Heating furnace temperature computer control method based on process neural network

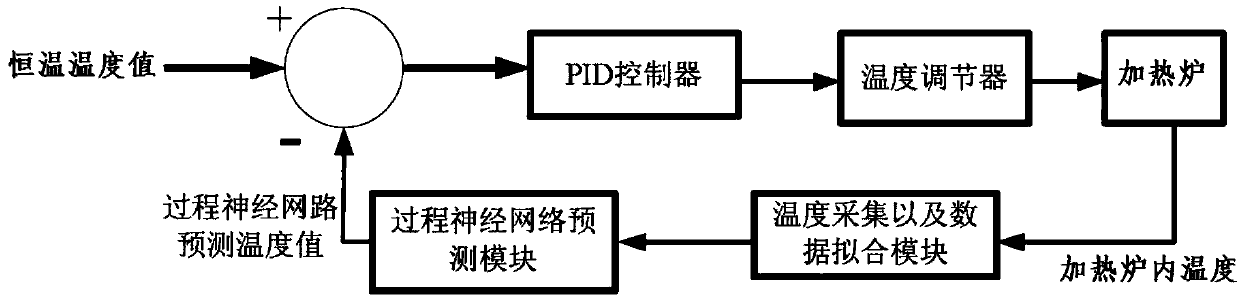

A process neural network and control method technology, applied in the field of computer control of heating furnace temperature, can solve problems such as difficulty in establishing an accurate mathematical model and inability to ensure stable control of constant temperature process temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

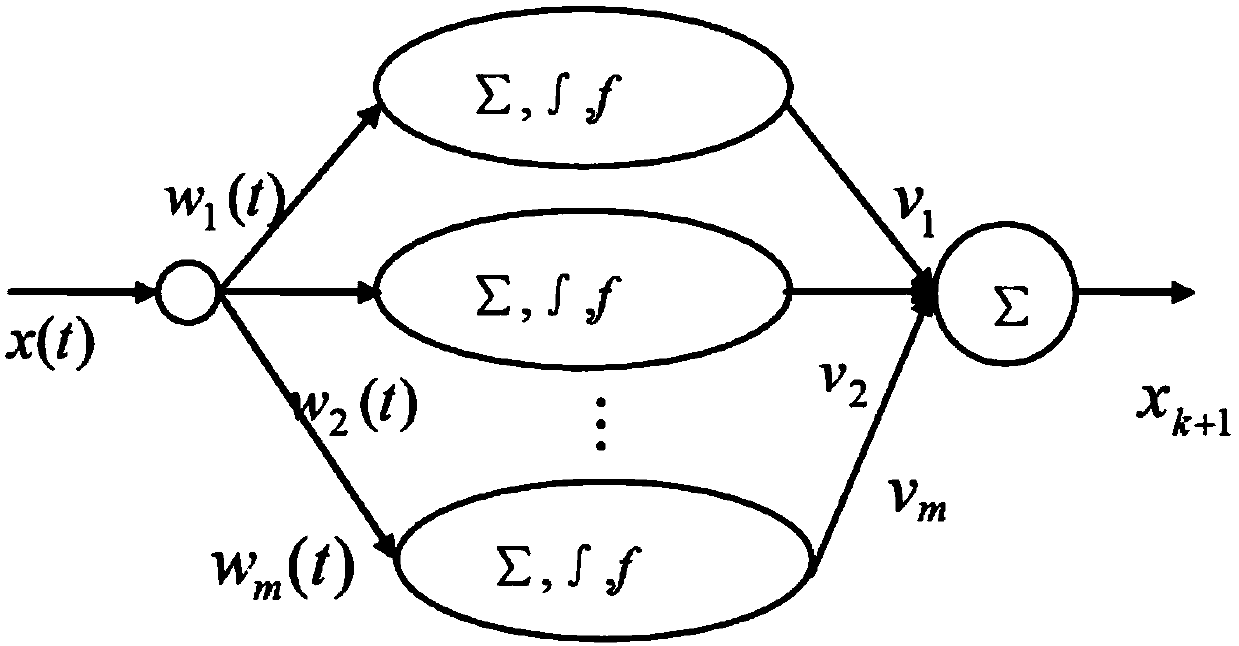

[0044] Step 1: Establish a furnace temperature prediction model based on the process neural network;

[0045] (1) Data collection and fitting;

