Experiment evaluation method of compact sandstone gas reservoir damage by simulating gas production process

A technology of tight sandstone and evaluation methods, applied in the direction of material inspection products, instruments, analytical materials, etc., can solve the problems of not considering the process of gas production, inability to simulate the state of gas reservoirs, and failure to effectively establish, etc., to achieve low economic cost , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

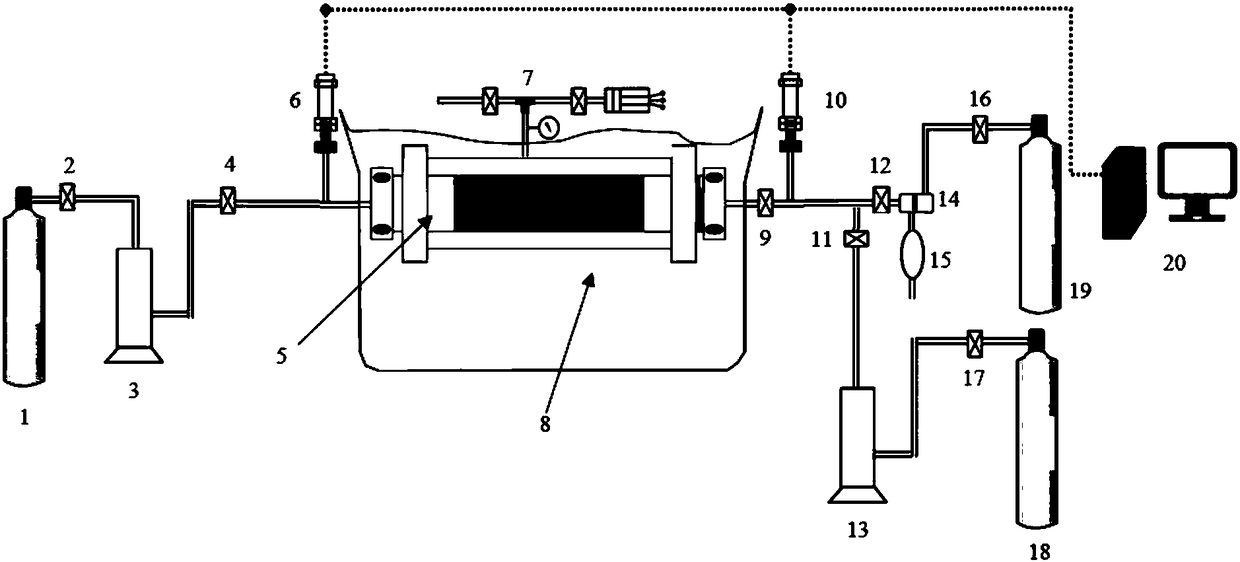

Embodiment 1

[0028] In order to verify the reliability of the present invention, the typical tight sandstone rock sample in the Dibei block of the Tarim Basin was used as the experimental rock sample, and the reservoir protection ability of the field drilling fluid was evaluated by using the drilling fluid of the sulfonium polymer system on site. The specific operation steps are as follows:

[0029] (1) Select tight sandstone rock blocks, drill several standard core columns, and dry the rock samples at 60°C for 48 hours;

[0030] (2) The rock core column in the step (1) is packed into the rock core holder 5, a certain confining pressure is applied, the heating system 8 is turned on, the rock core holder 5 is heated to the gas layer temperature, and the temperature is kept stable;

[0031] (3) After checking the airtightness of the device, close the valve 4, open the valve 2, fill a certain amount of nitrogen into the intermediate container 3, and close the valve 2;

[0032] (4) close valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com