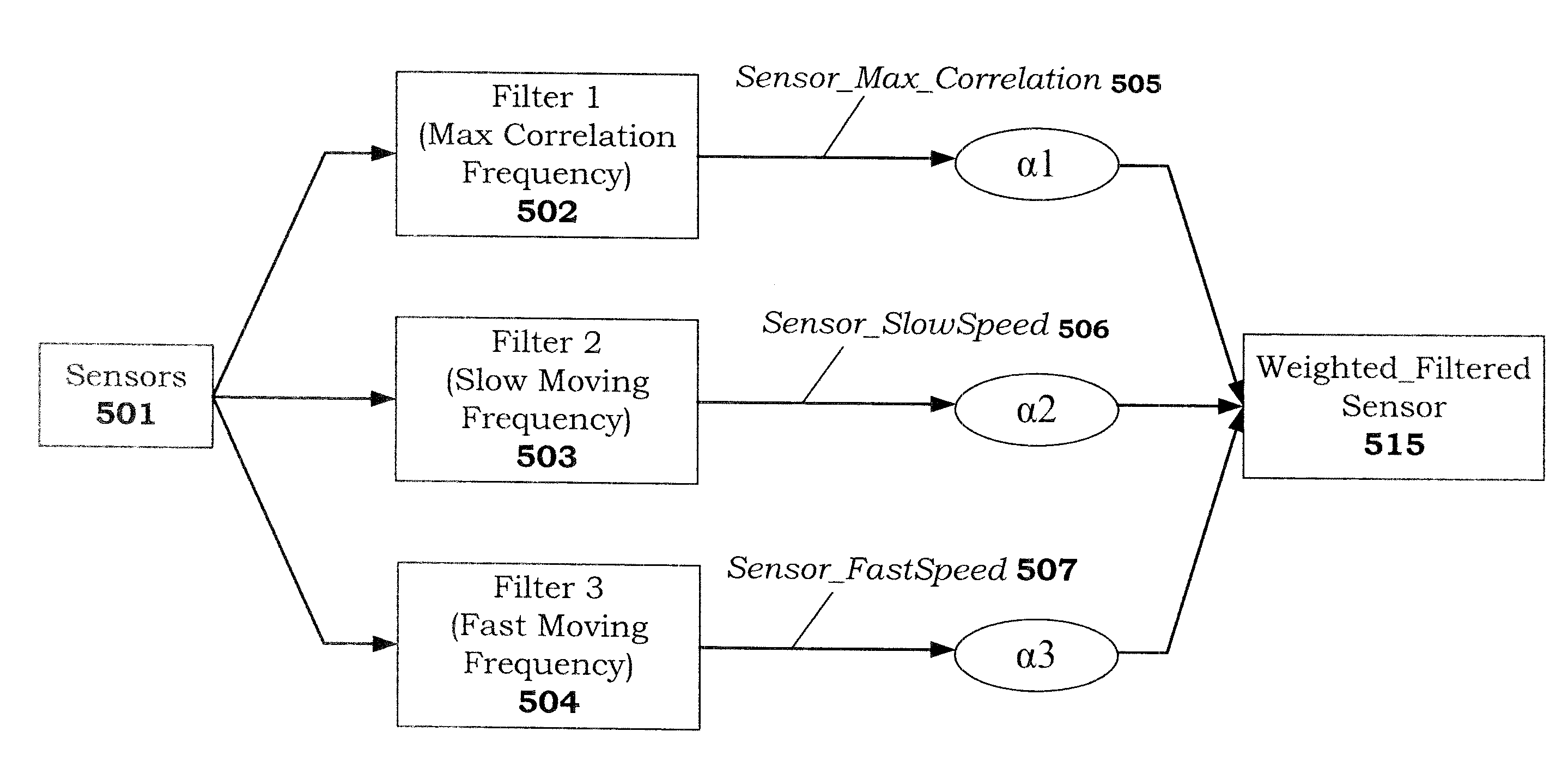

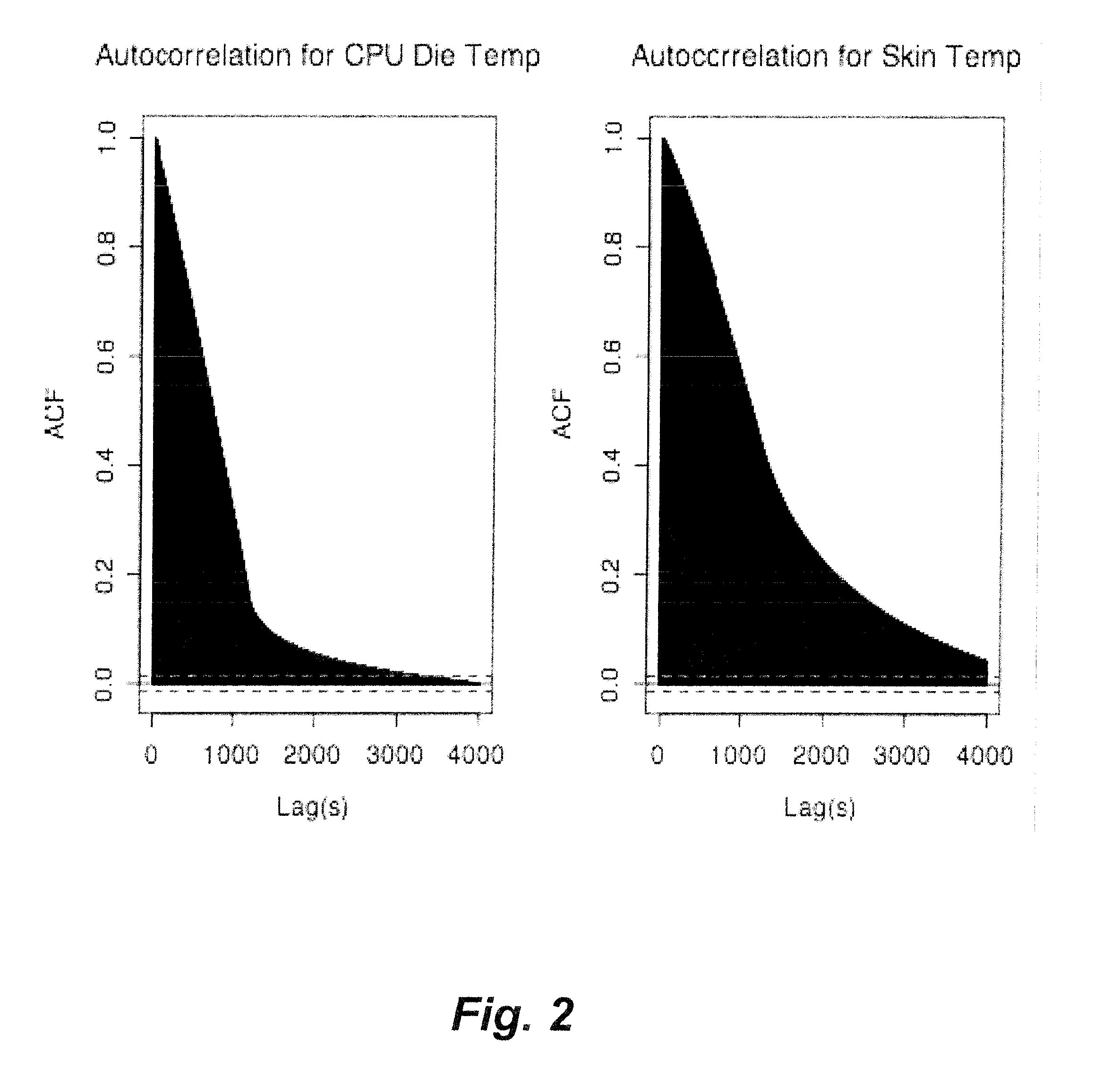

Methods and apparatuses are disclosed to estimate temperature at one or more critical points in a data processing system comprising modeling a steady state temperature portion of a thermal model at the one or more critical points using regression analysis; modeling the transient temperature portion of the thermal model at the one or more critical points using a filtering algorithm; and generating a thermal model at the one or more critical points by combining the steady state temperature portion of the thermal model with the transient temperature portion of the thermal model. The thermal model may then be used to estimate an instantaneous temperature at the one or more critical points or to predict a future temperature at the one or more critical points.

Owner:APPLE INC

Method for building mountainous area surface temperature base line and application

InactiveCN103530499AExpressing temperature space continuous distributionSpecial data processing applicationsLongitudeLandform

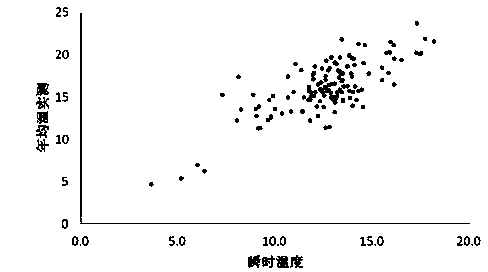

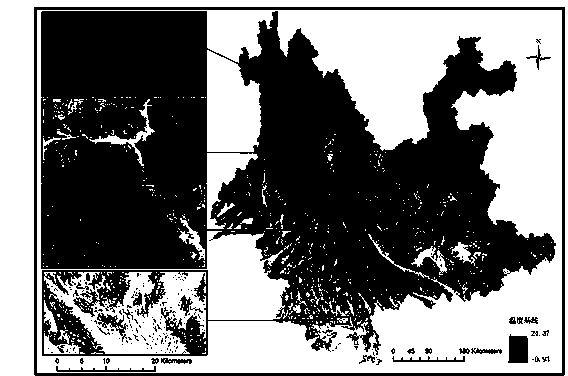

The invention discloses a method for building a mountainous area surface temperature base line and application, and relates to the measurement and application of mountainous area surface temperature base lines. A transient temperature field distributed continuously in MODIS thermal infrared remote sensing image inversion spaces is combined with longitude and latitude raster data to build the annual average temperature linear estimation model of a weather station as the calibration model of the transient surface temperature field. The model corrects the transient temperature field to obtain the mountainous area surface temperature base line. In YunnanProvince with the mountain landform as the main landform, the temperature base line with a 90m*90m grid as a unit is built, the temperature distribution characteristics and rules of the area are reflected, and the average temperature base line value of a 90m*90m land parcel can be found out in a quantitative mode. The temperature base line is used as basic data to be combined with an expert scoring method to respectively build a Yunnan Province pine wilt disease occurrence risk pre-warning model and a Yunnan Province forest fire danger long-term forecast model.

Owner:SOUTHWEST FORESTRY UNIVERSITY

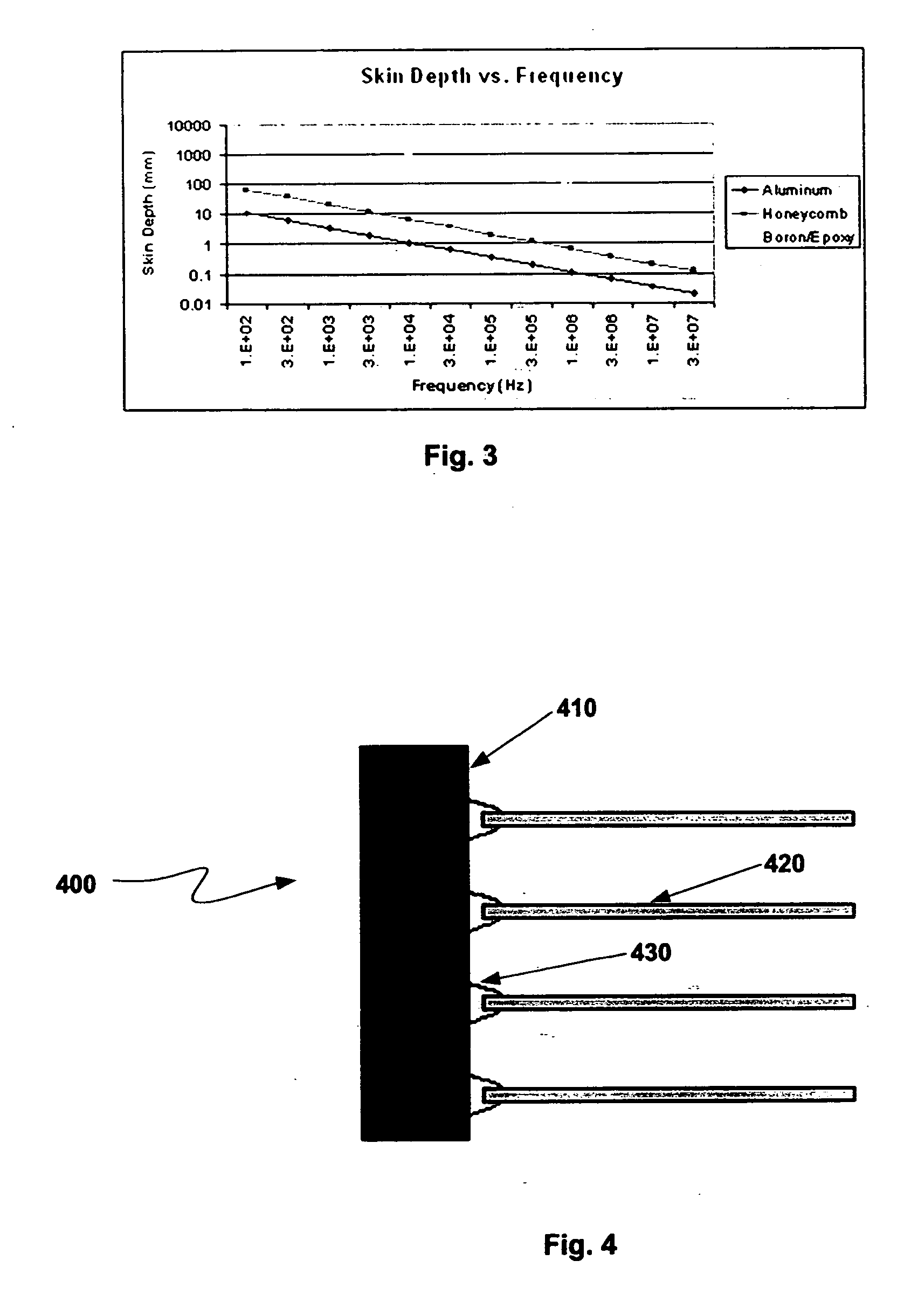

Inductively heated transient thermography method and apparatus for the detection of flaws

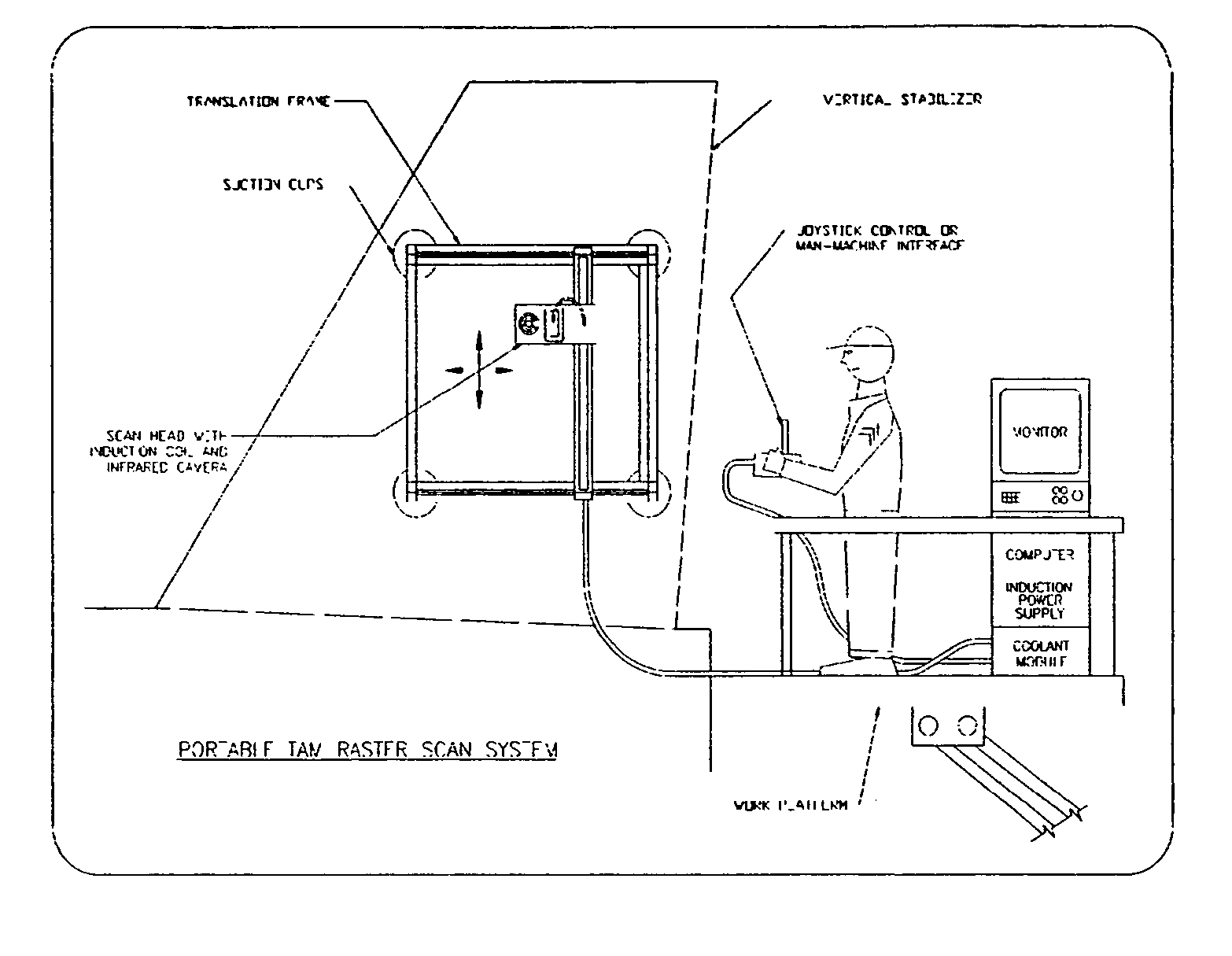

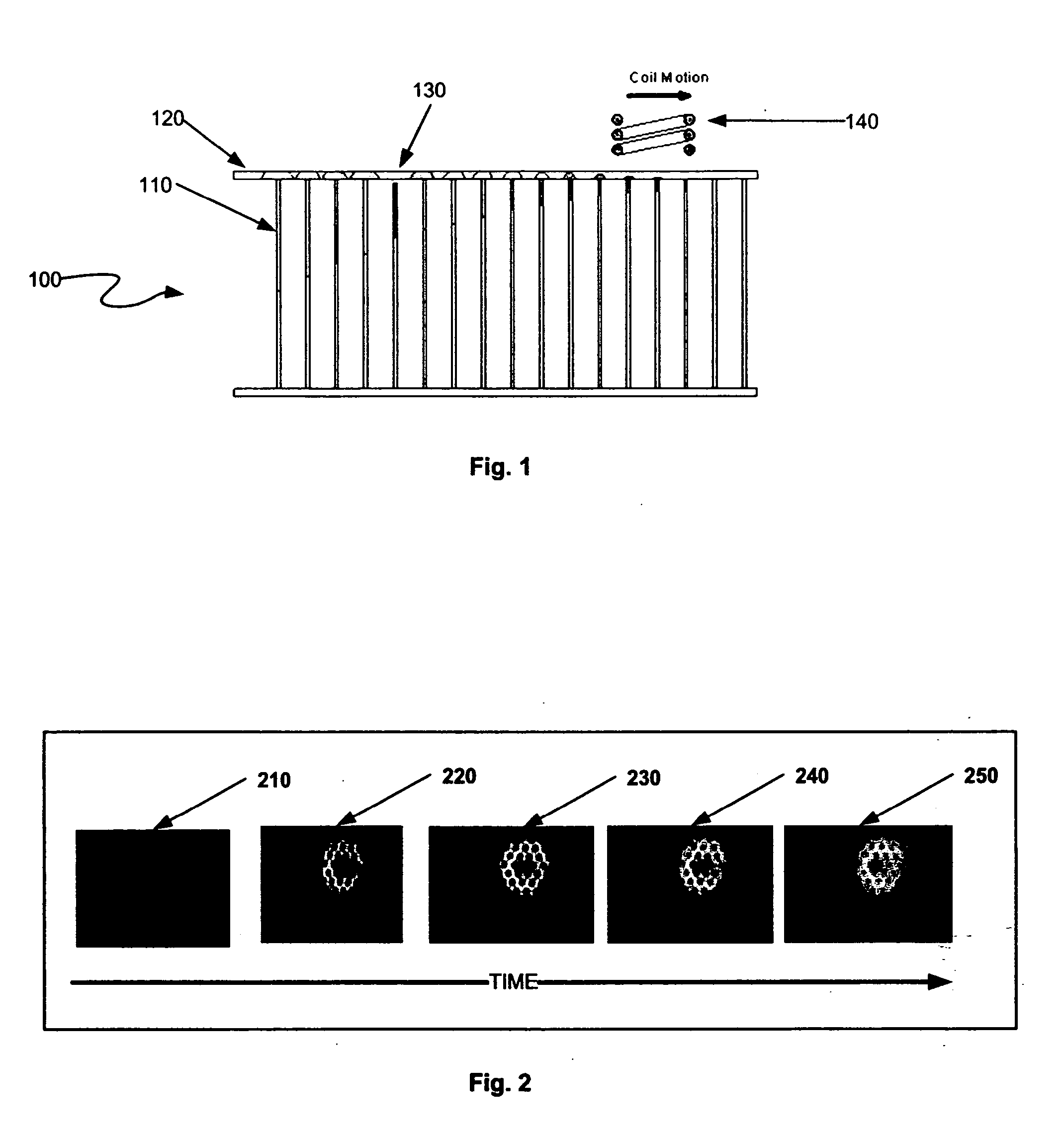

InactiveUS20050207468A1Radiation pyrometryWeather/light/corrosion resistanceNon destructiveDiffusion

A method and apparatus for non-destructive testing of a structure including the deposition of energy volumetrically into an object and detecting transient temperatures at a surface of the object caused by diffusion of the deposited energy. The energy is typically induced within the object by an induction coil and viewed by an IR camera as the transient energy exits the surface of the object.

