Patents

Literature

273 results about "Component Object Model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Component Object Model (COM) is a binary-interface standard for software components introduced by Microsoft in 1993. It is used to enable inter-process communication object creation in a large range of programming languages. COM is the basis for several other Microsoft technologies and frameworks, including OLE, OLE Automation, Browser Helper Object, ActiveX, COM+, DCOM, the Windows shell, DirectX, UMDF and Windows Runtime. The essence of COM is a language-neutral way of implementing objects that can be used in environments different from the one in which they were created, even across machine boundaries. For well-authored components, COM allows reuse of objects with no knowledge of their internal implementation, as it forces component implementers to provide well-defined interfaces that are separated from the implementation. The different allocation semantics of languages are accommodated by making objects responsible for their own creation and destruction through reference-counting. Type conversion casting between different interfaces of an object is achieved through the QueryInterface method. The preferred method of "inheritance" within COM is the creation of sub-objects to which method "calls" are delegated.

Interactive complex task teaching system that allows for natural language input, recognizes a user's intent, and automatically performs tasks in document object model (DOM) nodes

ActiveUS7983997B2Error detection/correctionDigital computer detailsRepetitive taskComponent Object Model

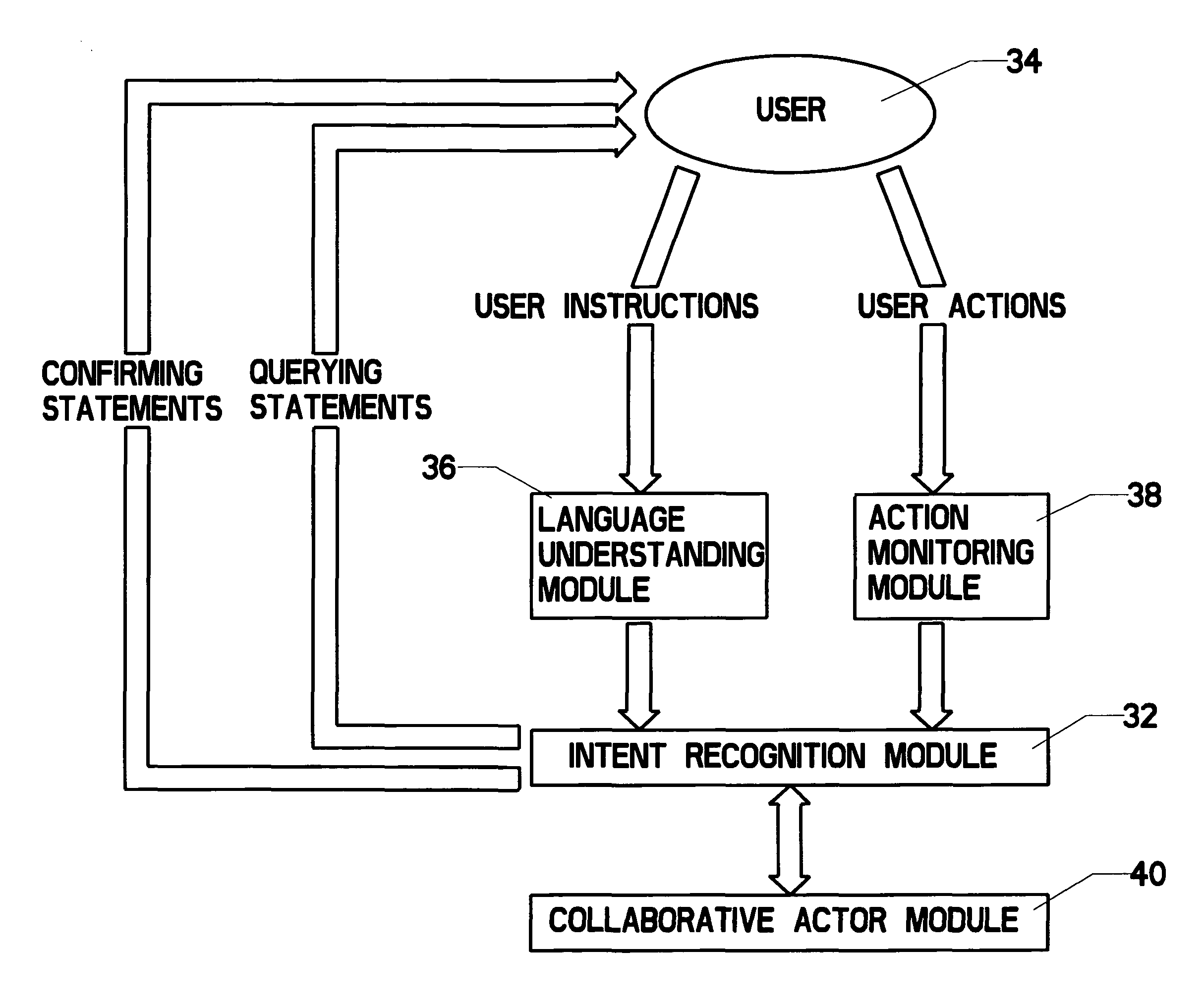

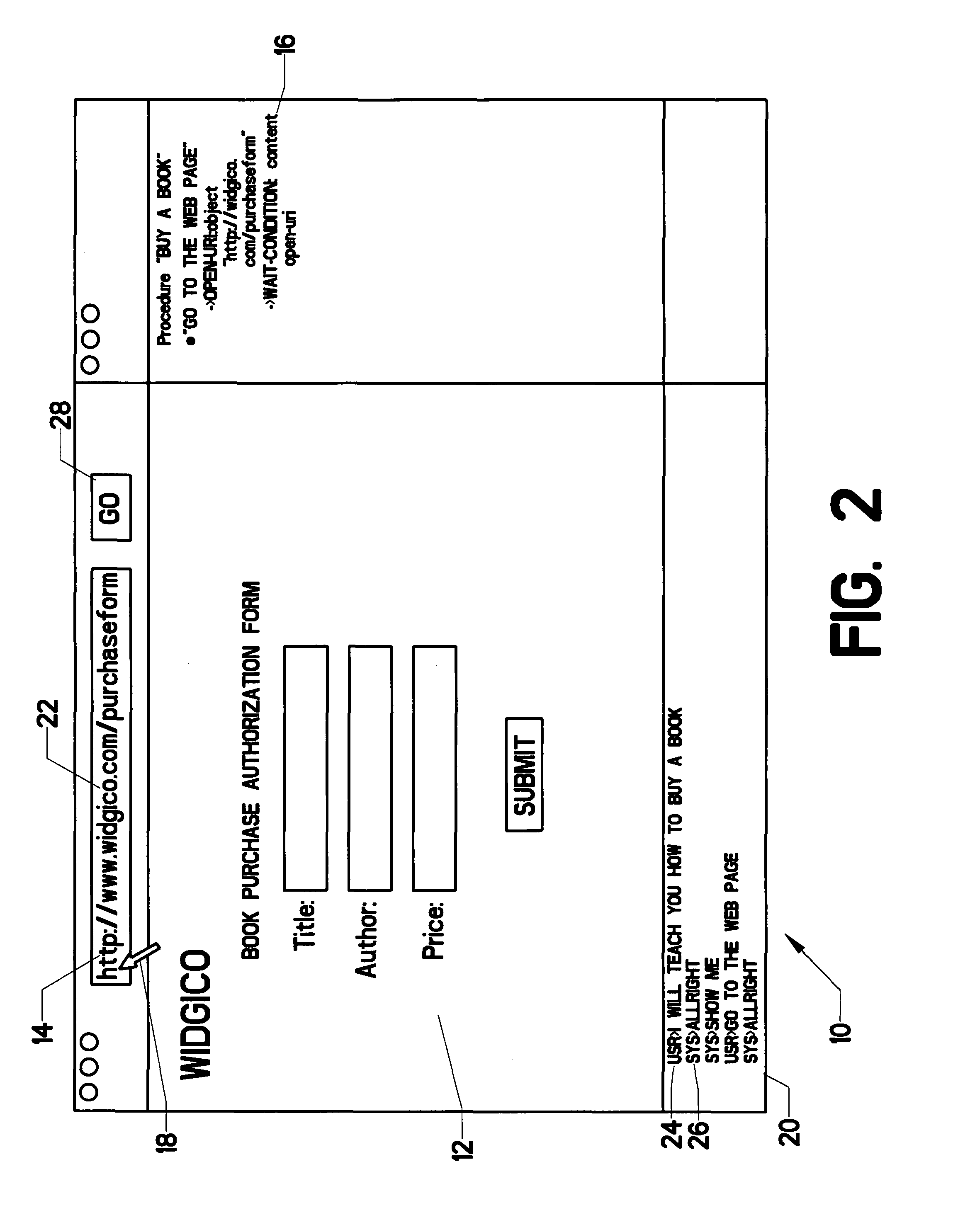

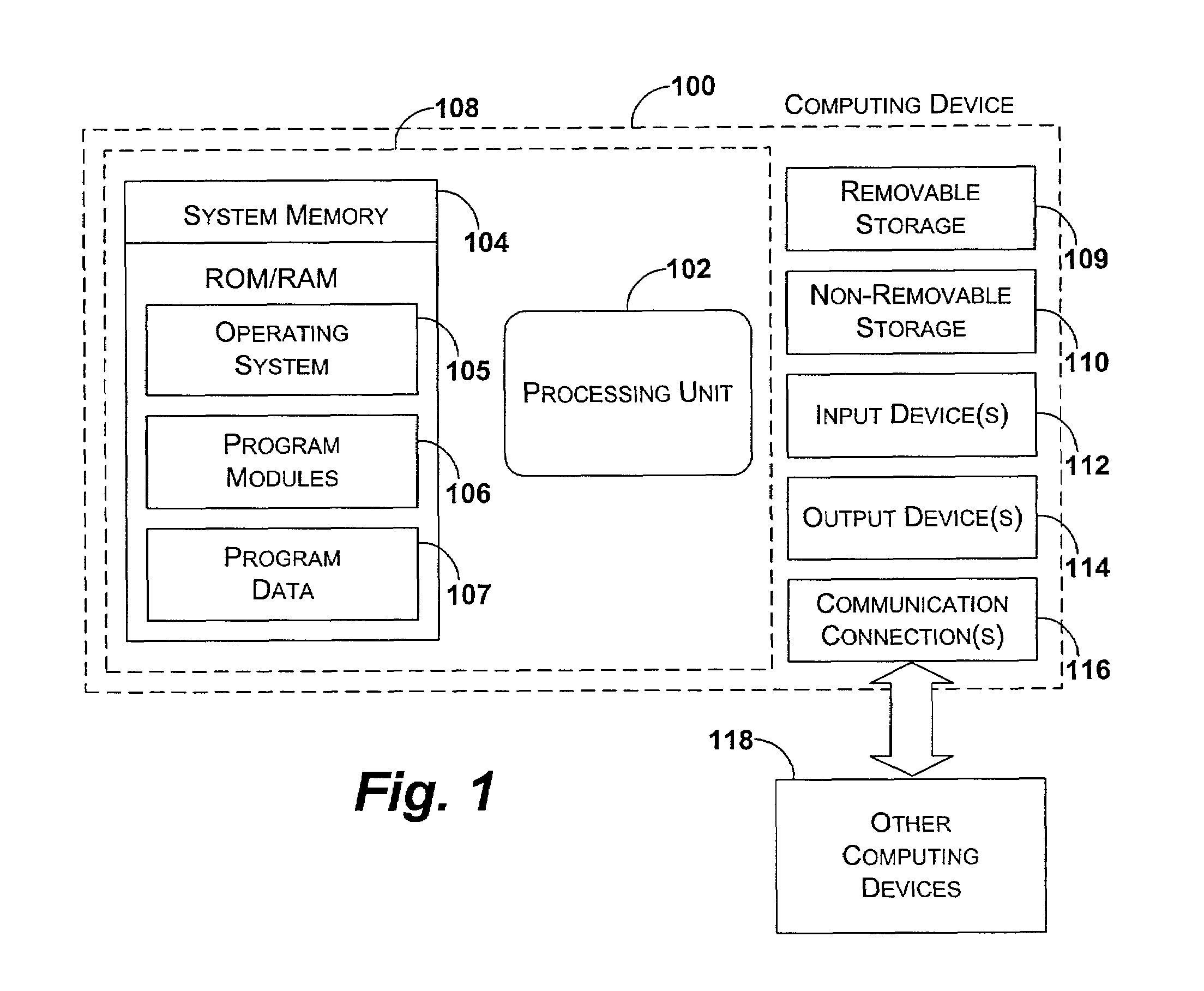

A system which allows a user to teach a computational device how to perform complex, repetitive tasks that the user usually would perform using the device's graphical user interface (GUI) often but not limited to being a web browser. The system includes software running on a user's computational device. The user “teaches” task steps by inputting natural language and demonstrating actions with the GUI. The system uses a semantic ontology and natural language processing to create an explicit representation of the task that is stored on the computer. After a complete task has been taught, the system is able to automatically execute the task in new situations. Because the task is represented in terms of the ontology and user's intentions, the system is able to adapt to changes in the computer code while still pursuing the objectives taught by the user.

Owner:FLORIDA INST FOR HUMAN & MACHINE COGNITION

Extensible markup language (XML) server pages having custom document object model (DOM) tags

InactiveUS6981212B1Improve performanceMultiple digital computer combinationsWebsite content managementComponent Object ModelExtensible markup

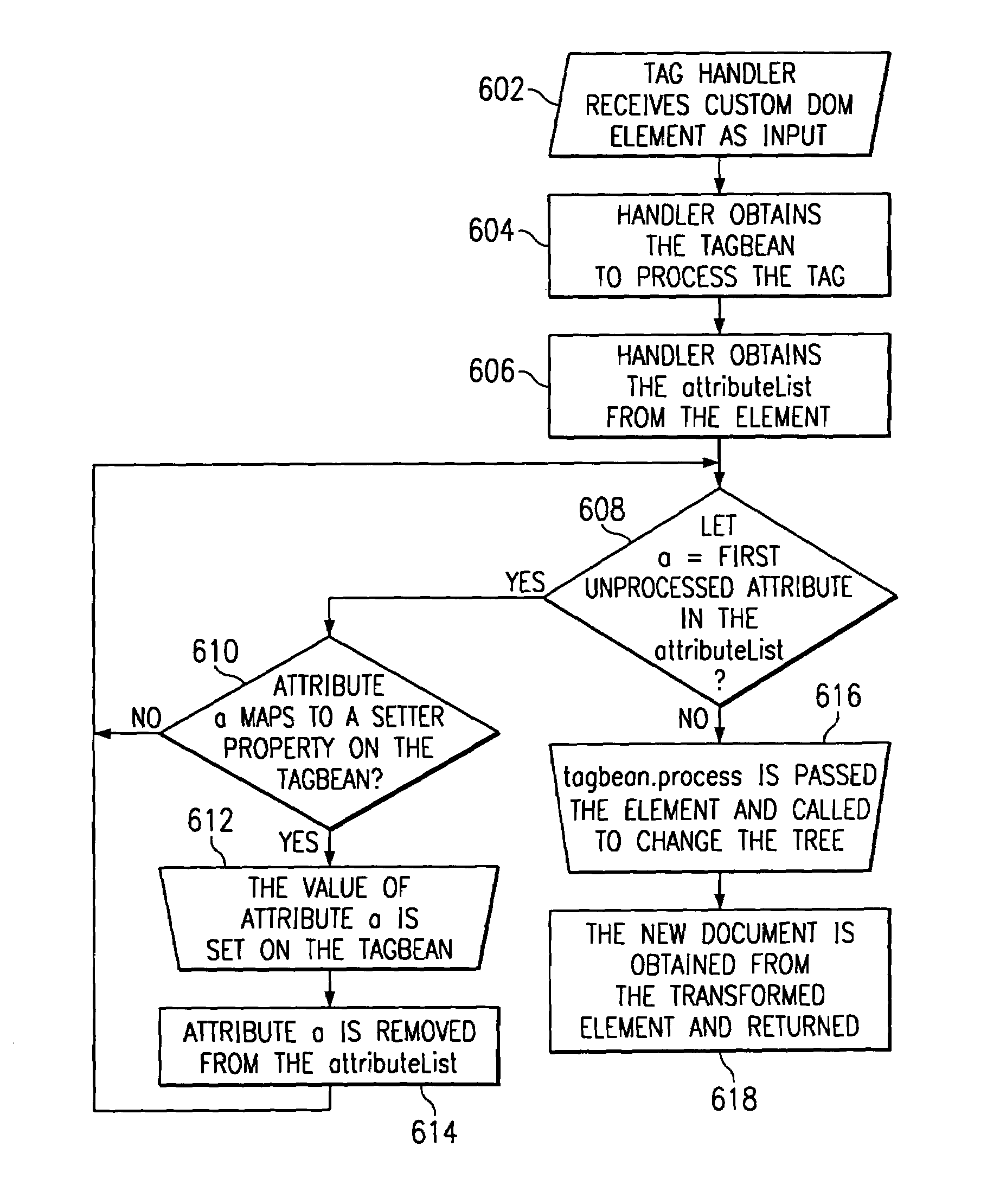

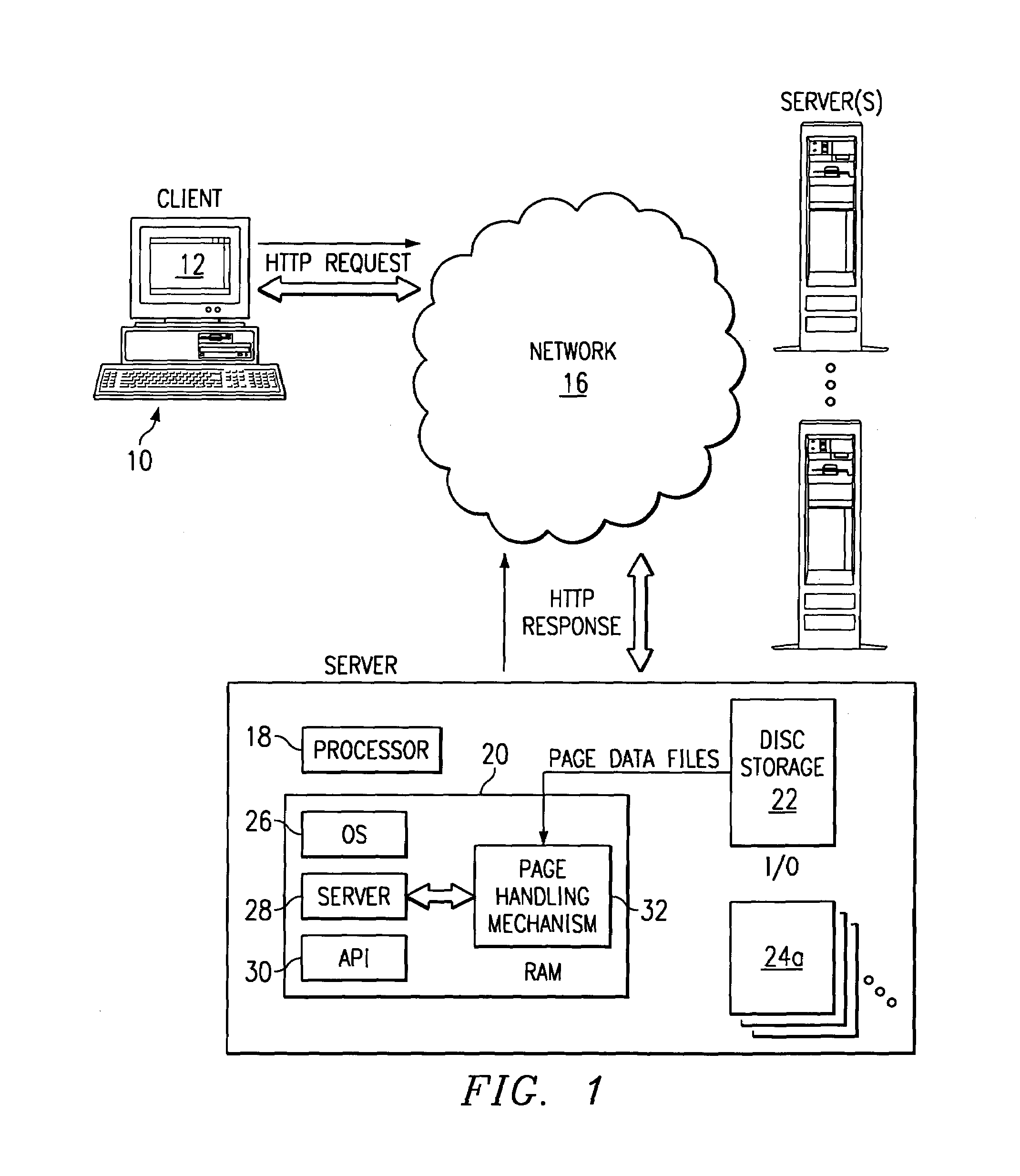

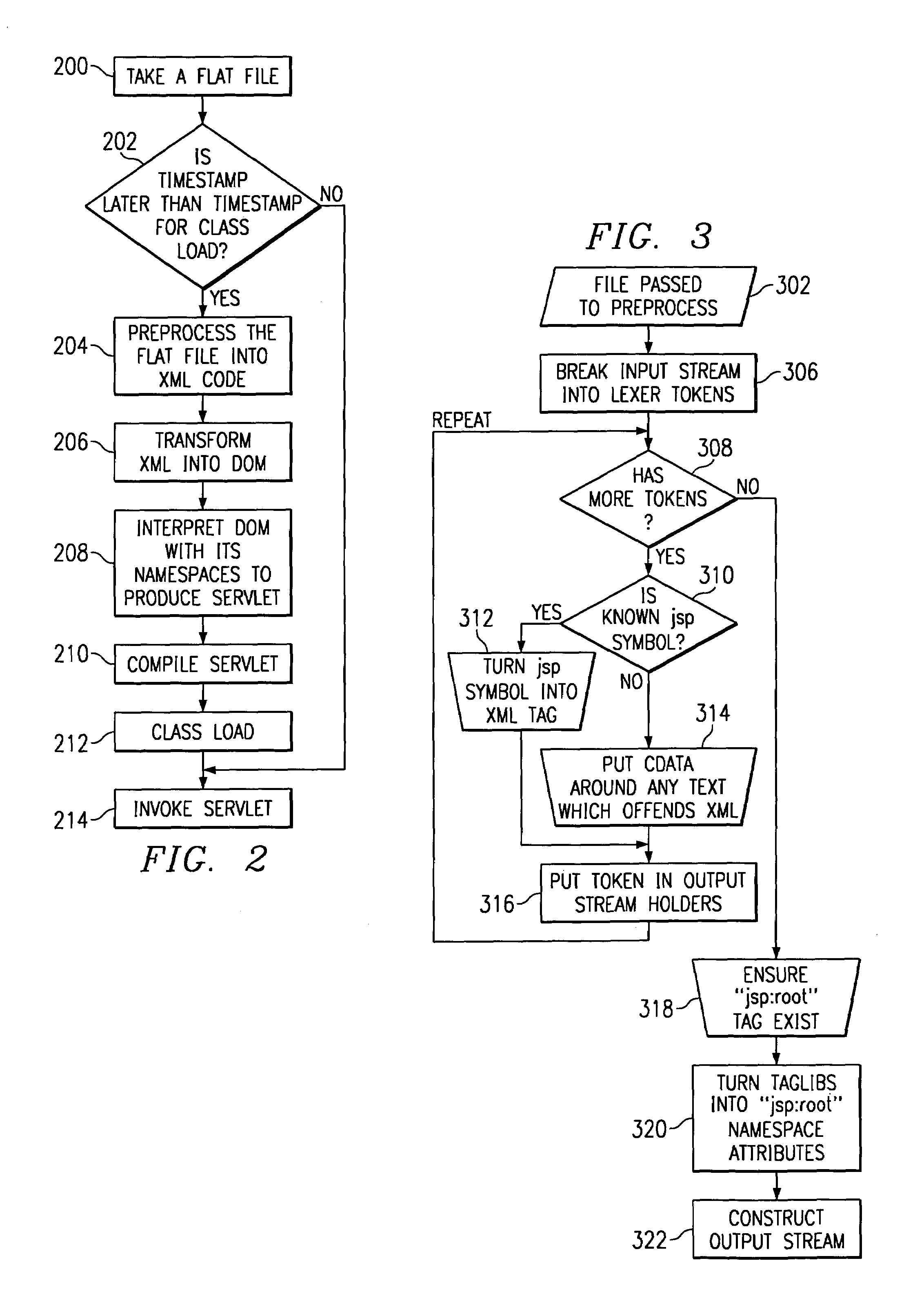

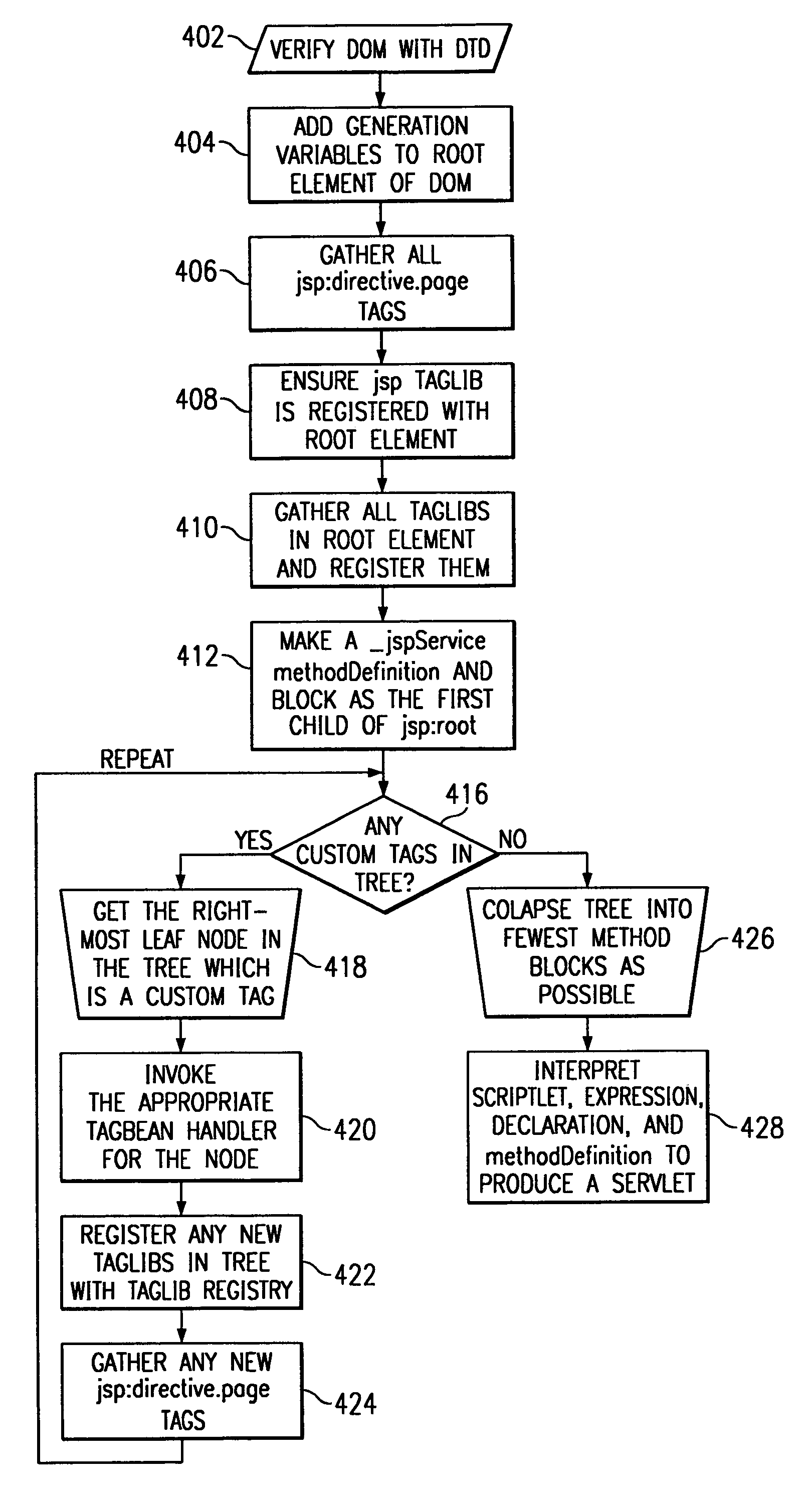

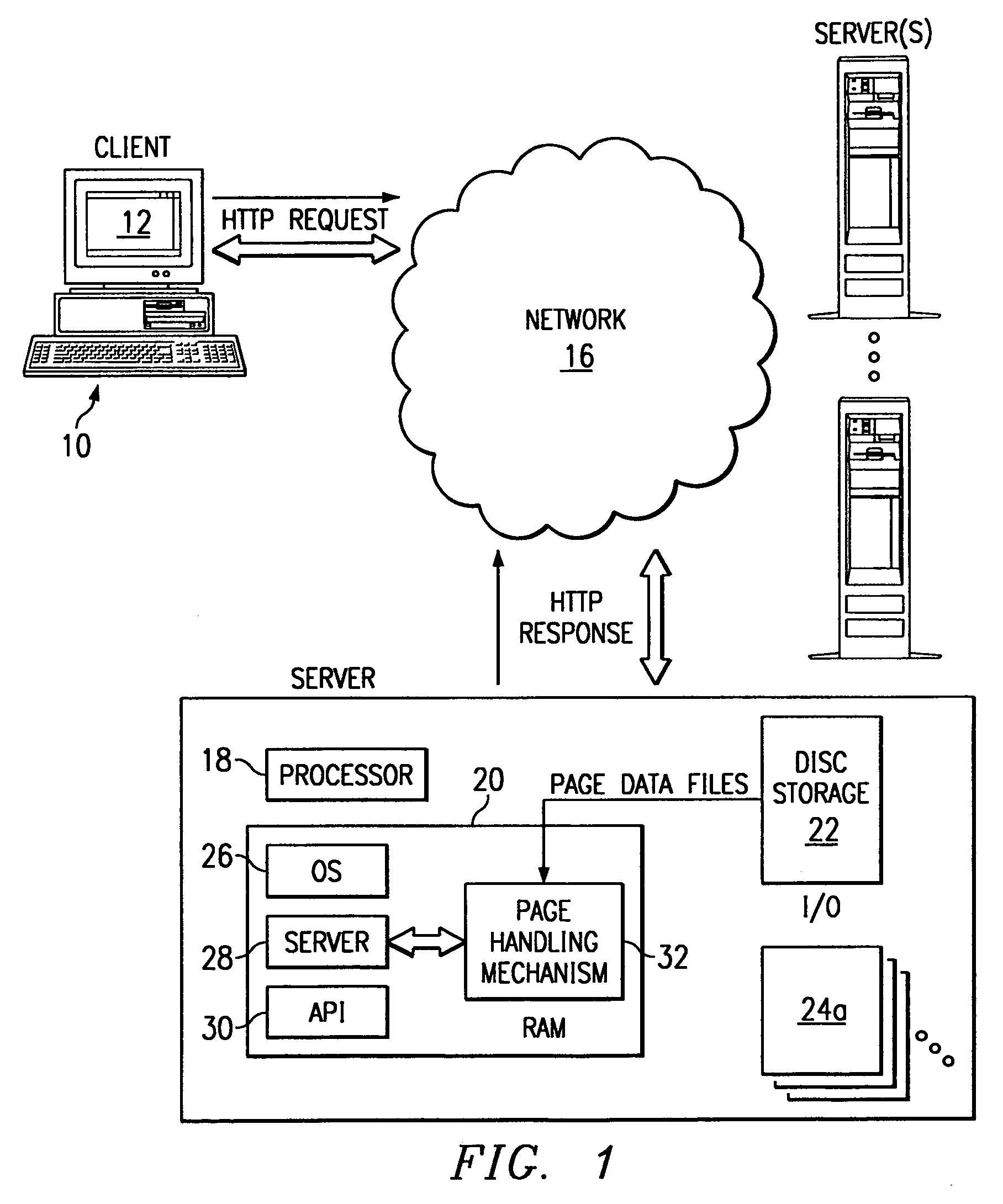

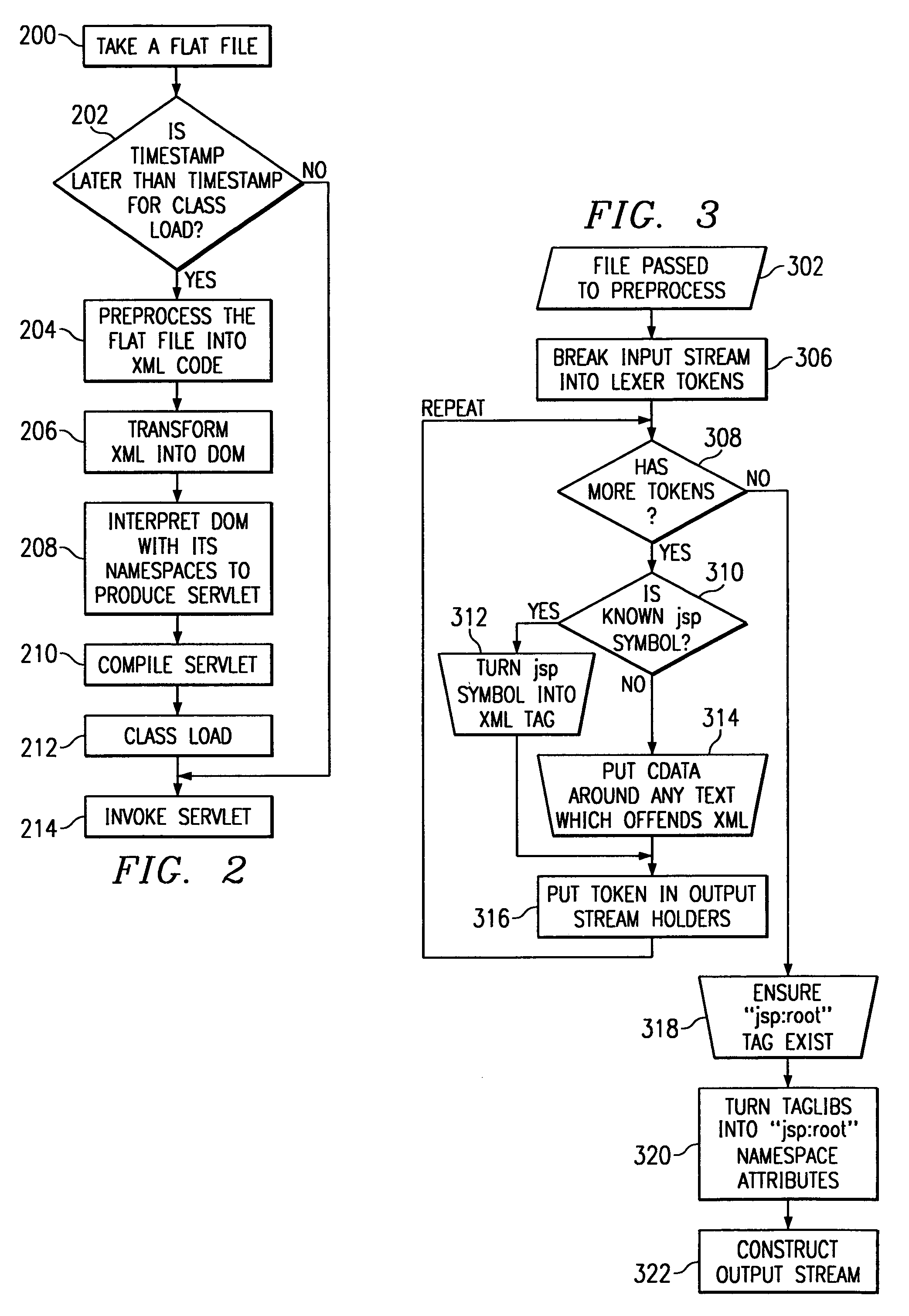

A method for serving a web page uses eXtensible Markup Language (XML) server pages. The first time a page is accessed, a given flat file is parsed into an XML Document Object Model (DOM), and required tag libraries are loaded. The DOM tree is then traversed, preferably in a depth-first, inside-out manner to locate custom tags. Upon locating a custom tag, if the tag is registered as a Java object, the object is loaded. A process method is then called on the object, passing the custom tag's tree node. The Java object then examines the custom tag and replaces it with an object, e.g., script code. Alternatively, if the tag is registered as an XSL stylesheet, the stylesheet is loaded and passed, together with the DOM, to an XSL processor. The processor applies the template to the custom tag and replaces it with given script code. Once all custom tags are reduced to HTML and script code, the DOM is compiled into a Java servlet to service the client request.

