Patents

Literature

52results about How to "Good adaptability to working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

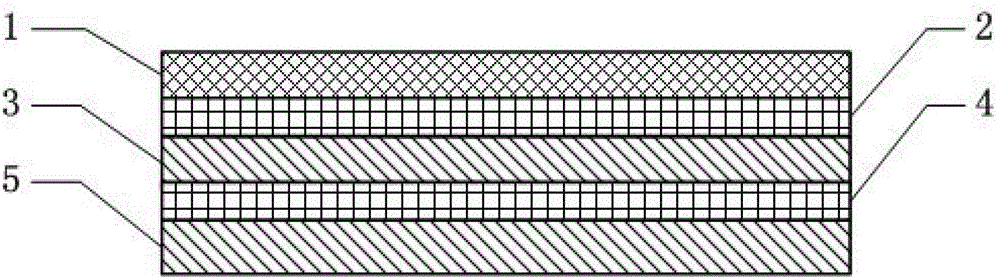

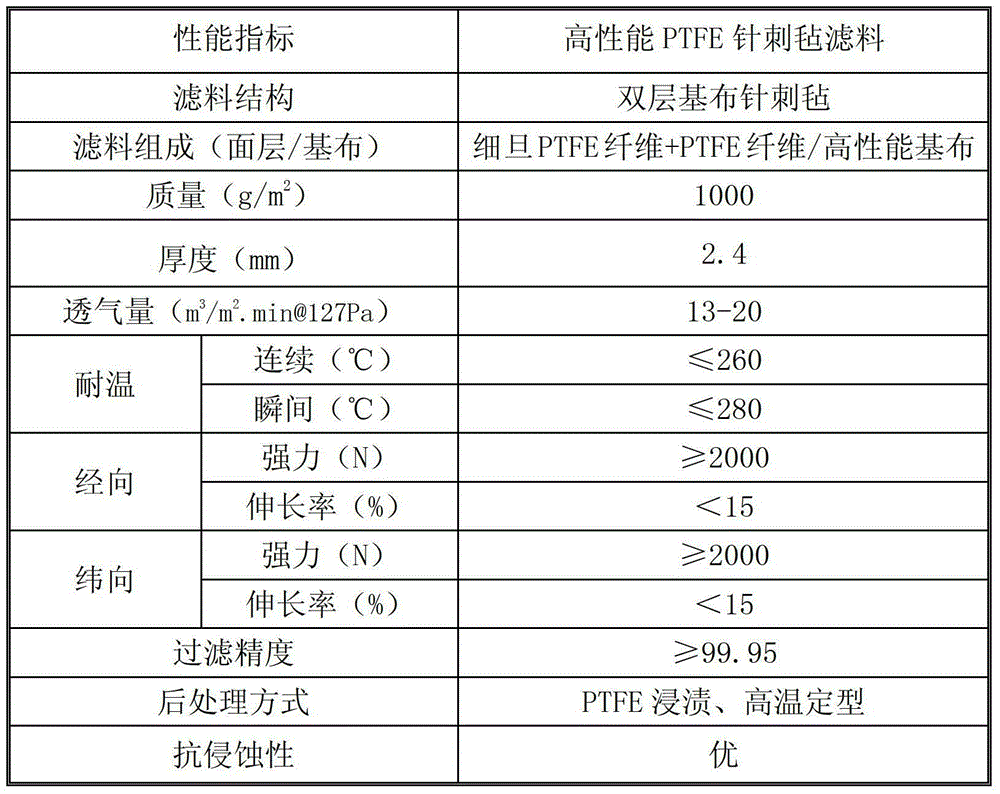

High-performance PTFE (Polytetrafluoroethylene) needled felt filter material and preparation process thereof

ActiveCN103432827ASmall apertureHigh porositySynthetic resin layered productsFiltration separationHeat resistanceFilter material