Owner:MCCULLOUGH ROBERT W +1

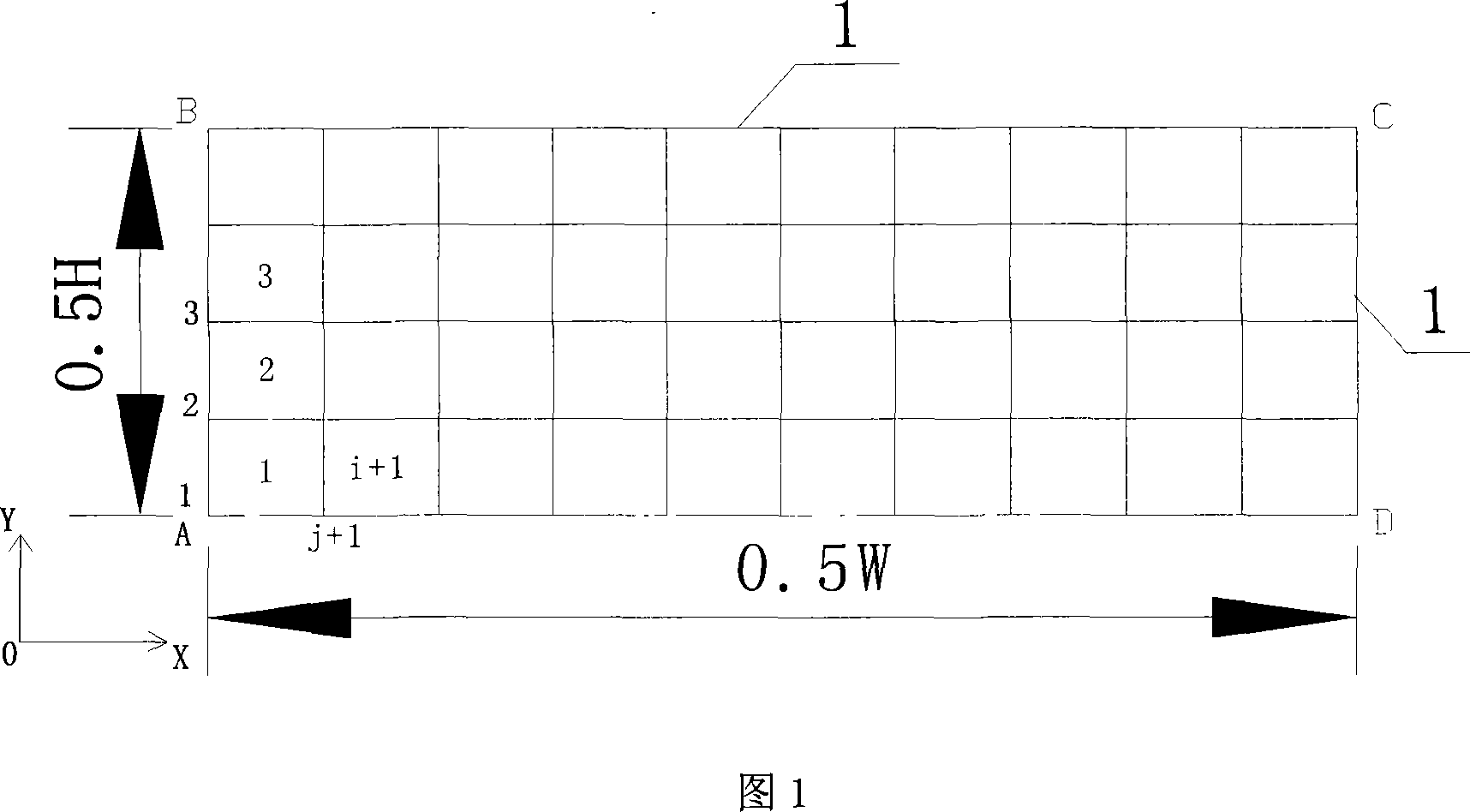

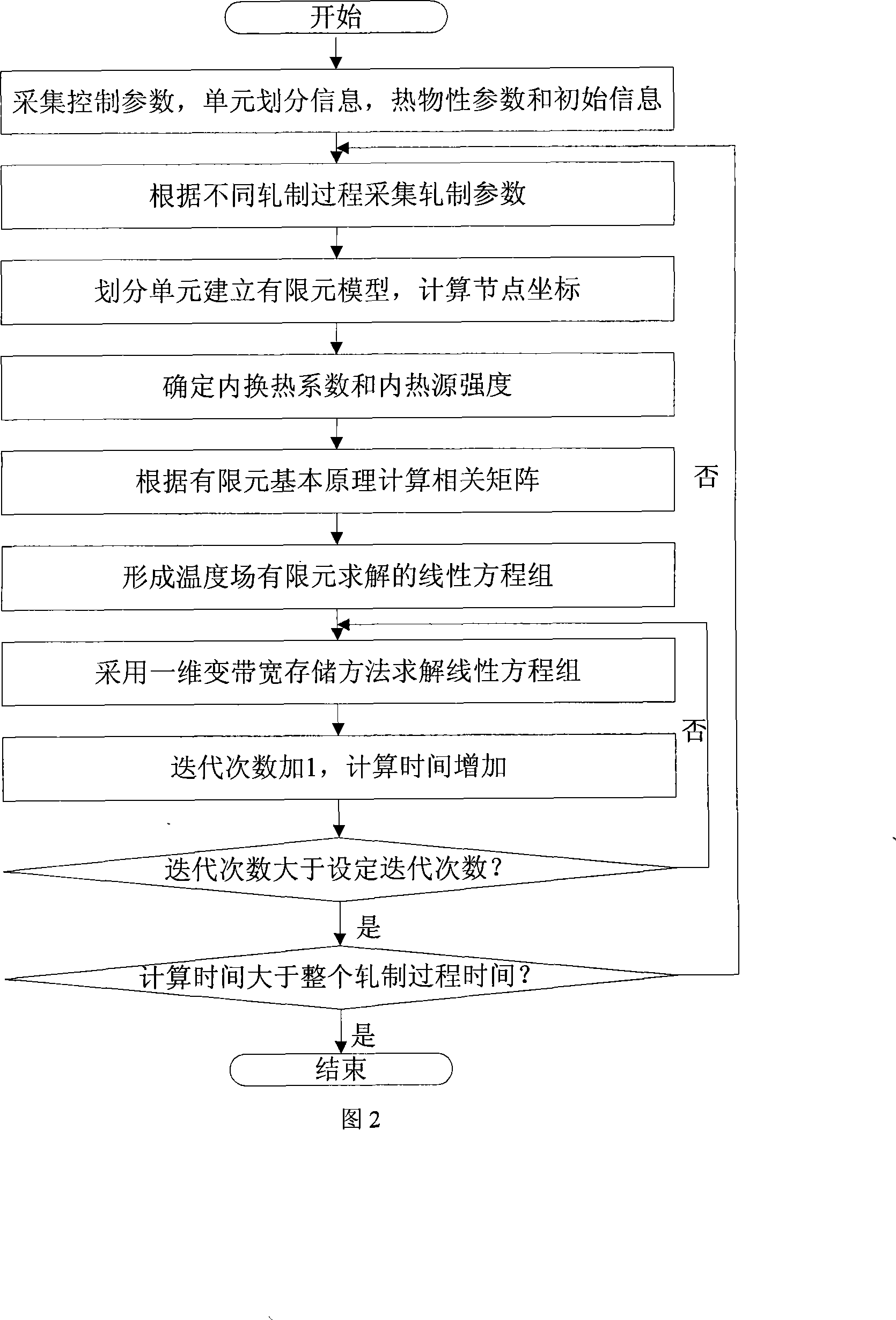

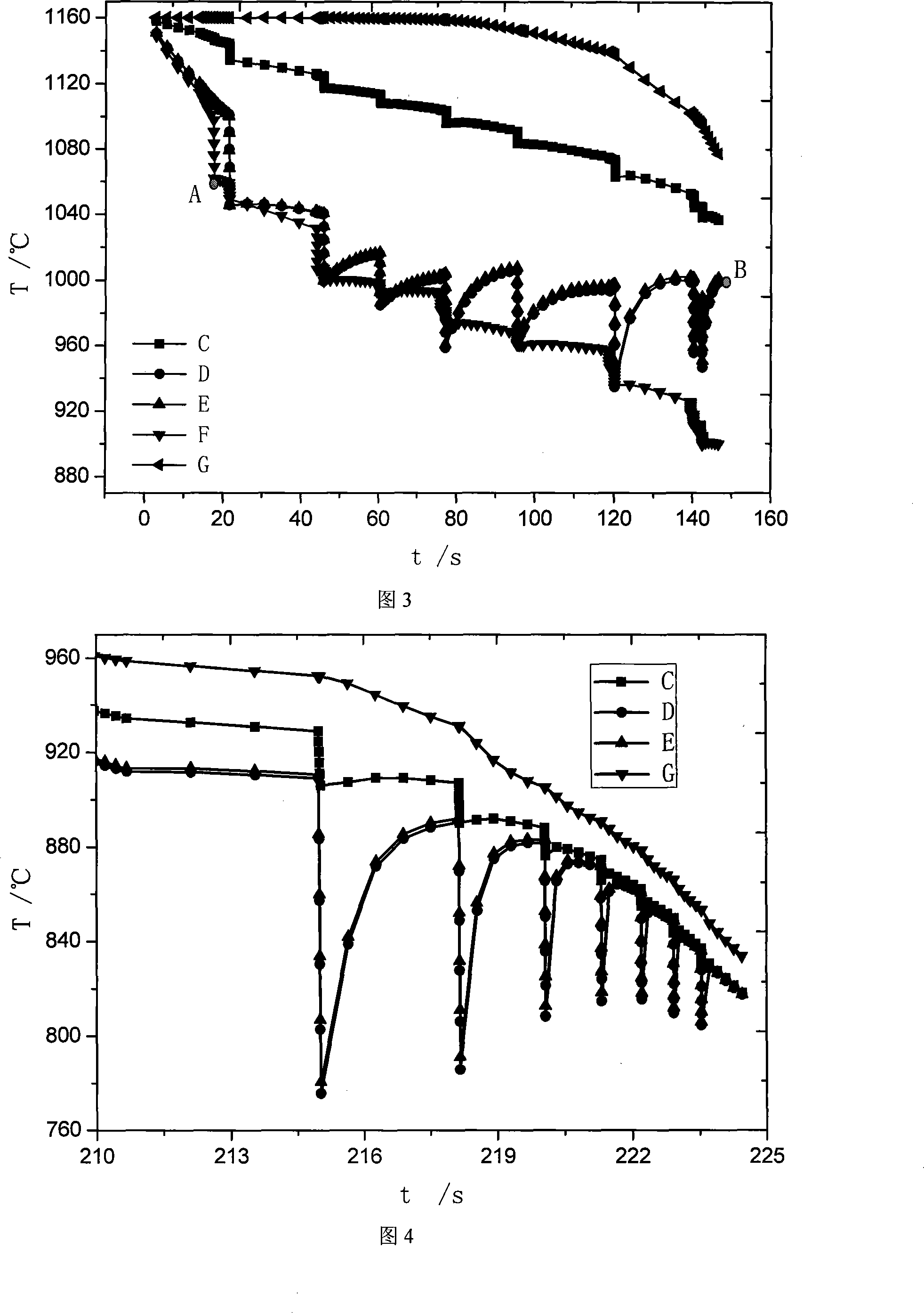

Method for forecasting finite element of hot rolling process plate belt temperature field

InactiveCN101178746AHigh temperature prediction accuracyImprove applicabilitySpecial data processing applicationsElement analysisTemperature forecasting

A finite element method of forecasting slab band temperature field during a hot rolling process belongs to the rolling technique field, and comprises the following steps: (1) collecting rolling process data; (2) carrying out unit division to cross section, establishing finite element analysis model, coding a unit node, and calculating a node coordinate; (3) ensuring border heat transfer coefficient and internal heat source intensity according to different rolling processes; (4) calculating the type-function of quadrangle isoparametric unit, B matrix, Jacobian matrix J and Jacobian matrix determinant |J| by using the finite element basic principle; (5) assembling the temperature rigidity matrix and dynamic heating matrix of the finite unit; (6) solving linear system of equations by adopting unidimensional variable bandwidth storage to obtain transient temperature field. The invention has the advantages that: the invention can obtain very high temperature forecasting precision and detailed information of the entire hot rolling slab band temperature distribution, which provides set and optimized parameter for rolling process, moreover, the invention has strong adaptability, reduces calculating time and improving calculating efficiency.

Owner:NORTHEASTERN UNIV

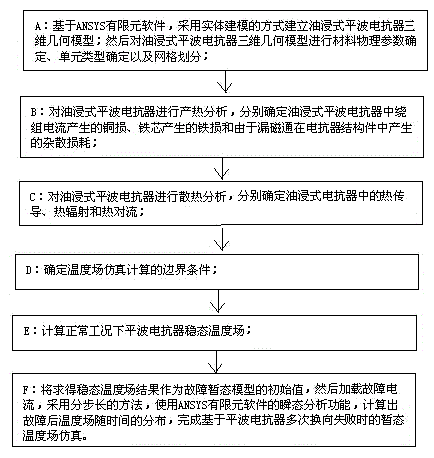

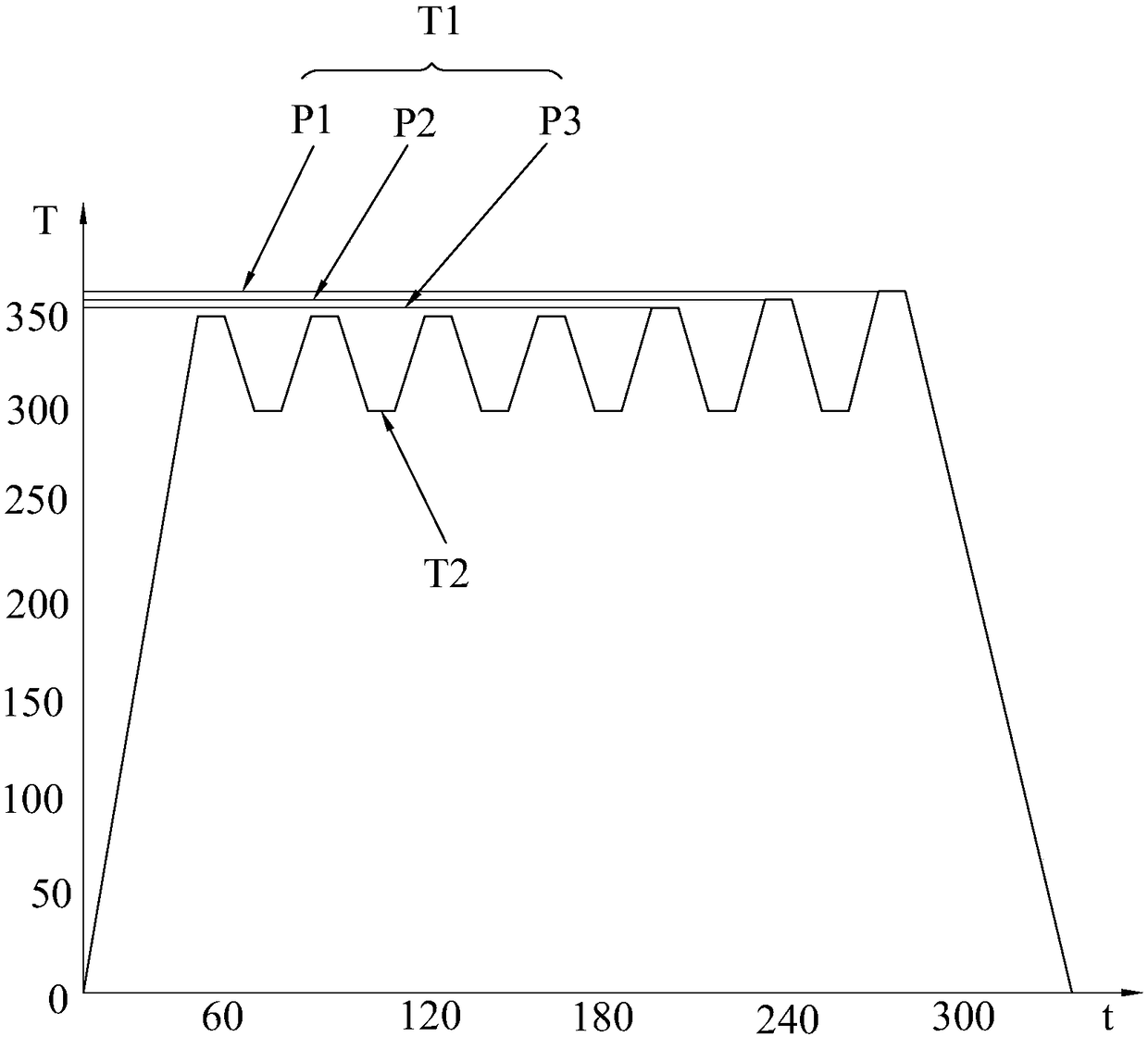

Transient temperature field simulation method based on multiple commutation failures of smoothing reactor

ActiveCN104834781ASpecial data processing applicationsSteady state temperatureFinite element software

The invention discloses a transient temperature field simulation method based on multiple commutation failures of a smoothing reactor. The method comprises the following steps that A, an oil immersed type smoothing reactor three-dimensional geometrical model is built in a solid modeling mode on the basis of ANSYS finite element software; B, an oil immersed type smoothing reactor is subjected to heat generating analysis; C, the oil immersed type smoothing reactor is subjected to heat radiation analysis; D, the boundary conditions of temperature field simulation calculation are determined; E, the steady temperature field of the smoothing reactor under the normal work condition is calculated; F, the obtained steady temperature field result is used as an initial value of a failure transient model, then, the failure current is loaded, a step-length method is adopted, the distribution of the temperature field along with time after the failure is calculated, and the transient temperature field simulation method based on multiple commutation failures of the smoothing reactor is completed. The method has the advantage that basis is provided for checking the maloperation reason of a smoothing reactor gas relay and setting the gas checking setting valve of the smoothing reactor.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

