Testing device for drop rate of cigarette combustion cone

A test device and combustion cone technology, applied in the direction of measuring device, material analysis through optical means, instruments, etc., can solve problems such as excessive variable, uneven installation of cigarettes, judgment errors, etc., to achieve accurate test results and avoid smoke Leakage, avoiding the effect of cigarette deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

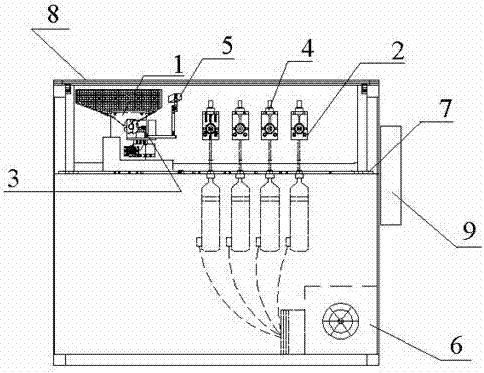

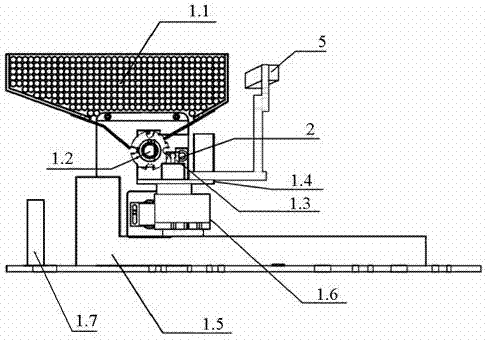

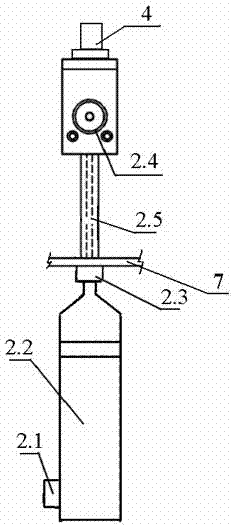

[0028] Such as Figure 1-3 As shown, the cigarette burning cone drop rate testing device of this embodiment includes a base 7, four suction devices 2 arranged side by side, a clamping device 1, an ignition device 3, a simulated ash device 4, and an imaging detection device 5 With the PLC controller 9, four suction devices 2 are arranged side by side on the side of the base 7, the clamping device 1 is arranged next to the suction device 2, the simulated ash ejection device 4 is arranged on the top of the suction device 2, and the clamping device 1 It includes a smoke storage device 1.1, a drum 1.2 located under the smoke storage device 1.1, a gripper located on one side of the drum wheel 1.2, a photoelectric sensor switch 1.7, and the photoelectric sensor switch 1.7 is located on the base 7 on the side of the drum wheel 1.2 .

[0029] The base 7 is provided with horizontal guide rails and 5 longitudinal guide rails, the smoke storage device 1.1 is located at the end of the fir...

Embodiment 2

[0047] Such as Figure 4 As shown, in this embodiment, the imaging mechanism includes two industrial cameras, one camera takes pictures of cigarettes from a direction of 30 degrees to the horizontal guide rail, and the other simultaneously takes pictures from a direction of 30 degrees to the longitudinal guide rail. The collected signals are input to the PLC in parallel, if any signal is 1, it is determined that the cigarette burning cone has fallen, and the proportion of the final burning cone falling in this group is calculated. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com