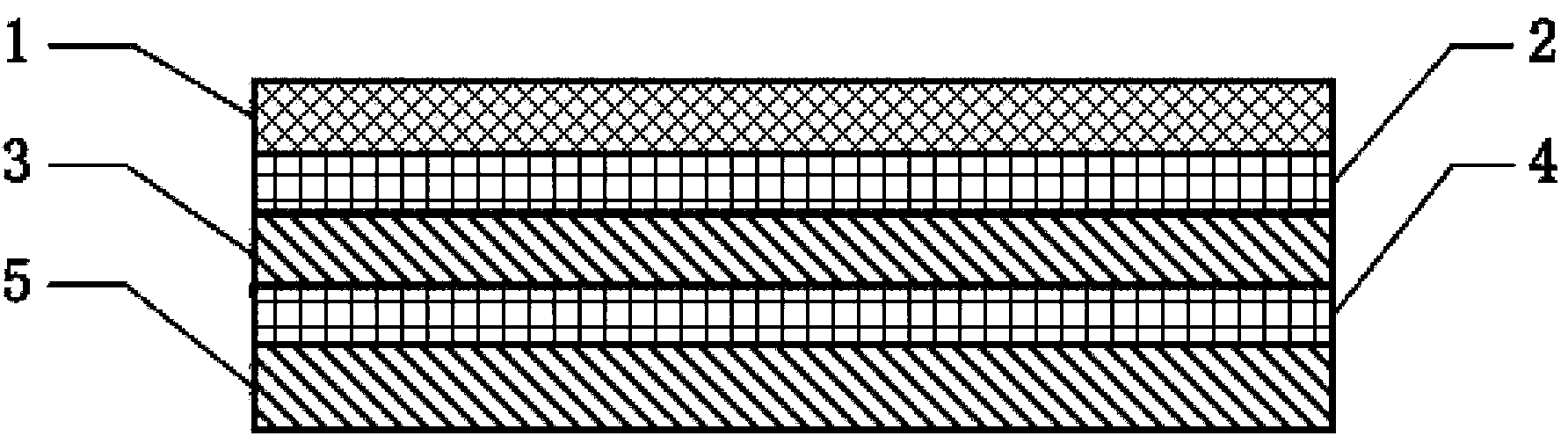

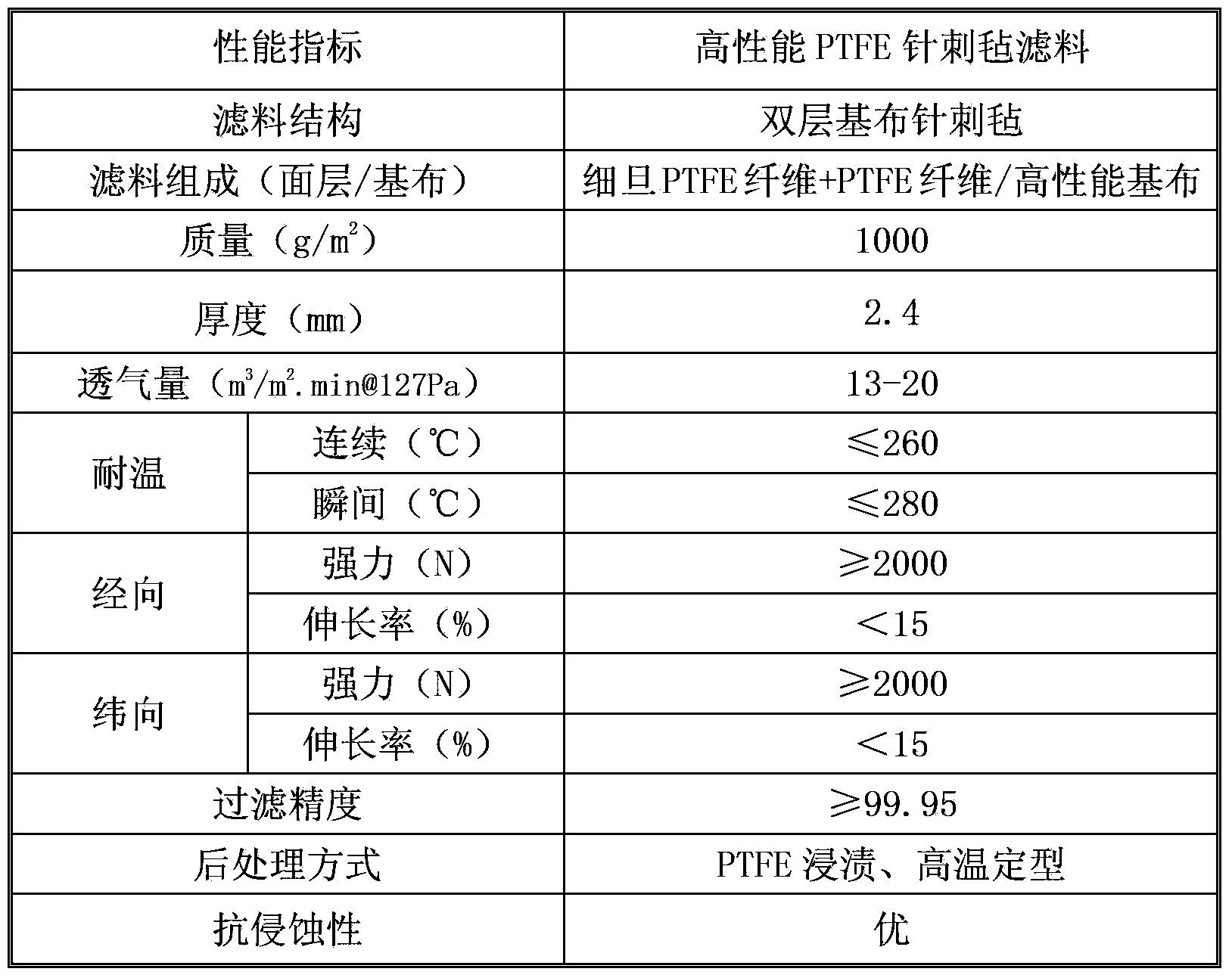

The invention provides a high-performance PTFE (Polytetrafluoroethylene) needled felt filter material and a preparation process thereof. The filter material sequentially comprises a fine denier PTFE fiber mesh layer, a first base fabric layer, an upper PTFE fiber mesh layer, a second base fabric layer and a lower PTFE fiber mesh layer; the fine denier PTFE fiber mesh layer is made by pre-treating, pre-opening and carding a fine denier PTFE fiber, the first base fabric layer and the second base fabric layer are made by pre-treating PTFE base fabrics, and the upper PTFE fiber mesh layer and the lower PTFE fiber mesh layer are made by pre-treating, pre-opening and carding common PTFE fibers. The filter material provided by the invention is stable in structure, high in filter precision and strength, and good in heat resistance and corrosion resistance, and is used for filtering smoke and collecting products under various complex working conditions.

