Transformer winding hot-spot temperature forecasting evaluation system with self-adaption function

A transformer winding and hot spot temperature technology, which is applied to thermometers with physical/chemical changes, thermometers, and thermometers with electric/magnetic elements that are directly sensitive to heat, can solve the problem of poor timeliness, poor accuracy, and inability to monitor and analyze transformer temperature. Change trends and other issues to achieve the effect of improving prediction accuracy and high calculation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

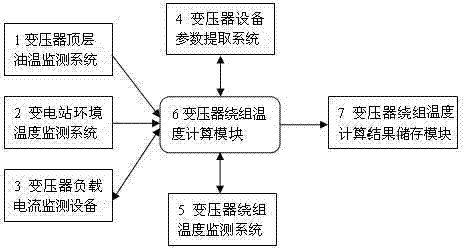

[0019] figure 1 Shown is the principle structural block diagram of the present invention. It can be seen from the figure that the present invention is a transformer winding hot spot temperature prediction and evaluation system with adaptive function, which includes a transformer top layer oil temperature monitoring system 1, a substation ambient temperature monitoring system 2, a transformer load current monitoring device 3, and a transformer equipment parameter extraction system 4. A transformer winding temperature monitoring system 5 , a transformer winding temperature calculation module 6 and a transformer winding temperature calculation result storage module 7 . The working principle and process of the present invention are: turn on the power supply, turn on the transformer top layer oil temperature monitoring system 1, the transformer load current monitoring equipment 3 and the transformer winding temperature monitoring system 5, save the relevant equipment parameter info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com