Rock relaxation test mechanism and test apparatus of same

A technology of testing mechanism and experimental device, which is applied in the direction of measuring device, testing material strength by using one-time impact force, instrument, etc. It can solve the problems of sample displacement, manual adjustment of pendulum, injury, etc., and achieve effective fixation and rapid assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

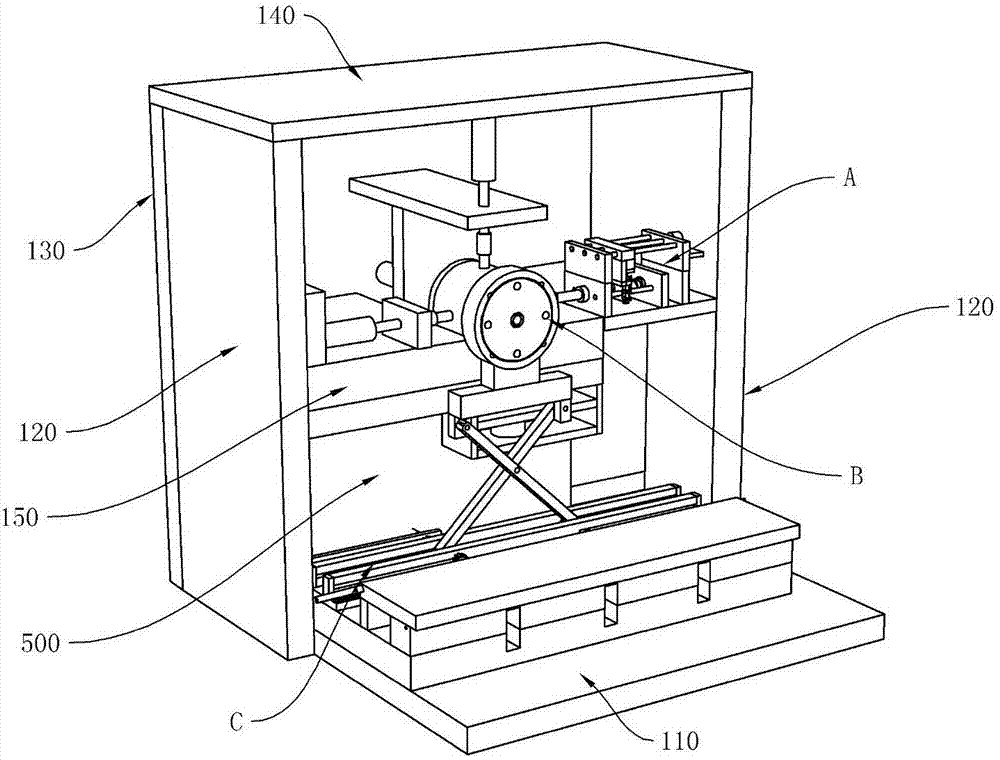

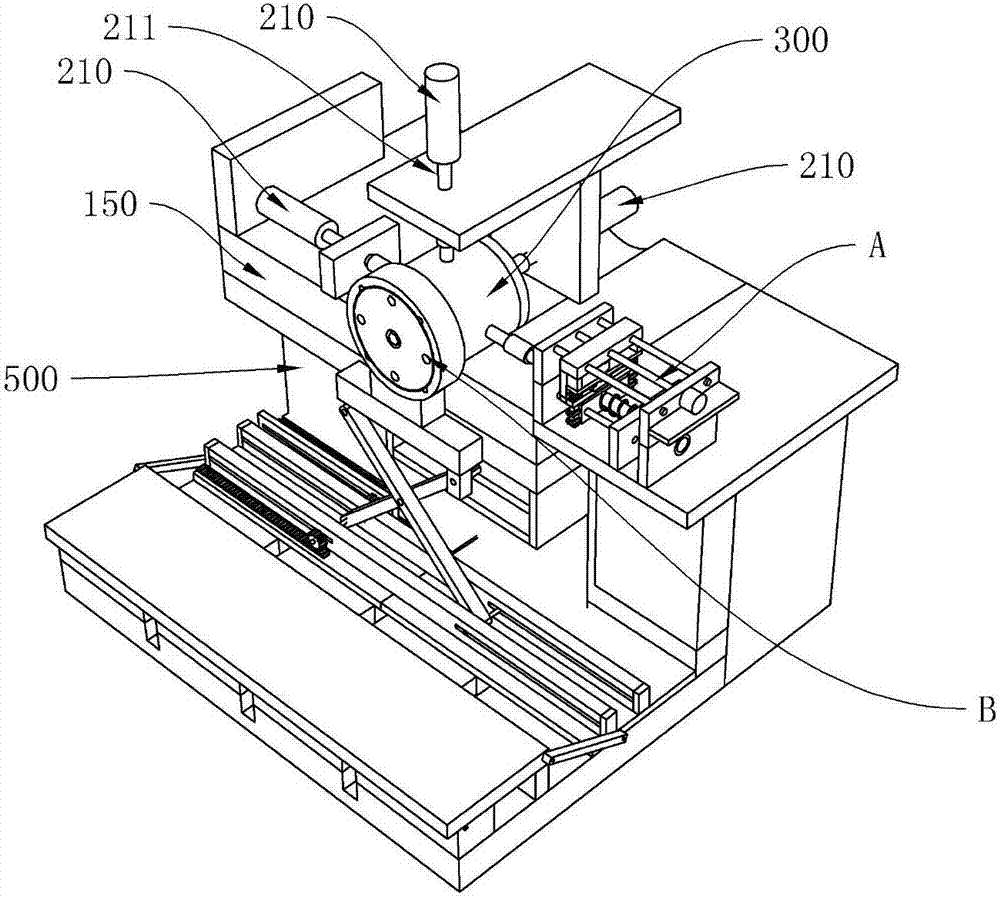

[0078] see Figure 1-Figure 3 , a relaxation-disturbance comprehensive experimental device, comprising a frame, a disturbance generating mechanism A, a relaxation testing mechanism; the frame includes, a bottom plate 