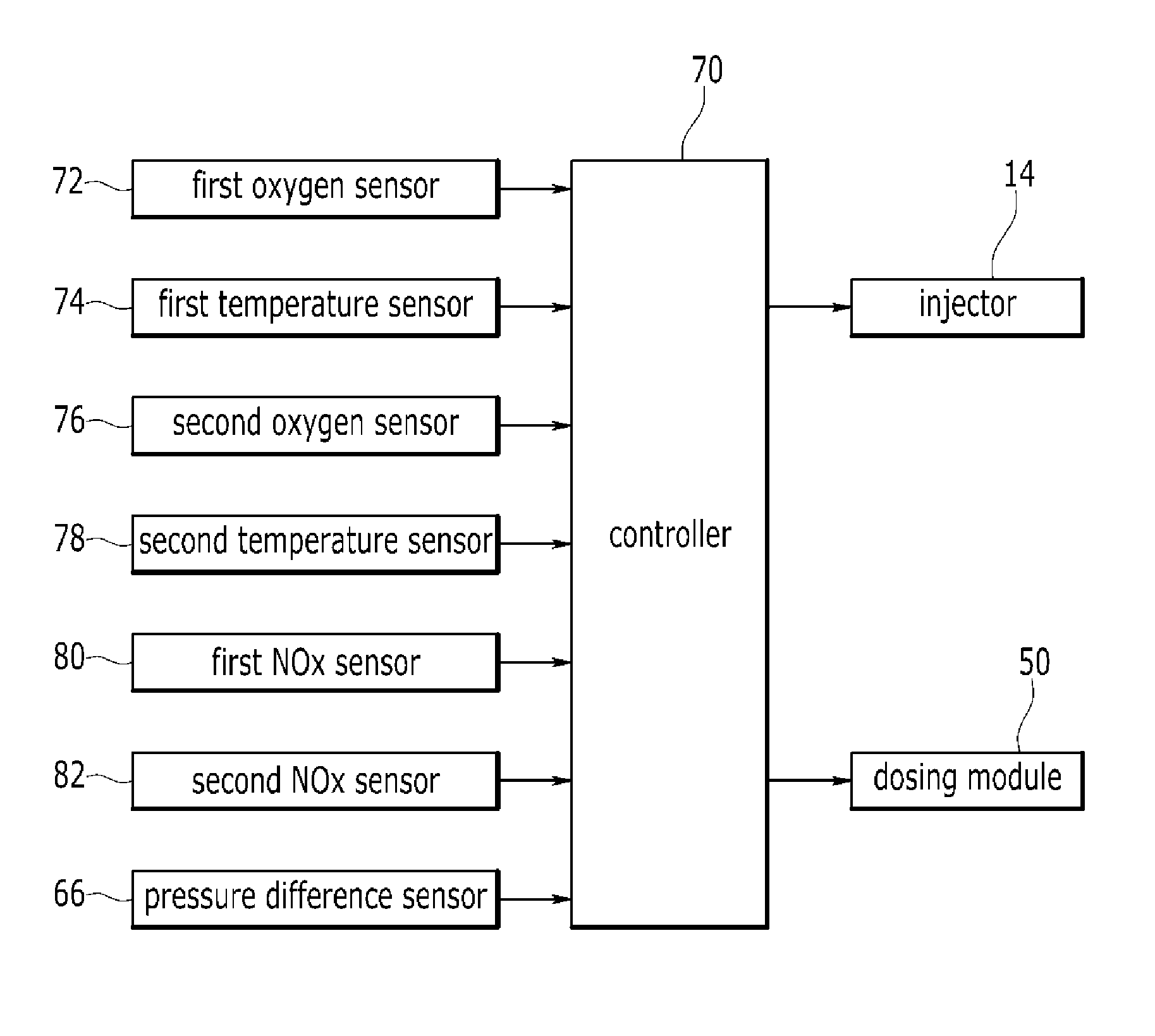

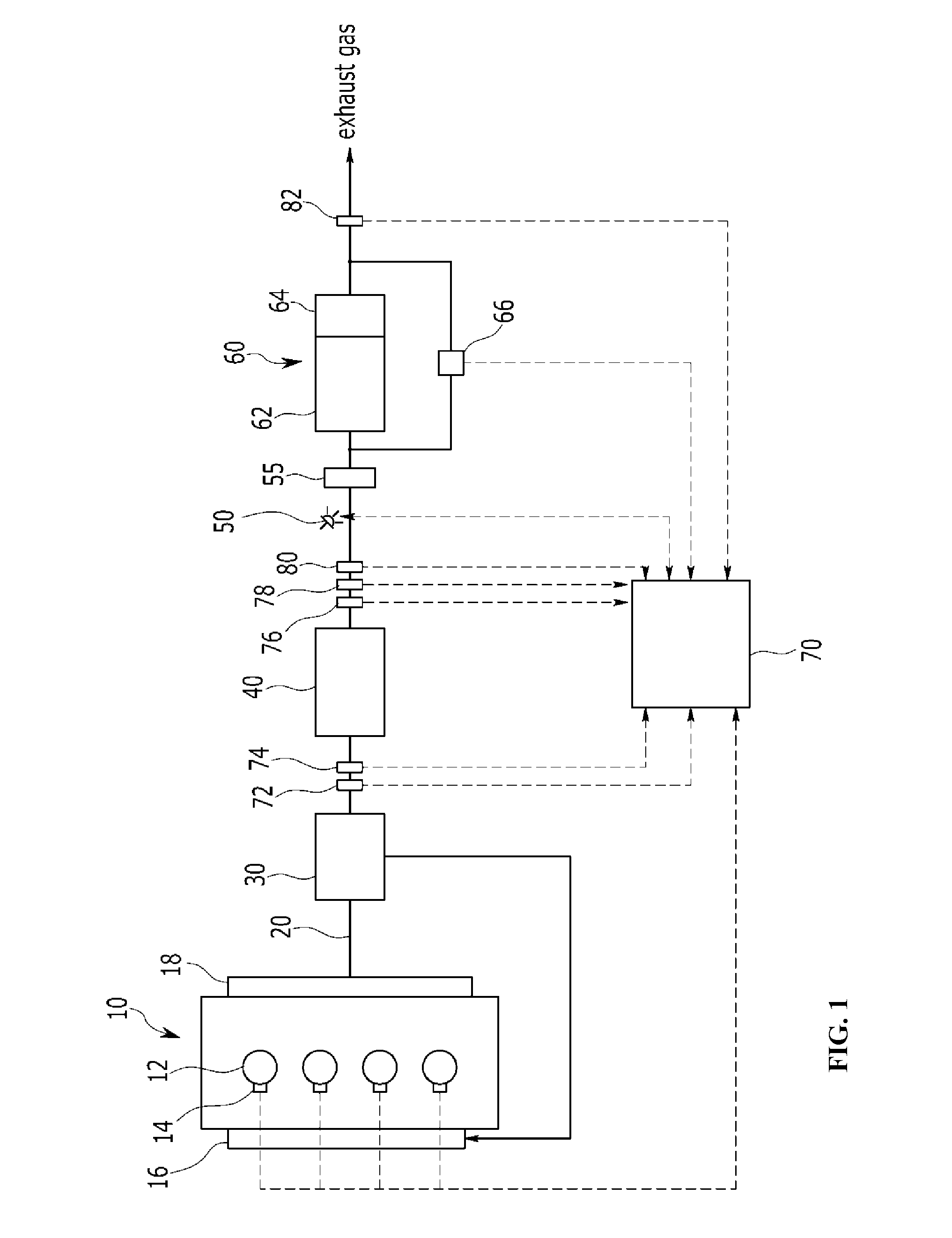

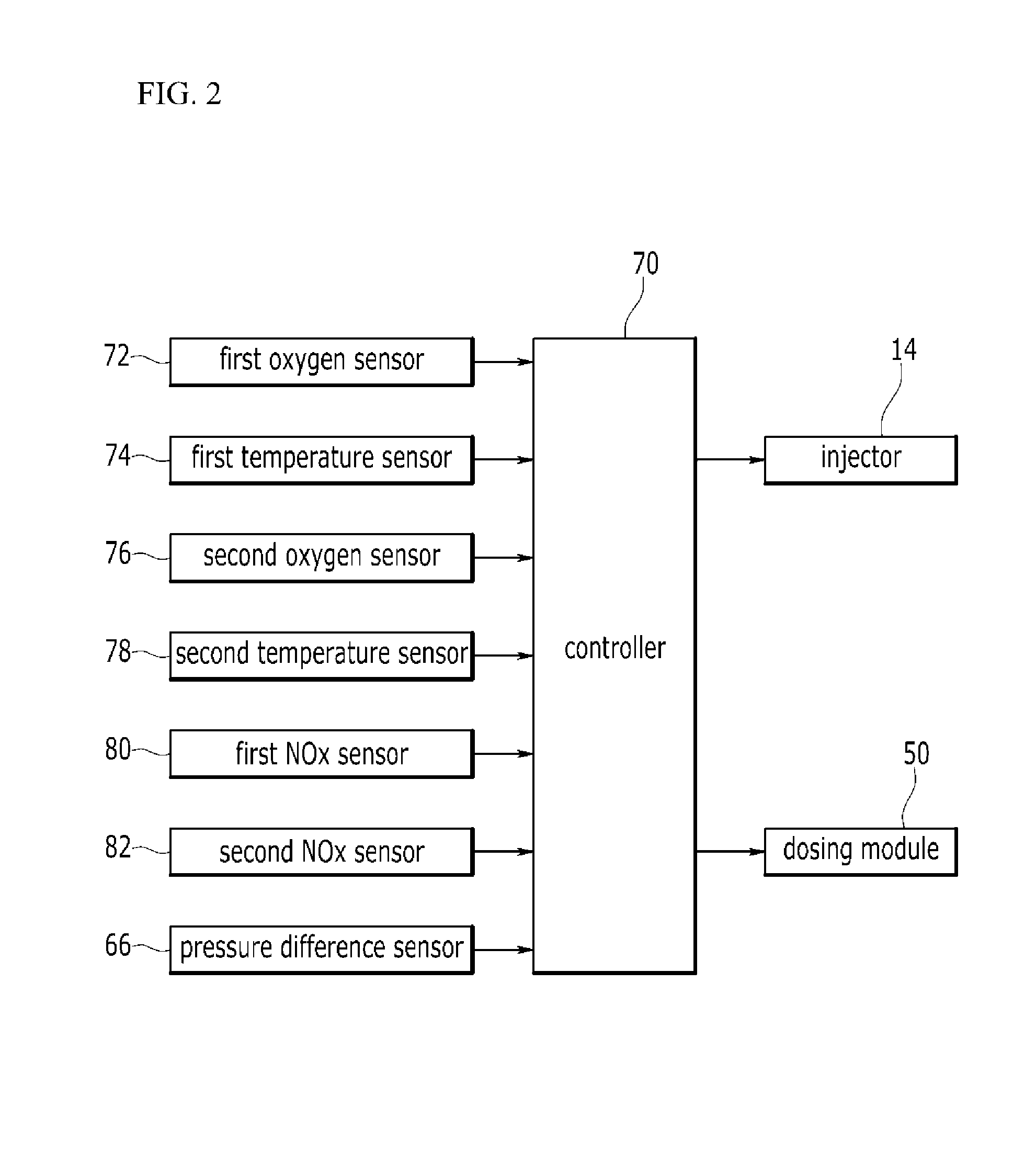

System and method of purifying exhaust gas

InactiveUS20150143798A1Improve purification efficiencyReduce NOxElectrical controlInternal combustion piston enginesExhaust fumesNitrogen oxide

A system of purifying exhaust gas may include an engine including an injector, a lean NOx trap (LNT) adapted to absorb nitrogen oxide (NOx) contained in the exhaust gas at a lean air / fuel ratio, to release the absorbed nitrogen oxide at a rich air / fuel ratio, and to reduce the nitrogen oxide contained in the exhaust gas or the released nitrogen oxide, a dosing module adapted to inject reducing agent into the exhaust gas, a selective catalytic reduction catalyst on a diesel particulate filter (SDPF) adapted to trap particulate matter and to reduce the nitrogen oxide using the reducing agent injected through the dosing module, and a controller performing denitrification (DeNOx) using the LNT when temperature of the exhaust gas may be lower than transient temperature, and performing denitrification using the SDPF when the temperature of the exhaust gas may be higher than or equal to the transient temperature.

Owner:HYUNDAI MOTOR CO LTD

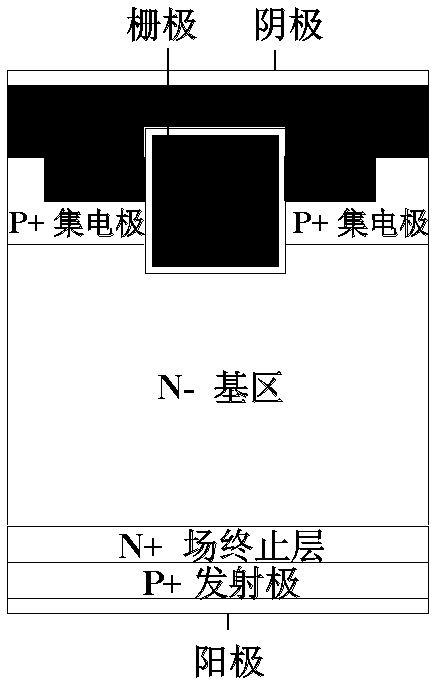

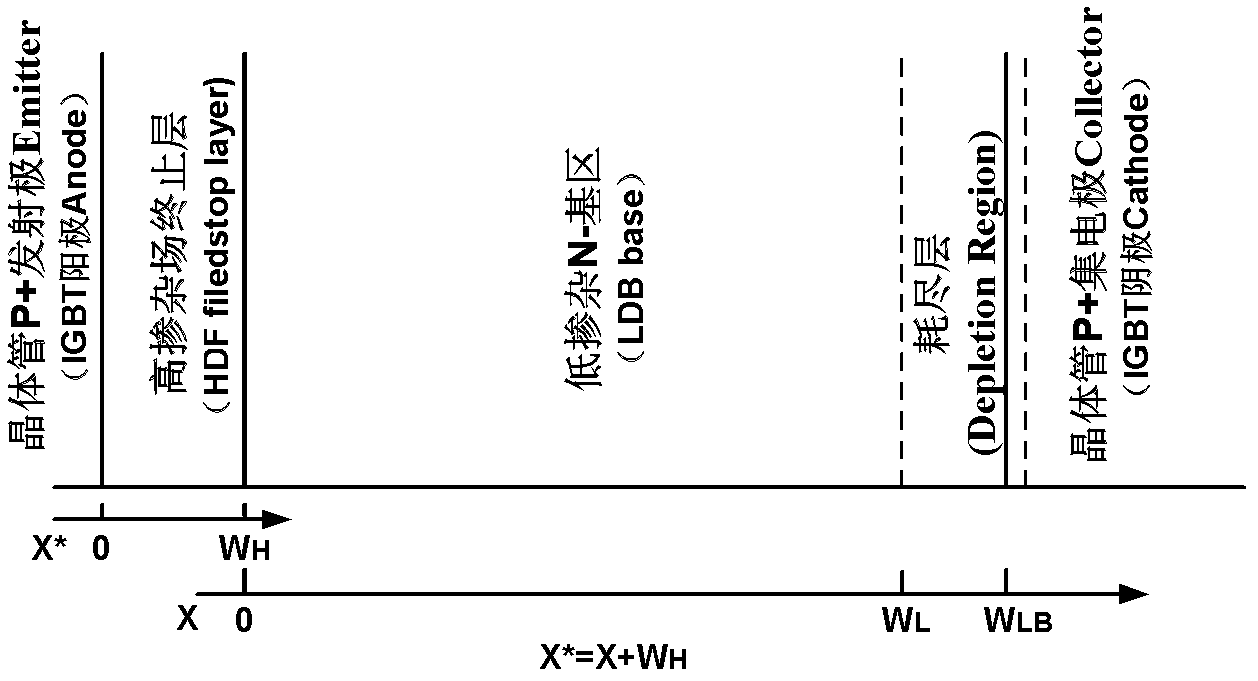

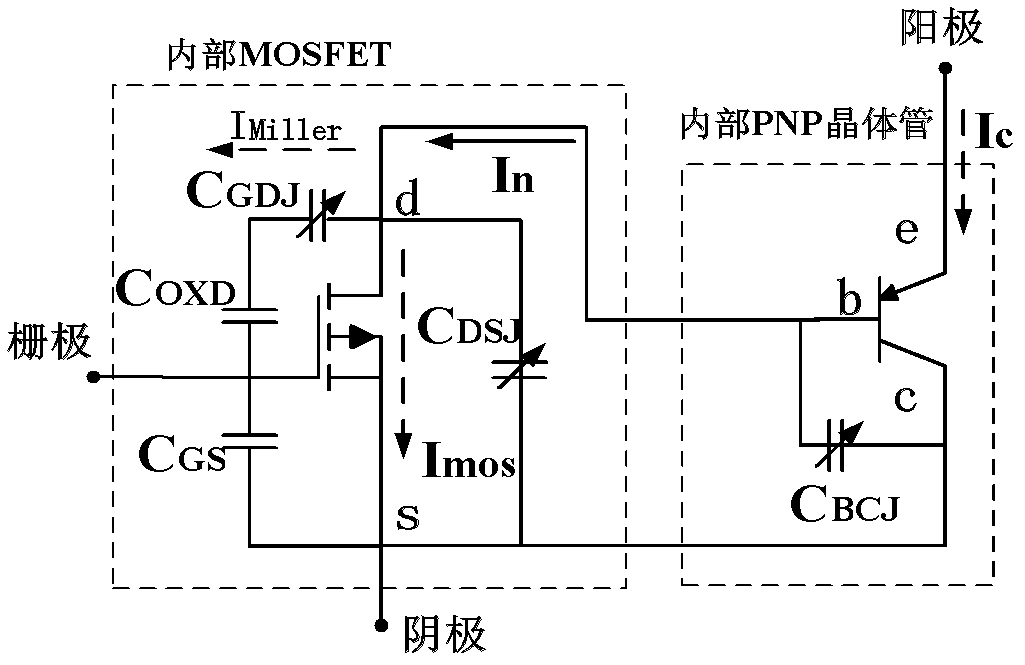

Electro-thermal simulation method for FS (Field Stop) type IGBT (Insulated Gate Bipolar Transistor) transient temperature characteristic

ActiveCN102368274AEasy to buildHigh precisionSpecial data processing applicationsTransconductanceThermal simulation

The invention provides an electro-thermal simulation method for FS (Field Stop) type IGBT (Insulated Gate Bipolar Transistor) transient temperature characteristic. An FS type IGBT switching transient working process is actually tested and is analyzed by being combined with an IGBT working principle and a semiconductor physical principle to determine that the IGBT transient temperature characteristic is mainly influenced by life of internal excess carrier, so that the electro-thermal simulation method is established. The method comprises the following steps of: actually testing carrier life values extracted at different temperatures to acquire a relational expression of the carrier life and temperature; calculating through an empirical value formula to acquire a relational expression amongthreshold voltage, transconductance, emitter saturation and current as well as the temperature; and adding temperature related parameters into an FS type IGBT current tailing stage current analyticalexpression and a switching transient model equation set and calculating to acquire transient working waveform of the FS type IGBT at different temperatures. The electro-thermal model simulation method provided by the invention simultaneously has the advantages of simple parameter calculation and high accuracy.