Owner:IBM CORP

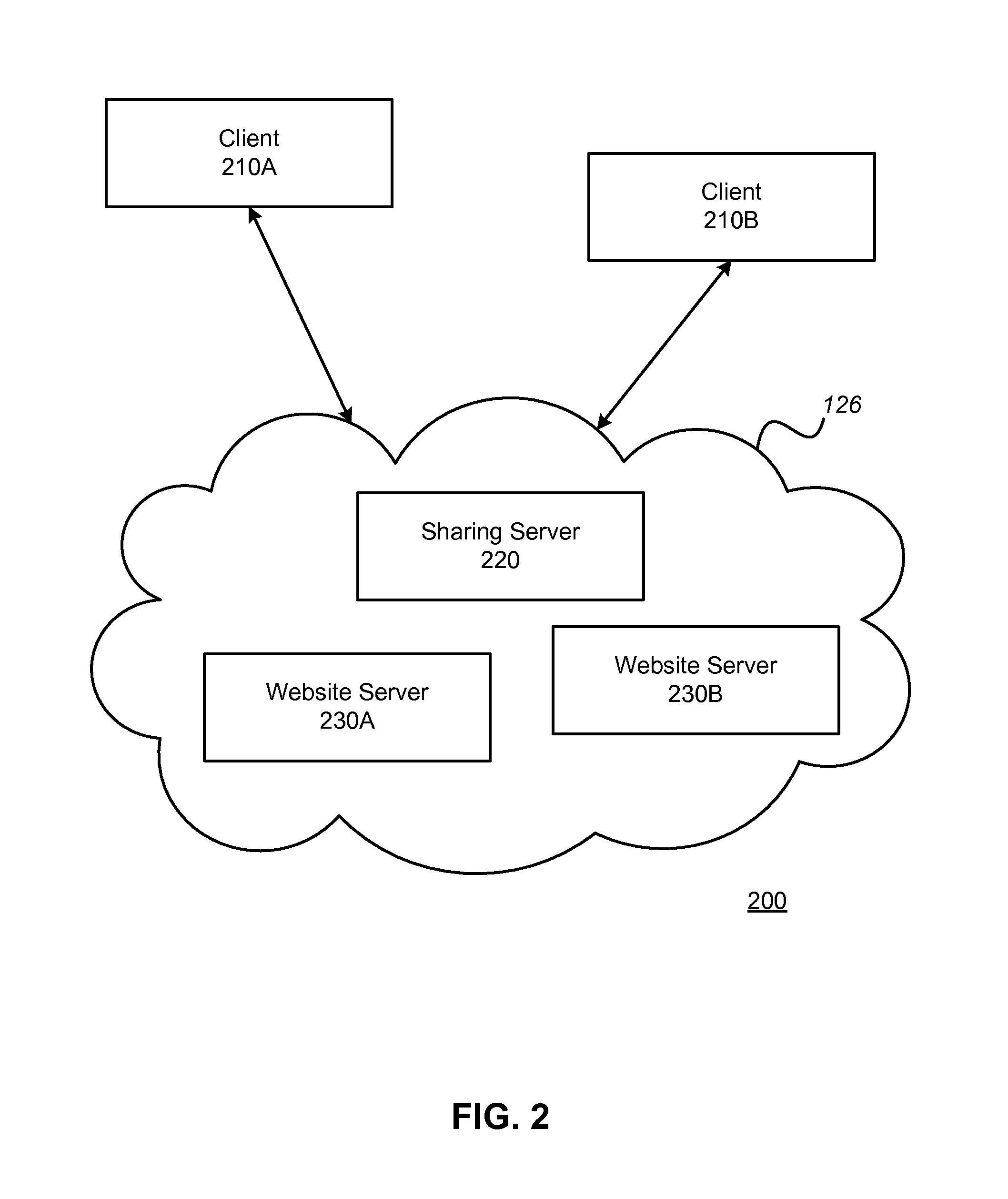

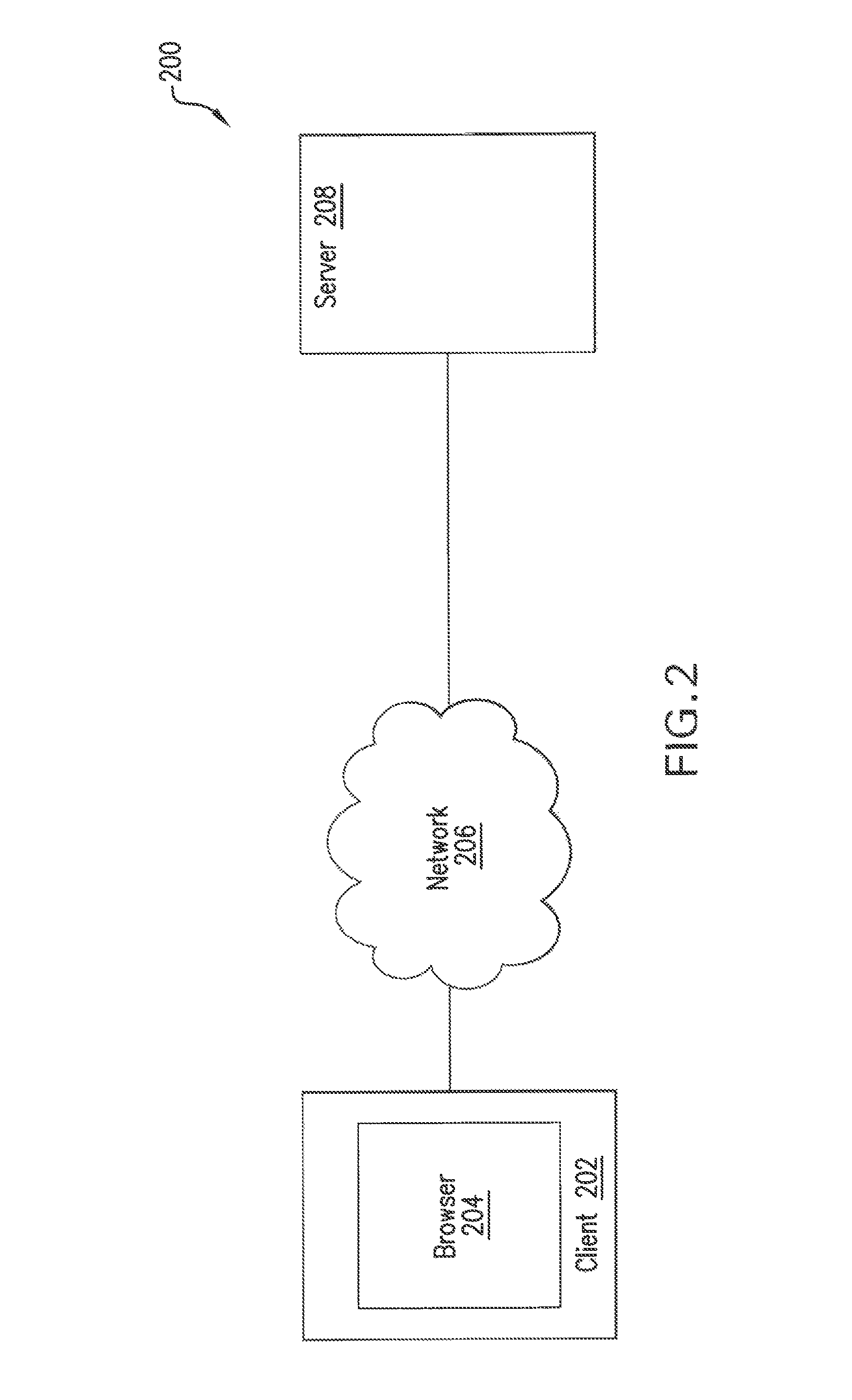

Bi-directional sharing of a document object model

InactiveUS8806024B1Multiple digital computer combinationsOffice automationComponent Object ModelThe Internet

A system and a method are disclosed for bi-directionally sharing DOMS in order to enable a shared internet browsing experience between first and second client computing devices. The client computing devices share the DOMs of the webpages each is currently viewing via a central server. In this manner, the webpage being viewed at the first client computing device is rendered at the second client computing device and the webpage being viewed at the second client computing device is rendered at the first client computing device.

Owner:OMG HLDG

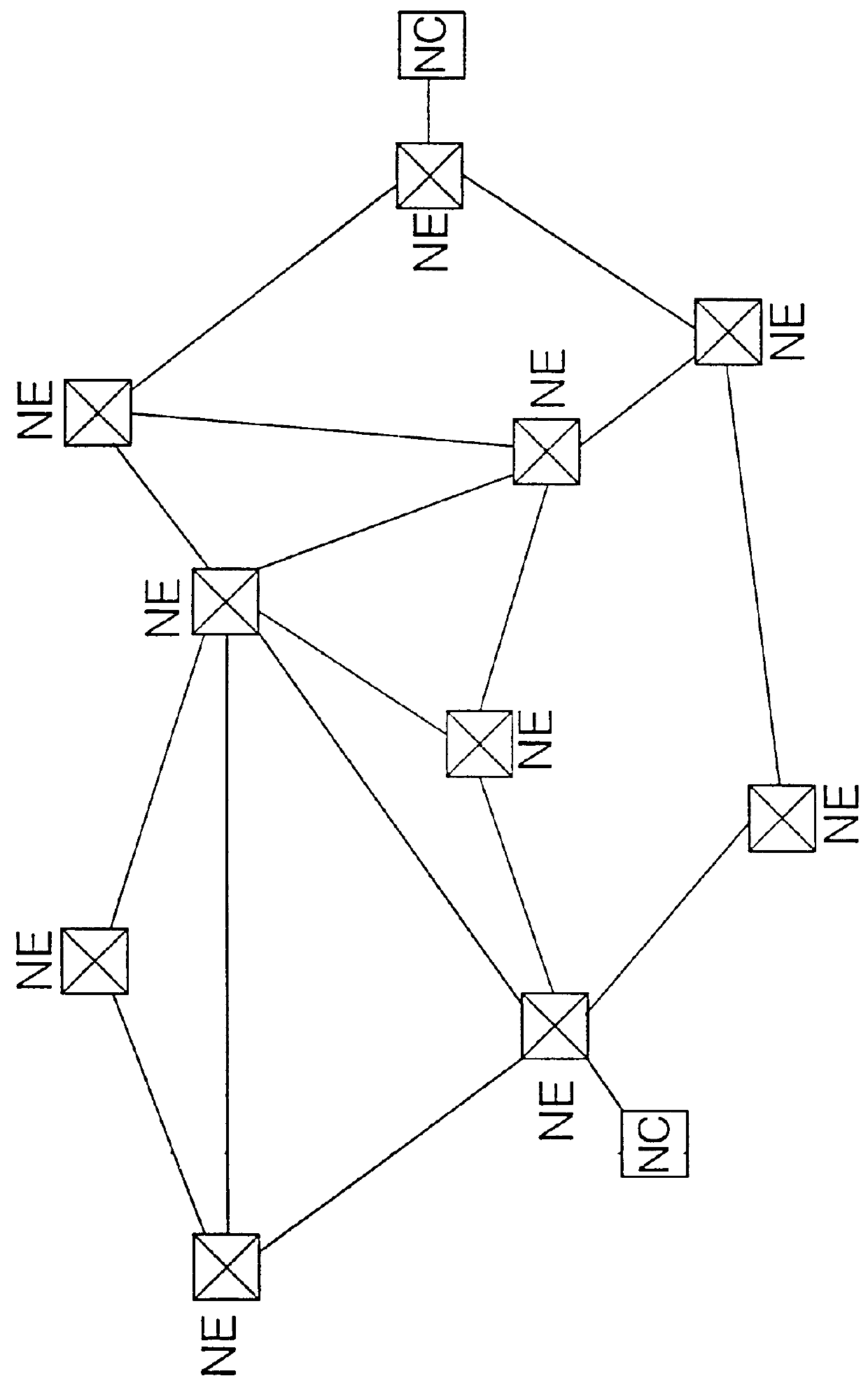

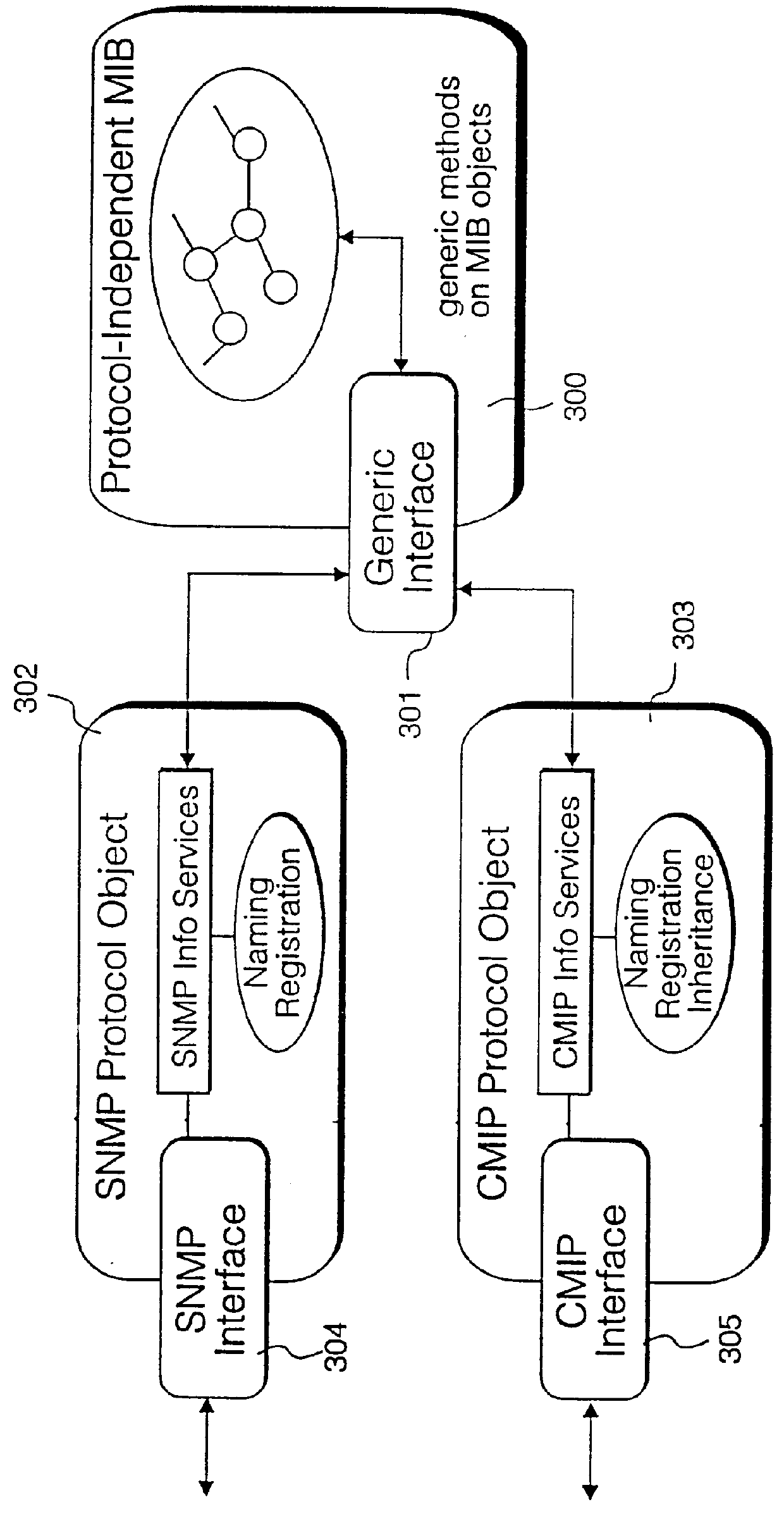

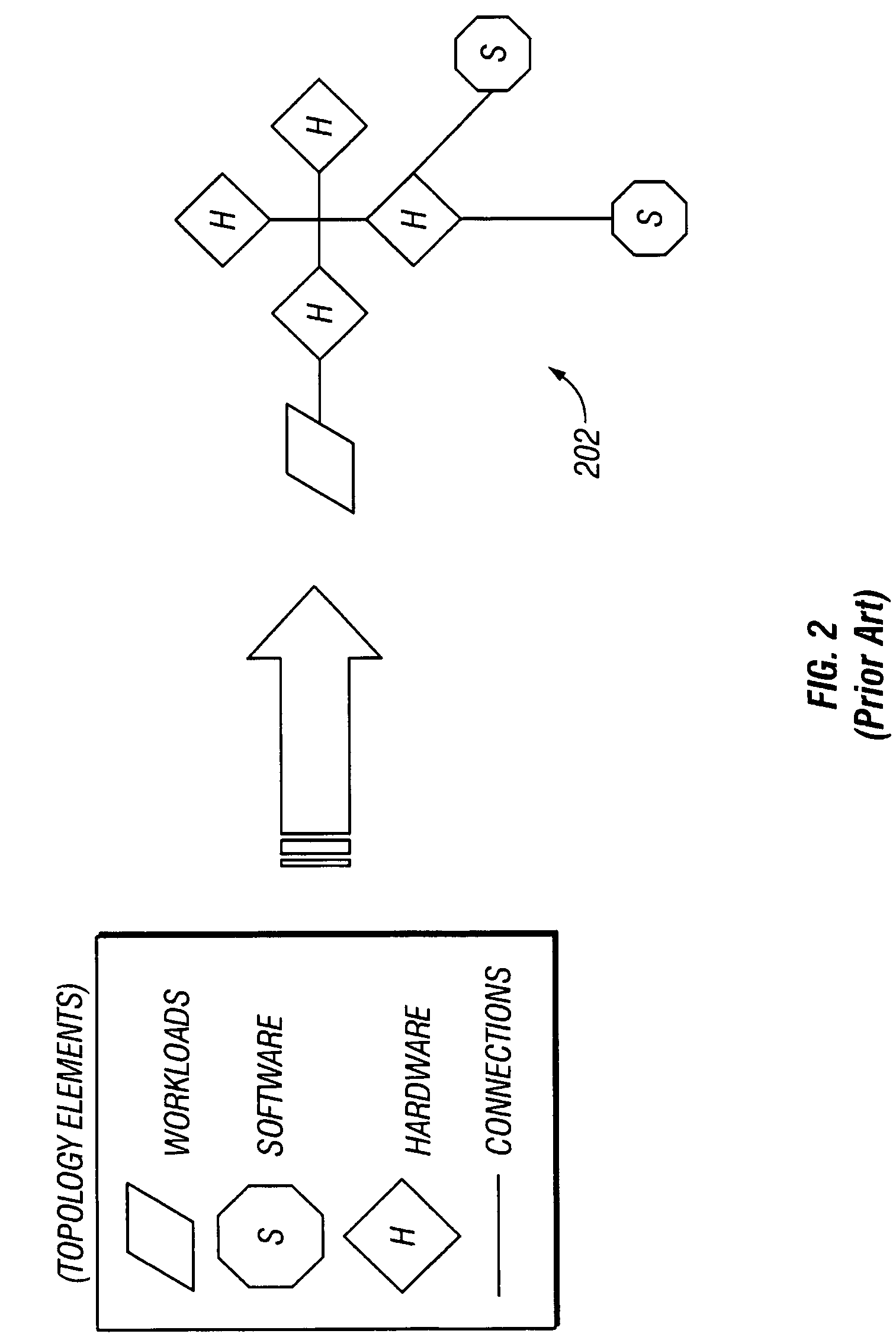

Management system architecture and design method to support reuse

A management base of a communications network manager is constructed using object oriented techniques. A network comprises a plurality of physical resources in the form of components and assemblies of components, which are distributed across the network. A management system for the network is constructed in an evolutionary manner by representing an overall functionality of the network by an application model in which each function of the network is modeled independently of its implementation, decomposing the application model into an implementation model in which every function represented in the application model is represented in the implementation model, representing the application model as a plurality of objects, representing the implementation model as another plurality of objects, connecting the objects of the application model and implementation model together to obtain a combined object model, and constructing a management base according to the combined object model.

Owner:NORTEL NETWORKS LTD

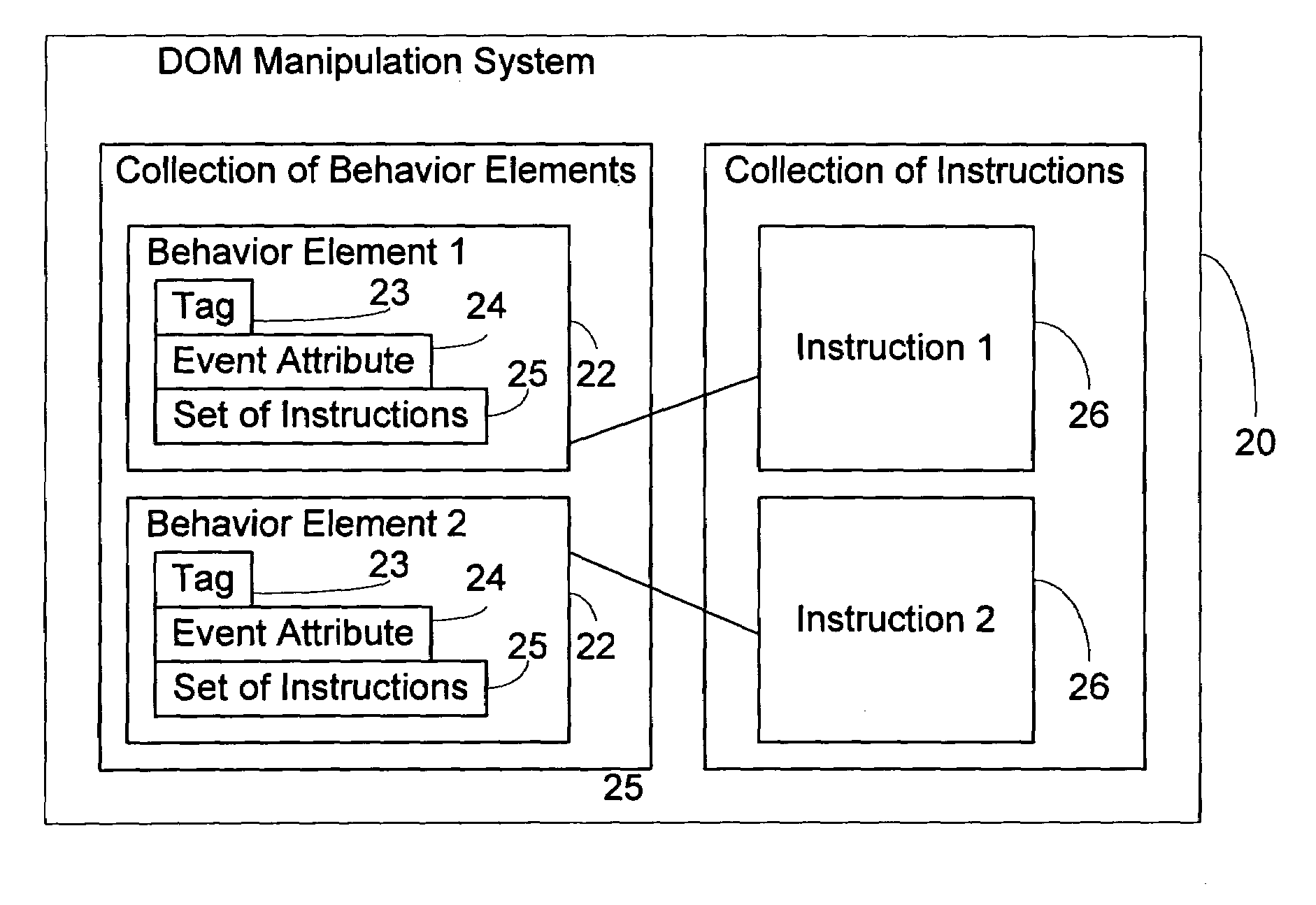

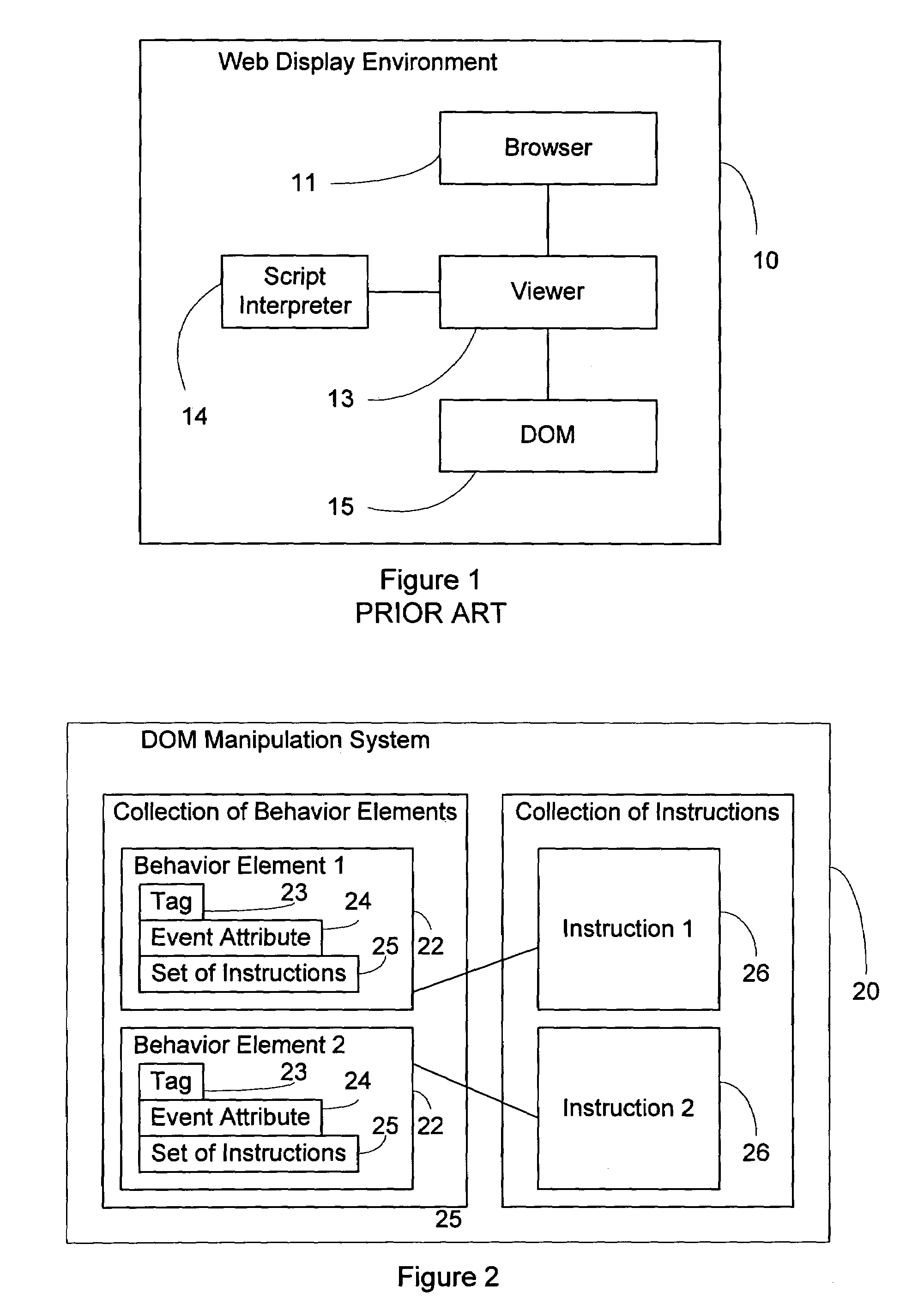

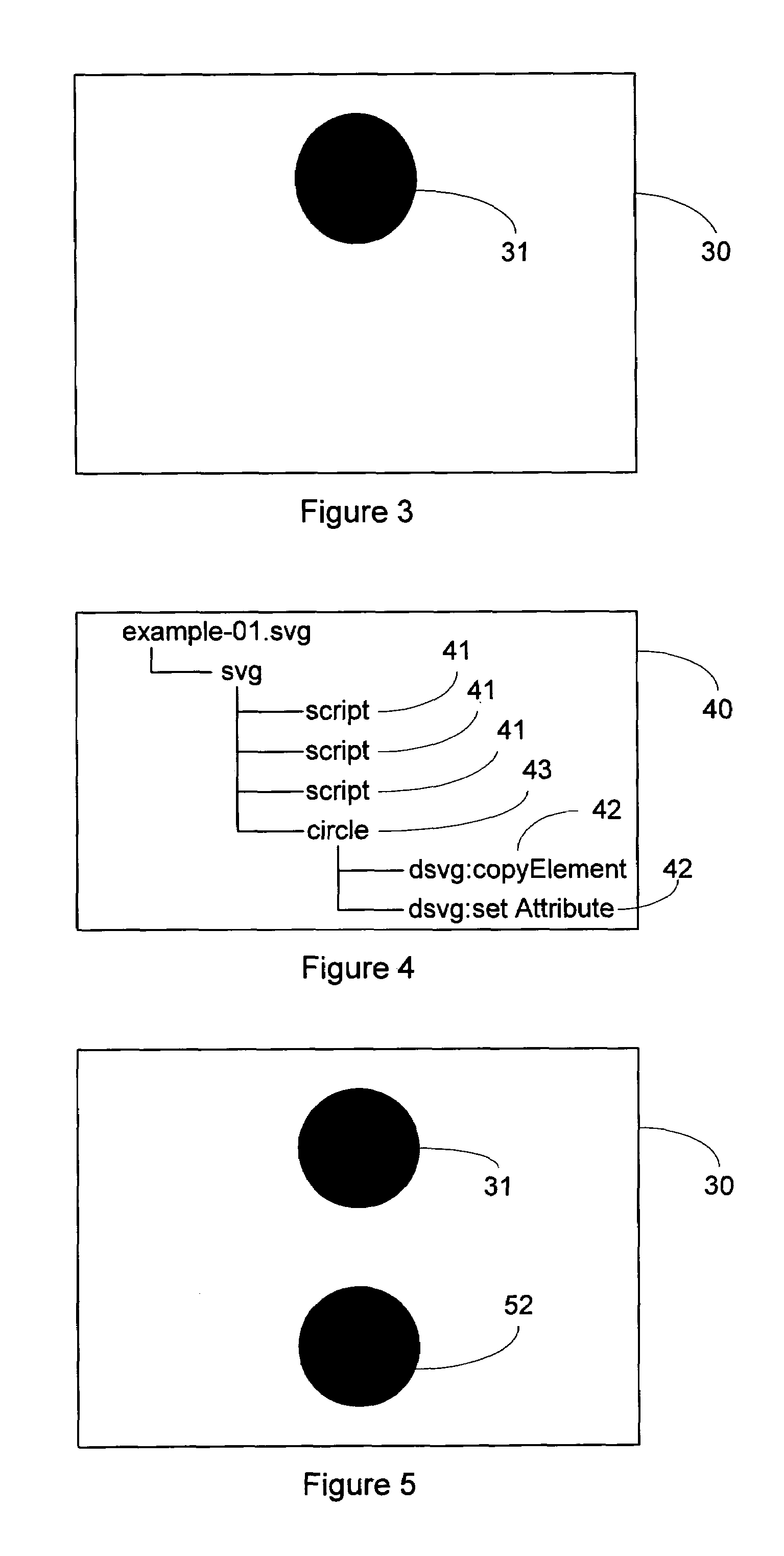

System and method for manipulating a document object model

ActiveUS7669183B2Website content managementExecution for user interfacesComponent Object ModelDocument Object Model

A system for manipulating a document object model is provided. The system comprises a collection of document object model behavior elements, and a collection of scripts for performing actions associated with the set of behavior elements. Each behavior element comprises a name following a predetermined naming convention, an event attribute for associating the behavior element to an event, and other attributes for describing features of the behavior element. Each script is associated with a behavior element.

Owner:COREL CORP +1

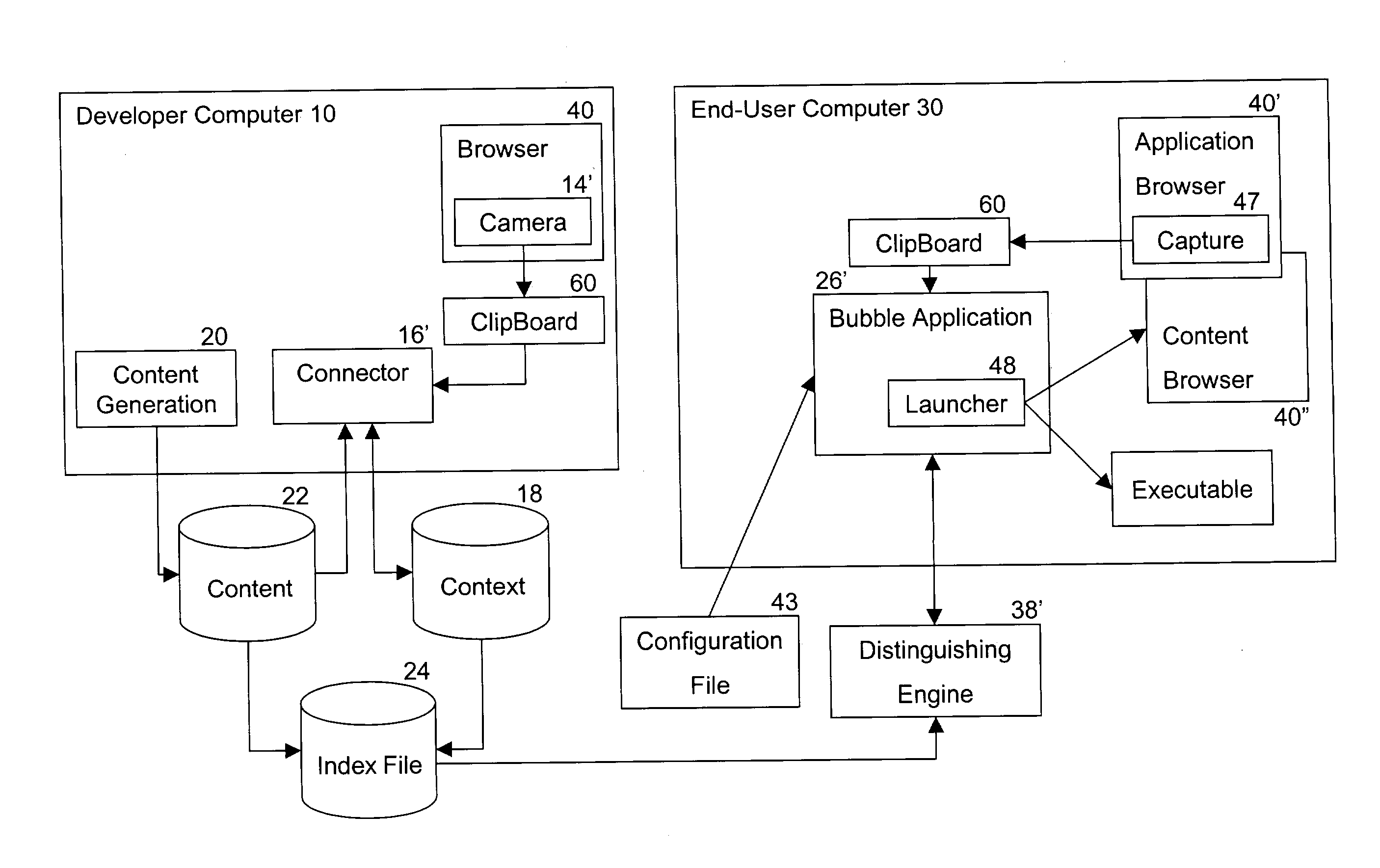

Content management system

InactiveUS20030164855A1Similar degree of easeThe degree of freedom becomes largerStill image data indexingCathode-ray tube indicatorsComponent Object ModelDocumentation procedure

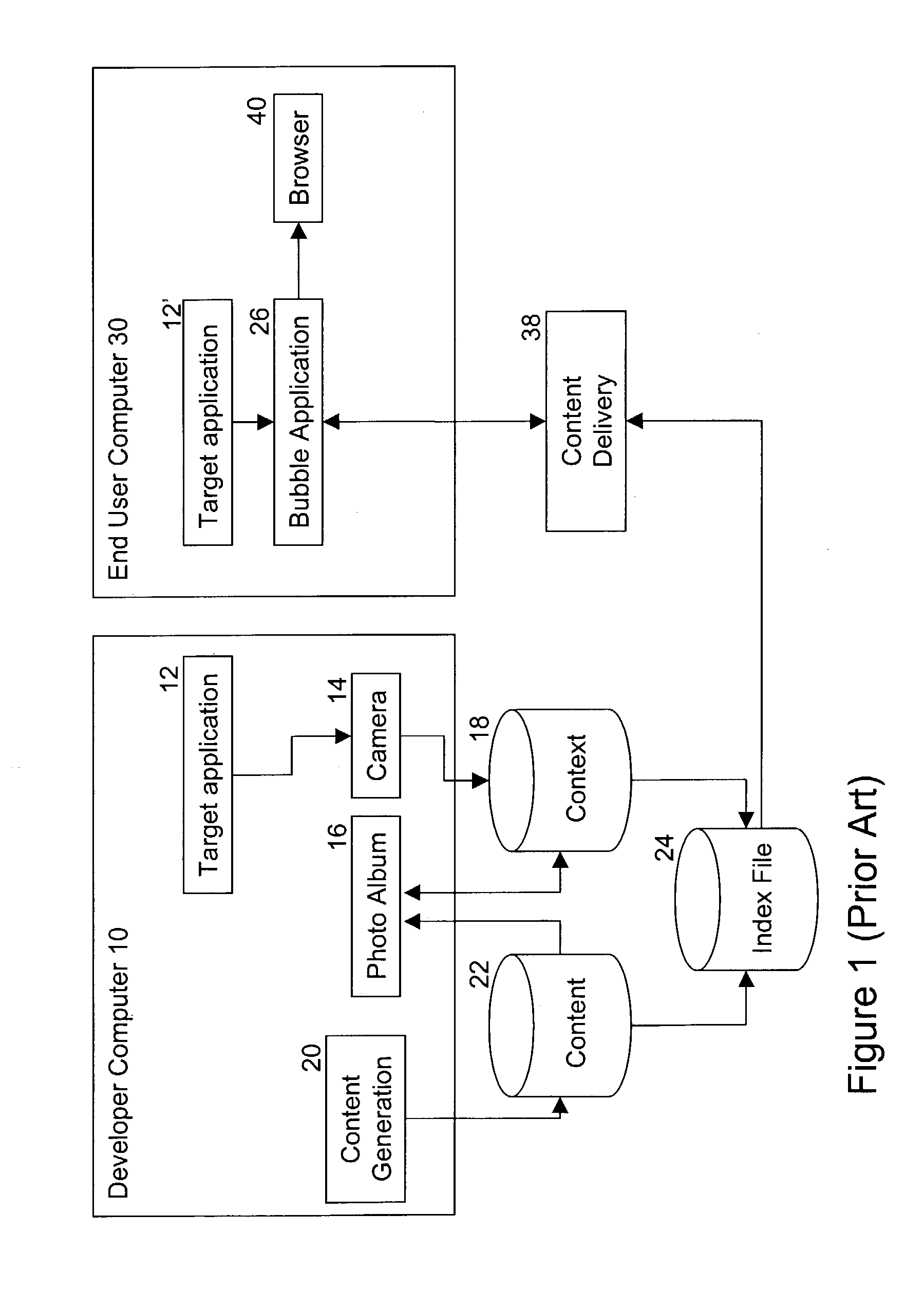

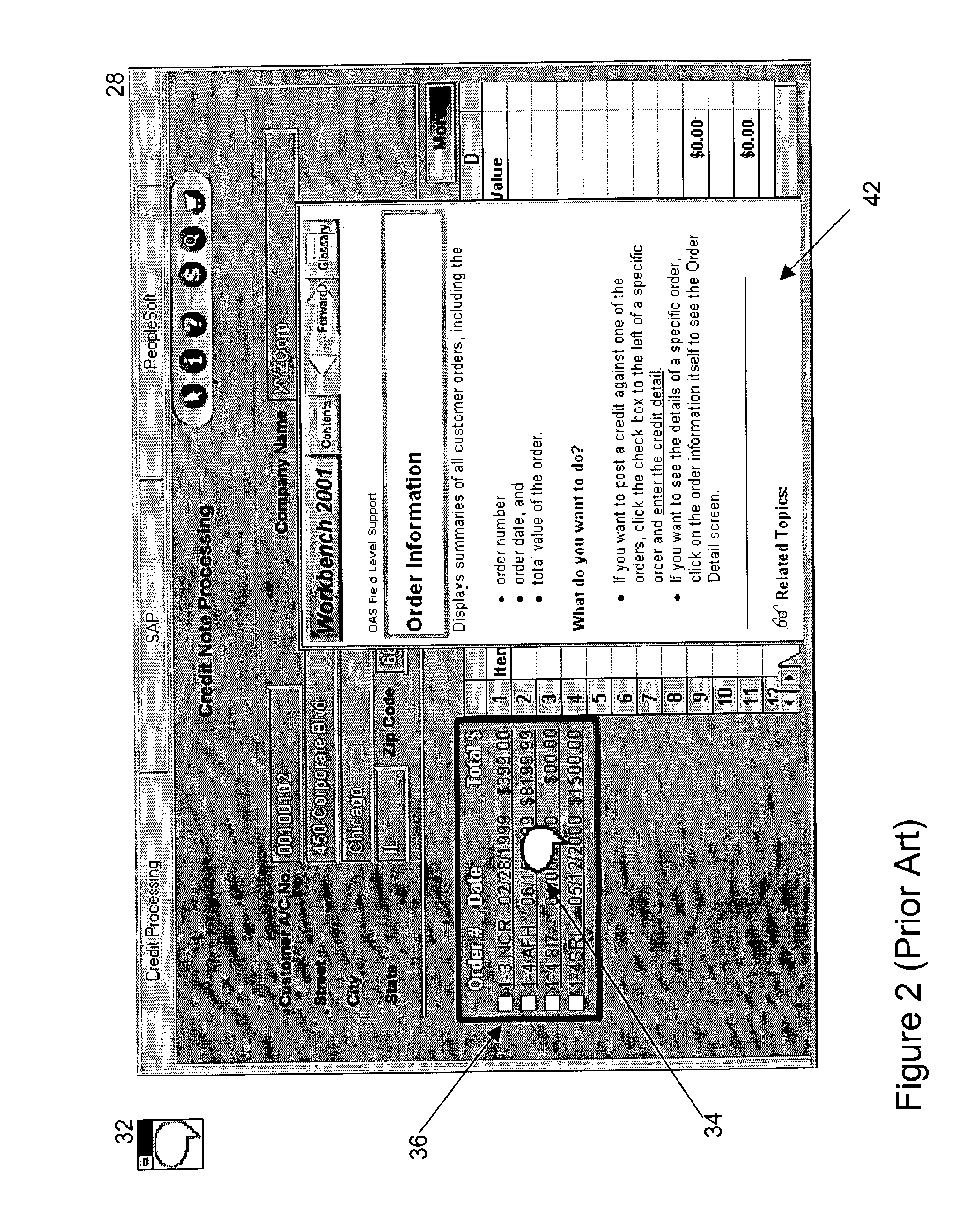

A content management system for providing content that is specific to the execution context of a user application is disclosed. The invention relates specifically to applications that have a display in a browser that generates a document object model. The system comprises a development tool that is operative to record a specific execution context of the user application. The development tool makes a record that includes at least part of a document object model constructed by the browser and to associates content with the record. The system also comprises a content display tool that is operative to compare the execution context of the executing user application with records made by the development tool and to display content associated record having a corresponding execution context.