110, a side plate 120, a rear plate 130, a top plate 140, and the side plate 120. The bottom and top of the rear plate 130 are respectively connected and fixed to the bottom plate 110 and the top plate 140, and a supporting plate 150 is connected and fixed between the two side plates 120, and an oil tank 500 for storing hydraulic oil is provided under the supporting plate 150;

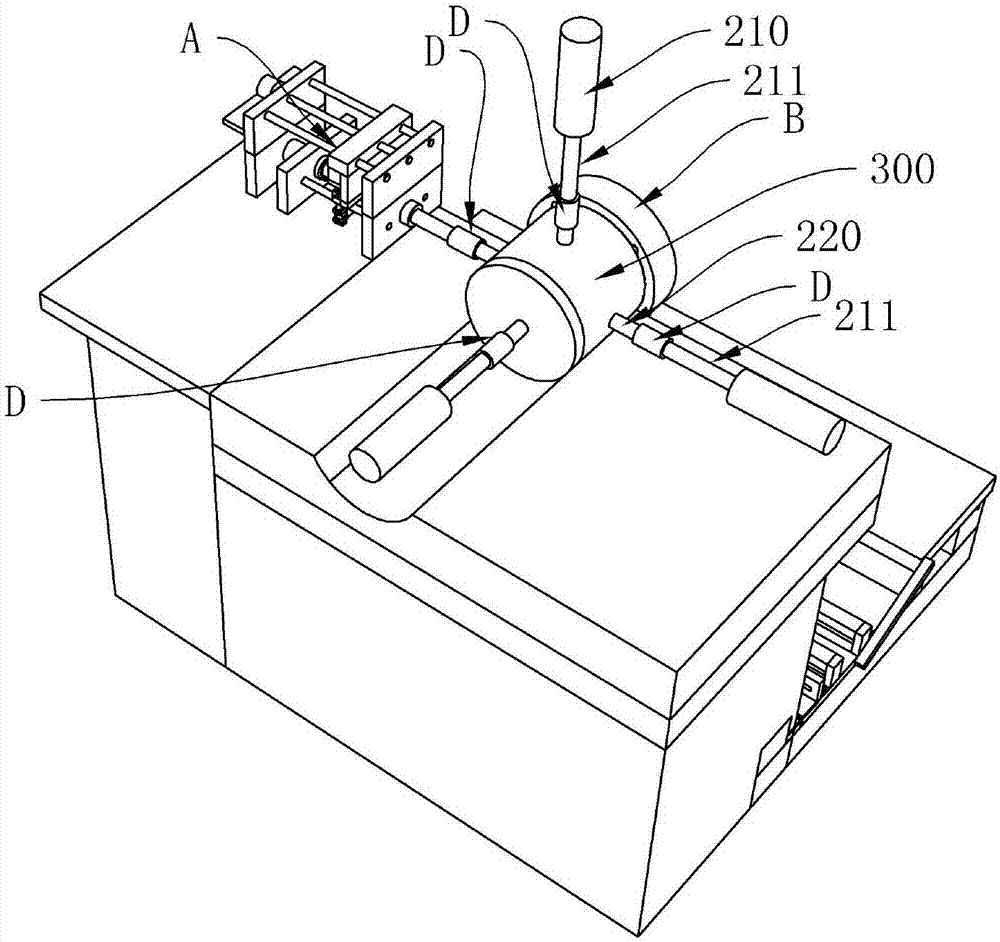

[0079] The supporting plate 150 is fixed with a slack testing mechanism and a disturbance generating mechanism A. The slack testing mechanism includes a loading cylinder 210. There may be three loading cylinders 210 and they are respectively arranged with the loading shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com