Overheat steam temperature multi-target control method of ultra-supercritical unit

A technology of ultra-supercritical unit and control method, which is applied in the direction of self-adaptive control, general control system, control/regulation system, etc. It can solve the problems of superheater metal tube wall overtemperature, coupling oscillation, and affecting equipment safety, etc., to achieve broaden The effect of the range of applications and the difficulty of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are used to describe the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

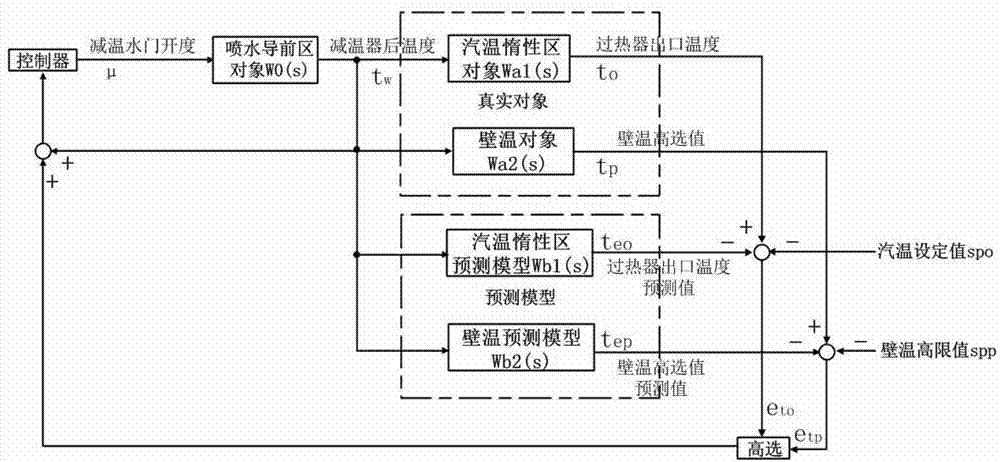

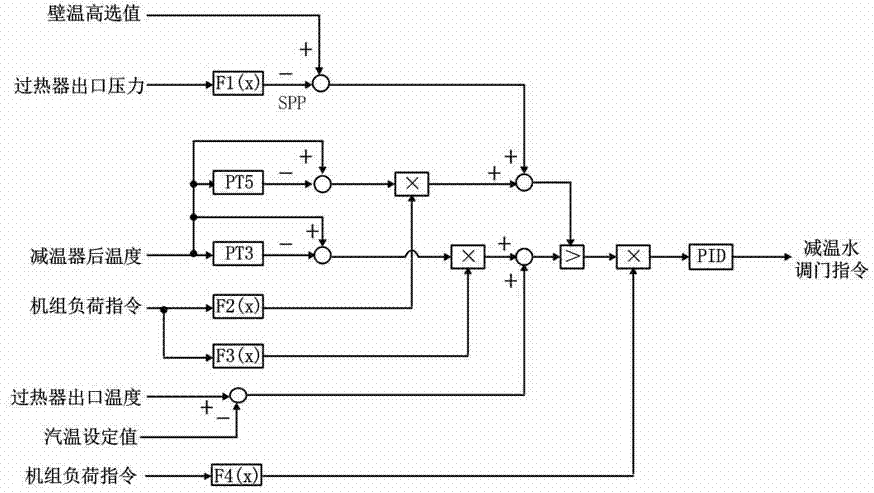

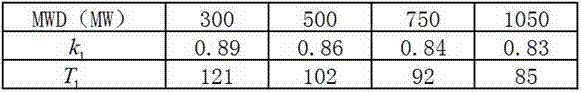

[0023] like figure 1 A multi-objective control method for the superheated steam temperature of an ultra-supercritical unit is shown, including the multi-objective control method of the outlet temperature control method and the tube wall metal temperature control method; using the model prediction control method, the steam temperature inert zone prediction model is established respectively and the wall temperature prediction model, and use the large value of the deviation between the two prediction models and the actual measured parameters as one of the feedback adjustment components; according to the feedback adjustment component in the control method predicted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com