Owner:BAYDON SOLUTIONS

Method and system for managing component objects used in a plurality of composite objects

InactiveUS20110055289A1Avoids wasteful orderingAvoid wastingDigital data processing detailsResourcesComponent Object ModelComposite object

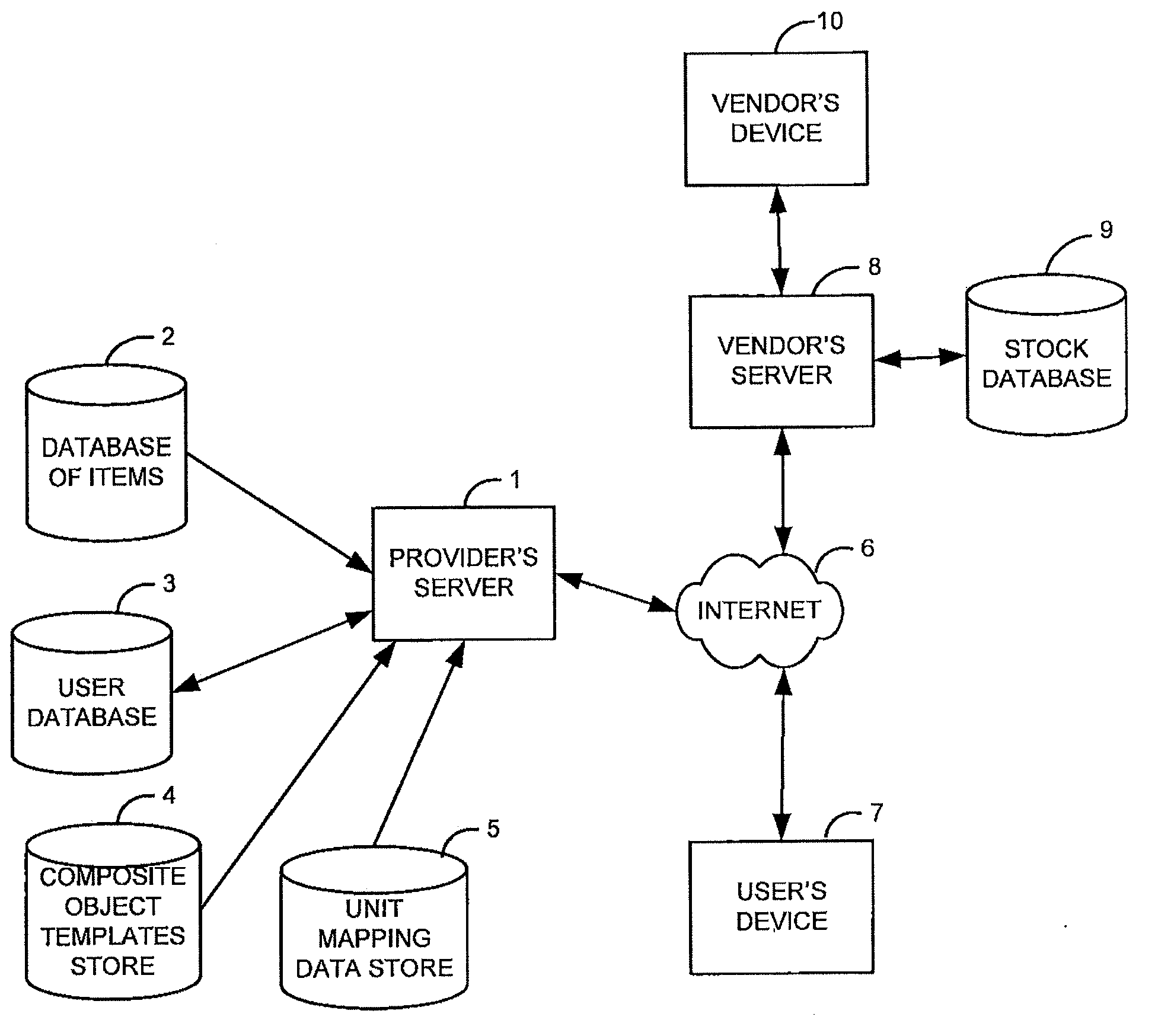

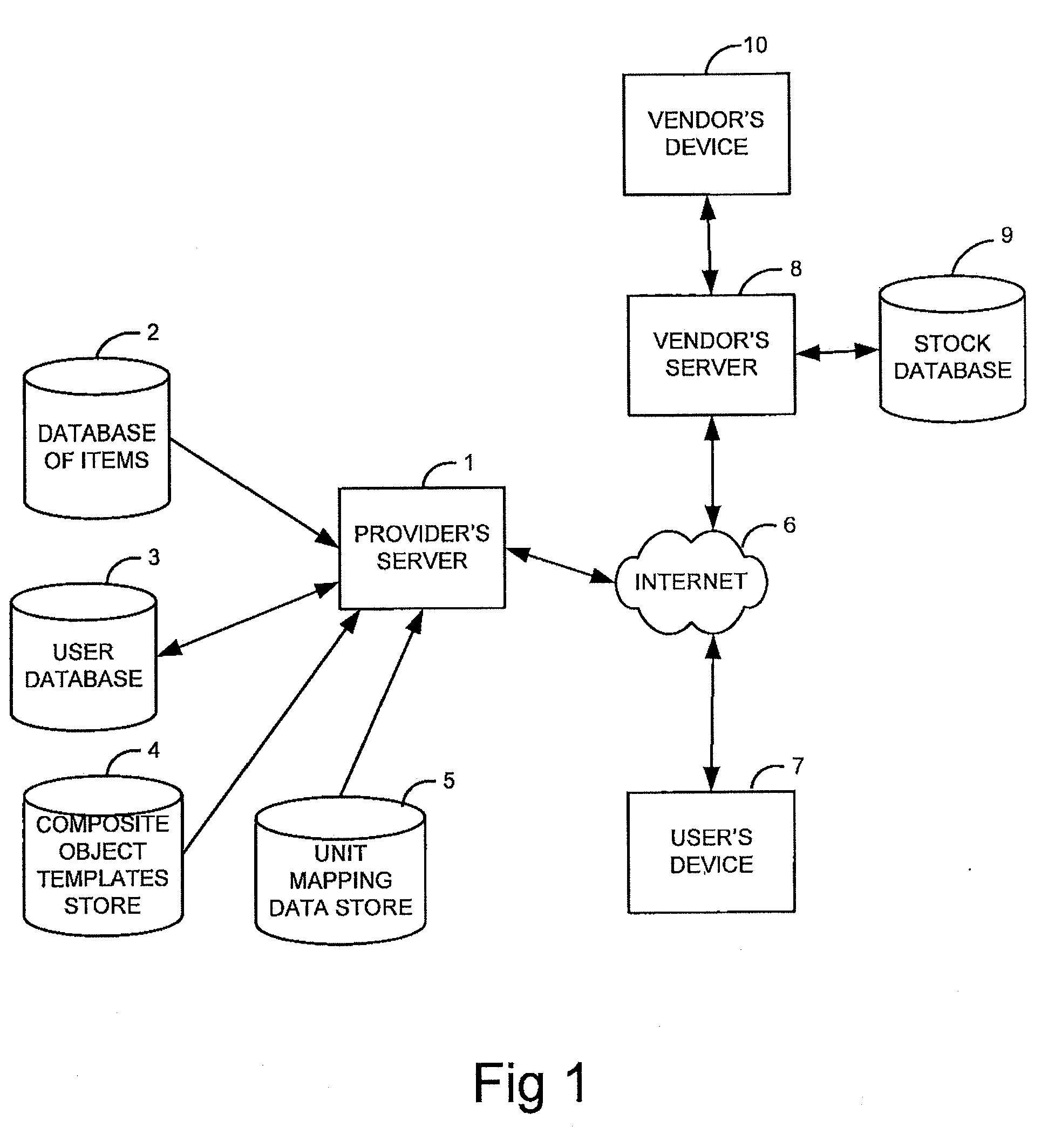

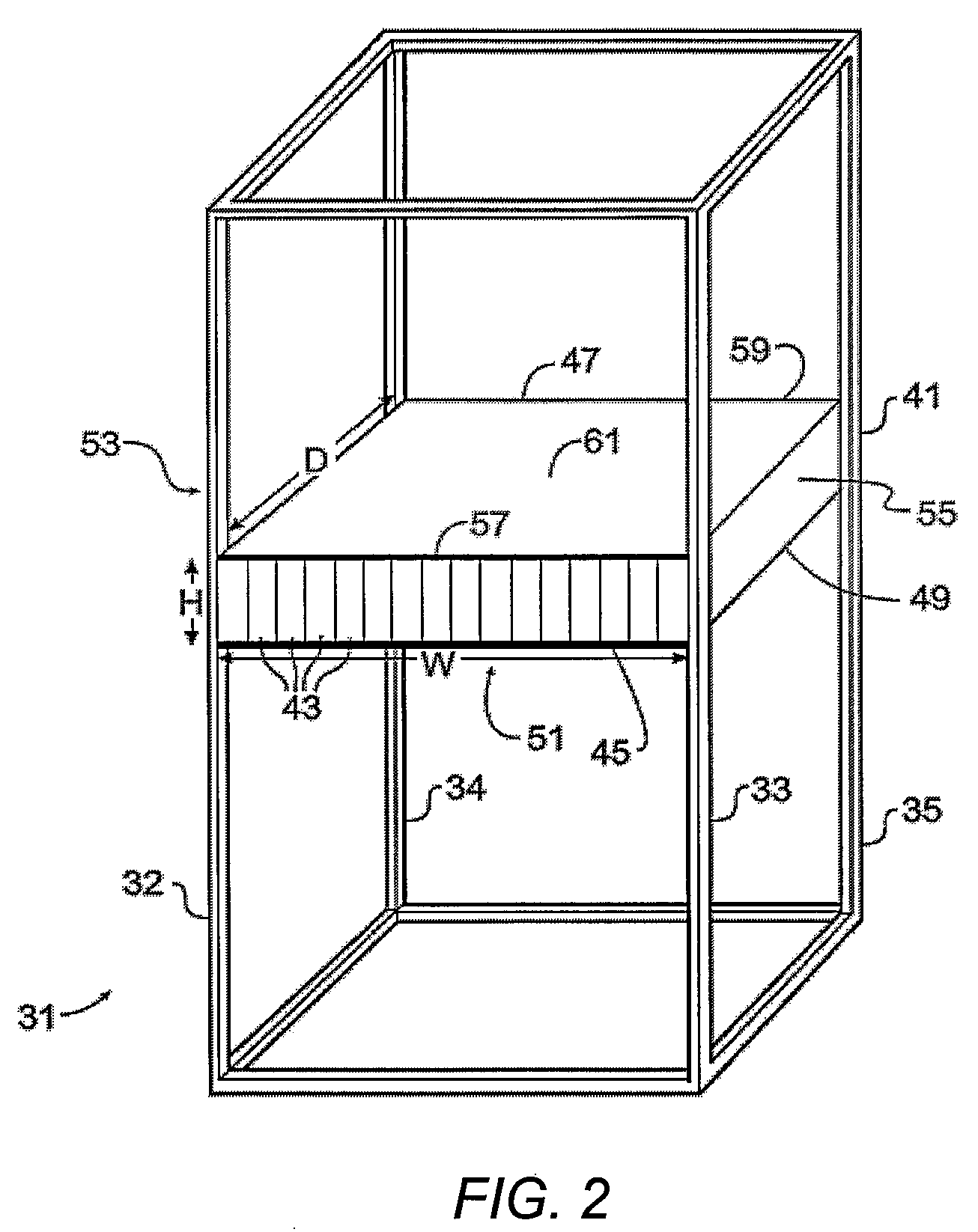

A composite physical object is formed of a plurality of component physical objects, which component physical objects can be used in a multiplicity of composite physical objects and a data management system and method is provided to manage the relationships. A user interface is provided to enable selection of component or composite objects for the addition or removal of component physical objects from the list. Because the relationship between component objects and composite objects is maintained, if a user selects to remove a component physical object from the list, its related component physical objects to be used in a composite object can be identified and also automatically removed. Similarly, operating the other way around, a user can select a composite object to be removed and this will result in the removal of all component physical objects in the list which are used in the composite object.

Owner:ENNIS RUSSEL

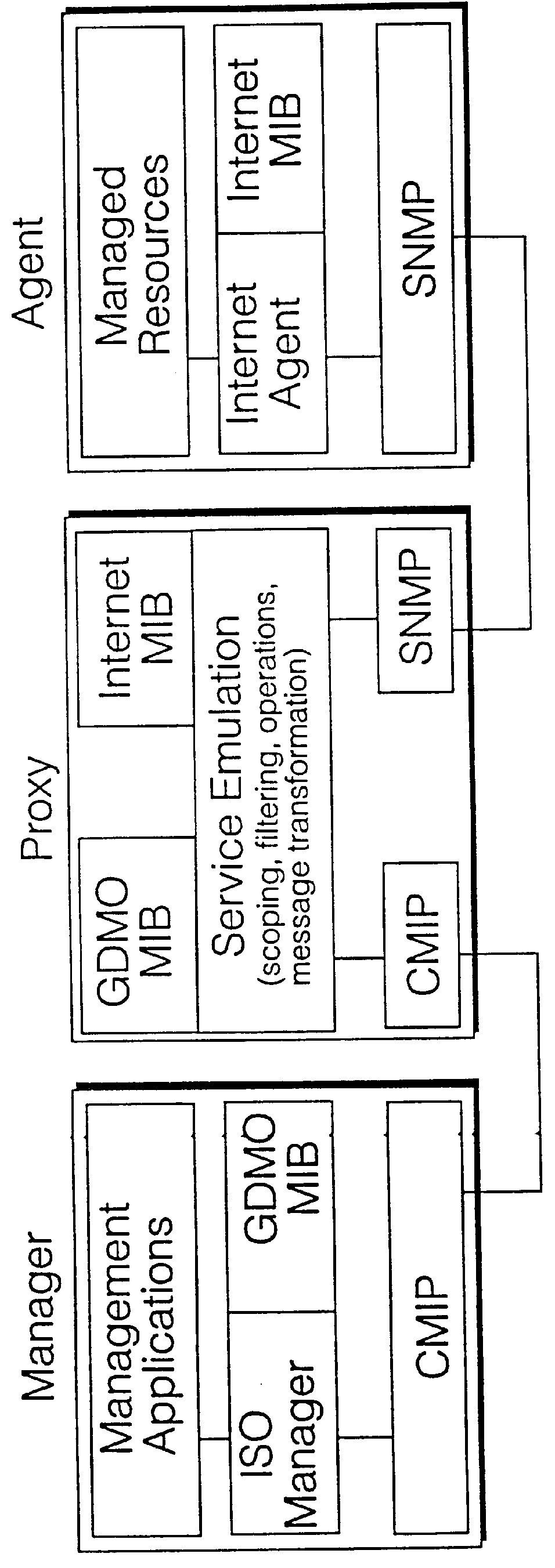

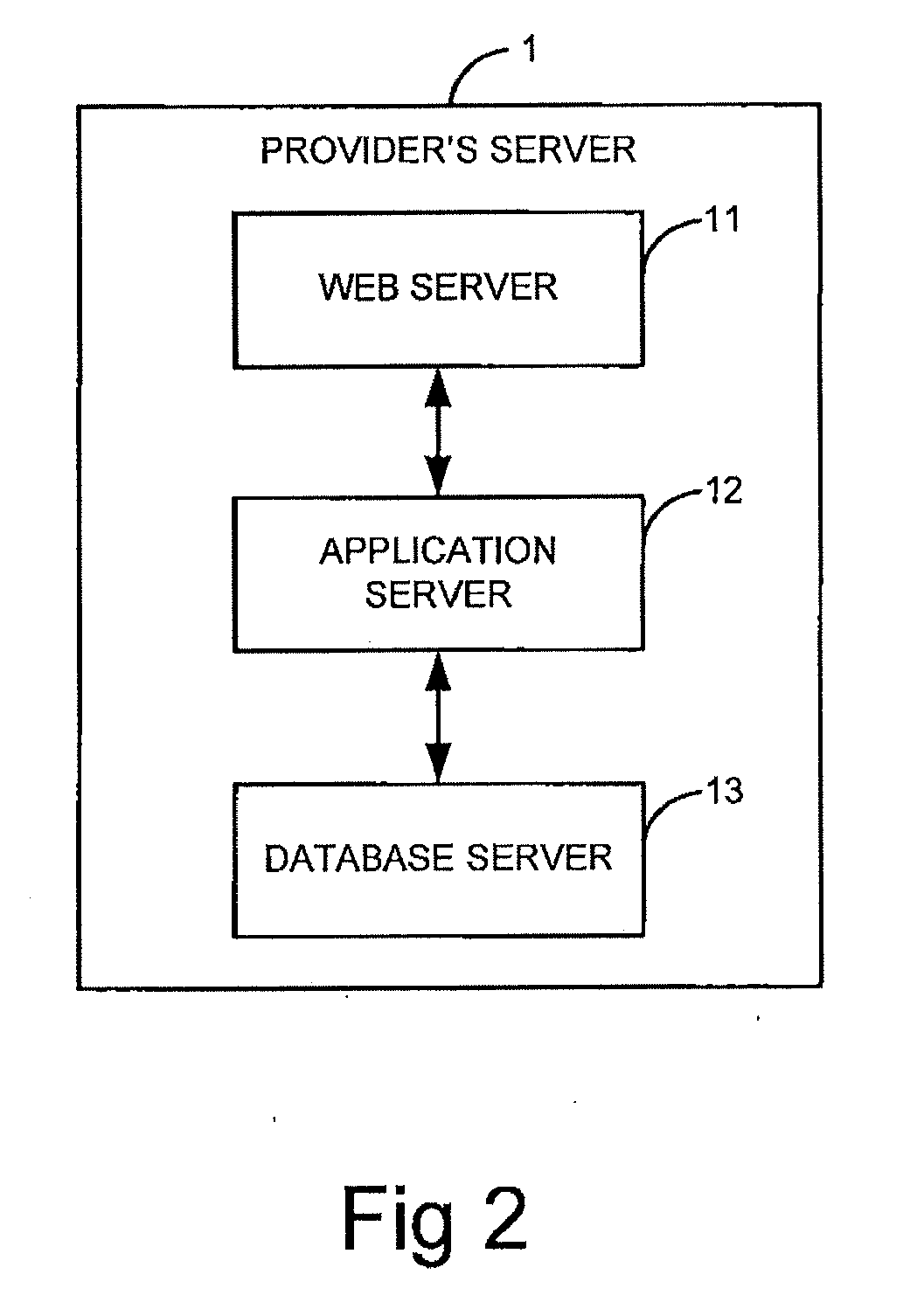

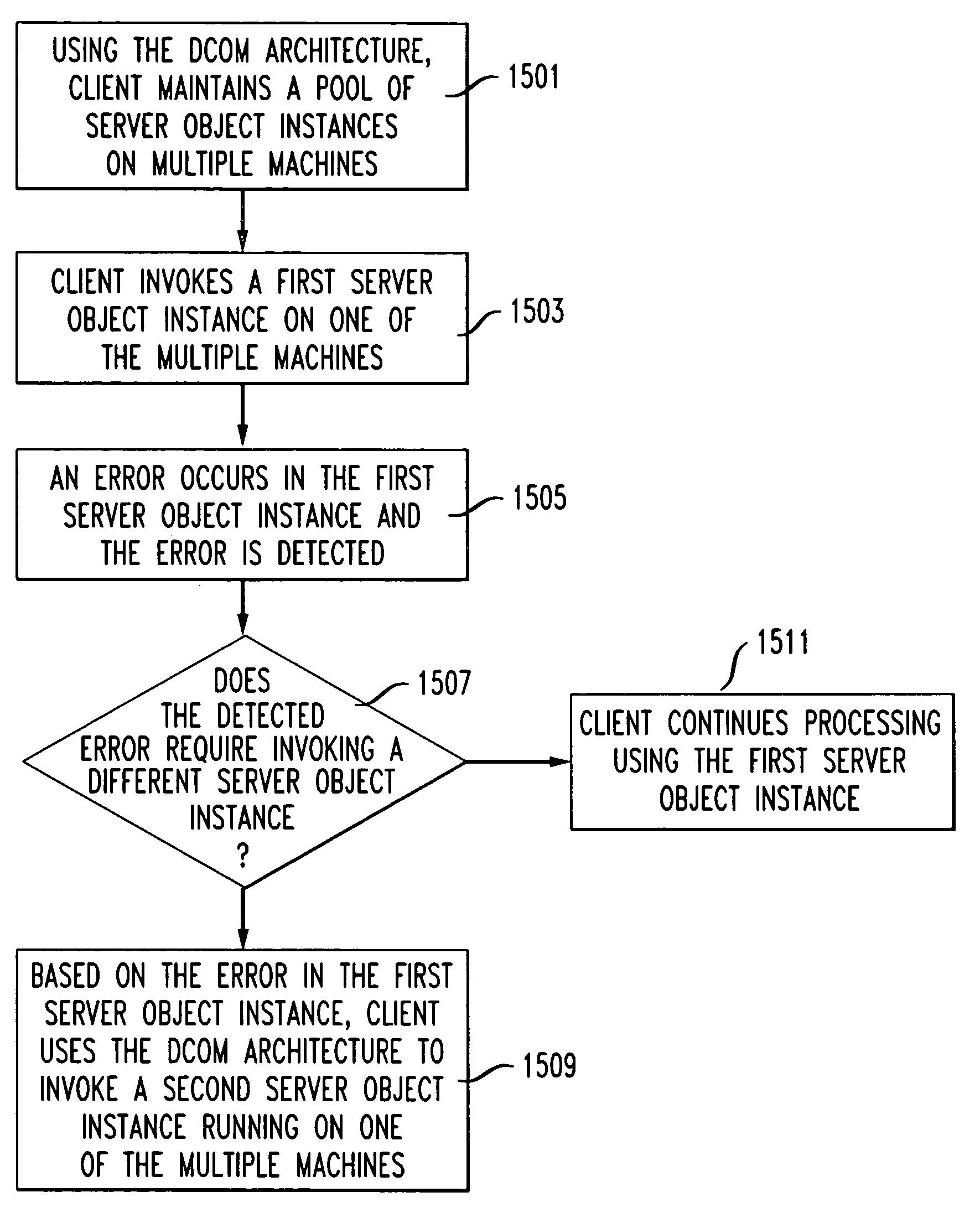

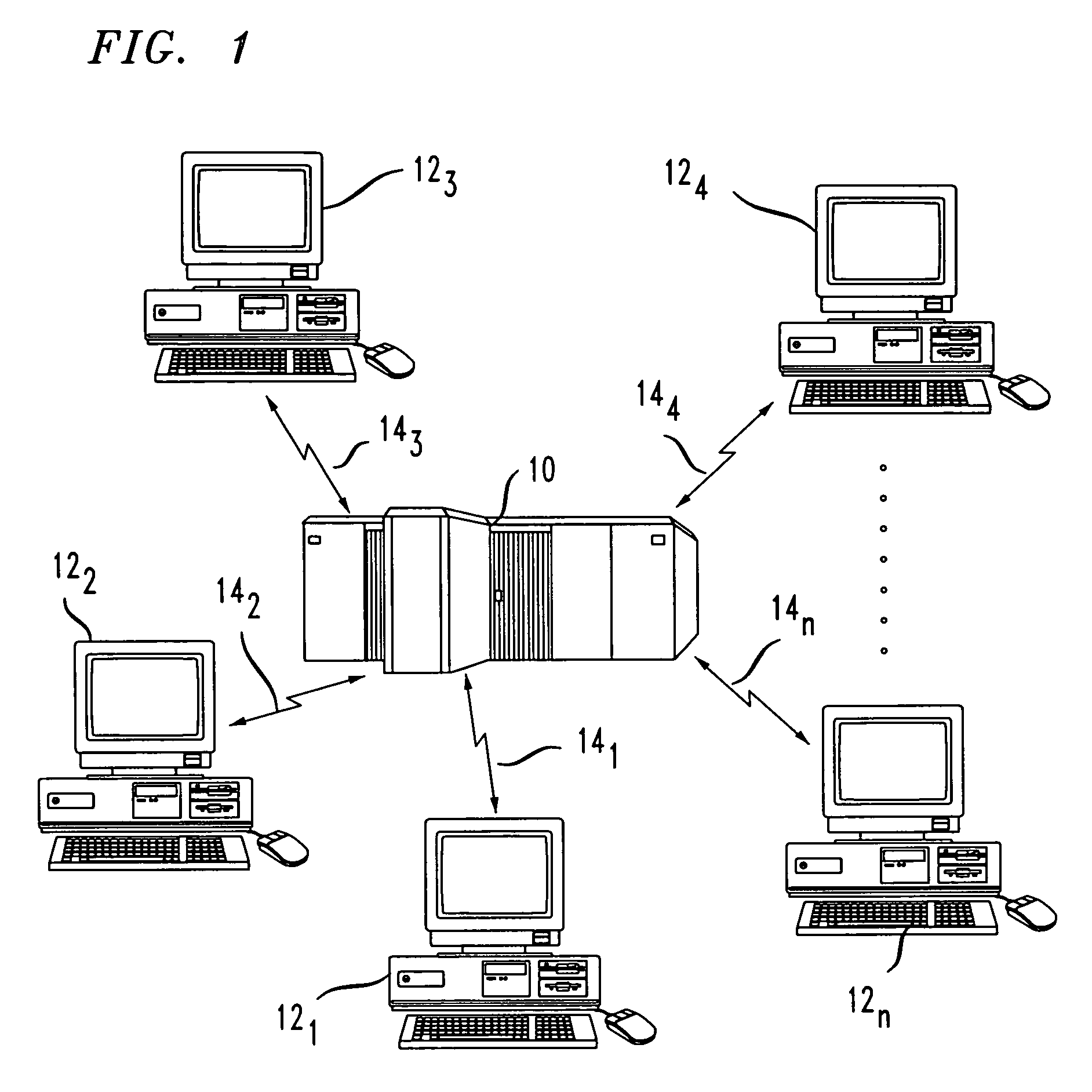

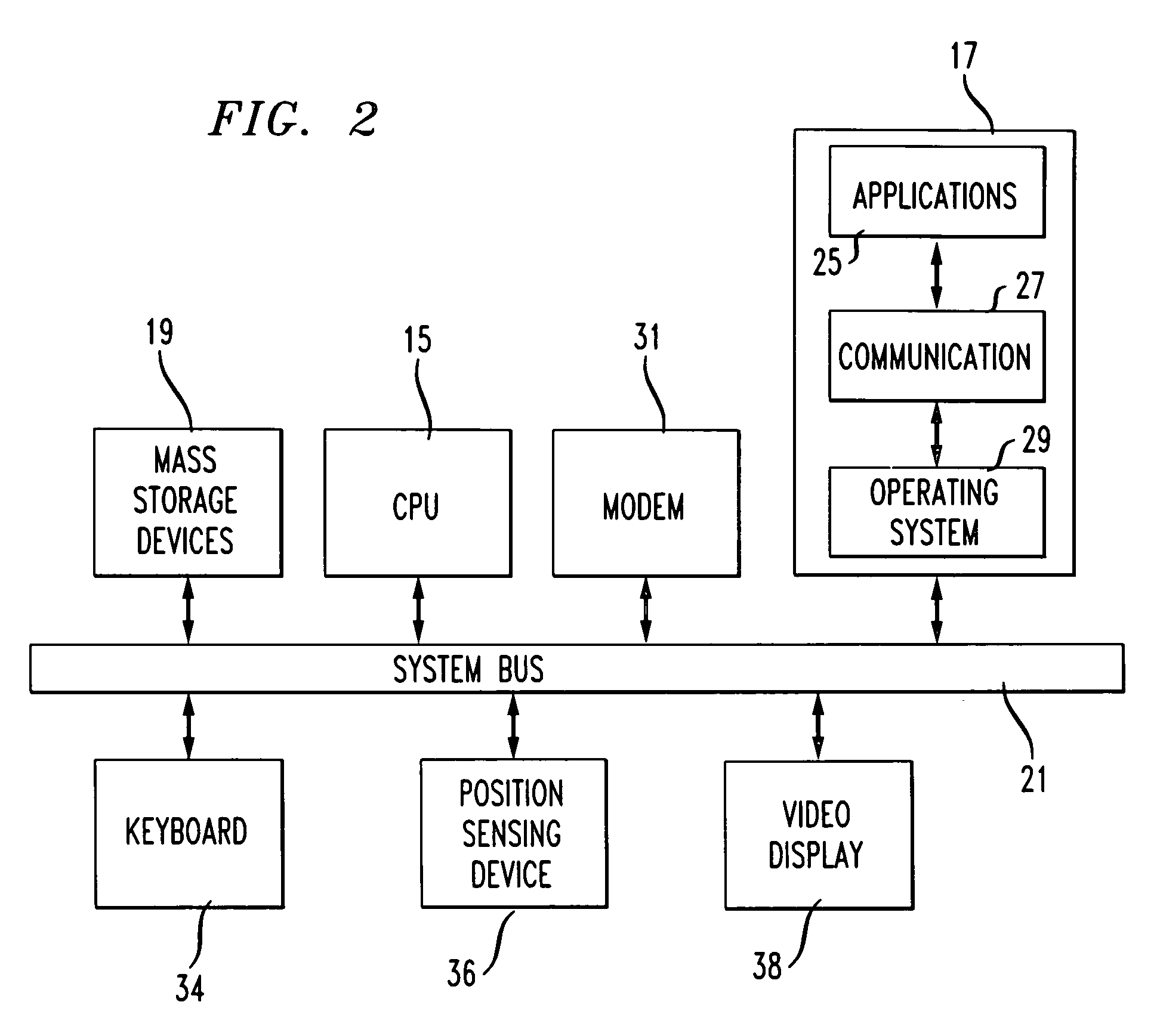

Method and system for providing reliability and availability in a distributed component object model (DCOM) object oriented system

InactiveUS7082553B1Improve reliabilityImprove availabilityError detection/correctionDistributed Component Object ModelFailover

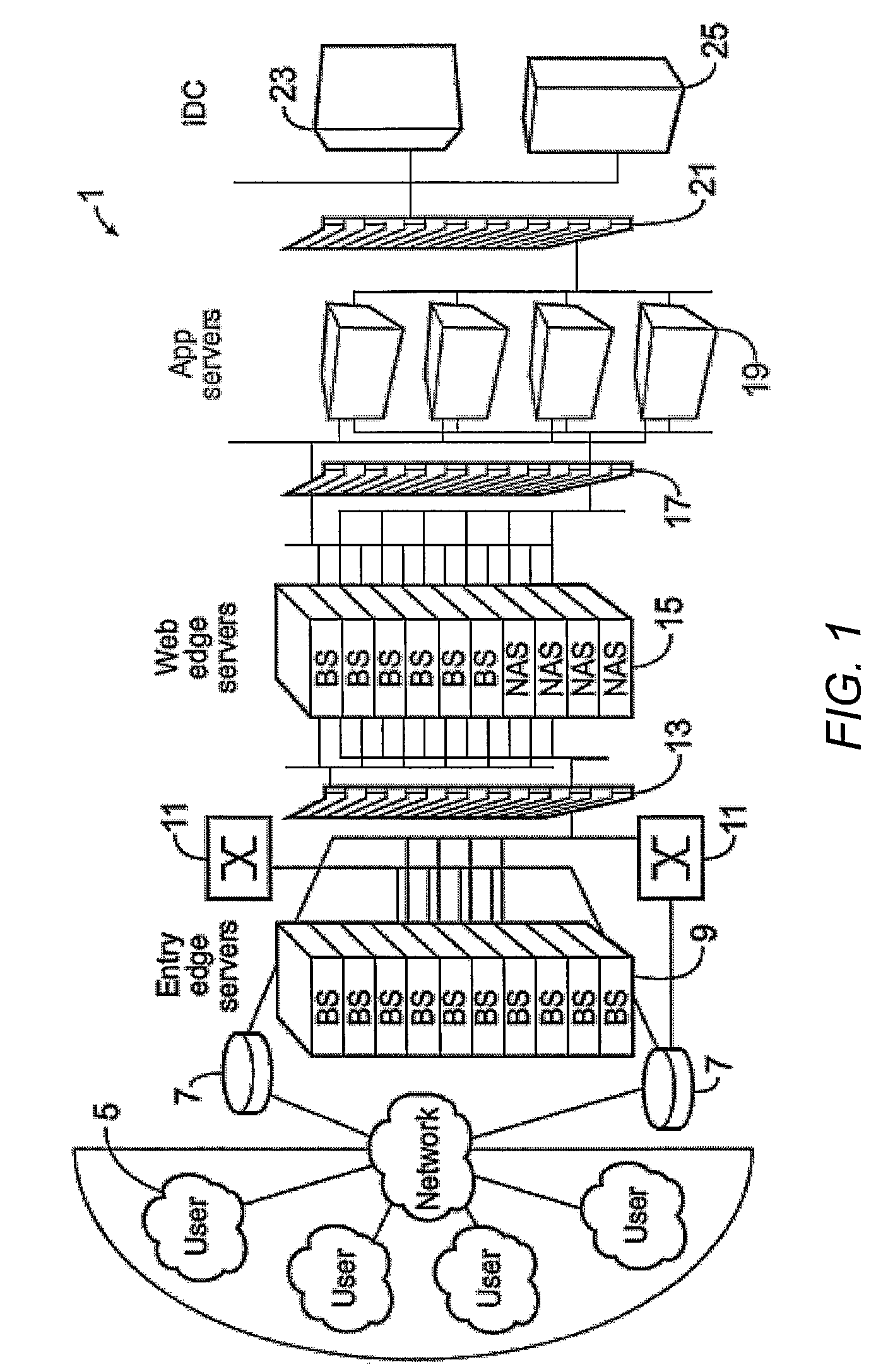

A method and system for improving reliability and availability in distributed computer applications. The method and system may be used in the context of primary-backup, failover recovery. The method involves software-fault tolerance using technique of structured storage; referral components; and wrappers. The method and system exploit the platform and operating system independence of component object models to allow the dynamic linkage of different component objects, the objects being resident on different inter-linked machines, based on the application requirements at any given point in time.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

