Patents

Literature

58 results about "Temperature forecasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forecasting finite element of hot rolling process plate belt temperature field

InactiveCN101178746AHigh temperature prediction accuracyImprove applicabilitySpecial data processing applicationsElement analysisTemperature forecasting

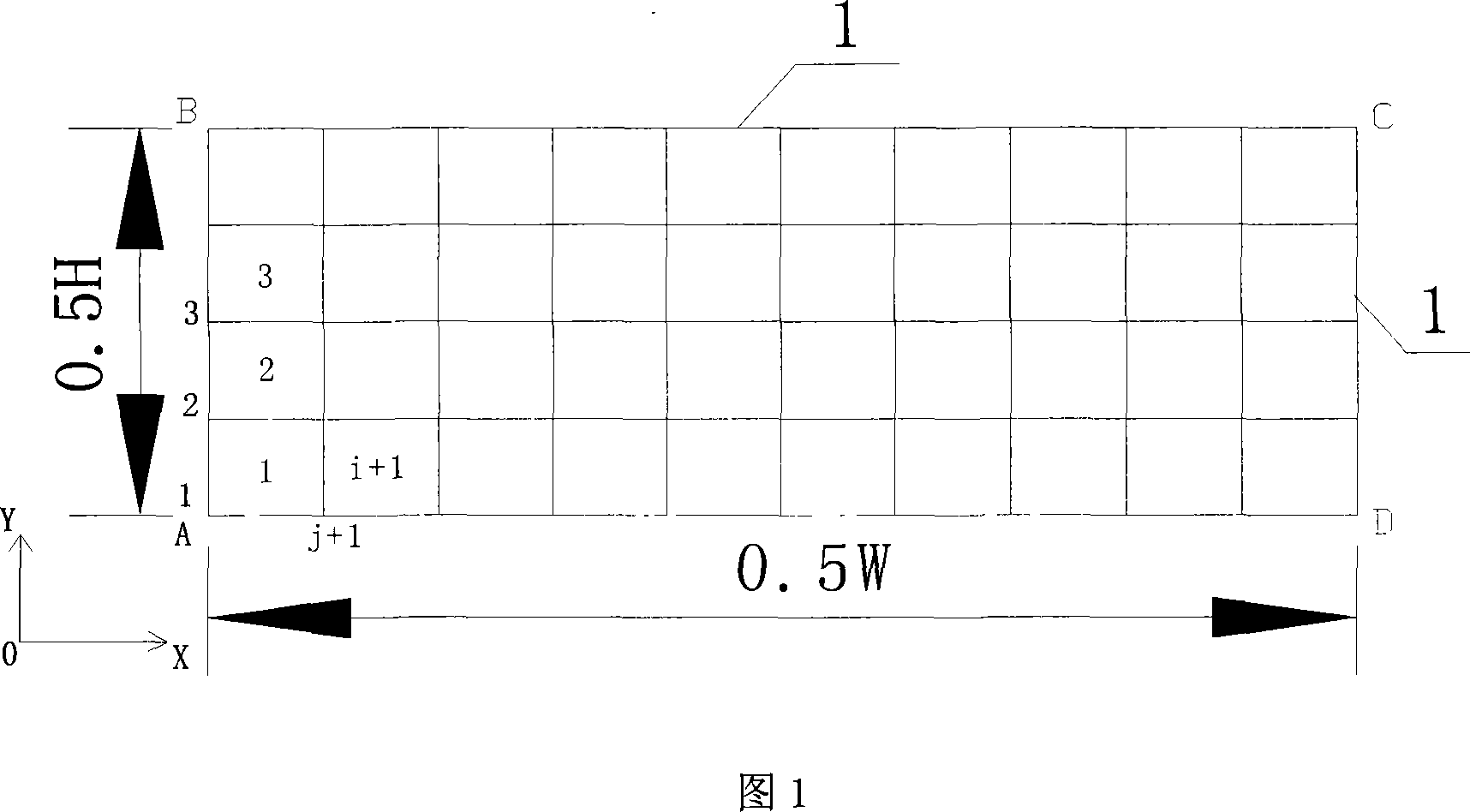

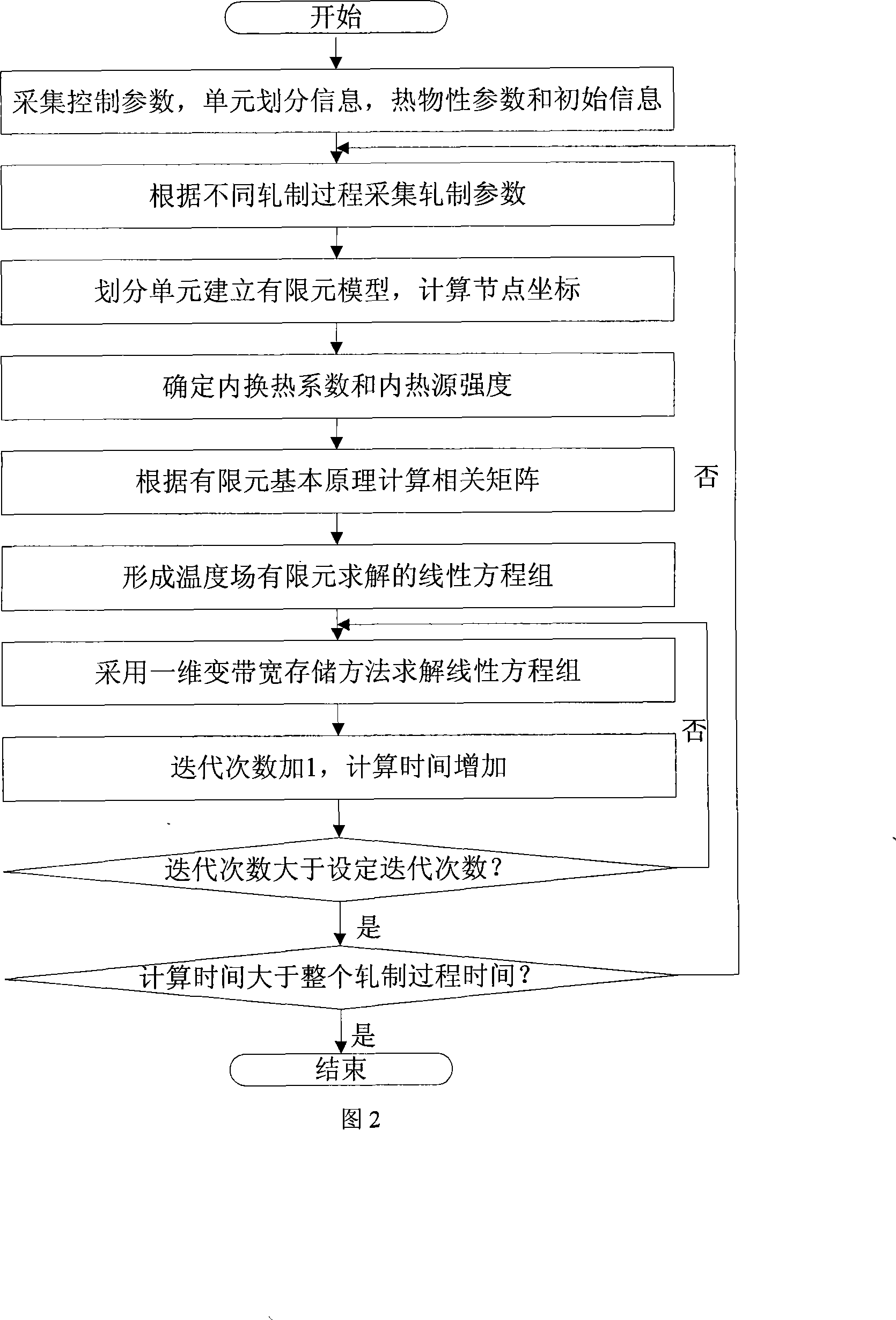

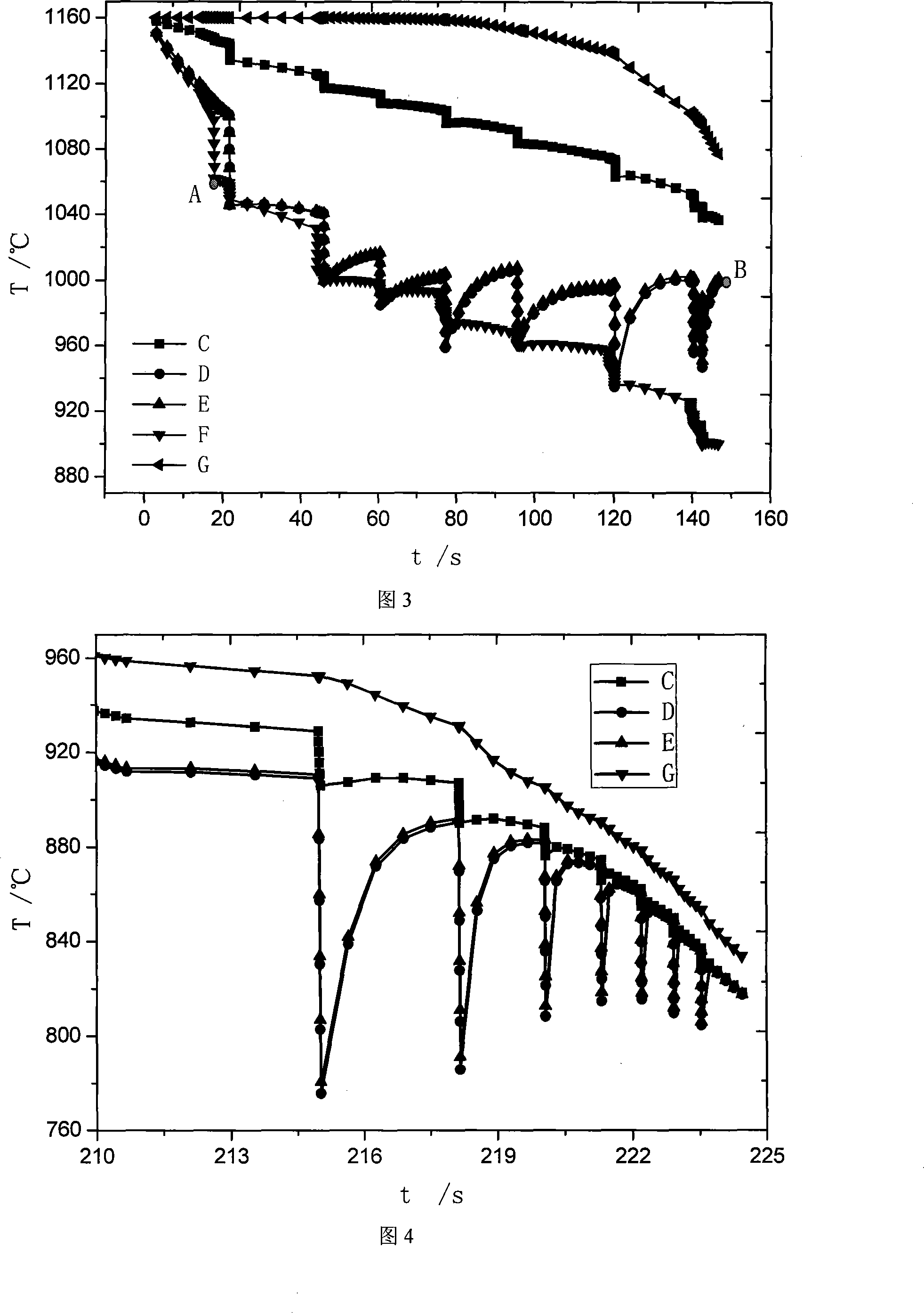

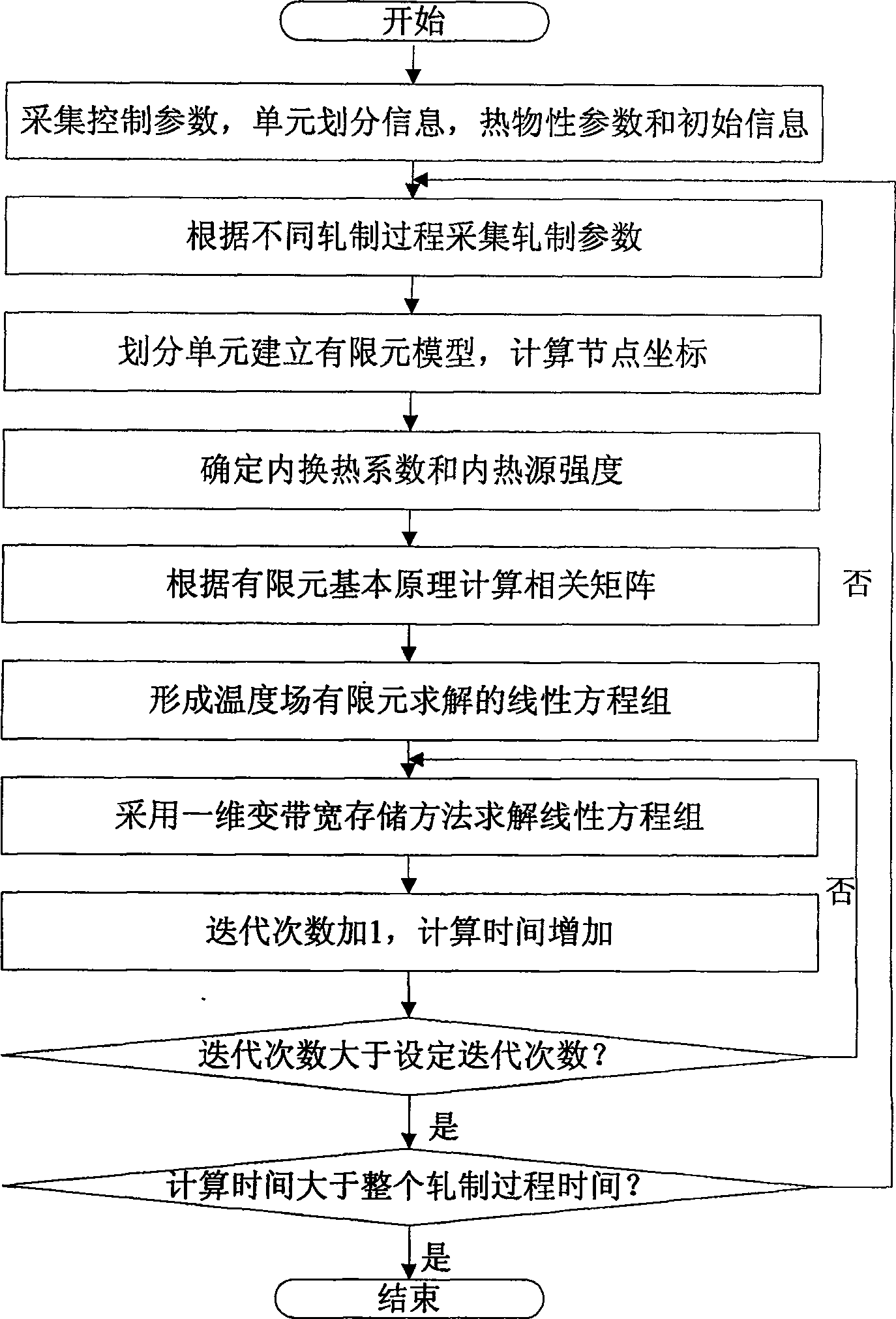

A finite element method of forecasting slab band temperature field during a hot rolling process belongs to the rolling technique field, and comprises the following steps: (1) collecting rolling process data; (2) carrying out unit division to cross section, establishing finite element analysis model, coding a unit node, and calculating a node coordinate; (3) ensuring border heat transfer coefficient and internal heat source intensity according to different rolling processes; (4) calculating the type-function of quadrangle isoparametric unit, B matrix, Jacobian matrix J and Jacobian matrix determinant |J| by using the finite element basic principle; (5) assembling the temperature rigidity matrix and dynamic heating matrix of the finite unit; (6) solving linear system of equations by adopting unidimensional variable bandwidth storage to obtain transient temperature field. The invention has the advantages that: the invention can obtain very high temperature forecasting precision and detailed information of the entire hot rolling slab band temperature distribution, which provides set and optimized parameter for rolling process, moreover, the invention has strong adaptability, reduces calculating time and improving calculating efficiency.

Owner:NORTHEASTERN UNIV

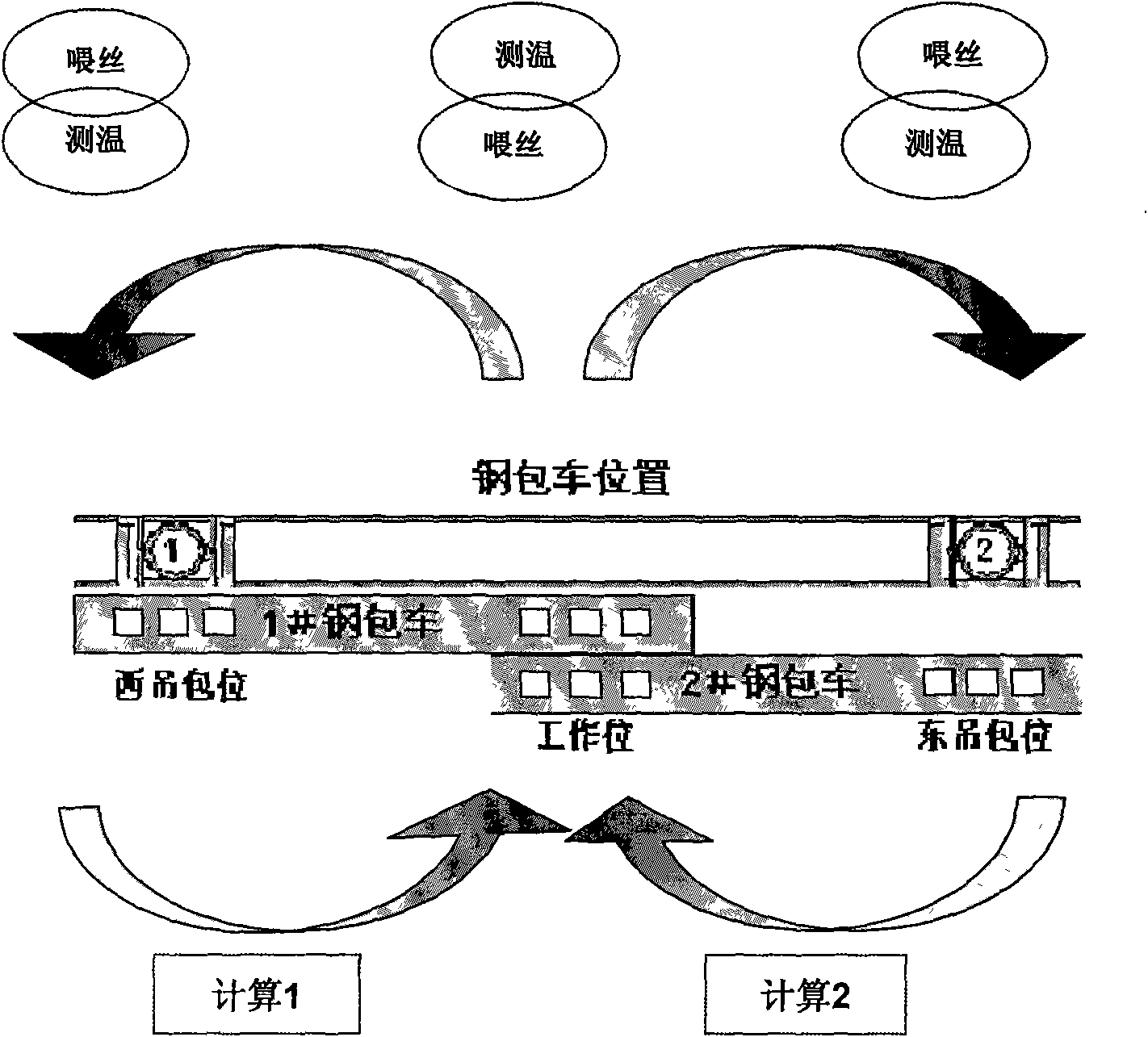

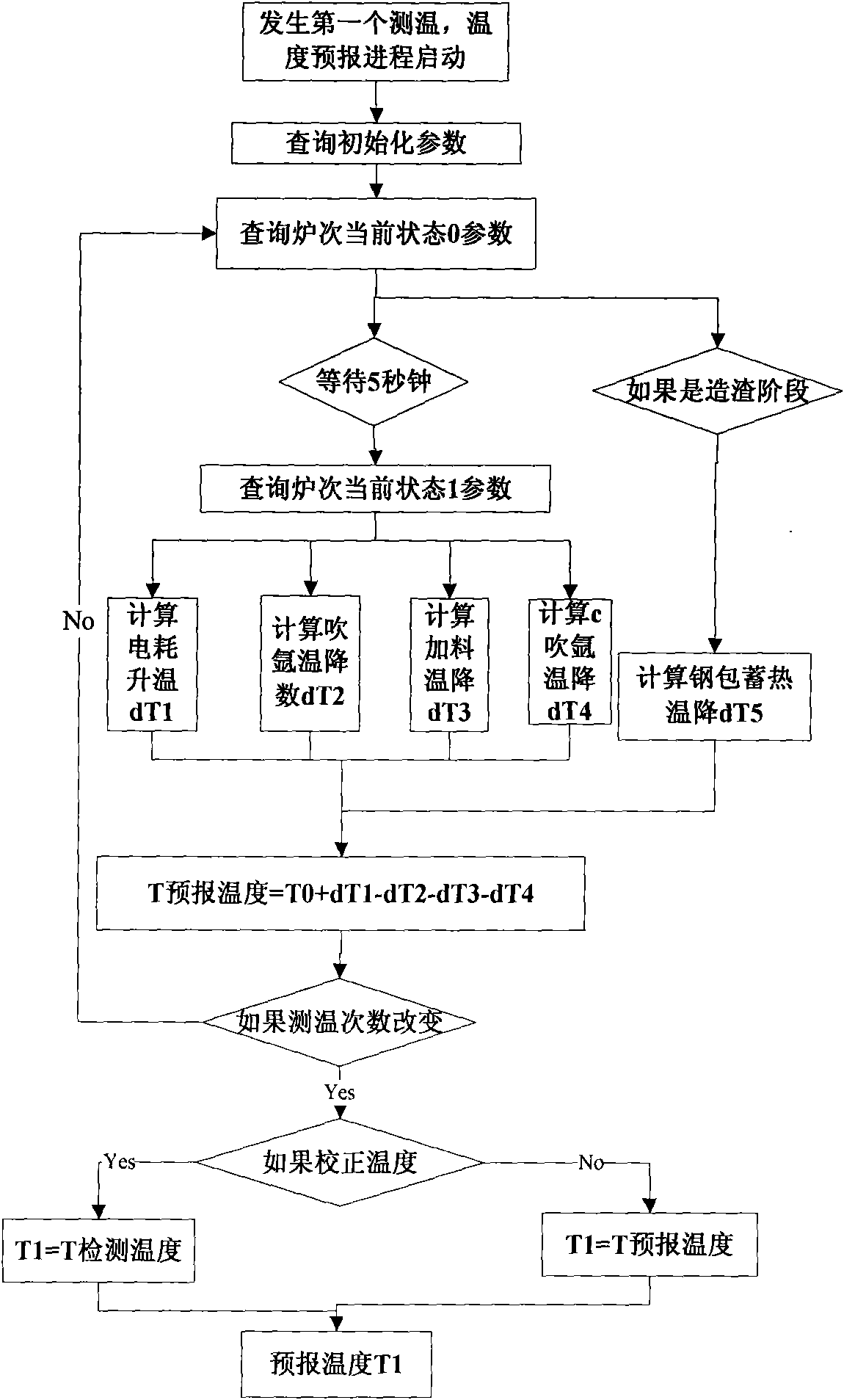

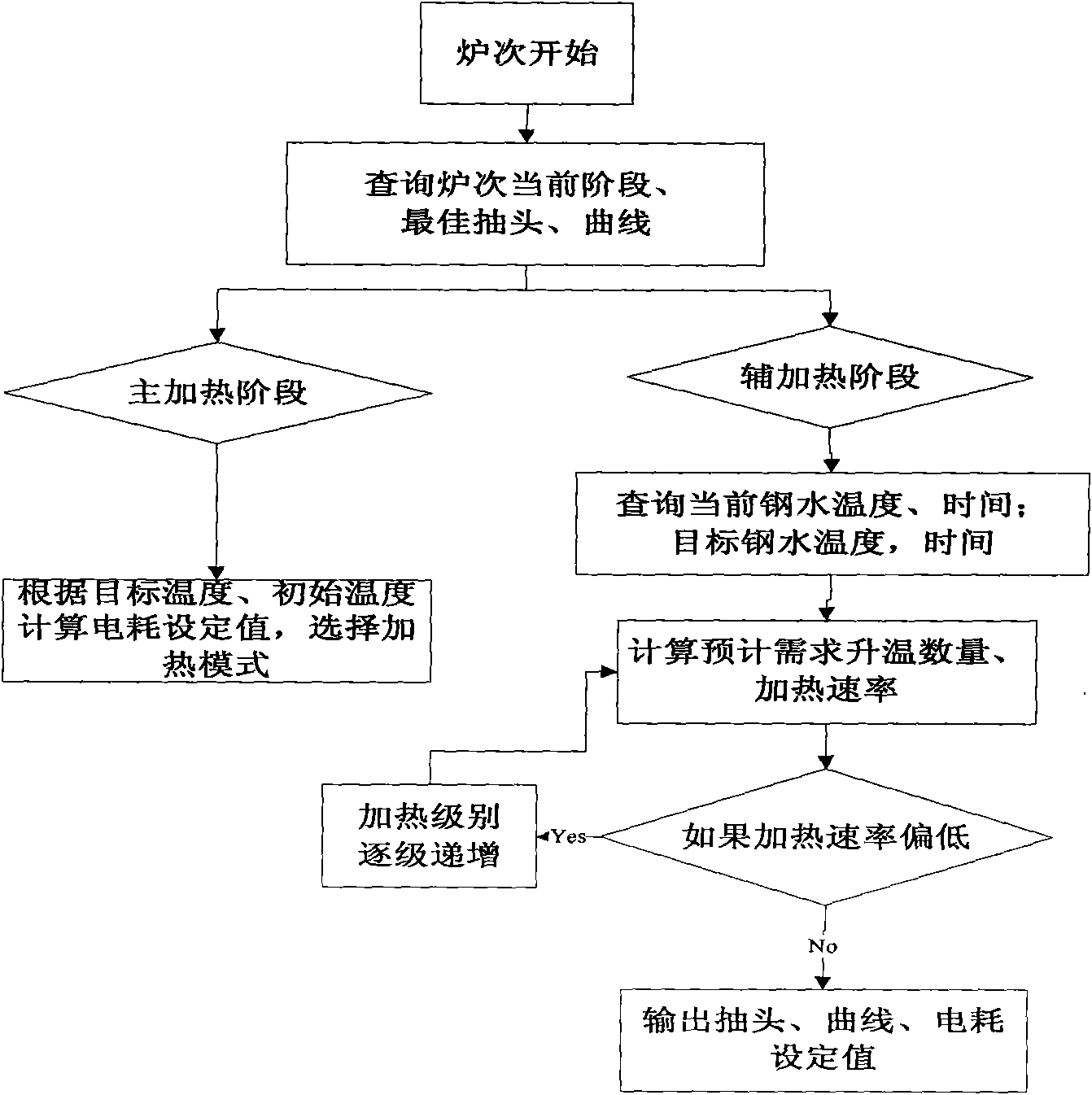

System for controlling forecast of molten steel temperature of double-station LF furnace

