Method for forecasting finite element of hot rolling process plate belt temperature field

A hot rolling process and finite element technology, applied in the field of rolling, can solve problems such as low precision and low professionalism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

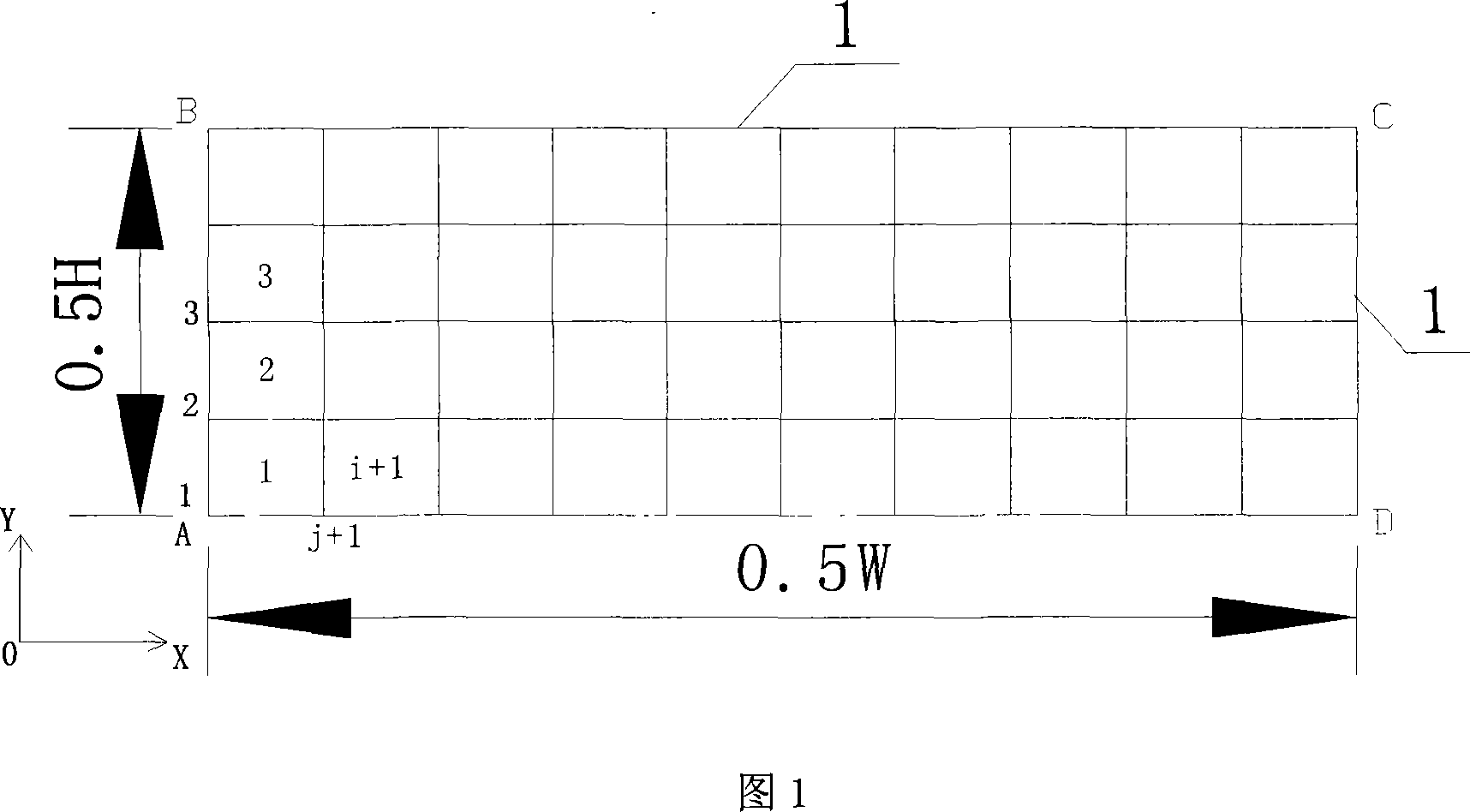

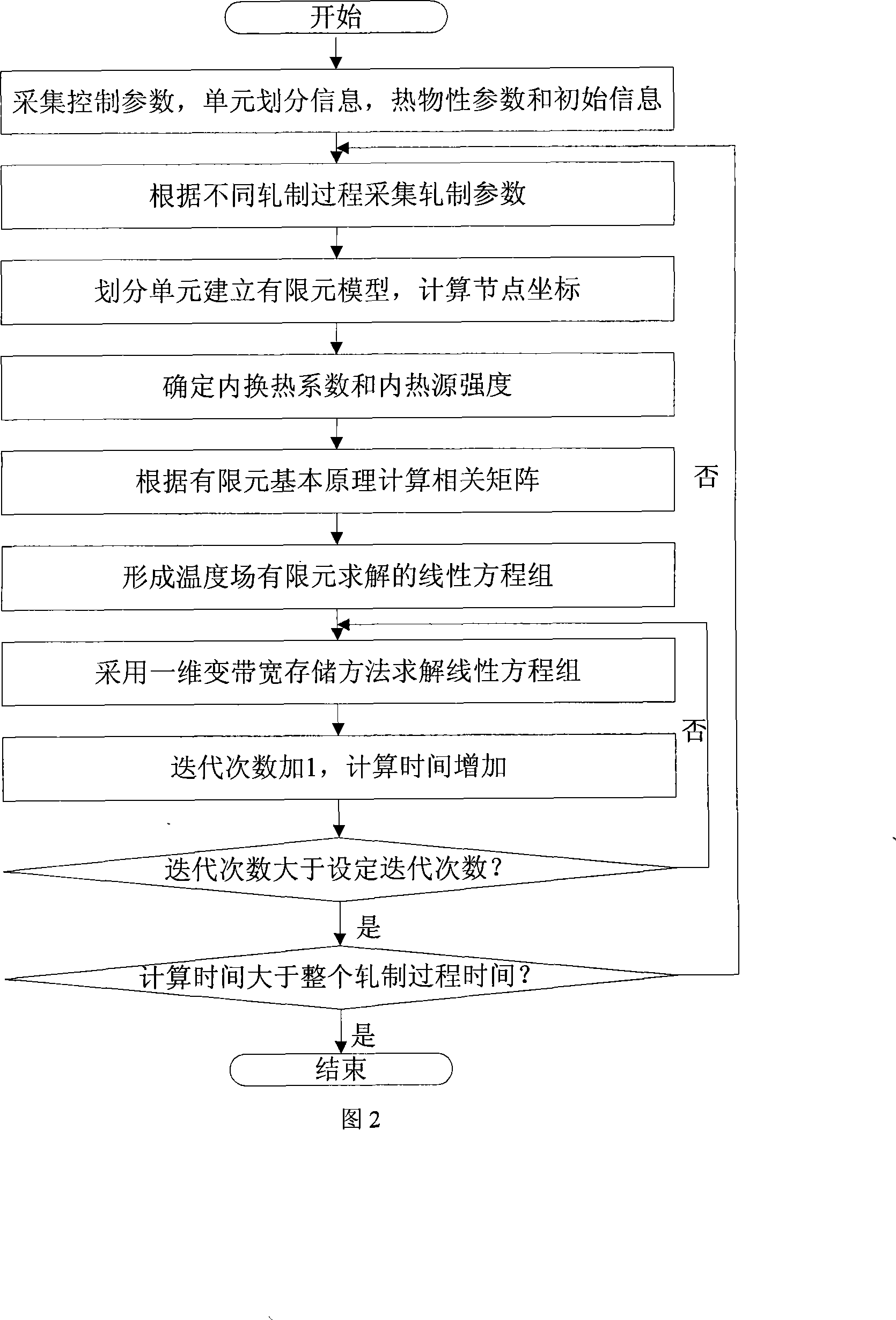

Method used

Image

Examples

Embodiment Construction

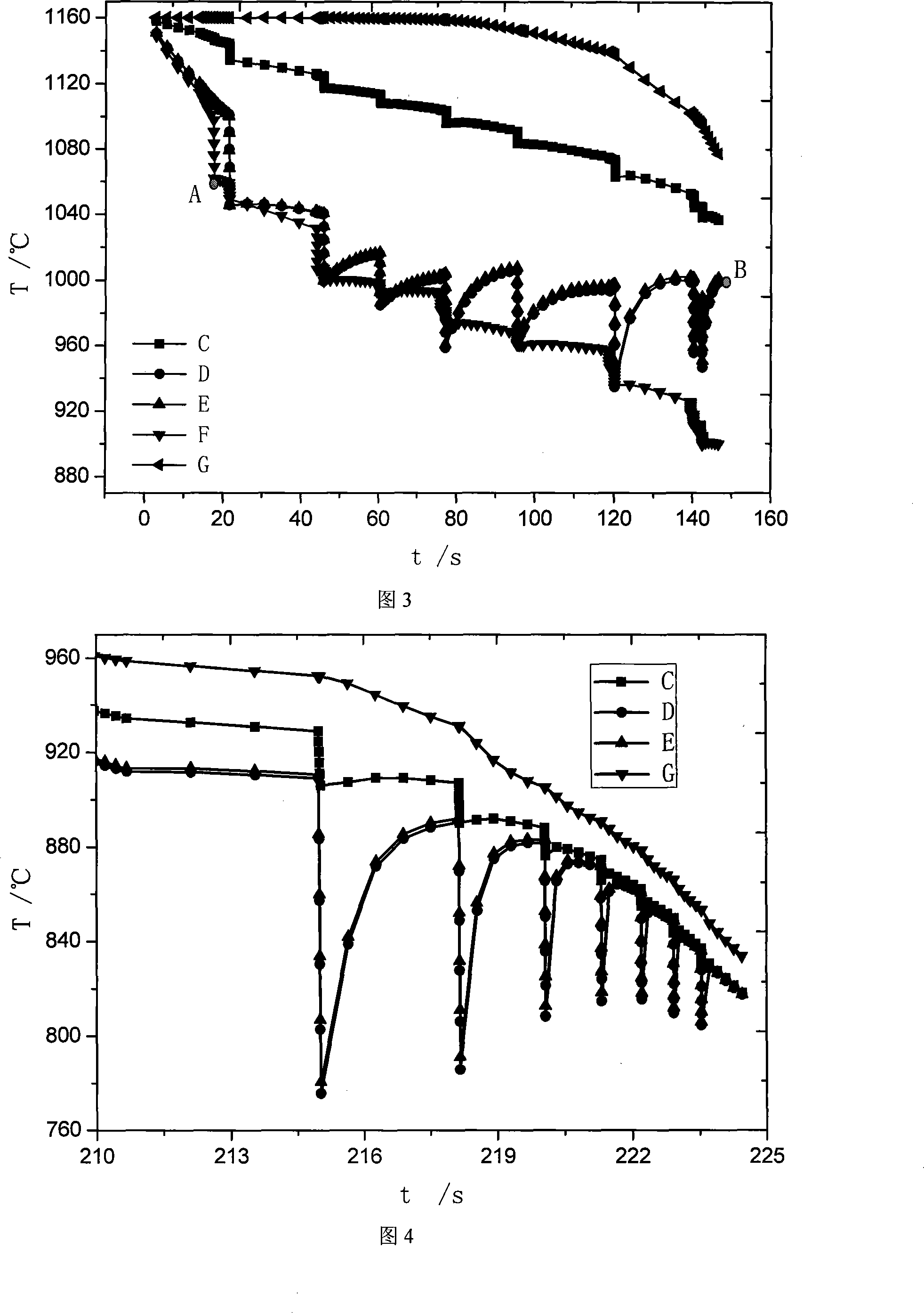

[0073] The hot rolling process of a steel grade is selected as the calculation object, and the temperature evolution law of the whole process from exiting the heating furnace to finishing rolling is analyzed by using the finite element method.

[0074] Hot continuous rolling process in a steel mill. There are 4 stands in the rough rolling process, and the second stand is a reversible stand; there are 7 stands in the finish rolling process. The reversible stand is rolled 5 times, and the rest of the stands are rolled once.

[0075] Example: See Table 1 for calculation conditions.

[0076] Table 1

[0077] parameter name

value

iterations

density

Initial temperature of rolled piece

Roll temperature

ambient temperature

unit division

Rolled piece initial width

Initial thickness of rolled piece

rolling pressure

Phosphate removal water flow

5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com