Molten steel steelmaking process temperature control system and method based on self-learning

A technology for controlling the system and molten steel temperature, applied in the field of steelmaking and smelting, can solve problems such as steel leakage, high temperature of molten steel leaving the station, and untimely information communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

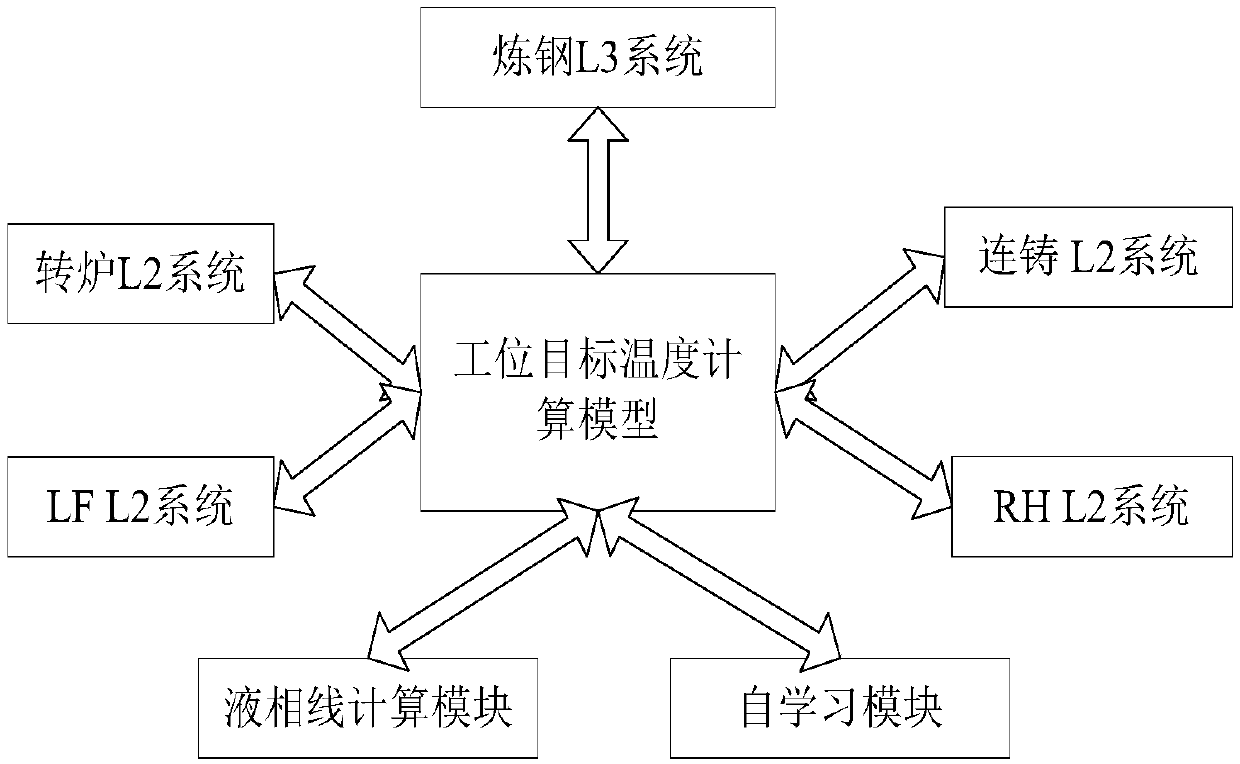

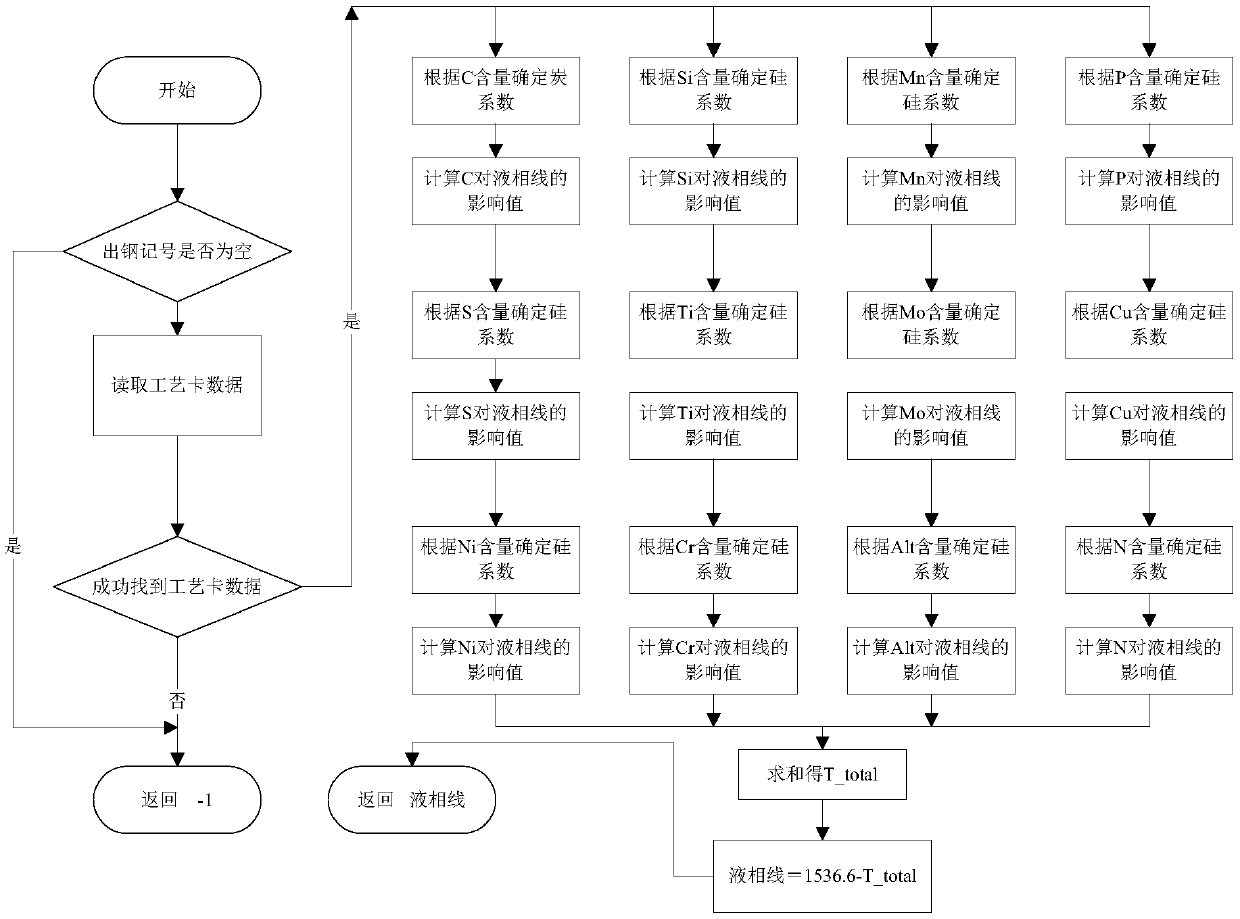

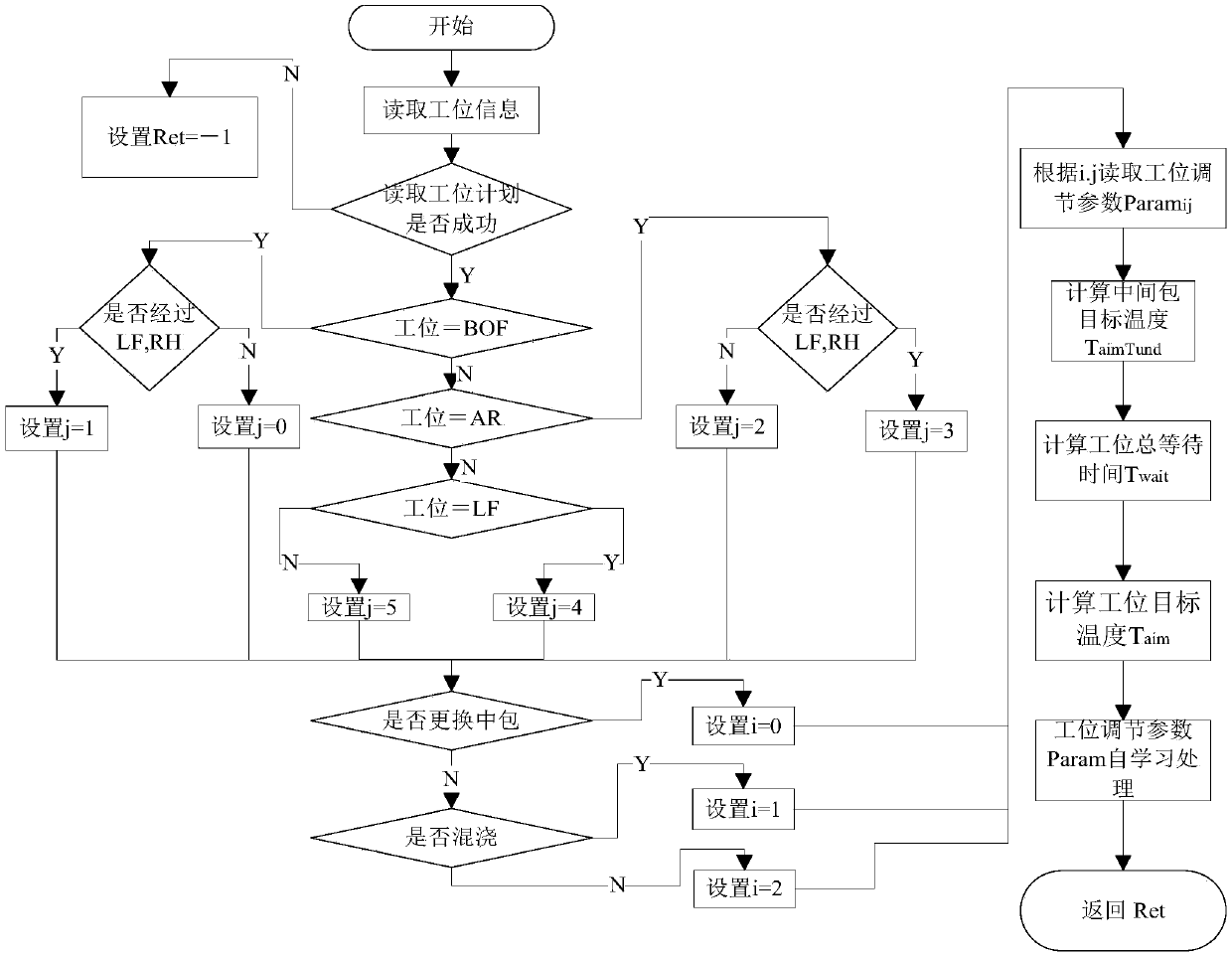

[0063] Embodiment 1: see figure 1 , a kind of steelmaking molten steel process temperature control method based on self-study, described method is specifically as follows, (1) calculate station target outbound temperature, at first determine following parameter list according to historical data, then use