ActiveCN101592964AImprove accuracyAccurate forecastTemperatue controlProgramme control in sequence/logic controllersAutomatic controlData acquisition

The invention relates to a system for controlling the forecast of molten steel temperature of a double-station LF furnace, which belongs to the technical field of LF furnace automatic control. The system comprises hardware for detecting forecast control on line and a software processing module, and is characterized in that the hardware comprises a temperature thermocouple connected with a production process database of the LF furnace through an Ethernet; and the software processing module comprises a data acquisition module, a double-station processing module, a temperature correction module, a molten steel temperature forecasting module, a parameter self-learning module, a molten steel temperature control module and a historical data query module. The system has the advantages of accurate forecast, reliability, practicability and high automation level.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

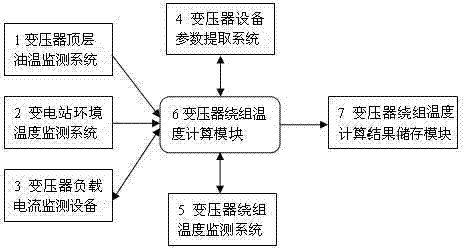

Transformer winding hot-spot temperature forecasting evaluation system with self-adaption function

ActiveCN103698033AGet the coil temperatureTrue restorationThermometers using electric/magnetic elementsThermometers using physical/chemical changesMonitoring systemTemperature forecasting

The invention discloses a transformer winding hot-spot temperature forecasting evaluation system with a self-adaption function. The transformer winding hot-spot temperature forecasting evaluation system mainly comprises seven parts such as a transformer top layer oil temperature monitoring system, a transformer substation environment temperature monitoring system and transformer load current monitoring equipment. The transformer winding hot-spot temperature forecasting evaluation system has the advantages that the temperature change trend after the transformer load increase can be monitored, the coil temperature of a transformer is accurately known in real time, in addition, the temperature change trend of the transformer is forecast, the transformer equipment can be fully utilized for testing the temperature influence after the load capacity increase, and the evaluation means is provided for the overload operation feasibility of an electric network system at the peak period under the condition of not damaging the insulation performance of the transformer equipment.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

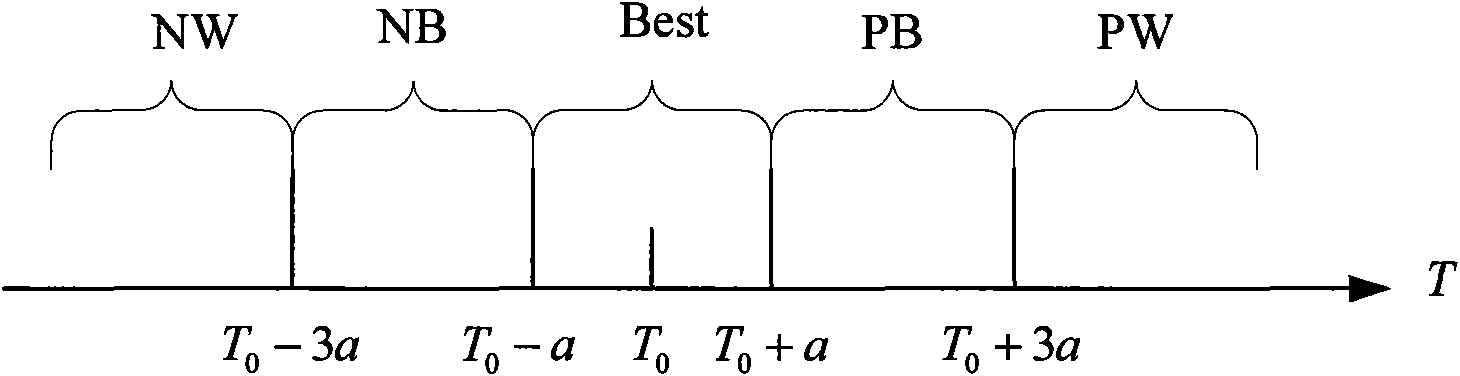

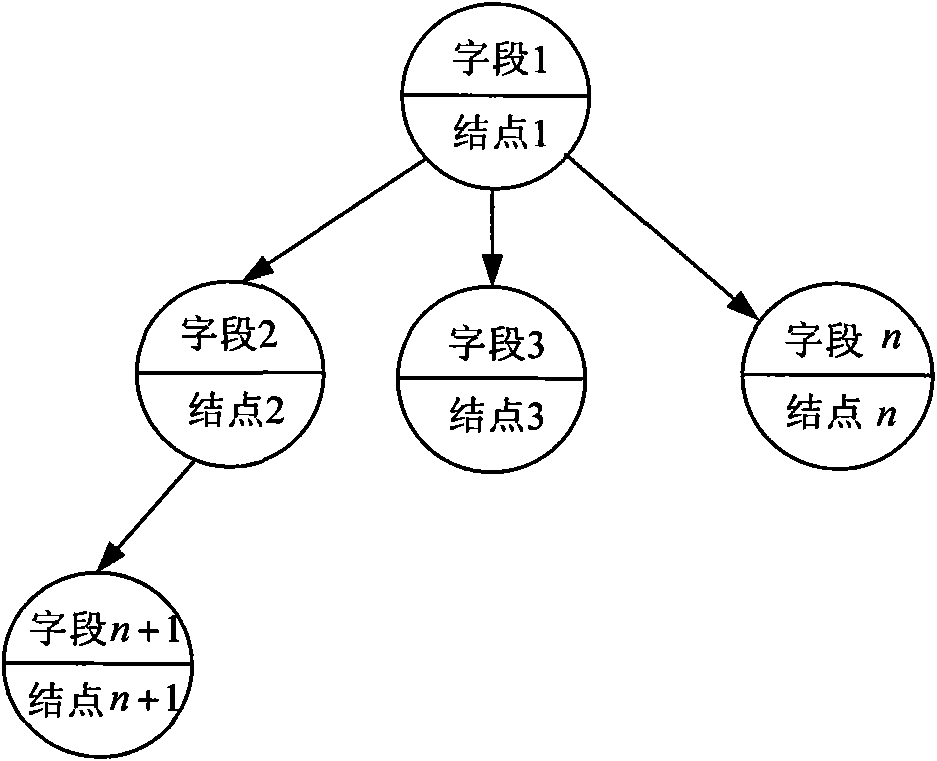

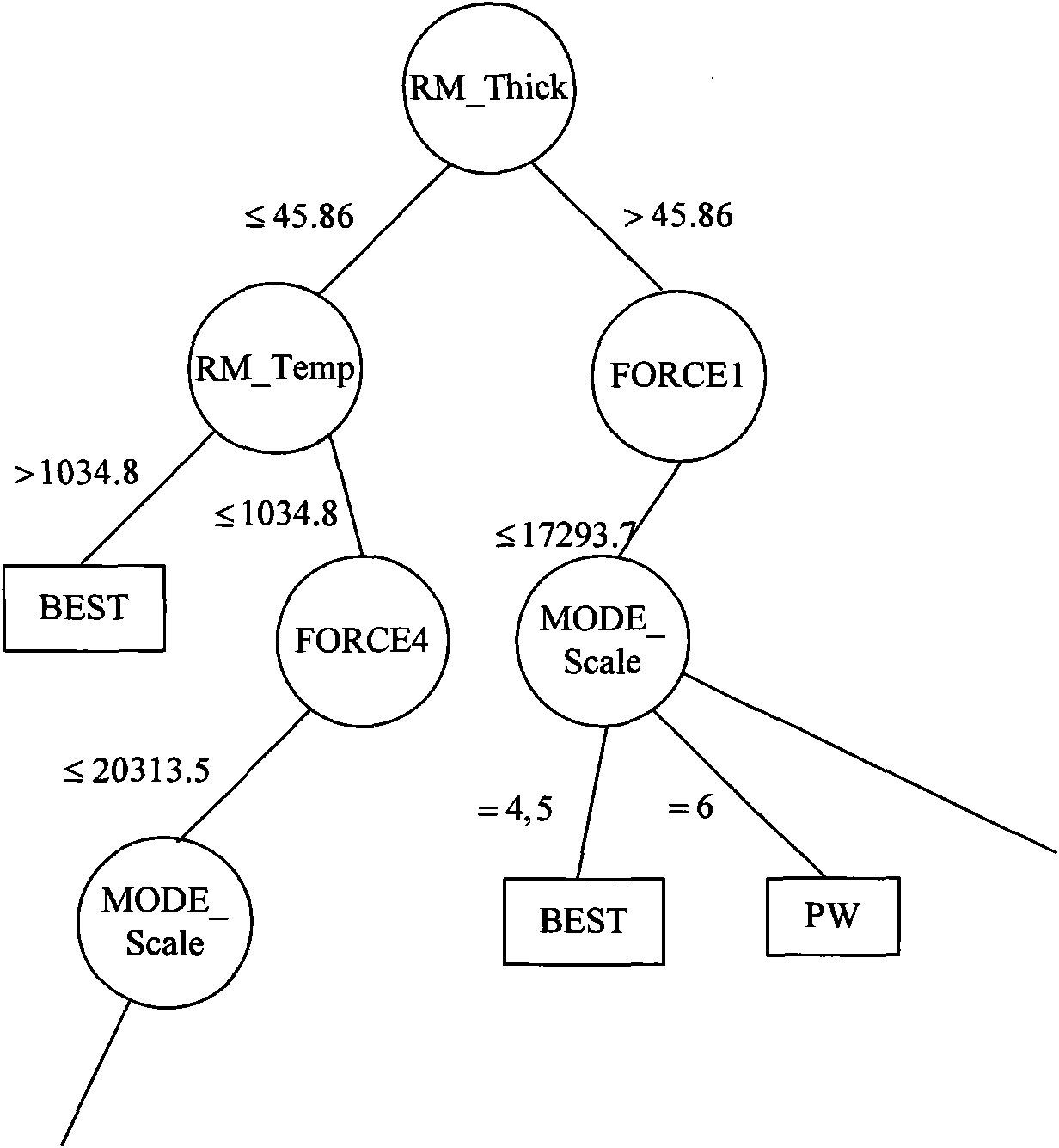

Decision tree-based method for extracting key characteristic variables of finish rolling temperature control process

The invention relates to a decision tree-based method for extracting key characteristic variables of a finish rolling temperature control process. The method comprises the following steps: finish rolling process data are pretreated, process data taking band steel numbers as indexes are converted into decision attribute vectors taking finish rolling temperature as a target attribute, and nonlinear discretization is performed on the finish rolling temperature; a decision tree method is used for calculating the information gain rate of each discrete or continuous value decision attribute; and the effect of each attribute on the finish rolling temperature is determined according to the information gain rate, the decision attribute vectors are reordered according to the values of information gain rates, and key characteristic variables with decisive effect on the finish rolling temperature are extracted in accordance with the finish rolling process mechanism and model precision requirements. The method can determine which key variables have a decisive effect on the finish rolling temperature according to the actual field process data, thereby laying a foundation for establishing a finish rolling temperature forecast model and a finish rolling temperature correction model.

Owner:浙江汇高机电科技有限公司

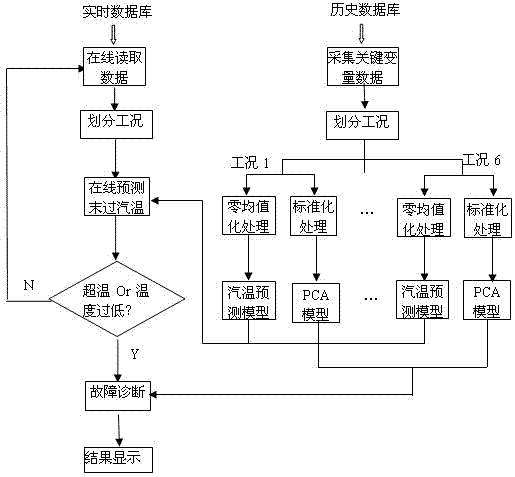

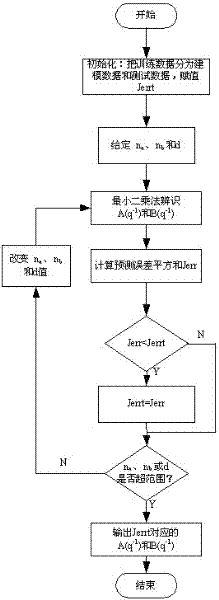

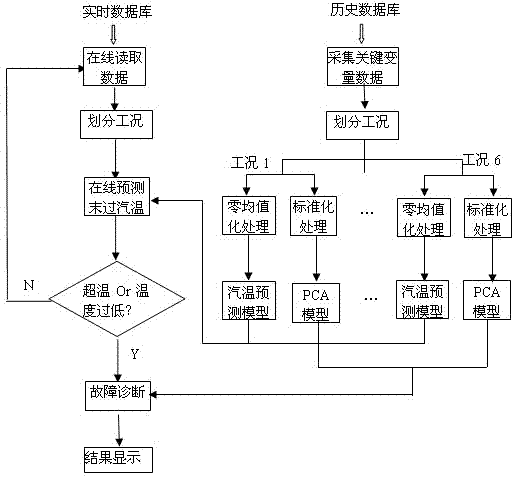

Method for carrying out early warning of abnormal superheated steam temperature and fault diagnosis on direct current megawatt unit

InactiveCN102331772AQuickly determine the cause of failureElectric testing/monitoringTemperature forecastingEngineering

The invention discloses a method for carrying out early warning of an abnormal superheated steam temperature and fault diagnosis on a direct current megawatt unit. The method comprises the following steps of: dividing working conditions; identifying parameters of a superheated steam temperature forecasting model under typical working conditions; carrying out on-line forecasting on a superheated steam temperature tendency; and carrying out fault diagnosis. A diagnostic message provided by the method faces a field centralized control operator; and the operator can obtain contribution information of each variable to fluctuation of the steam temperature by clicking in an early warning state, so that the operator can rapidly determine a fault reason and timely treat a field fault. Due to the adoption of the method, the superheated steam temperature tendency can be forecasted a plurality of minutes early; and the provided diagnostic message faces the field centralized control operator and the operator can obtain the contribution information of each variable to fluctuation of the steam temperature by clicking in the early warning state, so that the operator can rapidly determine the fault reason and timely treat the field fault. The invention provides the rapid, simple and convenient method for safe and stable operation of the large-scale direct current unit.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

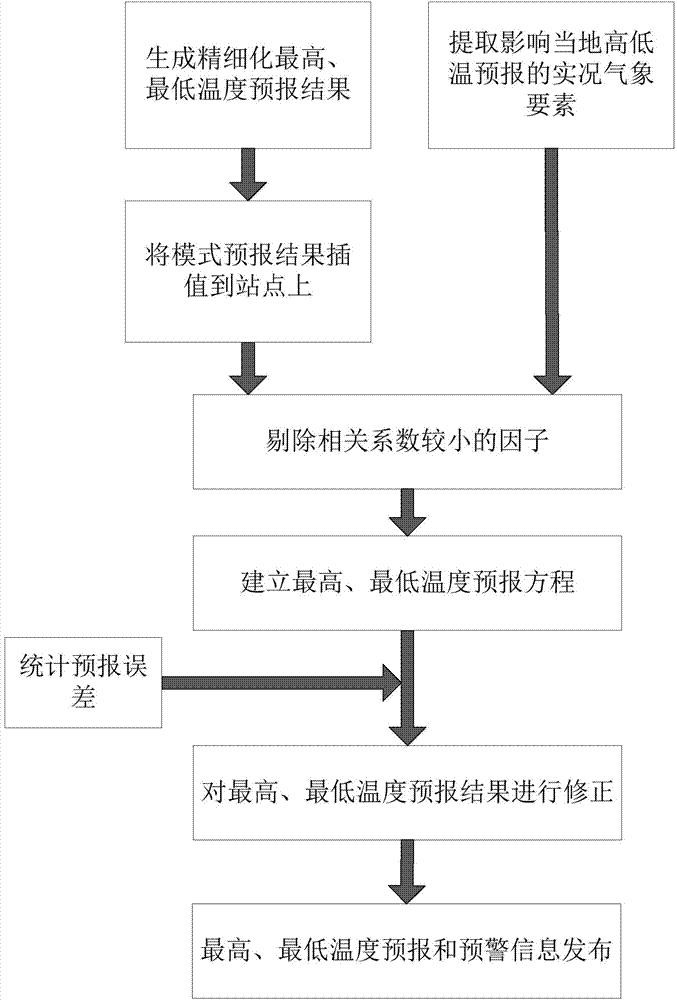

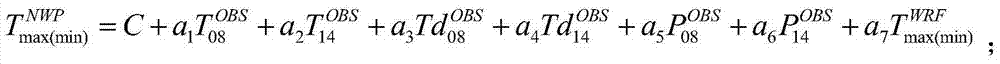

Power grid high low temperature refined early warning method in combination with dynamic correction

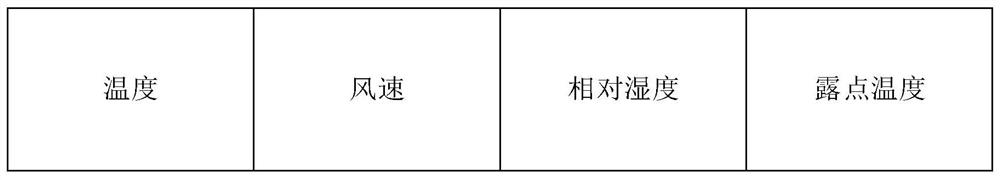

InactiveCN104849776ASolve high temperatureResolve resolutionHuman health protectionData processing applicationsWeather factorExtreme weather

The invention discloses a power grid high low temperature refined early warning method in combination with dynamic correction, comprising the steps of: S1, forecasting local weather to generate highest and lowest temperature forecast results and extracting live weather factors influencing local temperature forecast results; S2, establishing highest and lowest temperature forecast equations in dependence on generated temperature forecast results and selected live weather factors; S3, counting highest and lowest temperature forecast errors based on actually measured highest and lowest temperature information and forecast results, and correcting the highest and lowest temperature forecast results based on the temperature forecast errors to obtain final forecast results of highest and lowest temperatures; and S4, performing electric power equipment priority forecasting based on the final forecast results of highest and lowest temperatures and publishing early warning information. The power grid high low temperature refined early warning method can effectively solve the problem of great differences between a power grid system high temperature and low temperature forecast effect and an actually measured result, timely and effectively take corresponding measures to cope with extremely high and low temperatures, and mitigate damage caused by extreme weather.

Owner:STATE GRID CORP OF CHINA +3

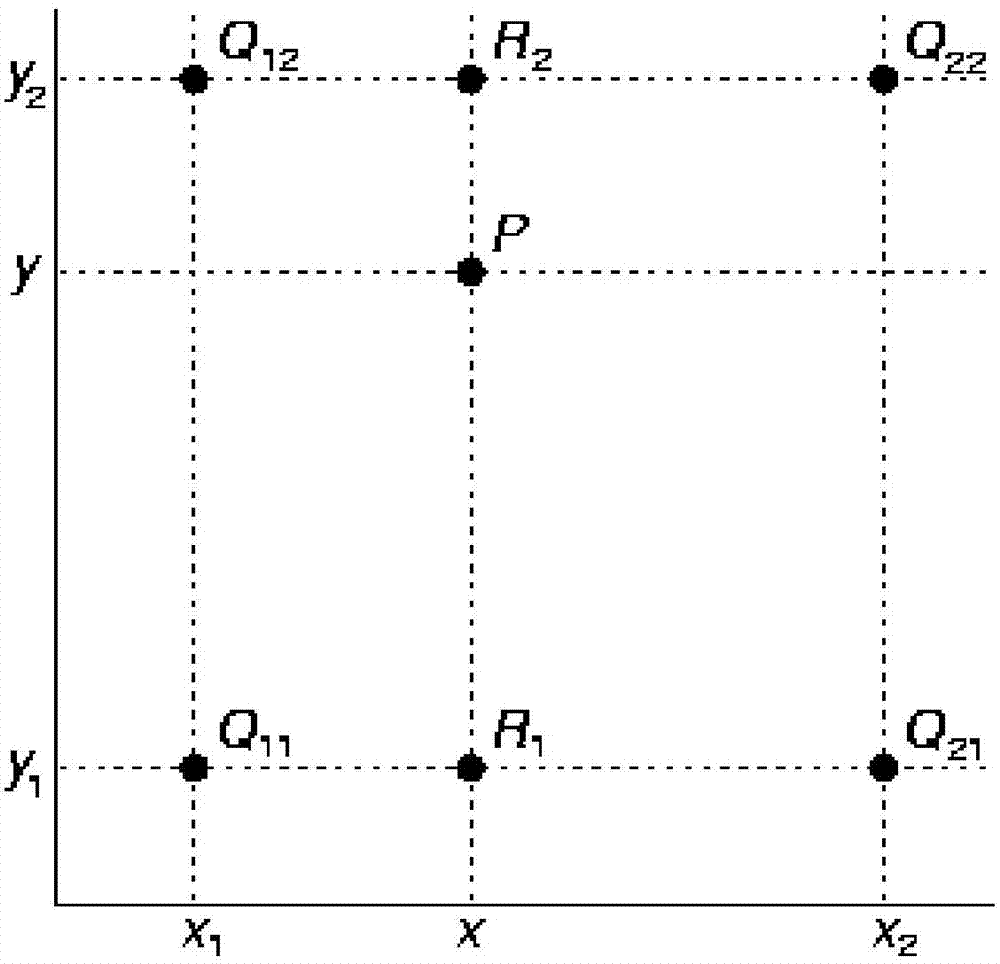

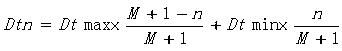

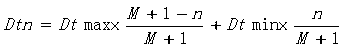

Method for correcting sliding deviation of refinement temperature prediction

ActiveCN109085664AImprove accuracySmall amount of calculationWeather condition predictionICT adaptationTemperature forecastingNumerical models

The invention discloses a method for correcting sliding deviation of refinement temperature prediction. The method comprises: obtaining a weather prediction product with temperature numerical value ofa real-time point; calculating daily highest and lowest temperature prediction of the real-time point; determining a temperature prediction deviation statistic and an optimal sliding statistic period; performing a deviation sliding statistic of the daily highest and lowest temperature prediction; performing the correction of the deviation of the refinement temperature prediction according to thecorrected deviation of the daily highest and lowest temperature prediction; reporting the corrected temperature from a real-time point to a prediction site or a intelligent grid point; developing a timing running program according to the numerical prediction product and the real-time product which automatically runs every day; and outputting a corrected temperature site or a intelligent grid prediction product in real-time to realize the correction of the sliding deviation of the temperature prediction. According to the method for correcting the sliding deviation of the refinement temperatureprediction, the deviation correction can be realized by the sliding statistic on the numerical model temperature prediction, accuracy of the numerical prediction product can be not only improved, a data statistics collation process of long-term sequences can be simplified.