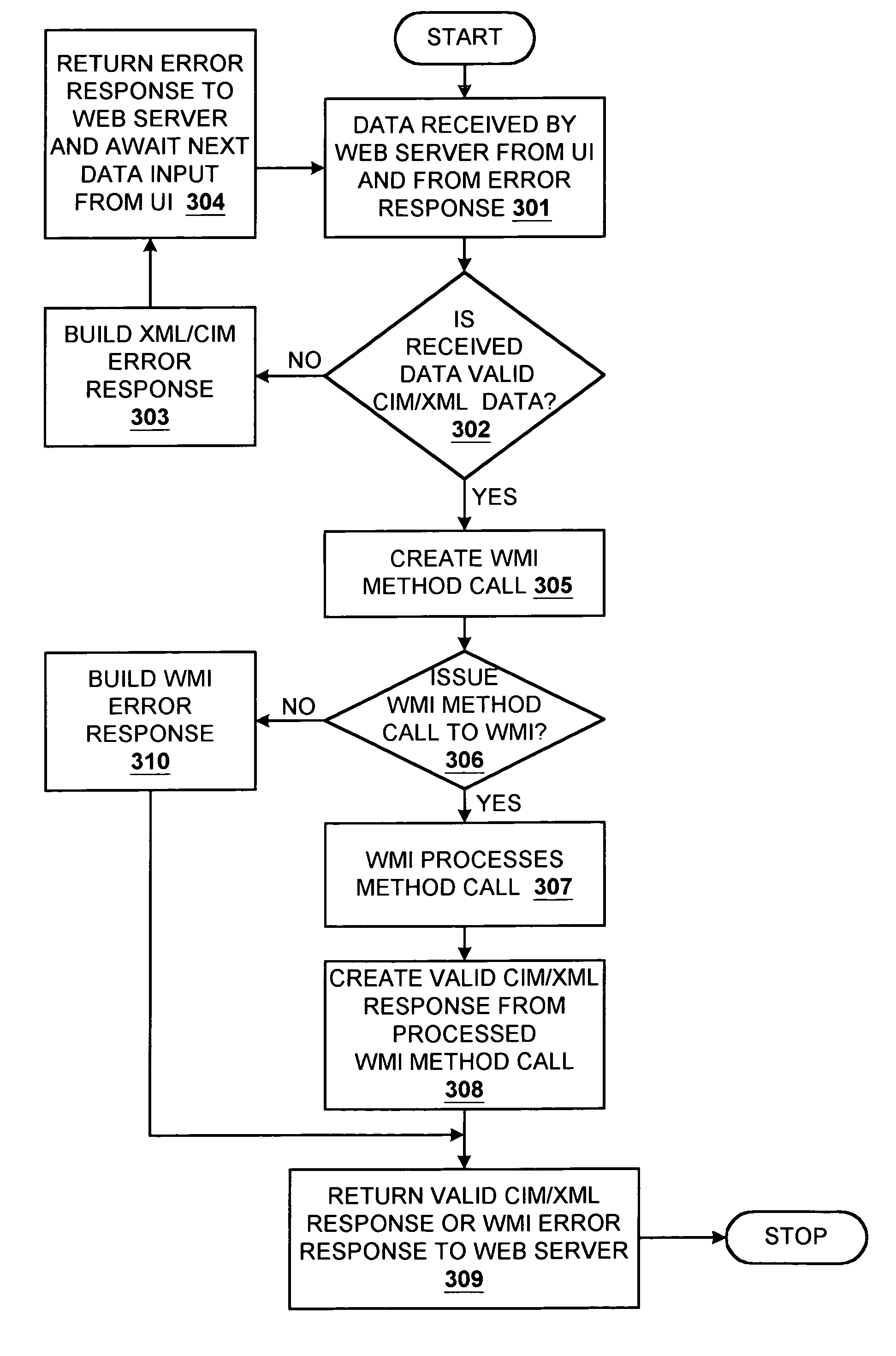

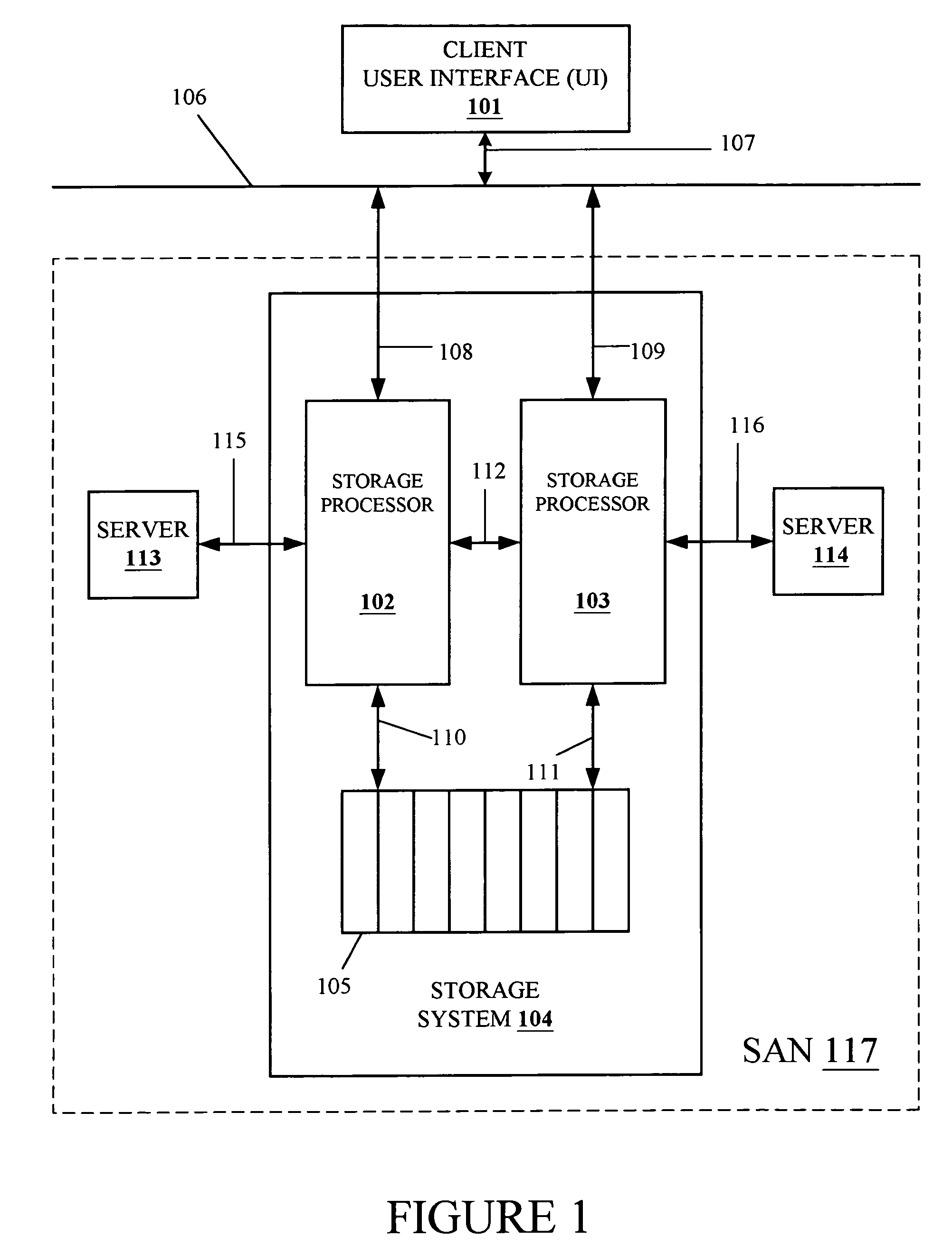

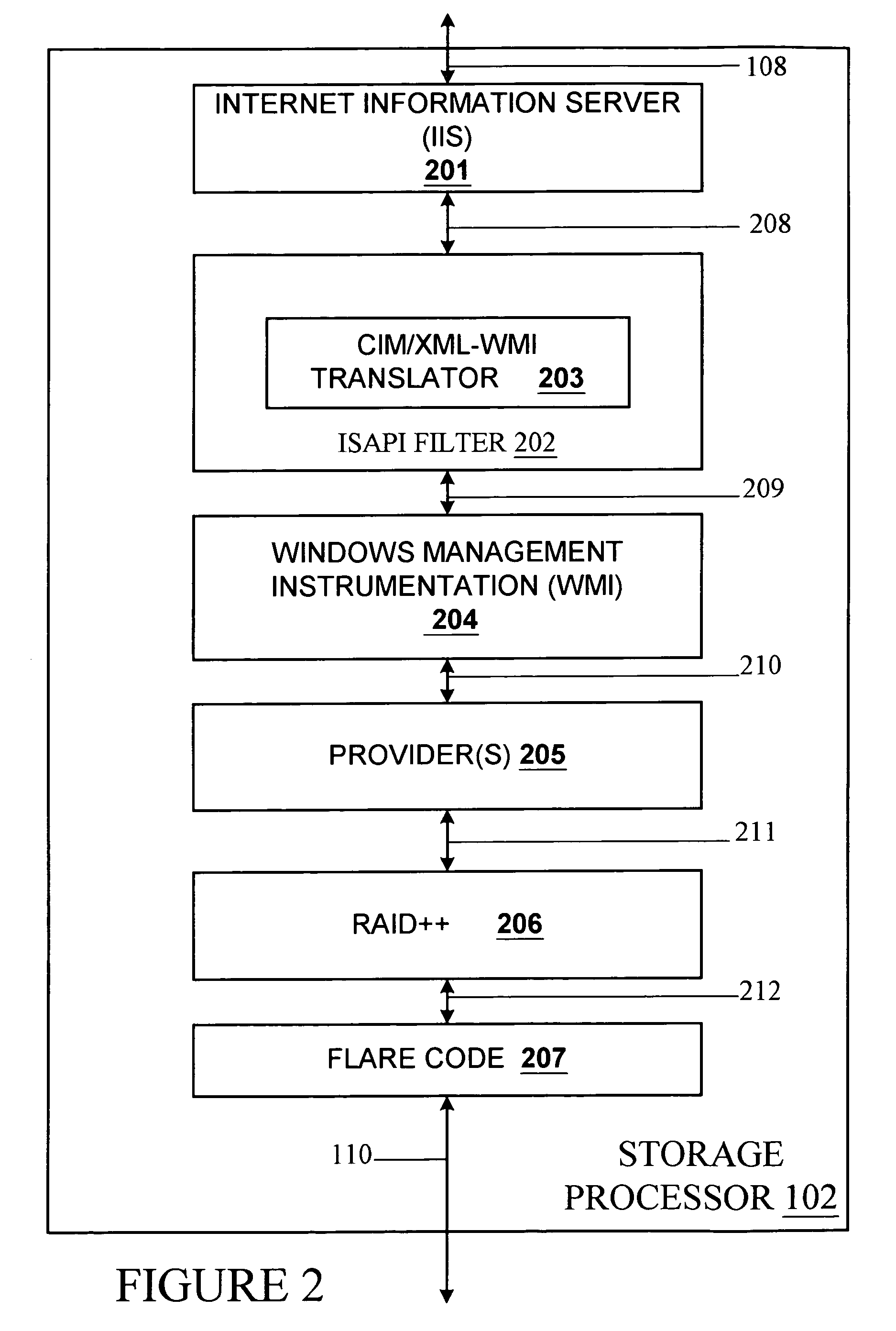

Common Information Model (CIM) translation to and from Windows Management Interface (WMI) in client server environment

InactiveUS6971090B1Interprogram communicationTransmissionComponent Object ModelDistributed Component Object Model

A protocol translator for use in a storage system or storage area network for translating between incompatible communication protocols. Apparatus, methodology, computer program product and interface embodiments are disclosed, and code examples are provided, for translating between Common Information Model / eXtensible Markup Language / Hyper Text Transfer Protocol (CIM / XML / HTTP) and Windows Management Interface / Distributed Component Object Model (WMI / DCOM) communication protocols for distributed management software used within a storage system or storage area network in a client server environment.

Owner:EMC IP HLDG CO LLC

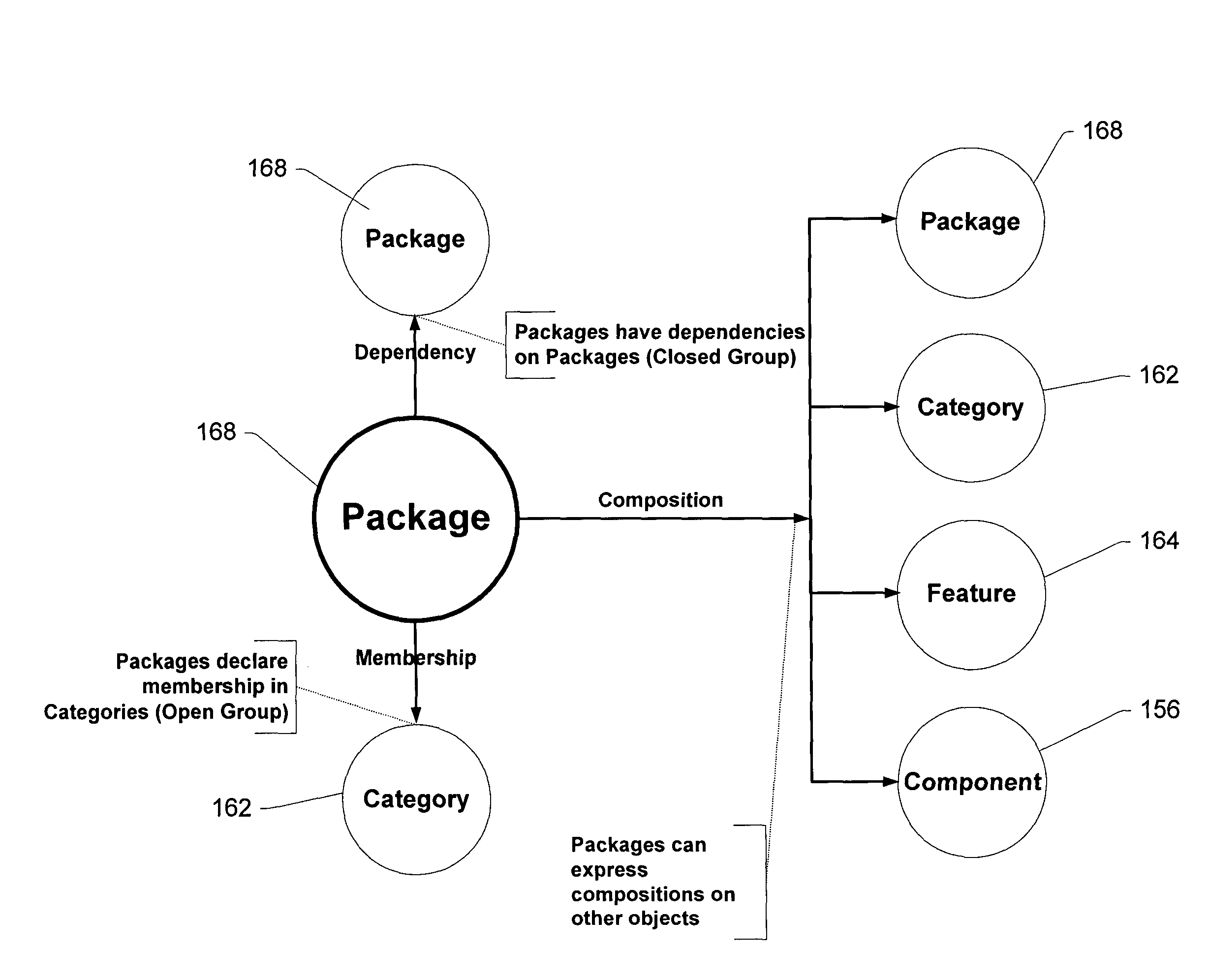

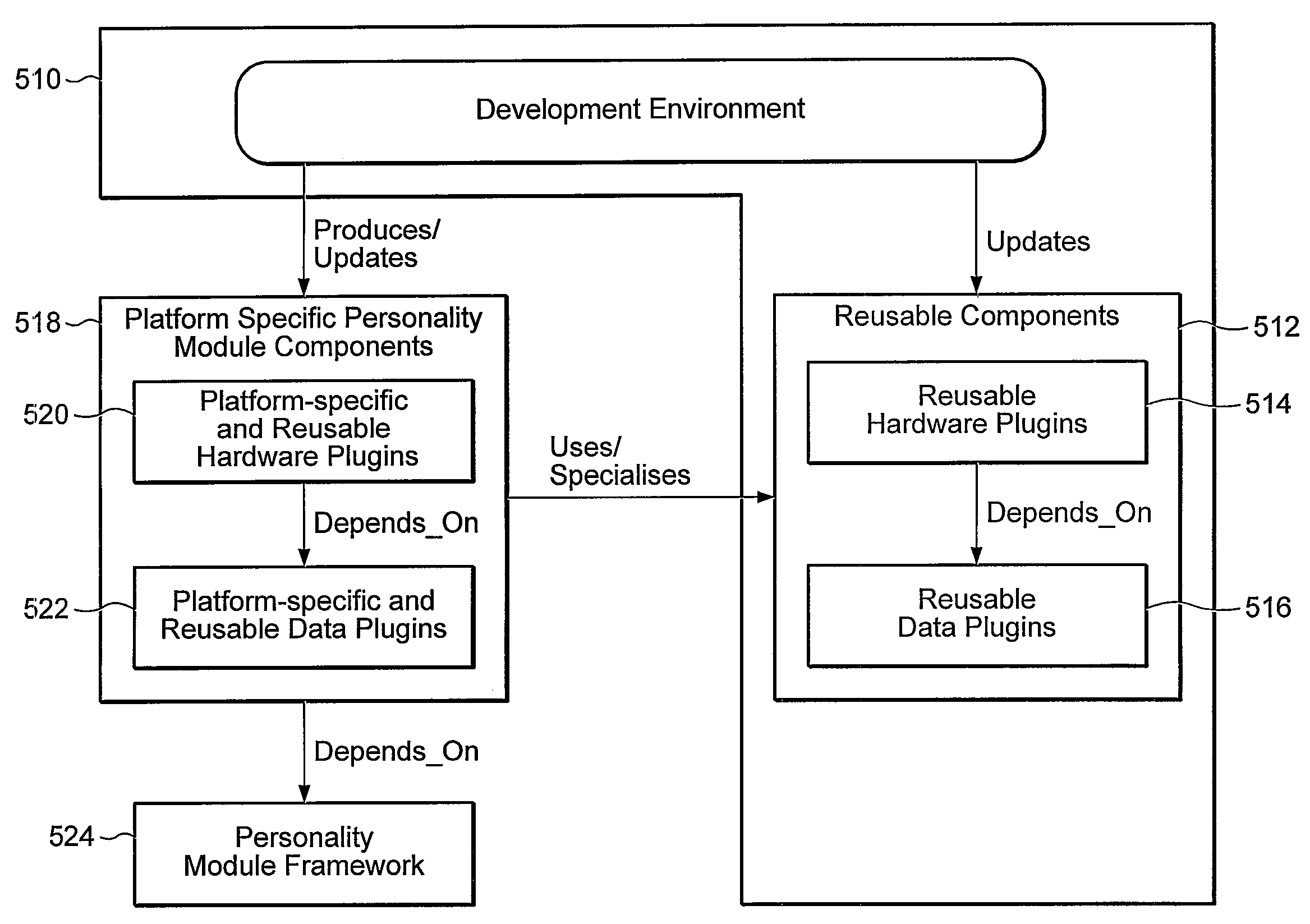

Software componentization for building a software product

ActiveUS7562346B2Easy to createLess laborLink editingProgram control using stored programsComponent Object ModelOperational system

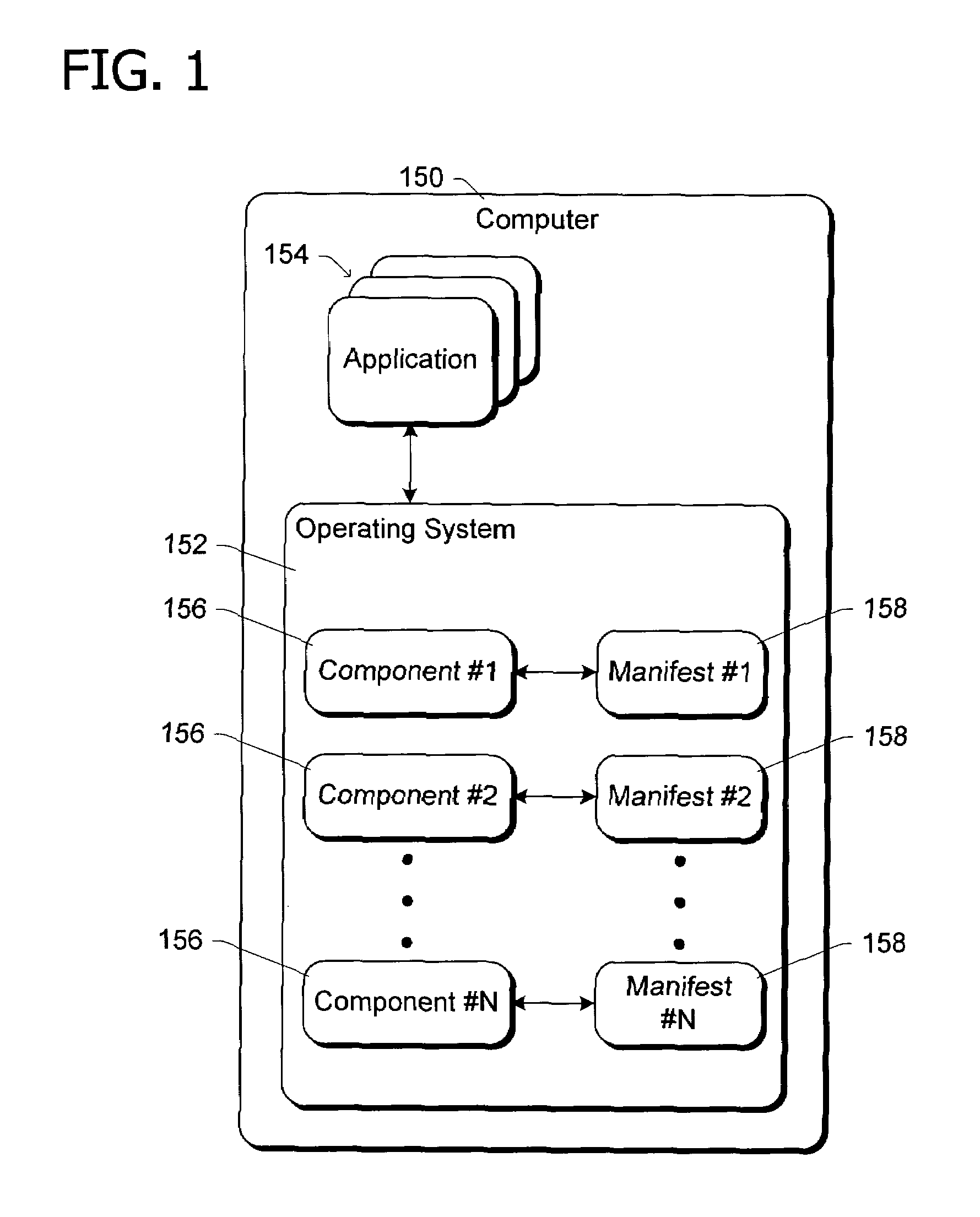

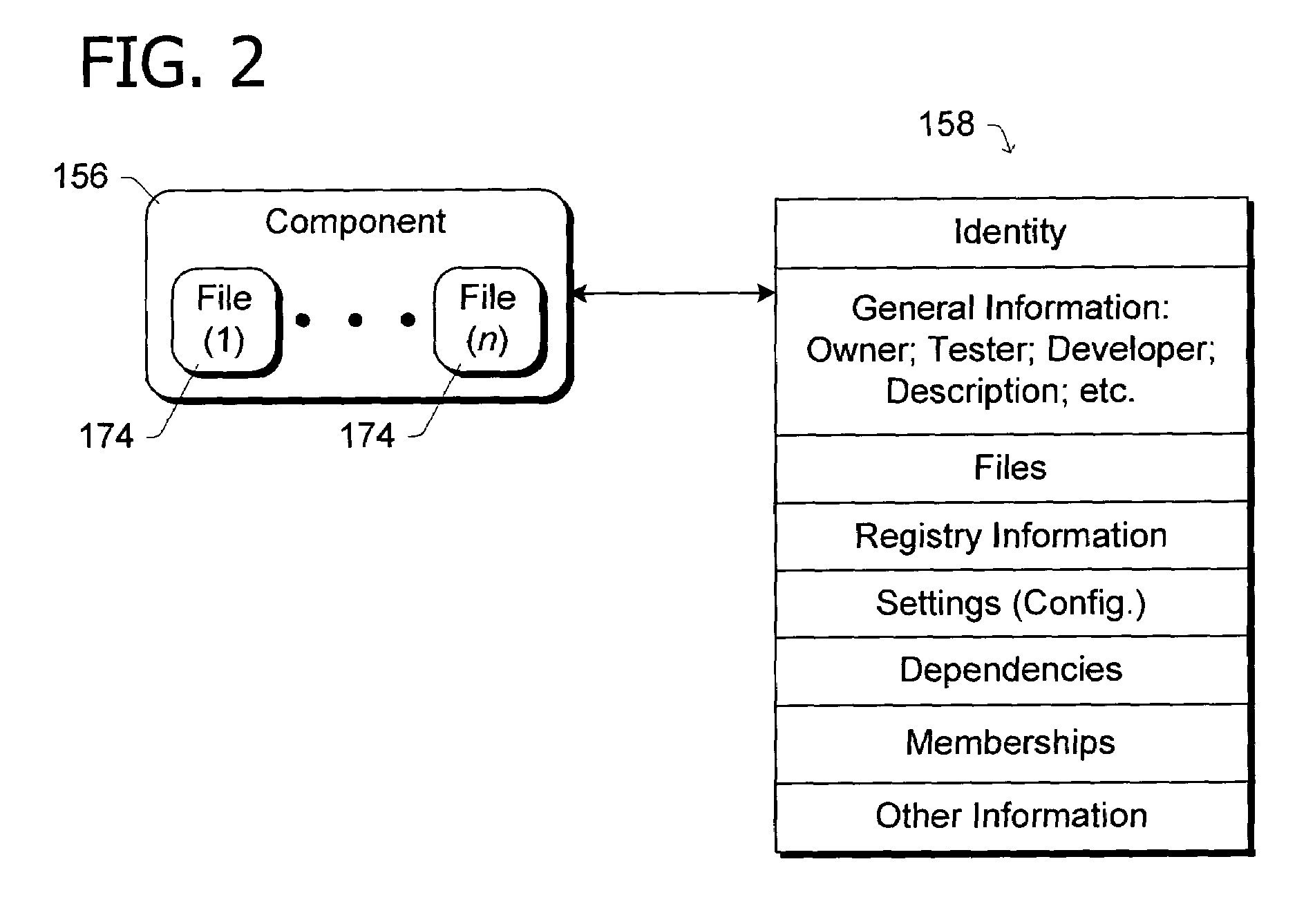

A componentization schema representing files from which an operating system or other software product is built. According to the schema, a component object represents one or more of the files. The component object has a manifest that identifies the component and specifies any dependencies between the component and other objects. Grouping objects according to the dependencies specified in manifests permits building the software product. A feature object defined by at least one component object represents a feature of the software product and a product object defined by at least one feature object represents the software product.

Owner:MICROSOFT TECH LICENSING LLC

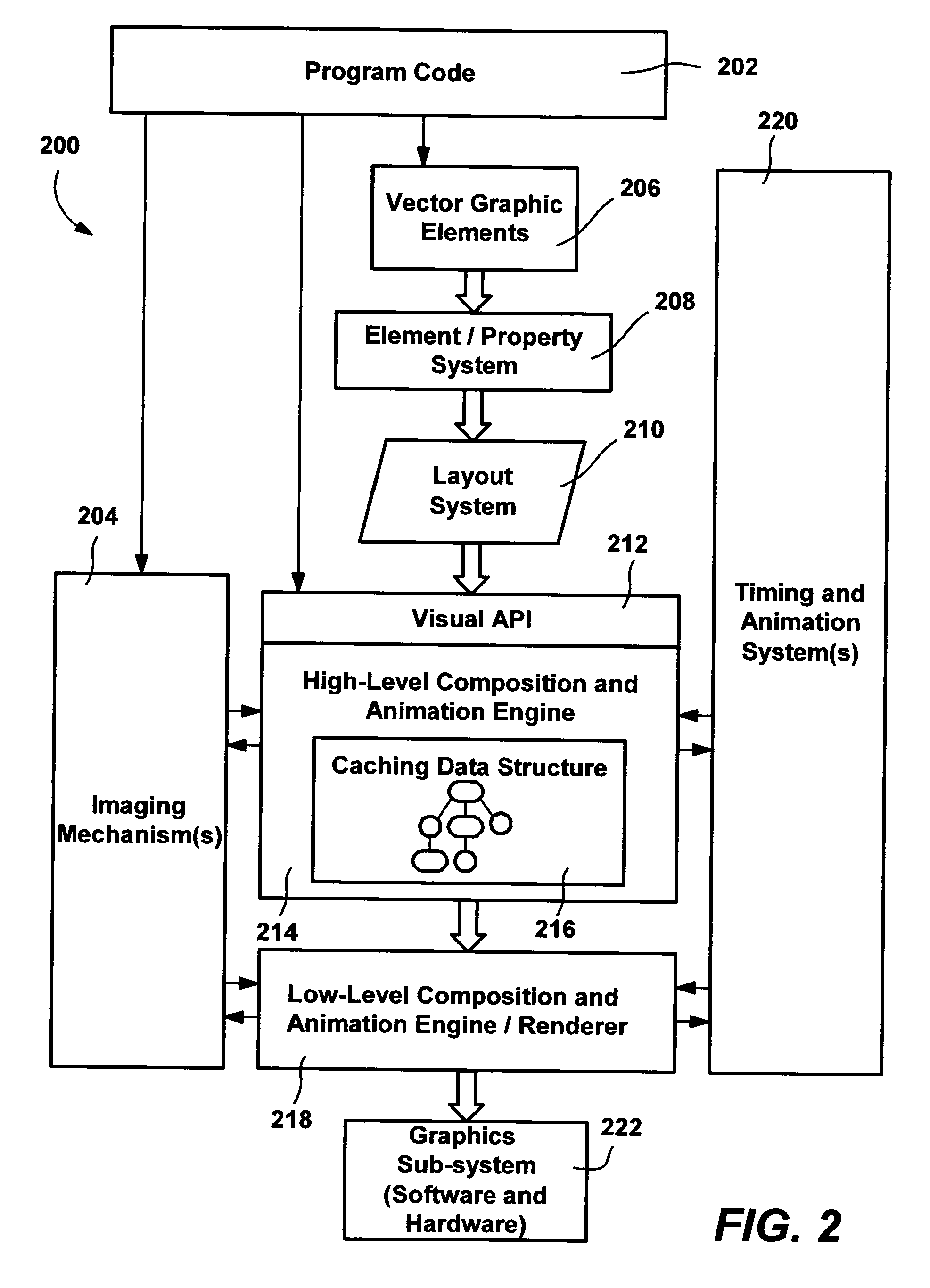

Markup language and object model for vector graphics

InactiveUS7417645B2Consistent interfaceComplex designDrawing from basic elementsCathode-ray tube indicatorsComponent Object ModelDocument Object Model

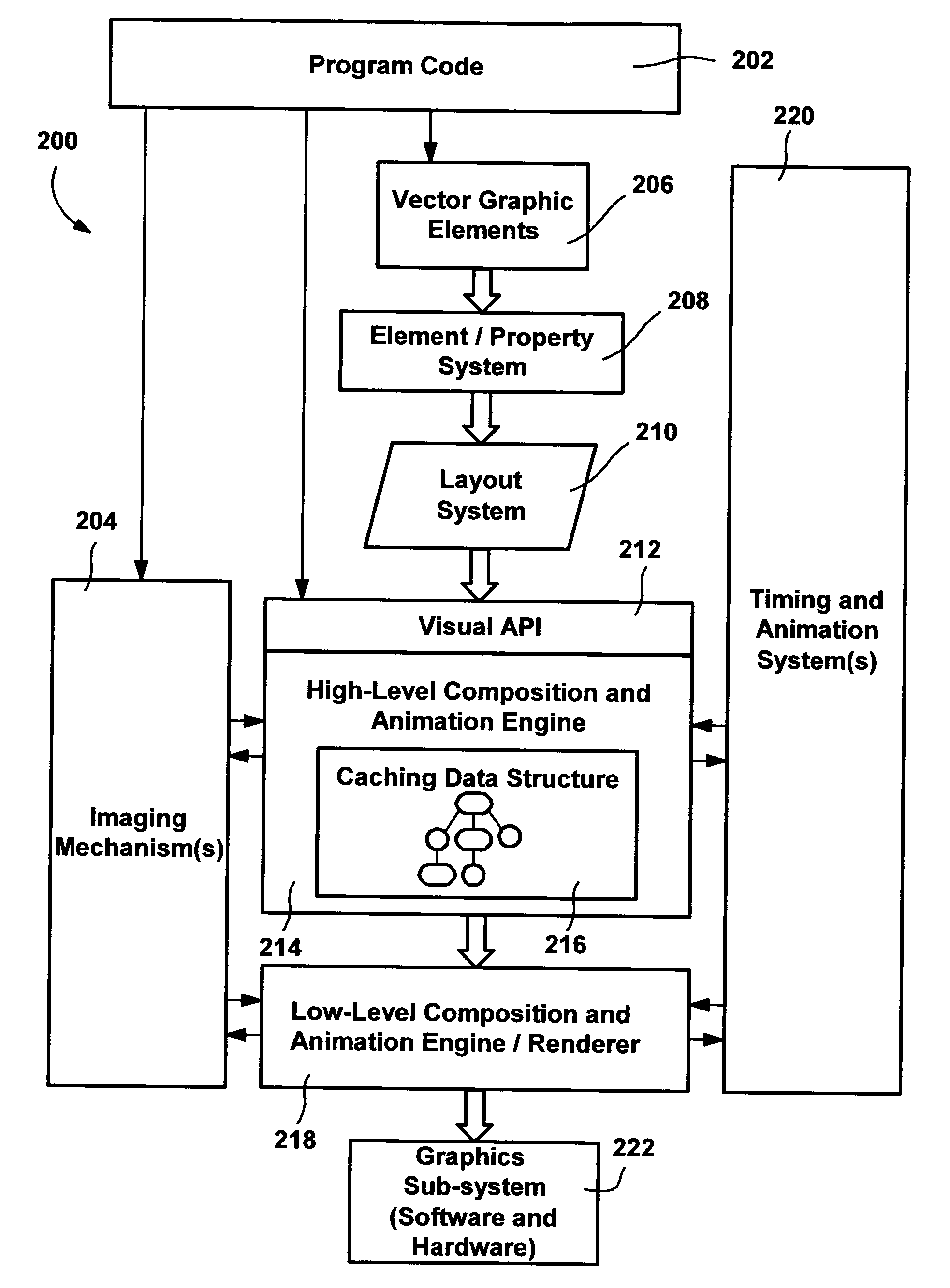

An element object model and a vector graphics markup language for using that element object model in a manner that allows program code developers to consistently interface with a scene graph data structure to produce graphics. The vector graphics element object model generally corresponds to shape elements and other elements including image and video elements that correlate with a scene graph object model of the scene graph. Markup may be parsed into data including elements in an element tree that is translated into the objects of a scene graph data structure. Other markup may be translated directly into data and calls that create the scene graph objects. The markup language provides distinct ways to describe an element, including a simple string format or complex property syntax, which may be named, enabling reuse in other locations in the markup.