Owner:辽宁新洪源环保材料有限公司

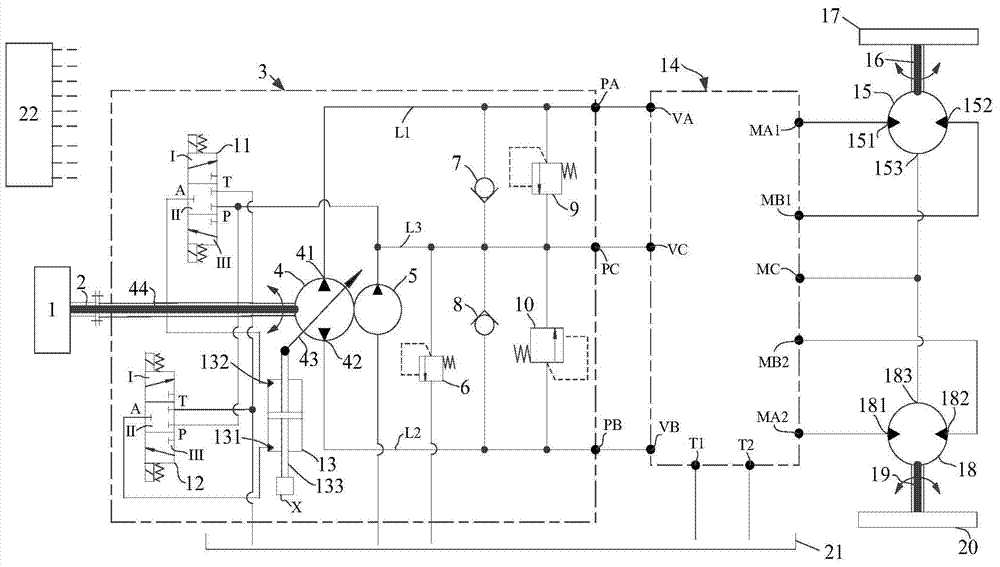

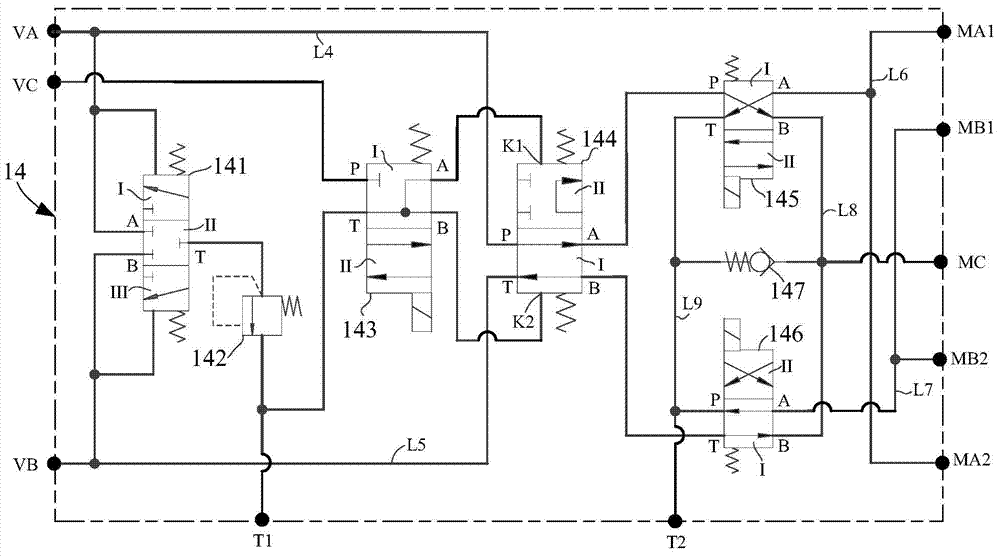

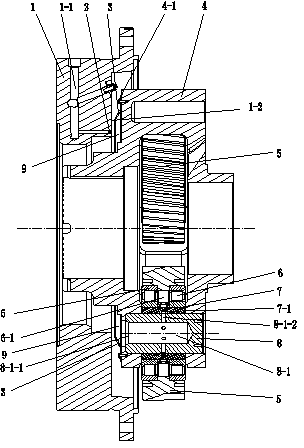

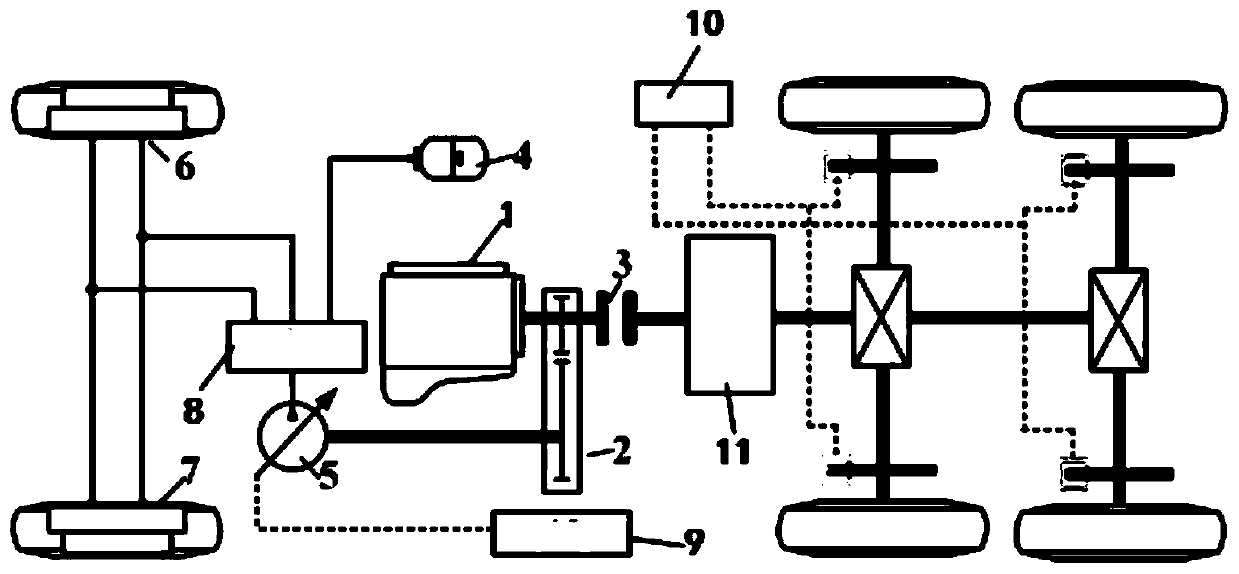

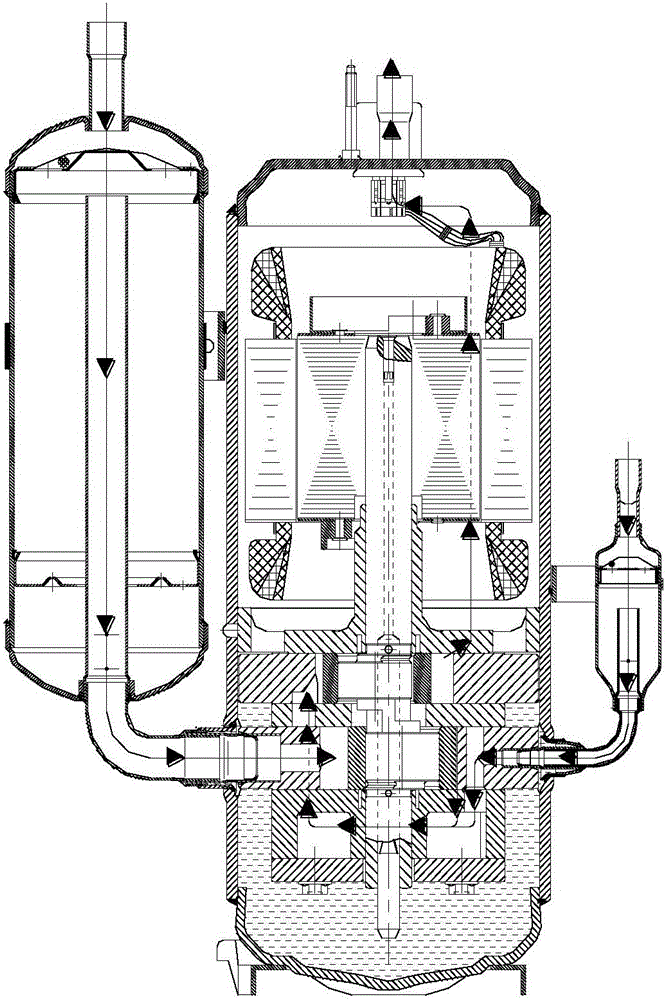

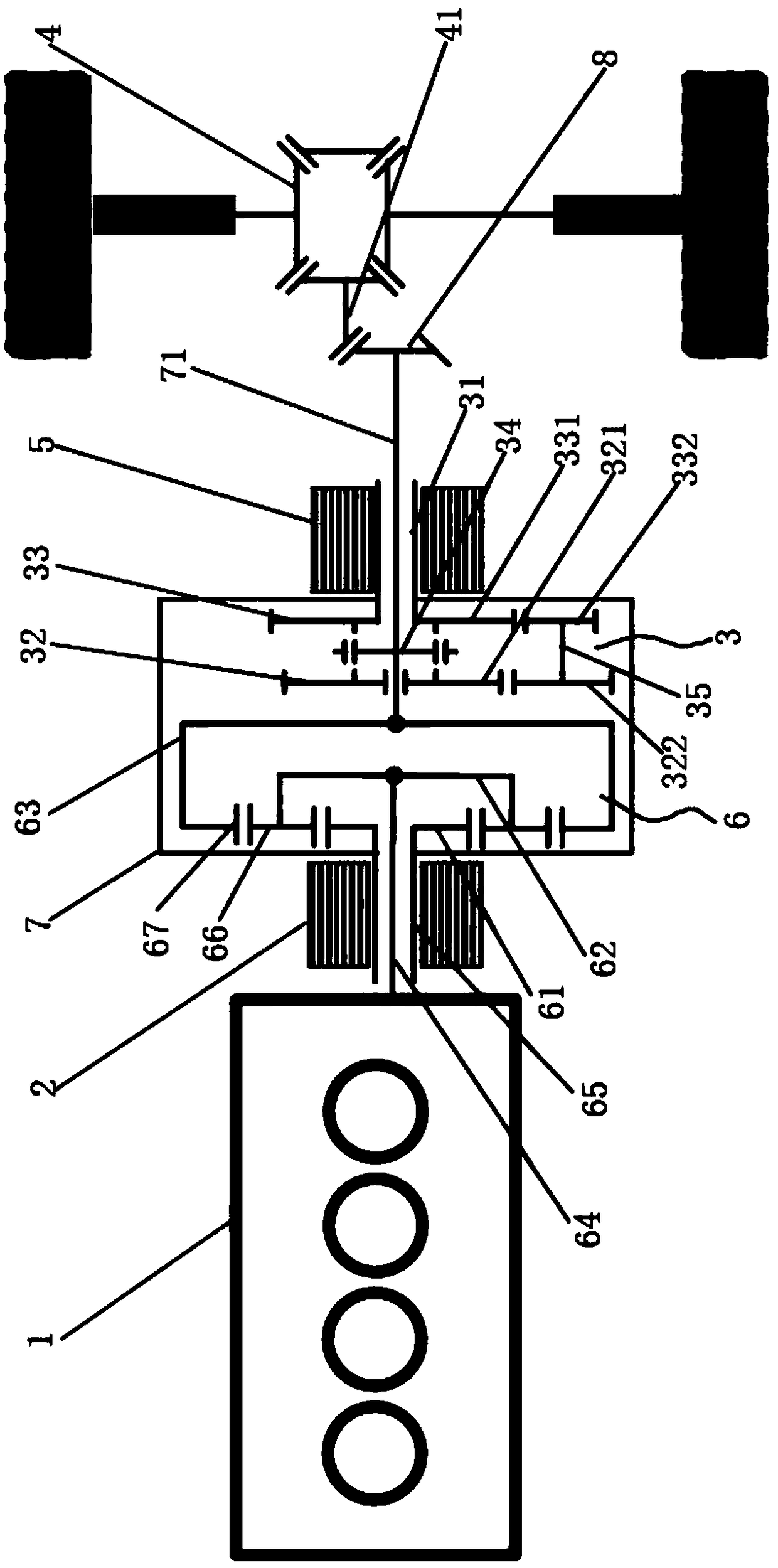

Closed type hydraulic transmission system

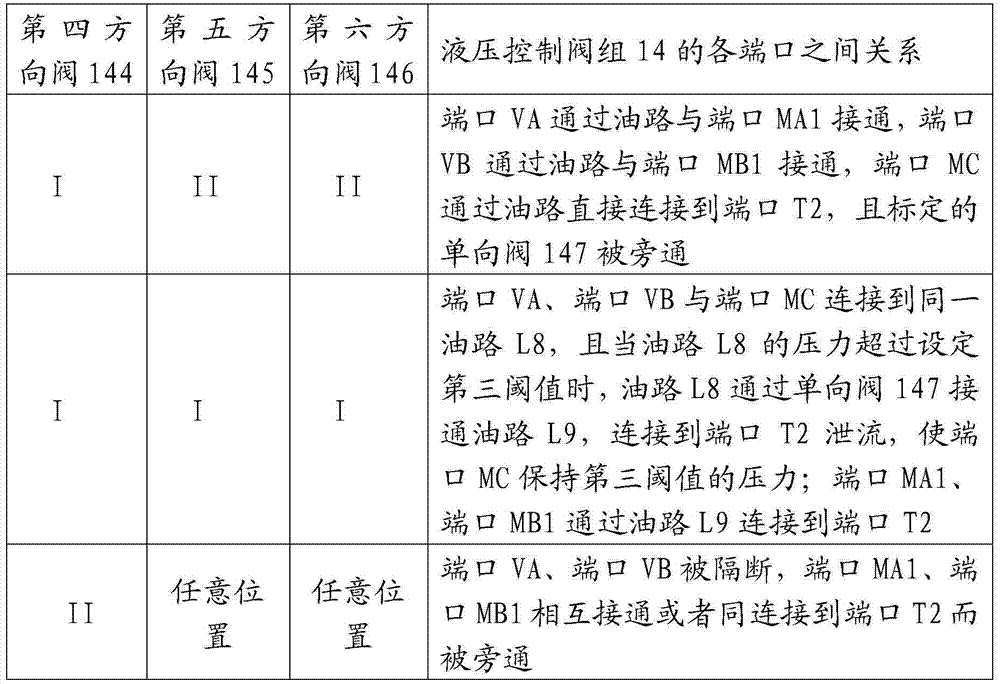

InactiveCN103790876AHigh delivery pressureQuick responseServomotor componentsServomotorsHydraulic pumpControl valves

The invention discloses a closed type hydraulic transmission system which solves the problem that impact pressure on a motor shell caused by high-pressure oil during status switching and a certain amount of pressure existing in a loop when a hydraulic motor does not work produce resistance on vehicle running. The closed type hydraulic transmission system comprises a power input mechanism, a hydraulic pump assembly, a hydraulic control valve set, a first hydraulic motor, a second hydraulic motor, a non-pressurization oil tank and a control unit. The power input mechanism is in mechanical connection with the hydraulic pump assembly which is in pipeline connection with the hydraulic control valve set, the hydraulic control valve set is in pipeline connection with the first hydraulic motor and the second hydraulic motor respectively, the first hydraulic motor is in mechanical connection with a load mass body of the first hydraulic motor, the second hydraulic motor is in mechanical connection with a load mass body of the second hydraulic motor, both the hydraulic pump assembly and the hydraulic control valve set are in pipeline connection with the non-pressurization oil tank, and the control unit is connected with the hydraulic pump assembly and the hydraulic control valve set through signal wires.