Owner:山东省气象科学研究所

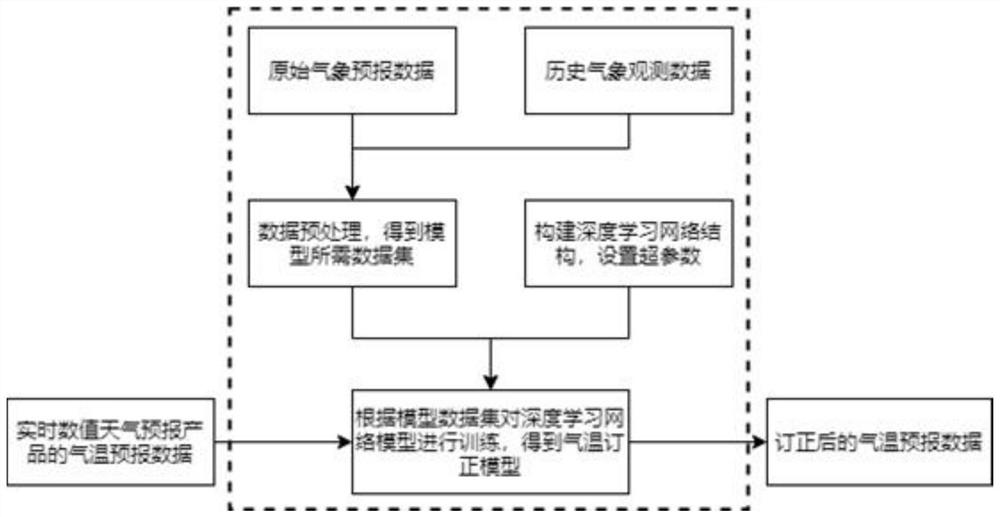

Air temperature forecast data correction method based on deep learning

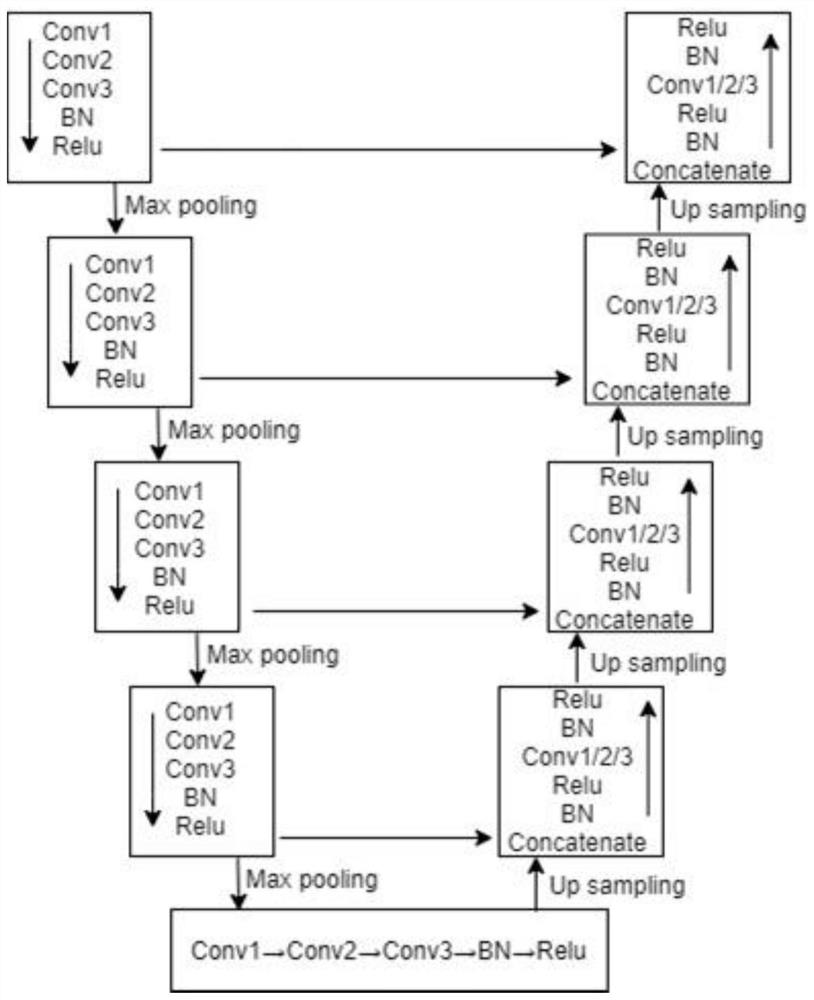

PendingCN113807432AHigh precisionHigh spatio-temporal resolutionCharacter and pattern recognitionNeural architecturesNear neighborLearning network

The invention belongs to the technical field of weather forecast, and particularly relates to an air temperature forecast data correction method based on deep learning. In a data preprocessing stage, a nearest neighbor interpolation method is used for converting air temperature forecast data into lattice point data, meanwhile, the spatial resolution is improved, and Gaussian filtering is adopted for carrying out smoothing processing on the air temperature data, so that Gaussian noise is removed; in the stage of constructing a deep learning network structure, the time resolution is improved by using up-sampling processing, meanwhile, time features are extracted by using LSTM, weighted fusion is performed on the time features and numerical forecasting features extracted by a UNet network, and the temperature forecasting precision is improved by using the nonlinear mapping capability of the deep learning network and the information extraction capability of lattice point data. In conclusion, according to the air temperature forecast data correction model, a more accurate correction value can be calculated, the temporal-spatial resolution of air temperature forecast can be improved, manpower consumption can be reduced, and a high-resolution and accurate-analysis correction service is provided for future refined grid point forecast.

Owner:成都卡普数据服务有限责任公司

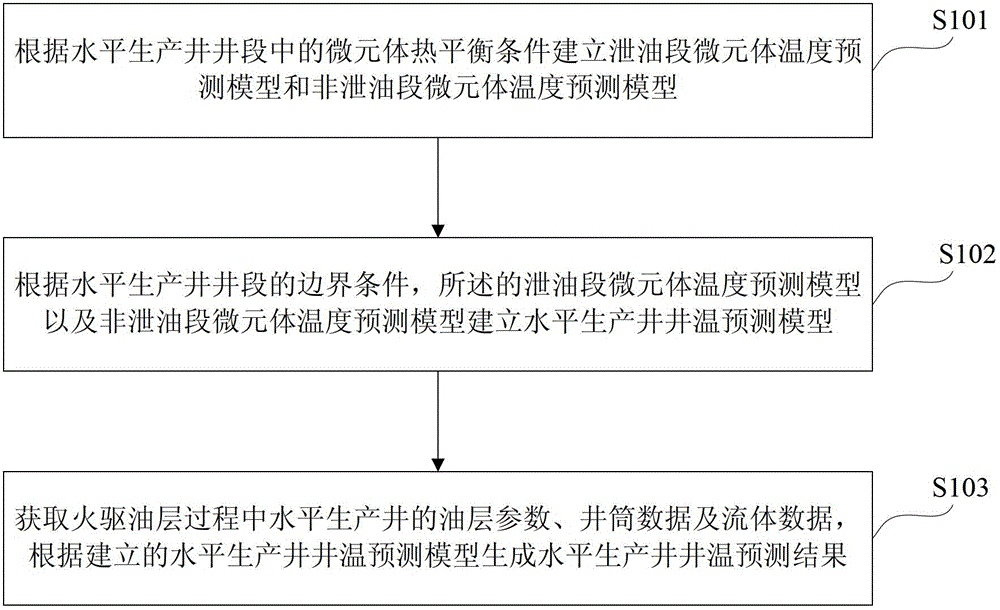

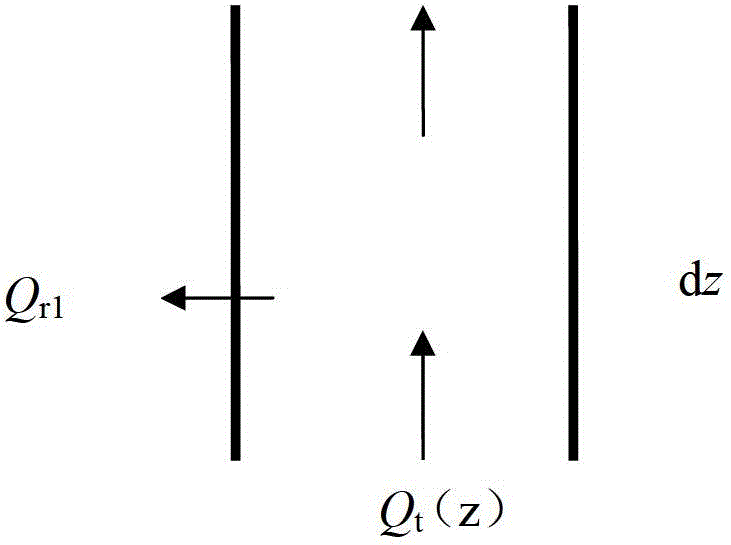

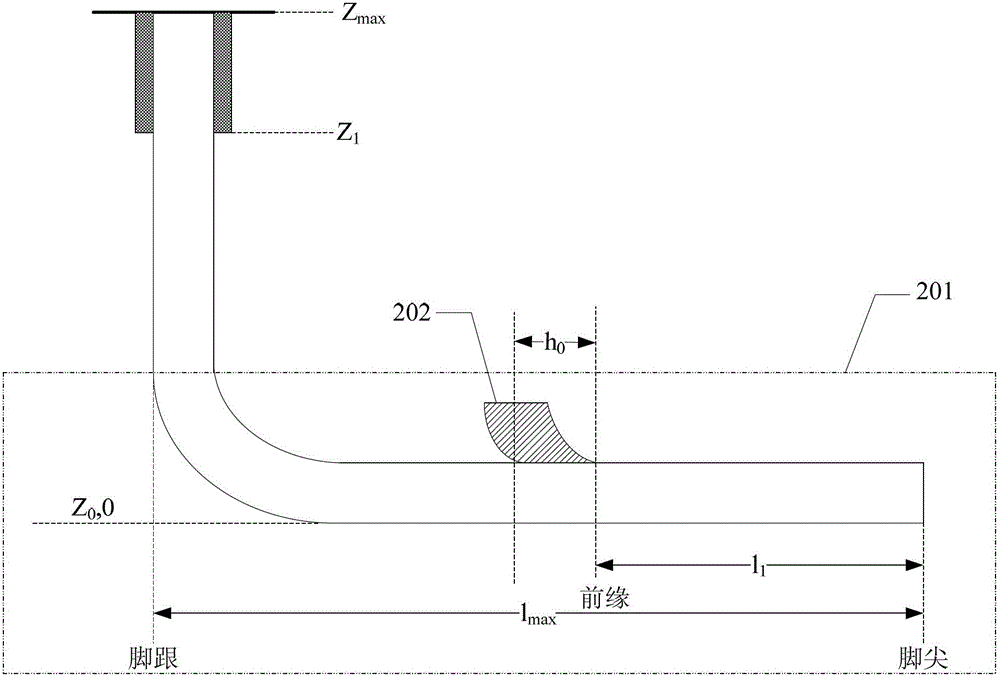

Well temperature forecasting method for horizontal production well in fire flooding process

The invention discloses a well temperature forecasting method for a horizontal production well in a fire flooding process. The method comprises the following steps of: constructing an oil release section infinitesimal body temperature forecasting model and a non oil release section infinitesimal body temperature forecasting model according to an infinitesimal body heat balance condition in a well section of the horizontal production well; constructing a horizontal production well temperature forecasting model according to a boundary condition of the well section of the horizontal production well, the oil release section infinitesimal body temperature forecasting model and the non oil release section infinitesimal body temperature forecasting model; and generating a horizontal production well temperature forecasting result according to input oil layer parameters of the horizontal production well in an oil layer fire flooding process, well barrel data and fluid data as well as the constructed horizontal production well temperature forecasting model.

Owner:PETROCHINA CO LTD

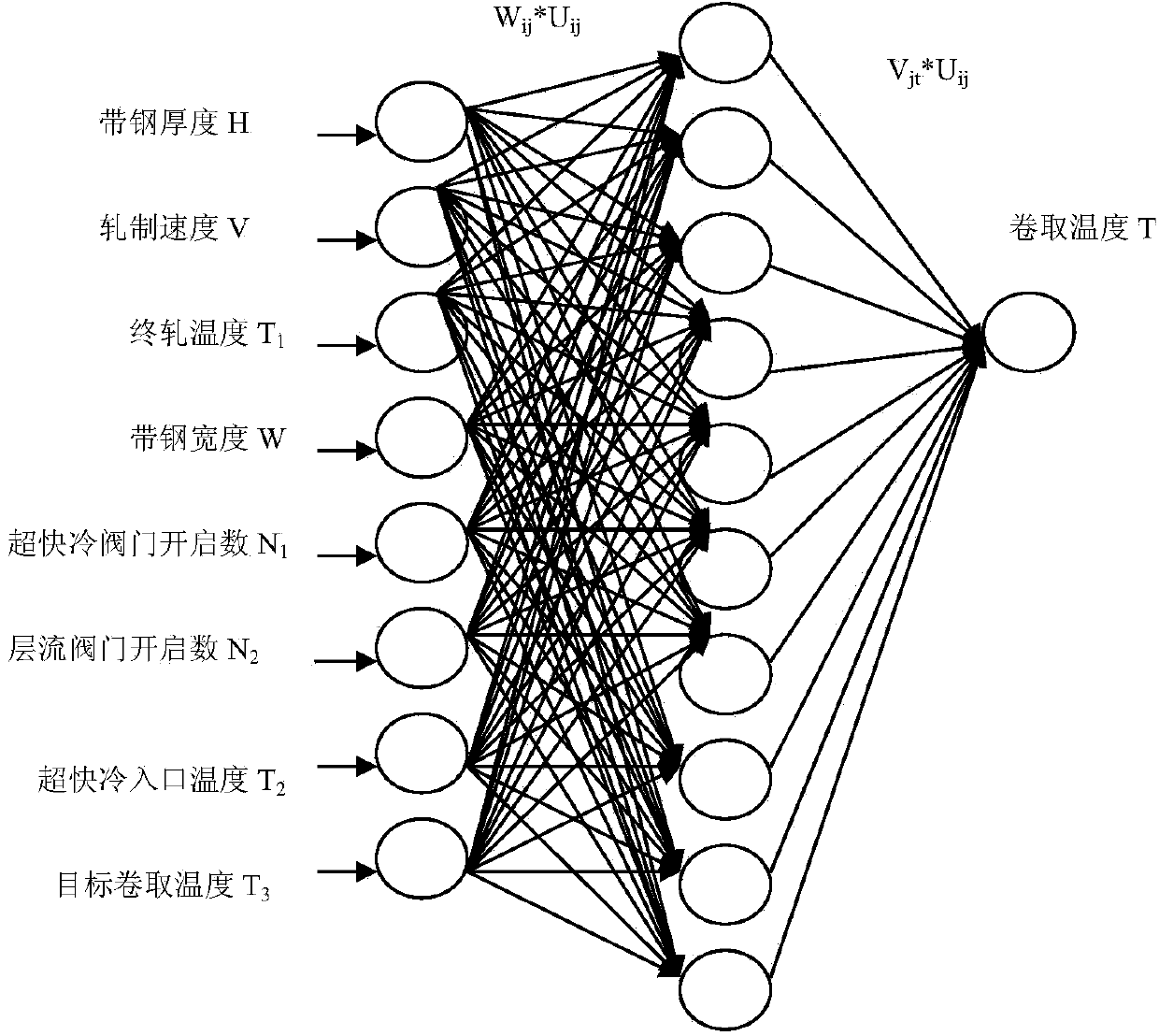

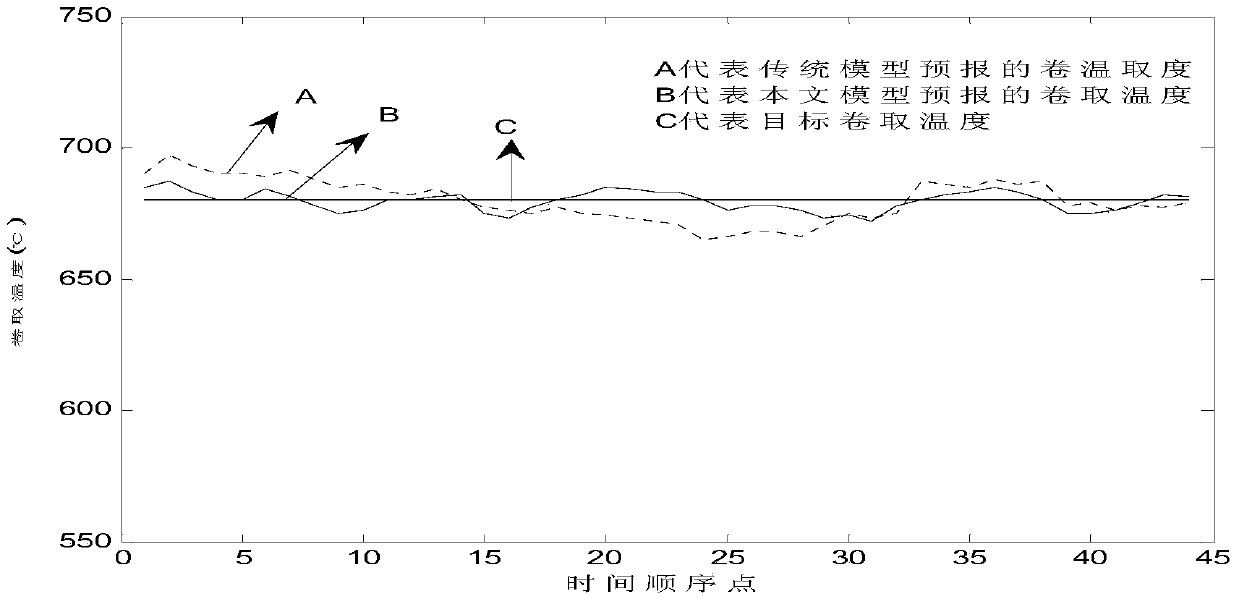

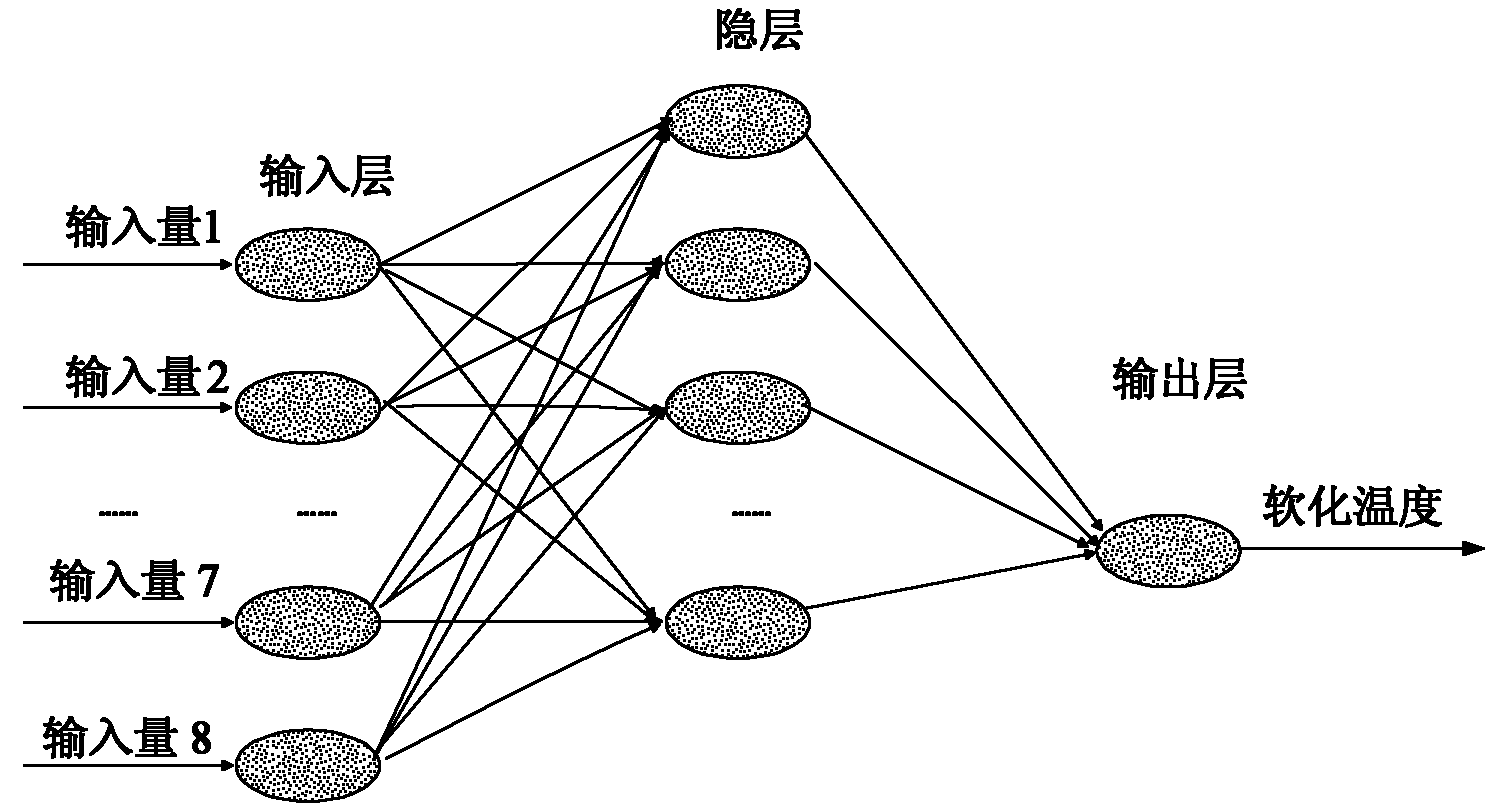

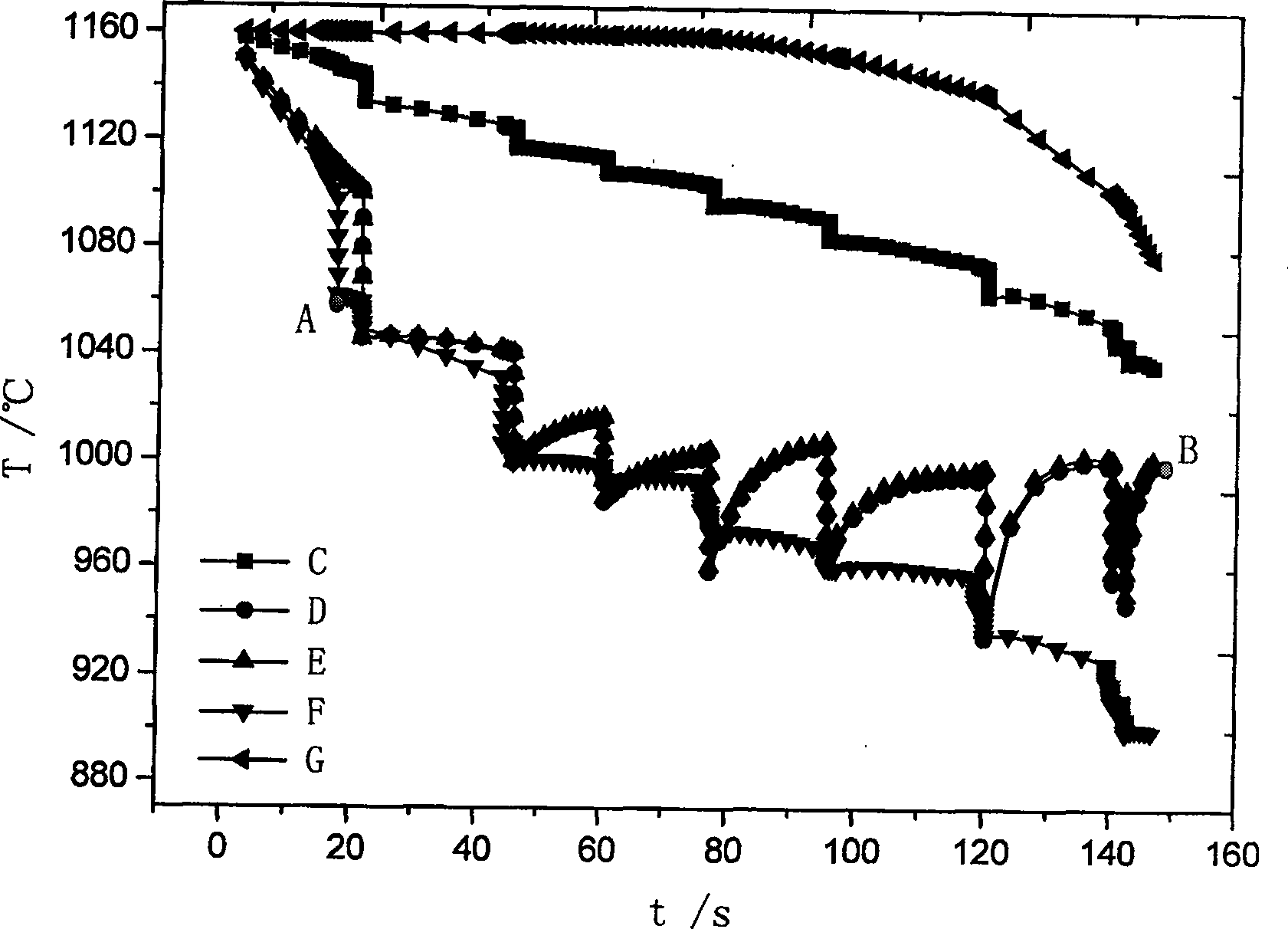

Hot-rolling coiling temperature forecasting method based on relevant neural network

ActiveCN103464475AAccurate coiling temperature controlTemperature control deviceTemperature controlHidden layer

The invention provides a hot-rolling coiling temperature forecasting method based on a relevant neural network. Data of strip steel thickness H, rolling velocity V, finish rolling temperature T1, strip steel width W, super rapid cooling valve opening quantity N1, laminar flow valve opening quantity N2, super rapid cooling inlet temperature T2 and target coiling temperature T3 are collected through a personal digital assistant (PDA) terminal, an input matrix [H, V, T1, W, N1, N2, T2, T3] is built, and an output matrix [T] is built. If [V, T1, W, N1, N2, T2, T3] is supposed to be not changed, Y is defined to be an influence degree of the H. According to influence degrees, corresponding influence degrees are given to the weight of the input end and a hidden layer and to the weight of the hidden layer and an output layer, three layers of ASBP neutral networks are built, the actual coiling temperature is output, ASBP neutral network training is conducted, and coiling temperature forecasting is conducted by using actual testing data. By means of the method, a coiling temperature forecasting error range is reduced from -20 DEG C-20 DEG C to -10 DEG C-10 DEG C, and coiling temperature control is more accurate.