Owner:MICROSOFT TECH LICENSING LLC

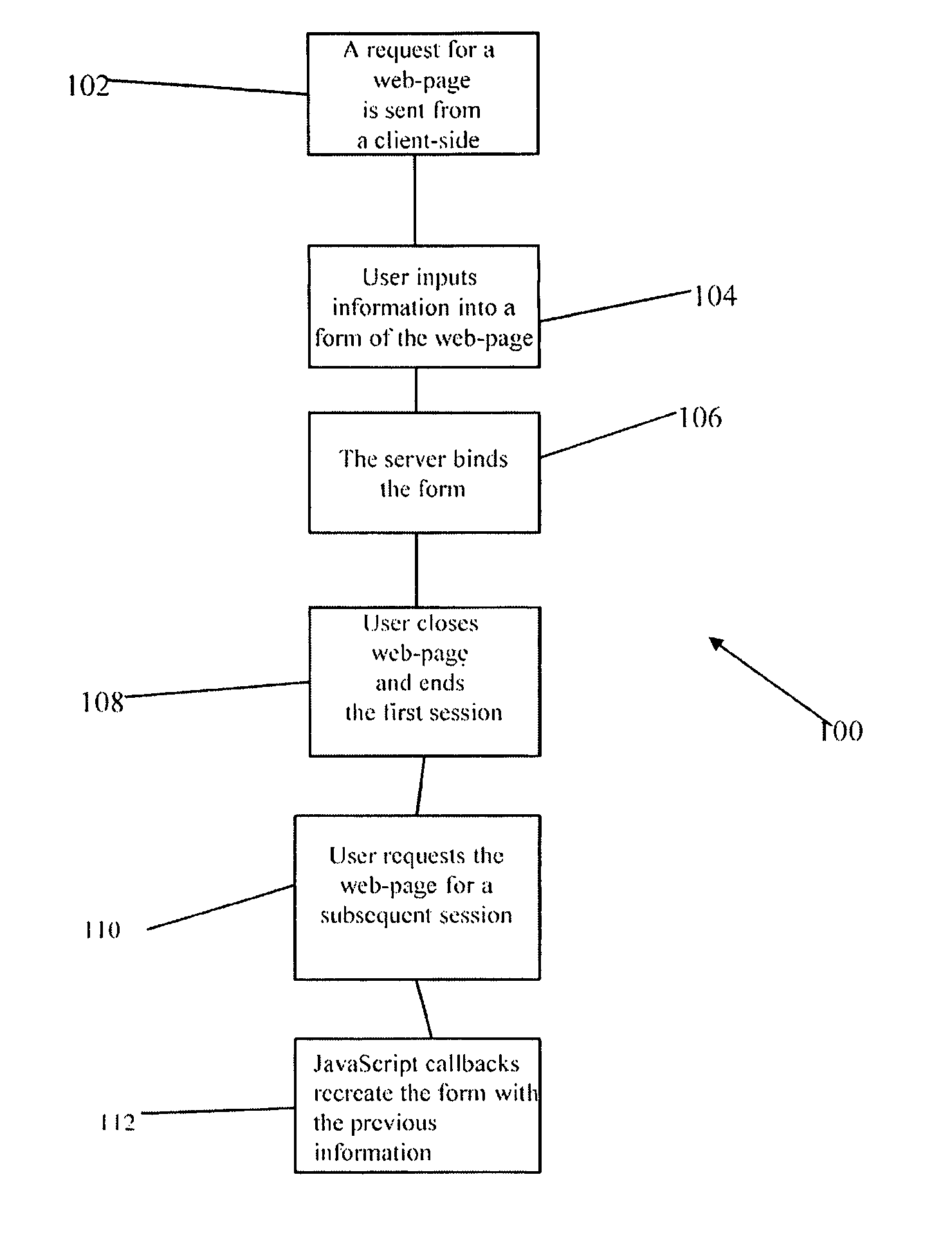

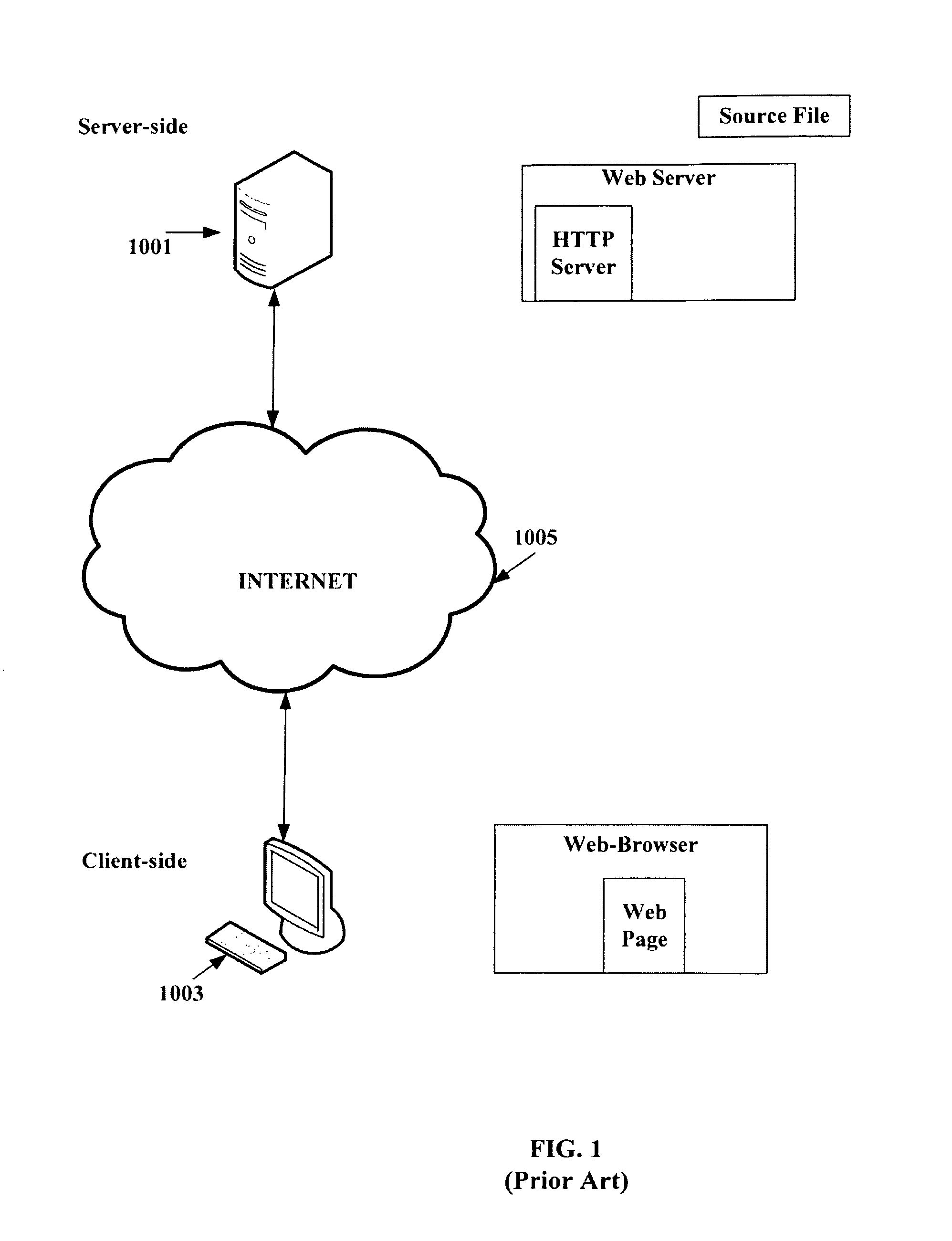

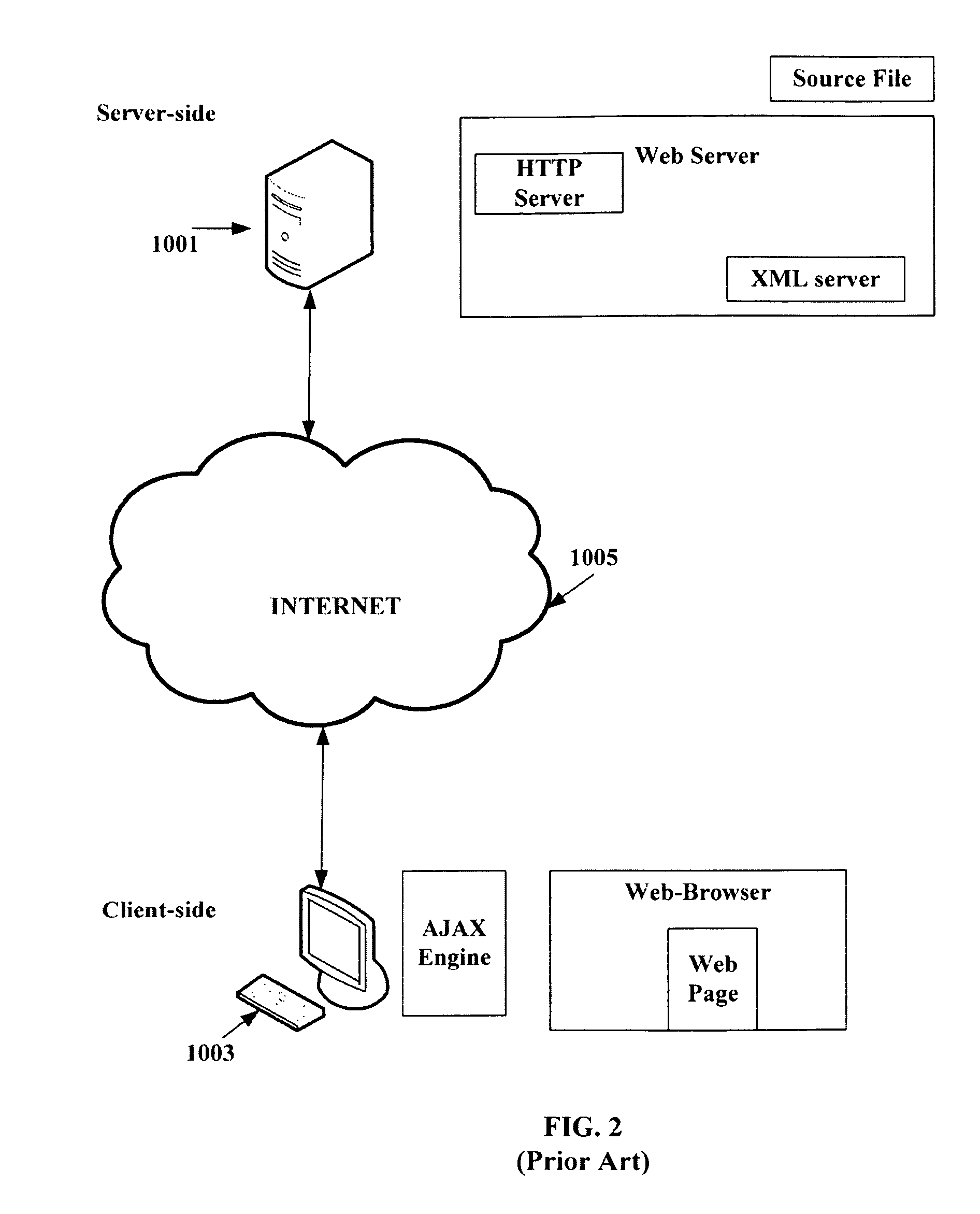

System and method for binding a document object model through JavaScript callbacks

ActiveUS8335982B1Reduce in quantityEasy to cacheProgram controlSpecial data processing applicationsComponent Object ModelDocumentation

A system and method for binding a form through a JavaScript callback is disclosed herein. During a first session, inputted information in a form is bound with a plurality of JavaScript callbacks. When the session is closed and again reopened, the inputted form is called containing the information inputted from the first session.

Owner:APPCELERATOR

Capturing the visual content of browser windows

InactiveUS20110252305A1Easy to operateEfficient captureTransmissionSpecial data processing applicationsComponent Object ModelDocument Object Model

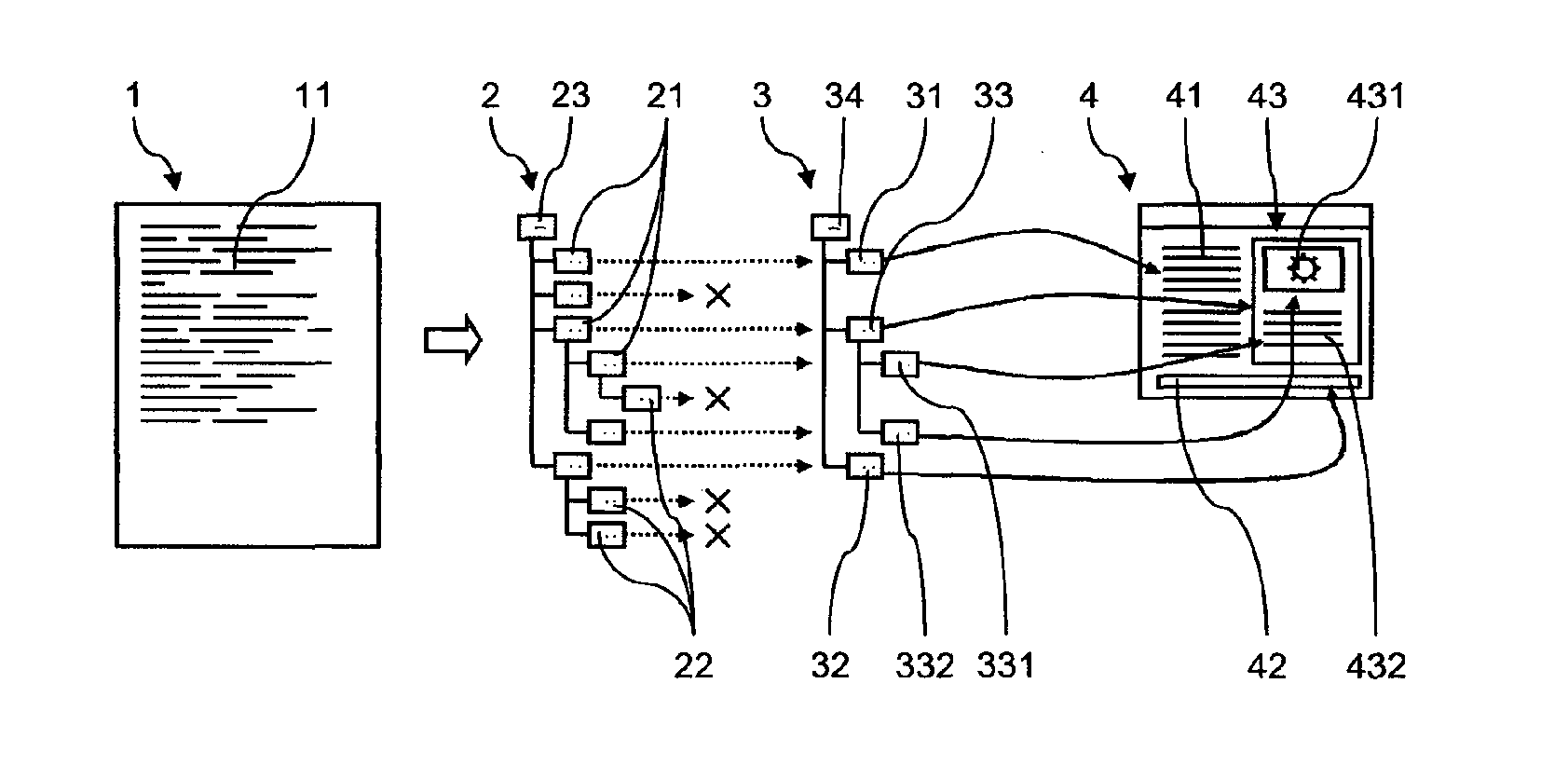

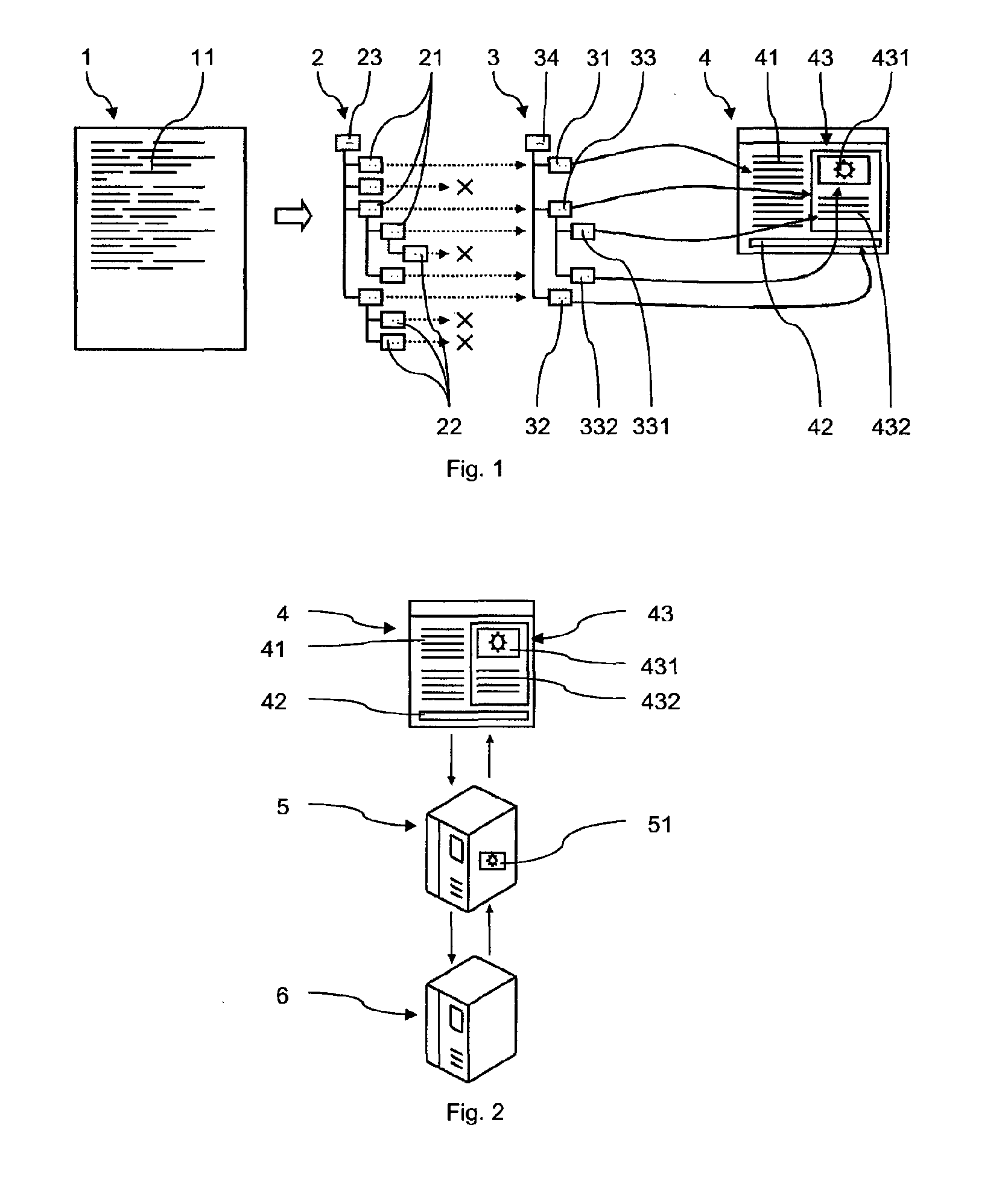

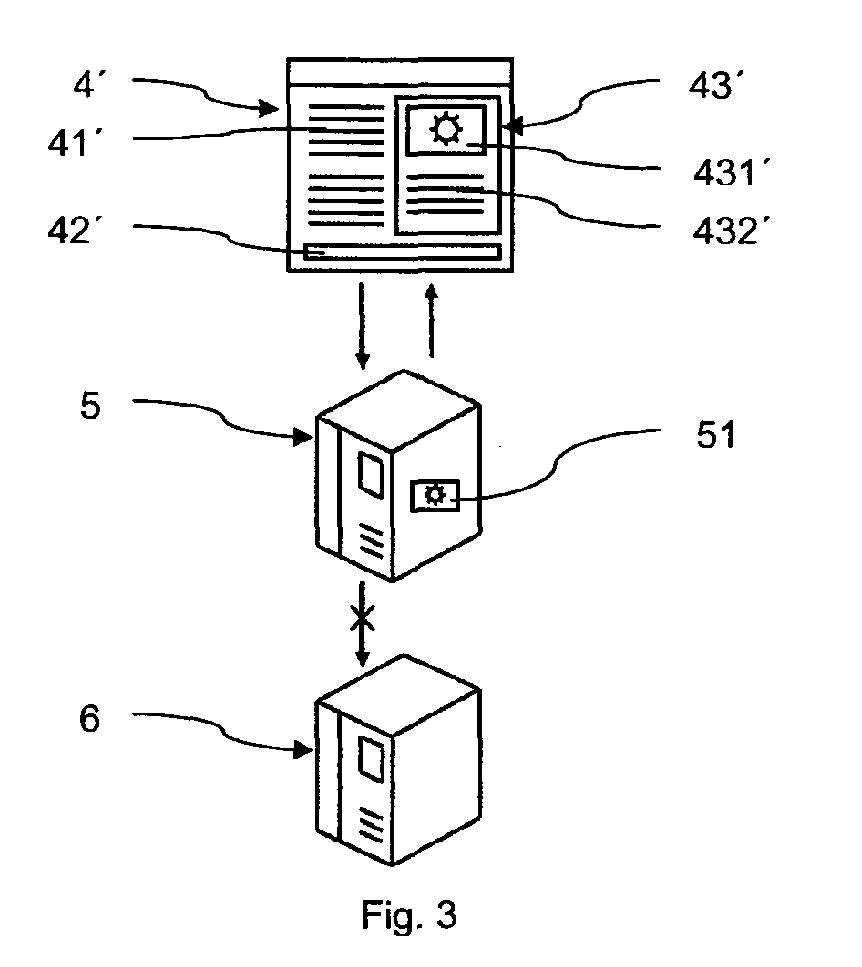

In a method for capturing the display of at least one document displayed in at least one browser display unit (4), wherein the browser display unit (4) is generated by a browser program executed on a source computer and the browser program generates a document object model (2) as interface for access to the document displayed in the browser display unit (4), the display objects (21) of the document object model (2) which are relevant to the display of the document in the browser display unit (4) are captured at least partially in a predefined data structure (3), and the document object model (2) is monitored so that changes of the display objects (21) of the document object model (2) are captured. The method of the invention enables an automated, efficient and generic capturing of the display of a document displayed by means of the browser program, for example a webpage. The method of the invention can enable an efficient operation of different appropriate applications.

Owner:UNBLU

Method for processing a document object model (DOM) tree using a tagbean

InactiveUS6981211B1Easy to replaceDigital computer detailsSemi-structured data mapping/conversionComponent Object ModelTheoretical computer science

Owner:IBM CORP

Three-dimensional reconstruction method for binocular stereo vision

InactiveCN108335350AAvoid excessive dependenceNarrow searchImage analysisImage renderingComponent Object ModelTriangulation

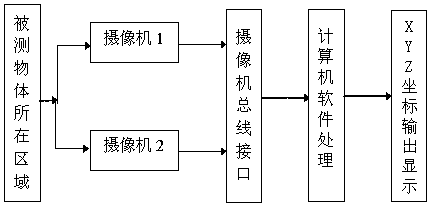

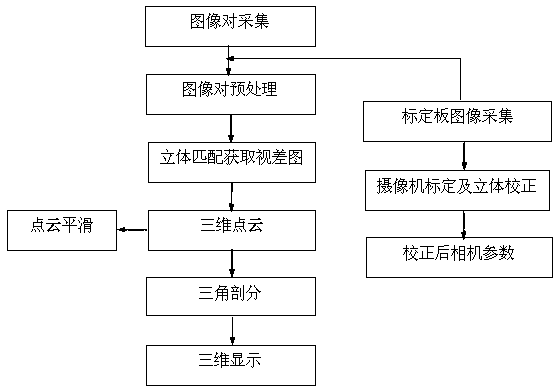

The invention provides a three-dimensional reconstruction method for binocular stereo vision. The method comprises the steps of performing image pair collection: obtaining images of a calibration plate and an object; performing camera calibration: performing calibration on a camera based on a Zhengyou Zhang calibration method to obtain initial internal and external parameters of the camera; performing stereo rectification: performing rectification on a distortion parameter through epipolar constraint to obtain a rectified image pair; performing image processing: obtaining a region of interest,and balancing brightness difference between left and right images, thereby searching for matching points; performing stereo matching: implementing a multi-grid intensive stereo matching algorithm toobtain a continuous smooth disparity map; and performing point cloud rebuilding and model rebuilding: obtaining a point cloud chart of the object, performing point cloud optimization, and obtaining acomplete object model through triangulation of a greedy algorithm. The smooth model with no obvious difference with the real object can be obtained; and the method can be used for three-dimensional reconstruction of multiple scenes.

Owner:LIAOCHENG UNIV

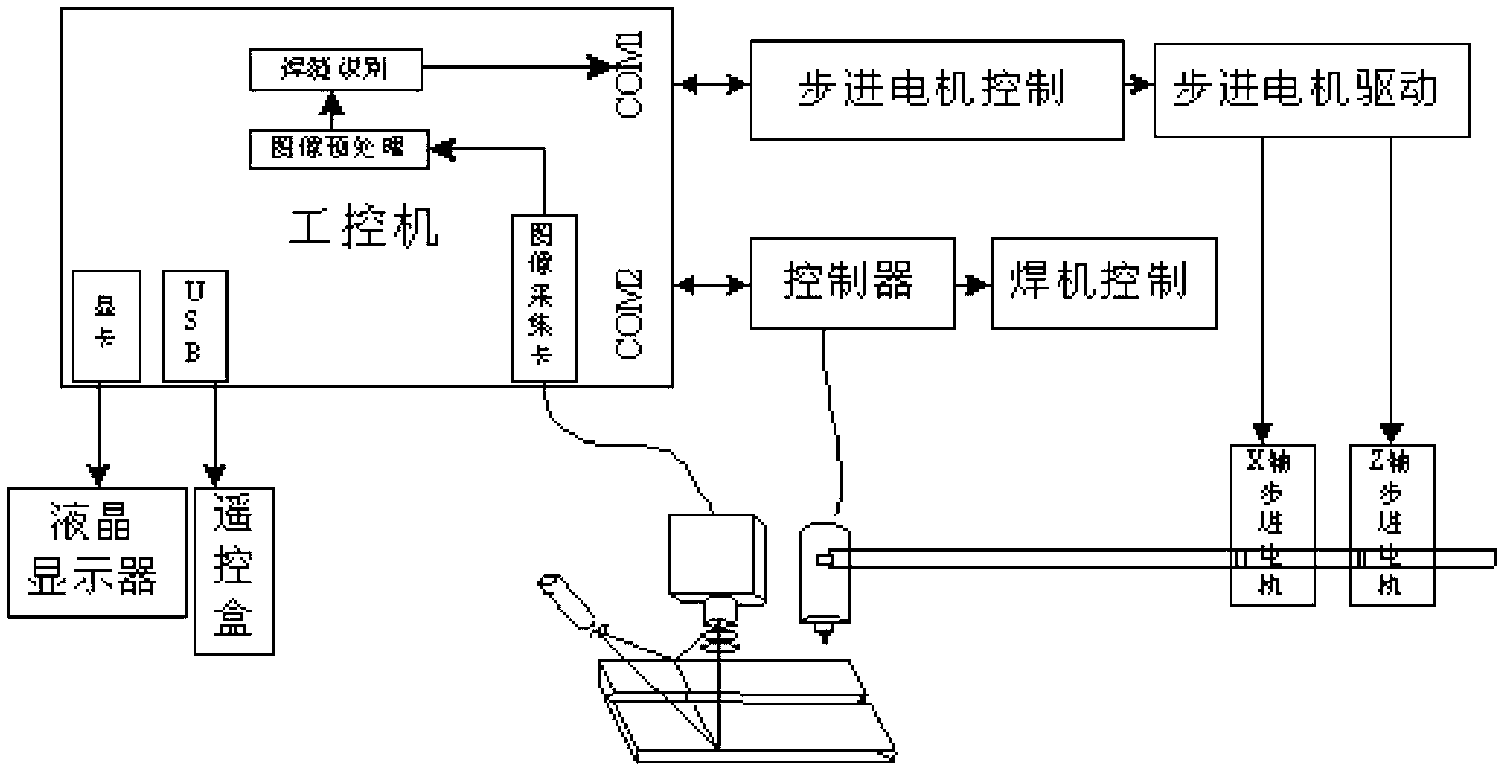

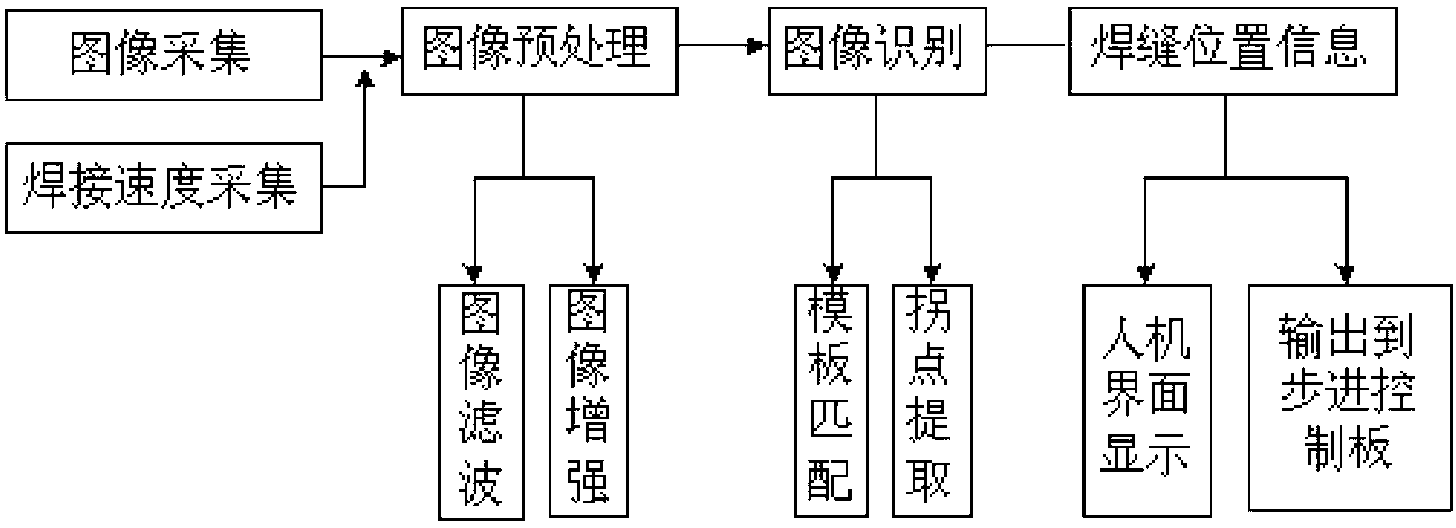

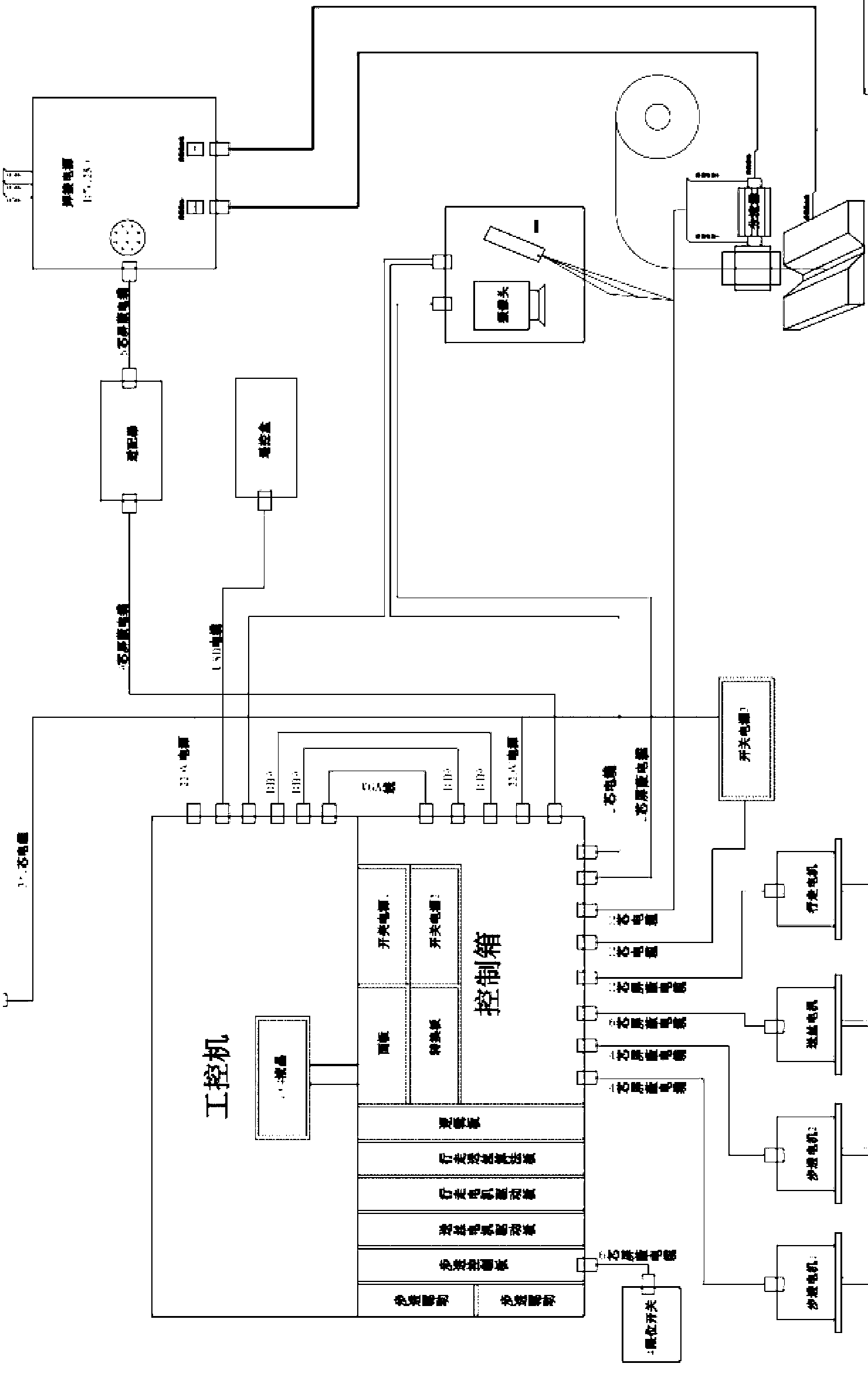

Laser visual tracking system

InactiveCN103203526AImprove anti-interference abilityEliminate lead errorArc welding apparatusComponent Object ModelMachine control

The invention discloses a laser visual tracking system, which mainly comprises an industrial personal computer, wherein a COM 1 (Component Object Model) port of the industrial personal computer is connected with an X axis motor and a Z axis motor through a motor control and drive circuit; output ends of the X-axis motor and the Z-axis motor are connected with a welding torque; the controller of the welding torque and a welding machine control circuit are connected with the industrial personal computer; the industrial personal computer is also connected with a laser sensor for acquiring information on the welding torque and a workpiece in real time and delivering the acquired information to the industrial personal computer; the laser sensor is a visual sensing module and mainly comprises a camera and a laser diode; the camera is vertically aligned with the workpiece; a laser is slantwise arranged and forms an angle of 30 degrees with the laser; laser emitted by the laser irradiates the workpiece to form a narrow light strip; after the light strip is reflected or refracted by the workpiece, the light strip enters the camera to image, and the image is transferred to the industrial personal computer for processing; after the image is analyzed and processed by the industrial personal computer, an action command is emitted to the welding torque, the X-axis motor and the Z-axis motor.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