[0046] The heating furnace temperature is collected every 1s, and each continuous 60 groups of heating furnace temperature values x 60 ,x 59 ,x 58 ,...x 1 Perform data fitting to obtain the time-varying function x(t)=at 4 +bt 3 +ct 2 +dt+e, where the values of the fitting coefficients a, b, c, d, e are obtained by polynomial fitting according to the real-time collected data;

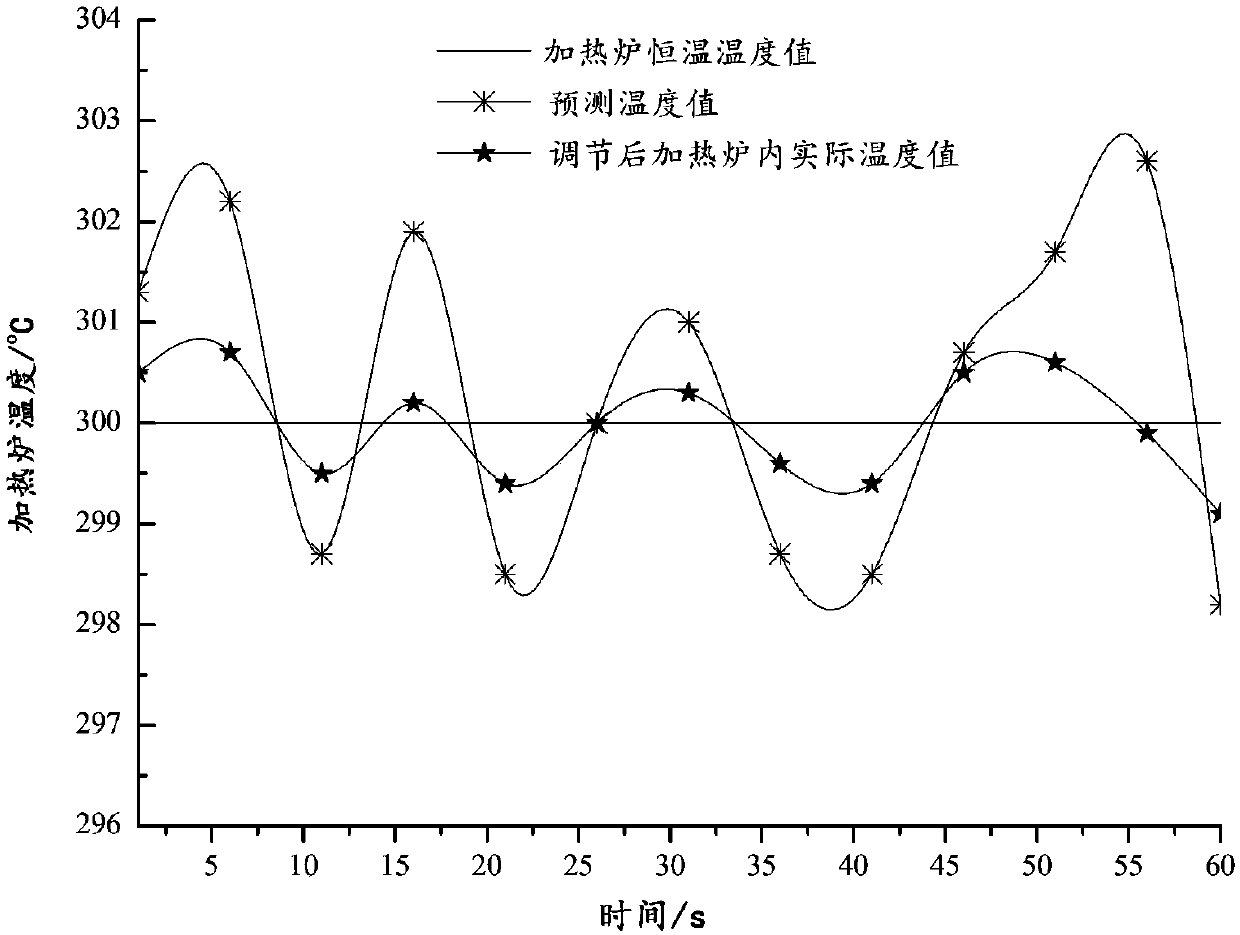

[0047] During the whole process of heating the furnace at a constant temperature of 300°C, a period of 60 seconds is randomly selected for analysis, and the temperature of the heating furnace is collected every 1 second. The 60 groups of temperature values of the heating furnace collected during the 60 seconds are as follows:

[0048]

[0049]

[0050]

[0051] The temperature value collected in 60 seconds is fitted with a quartic polynomia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com