Owner:JILIN UNIV

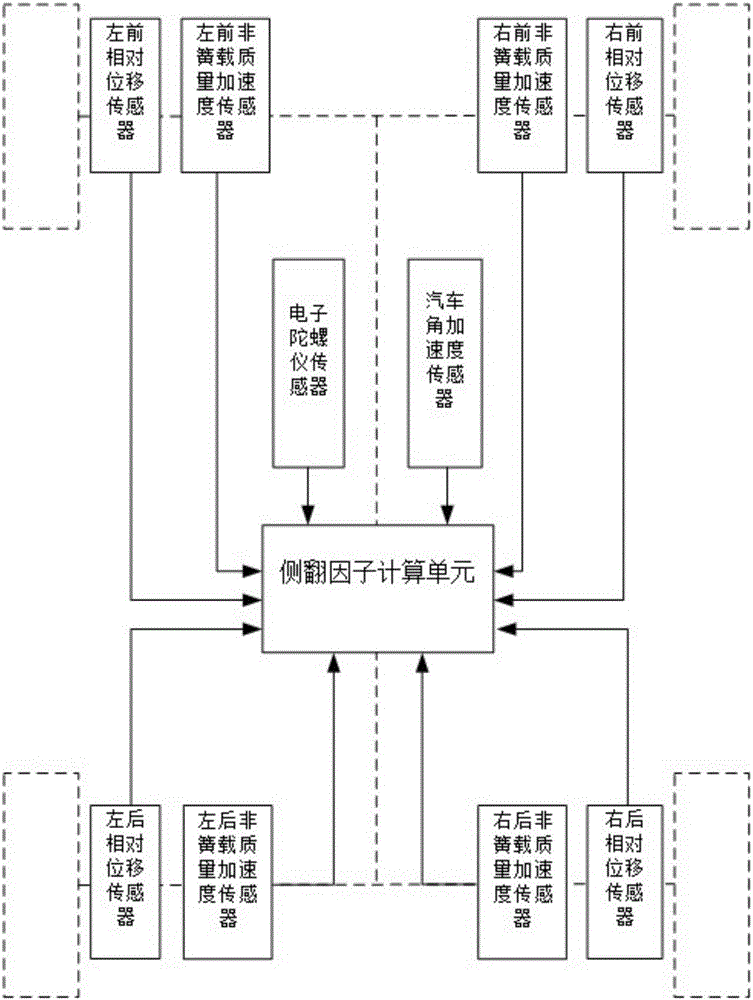

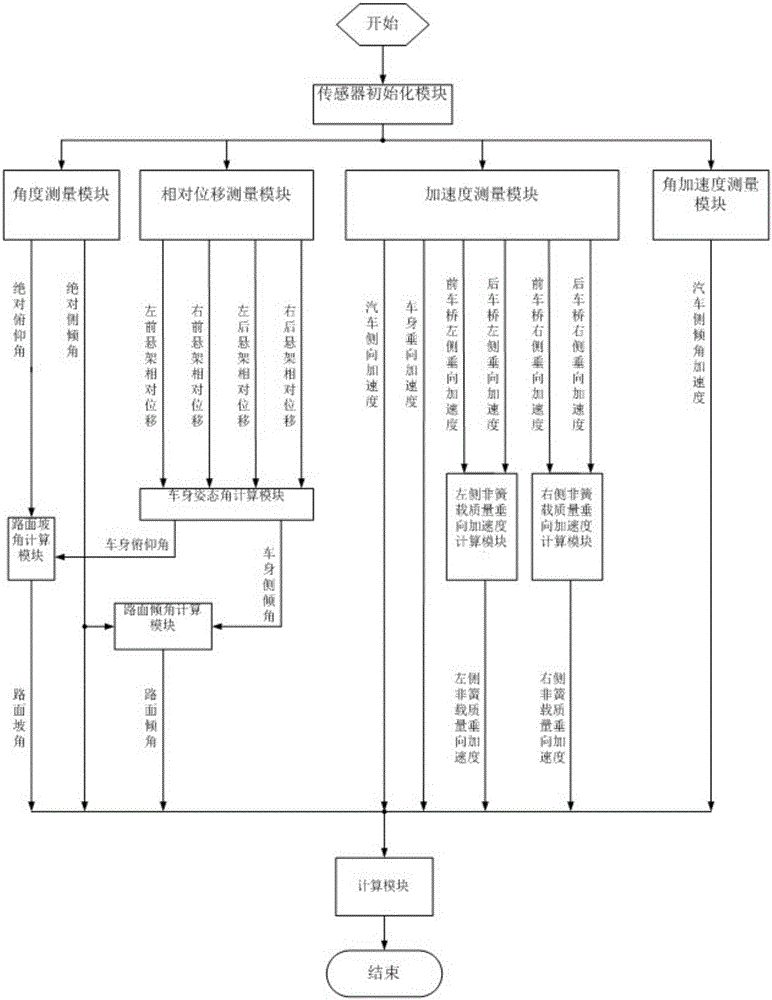

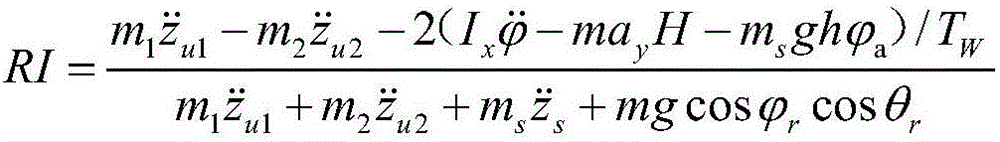

Multi-condition vehicle rollover index calculation device and calculation method thereof