Owner:NAVAL UNIV OF ENG PLA

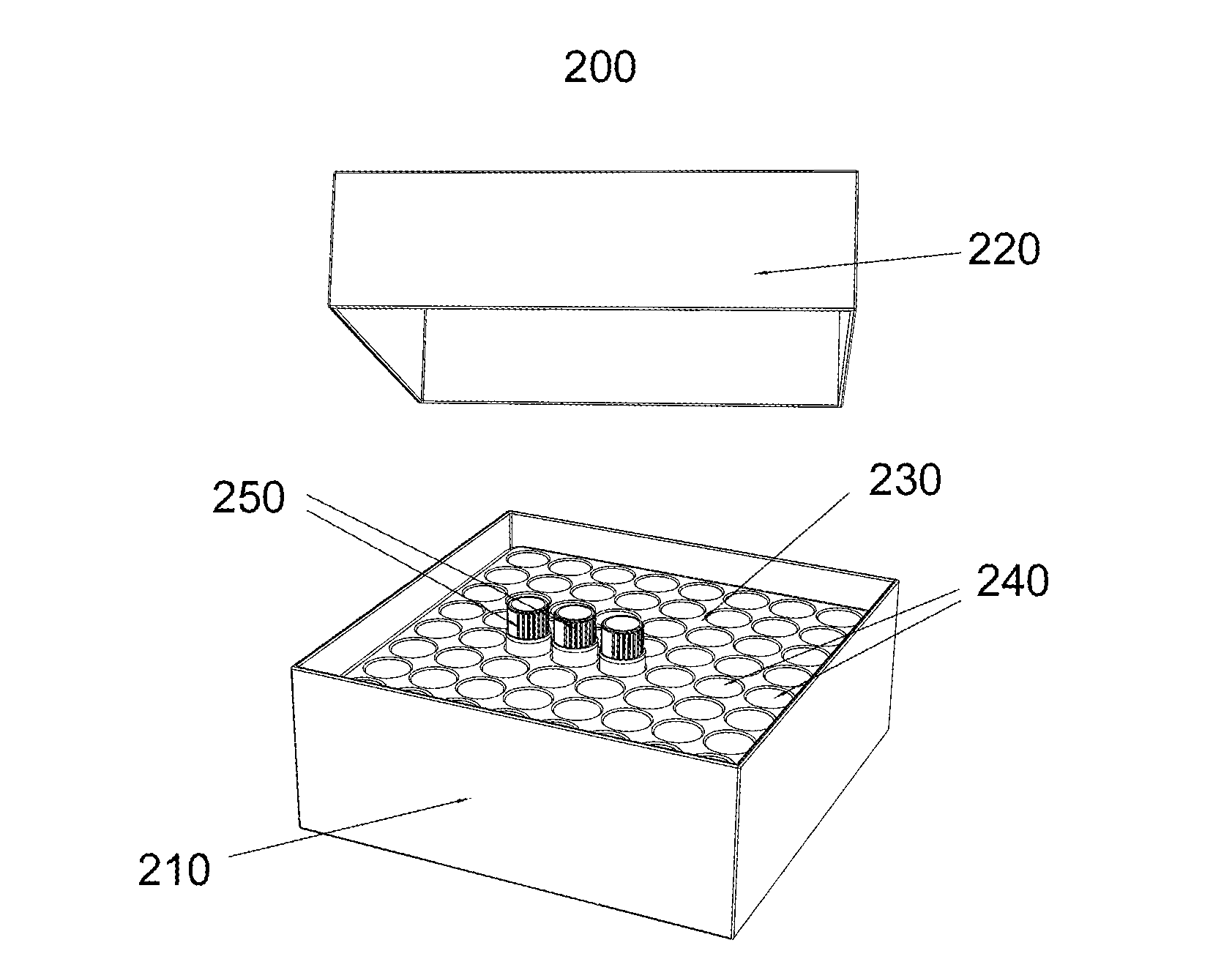

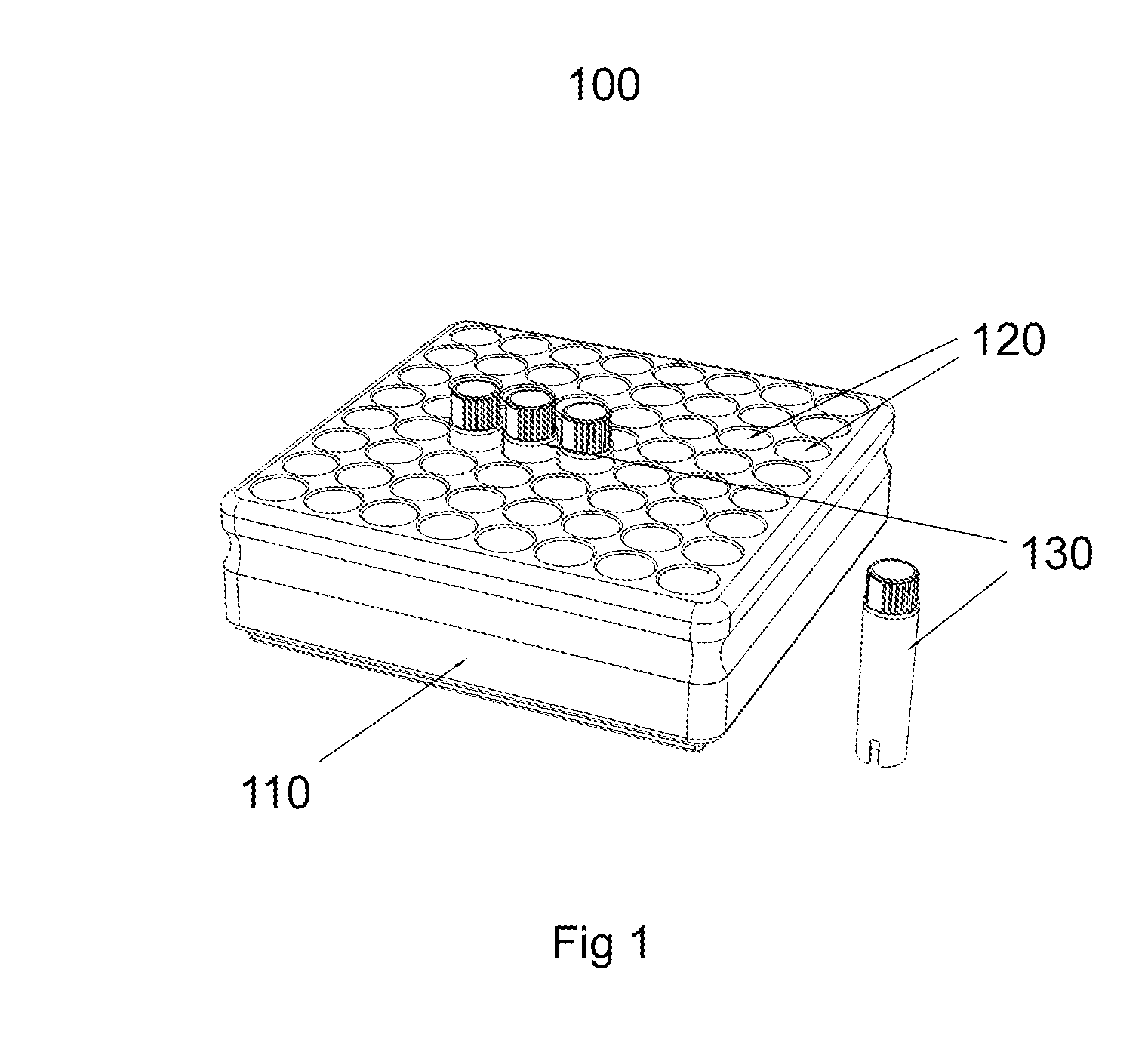

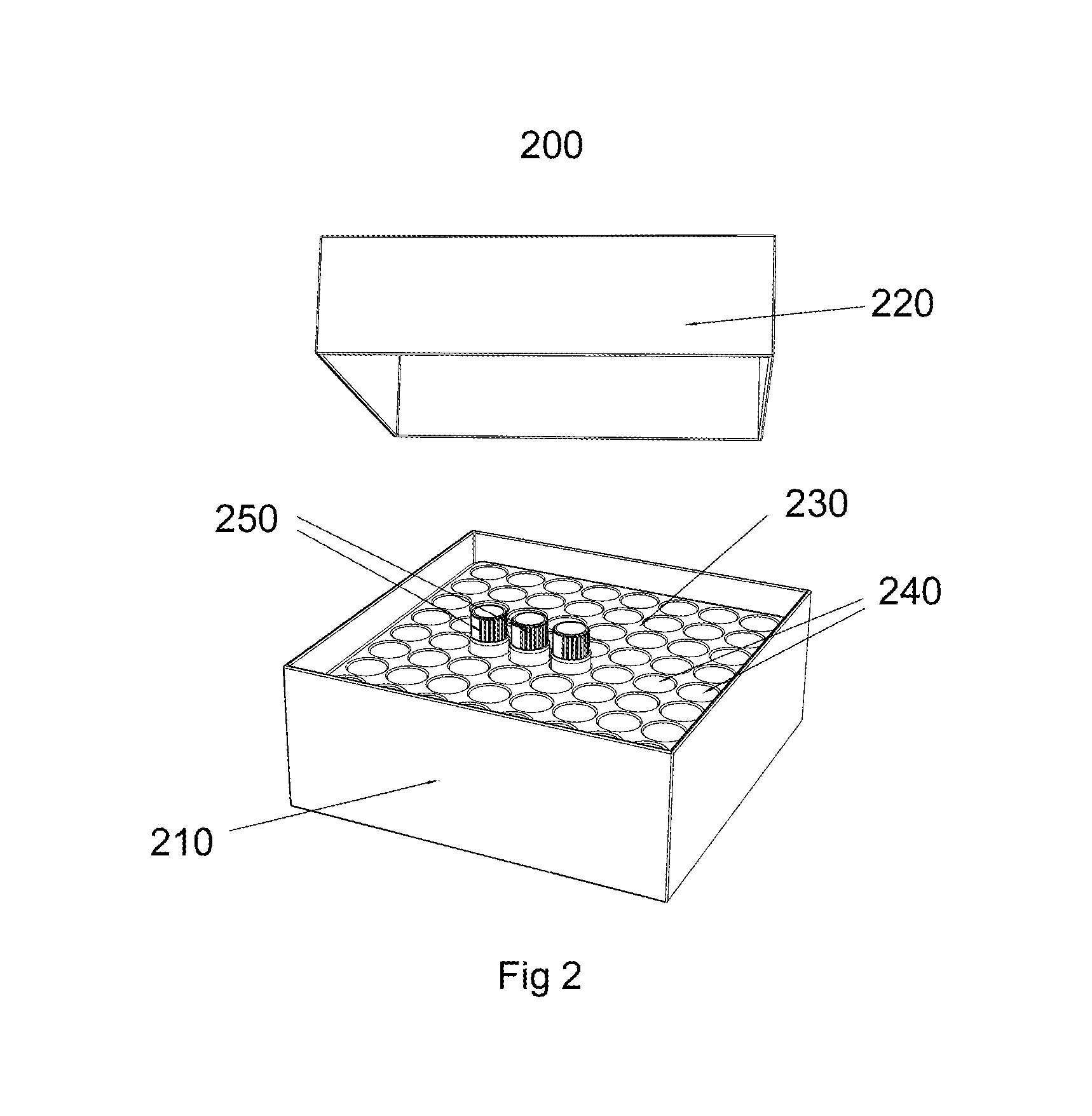

Preventing sample degradation from transient temperature fluctuations

InactiveUS20130025298A1Efficient solutionSuppress fluctuationsDead animal preservationHeat transfer modificationEngineeringTransient temperature

Methods and devices can protect samples maintained at controlled temperatures from degradation due to transient temperature fluctuations.

Owner:COOL LAB LLC

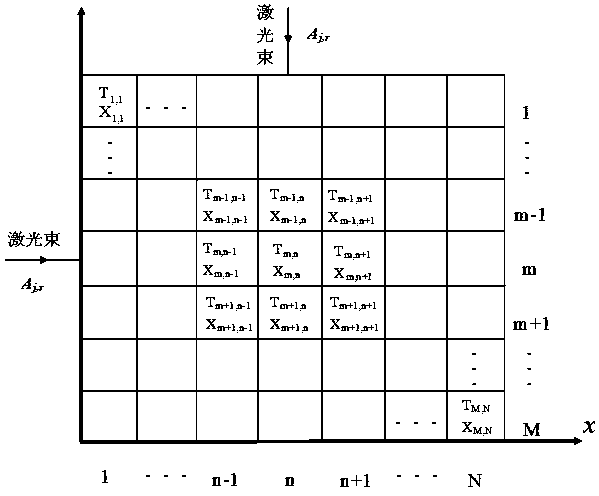

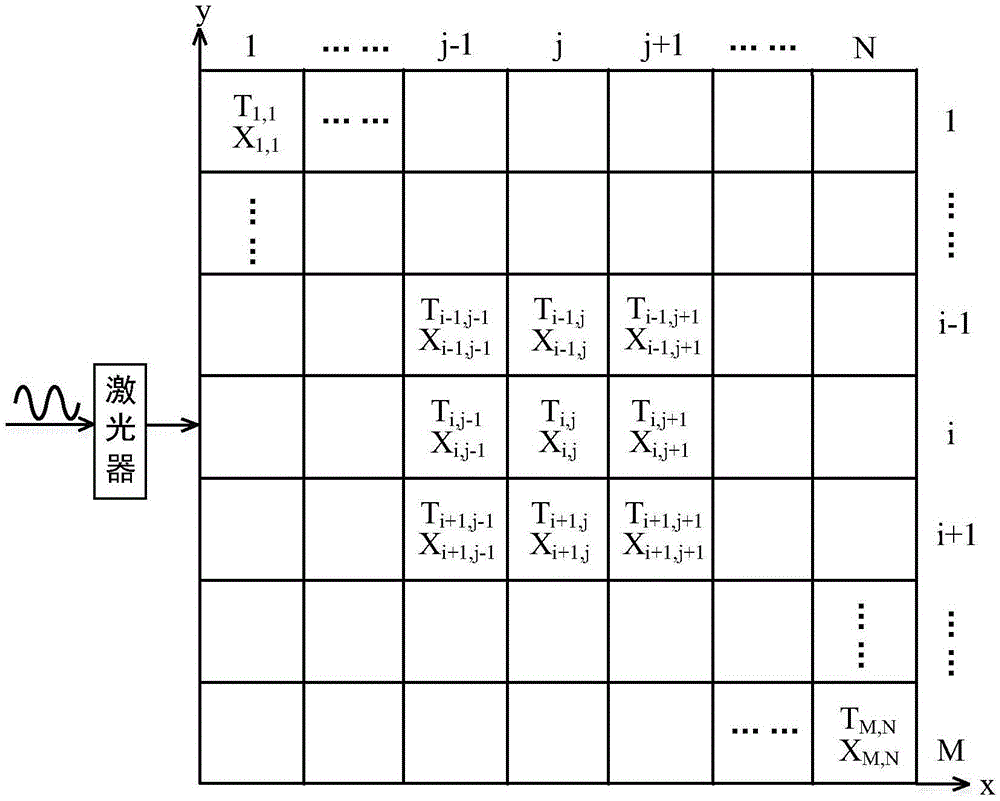

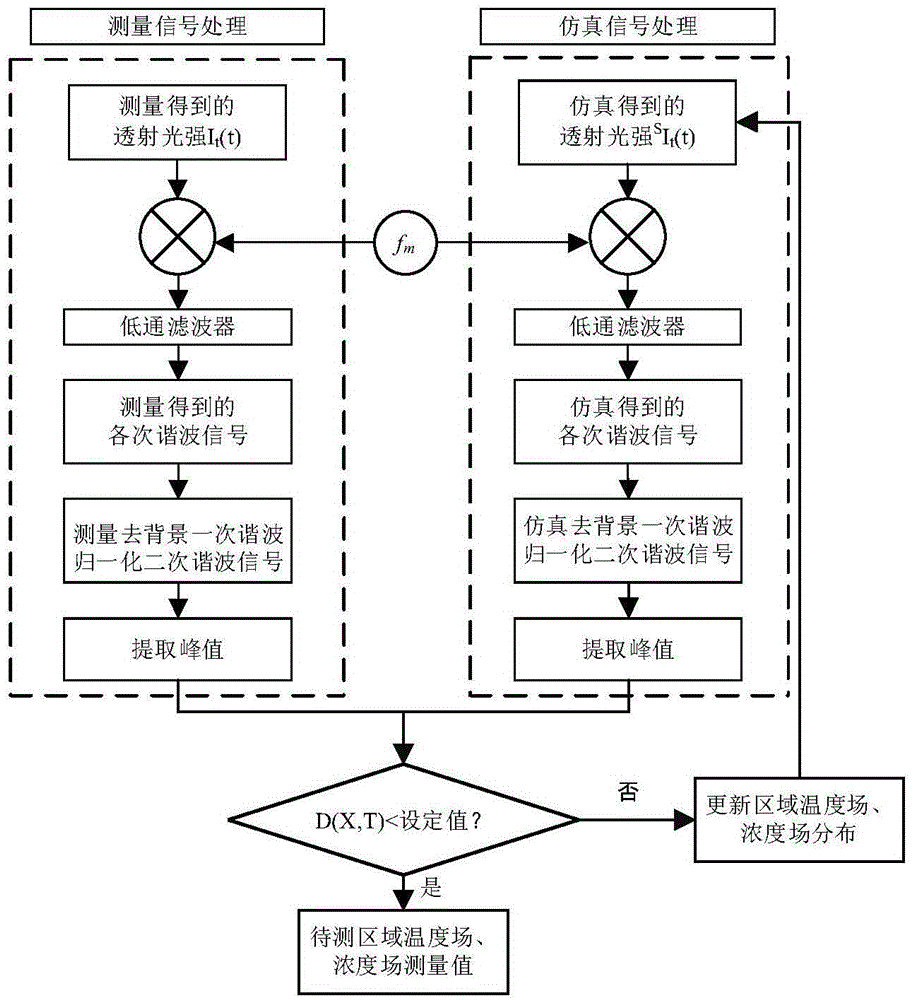

Method for simultaneously measuring distribution of high-temperature gas two-dimensional transient temperature field and concentration field based on hyper spectrum

The invention discloses a method for simultaneously measuring distribution of a high-temperature gas two-dimensional transient temperature field and concentration field based on a hyper spectrum, and belongs to the technical field of laser absorption spectrums. The method comprises the steps that a laser array is distributed on a high temperature area to be measured, hyper spectrum scanning is carried out on the area to be measured, an area temperature field and a vapor concentration field are measured through the spectral absorption of vapor characteristic spectral lines, and meanwhile the distribution of a gas concentration field is measured through the characteristic spectrum absorption of other gas. Grid scattering is carried out on the area to be measured in measurement, laser beams are distributed on the rows and columns of a grid respectively, broadband spectrum scanning is carried out on the characteristic spectral line of gas to be measured, and the inversion of the temperature field and the gas composition concentration field is achieved through a spectrum absorption rate obtained through the scanning with the help of an intelligent optimization algorithm.

Owner:SOUTHEAST UNIV

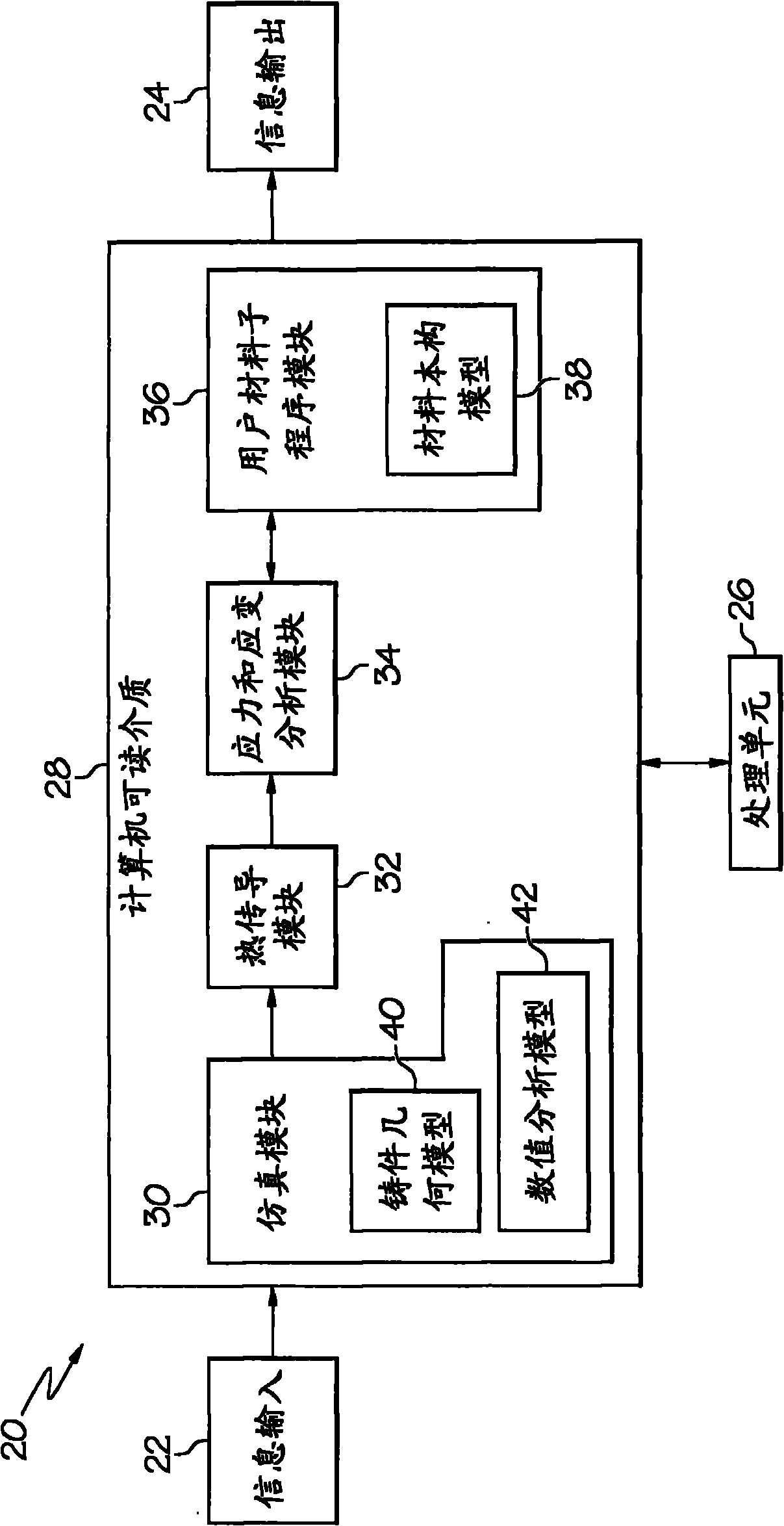

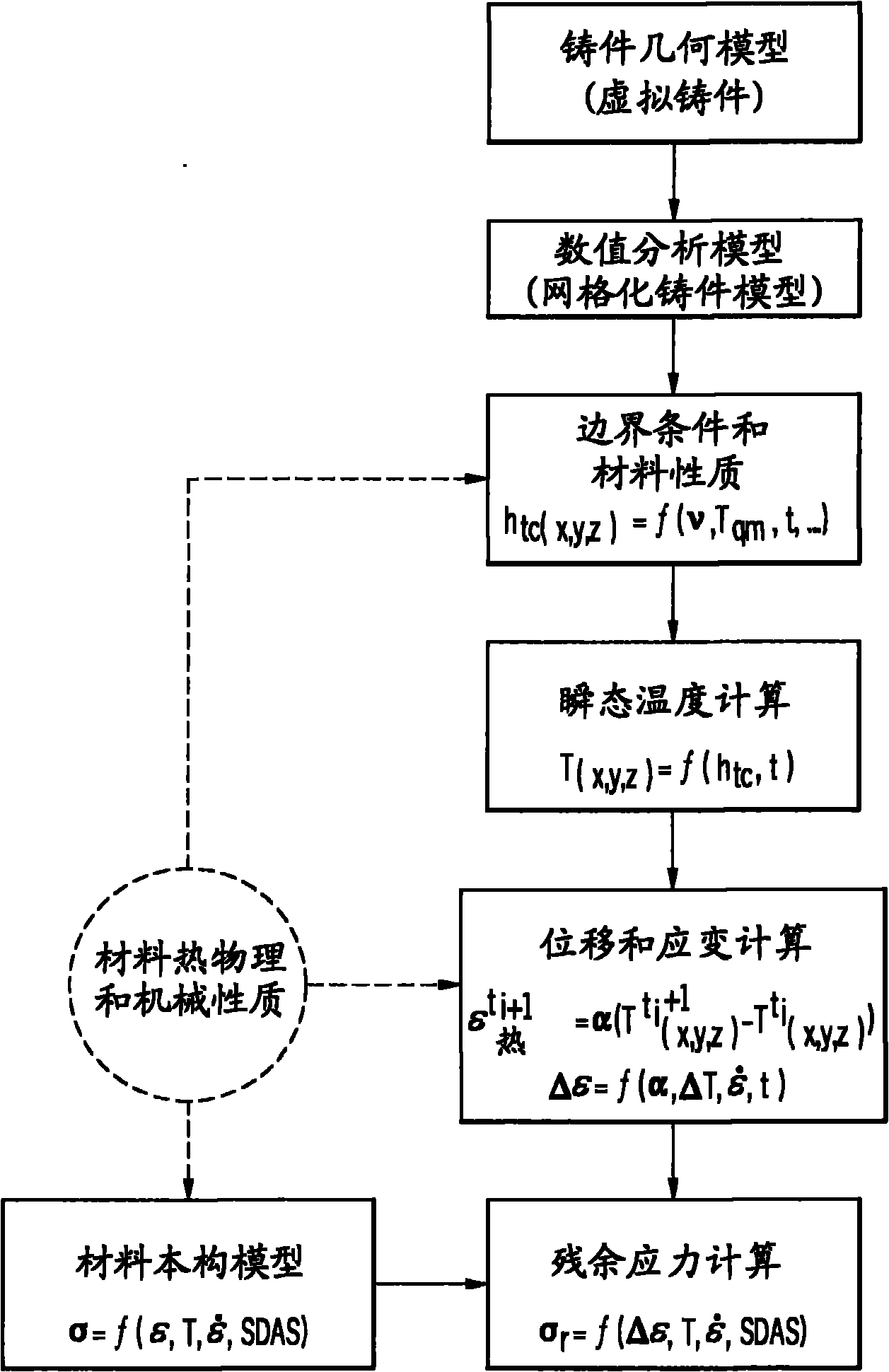

Methods of predicting residual stresses and distortion in quenched aluminum castings

ActiveCN101887472ADesign optimisation/simulationSpecial data processing applicationsQuenchingDistortion

Computational systems, methods, and articles of manufacture to predict at least one of residual stresses and distortion in quenched aluminum castings. Residual stresses and distortion may be predicted through incorporating thermal strains induced during quenching with the nonlinear constitutive behavior of quenched microstructures of a quenched aluminum casting, wherein thermal strains arise generally from non-uniform transient temperature distribution of the casting during quenching. The transient temperature distribution of the aluminum casting during quenching may be calculated based on heat transfer coefficients specific to one or more nodes, elements and / or zones on the surfaces of the aluminum casting. The nonlinear constitutive behavior of the quenched aluminum casting may be modeled as functions of temperatures, strain rates, and microstructure variations. A material constitutive model accounts for not only strain hardening and creep, but also precipitate hardening. Thereby, residual stresses and distortion in the quenched aluminum castings can be predicted using the embodiments.

