Computing method for predicting temperature field of cold-roll strip steel

A technology of cold-rolled strip steel and calculation method, which is applied in the direction of metal rolling, metal rolling, rolling mill control device, etc., and can solve the problem of softening of strip material, affecting the shape quality of strip steel, and the limitation of calculation accuracy of cold-rolled strip temperature field And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific embodiment the present invention will be further described:

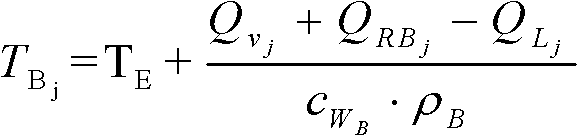

[0039] The embodiment selects a certain pass cold rolling process of ST12 steel as the calculation object. The entrance thickness is 2.30mm; the exit thickness is 1.63mm. There are 38 areas, and the strip steel in the roll gap is divided into 20 areas along the length direction of the strip steel. Other calculation initial parameters are shown in Table 1.

[0040] Table 1

[0041]

[0042]

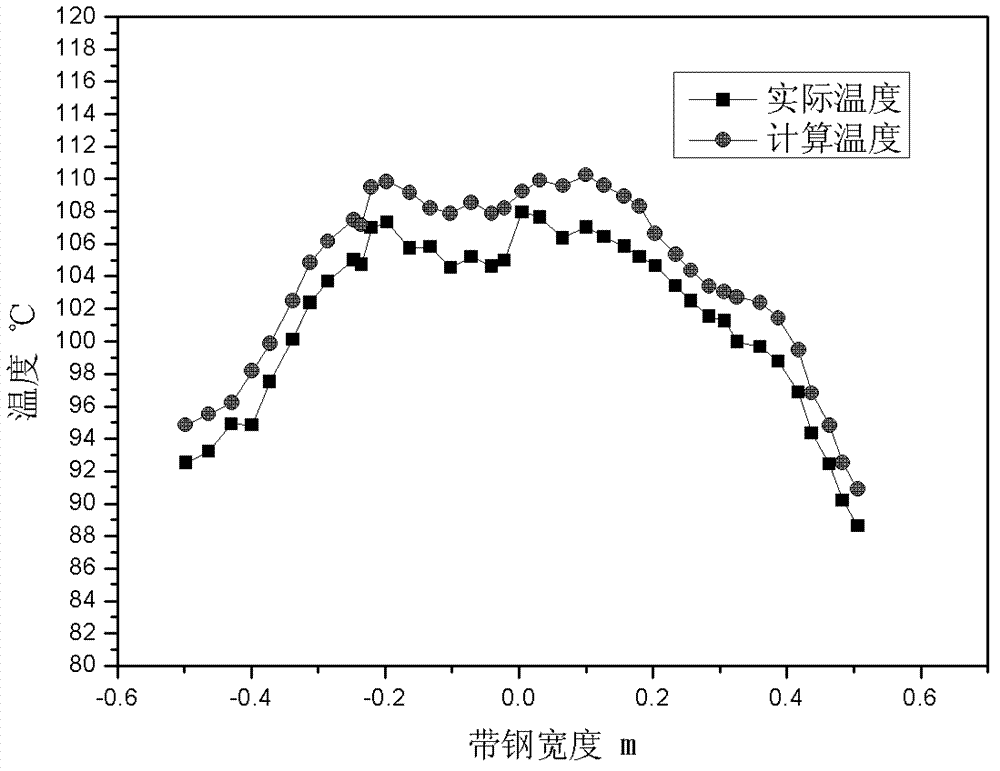

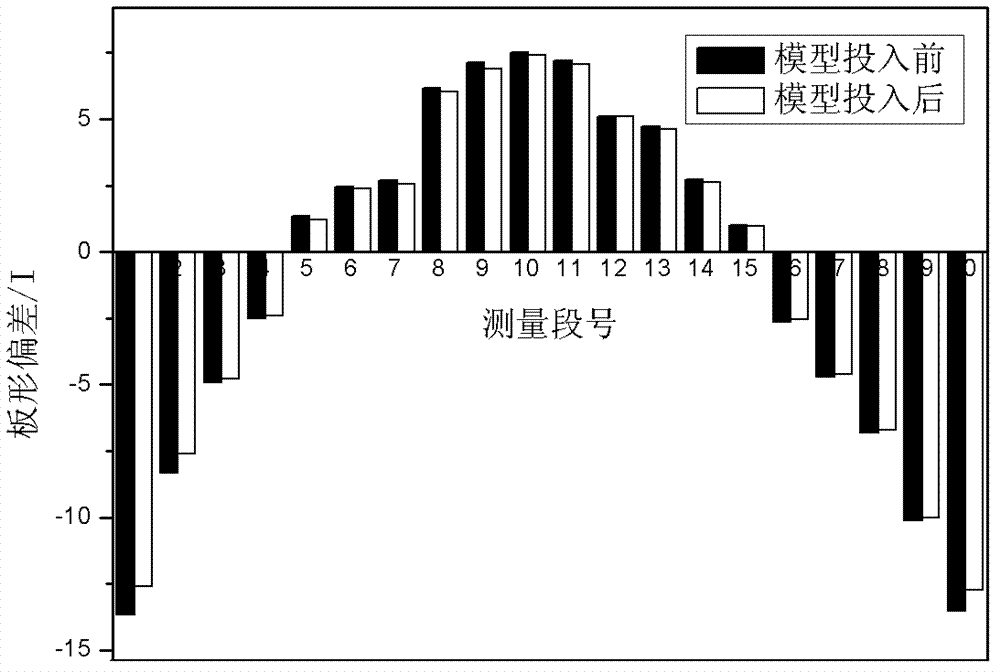

[0043] Using the numerical integration method to calculate and analyze the temperature change of the cold-rolled strip temperature field, the calculation results are as follows figure 1 As shown, the calculated strip temperature is in good agreement with the actual measured temperature, and the error is controlled within 3%, which proves the accuracy and reliability of the model of the present invention. The method of the invention can obtain the temperature distribution in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com