Electric arc furnace terminal temperature prediction system based on SVM

A technology of end-point temperature and forecasting system, which is applied in the direction of temperature control using electric method, general control system, control/regulation system, etc., which can solve the limitation of application, local minimum point of neural network, structure and type design relying on expert experience, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Figure 1~Figure 10 It is a specific implementation of the present invention.

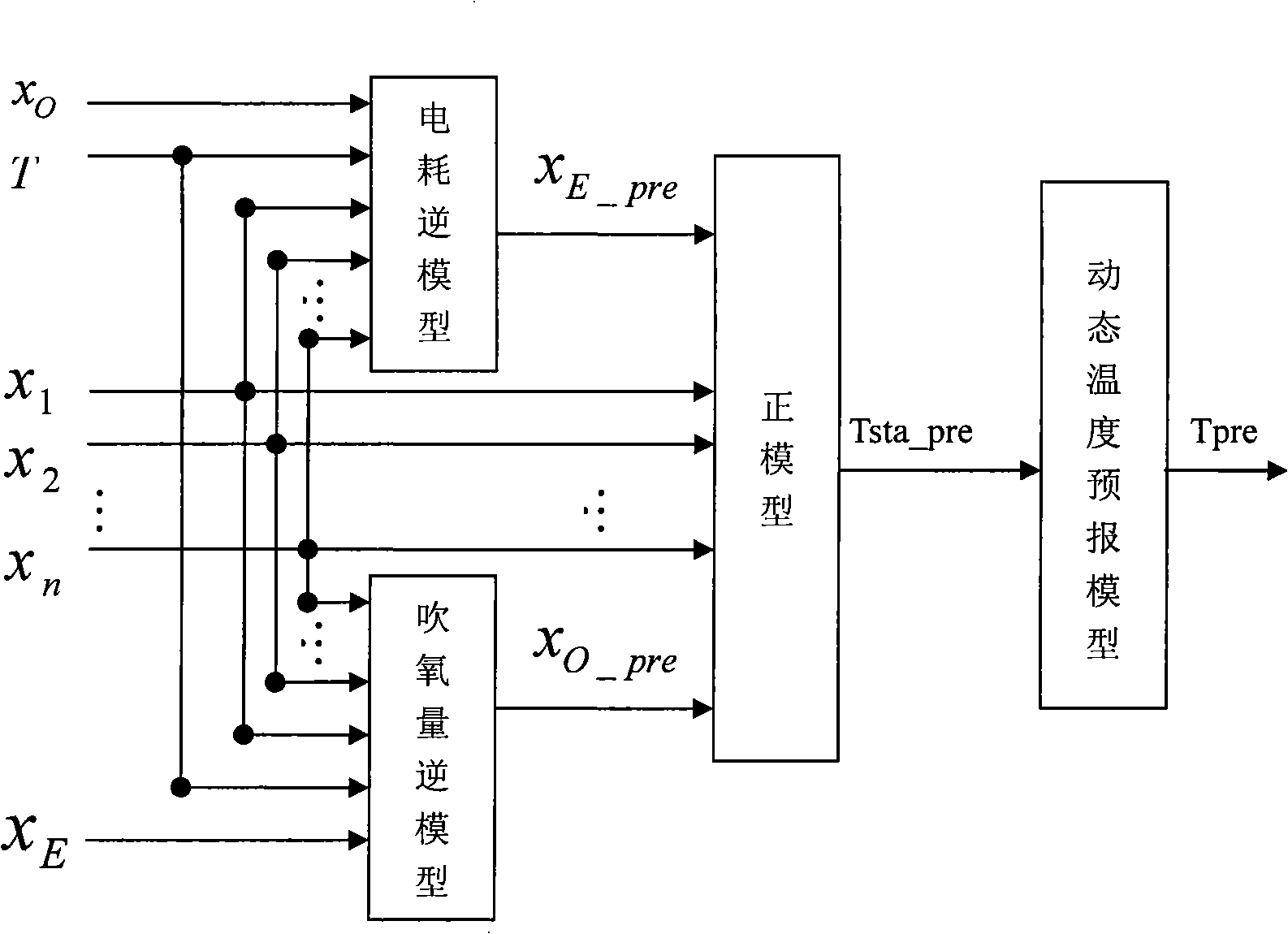

[0028] In practical applications, according to the required target temperature, the inverse model is used to predict the blowing plan required to reach the target temperature. When the blowing plan is satisfied, the current temperature can be predicted based on the positive model, and this temperature is used as a dynamic temperature forecast The starting temperature of the model is used for real-time prediction of the process temperature to achieve the purpose of controlling the end temperature of molten steel. Picture 10 It is the application flow chart of the molten steel endpoint temperature prediction model.

[0029] figure 1 It is the structure and connection mode of the static temperature prediction model and the dynamic temperature prediction model. The static temperature pre-model is a combination of the power consumption inverse model, the oxygen blowing inverse model and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com