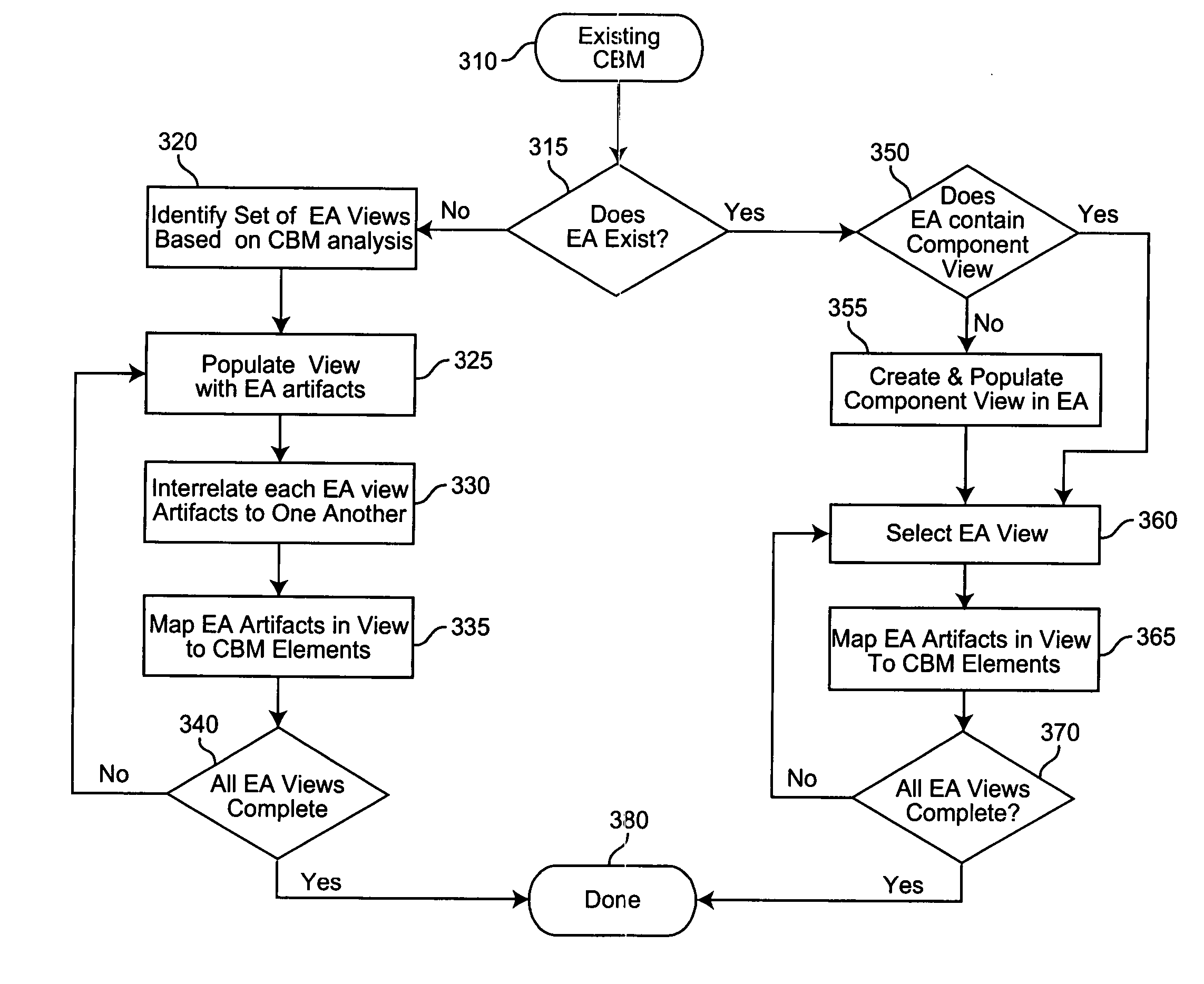

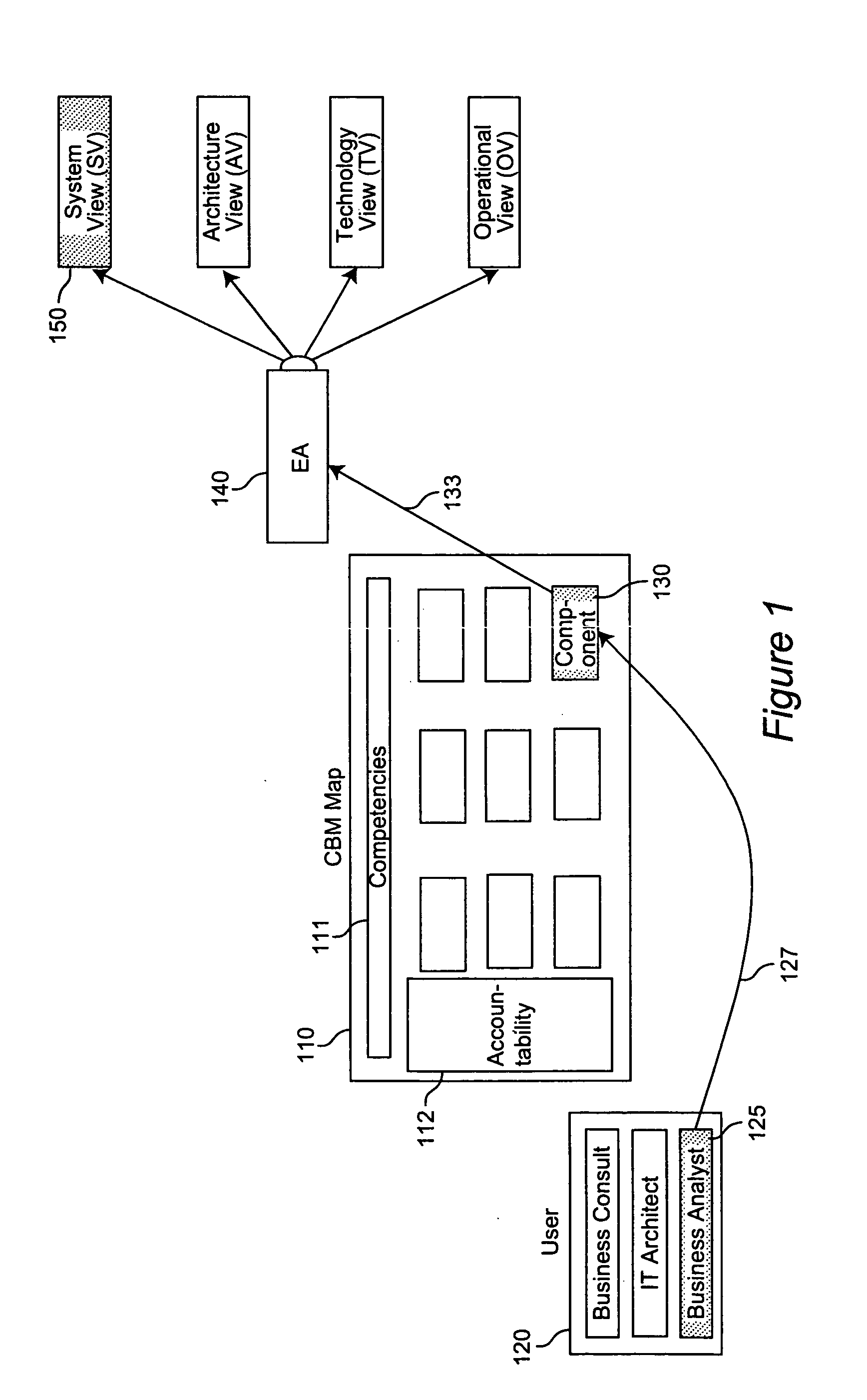

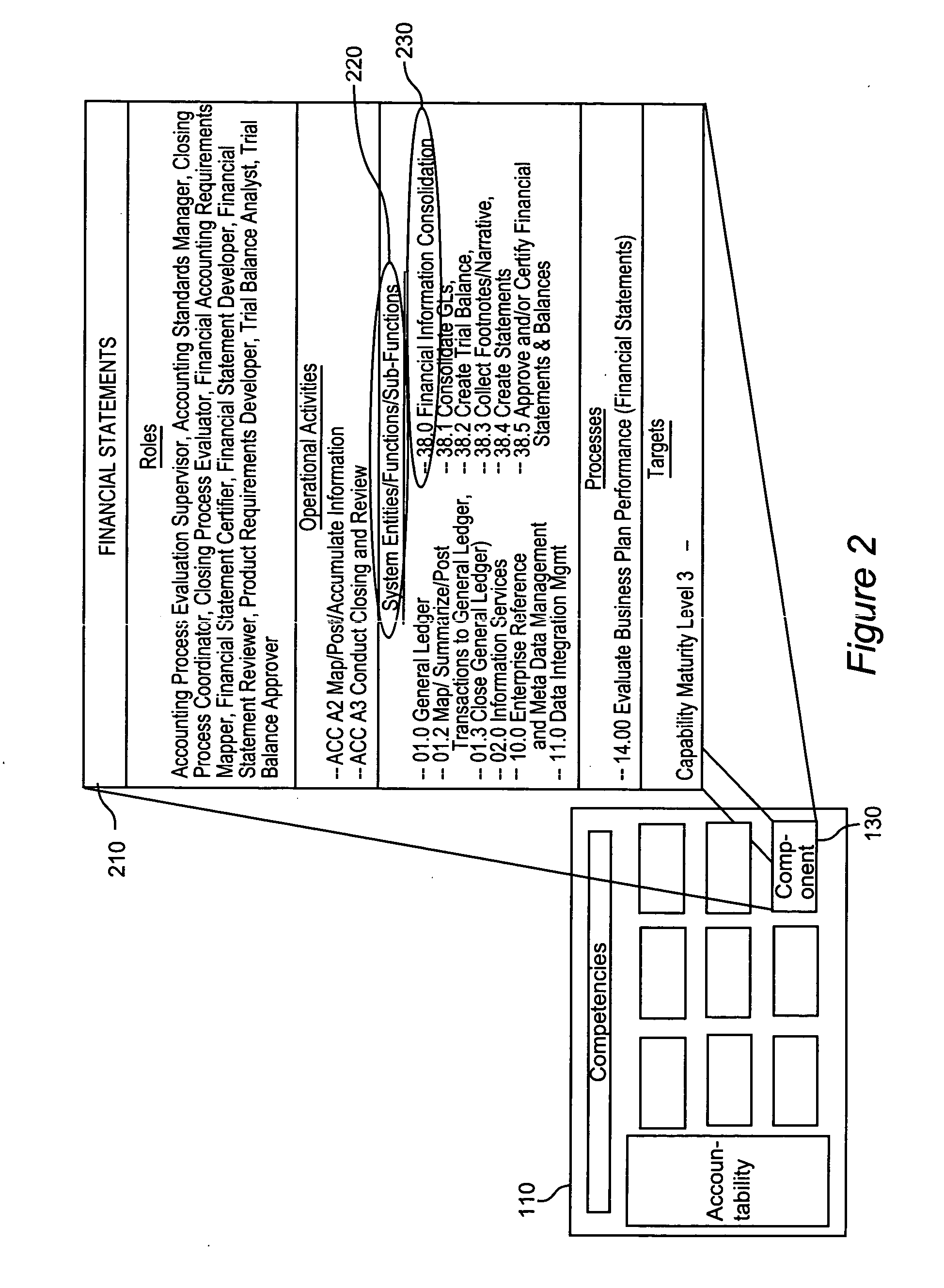

Method and system for constructing, managing and using enterprise architecture in a component busines model

InactiveUS20070021993A1Eliminate duplicationFacilitating creation and modification and useOffice automationResourcesComponent Object ModelComponent business model

A method and system is described for an enterprise architecture being viewed through a component business model of an organization, where the artifacts of the enterprise architecture are mapped to corresponding elements of the component business model. A metamodel is used to integrate a model of the enterprise architecture with the component business model. Views of the enterprise architecture are coupled to the layers of a component business model stack.

Owner:IBM CORP

Management object model for performing management of a computer system

ActiveUS7665071B1TransmissionSpecific program execution arrangementsComponent Object ModelManagement object

A management system is provided for the generation of a management object model for performing management of a computer system. The object model includes a structured hierarchy of objects representing components of a computer system. The management system can include component modules operable to define mappings from instrumentation of the components to objects representing those components and configuration modules operable to configure associations between the component modules for the generation of the management object model.

Owner:ORACLE INT CORP

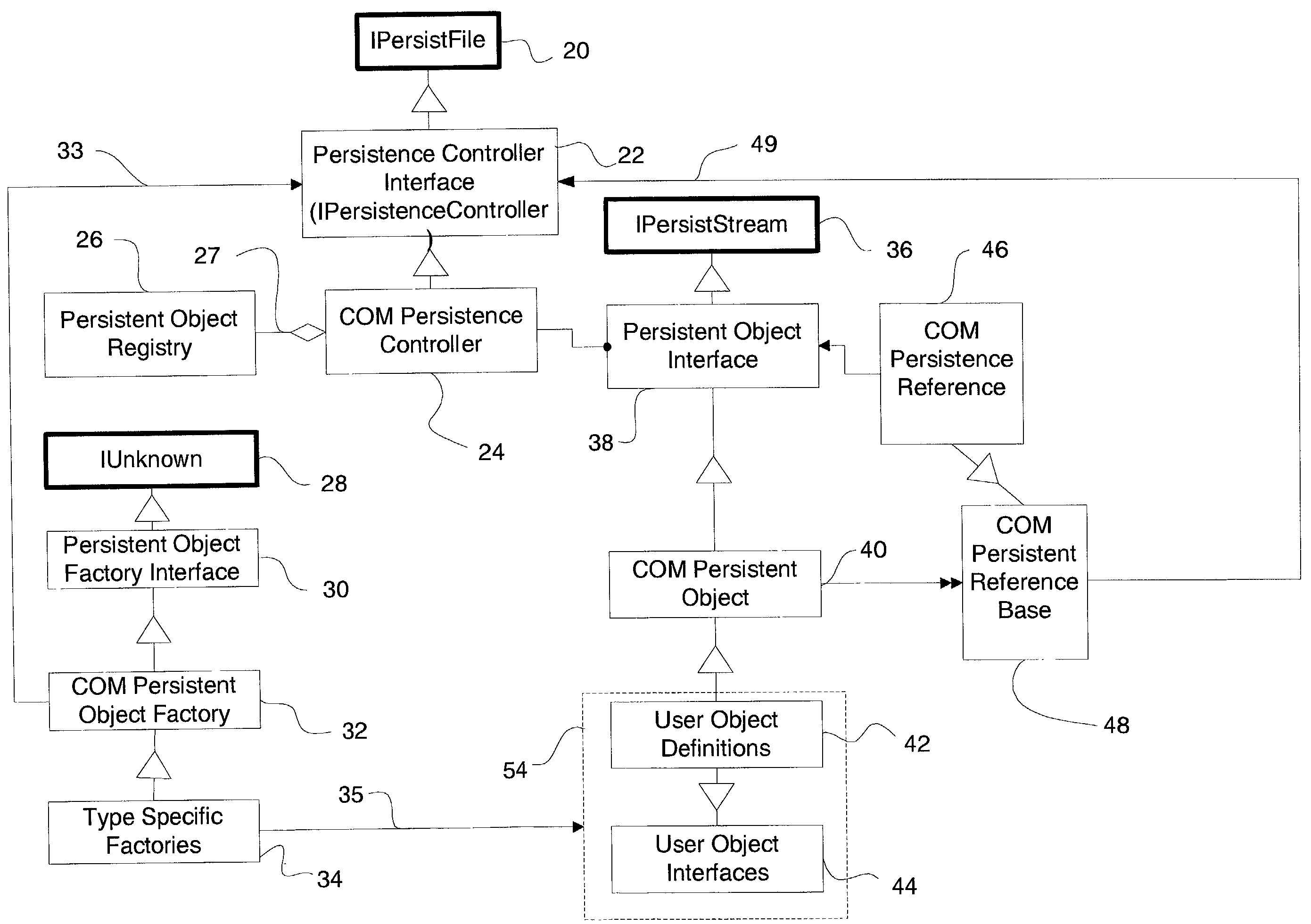

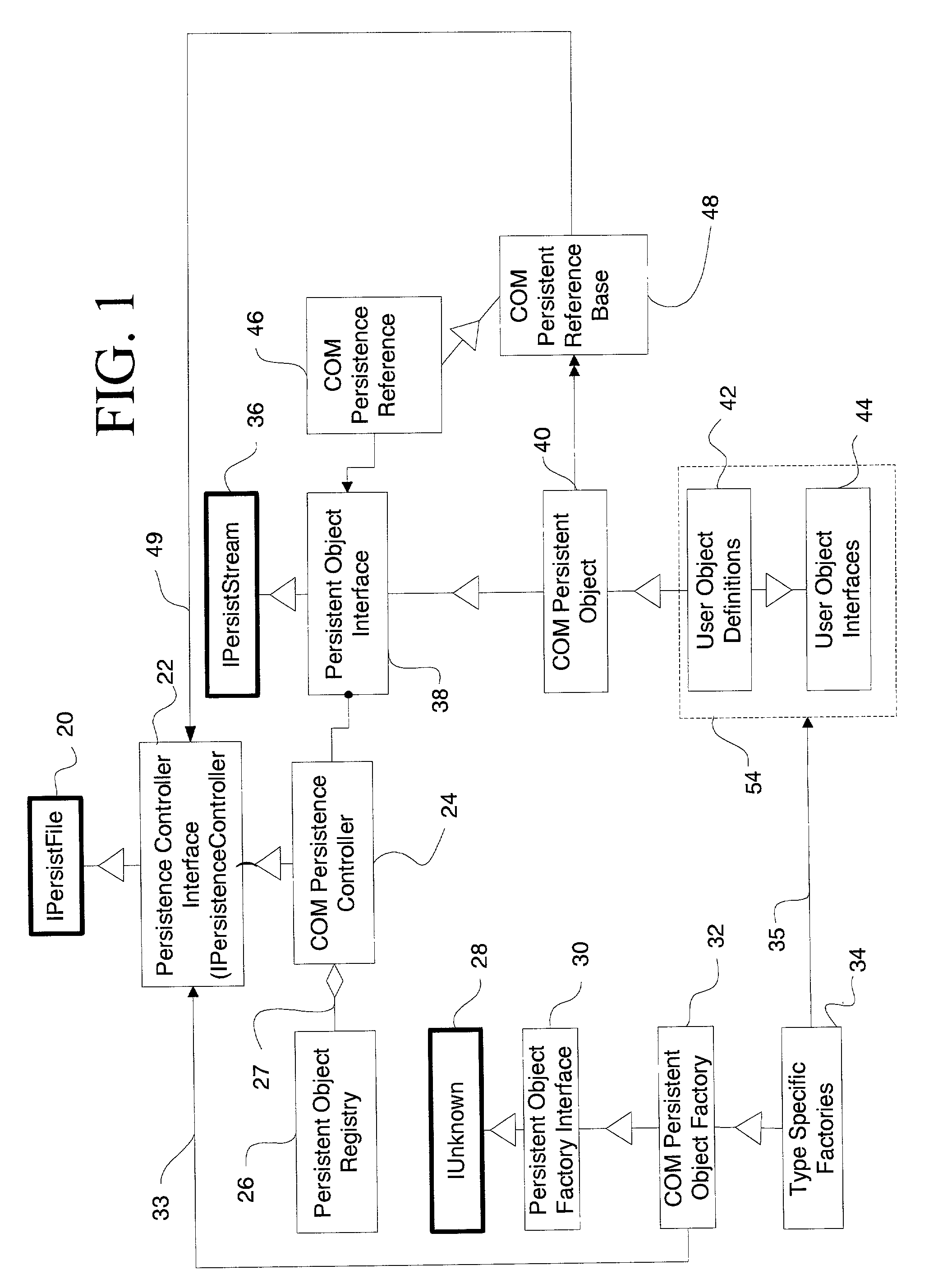

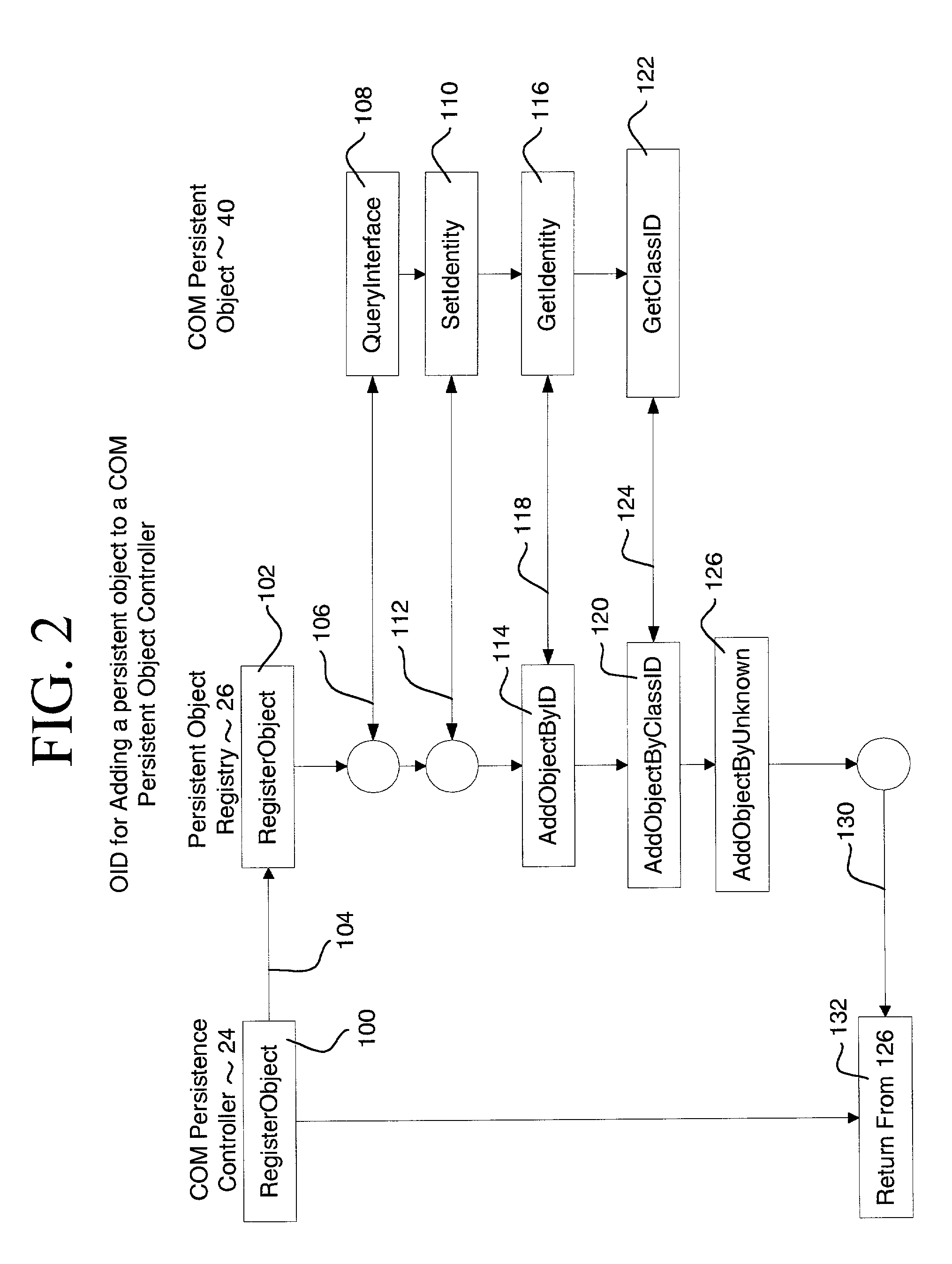

COM persistence model

InactiveUS7069540B1Specific program execution arrangementsMemory systemsComponent Object ModelLoad cycle

Software and methods for extending preexisting objects to support persistence. One use of the present invention is to extend component object model (COM) objects to support persistence in a simple, predefined system. COM objects may be saved to persistence storage and loaded from persistence storage using user-provided save and load methods. When objects are constructed, the objects are added to a Persistent Object Registry. Objects preferably utilize smart pointers, rather than simple pointers, in order to enable restoration of the pointer values after a save and load cycle. The smart pointers include an object ID along with the address. The object ID, together with the information stored in the Persistent Object Registry, may be used to restore a pointer value after loading. Objects may be saved by streaming the objects out and loaded by streaming the objects back into memory from a file.

Owner:UNISYS CORP

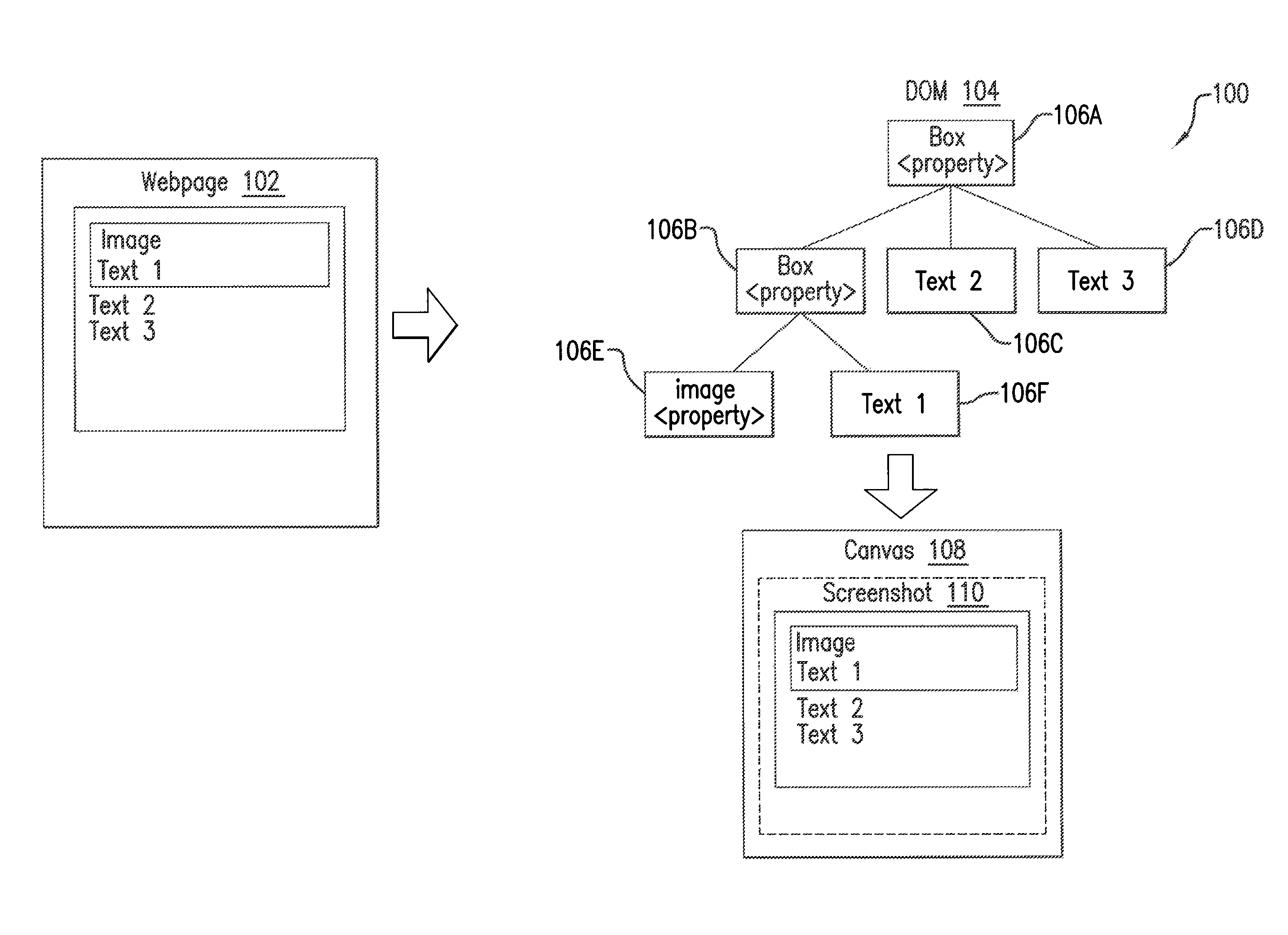

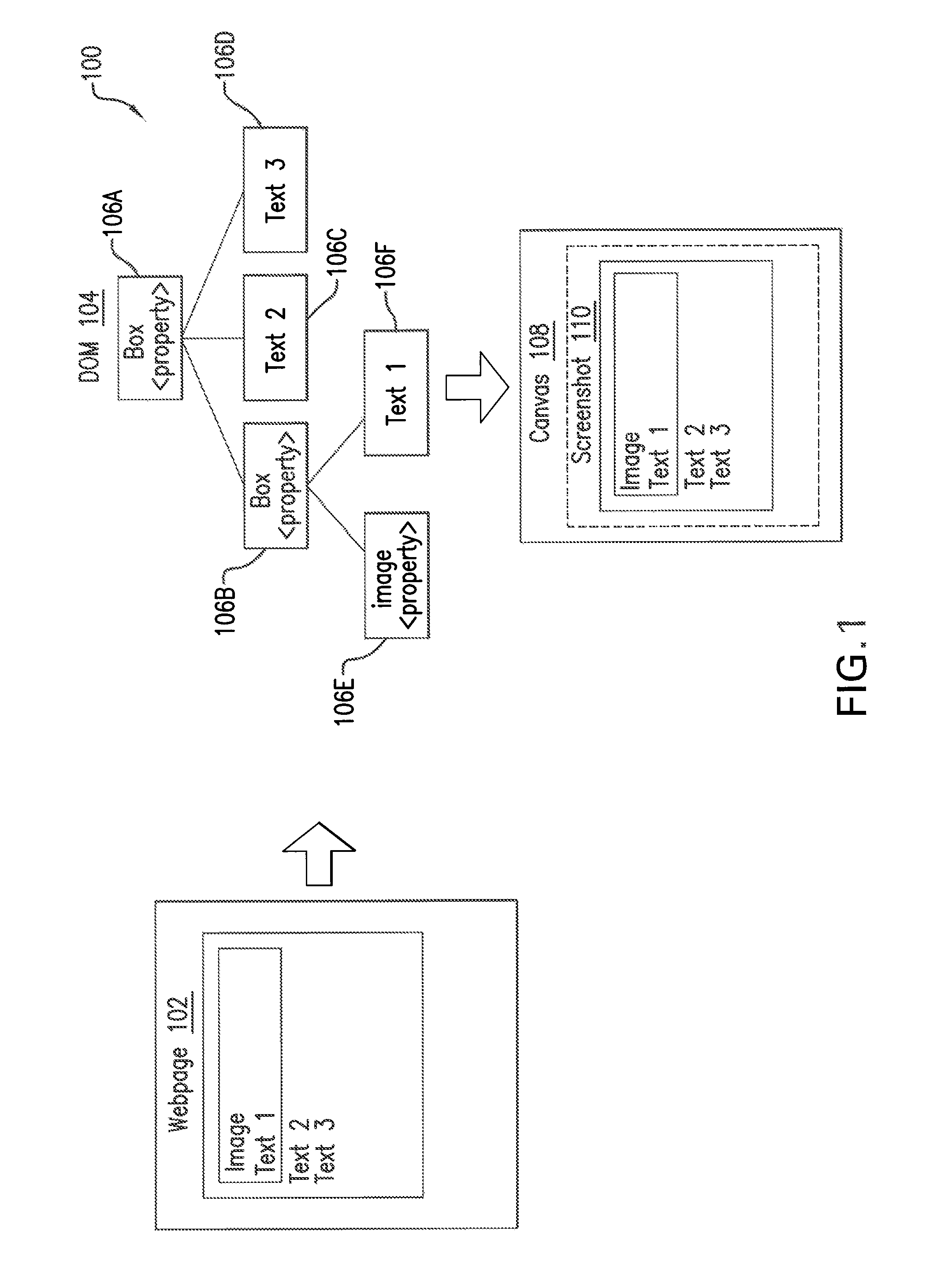

Rendering approximate webpage screenshot client-side

ActiveUS8225197B1Web data indexingExecution for user interfacesComponent Object ModelComputer graphics (images)

Methods, systems, and apparatuses, including computer programs encoded on a computer storage medium, for rendering an approximate webpage screenshot client-side are disclosed. A system may receive an indication to render a screenshot of a webpage presented on the client device, and create a canvas at the client device. The system may traverse a document object model (DOM) of the webpage, whereby for each of one or more nodes in the DOM, the system may identify a property of a respective node and render data in the respective node on the canvas based on the property.

Owner:GOOGLE LLC

Main steam temperature predictive control method of ultra supercritical unit of thermal power plant

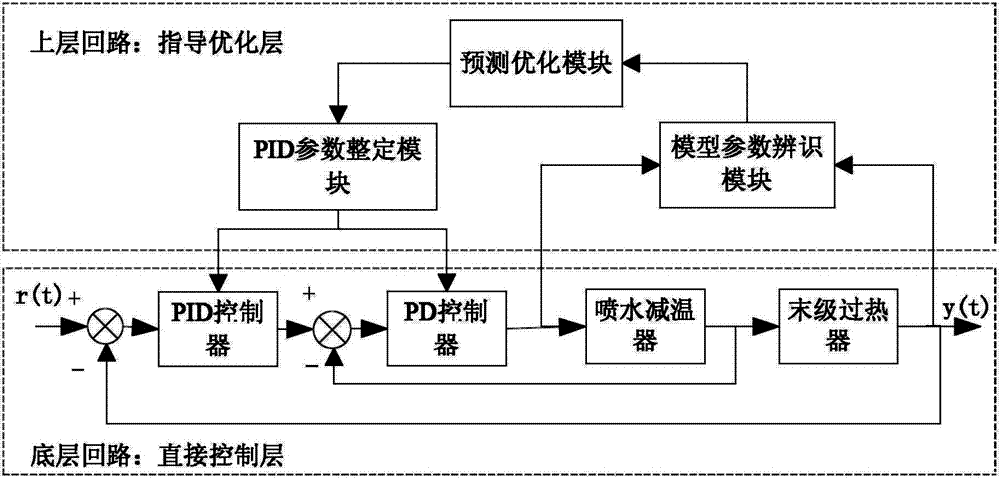

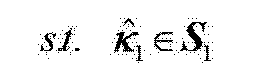

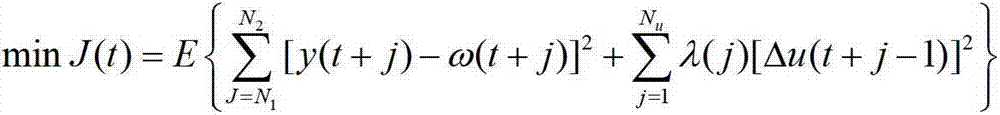

ActiveCN102777879ATo achieve the purpose of adaptive control of main steam temperatureImprove stabilityBoiler controlAdaptive controlComponent Object ModelOnline model

The invention relates to a main steam temperature predictive control method of an ultra supercritical unit of a thermal power plant. A layered control structure is arranged, the layered control structure consists of a bottom direct control layer and an upper guide optimization layer, and the upper guide optimization layer realizes model parameter identification, prediction optimization and PID (Proportion Integration Differentiation) parameter setting control; and the bottom direct control layer is in a cascade system structure and comprises main loop control and assistant loop control, and a PID controller orienting a DCS (distributed control system) is directly controlled. The control method can be used for replacing a control engineer to set PID parameters, on-line model identification and control parameter setting methods are directly adopted to achieve the purpose of main steam temperature self-adaptive control, the application of an advanced control technology and an intelligent optimization technology under a DCS is realized, the stability and the robustness are stronger, and a changing process of a controlled object model of the main steam temperature under a variable load can be adapted.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

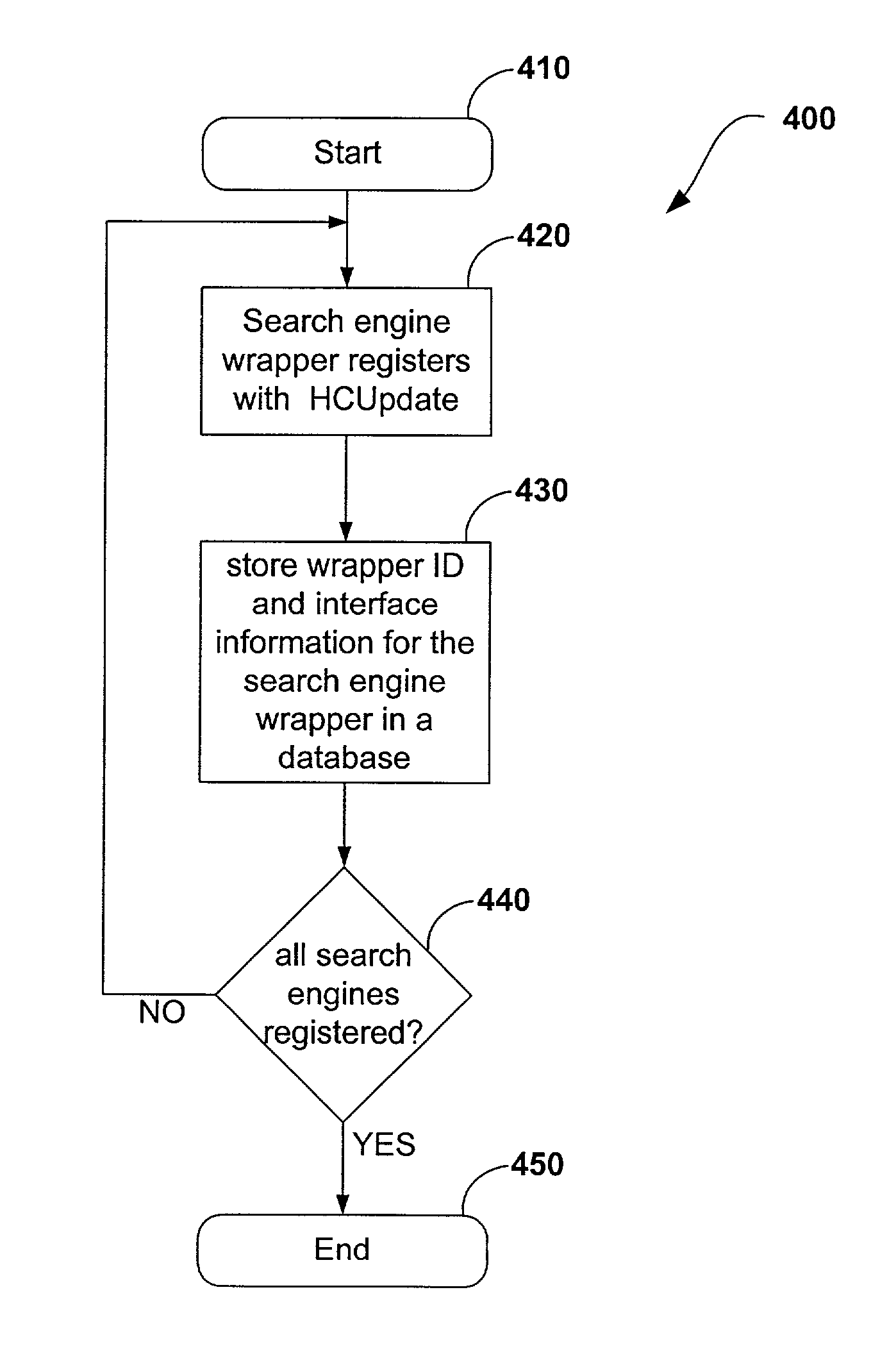

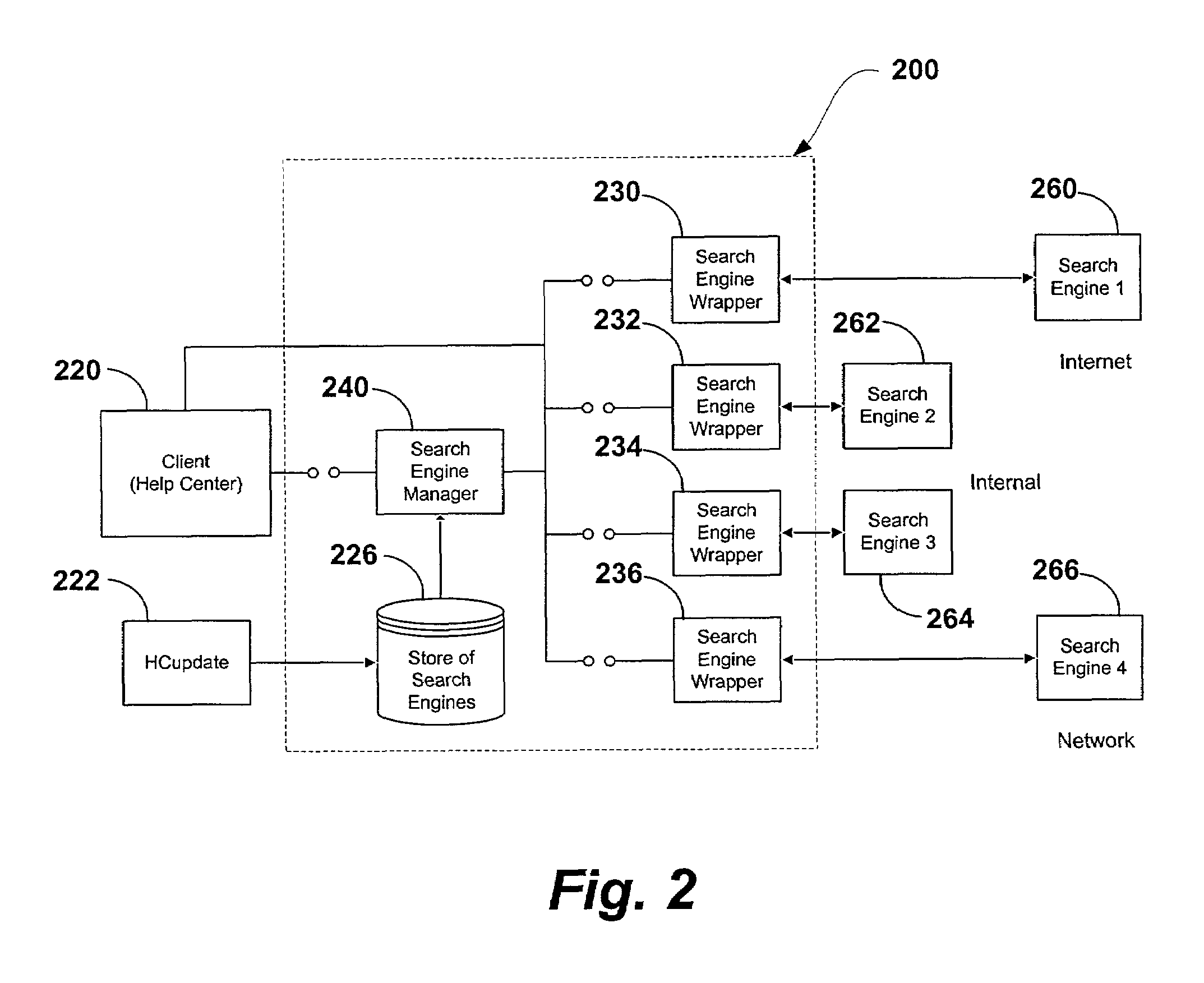

System and method for searching multiple disparate search engines

InactiveUS7451136B2Convenient registrationImprove search capabilitiesData processing applicationsWeb data indexingComponent Object ModelClient-side

Described is a system and method for searching multiple disparate search engines. More particularly, a search system provides search engine manager that operates to provide a standard interface with which one or more search engines may be queried through a search client. The search system being extensible, allows for the addition of search engines beyond the time of the initial construction of the search system. Each search engine, being wrapped around a COM (component object model) object, first registers with the search system through the wrapper, the wrapper providing communication between the search engine manager and the search engine. When initiated by a client, a query is transmitted to the search engines in series, the search engines execute the query in parallel, and the results are returned asynchronously to the client.