Owner:ANGANG STEEL CO LTD

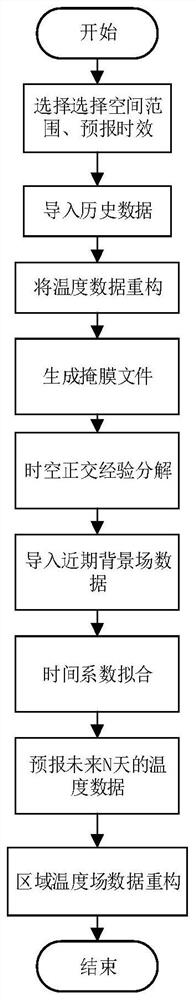

Seawater temperature field prediction method based on improved EOF

PendingCN111815041AReduce data volumeGuaranteed effective timeForecastingComplex mathematical operationsPredictive methodsTemperature forecasting

The invention relates to a seawater temperature field prediction method based on improved EOF, and the seawater temperature field prediction method comprises the following steps: reconstructing historical data; extracting geographic information of the current sea area to form a mask file; obtaining spatial change characteristic parameters through spatial-temporal orthogonal empirical decomposition; fitting a time coefficient; forecasting the temperature in the future N days; and performing regional temperature field reconstruction. According to the seawater temperature field prediction method,on the basis of a traditional spatio-temporal empirical orthogonal decomposition method, ocean elements are reconstructed in time and space, and a good prediction result is obtained. Through multipleverifications, the seawater temperature field prediction method can achieve the long-time prediction of the temperature field. In engineering application, computing resources are saved, and practicability is high, and future ocean temperature forecasting information can be provided for ship navigation and other offshore platforms.

Owner:青岛哈船海智科技有限公司

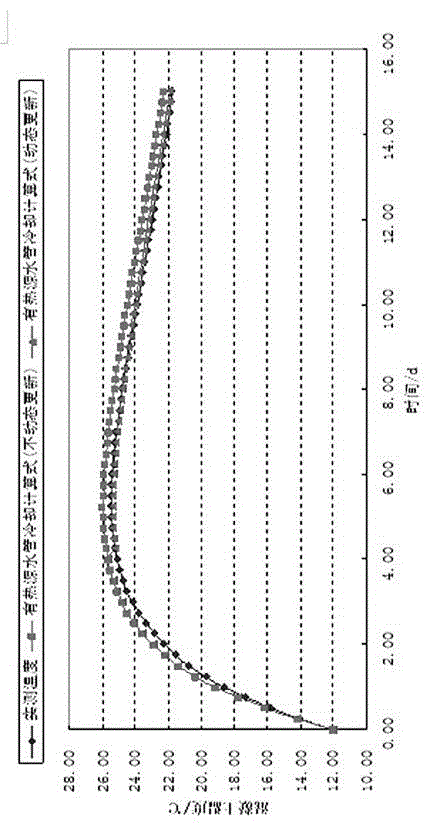

Fast forecasting method for initial water cooling temperature field for concrete dam

ActiveCN104480894AHydraulic engineering apparatusFoundation engineeringTemperature forecastingWater cooling

The invention discloses a fast forecasting method for an initial water cooling temperature field for a concrete dam. The fast forecasting method for the initial water cooling temperature field for the concrete dam includes steps that A) building a fast forecasting model for the initial water cooling temperature field for the concrete dam with a heat source and an adiabatic outer surface; B) leading in adjustment items to reflect plane heat dissipation influence, and dynamically updating important items of the fast forecasting model for the initial water cooling temperature field for the concrete dam based on the actual temperature of a concrete pouring storehouse so as to eliminate errors caused by uncertain factors and build the fast forecasting model for the temperature of the pouring storehouse in the initial cooling period of the concrete dam which takes outside temperature into account. According to the fast forecasting method for the initial water cooling temperature field for the concrete dam, adjustment items are led into the fast forecasting model for the initial water filling for the concrete dam so as to reflect the plane heat dissipation influence, and important items of a water pipe cooling temperature forecasting model are updated dynamically based on the current actual temperature of the pouring storehouse so as to build the fast and precise concrete dam temperature forecasting model with small calculation workload.

Owner:CHINA THREE GORGES UNIV

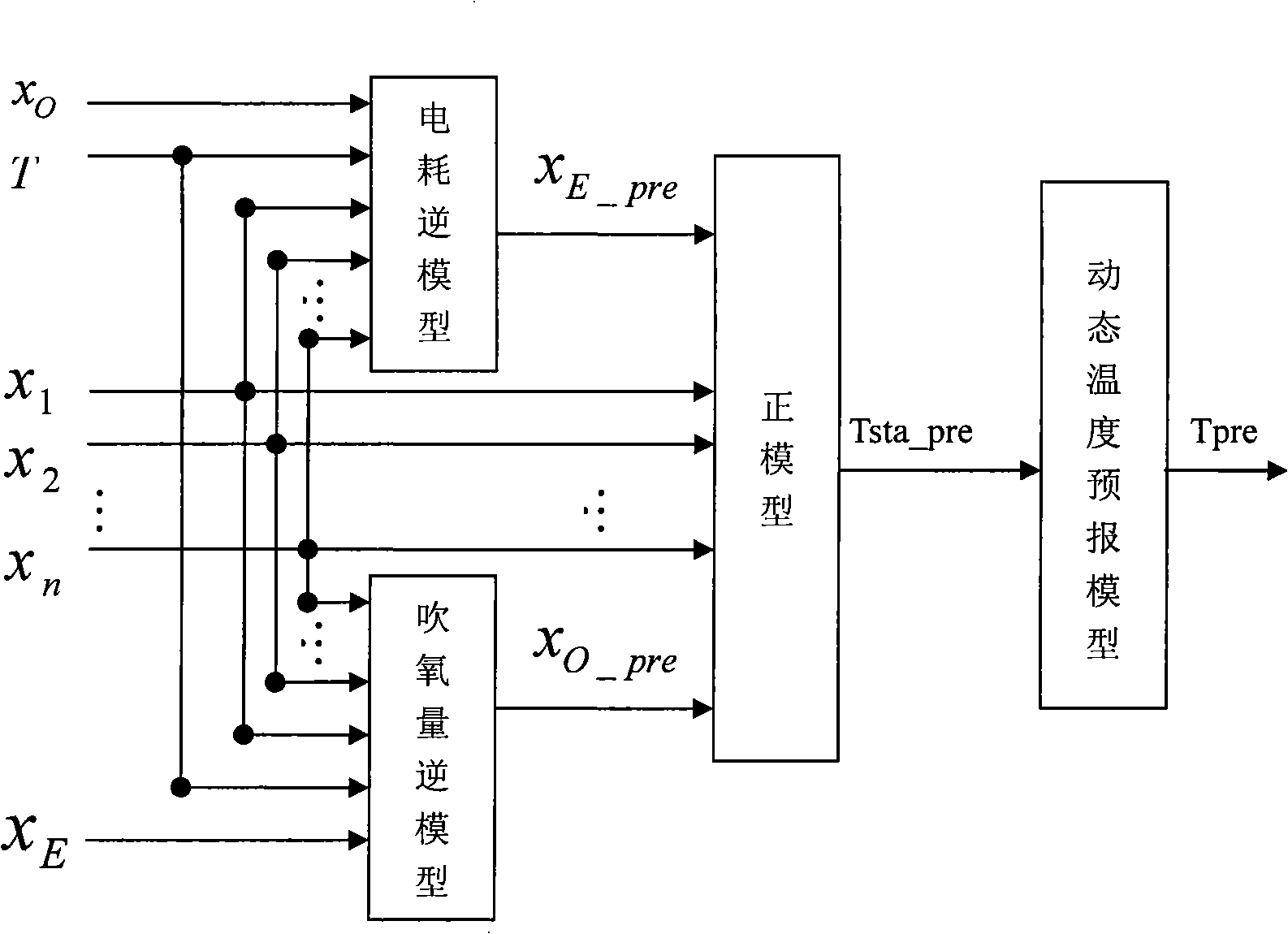

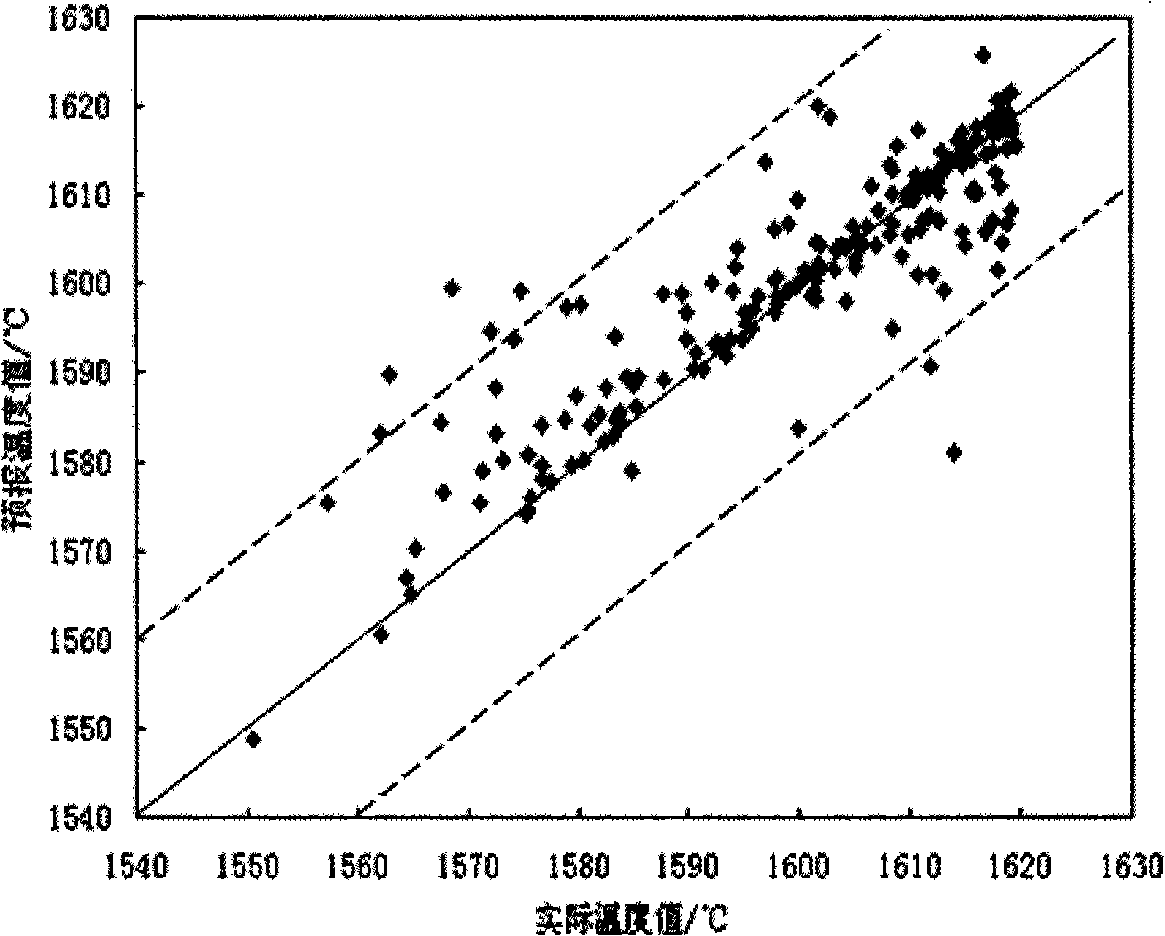

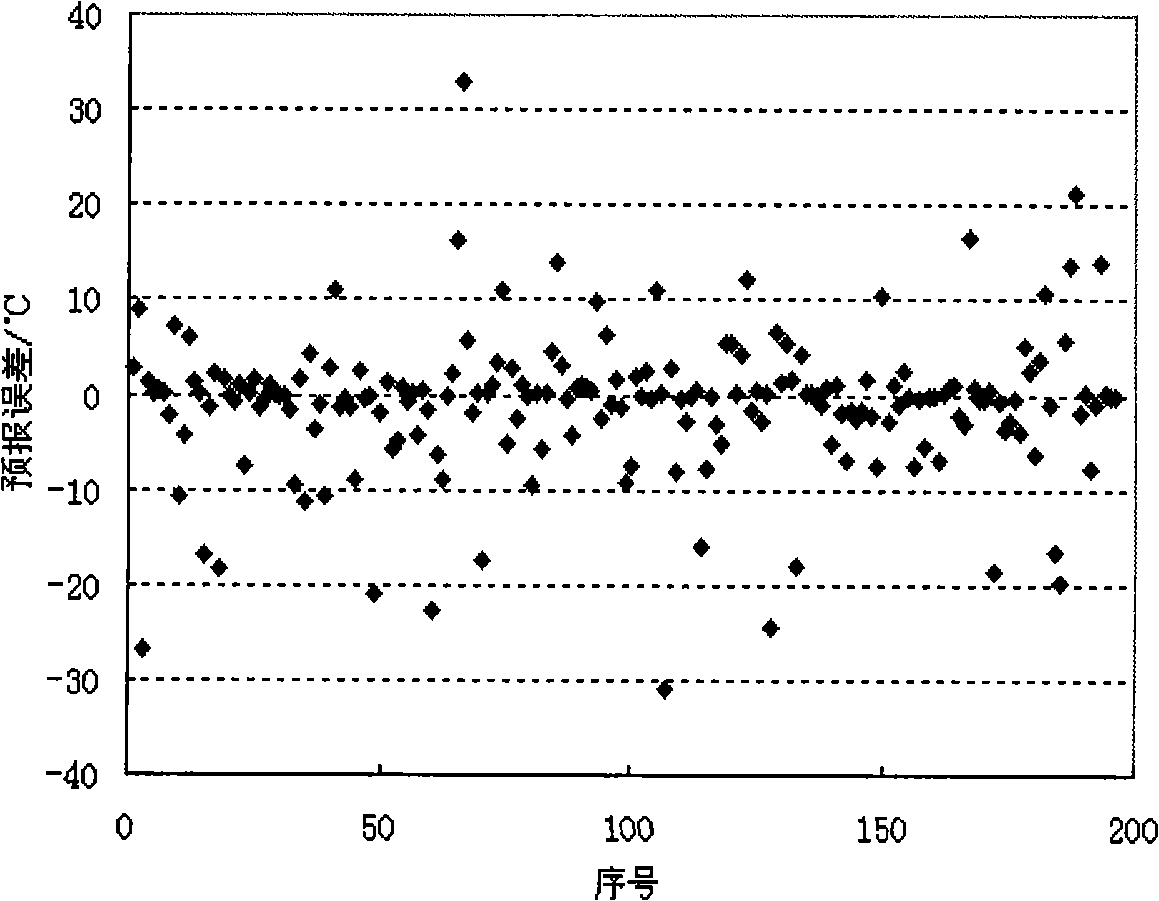

Electric arc furnace terminal temperature prediction system based on SVM

InactiveCN101403567ALighting and heating apparatusSimulator controlElectric arc furnaceTemperature forecasting

A prediction system for electric arc furnace terminal temperature based on SVM belongs to the technical field of steel enterprise steelmaking automation. The system includes a static temperature prediction model and a dynamic temperature prediction model. The static temperature prediction model is composed of two inverse models and a positive model, wherein, the inverse model comprises an oxygen blowing quantity inverse model and an electric consumption inverse model, and the output of the inverse models is taken as the input of the positive model; and the output of the static temperature prediction model is taken as the input of the dynamic temperature model. The dynamic temperature prediction model is used for predicting temperature of molten steel at real time, and the static temperature prediction model is used for providing original temperature for the dynamic temperature prediction model. The precision of the static temperature prediction model is improved by establishing the inverse models through the two important control variable quantity of oxygen blowing quantity and electric consumption; moreover, the data used for establishing the models is actual data coming from the site. The prediction system has the advantages of predicting current temperature according to the positive model, and the temperature is taken as the original temperature of the dynamic temperature prediction model for predicting temperature in process at real time.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

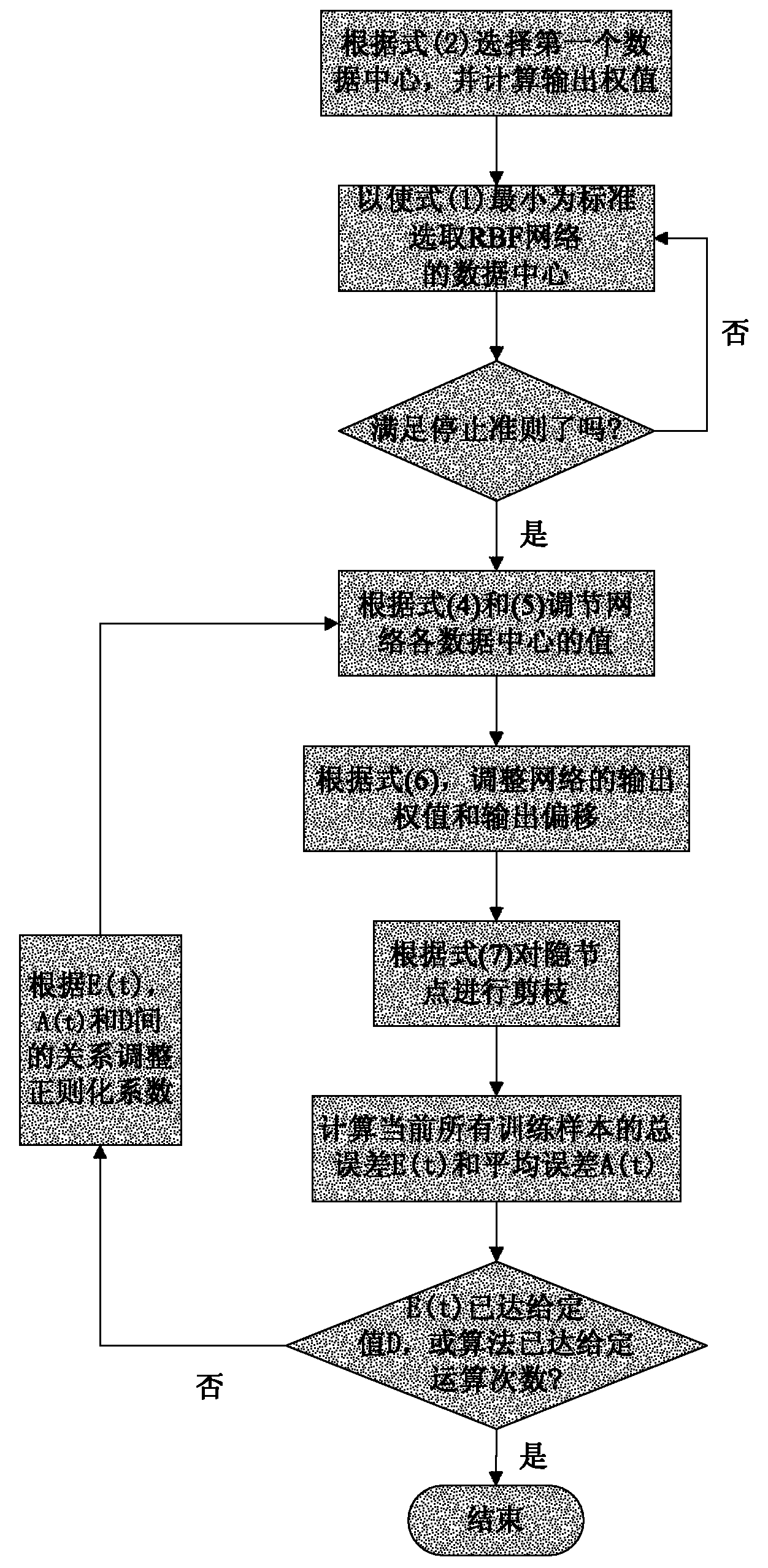

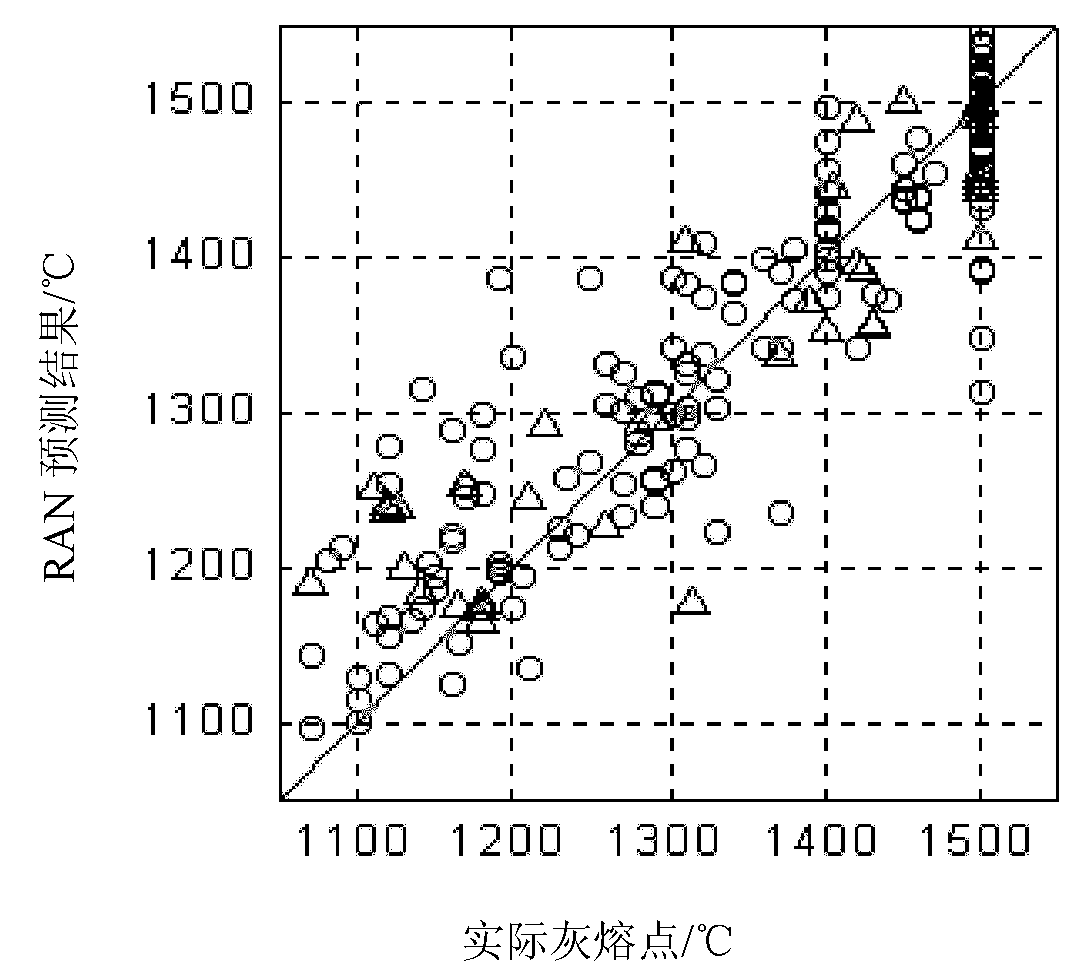

Coal ash fusion temperature forecasting method based on construction-pruning mixed optimizing RBF (Radial Basis Function) network

InactiveCN101968832ADynamically adjust the number of hidden nodesSmall structureSpecial data processing applicationsNeural learning methodsData centerCoal

The invention discloses a coal ash fusion temperature forecasting method based on a construction-pruning mixed optimizing RBF (Radial Basis Function) network, which is characterized by comprising the following two stages of crude regulation and fine regulation: the crude regulation stage comprises the steps of dynamically increasing the number of hidden nodes according to a principle of enabling an energy function to be minimum, selecting corresponding sample input as a data center and stopping till the number of the hidden nodes meets a stopping criterion; the fine regulation stage comprisesthe steps of further regulating the structure and the parameters of the RBF network, which are obtained through the crude regulation by using a Gaussian regularization method, establishing the corresponding construction-pruning mixed optimizing RBF network on the basis of the chemical constituents of coal ash, and forecasting coal ash fusion temperature through the construction-pruning mixed optimizing RBF network. A construction-pruning mixed optimizing algorithm (CPHM) effectively integrates the advantages of a construction algorithm and a pruning algorithm, can not only dynamically regulate the number of the hidden nodes of the RBF network, but also enable the data center of the RBF network to change in a self-adaption way; and in addition, the invention has the advantages of smaller structure, better generalization capability and higher robustness.

Owner:SOUTHEAST UNIV

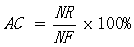

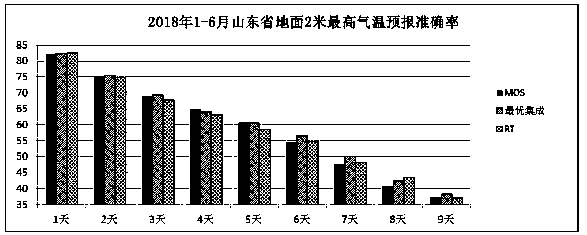

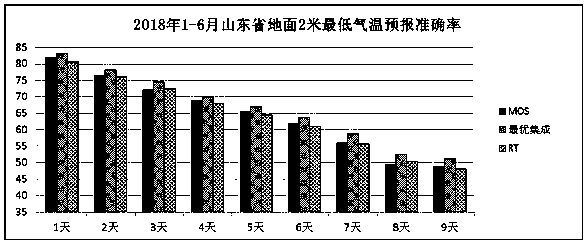

Temperature intelligent grid optimal integrated forecasting method

ActiveCN110068878AImprove accuracyWeather condition predictionTemperature forecastingBusiness forecasting

The invention relates to a temperature intelligent grid optimal integrated forecasting method. The method comprises following steps of: processing a numerical forecasting product, obtaining temperature real condition and a forecasting value of an observation station, selecting an optimal numerical forecasting product, correcting temperature forecasting, analyzing forecasting effects of different objective correction methods, researching a proper, optimal integrated forecasting method, generating a temperature intelligent grid optimal integrated forecasting product, so as to realize business operation. The method aims to find the optimal forecasting way. The first step is to find an optimal numerical mode, temperature forecasting is corrected based on the optimal numerical mode, object correction methods that forecast better and complement each other are to be find, and temperature forecasting accuracy is further improved by forecasting optimal sets of different correction methods.