Owner:GM GLOBAL TECH OPERATIONS LLC

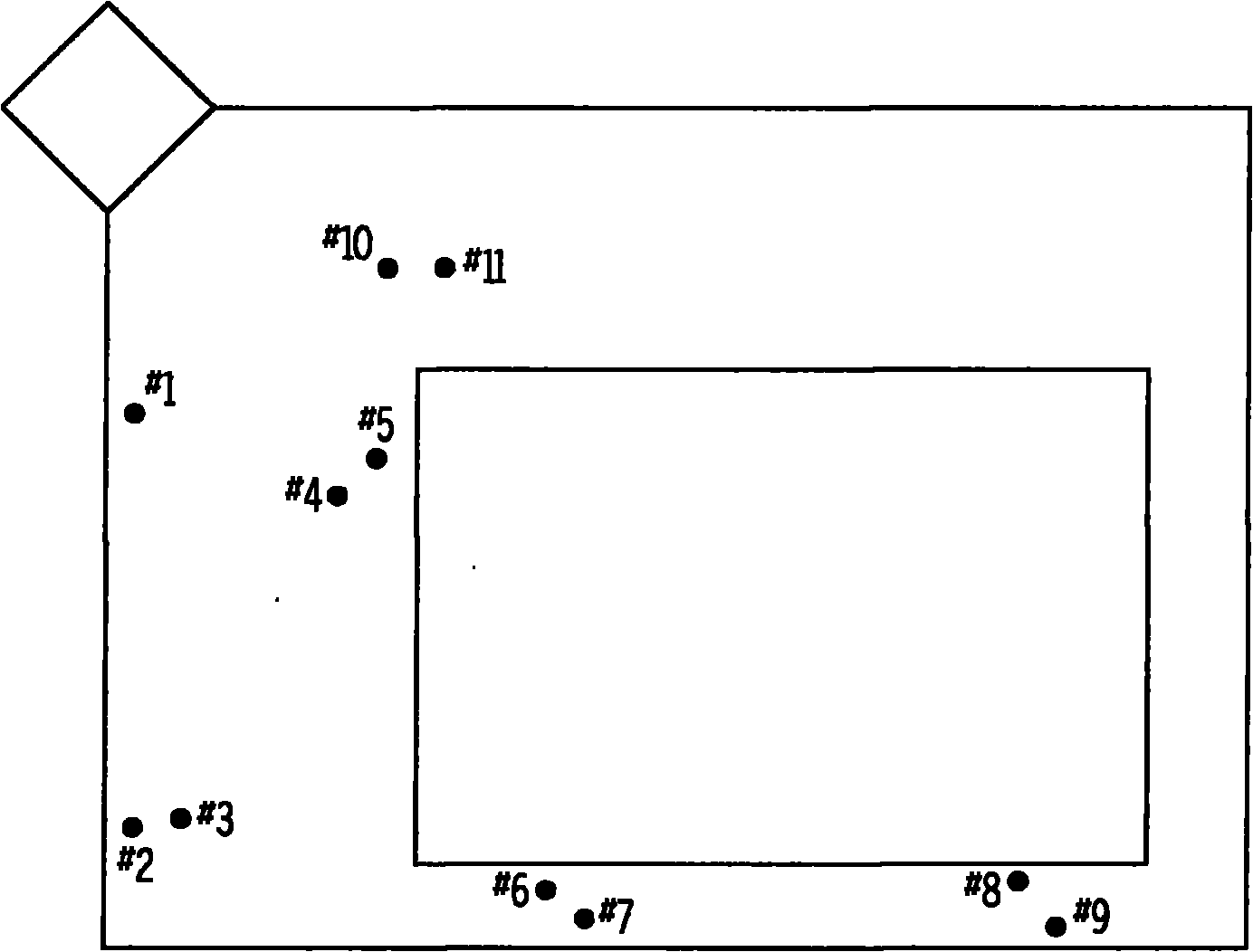

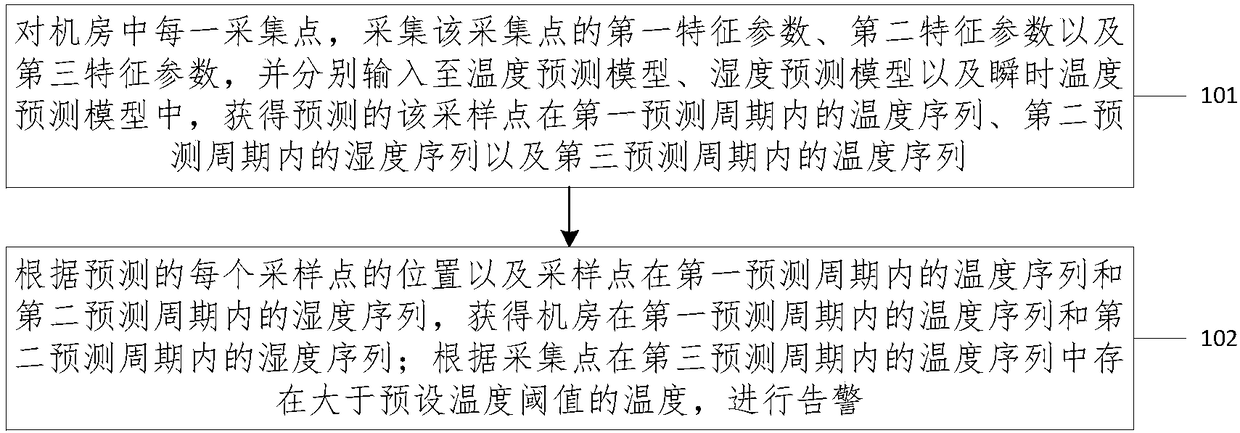

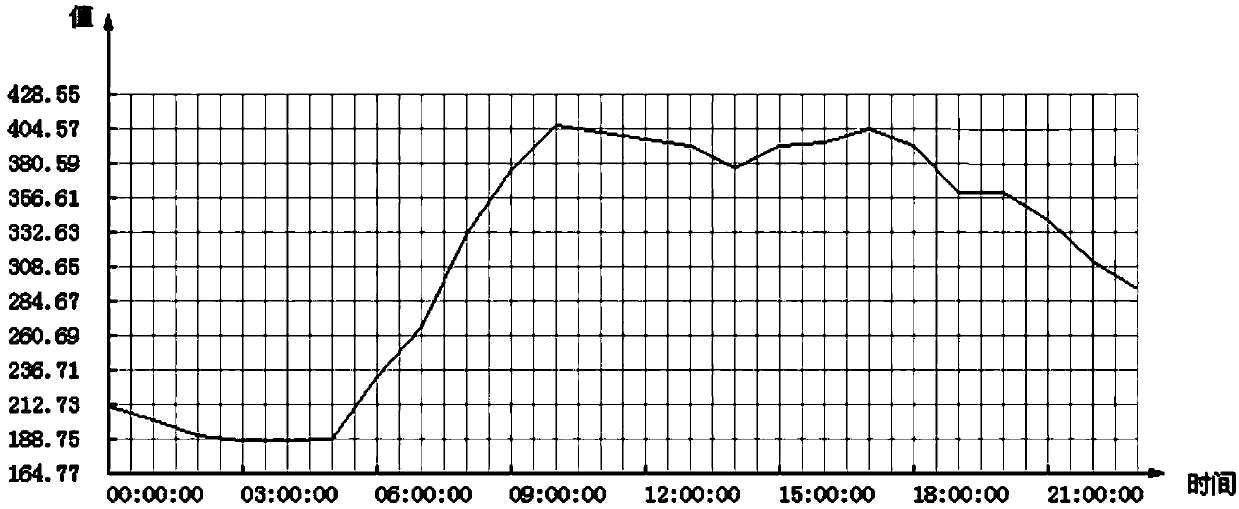

Method and system for predicting temperature and humidity environment of machine room

InactiveCN108518804AReduce incidenceImprove efficiencyMechanical apparatusSpace heating and ventilation safety systemsAlgorithmPower usage effectiveness

The invention provides a method and system for predicting the temperature and humidity environment of a machine room. The method comprises the steps that as for each sampling point in the machine room, a first characteristic parameter, a second characteristic parameter and a third characteristic parameter of the sampling point are collected, the first characteristic parameter is into a temperaturepredicting model to obtain the predicted temperature sequence of the sampling point in the first prediction period, the second characteristic parameter is input into a humidity predicting model to obtain the predicted humidity sequence of the sampling point in the second prediction period, and the third characteristic parameter is input into a transient temperature predicting model to obtain thepredicted temperature sequence of the sampling point in the third prediction period; the temperature sequence of the machine room in the first prediction period and the humidity sequence of the machine room in the second prediction period are obtained according to the predicted position of each sampling point and the temperature sequence of the sampling point in the first prediction period and thehumidity sequence of the sampling point in the second prediction period; and an alarm is given when temperature greater than the preset temperature threshold exists in the temperature sequence of each sampling point in the third prediction period. By means of the method and system for predicting the temperature and humidity environment of the machine room, energy consumption of the machine room is reduced, the energy utilization efficiency is improved, and the accident occurrence rate of the machine room is reduced.

Owner:WUHAN WULIANYUAN TECH CO LTD +2

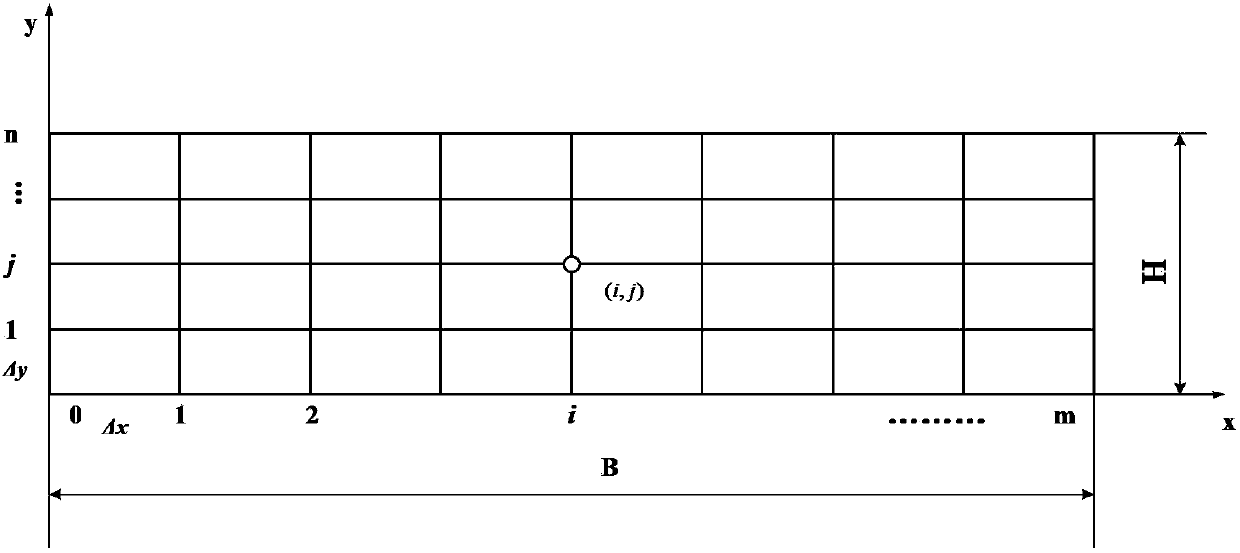

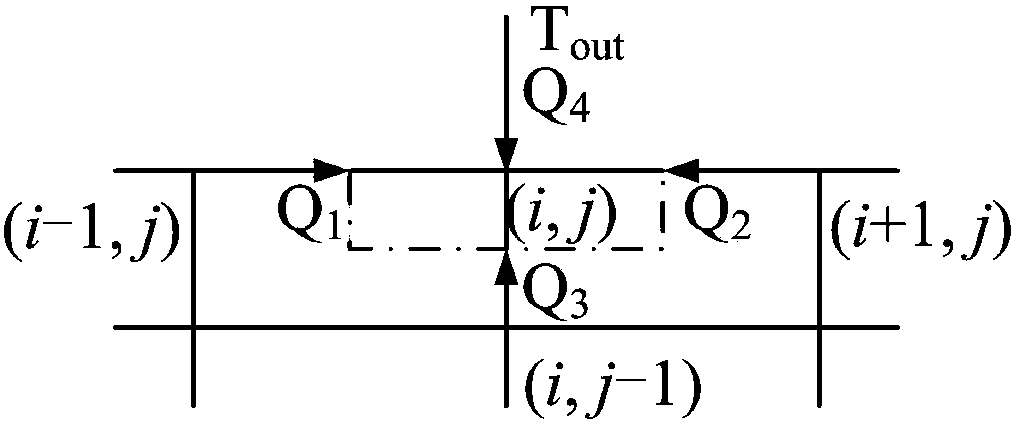

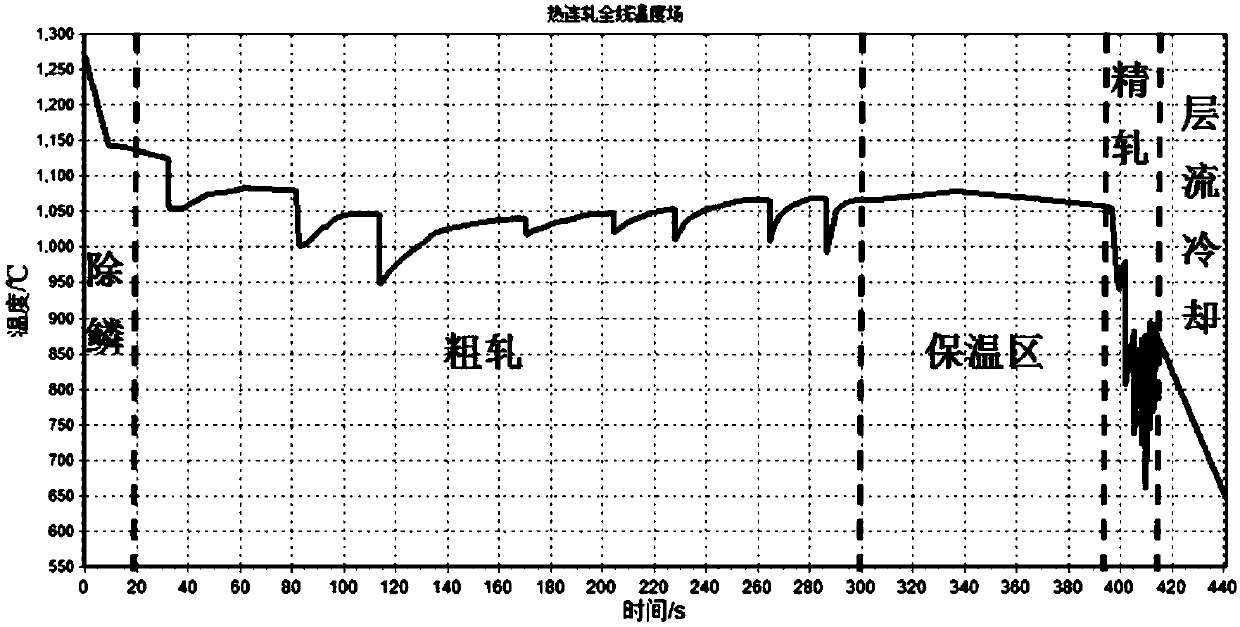

Two-dimensional alternate difference method for predicting plate-belt temperature field during hot rolling

ActiveCN107066737AThe solution accuracy is not highOvercome stabilityDesign optimisation/simulationSpecial data processing applicationsFinite difference modelMaterials science

The invention provides a two-dimensional alternate difference method for predicting a plate-belt temperature field during hot rolling and belongs to the technical field of rolling. According to the method, (1) plate blank incoming material parameters and rolling course data are collected; (2) difference grid division is conducted on a plate-belt cross section, grid nodes are numbered, and a finite difference model is established; (3) according to technological parameters of different rolling courses, boundary conditions and an internal thermal source are determined; (4) an explicit-implicit alternate difference format is adopted, and a heat conduction differential equation is transformed into a differential equation format; (5) a chasing method is used to solve a differential equation set rapidly, so that an instant temperature field of plates and belts can be obtained; and prediction is completed. The method considers field working conditions and boundary conditions during hot rolling comprehensively, and universality is high; the plate-belt temperature field at each stage during the whole hot rolling course, as well as the plate-belt temperature field of the whole hot rolling line can be predicted, information is detailed and accurate, and prediction accuracy is high; and computation duration of the hot rolling plate-belt temperature field is short, computation efficiency is high, and the method can be used in an offline or online manner.

Owner:UNIV OF SCI & TECH BEIJING

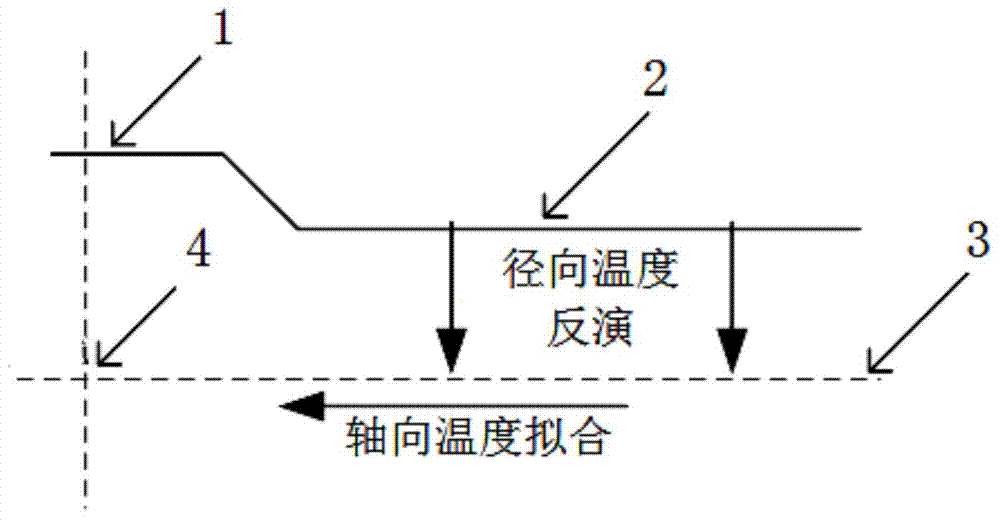

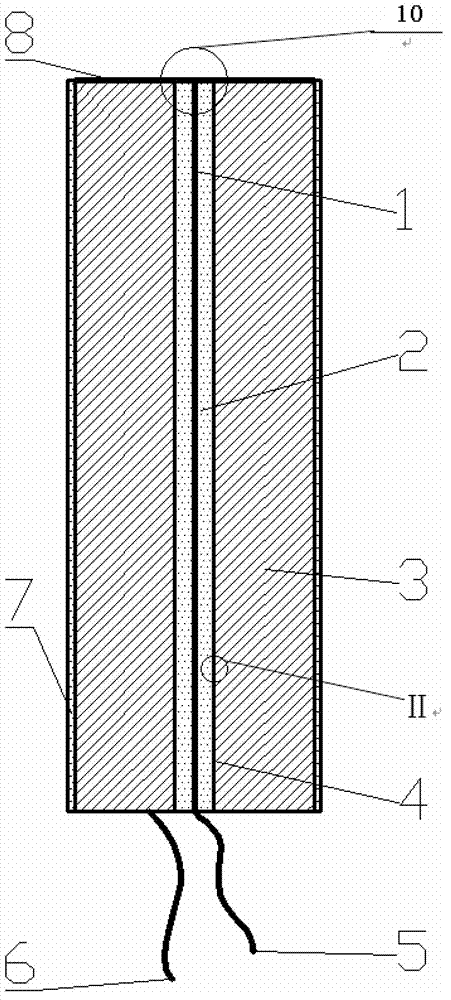

Cable-joint cable core temperature inversion method and system on basis of surface temperature of cable

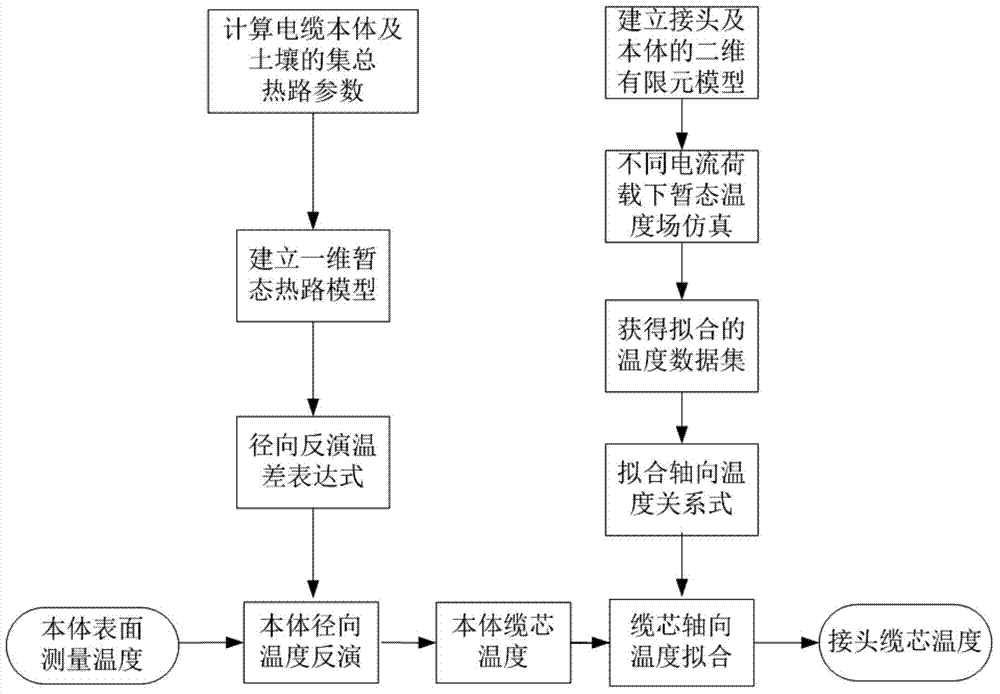

ActiveCN104776938AAccurate temperatureGuaranteed safe operationThermometer detailsThermometer applicationsTransient stateCore temperature

The invention provides a cable-joint cable core temperature inversion method and a cable-joint cable core temperature inversion system on the basis of a surface temperature of a cable. The cable-joint cable core temperature inversion method comprises the following steps: S1, carrying out radial temperature inversion according to a cable one-dimensional transient thermal circuit model and a temperature of a surface temperature measured point of a cable body so as to obtain an inversion transient temperature of a cable core fit point; S2, constructing a cable two-dimensional temperature field simulation module by adopting a finite element temperature field simulation method and simulating transient temperatures of a cable core contact point and the cable core fit point under different loading currents and at different moments so as to obtain a transient temperature simulated data set; S3, using the transient temperature of the cable core contact point as an independent variable, using the transient temperature of the cable core fit point as a dependent variable and carrying out fitting on the transient temperature simulated data set so as to obtain a cable core axial temperature function; S4, combining the inversion transient temperature of the cable core fit point with the cable core axial temperature function to obtain a temperature of the cable core contact point. According to the invention, the accurate temperature of the cable core contact point can be obtained by utilizing the surface temperature of the cable body through inversion and fitting; the cable-joint cable core temperature inversion method and the cable-joint cable core temperature inversion system are simple, convenient and rapid.