formula: station target temperature= Tundish molten steel target temperature TaimTund + total waiting time of molten steel Twait * station temperature drop coefficient Coeff i +Station superheat SH i +Station adjustment parameter Param ij Calculate the target exit temperature for the station.

[0064] ① Analyze the historical data and establish the station adjustment parameter table. The initial data is as follows:

[0065] BOF BOF1 AR AR1 LF RH Tundish Change 5.0 13.05 4.3 8.8 3.4 4.6 MixFlag 6.3 13.4 3.6 9.1 3.2 5.4 Others 3.9 8.4 2.5 6.1 2.33 2.32

[0066] Station temperature drop coefficient table Coeff:

[00...

example

[0078] The converter is processing a furnace, and the calculation is as follows:

[0079] The steel type is: GV5950E2; look up the standard data and related parameters of this steel type, and calculate the liquidus line: 1517°, the superheat of the tundish is 25°, the superheat of the converter is 20°, the temperature drop of tapping is 15°, and the furnace is planned to be replaced package, the furnace plan is processed by LF, it can be seen that i=0, j=1.

[0080] Time at that time: 23:16:26, May 9;

[0081] Planned pouring time: 00:40:00, May 10

[0082] The calculated total waiting time is 83.57 minutes

[0083] The station temperature drop coefficient is 0.56

[0084] Station adjustment parameter Param 01 The lookup table is 13.05

[0085] The target temperature of the station is: 1517+25+20+15+83.57*0.56+13.05=1636.5°

[0086] (2) Self-learning process of station adjustment parameters

[0087] Taking the above converter molten steel as an example, the calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com