Owner:山东省气象科学研究所

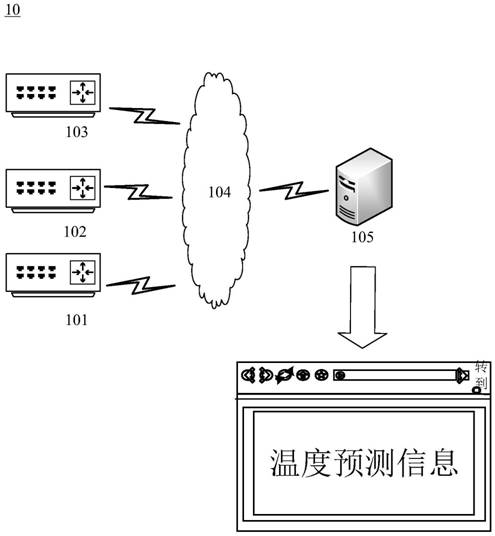

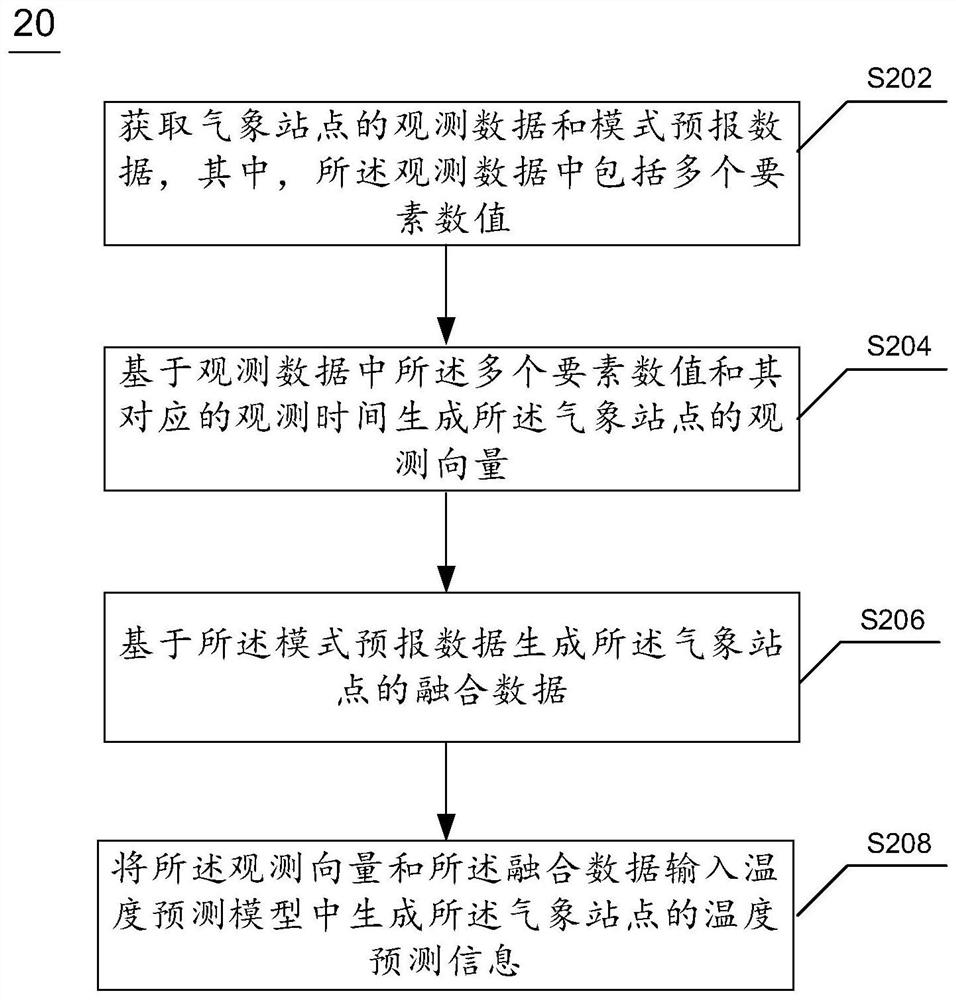

Temperature information prediction method and device

PendingCN112308281AScale upAccurate temperature forecast resultsForecastingObservation dataPredictive methods

The invention relates to a temperature information prediction method and device. The method comprises the steps: acquiring observation data and mode prediction data of a meteorological station, wherein the observation data comprise a plurality of element values; generating an observation vector of the meteorological station based on the plurality of element values in the observation data and the corresponding observation time; generating fusion data of the meteorological station based on the mode prediction data; and inputting the observation vector and the fusion data into a temperature prediction model to generate temperature prediction information of the meteorological station, wherein the temperature prediction model is generated through a gradient boosting algorithm. According to thetemperature information prediction method and device, historical observation data and mode prediction data can be fused, the site data scale is expanded, and a more accurate temperature prediction result is obtained.

Owner:北京嘉韵楷达气象科技有限公司 +1

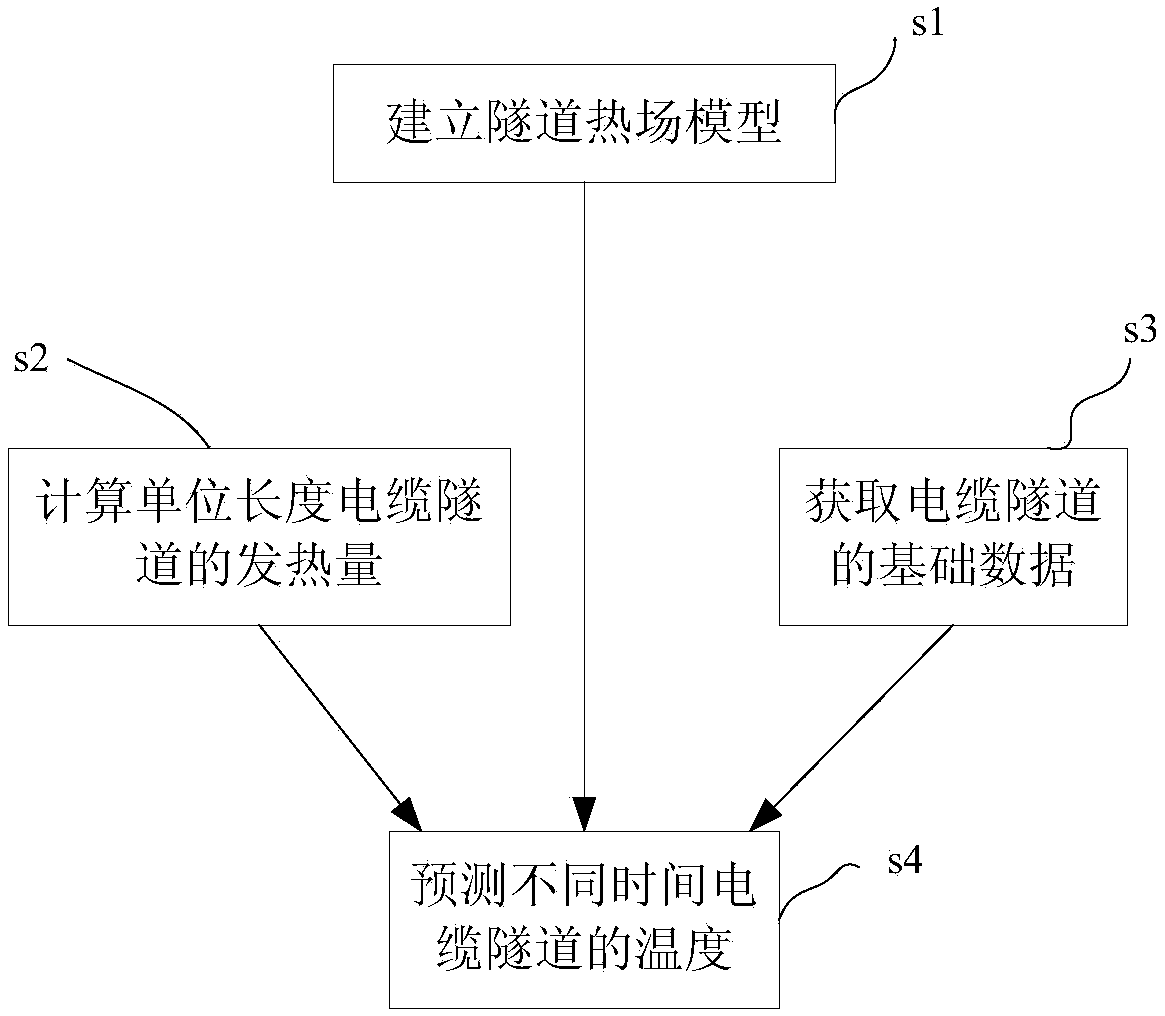

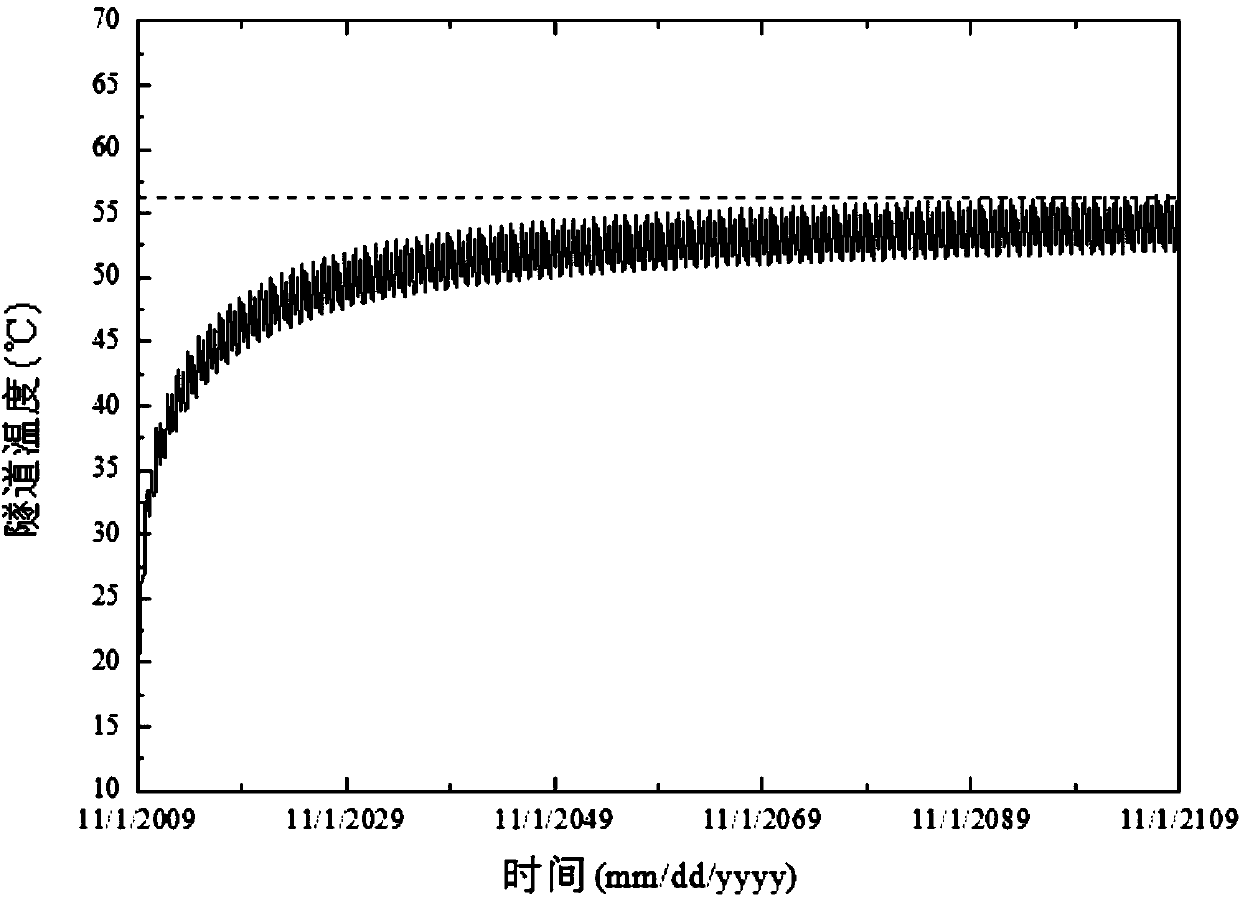

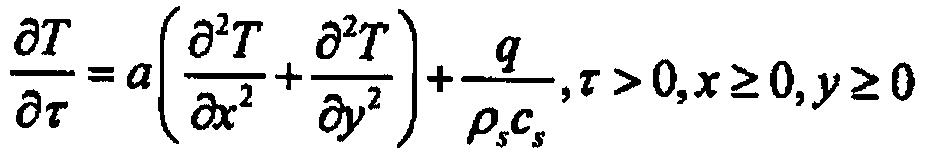

Long-term temperature forecasting method for power cable tunnel

InactiveCN103424210AHigh precisionEffective guidanceThermometer applicationsPower cablePredictive methods

The invention relates to a long-term temperature forecasting method for a power cable tunnel. The method includes the steps: 1) building a tunnel heat field model to obtain a temperature change trend; 2) acquiring the highest load of a current cable circuit under a normal working condition and calculating the heating value of the cable tunnel per unit length according to the highest load; 3) acquiring basic data of the cable tunnel; 4) forecasting the temperature of the cable tunnel at different time by the aid of the tunnel heat field model according to the steps 2) and 3) to generate a temperature forecasting curve. Compared with the prior art, the method has the advantages that forecasting accuracy and reasonable usability of resources are improved and the like.

Owner:STATE GRID CORP OF CHINA +2

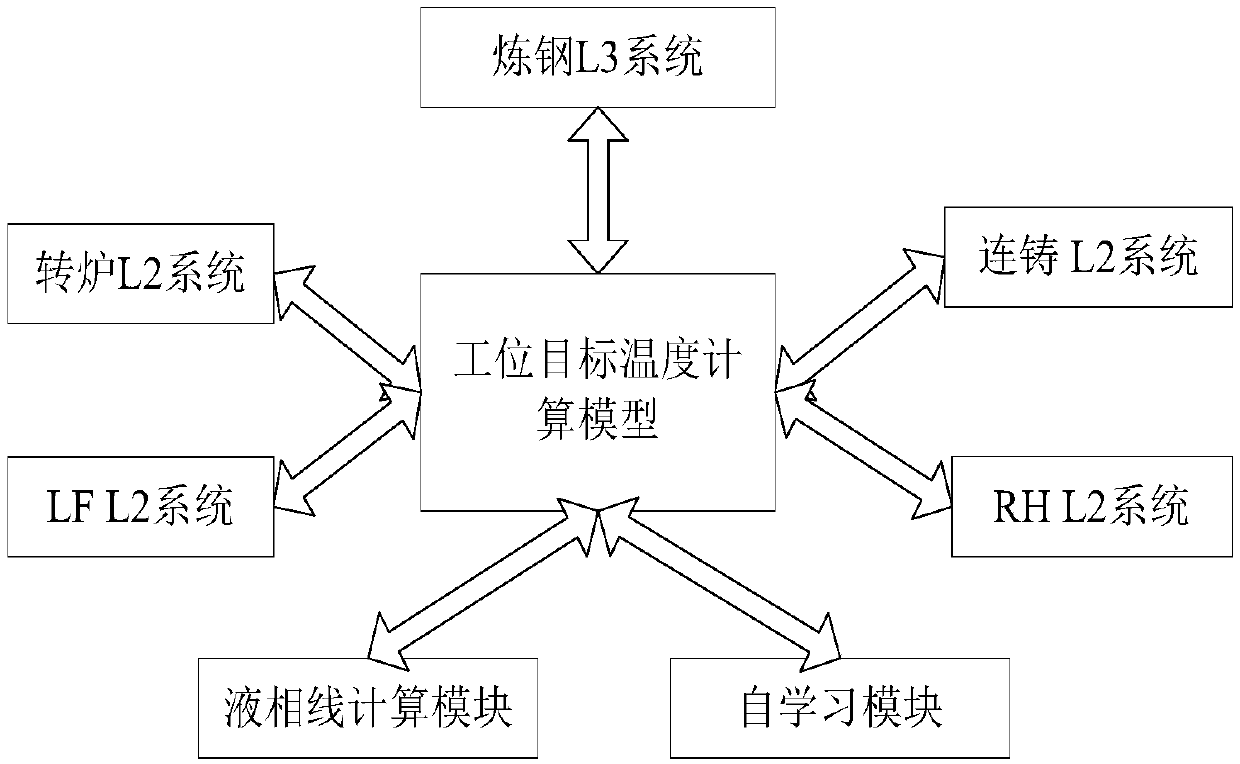

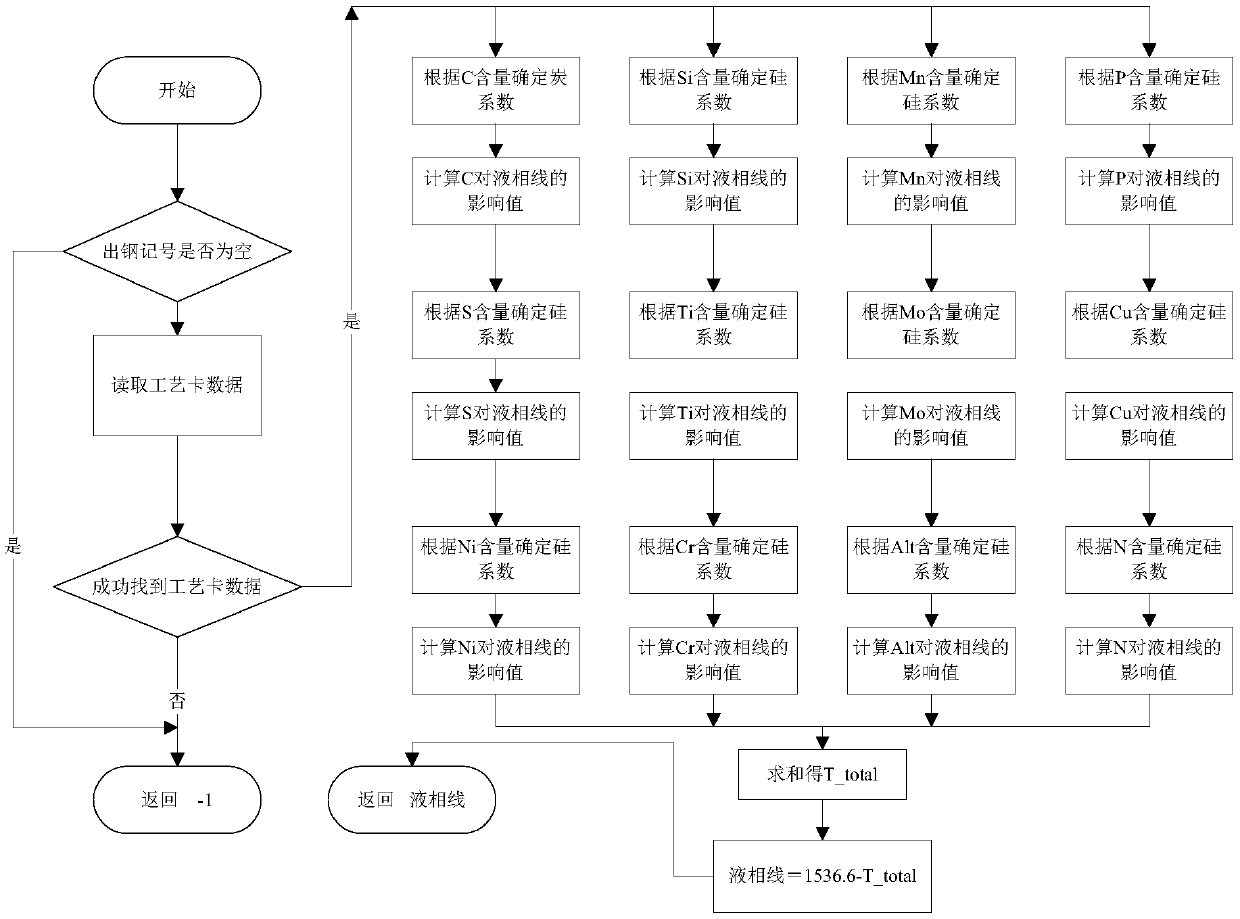

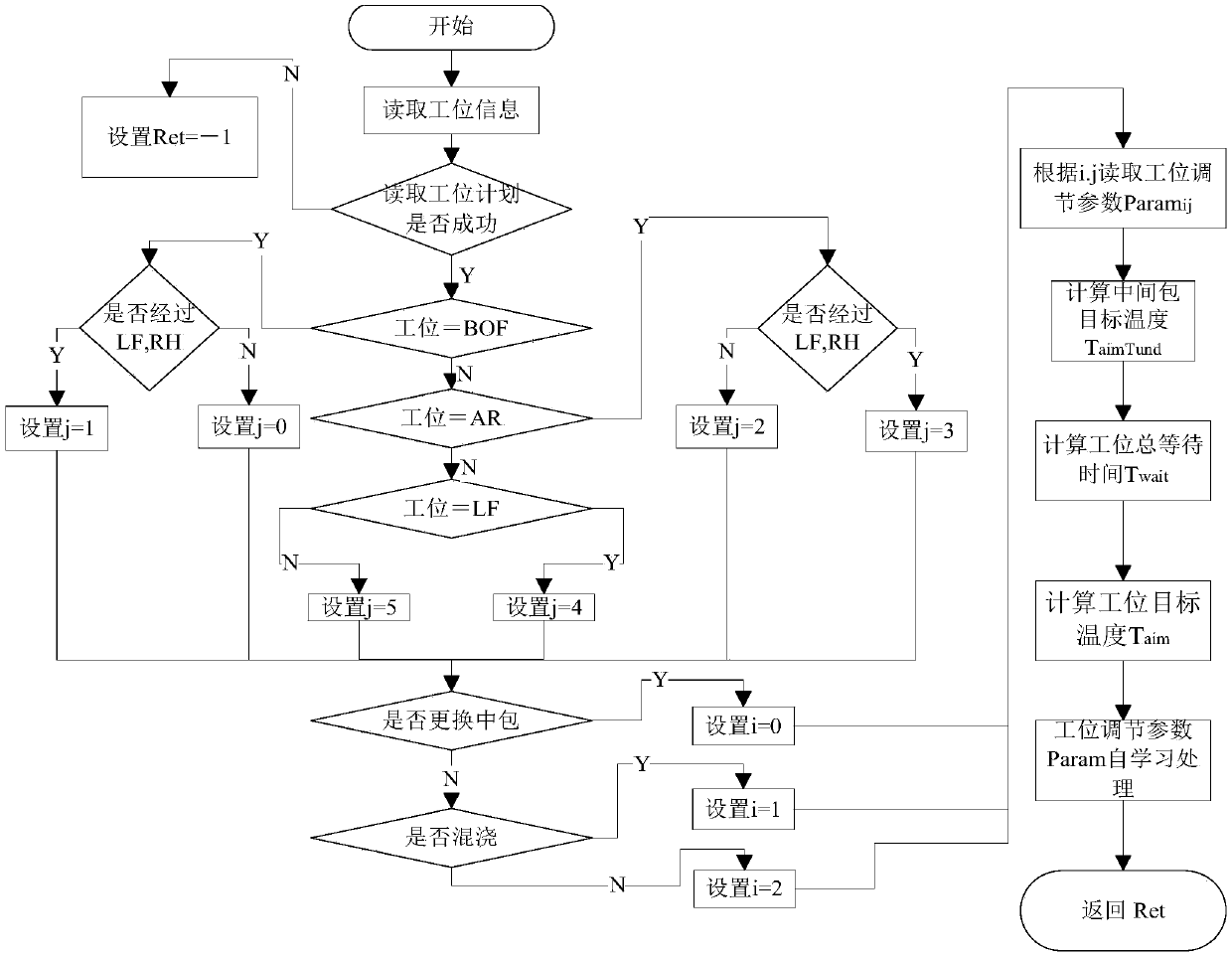

Molten steel steelmaking process temperature control system and method based on self-learning

InactiveCN110850915AGuaranteed stabilityEasy to controlAuxillary controllers with auxillary heating devicesSteelmakingTemperature control

The invention relates to a molten steel steelmaking process temperature control system based on self-learning. The control system comprises a station outbound temperature calculation system, a stationadjustment coefficient self-learning function, an L3 plan receiving actual performance uploading system, a station target temperature control system and a molten steel temperature forecasting function. The station outbound temperature calculation system comprises calculation of outbound temperature of a converter, an argon blowing station, a refining furnace, a vacuum treatment furnace and calculation of continuous-casting tundish target temperature. The L3 plan receiving actual performance uploading system is used for receiving an L3 plan, the manufacturing standard and the operation standard and sending the heat production actual performance to the L3. The station adjustment parameter self-learning function automatically learns parameter values needing to be adjusted by plans and actualdeviations of the station under different conditions on the basis of historical data. The whole system is reasonable in design, various abnormal factors are considered in the calculation process, allstation L2 systems are connected in series, station adjustment parameters are self-learned, and the adaptability of the method is greatly enhanced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