Owner:MICROSOFT TECH LICENSING LLC

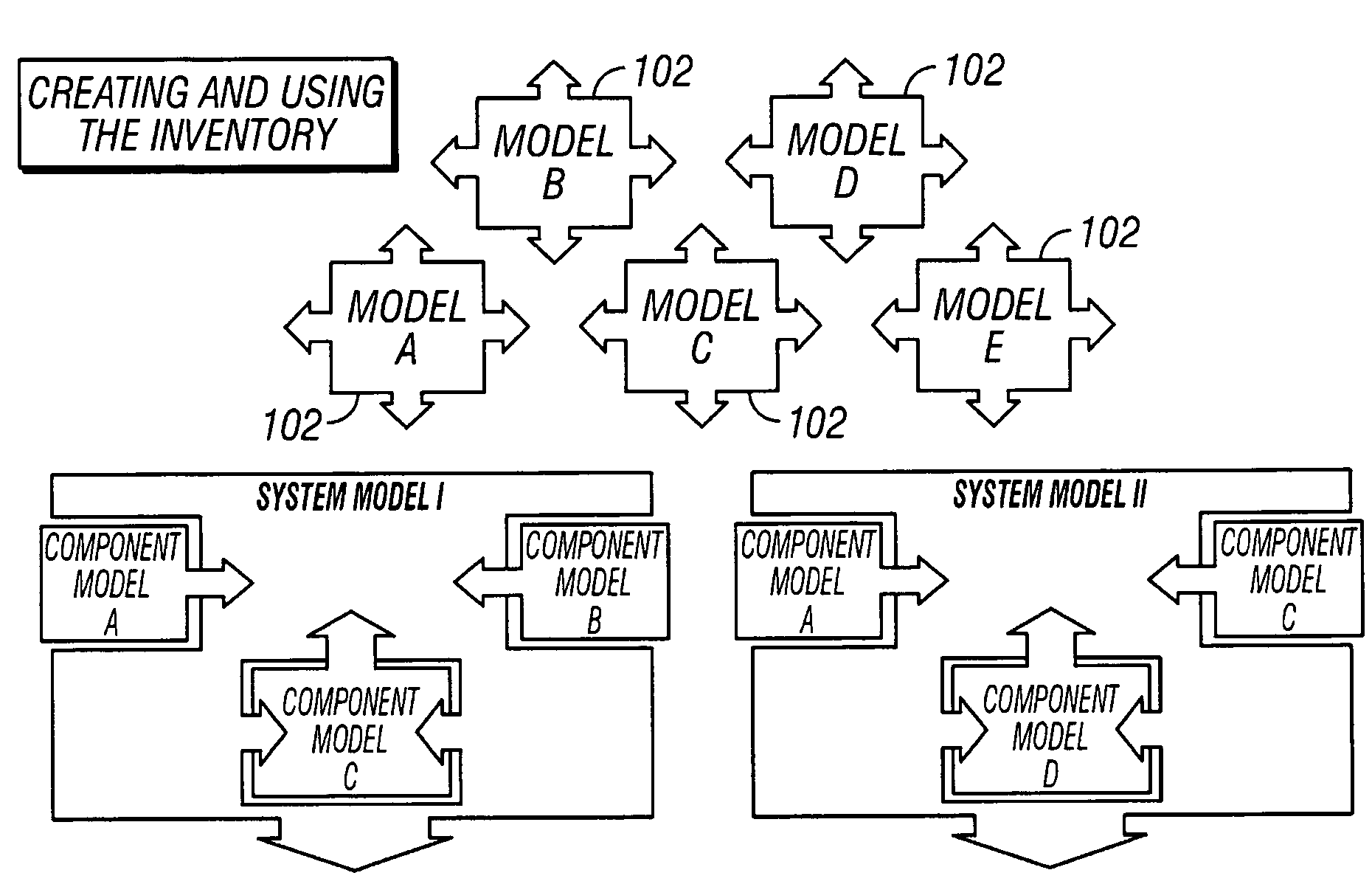

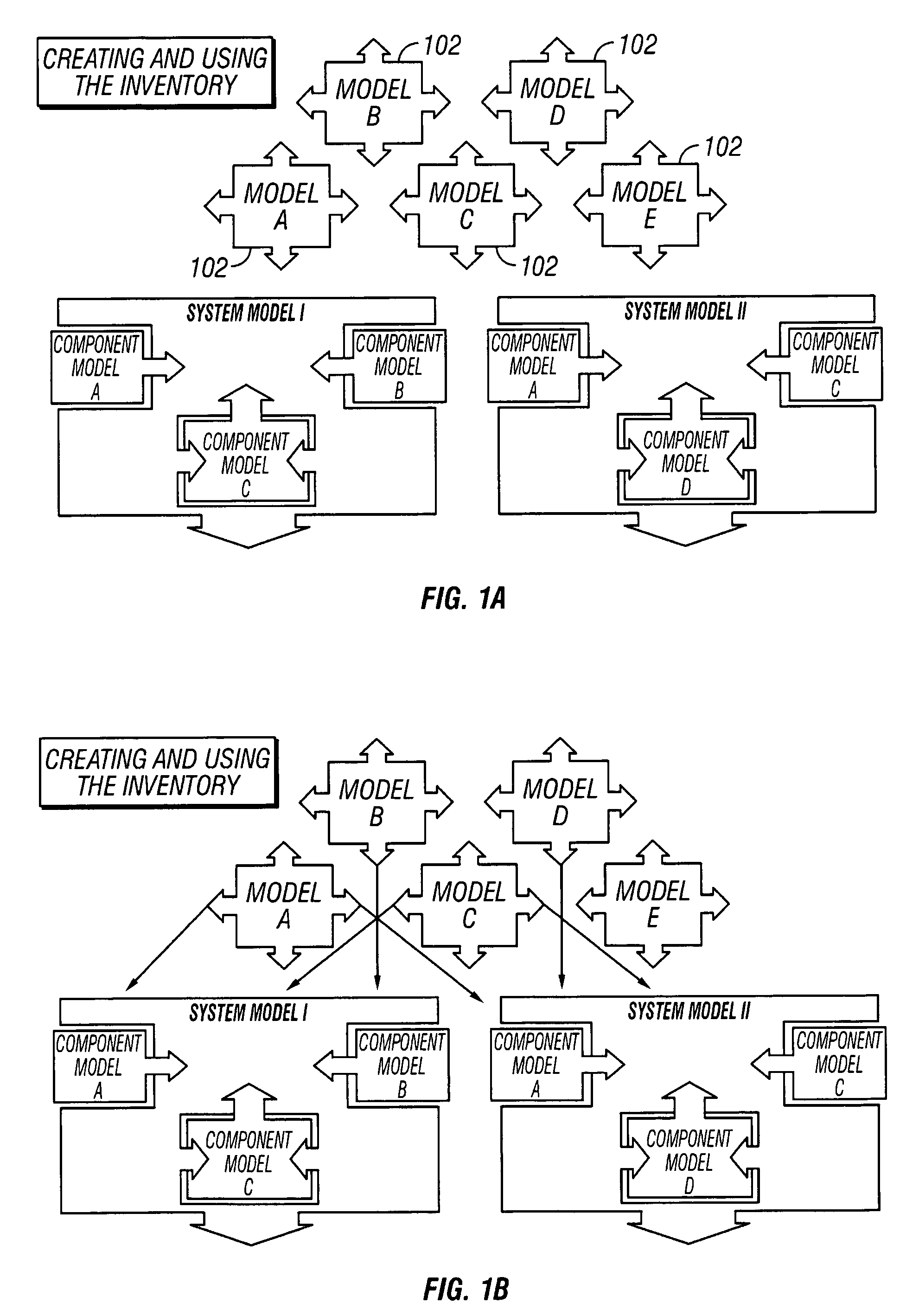

Common component modeling

InactiveUS7571082B2Technology managementComputation using non-denominational number representationComponent Object ModelComponent based model

A method and apparatus for producing predictive performance and capacity information employing a type of factory to reduce the ongoing cost of providing simulation models to answer questions raised by the various business entities is provided. To achieve this, a continual process for providing on-going performance information is provided. The core concept is the development and long-term reuse of component models to create other, more broadly scoped performance models. This requires the implementation of standard simulation model constructs to facilitate reuse, processes for the development of models and their use by clients, and a stable yet flexible repository for component models. The invention comprises processes, standards, templates, and software tools that implement a performance service that consists of the long term maintenance of predictive performance models for repeated use by lines of business to provide capacity planning information.

Owner:WELLS FARGO BANK NA

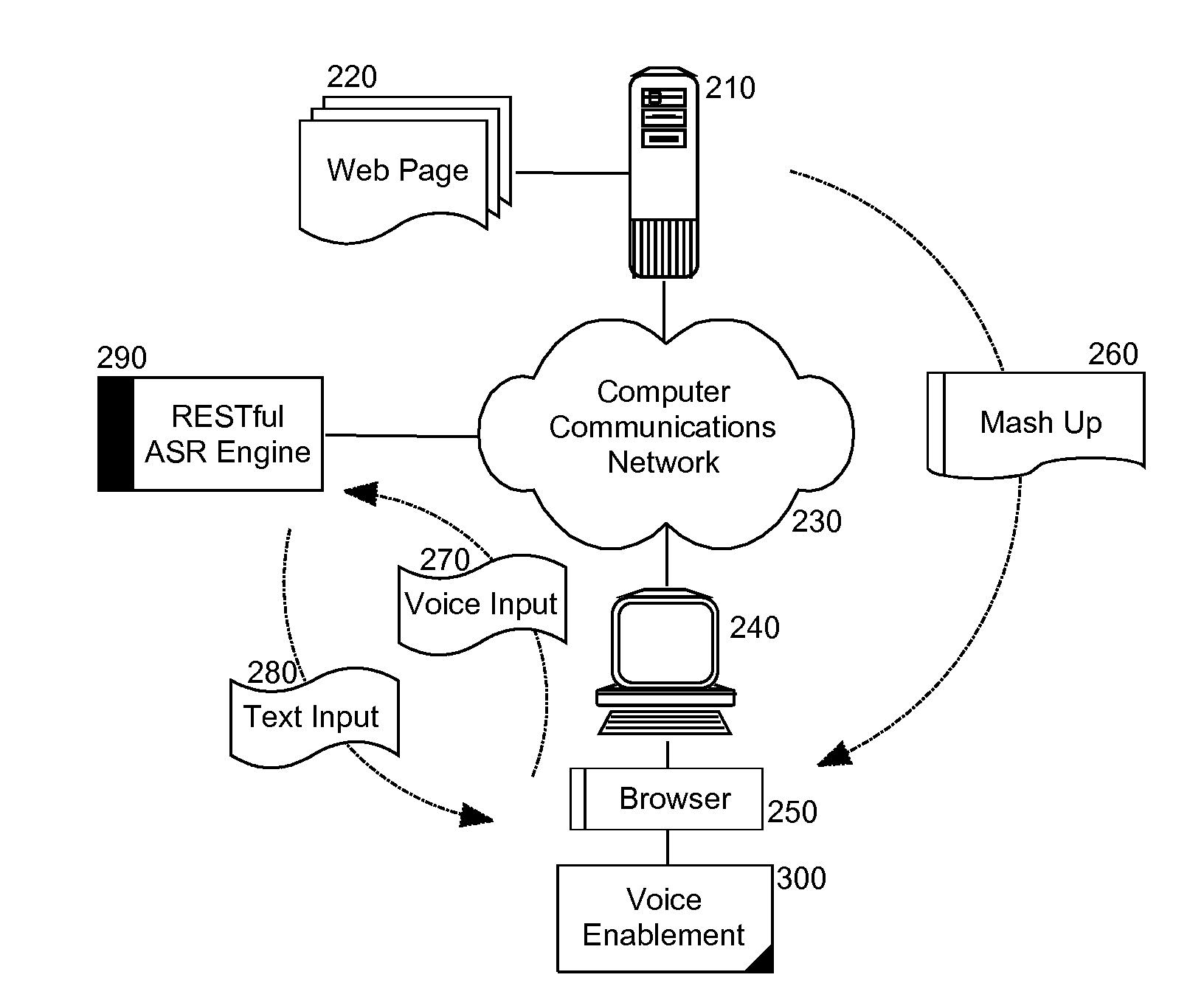

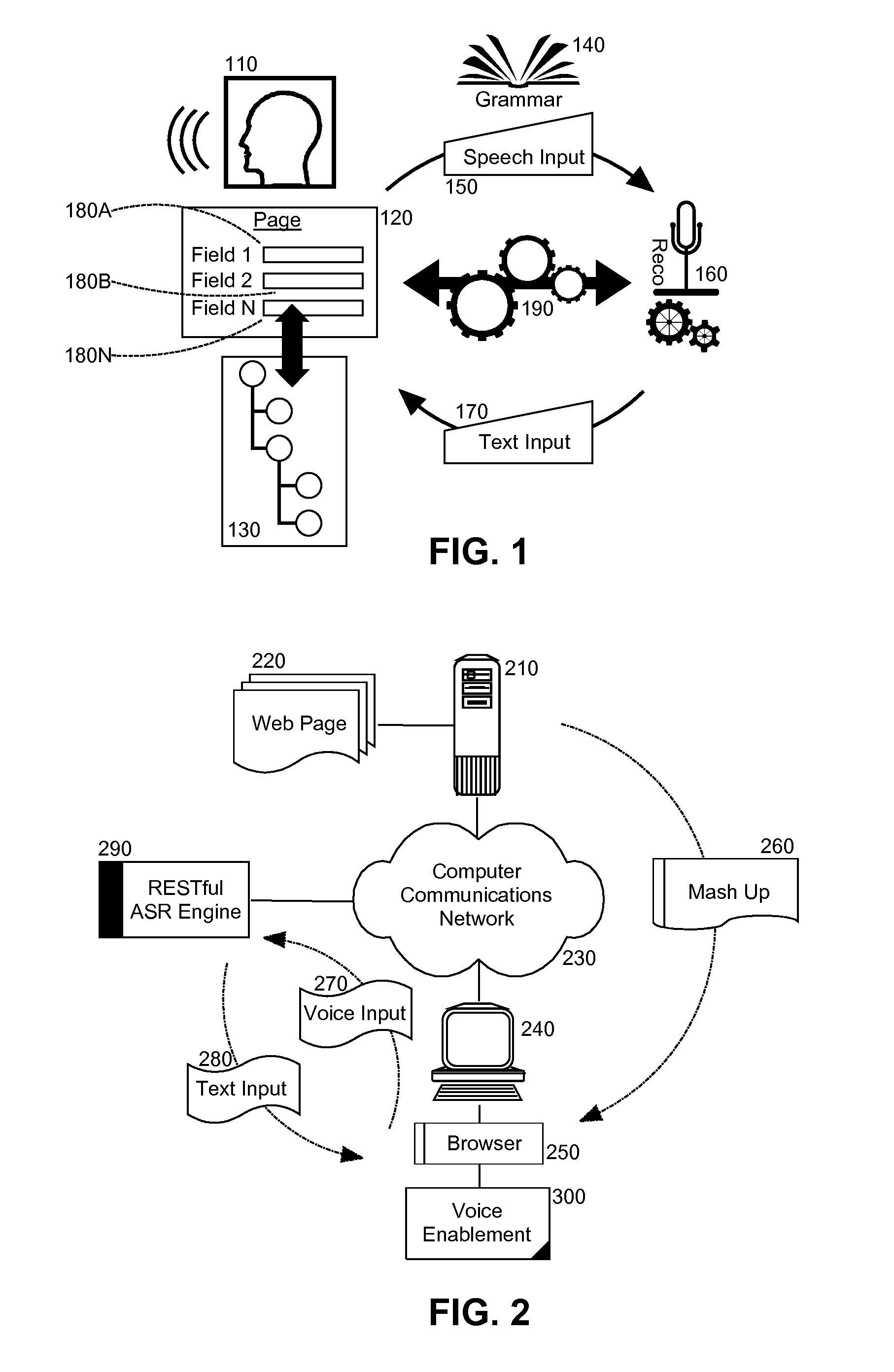

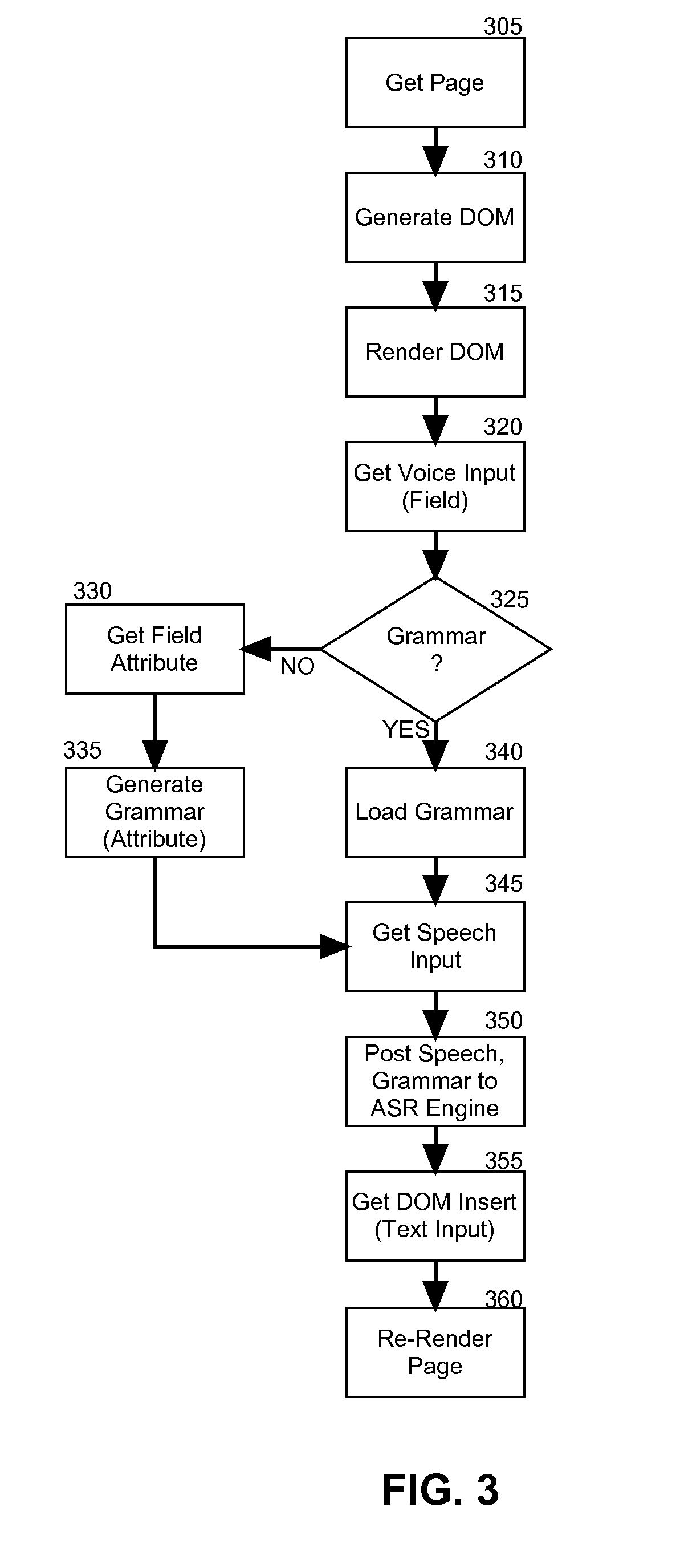

Automated voice enablement of a web page

Embodiments of the present invention provide a method, system and computer program product for the automated voice enablement of a Web page. In an embodiment of the invention, a method for voice enabling a Web page can include selecting an input field of a Web page for speech input, generating a speech grammar for the input field based upon terms in a core attribute of the input field, receiving speech input for the input field, posting the received speech input and the grammar to an automatic speech recognition (ASR) engine and inserting a textual equivalent to the speech input provided by the ASR engine into a document object model (DOM) for the Web page.

Owner:NUANCE COMM INC

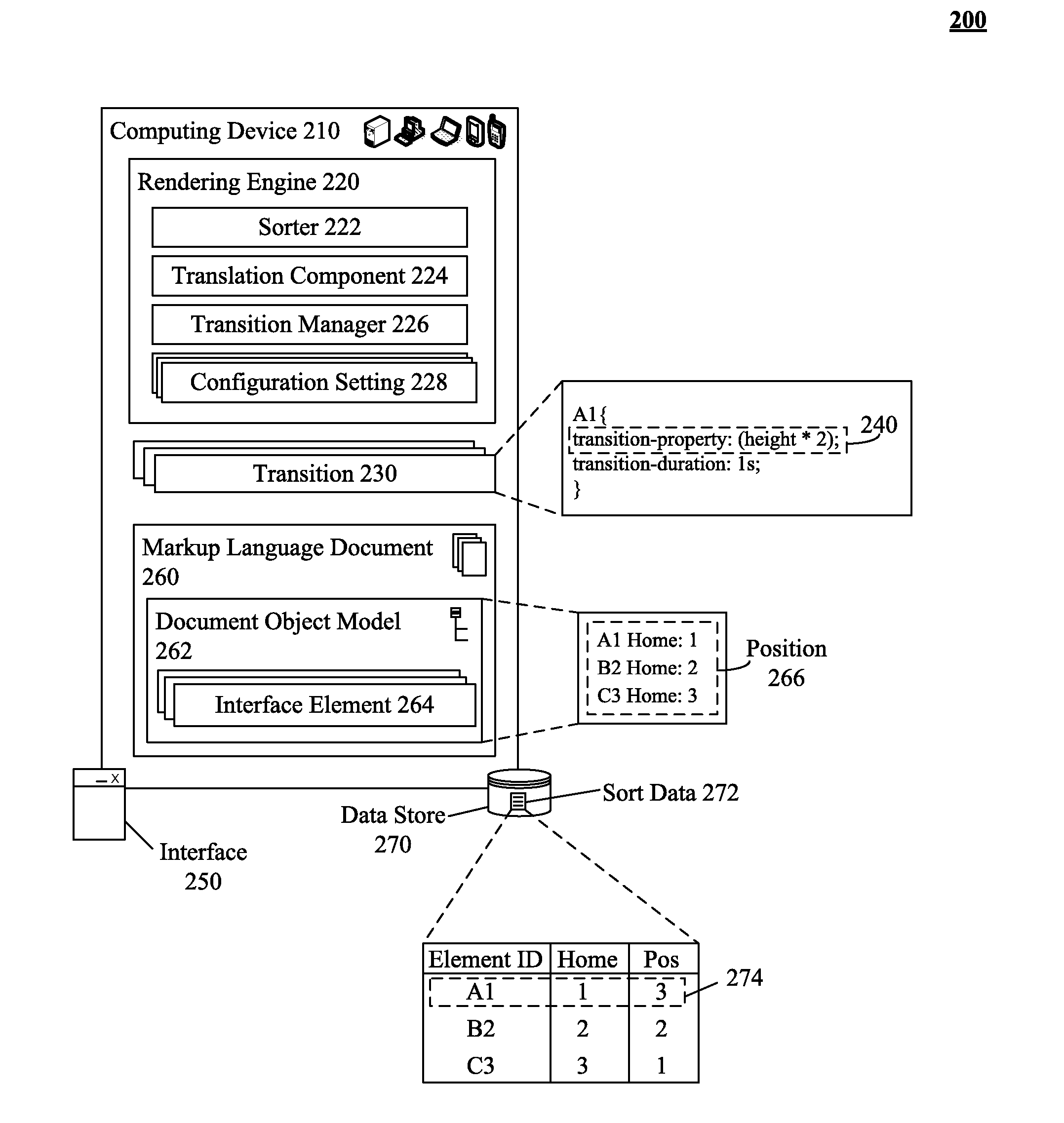

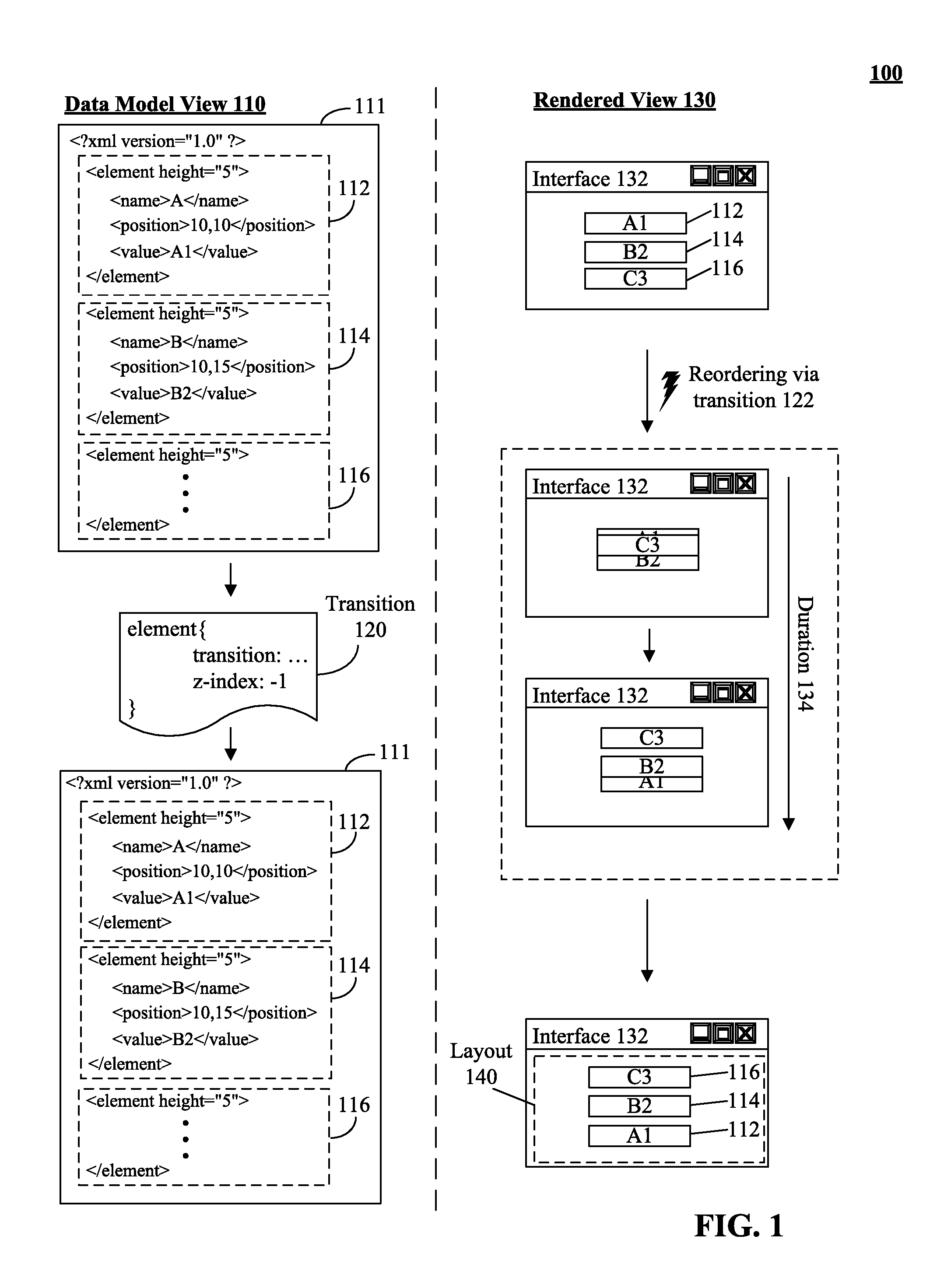

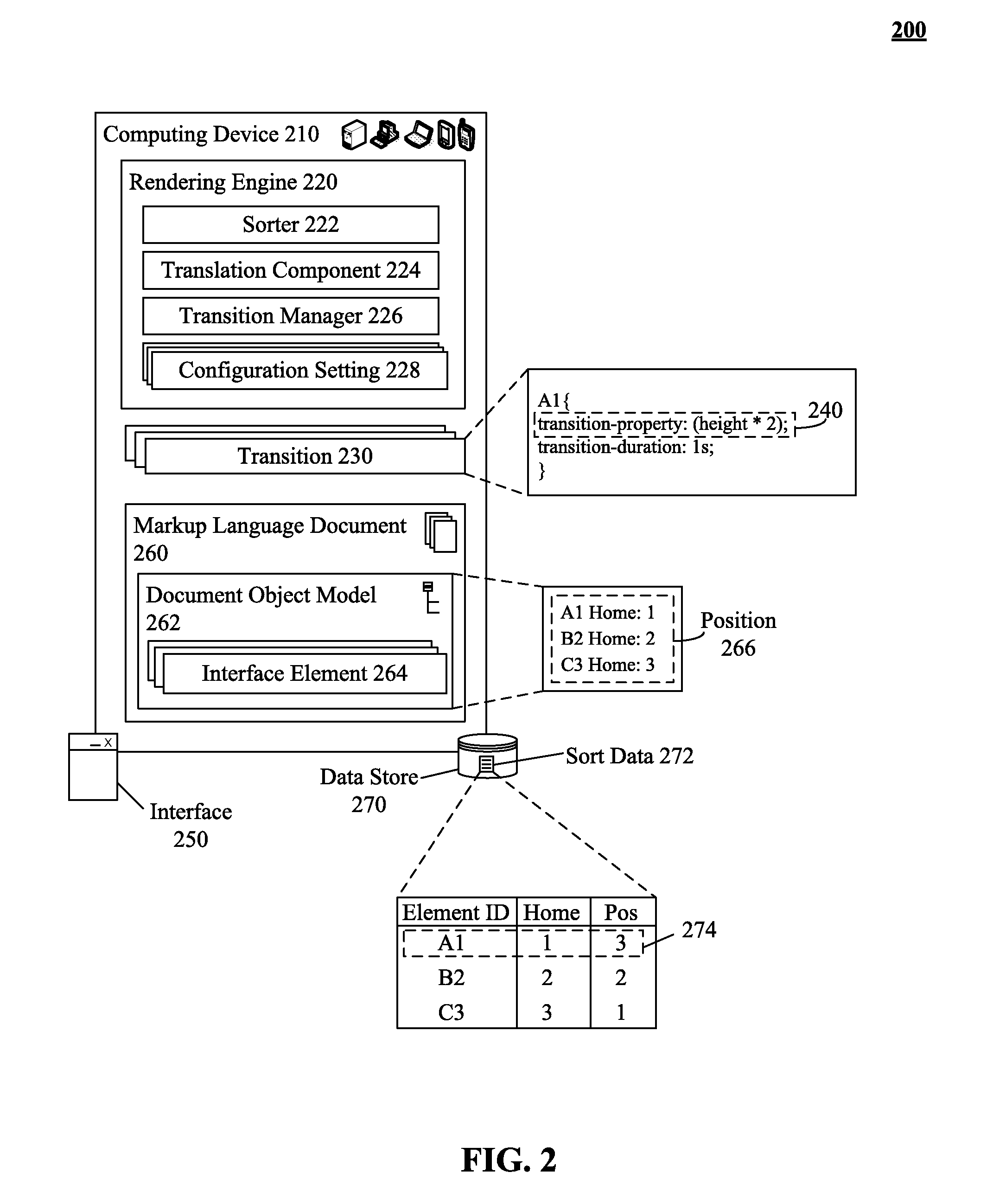

Utilizing a graphical transition to sort an interface element independently of a document object model

InactiveUS20130024763A1Digital data information retrievalSpecial data processing applicationsGraphicsComponent Object Model

One or more elements can be rendered within a canvas of an interface. The elements can be associated with an element attribute and an element data. The elements can be user interface elements. The elements can be associated with a document object model of a markup language document. The interface can be a Web browser. The elements can be visually sorted differently via a graphical transition effect. The transition effect can execute to sort the elements without modifying objects of the document object model, without changing the elements as specified in a mark document being rendered, and without changing the element data of the elements being sorted.