Owner:WUHAN UNIV

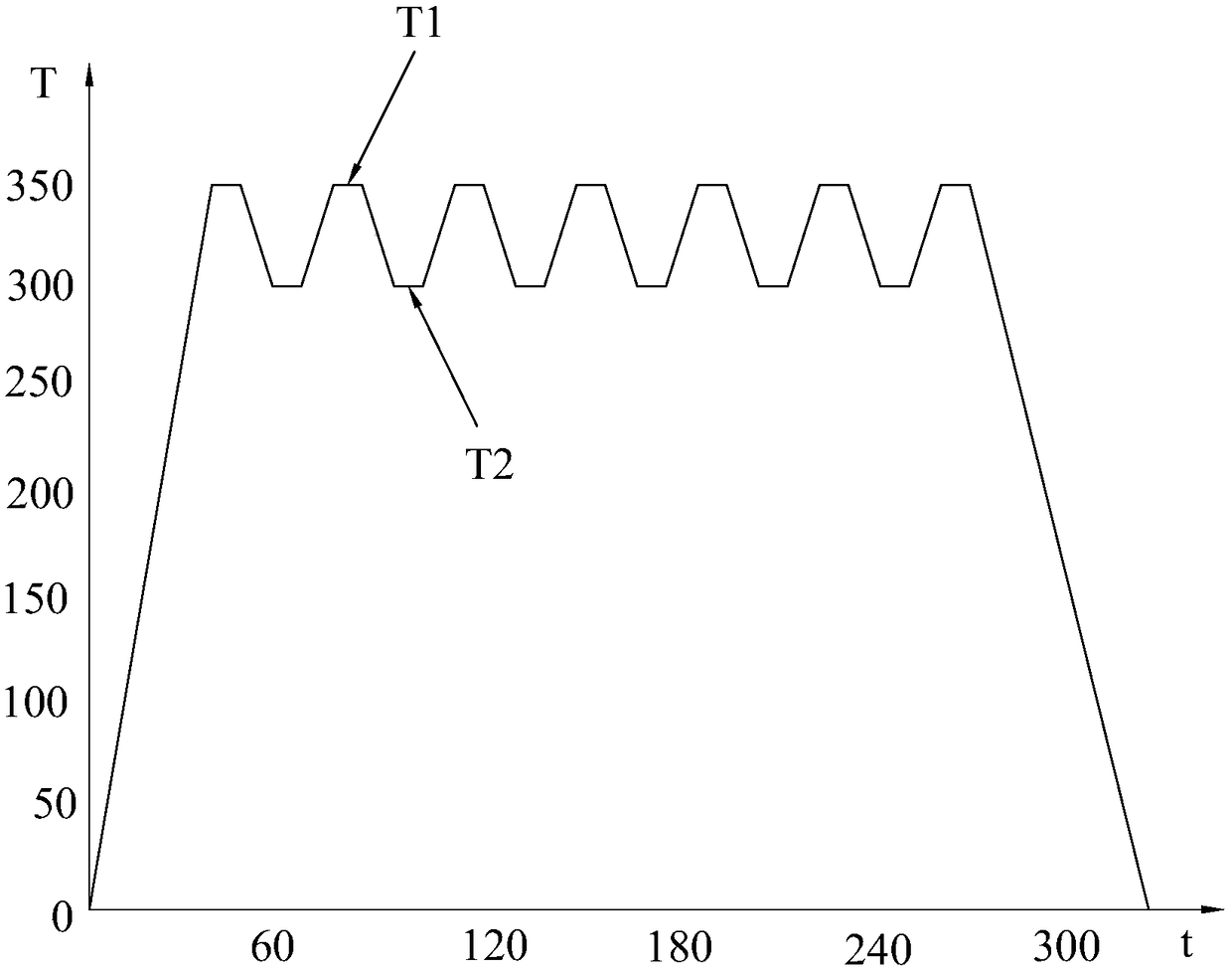

Heating element temperature control method and device and electronic smoking system

ActiveCN108851242AConstant heating temperature reductionAutomatically lower the constant temperatureTobacco devicesTemperature controlWorking temperature

The invention discloses a heating element temperature control method and device and an electronic smoking system. The heating element temperature control method comprises a pre-heating period and a constant-temperature period; the temperature of a heating element in the constant-temperature period comprises two temperature nodes which are the first constant temperature and the second constant temperature, and the first constant temperature is higher than the second constant temperature; when the heating element is continuously kept to exceed the first preset time at the first constant temperature, the temperature of the heating element is lowered to the second constant temperature; when the transient temperature of the heating element is lowered greatly at the second constant temperature,and the temperature of the heating element rises to the first constant temperature; the heating element keeps running at the two constant temperature points, the constant temperature is set to be twodifferent temperature nodes, and the heating element can provide low holding temperature, that is to say, the second constant temperature, in an abnormal working state; when the heating element is awaken, the temperature rises to the high working temperature, that is to say, the first constant temperature; not only is energy saved, but also the constant temperature time of a to-be-heated object can be prolonged.

Owner:DONGGUAN MYSMOK ELECTRONICS TECH CO LTD

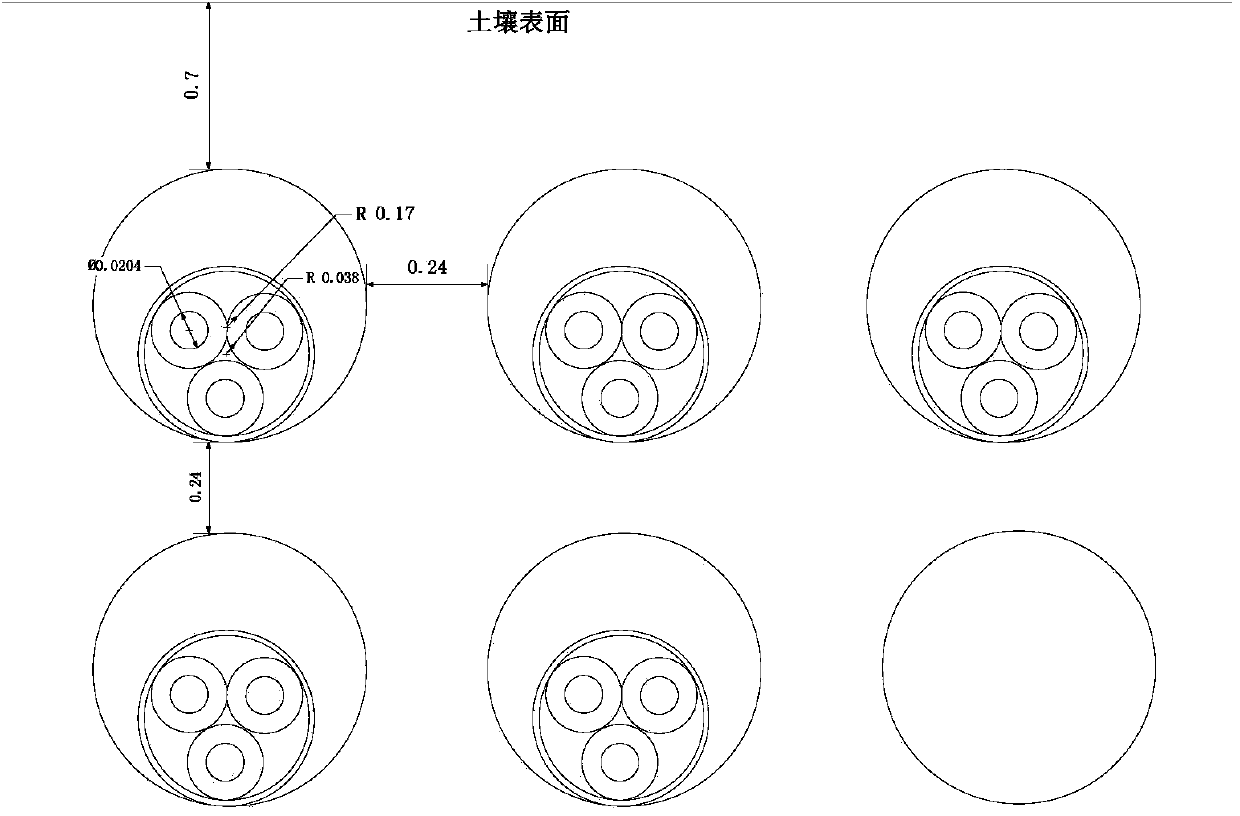

Cable group cable core transient temperature calculation method based on finite element method

InactiveCN103793558AImprove telemetry capabilitiesSolve agingSpecial data processing applicationsElectrical resistance and conductanceExtended finite element method

The invention provides a cable group cable core transient temperature calculation method based on a finite element method. The method includes the steps of firstly, checking the cable group laying condition, secondly, measuring relevant parameters of cables, thirdly, building a model for a cable group according to measured data, fourthly, dividing the cable model, fifthly, reading currents and determining alternating current resistance and thermal loads, sixthly, conducting simultaneous solution on all division units, and seventhly, repeatedly executing the fifth step and the sixth step, and repeatedly conducting iteration to get a cable core transient temperature. The cable group cable core transient temperature calculation method plays a significant role in solving the problem of cable core temperature when multiple cables are used at the same time under a complex laying condition, real-time temperature of cable cores can be accurately calculated, and judgment of the real-time operating state of cables can be facilitated.

Owner:XI AN JIAOTONG UNIV +1

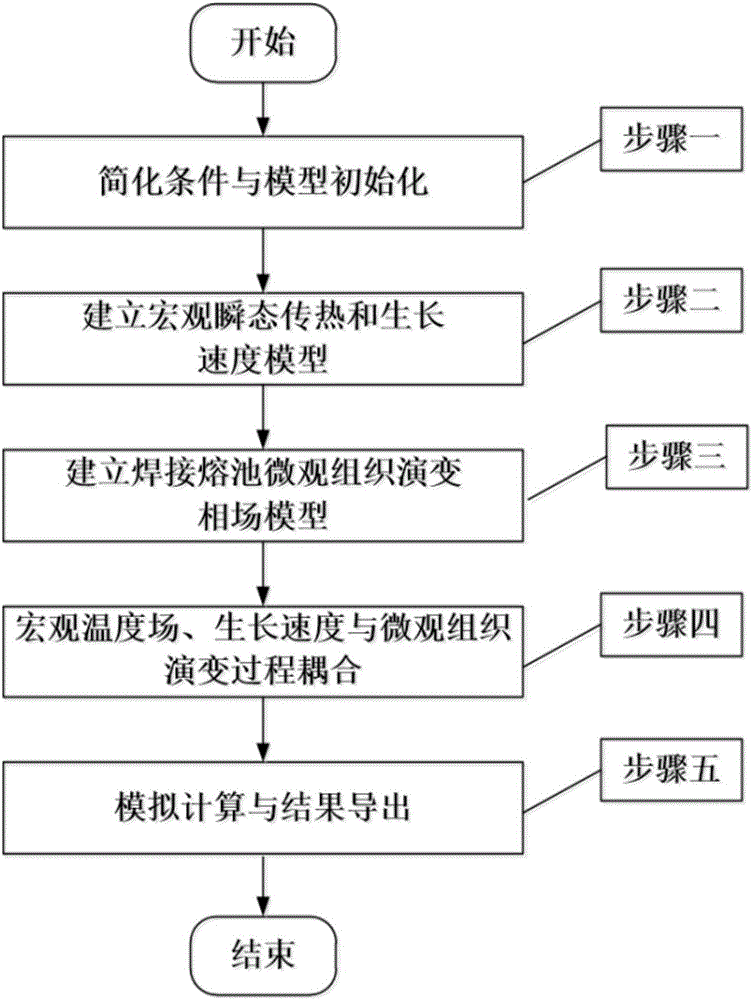

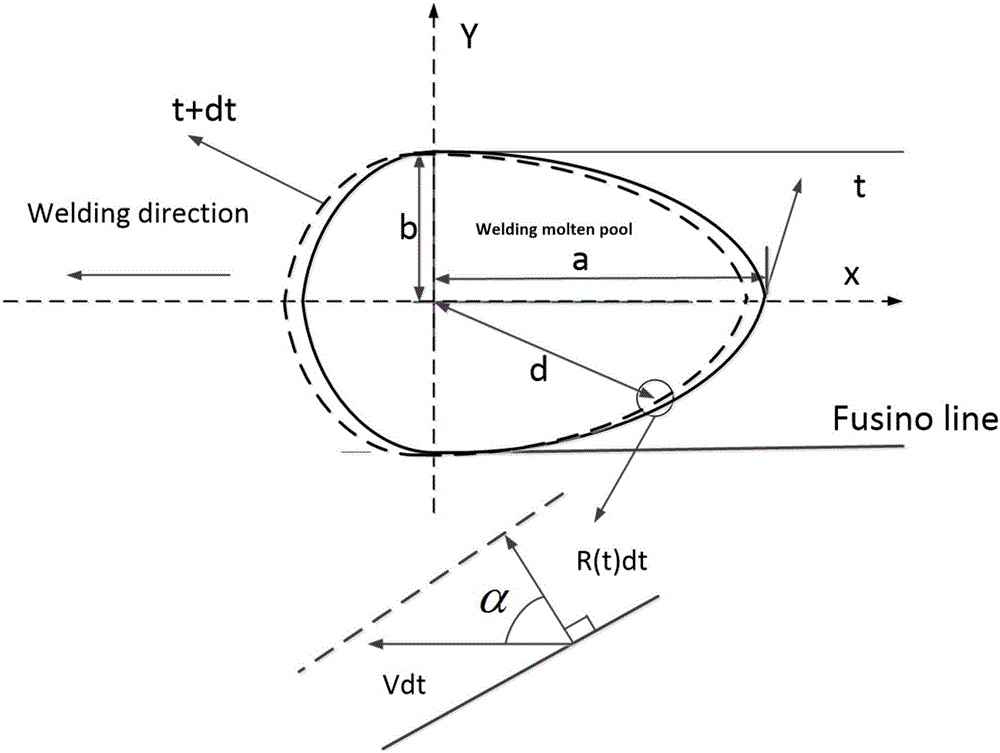

Phase-field method-based microstructure evolution simulation method in welding process in transient state

ActiveCN106407623ASimplify the initialization processDeepen understanding of the evolution processSpecial data processing applicationsMolten stateEngineering

The invention provides a phase-field method-based microstructure evolution simulation method in a welding process in a transient state. The phase-field method-based microstructure evolution simulation method in the welding process in the transient state comprises the following steps of simplifying conditions and initializing a model, building the model according to parameters of a solidification process of a welding pool; building a macro transient heat transfer and growth rate model, wherein the welding pool is regarded to be formed by combining two semi-elliptical spheres, one semi-elliptical sphere is in a molten state and the other semi-elliptical sphere is in a solidified state in the welding process; building the macro transient heat transfer and growth rate model on the basis of hypotheses; building a microstructure evolution model and building a phase-field model of simulating microstructure evolution of the welding pool on the basis of the Ginzburg-Landau theory; and carrying out macro-micro coupling calculation, introducing a transient temperature gradient and a dendrite growth rate into the model, calculating a macro-micro coupled phase-field model and obtaining a microstructure evolution simulation result of the welding pool.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