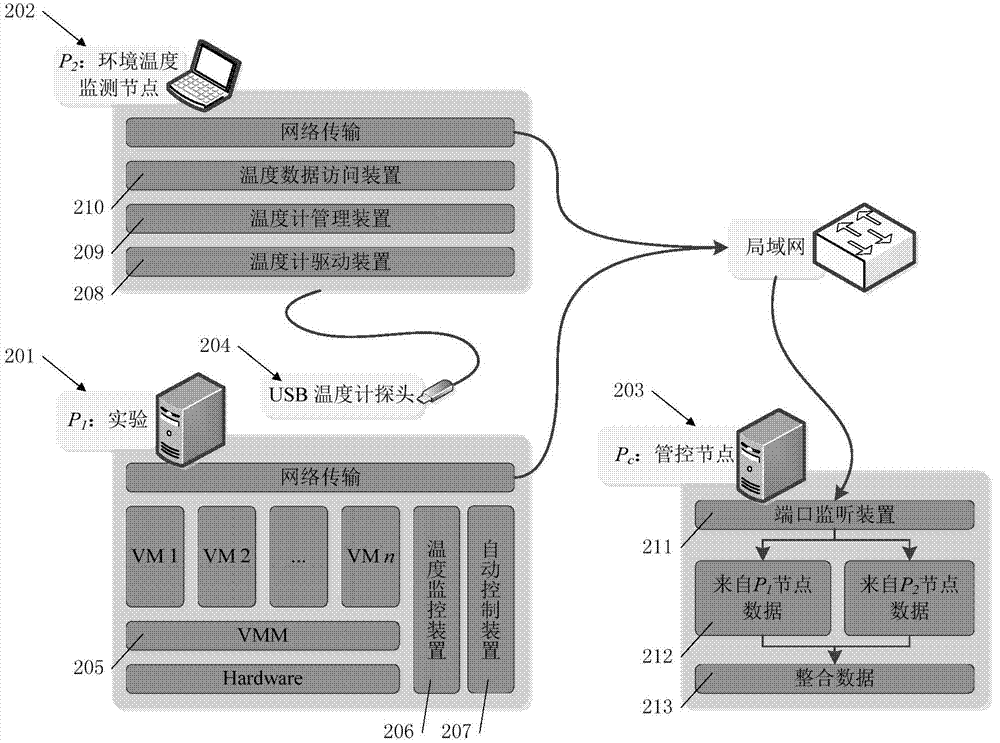

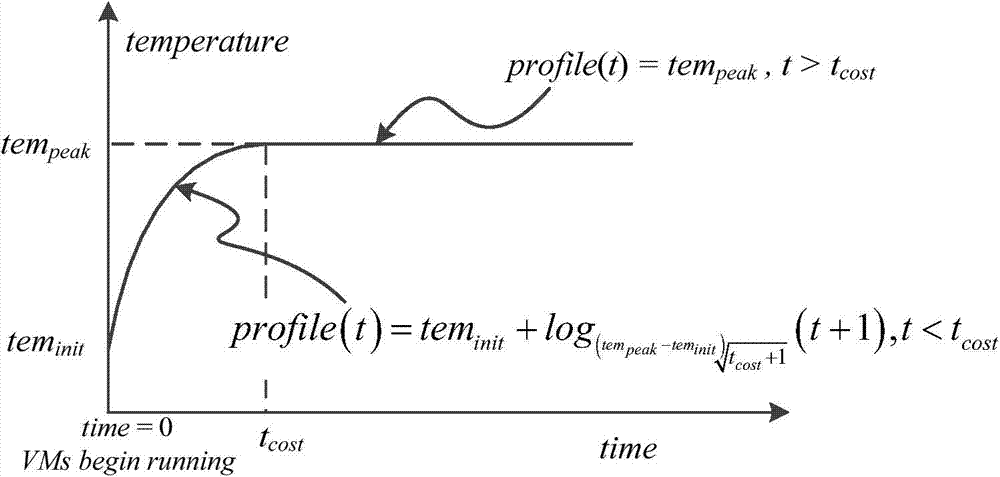

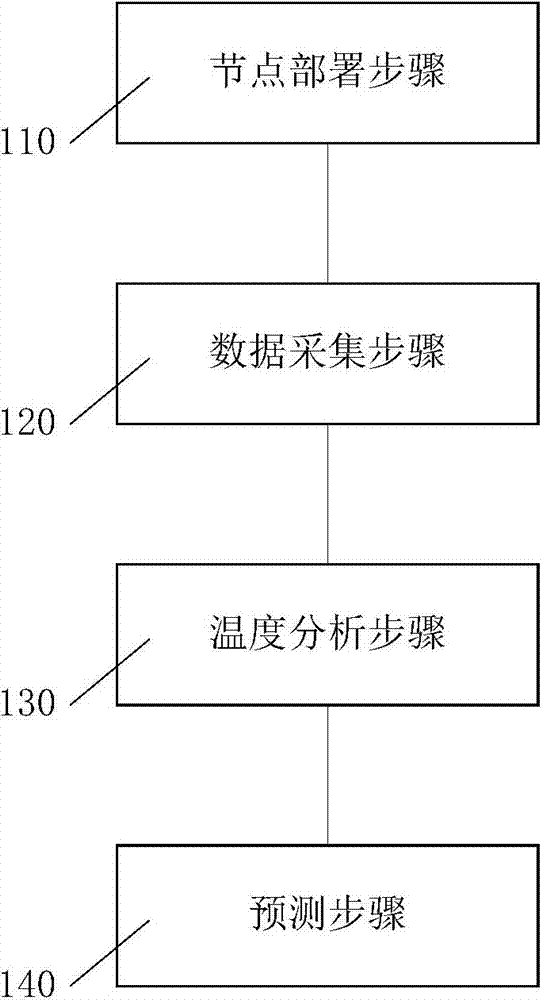

CPU temperature forecasting method and device for virtual machine

ActiveCN103677184AImprove forecast accuracyAccurate predictionHardware monitoringPower supply for data processingSupport vector machineData acquisition

The invention discloses a CPU temperature forecasting method for a virtual machine. The method comprises the steps of node deployment, data collection, temperature analysis and forecasting. Different running nodes comprising test nodes, environment temperature nodes and control nodes are built, a training model of a support vector machine is used for training output characteristics of the test nodes, a piecewise function is built on the basis of an output value of the training model, and a correct value is added to the piecewise function to obtain final forecasting data; in addition, the invention further discloses a CPU temperature forecasting device using the CPU temperature forecasting method for the virtual machine. The CPU temperature forecasting method and device for the virtual machine have the advantages of being high in forecasting precision, fast in modeling, small in calculated amount, and convenient to monitor remotely, supporting node separation and on-line forecasting, and having high application value.

Owner:ZHEJIANG UNIV

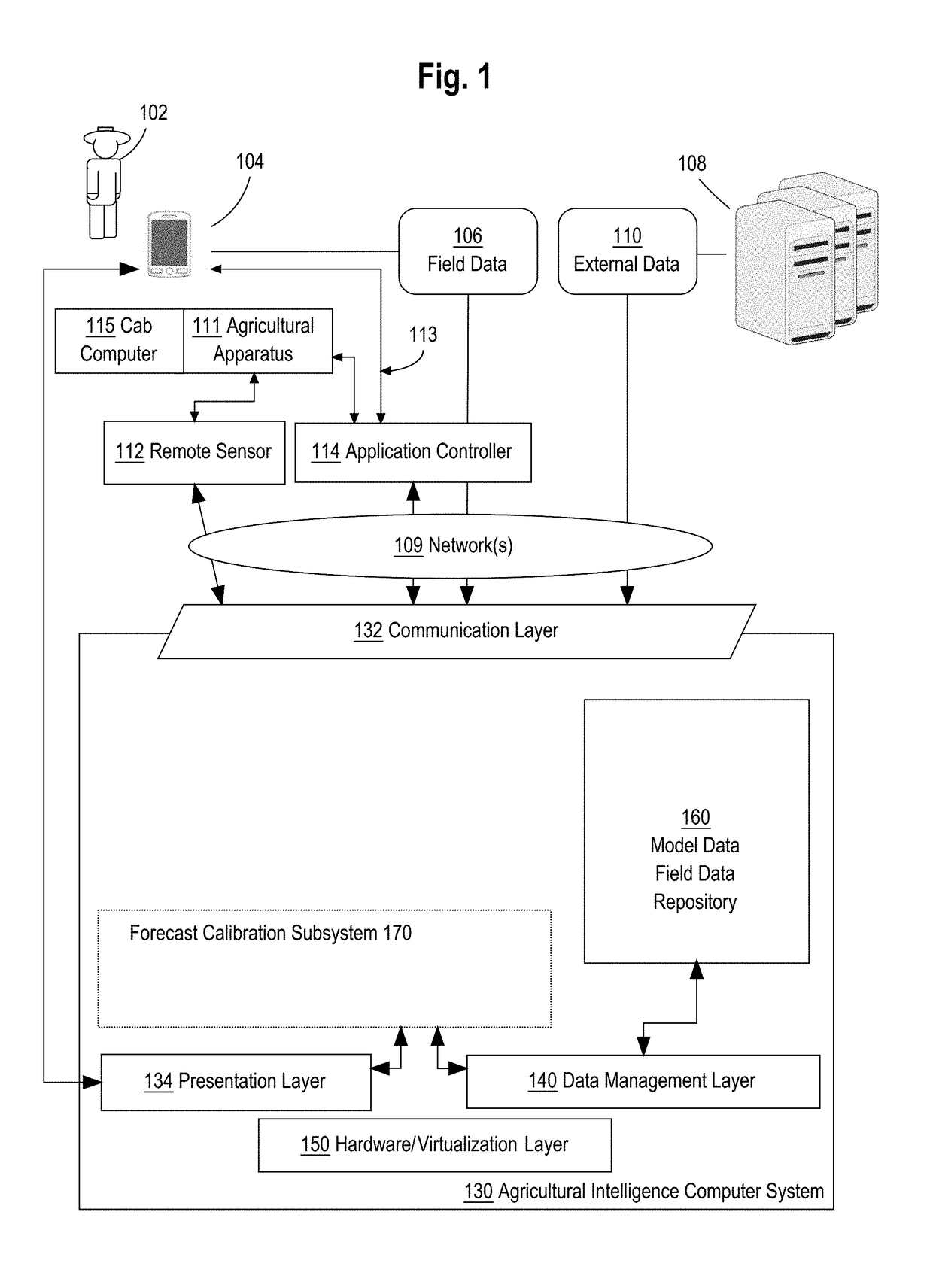

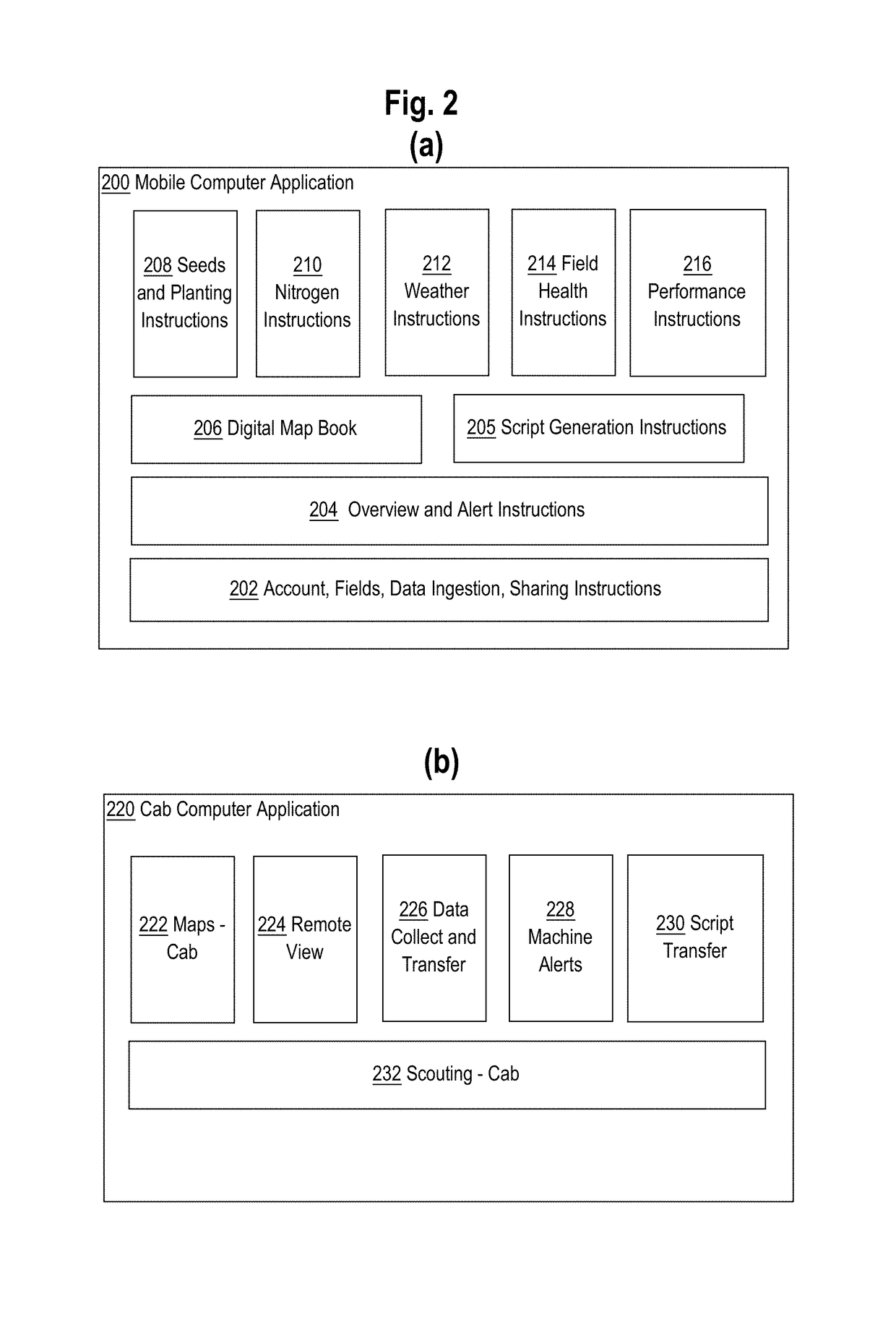

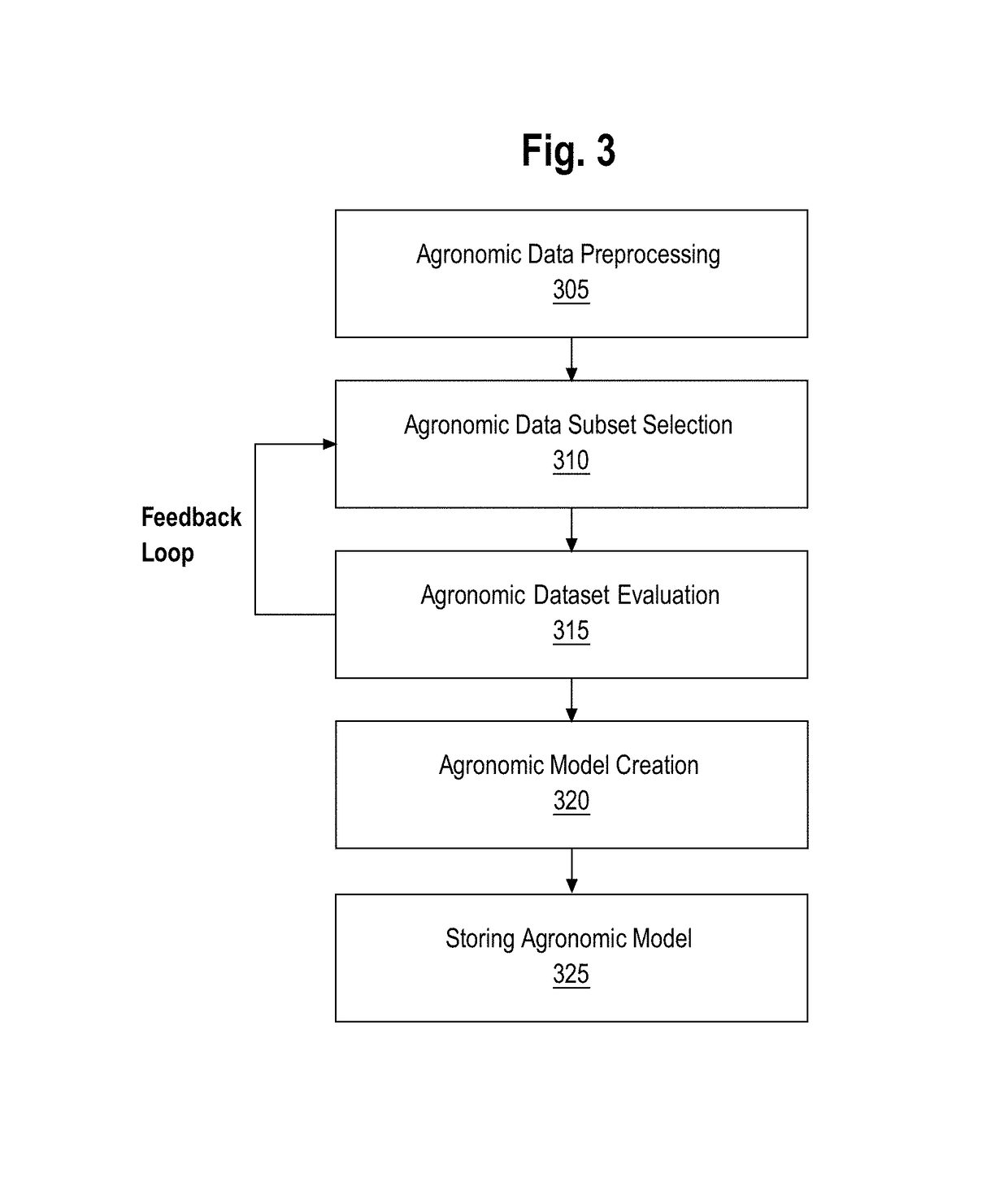

Long-range temperature forecasting

Owner:CLIMATE LLC

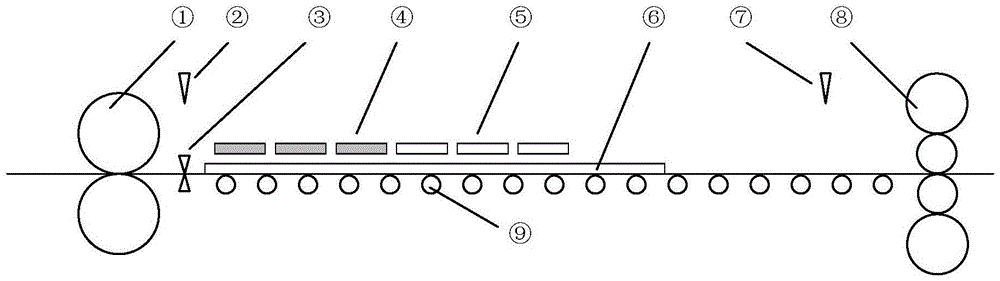

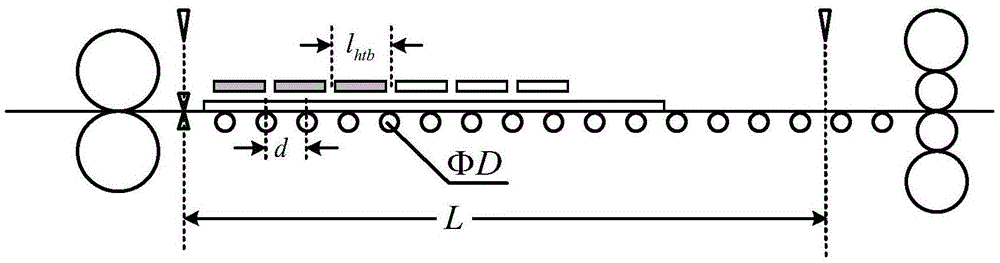

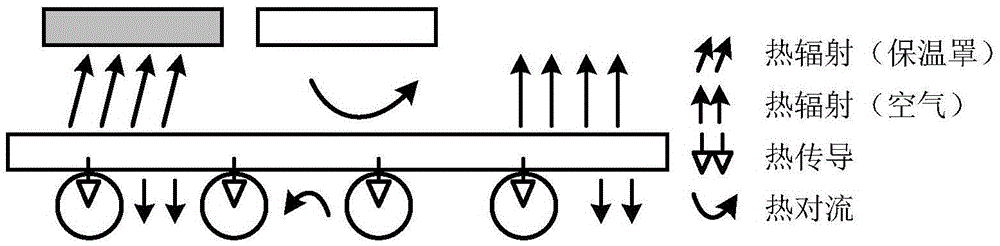

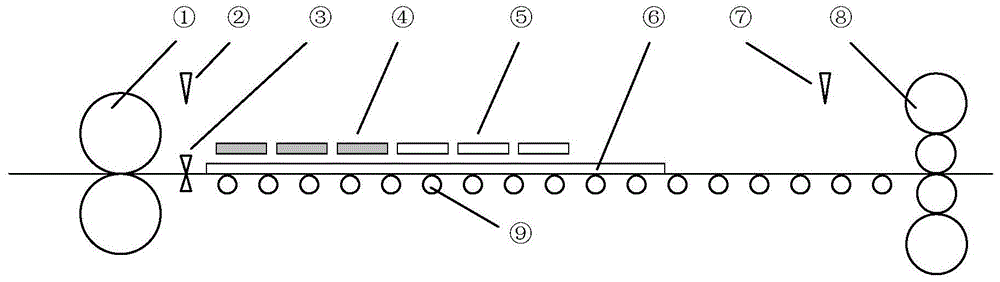

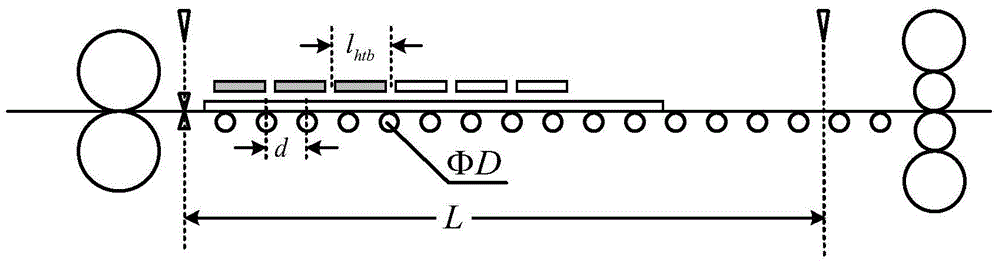

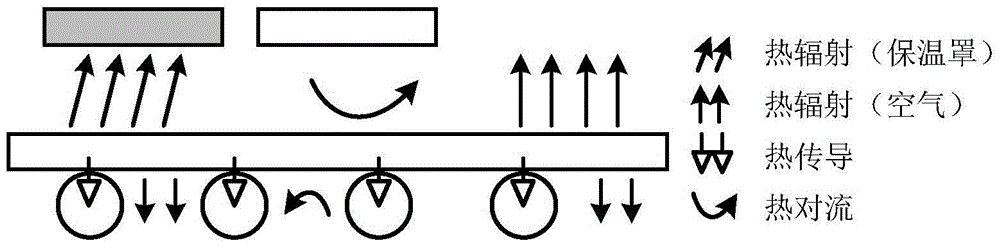

Temperature forecasting method for finish rolling inlet during hot continuous rolling

ActiveCN105537284ASolve the problem of inaccurate temperature measurementImprove forecast accuracyMeasuring devicesMetal rolling arrangementsTemperature forecastingContinuous rolling

The invention provides a temperature forecasting method for a finish rolling inlet during hot continuous rolling. The temperature forecasting method comprises the following steps that 1, intermediate transporting roller way parameters and PDI data are obtained; 2, a measured surface temperature average value of a rolled piece at a rough rolling outlet and a measured thickness average value of the rolled piece are obtained; 3, the actual operating speed of the rolled piece and the total operating time of the rolled piece on an intermediate transporting roller way are obtained; 4, the time for the rolled piece to pass the interior of an applied heat preserving cover, the time for the rolled piece to go through the exterior of the heat preserving cover, the time that the lower surface of the rolled piece and the intermediate transporting roller way are in contact and the time that the lower surface of the rolled piece and the external environment are in contact are calculated; 5, the upper surface temperature of the rolled piece and the lower surface temperature of the rolled piece are obtained when the rolled piece reaches the finish rolling inlet; and 6, the temperature of the rolled piece is calculated when the rolled piece reaches the finish rolling inlet during hot continuous rolling. According to the temperature forecasting method for the finish rolling inlet during hot continuous rolling, the temperature of the rolled piece at the finish rolling inlet can be accurately obtained in accordance with the heat exchange situations of the rolled piece during operating on the intermediate transporting roller way and through the surface temperatures measured through a pyrometer at the rough rolling outlet, the application situations of the heat preserving cover, and the thickness and operating speed of the rolled piece.