Owner:IBM CORP

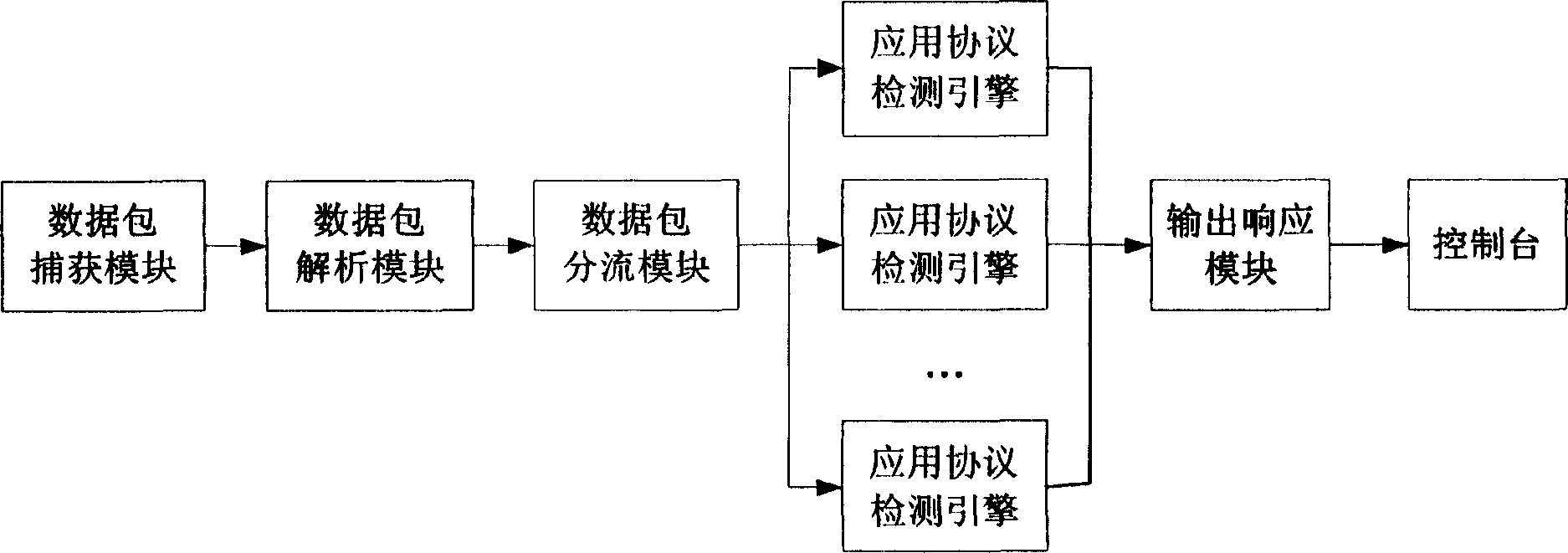

Network intrusion detection system and method based on application protocol detection engine

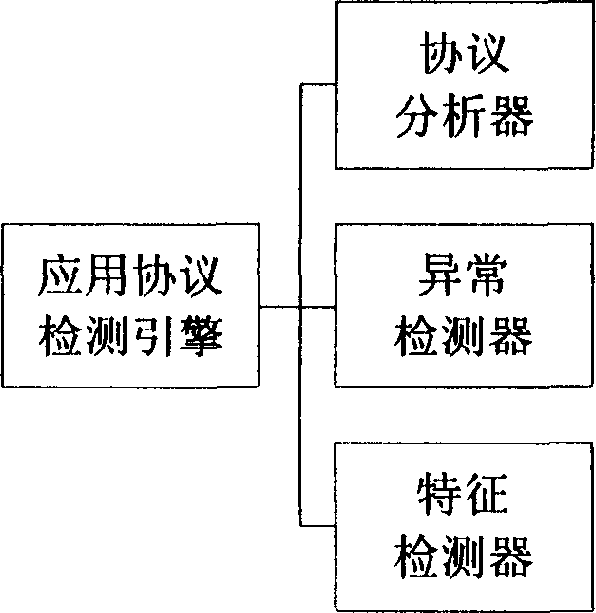

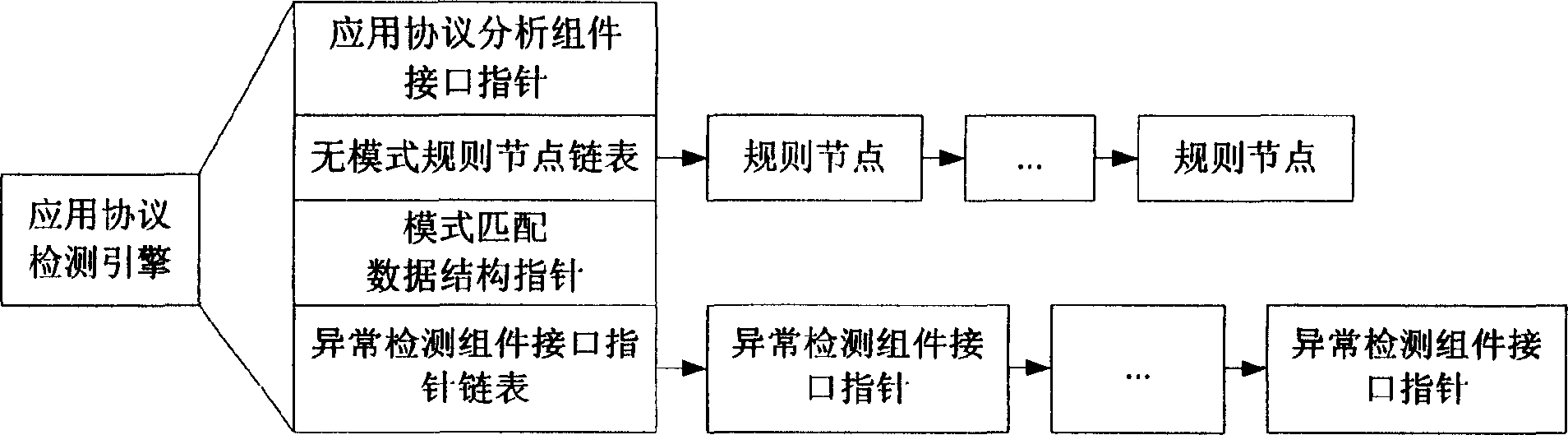

InactiveCN1738257AMake up for the defect of not being able to detect new attack methodsGuaranteed scalabilityData switching networksComponent Object ModelAnomaly detection

The invention provides a network invasion detecting system based on the application protocol detecting engine and its method. The application protocol detecting engine comprises three detector units as a application protocol analyzer, a abnormal detector and a feature detector while these detectors can all or partly use simply components object models and supply uniform calling interface. The character of said network invasion detecting method is that the invention comprises three steps as protocol analysis, abnormal detecting and feature detecting. The invention can solve the defect of present network invasion detecting system that the inability for detecting new invasion type; and the invention realizes components of the application protocol analyzer, the abnormal detector and the feature detector by the components technique, which allows the detecting component after decoding can connect the detecting system directly without decoding again, so the spreading and the maintenance of network invasion detecting system are improved.

Owner:PEKING UNIV

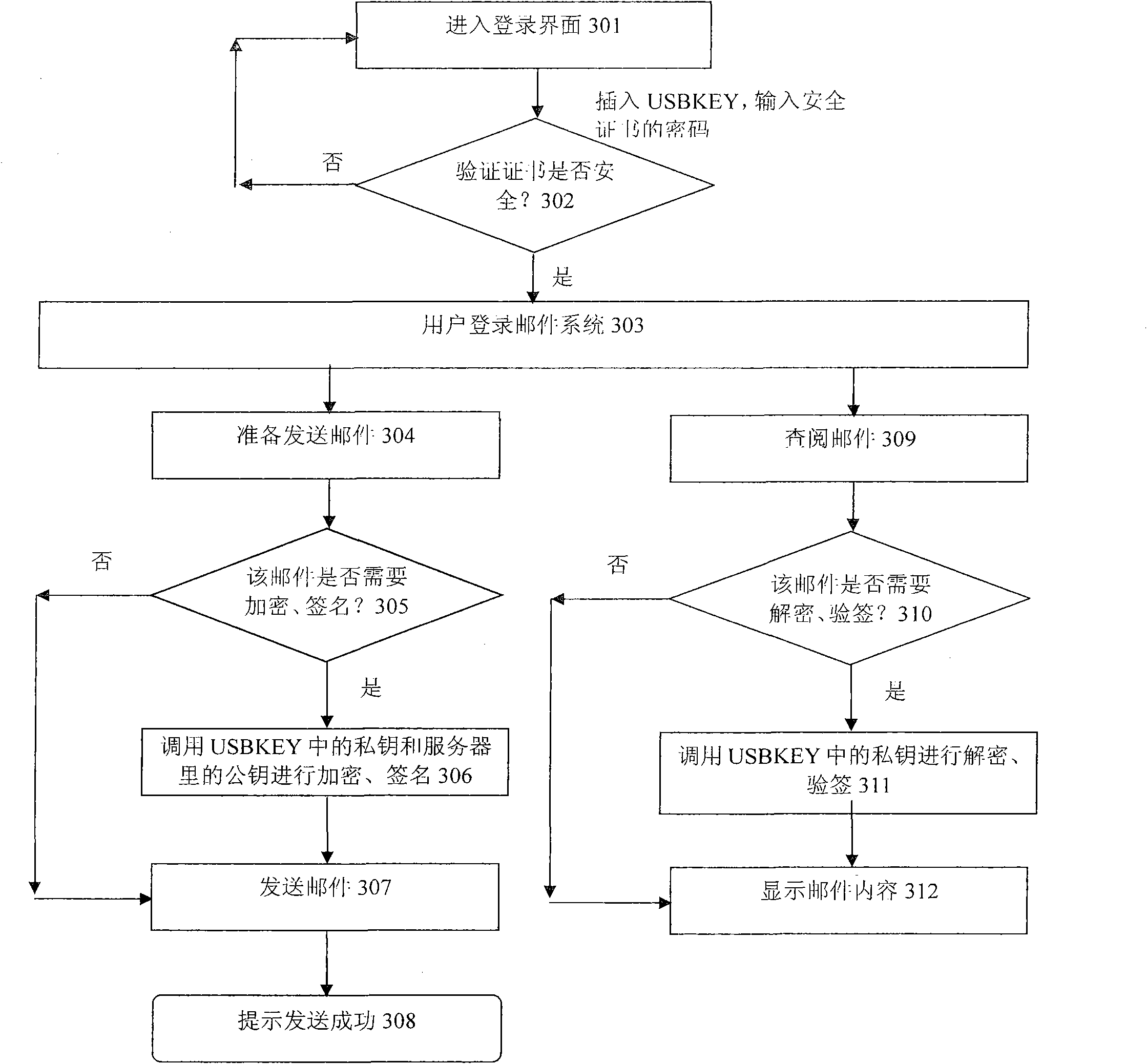

Safe mail system based on USBKEY (Universal Serial Bus Key) and mail encrypting-decrypting method

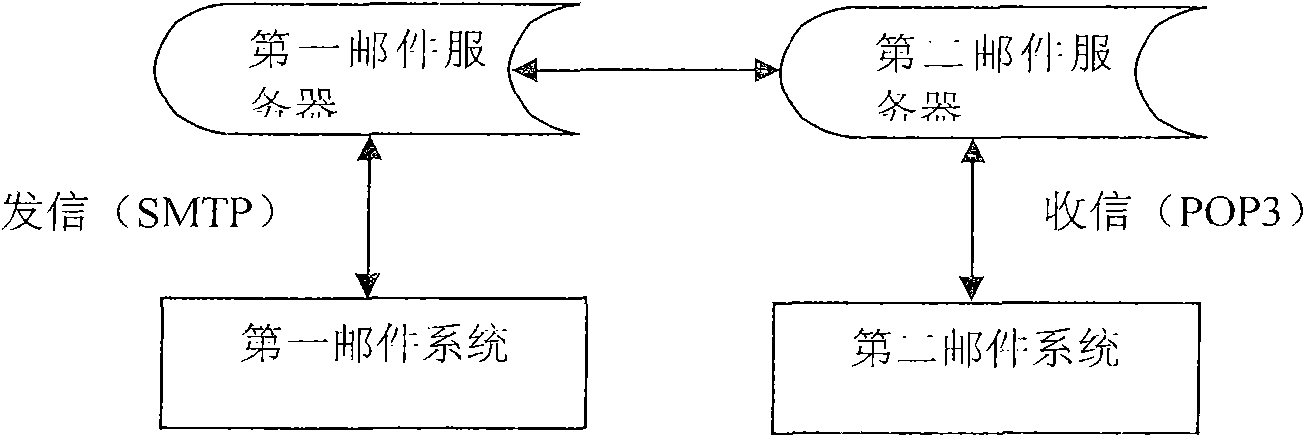

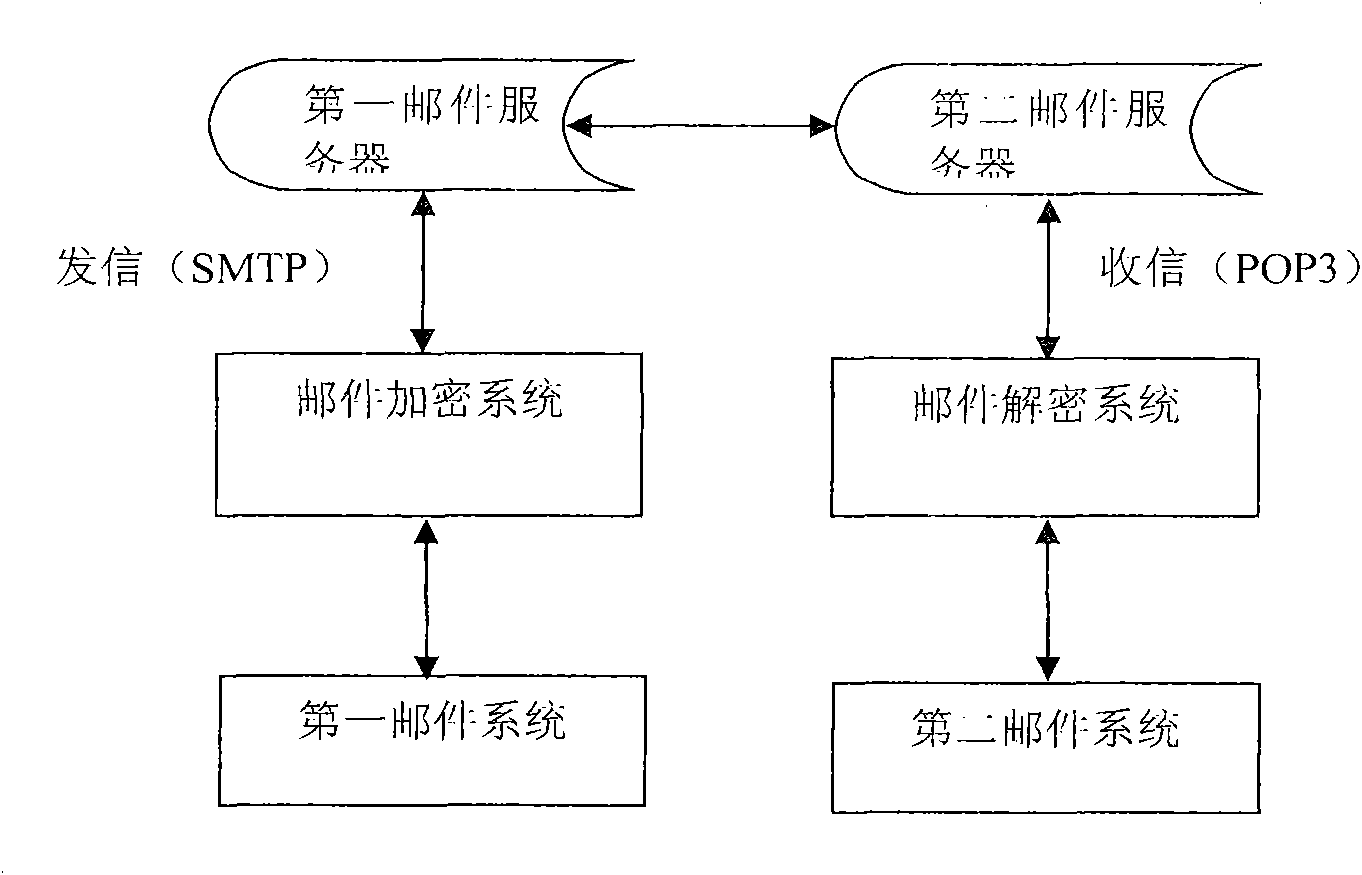

InactiveCN102118381AEnsure safetyAvoid security issuesPublic key for secure communicationUser identity/authority verificationComponent Object ModelV-mail

The invention discloses a safe mail system based on a USBKEY (Universal Serial Bus Key) and a mail encrypting-decrypting method. The system mainly comprises a first mail system, a second mail system, a mail encrypting system and a mail decrypting system. When logging in the mail system, a user is required to insert a USBKEY disc (including a private key certificate) and input the password of a certificate, besides inputting the password of an account; and if the input password is wrong, the user is refused to log in the system. When a mail is transmitted, a COM (Component Object Model) assembly calls a private key in the USBKEY disc to generate a Hash value, the mail is signed up by using the Hash value, and a public key of an addressee is called to encrypt the mail; and when the mail is looked up, the private key in the USBKEY disc is required to be called to decrypt a key to generate a Hash value by a browser COM assembly after the key of the addressee is obtained, the mail is decrypted and the signature of the mail is checked by using the Hash value, therefore, the mail is safer in the transmitting process, and the authenticity of the mail is also ensured.

Owner:ZHONGKE FANGDE SOFTWARE CO LTD

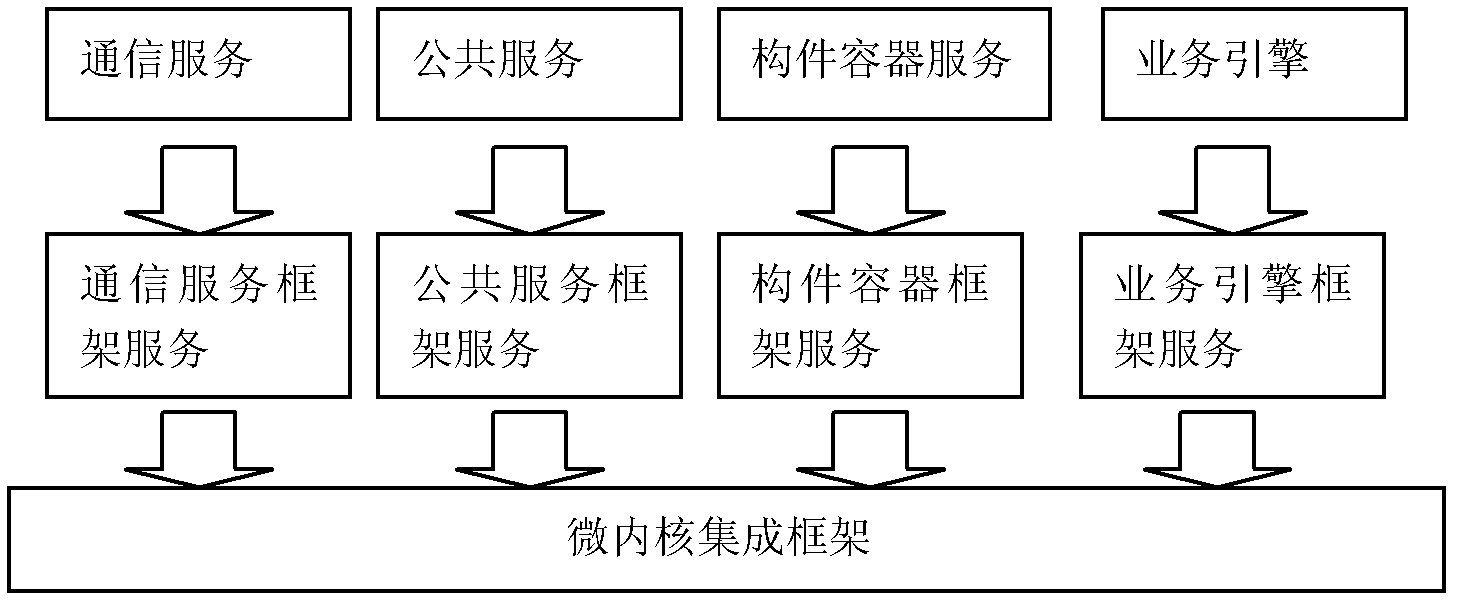

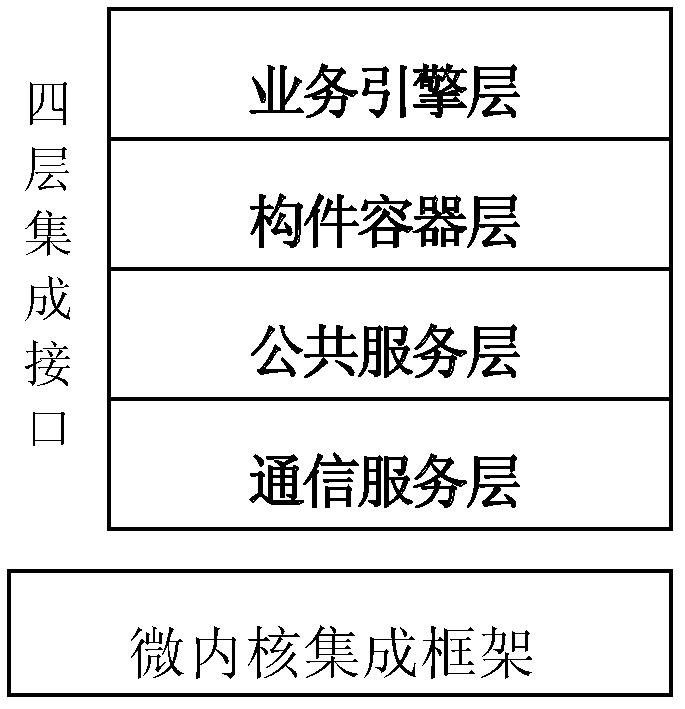

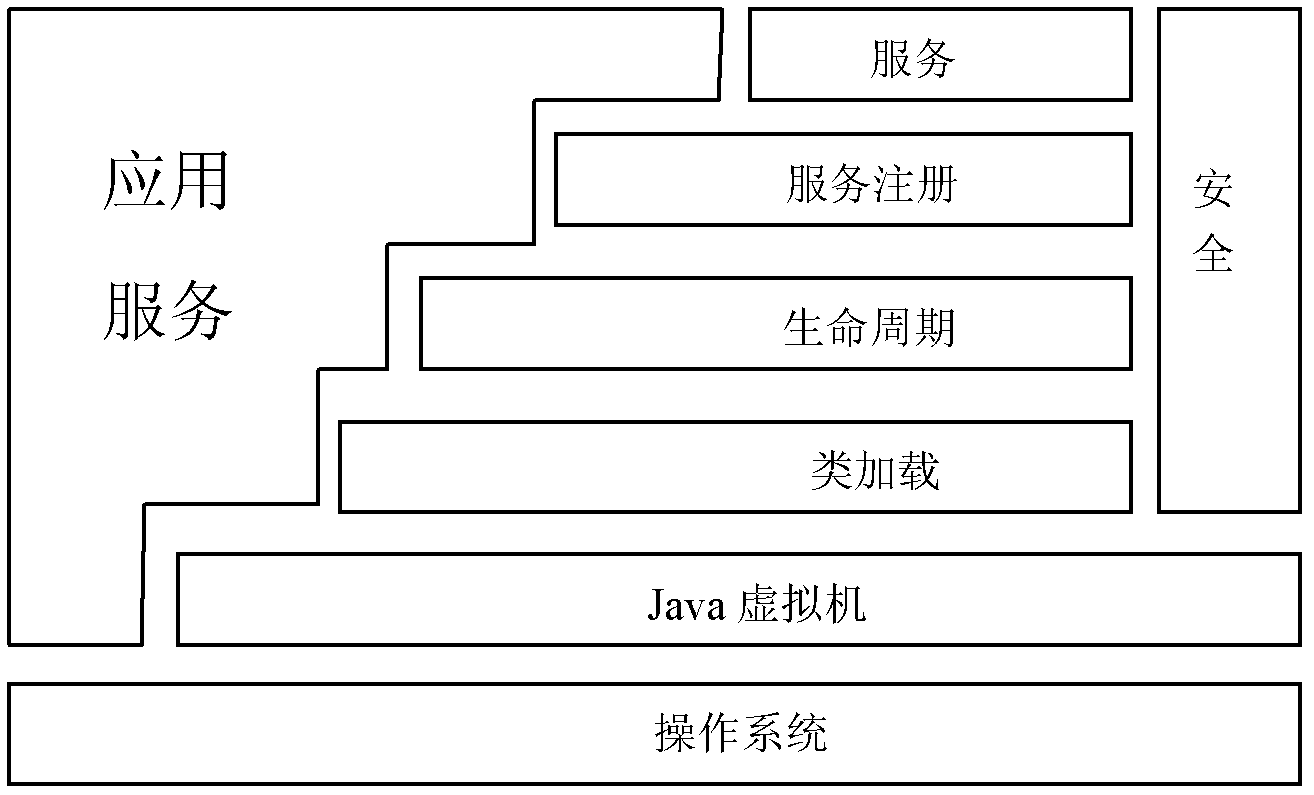

Complete network middleware operation support platform and integration method of heterogeneous middleware

InactiveCN102323879AImprove start-up efficiencyImprove operational efficiencySpecific program execution arrangementsComponent Object ModelDistributed Component Object Model

The invention relates to a complete network middleware operation support platform which can be used for integrating a plurality of conventional mainstream middleware technologies, and a method for integrating a heterogeneous middleware member on the platform. The platform disclosed by the invention comprises a microkernel integration frame, a communication service layer, a public service layer, a member container layer and a service engine layer, wherein the microkernel integration frame provides upper-level service integration interface specifications of a life cycle management and command interface, an interoperation interface and a deployer interface needed for deploying specific components, for the four categories of service layers. According to the invention, deep integration of mainstream middleware technologies, such as JEE (Java Enterprise Edition), Web service, CORBA (Common Object Request Broker Architecture), COM / DCOM (Component Object Model / Distributed Component Object Model), and the like, is realized. The complete network middleware operation support platform and the integration method of the heterogeneous middleware can be widely applied to integration of different application service technology systems.

Owner:PEKING UNIV

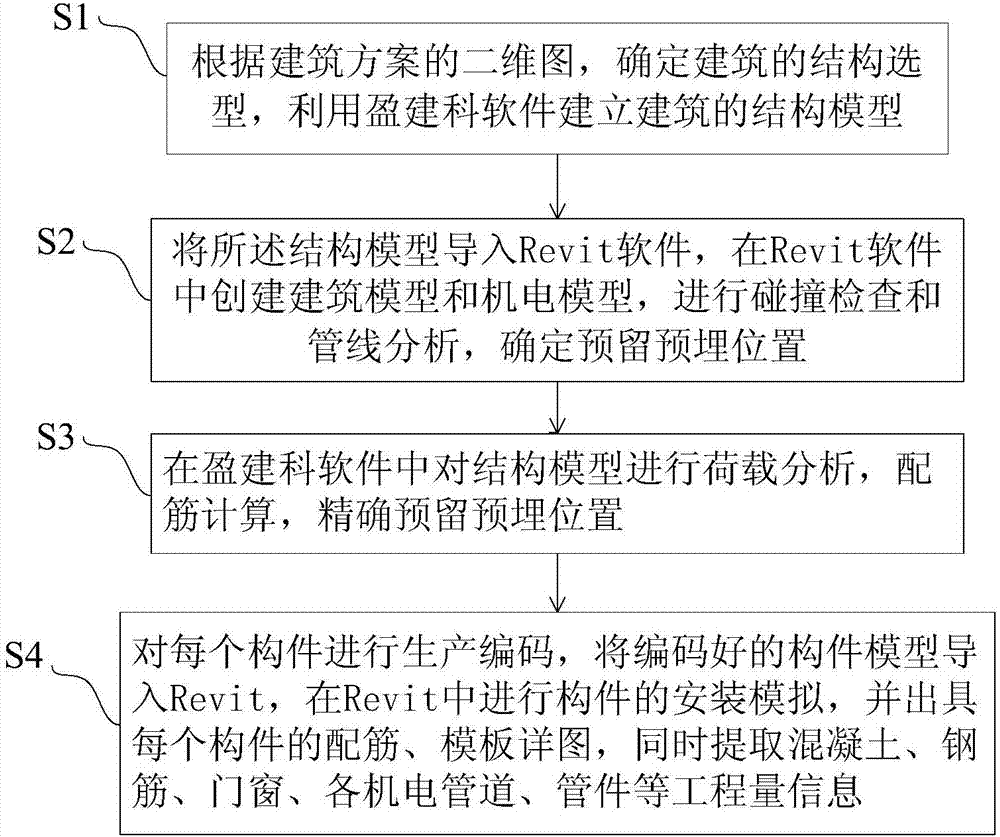

BIM technology-based fabricated concrete building design method

InactiveCN107977487ASimplify complexityOmit secondary modelingGeometric CADSpecial data processing applicationsComponent Object ModelBuilding design

The invention discloses a BIM technology-based fabricated concrete building design method. The method comprises the following steps of: determining a structure form selection of a building according to a two-dimensional diagram of a building scheme and establishing a structure model of the building by utilizing YJK software; importing the structure model into Revit software, creating a building model and an electromechanical model in the Revit software, and carrying out collision check and pipeline analysis to determine a reserved pre-embedded position; calculating, reinforcing and pre-embedding the structure model according to load information and the reserved pre-embedded position; carrying out production encoding on each component, importing an encoded component model into the Revit, carrying out installation simulation on the components in the Revit, and providing reinforcement and template detail drawings of each component. According to the method, the secondary design problem oftraditional fabricated concrete building components is avoided, so that different professional designers can carry out cooperative office, reserved pre-embedded position information of the componentsis accurate and the correctness of giving component machining detail drawings is improved.

Owner:山东住工装配建筑有限公司

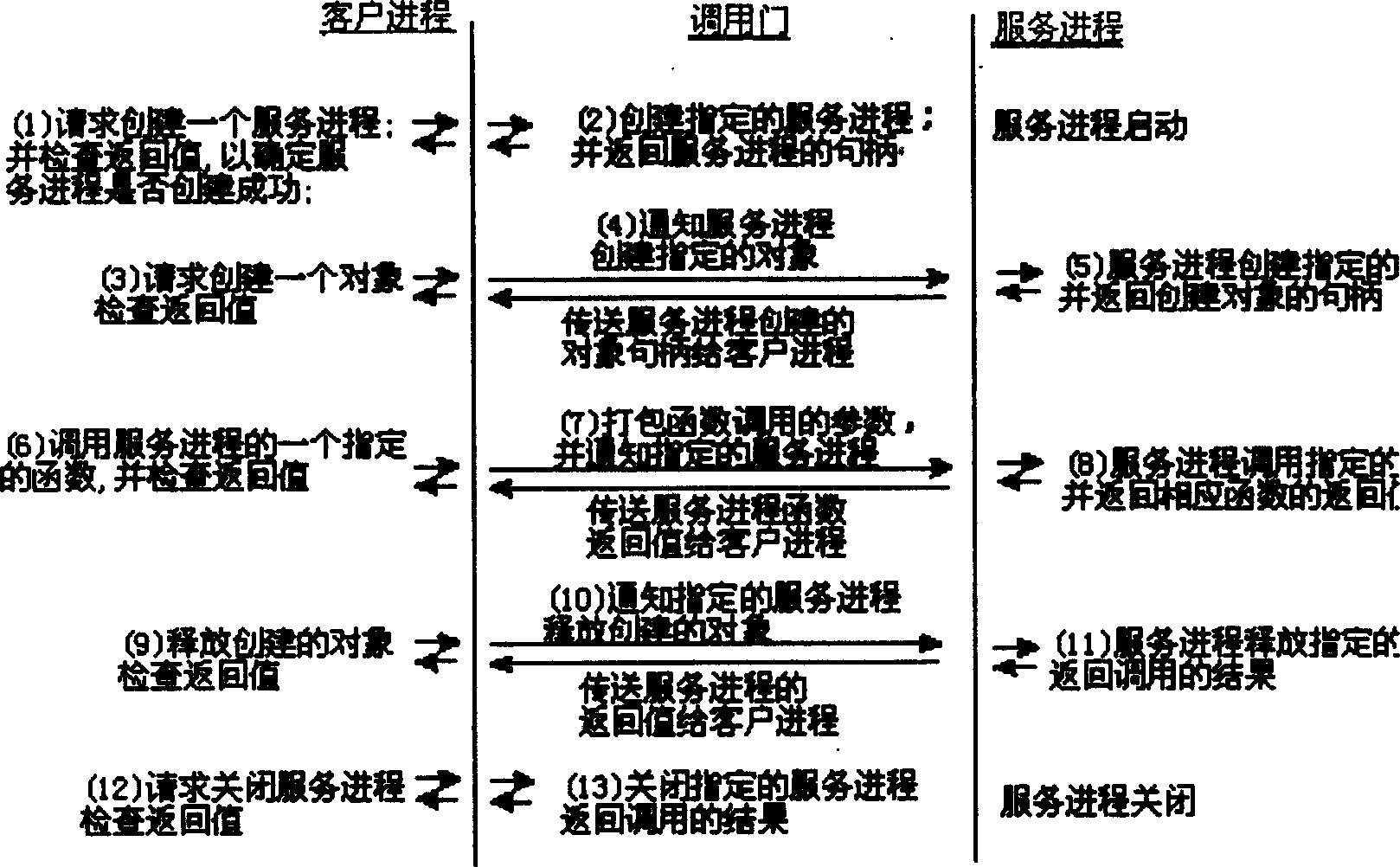

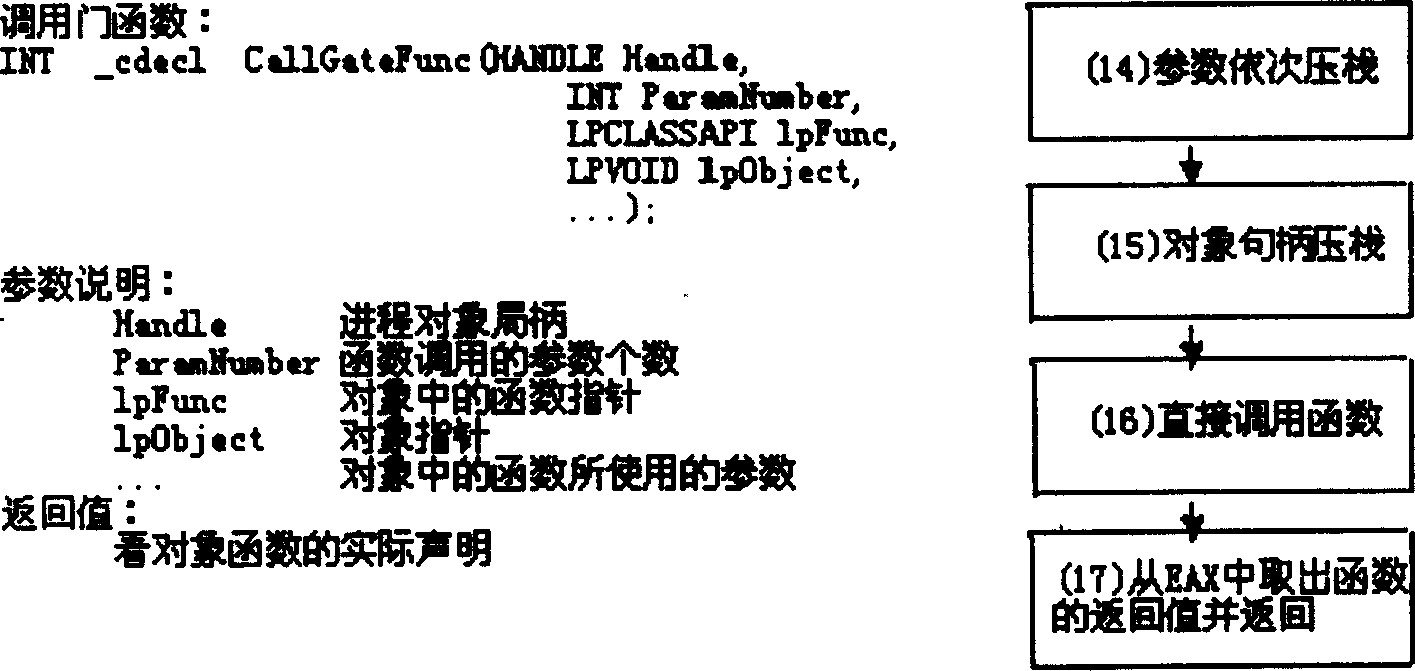

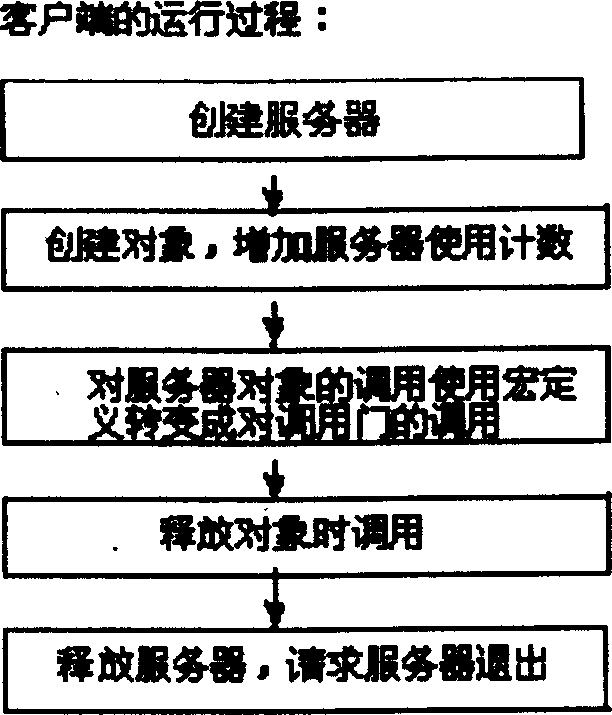

Inter-process calling gate technique

InactiveCN1470988AProgram initiation/switchingDigital computer detailsCall gateComponent Object Model

The invented technique makes a object in one process possible to call a function of object in another process. At final executing time, it is not dependent on the registration table. Moreover, the program in single instance through multi processes realizes multi instances. The component object model (COM) does not have such function. Meanwhile, the stub can be realized directly, without need of realizing DLL stub. Thus, client end and server end are totally transparent to developers so as to provide more opportunities to control procedures fro developers. Most programs developed by C languageare single instance and non-objectization. It is impossible to use COM technique to rebuild the said programs sometimes caused by large cost. The invention solves the issue through multi processes torealize multi instances and objectization.

Owner:梁肇新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com