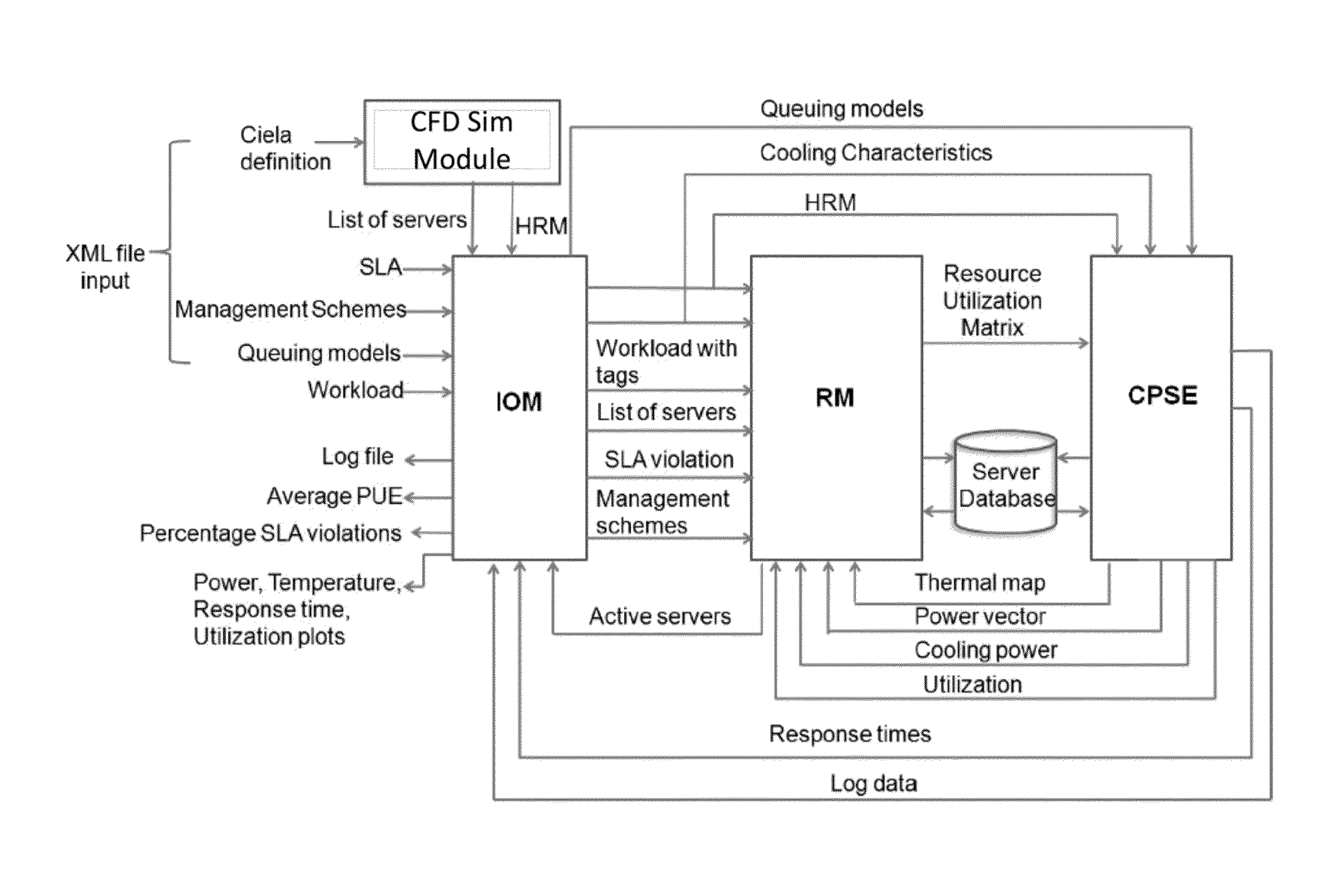

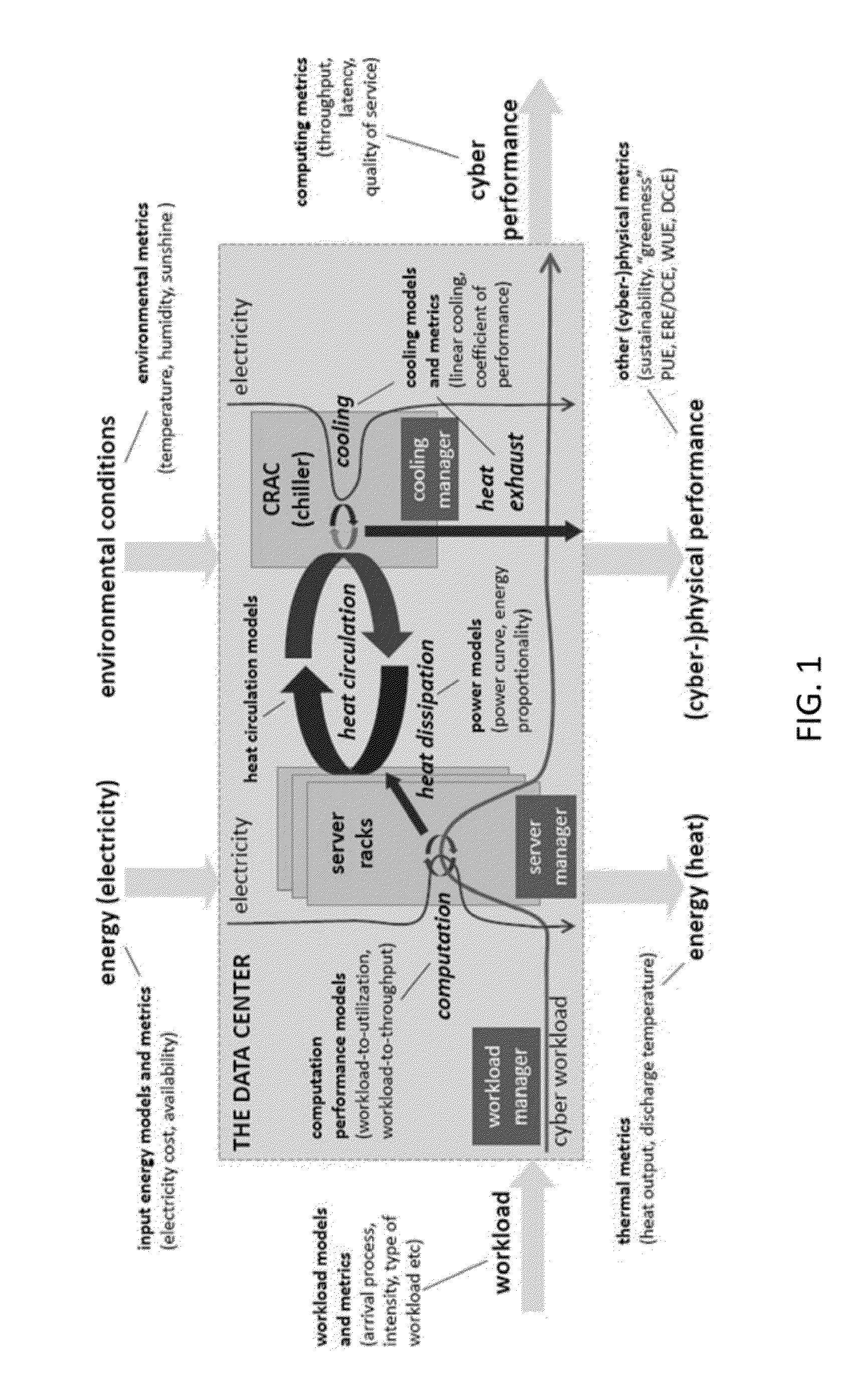

Systems, methods, and media for modeling transient thermal behavior

InactiveUS20140278333A1Analogue computers for nuclear physicsDesign optimisation/simulationHysteresisEvent trigger

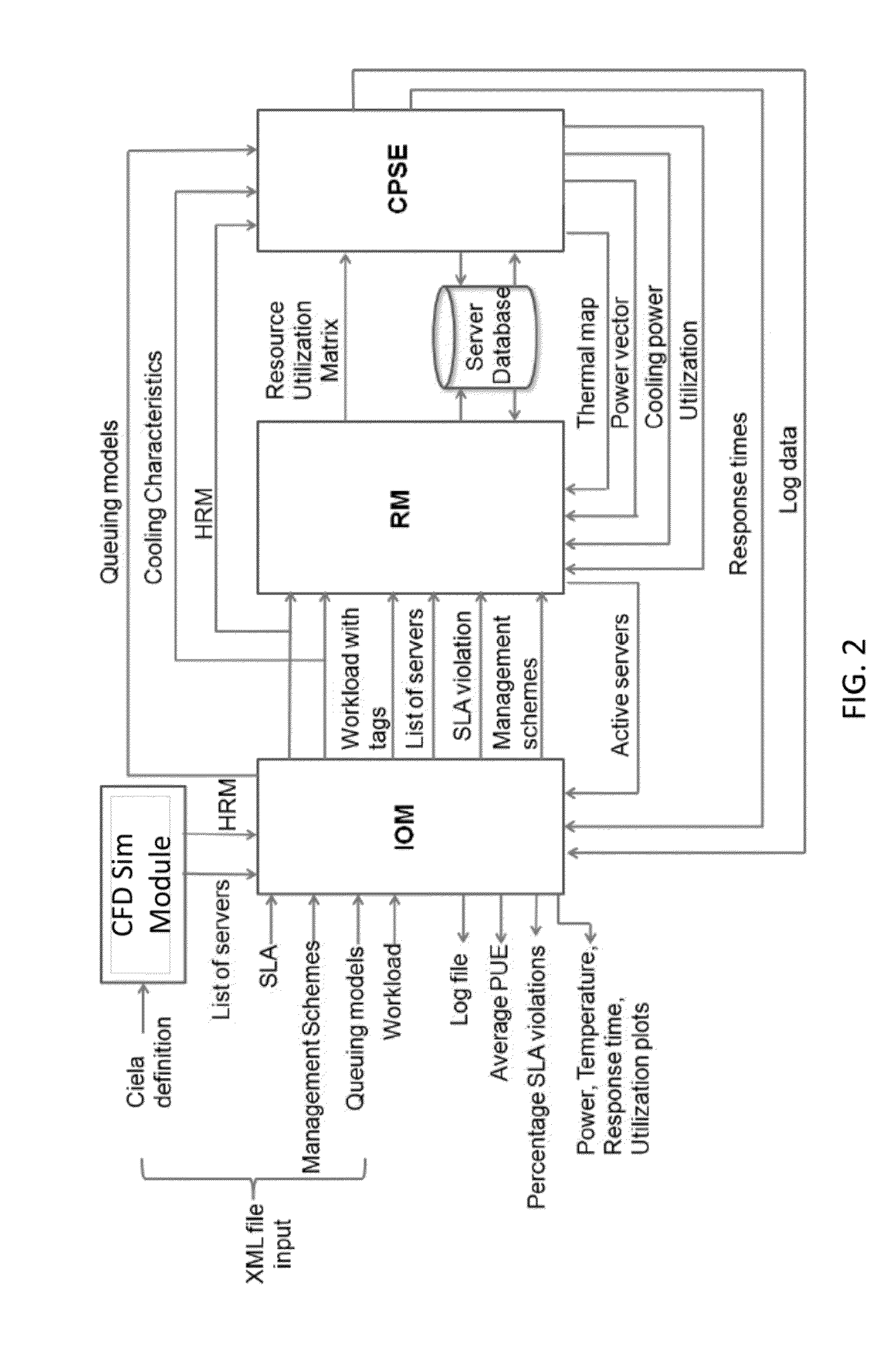

In some embodiments, systems for simulating thermal behavior in energy usage simulators are provided, the systems comprising: at least one hardware processor that: induces an event trigger to an environment, wherein the event trigger changes the behavior of the environment; performs computational fluid dynamics simulations on an environment based on a description of the environment to generate transient temperatures; generates a thermal map of the environment; predicts thermal behavior in the environment based on the thermal map; wherein thermal behavior includes division distribution, temporal distribution, and hysteresis; computes physical performance metrics based on the thermal behavior and on efficiency models; generates a resource utilization matrix (RUM) based on both the thermal behavior and workloads of equipment in the environment; generates a computational performance matrix based on the RUM and a supplied performance model; and computes computational performance based on the RUM and on performance models.

Owner:ARIZONA STATE UNIVERSITY

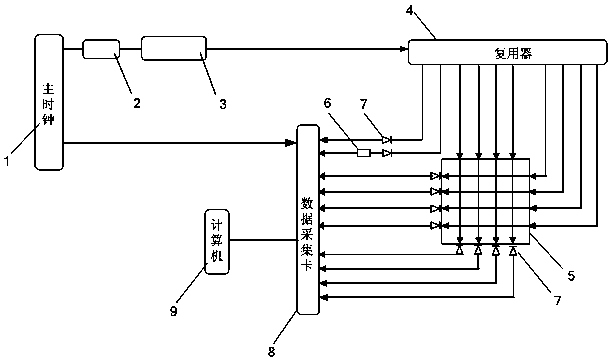

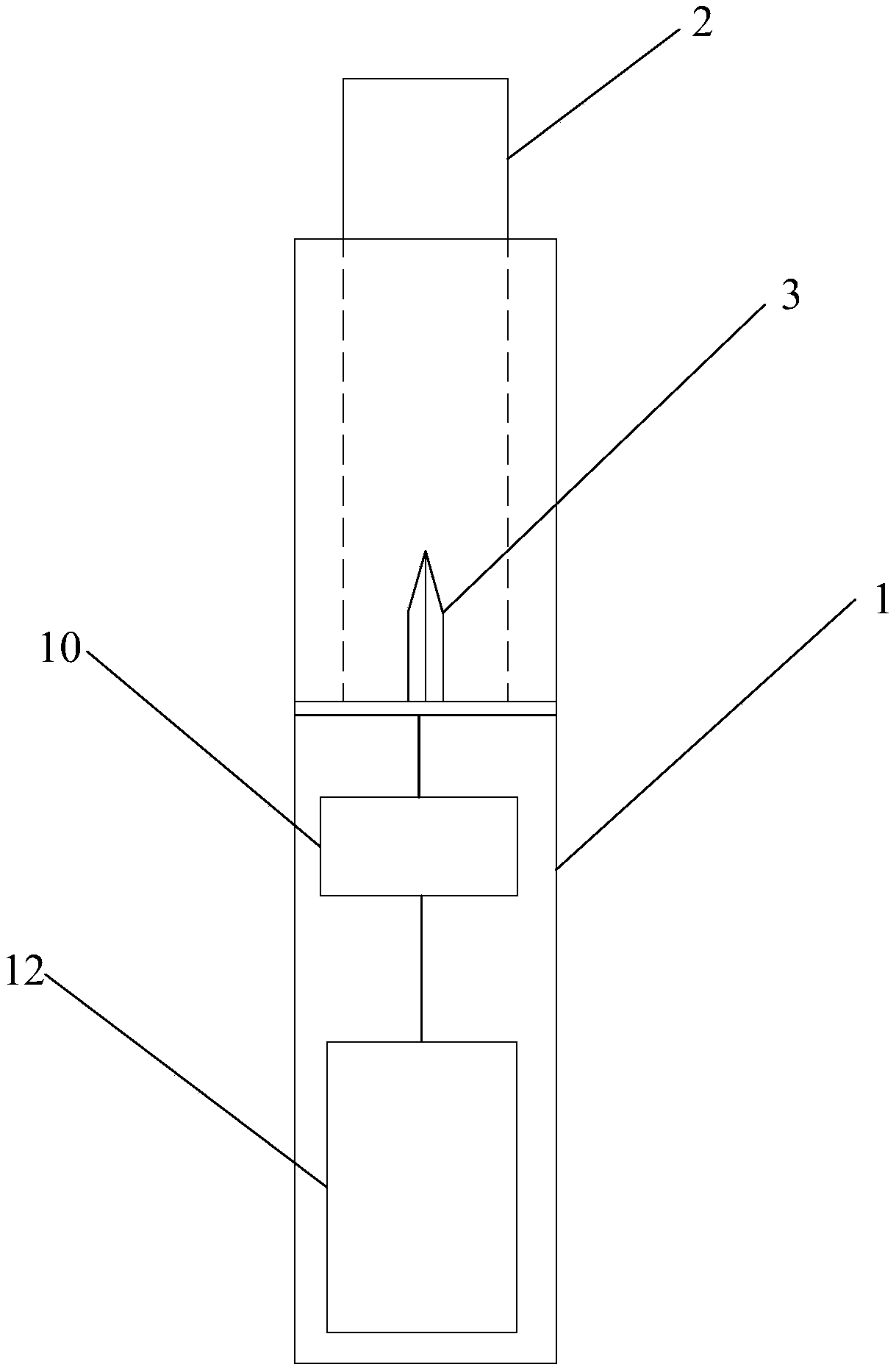

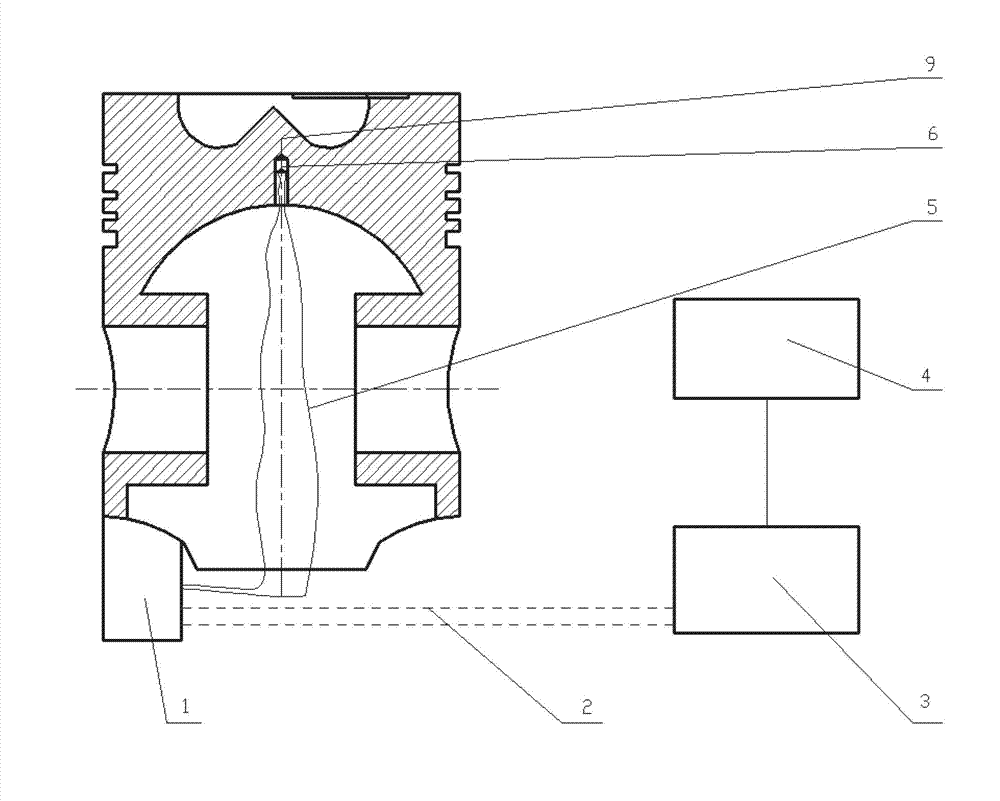

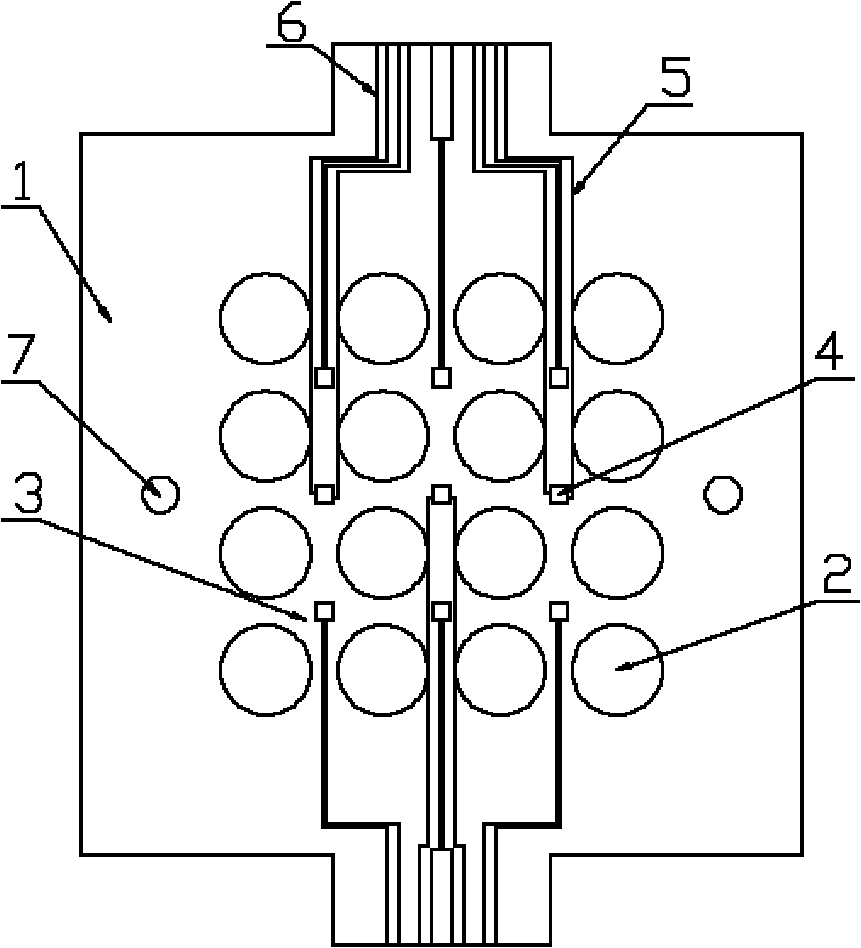

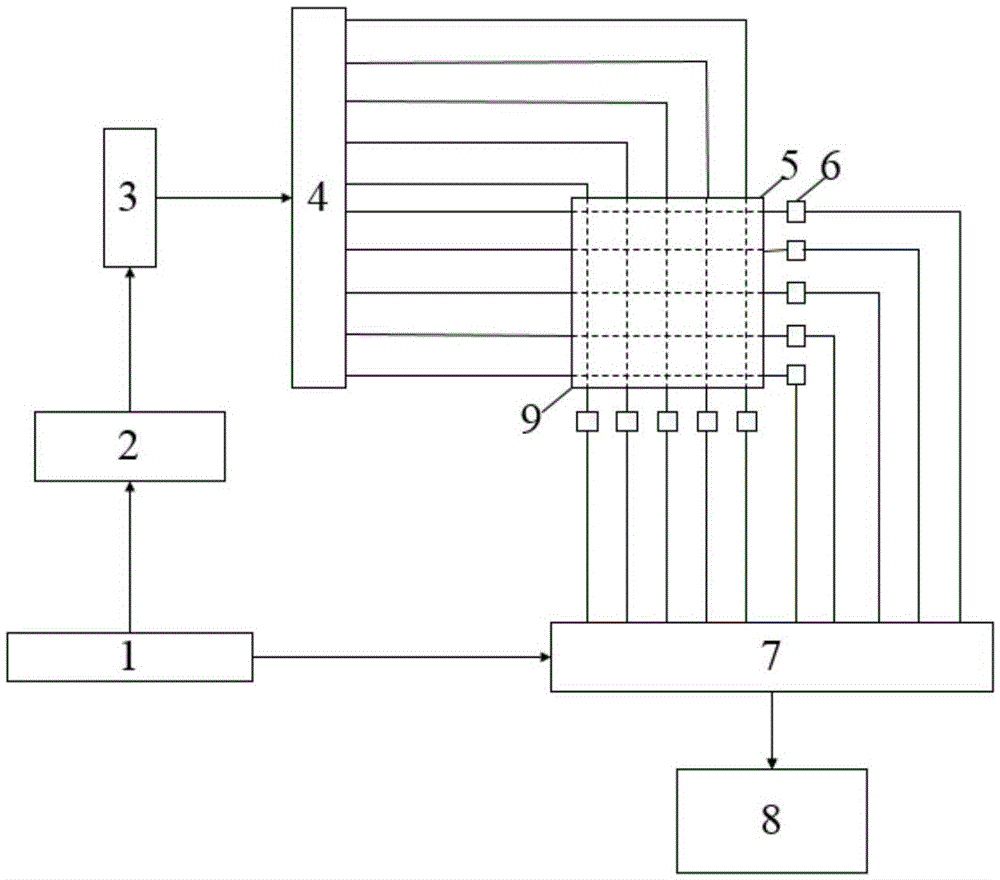

Transient temperature measuring system for diesel engine piston and measuring method thereof

ActiveCN102853930AEasy to manufactureEasy to placeThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesContinuous measurement

The invention discloses a transient temperature measuring system for a diesel engine piston and a measuring method thereof. The system comprises a data acquiring, amplifying and transmitting device, a signal receiving device, a computer, a temperature measuring screw and a compensating lead, wherein the temperature measuring screw is connected with the data acquiring, amplifying and transmitting device through the compensating lead; the data acquiring, amplifying and transmitting device is connected with the signal receiving device through a wireless transmission signal; and the upper end face of the temperature measuring screw is provided with a film thermocouple. The method comprises the following steps of: making a mask and a mask clamp; making a temperature measuring screw; installing; and measuring. According to the measuring system, temperature is measured by using an advanced film thermocouple preparation technology, so that short dynamic response time is ensured, high temperature measuring accuracy is realized, and continuous measurement can be performed. Meanwhile, a small screw structure is adopted, and a sensor is easy to manufacture and can be placed on the piston easily; and the transient temperature measuring system is simple in structure, is convenient to replace, and can be produced in a standard way. Due to the adoption of the transient temperature measuring system and the measuring method thereof, the problems of temperature testing of the diesel engine piston in a severe working environment and the problem of lead connection of the film thermocouple are solved.