Owner:NORTHEASTERN UNIV

Anisotropism-based sea surface temperature forecasting method for high-current area

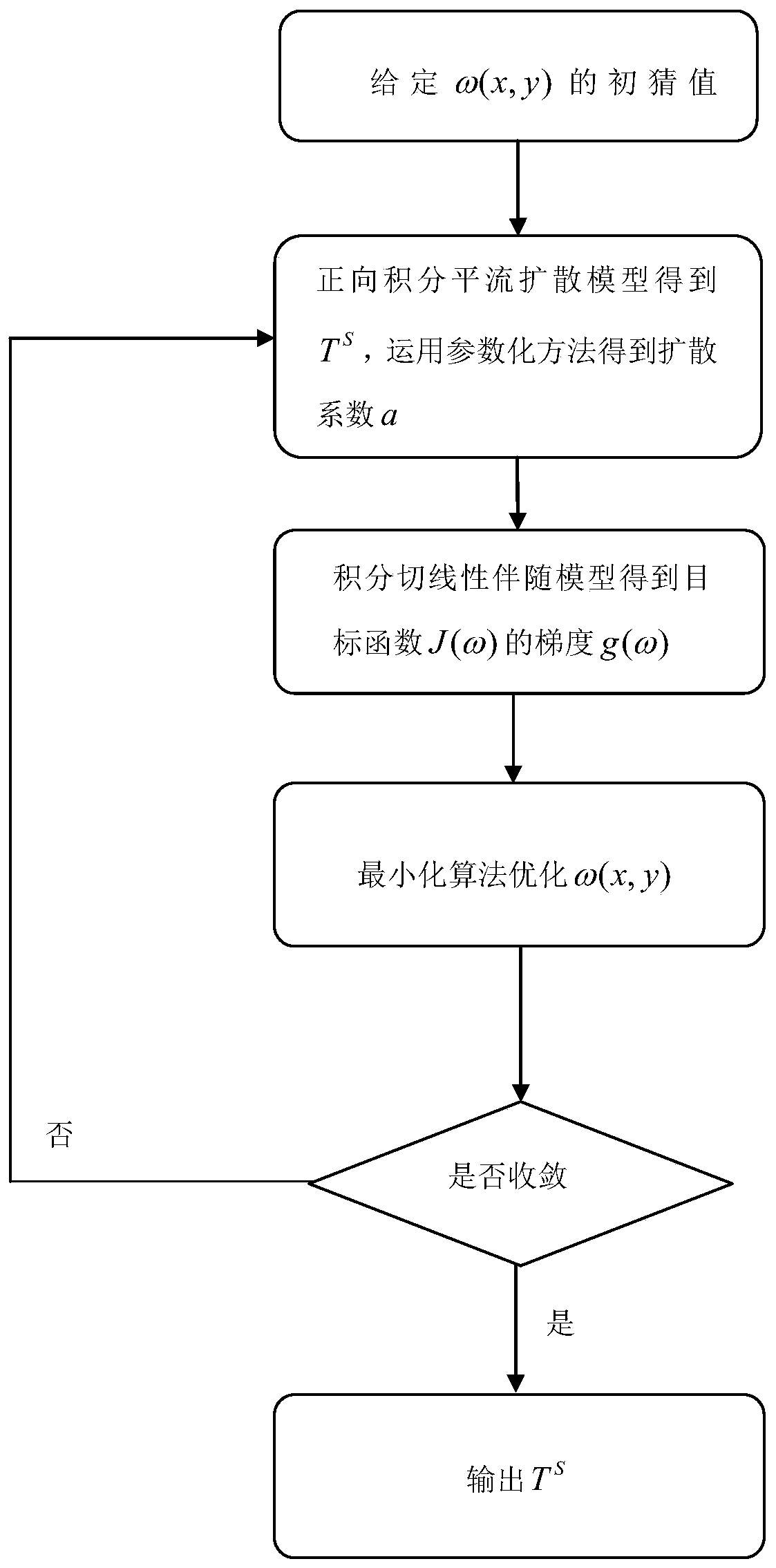

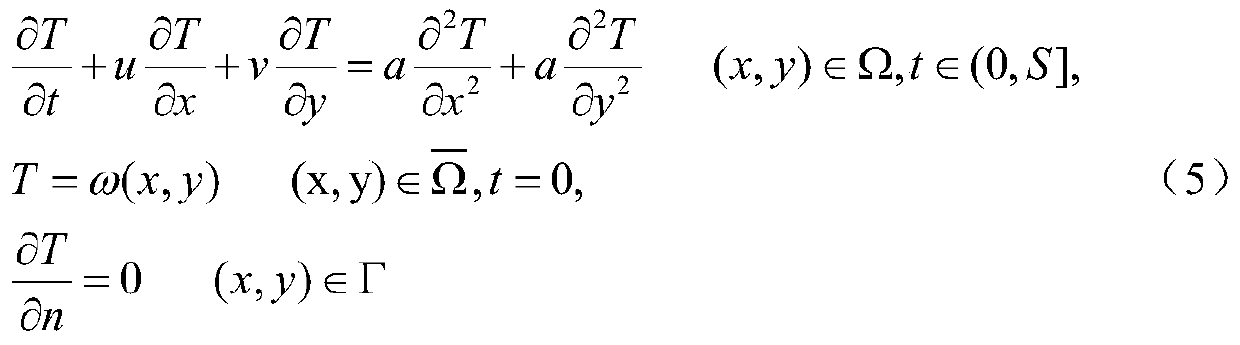

ActiveCN111275250AGuaranteed accuracyReduce mistakesForecastingICT adaptationMinimization algorithmTemperature forecasting

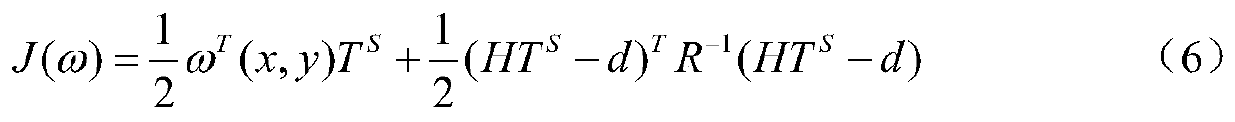

The invention discloses an anisotropy-based sea surface temperature forecasting method for a high-current area. The method comprises the following steps: (1) giving an initial guess value of a controlvariable omega (x, y); (2) T is set as a research variable, and TS is obtained from a 'time' t = 0 forward integral advection diffusion model to t = S; obtaining a diffusion coefficient a by using aparameterization method; (3) performing integral tangent on the linear adjoint model to obtain a gradient g (omega) of the target function J (omega); (4) minimizing an algorithm optimization control variable omega (x, y); (5) circulating the steps (2) to (4) until the control variable omega (x, y) enables the target function J (omega) to reach the minimum value, and outputting the TS at the moment; and (6) establishing an analysis field according to the TS obtained in the step (5), wherein the established analysis field provides an initial field for forecasting the sea surface temperature of the strong current area. Aiming at the characteristic of isotropy of original diffusion filtering, a method of adding an advection term to a diffusion equation and parameterizing a diffusion coefficient is adopted, and the influence of ocean current is added to the whole assimilation process, so that an assimilation result is closer to a true value.

Owner:TIANJIN UNIV

Method for forecasting finite element of hot rolling process plate belt temperature field

InactiveCN100495411CHigh temperature prediction accuracyImprove applicabilitySpecial data processing applicationsElement analysisTemperature forecasting

A finite element method of forecasting slab band temperature field during a hot rolling process belongs to the rolling technique field, and comprises the following steps: (1) collecting rolling process data; (2) carrying out unit division to cross section, establishing finite element analysis model, coding a unit node, and calculating a node coordinate; (3) ensuring border heat transfer coefficient and internal heat source intensity according to different rolling processes; (4) calculating the type-function of quadrangle isoparametric unit, B matrix, Jacobian matrix J and Jacobian matrix determinant |J| by using the finite element basic principle; (5) assembling the temperature rigidity matrix and dynamic heating matrix of the finite unit; (6) solving linear system of equations by adopting unidimensional variable bandwidth storage to obtain transient temperature field. The invention has the advantages that: the invention can obtain very high temperature forecasting precision and detailed information of the entire hot rolling slab band temperature distribution, which provides set and optimized parameter for rolling process, moreover, the invention has strong adaptability, reduces calculating time and improving calculating efficiency.

Owner:NORTHEASTERN UNIV LIAONING

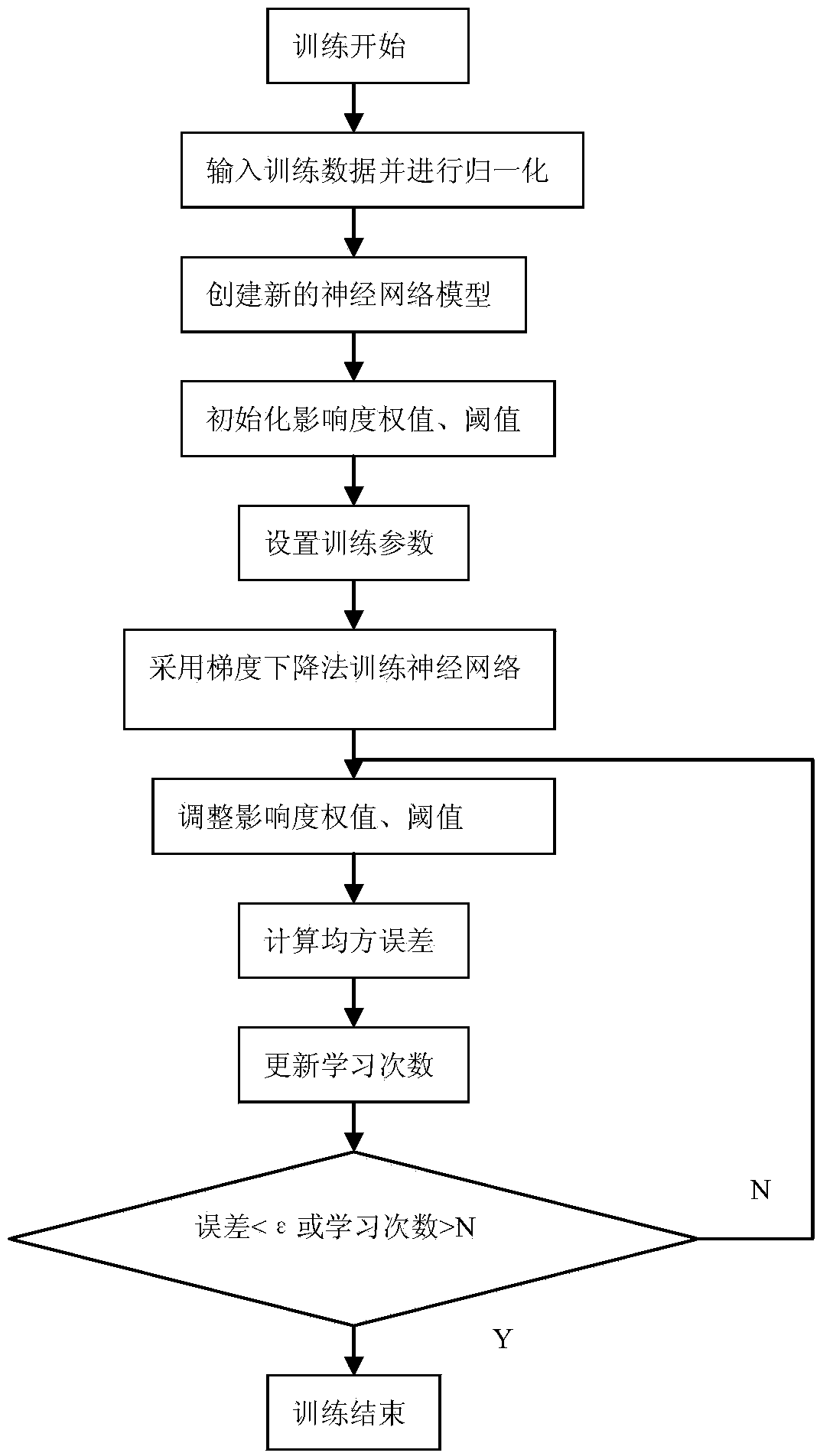

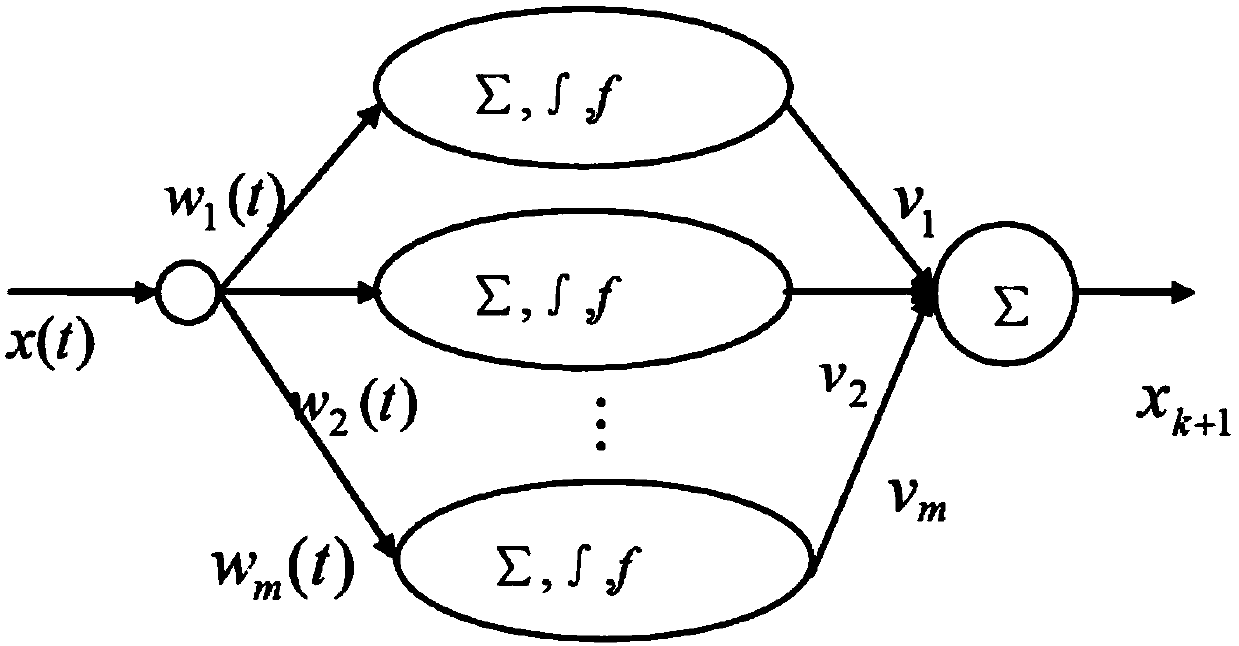

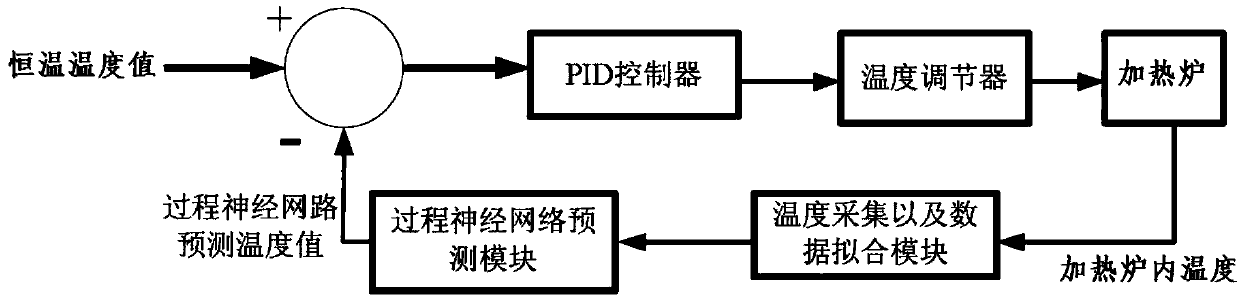

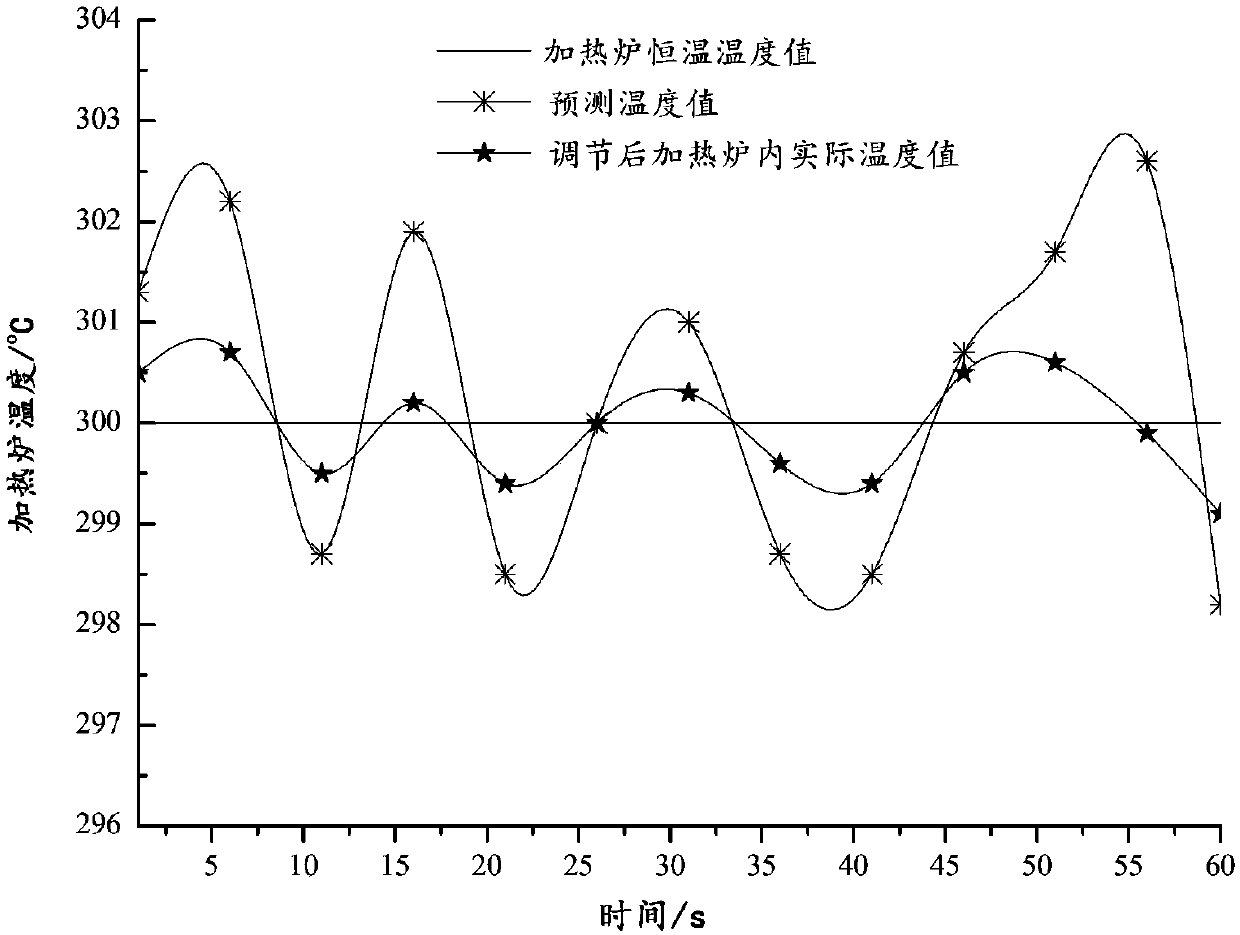

Heating furnace temperature computer control method based on process neural network

The invention discloses a heating furnace temperature computer control method based on a process neural network. The computer control method includes the steps: 1 building a heating furnace temperature forecasting model based on the process neural network: (1) acquiring and fitting data; (2) forecasting a temperature value of a heating furnace by a three-layer process neural network forecasting model; (3) performing learning and training by a gradient descent method until an error function is smaller than 0.5, and stopping training; 2 subtracting the temperature value of the (k+1) heatingfurnace forecasted by the three-layer process neural network forecasting model in the step 1 from a given temperature value to obtain temperature deviation, adjusting the temperature deviation by a PID (proportion integration differentiation) controller to control a temperature adjuster in the heating furnace, adjusting the actual temperature value of the (k+1) heating furnace in the heating furnace and enabling the deviation between the actual temperature value and the given temperature value not to exceed + / -1 DEG C. The temperature of the heating furnace can be stably controlled in thethermostatic process, so that the deviation between the internal temperature value and the given temperature value does not exceed + / -1 DEG C.

Owner:BEIHUA UNIV

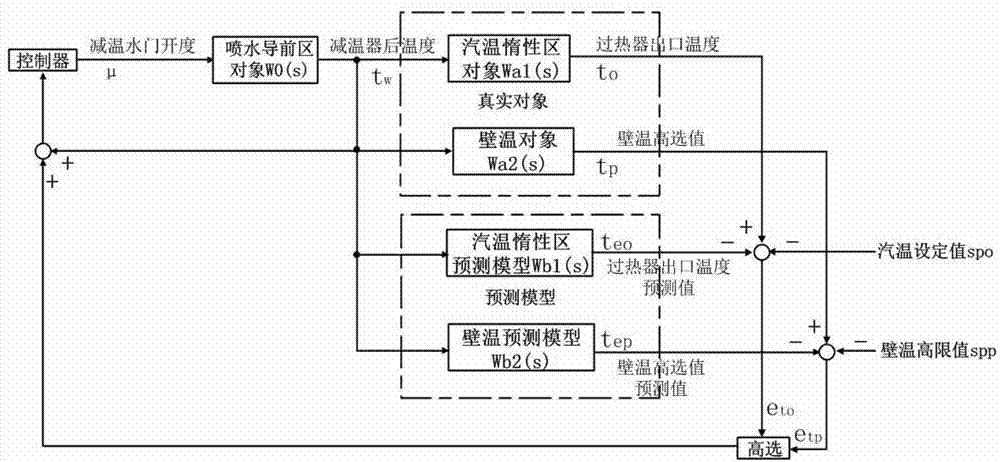

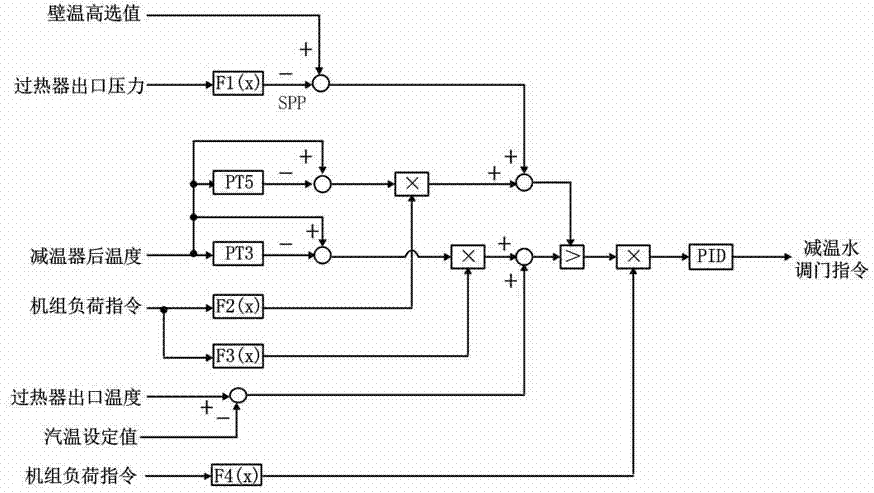

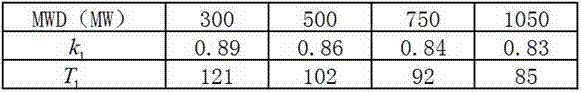

Overheat steam temperature multi-target control method of ultra-supercritical unit

InactiveCN107976909ADifficulty of SimplificationAdaptive controlTemperature controlTemperature forecasting

The invention relates to an overheat steam temperature multi-target control method of an ultra-supercritical unit, which is a multi-target control method consisting of an outlet temperature control method and a pipe wall metal temperature control method; by adopting a model forecasting control method, a steam temperature inert segment forecasting model and a wall temperature forecasting model areset up respectively; a bigger value of the bias values between two forecasting models and the actual measurement parameter is used as the one of feedback adjusting components; according to the feedback adjusting component in the model forecasting control method, two control targets of adjusting overheat steam temperature and finishing superheater metal wall temperature in the control feedback loopare reconciled to be the target of adjusting the post temperature of an object cooler of a front spraying guiding zone; the controller is designed specific to the object characteristics of the frontspraying guiding zone.

