All-process control method for main steam temperature of utility boiler

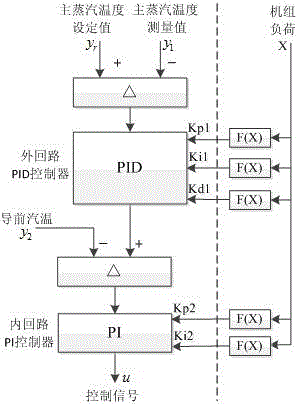

A main steam temperature and power station boiler technology, which is applied to the whole process control of the main steam temperature of the power station boiler, the main steam temperature control of the power station boiler, and the coal-fired generator set, can solve the problems of poor performance and instability of the main steam temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Specific steps are as follows:

[0056] Step 1. Divide the typical working conditions of power plant boiler operation:

[0057] According to the maximum load design capacity of the unit and the main operating load range, four typical operating point points are divided, and the four typical operating point points are respectively the boiler minimum stable combustion load operating point X 1 =40%Norm (Norm: unit rated load, such as 600MW unit, Norm=600), rated maximum load operating point X 4 =100%Norm and 2 typical operating point X divided equally between the above two operating point 2 =60%Norm and X 3 =80%Norm;

[0058] Step 2. Test the mathematical model of the main steam temperature at the typical operating point:

[0059] Through active load lifting or waiting for load peak-shaving operation of the unit, the system characteristic model at the typical operating point is tested by the disturbance test, such as (1)~(2);

[0060] The first-order inertia plus pure ...

Embodiment 2

[0092] In addition to dividing the 6 typical working condition points based on the maximum load design capacity of the unit and the main operating load range X 1 =40%Norm,X 2 =52%Norm,X 3 =64%Norm,X 4 =76%Norm,X 5 =88%Norm,X 6 =100%Norm, and the values of the adjustable filter time constants of the outer loop and the inner loop are respectively T f1 =0.4 , T f2 =0.5 Except, remaining steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com