Owner:DALIAN JIAOTONG UNIVERSITY

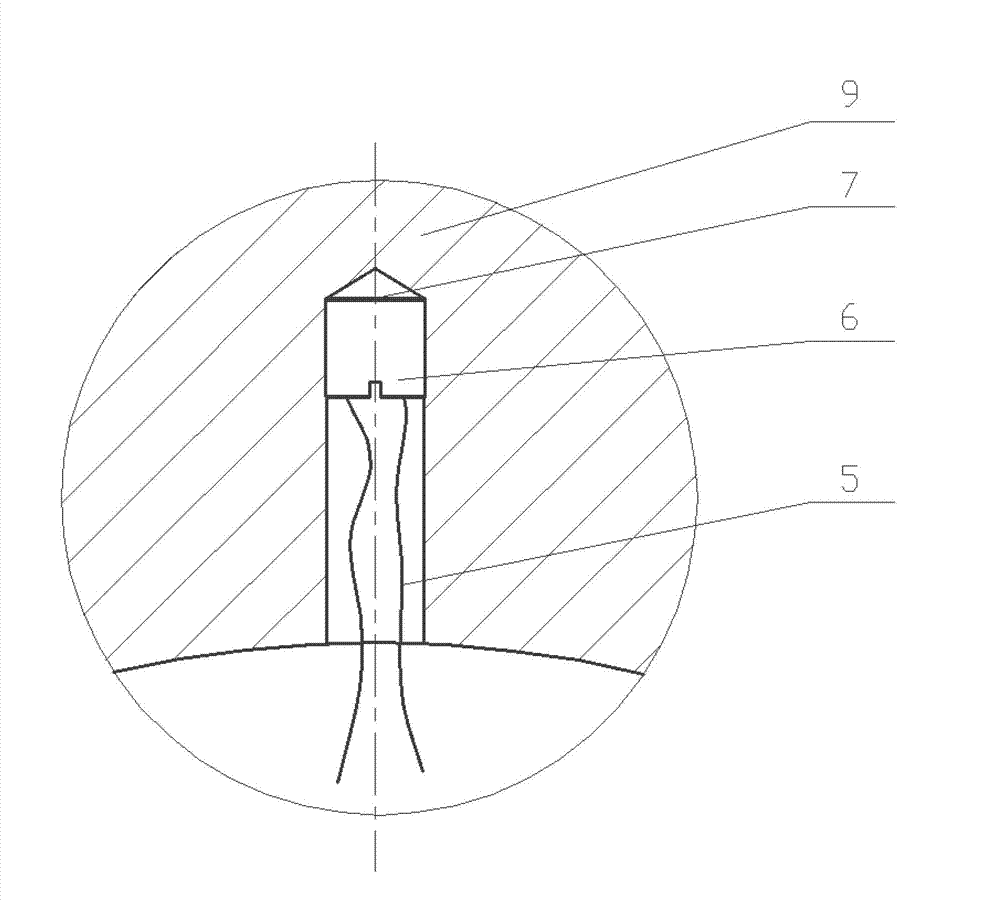

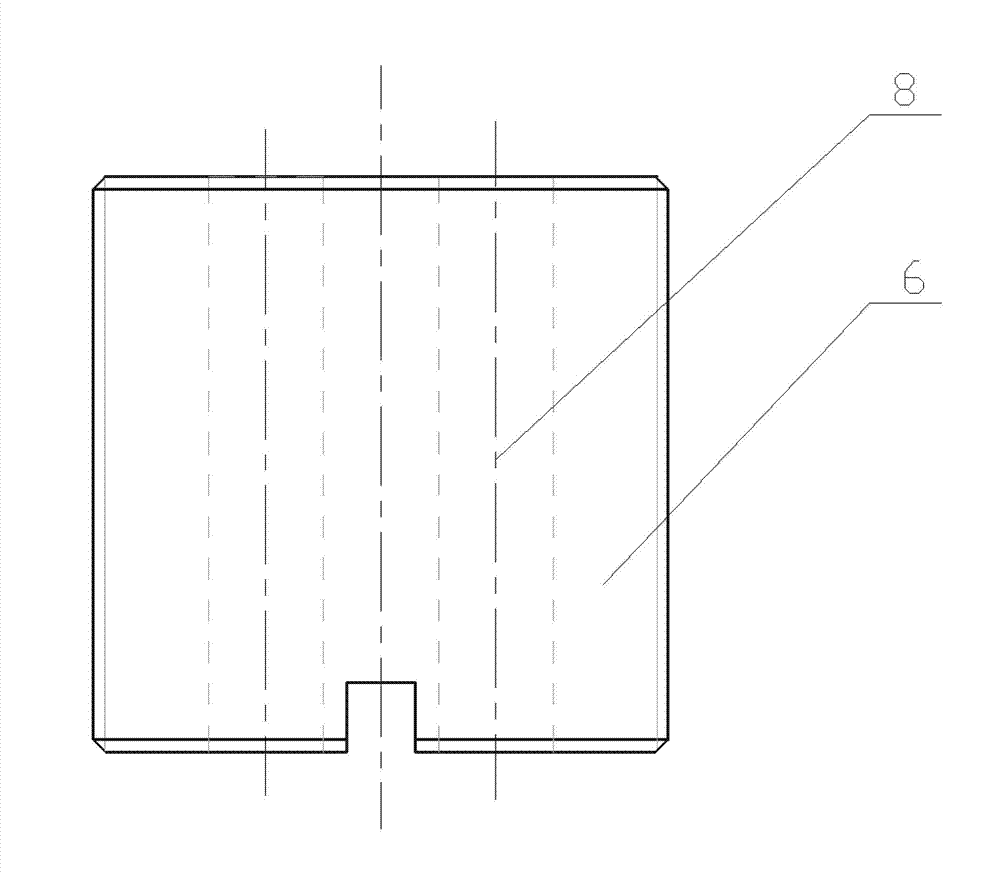

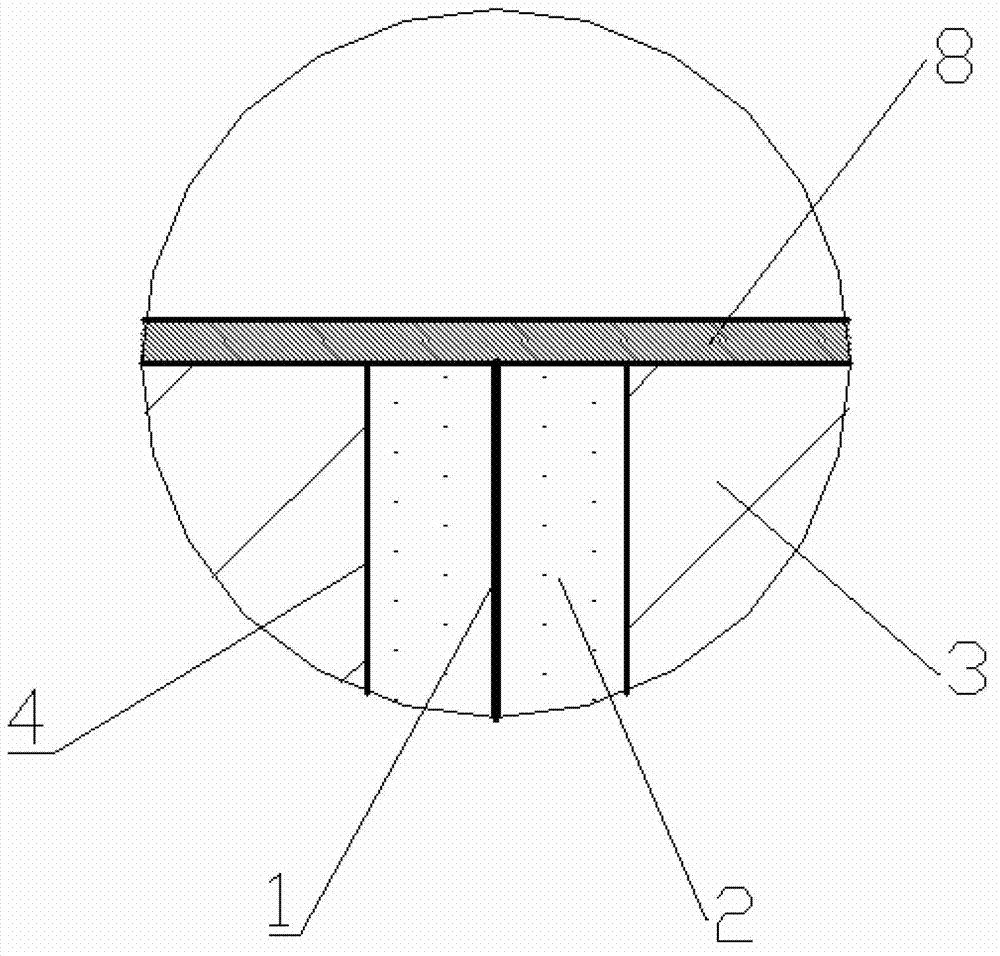

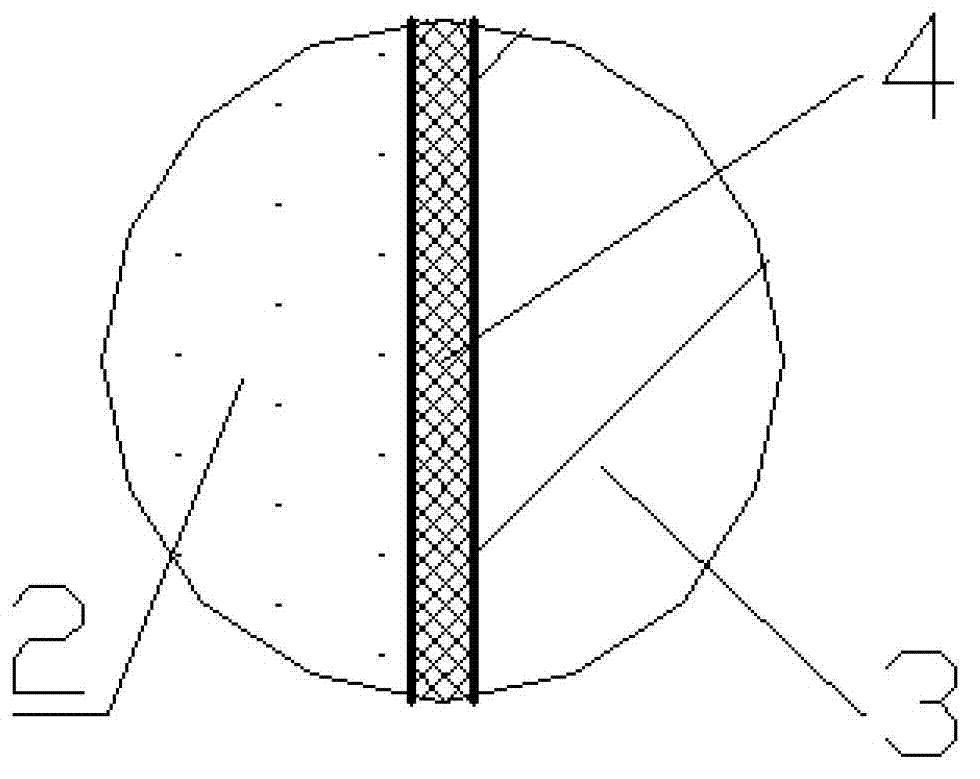

Needle-like coaxial thin-film thermocouple for measuring transient temperature

ActiveCN103245430AThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesThermodynamics

The invention discloses a needle-like coaxial thin-film thermocouple for measuring a transient temperature, and belongs to the technical field of sensors. The needle-like coaxial thin-film thermocouple comprises a thermocouple coaxial structure comprising a needle-like measuring end, thermal electrodes and an insulating layer, wherein the measuring end comprises a thermal electrode I and a thin-film coating, and the thin-film coating is arranged on the needle-like top surface of the thermocouple coaxial structure; the thermal electrode I is covered with the insulating layer; the insulating layer and a thermal electrode II are adhered with glue; the thin-film coating and the wire-shaped thermal electrode are connected to form a thermocouple thermal connection point which is the measuring end; a lead I is connected with the thermal electrode I, and a lead II is connected with the thermal electrode II; and the measuring end converts measured temperature signals into electrical signals and transmits the electrical signals to a cold junction compensation and signal conditioning module and a computer testing system through wires.

Owner:DALIAN JIAOTONG UNIVERSITY

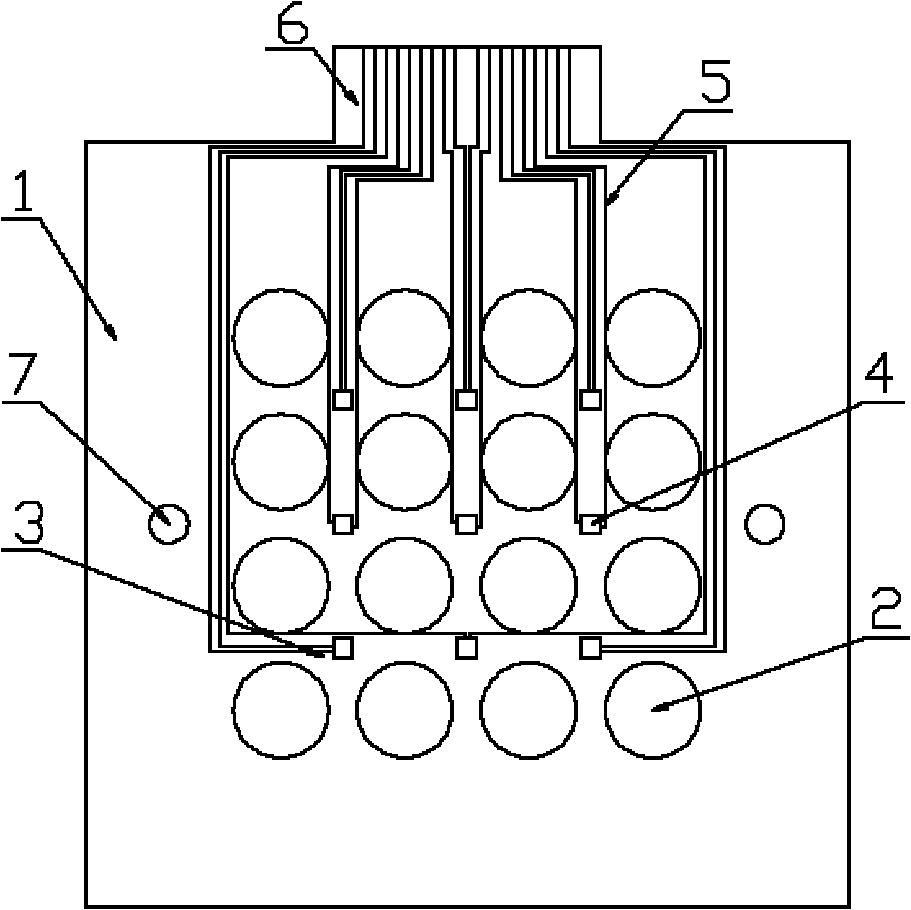

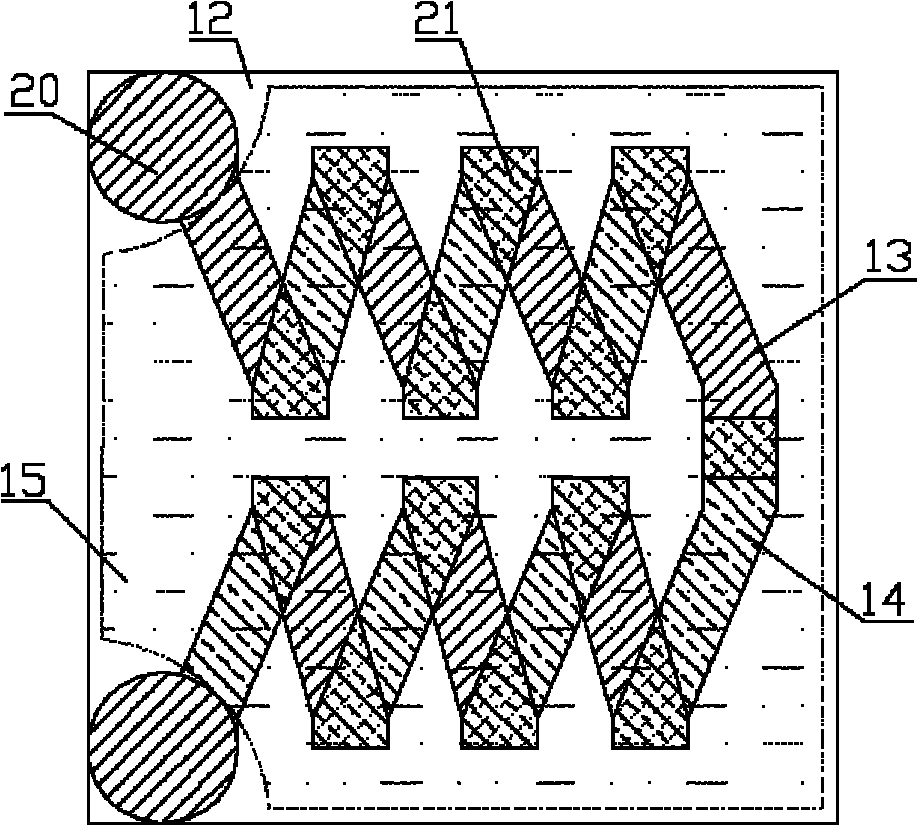

Insertion sheet for measuring internal temperature distribution of fuel cell

ActiveCN102116680ASimple structureSimplified steps for measuring temperature distributionThermometers using electric/magnetic elementsFuel cell auxillariesThin film thermocouplesFuel cells

The invention discloses an insertion sheet for measuring the internal temperature distribution of a fuel cell, which is a device for measuring the internal temperature distribution of a fuel cell. The insertion sheet comprises a stainless steel substrate with gold plated on two sides, a plurality of leak seams and ribs are arranged on the substrate, the size and the shape of the leak seams and the ribs are same with those of grooves and ridges on a flow field plate of the fuel cell to be measured, and the positions mutually correspond. The entire surfaces of the ribs between the leak seams are provided with a film thermocouple which is formed by plating four films through evaporation by using a vacuum plating technology. An outgoing line of a measuring head of the film thermocouple extends to the edge of the substrate by using a printed circuit method and is provided with a standard wiring port connected with an external circuit on the edge of the substrate. The insertion sheet for measuring the internal transient temperature distribution of the fuel cell is completely independent of an object to be measured, has a simple structure and a wide use range, is accurate for measurement and can be used for the online measurement of the internal temperature distribution situation of the fuel cell.

Owner:BEIJING UNIV OF TECH

Method for simultaneous measurement of high-temperature gas two-dimensional transient temperature field and concentration field

ActiveCN105548072AFast scanningAccurate detectionThermometers using physical/chemical changesColor/spectral properties measurementsLaser arrayWavelength modulation

The invention discloses a method combining hyper-spectrum and wavelength modulation for simultaneous measurement of high-temperature gas two-dimensional transient temperature field and concentration field. The method includes: arranging a laser array in a to-be-measured high-temperature area, and conducting hyperspectral scanning on the to-be-measured area to obtain water vapor absorption spectral line information, and carrying out demodulation with a digital phase lock technology to obtain each harmonic signal, then conducting background deduction first harmonic normalization processing, extracting the maximum amplitude value of the signal to measure regional temperature field and water vapor concentration field, and during measuring, conducting grid discretization treatment on the to-be-measured area, arranging laser beam at each row and each column of the grid to conduct broad spectrum scanning on the characteristic spectral line of the to-be-measured gas under a wavelength modulation mode, and using intelligent optimization algorithm to realize inversion of the temperature field and gas concentration field. The measurement method provided by the invention combines hyper-spectrum and wavelength modulation spectroscopy technologies, and is especially suitable for monitoring of high-temperature gas two-dimensional temperature field and concentration field on harsh industrial sites.

Owner:SOUTHEAST UNIV

Collector mirror for plasma-based, short-wavelength radiation sources

ActiveUS7329014B2Great expenditureImprove reflectivityMirrorsRadiation/particle handlingTransport mediumThermostat

The invention is directed to a collector mirror for short-wavelength radiation based on a plasma. It is the object of the invention to find a novel possibility for managing the temperature of a collector mirror for focusing short-wavelength radiation generated from a plasma which allows an efficient thermal connection to be produced between the optically active mirror surface and a thermostat system without the disadvantages relating to space requirements or high-precision manufacture of the collector mirror. This object is met, according to the invention, in that the collector mirror has a solid, rotationally symmetric substrate which comprises a material with high thermal conductivity of more than 50 W / mK and in which channels for cooling and temperature management are incorporated in the substrate so that a heat transport medium can flow through directly and for rapidly stabilizing the temperature of the optically active mirror surface. Heat of transient temperature spikes which occur in pulsed operation for plasma generation at the mirror surface and which temporarily exceed the temperature average by a multiple is quickly dissipated.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com