Owner:深圳市深汕特别合作区华润电力有限公司

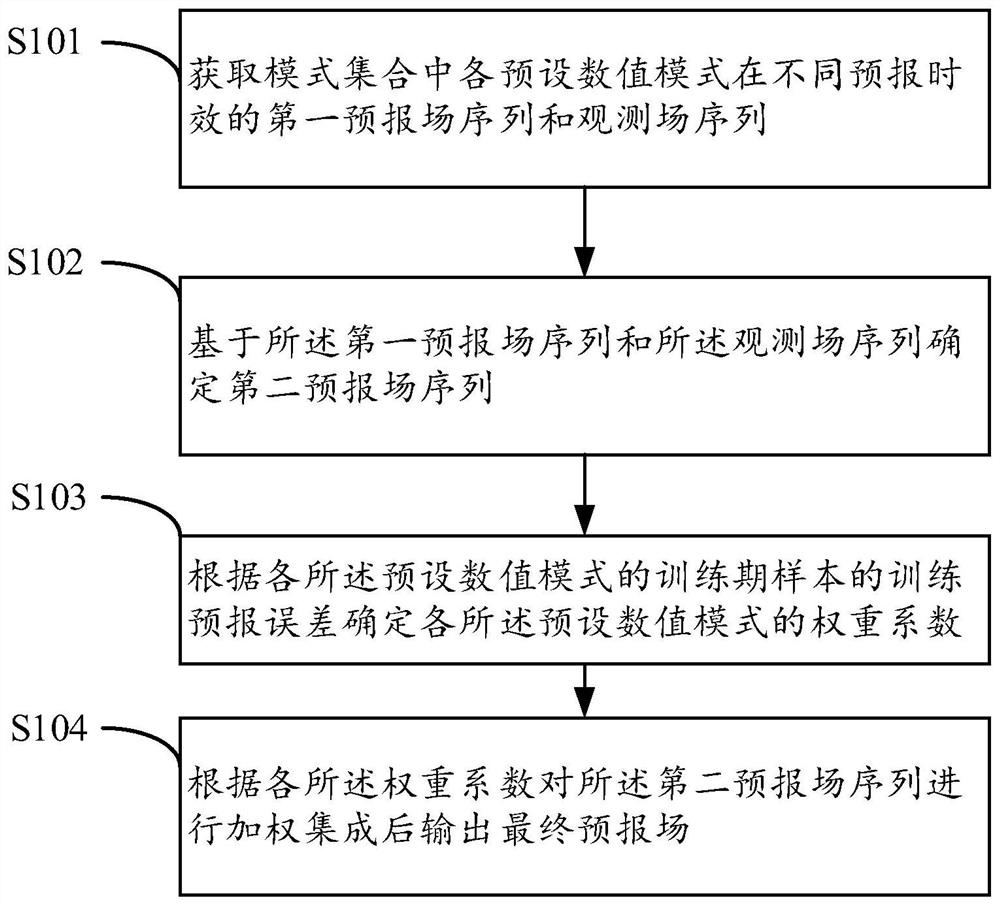

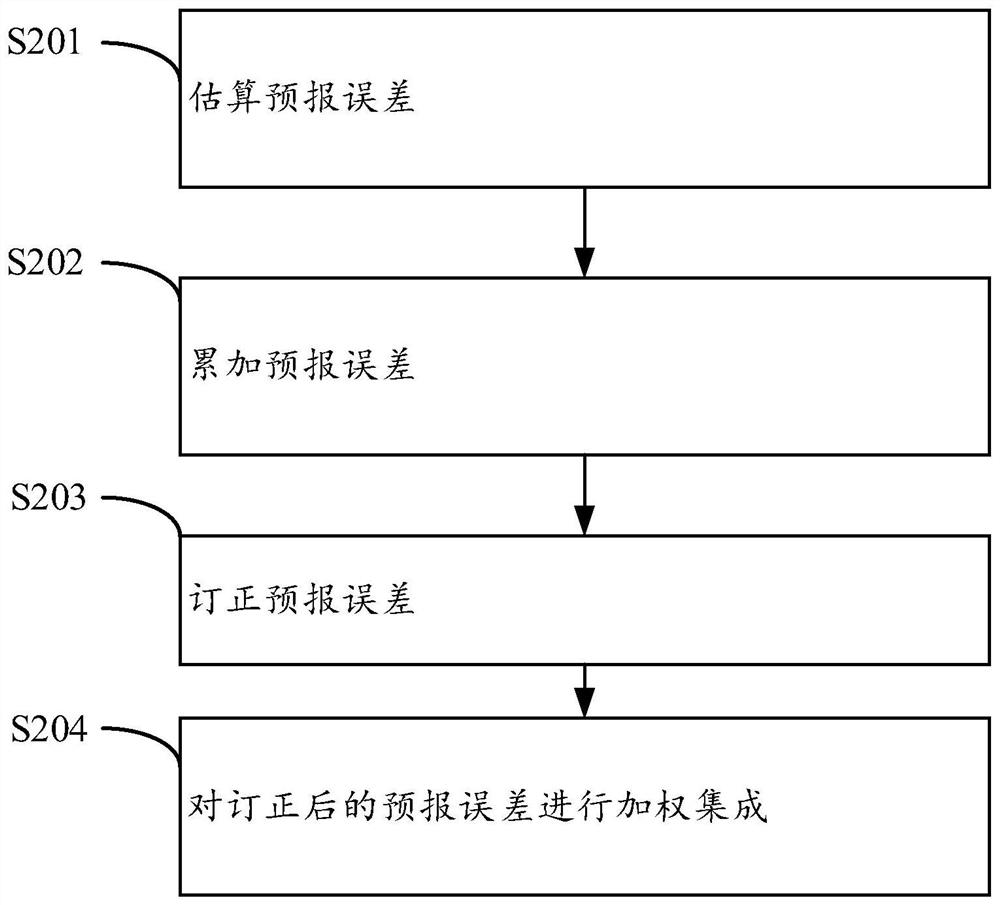

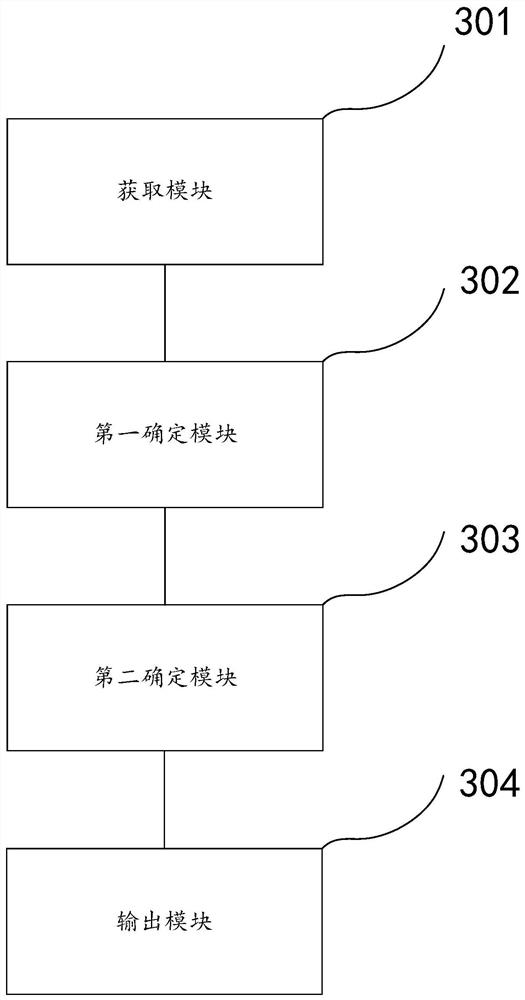

Temperature forecasting method and equipment

InactiveCN112859202AImprove accuracyImprove forecast accuracyWeather condition predictionMachine learningThermodynamicsSimulation

The invention discloses a temperature forecasting method and equipment. The method comprises the following steps of: acquiring a first forecast field sequence and an observation field sequence of each preset numerical mode in a mode set at different forecasting time periods; determining a second forecast field sequence based on the first forecast field sequence and the observation field sequence; determining a weight coefficient of each preset numerical mode according to the training forecast error of a training period sample of each preset numerical mode; and performing weighted integration on the second forecast field sequence according to each weight coefficient, and then outputting a final forecast field. Therefore, the accuracy of temperature forecast is improved.

Owner:固安县朔程燃气有限公司

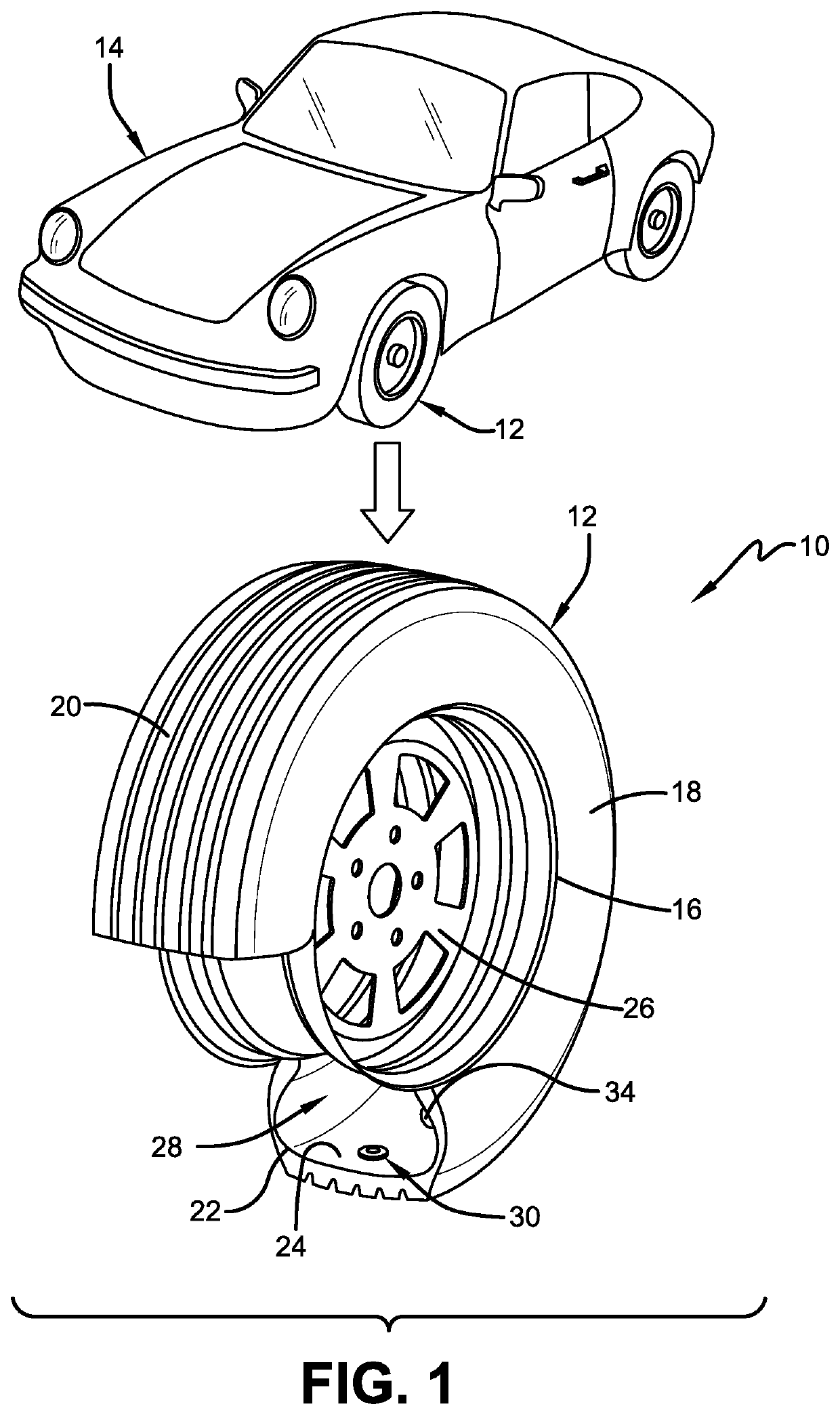

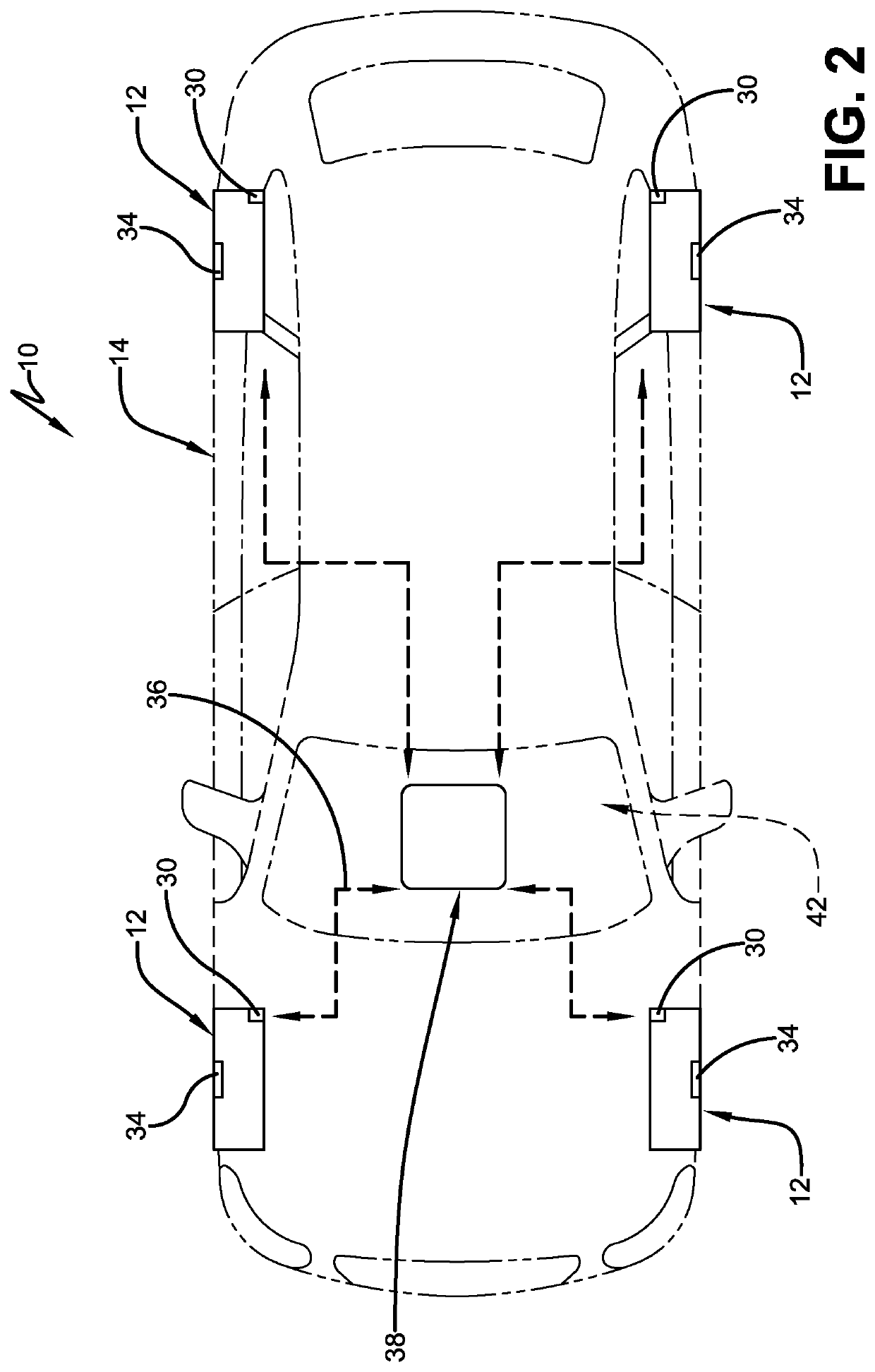

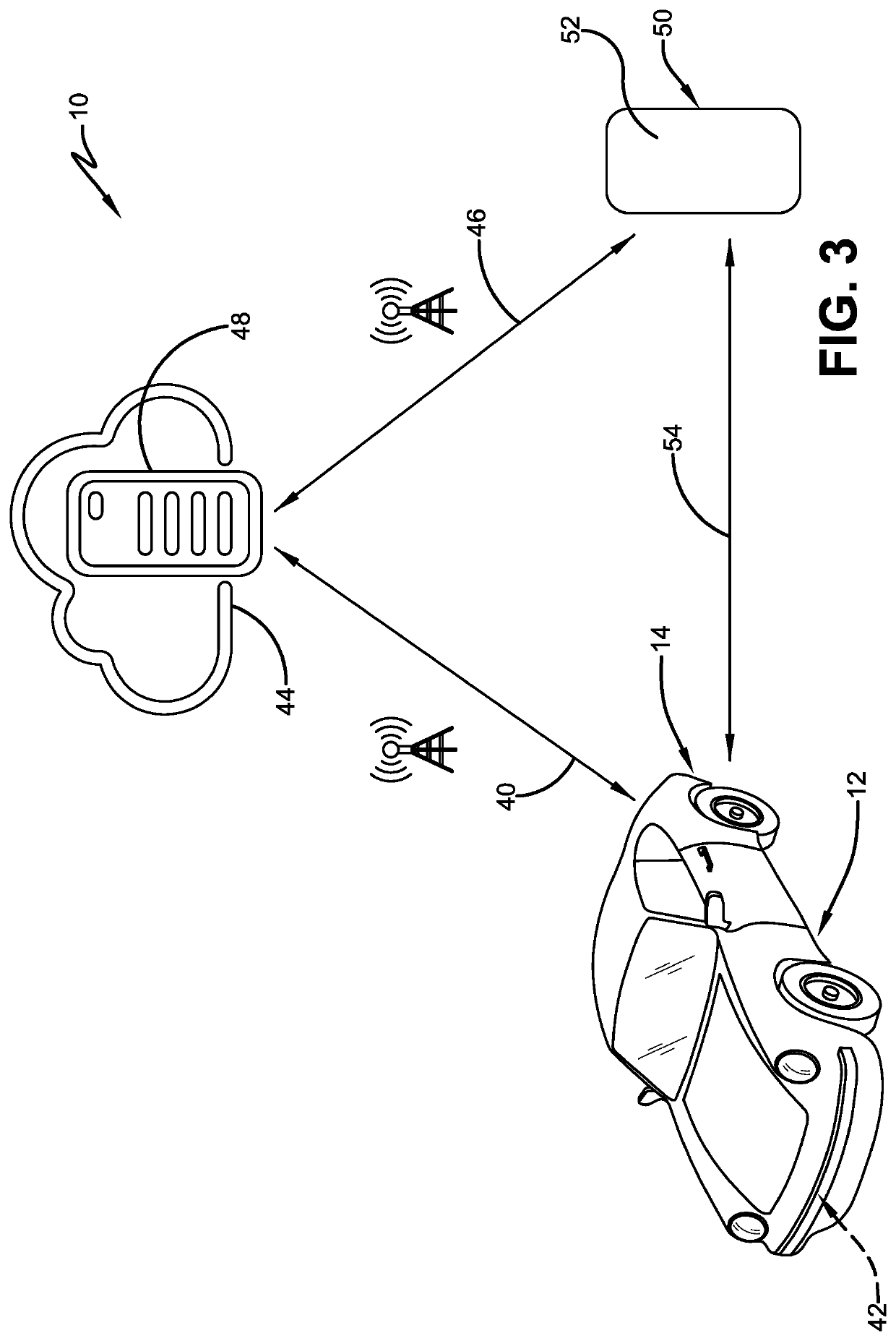

Tire high temperature forecasting system

PendingUS20220055422A1Registering/indicating working of vehiclesDesign optimisation/simulationElectronic communicationTemperature forecasting

A tire high temperature forecasting system includes at least one tire that supports a vehicle, and at least one sensor mounted on the tire for measuring a temperature of the tire. An electronic memory capacity is in a unit mounted on the tire for storing tire identification information. A processor is in electronic communication with the sensor and the electronic memory capacity, in which the processor receives and correlates the measured temperature, a time of the temperature measurement, and the tire identification information. Transmission means transmit the measured temperature, a time of the temperature measurement, and the tire identification information to a remote processor. The remote processor executes a forecasting model, and the forecasting model generates a forecast estimate. If the forecast estimate includes a predicted high temperature that is greater than a predetermined high temperature threshold for the tire, an alert is generated by the forecasting model.

Owner:THE GOODYEAR TIRE & RUBBER CO

A Method for Predicting the Entrance Temperature of Hot Continuous Rolling and Finishing Rolling

ActiveCN105537284BSolve the problem of inaccurate temperature measurementImprove forecast accuracyMeasuring devicesMetal rolling arrangementsTemperature forecastingContinuous rolling

The invention provides a method for predicting the entrance temperature of the hot continuous rolling finishing rolling, obtaining the parameters of the intermediate transport roller table and PDI data; obtaining the average value of the surface temperature of the measured rolling piece and the average thickness of the measured rolling piece at the rough rolling outlet; and obtaining the actual thickness of the rolling piece. Running speed, the total time the rolled piece runs on the intermediate transport roller table; separately calculate the time the rolled piece passes through the thermal insulation cover, the time the rolled piece experiences outside the thermal insulation cover, and the contact time between the lower surface of the rolled piece and the intermediate transport roller table. time and the time of contact with the external environment; obtain the upper surface temperature and upper surface temperature of the rolled piece when it reaches the finishing rolling entrance; calculate the temperature of the rolled piece when it reaches the hot continuous rolling finishing rolling entrance. According to the heat exchange situation of the rolled piece while running on the intermediate transport roller table, the present invention can accurately obtain the finishing rolling entrance through the surface temperature measured by the rough rolling outlet pyrometer and the use of the insulation cover, the thickness of the rolled piece and the running speed. The rolling stock temperature.

Owner:NORTHEASTERN UNIV LIAONING

Coal ash fusion temperature forecasting method based on construction-pruning mixed optimizing RBF (Radial Basis Function) network

InactiveCN101968832BDynamically adjust the number of hidden nodesSmall structureSpecial data processing applicationsNeural learning methodsData centerCoal

The invention discloses a coal ash fusion temperature forecasting method based on a construction-pruning mixed optimizing RBF (Radial Basis Function) network, which is characterized by comprising the following two stages of crude regulation and fine regulation: the crude regulation stage comprises the steps of dynamically increasing the number of hidden nodes according to a principle of enabling an energy function to be minimum, selecting corresponding sample input as a data center and stopping till the number of the hidden nodes meets a stopping criterion; the fine regulation stage comprisesthe steps of further regulating the structure and the parameters of the RBF network, which are obtained through the crude regulation by using a Gaussian regularization method, establishing the corresponding construction-pruning mixed optimizing RBF network on the basis of the chemical constituents of coal ash, and forecasting coal ash fusion temperature through the construction-pruning mixed optimizing RBF network. A construction-pruning mixed optimizing algorithm (CPHM) effectively integrates the advantages of a construction algorithm and a pruning algorithm, can not only dynamically regulate the number of the hidden nodes of the RBF network, but also enable the data center of the RBF network to change in a self-adaption way; and in addition, the invention has the advantages of smaller structure, better generalization capability and higher robustness.

Owner:SOUTHEAST UNIV

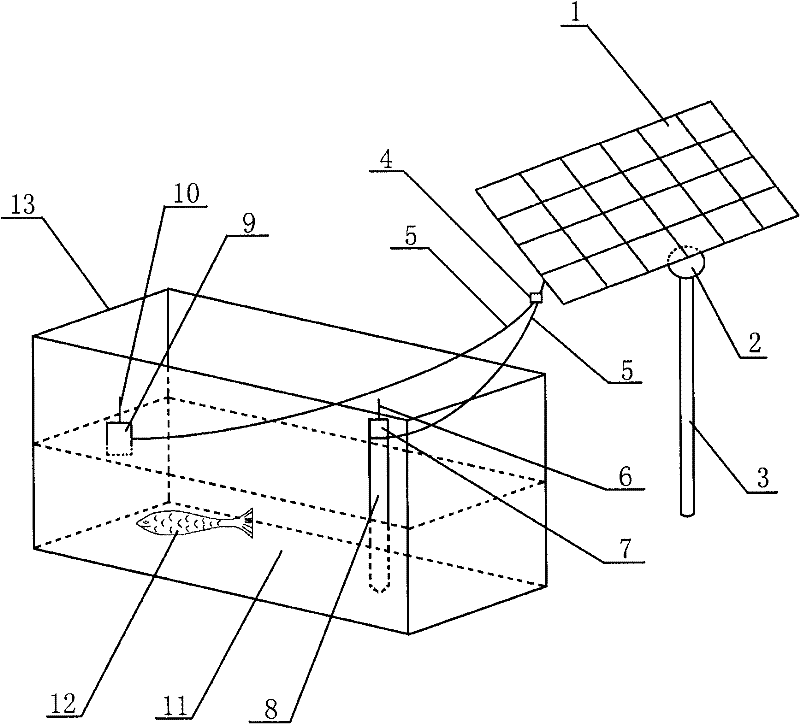

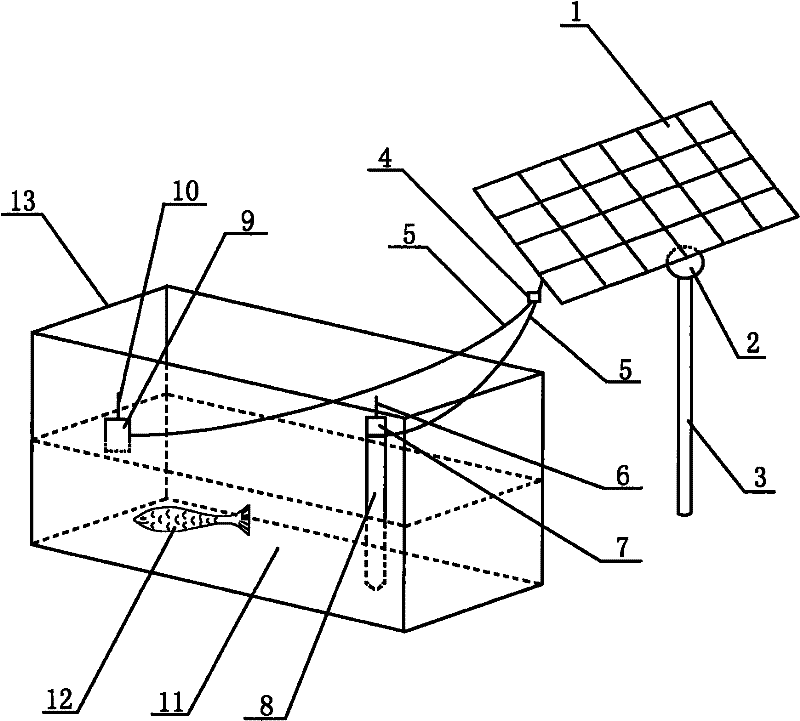

Temperature forecasting device in which solar photovoltaic generating system supplies power to temperature sensor

The invention relates to a temperature forecasting device in which solar photovoltaic generating system supplies power to a temperature sensor, belonging to the technical field of new energy Internet of things. Sunlight irradiates on solar cells arranged on a photovoltaic support post and a sun-following steering device, and the solar cells generate a stream of current; the stream of current is separated into two streams of current through a conductor wire and a current divider; a small part of current is supplied to the temperature sensor which is arranged in clear water in a fish bowl through the conductor wire; the temperature sensor is used for converting data of sensed temperature variation of the clear water into an electric signal; the electric signal is transmitted into the air through a wireless transmitting antenna which is arranged on the temperature sensor; most current is input into a wireless receiving antenna, a computer regulator and an electrical bar through the conductor wire; the electric signal is received by the wireless receiving antenna, and is transmitted to a computer controller for processing; and the computer controller is used for sending a command for instructing the electric bar to heat according to the temperature information transmitted by the electric signal, so that the water temperature of each part of the fish bowl is basically consistent with the temperature requirement on feeding live fish.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com