ActiveCN106197416AGood adaptability to working conditionsAssess rollover riskVehicle testingSustainable transportationRolloverRelative displacement

The invention discloses a multi-condition vehicle rollover index calculation device and a calculation method thereof. The device comprises a rollover index calculation unit, an electronic gyroscope sensor, a vehicle angular acceleration sensor, a left-front relative displacement sensor, a left-front unsprung mass acceleration sensor, a right-front relative displacement sensor, a right-front unsprung mass acceleration sensor, a left-rear relative displacement sensor, a left-rear unsprung mass acceleration sensor, a right-rear unsprung mass acceleration sensor and a right-rear relative displacement sensor. When the device works, the rollover index calculation unit is used for calculating rollover factors through data collected by the sensors according to a vehicle rollover dynamic law and evaluating the vehicle rollover risk. The device can be used for calculating the vehicle rollover risk under multiple conditions, provides the calculation result to drivers or other safety control devices, so that vehicle rollover can be effectively controlled and prevented.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Planet gear bearing forced lubricating device

ActiveCN102829165AImprove delivery efficiencyReduce in quantityGear lubrication/coolingGear wheelSpray nozzle

The invention discloses a planet gear bearing forced lubricating device for a wind power generation gearbox. The planet gear bearing forced lubricating device comprises a box body, a planet carrier, a planet gear, a bearing and a planet pin; the planet carrier is rotationally supported on the box body; the planet pin is arranged on the planet carrier; the planet gear is rotationally supported on the planet carrier by the bearing; the inner lateral surface of the planet carrier, which is opposite to the inner lateral surface of the box body, is provided with a ring-shaped convex retainer; a centrifugal oil collection cavity is formed between the inner lateral surface of the planet carrier and the inner wall of the ring-shaped convex retainer; the box body is provided with an oil injection duct and a spray nozzle is arranged on the box body; the oil injection duct is communicated with the spray nozzle; an outlet of the spray nozzle is toward the centrifugal oil collection cavity on the planet carrier; the planet pin is provided with an oil passage; an inlet of the oil passage is communicated with the centrifugal oil collection cavity; and an outlet of the oil passage is communicated to the position of the bearing positioned outside the planet pin. The planet gear bearing forced lubricating device has reasonable structure and is convenient to process and manufacture; and the oil supply can be regulated according to the working conditions.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

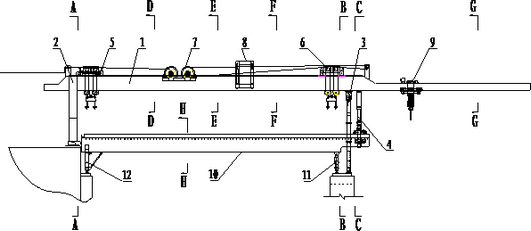

Through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine

InactiveCN102094394ARealize zero-distance erectionLower the altitudeBridge erection/assemblyOverhead craneBuilding construction

The invention relates to a through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine which belongs to the field of railway bridge erection equipment. A folding front support leg and an auxiliary support leg are connected on the bottom surface at the front part of a main girder of the lifting bridge girder erection machine, and the rear end of the main girder is connected with an O-shaped rear support leg; a front lifting girder overhead crane and a rear lifting girder overhead crane are arranged on the main girder, a hoisting component is mounted at the middle part of the main girder, a pilot girder lifting machine and a pilot girder through-hole overhead crane are connected on a track on the upper end surface of the main girder, and the pilot girder through-hole overhead crane is positioned at the front end of the main girder; and a lower pilot girder machine comprises a pilot girder front support leg and a pilot girder rear support leg of the main girder of a lower pilot girder, and the pilot girder front support leg and the pilot girder rear support leg are arranged at the front end part and the rear end part of the main girder of the lower pilot girder. The through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine has the advantages that the packing through-tunnel state of the through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine is the pilot girder front-mounted type state, and the pilot girder machine can be in place when going out of a tunnel, thereby greatly improving the erection efficiency for resetting the whole machine after going out of the tunnel, being good in adaptability to working conditions, saving construction time, saving construction cost, and being smooth, safe and reliable.

Owner:徐州徐工铁路装备有限公司

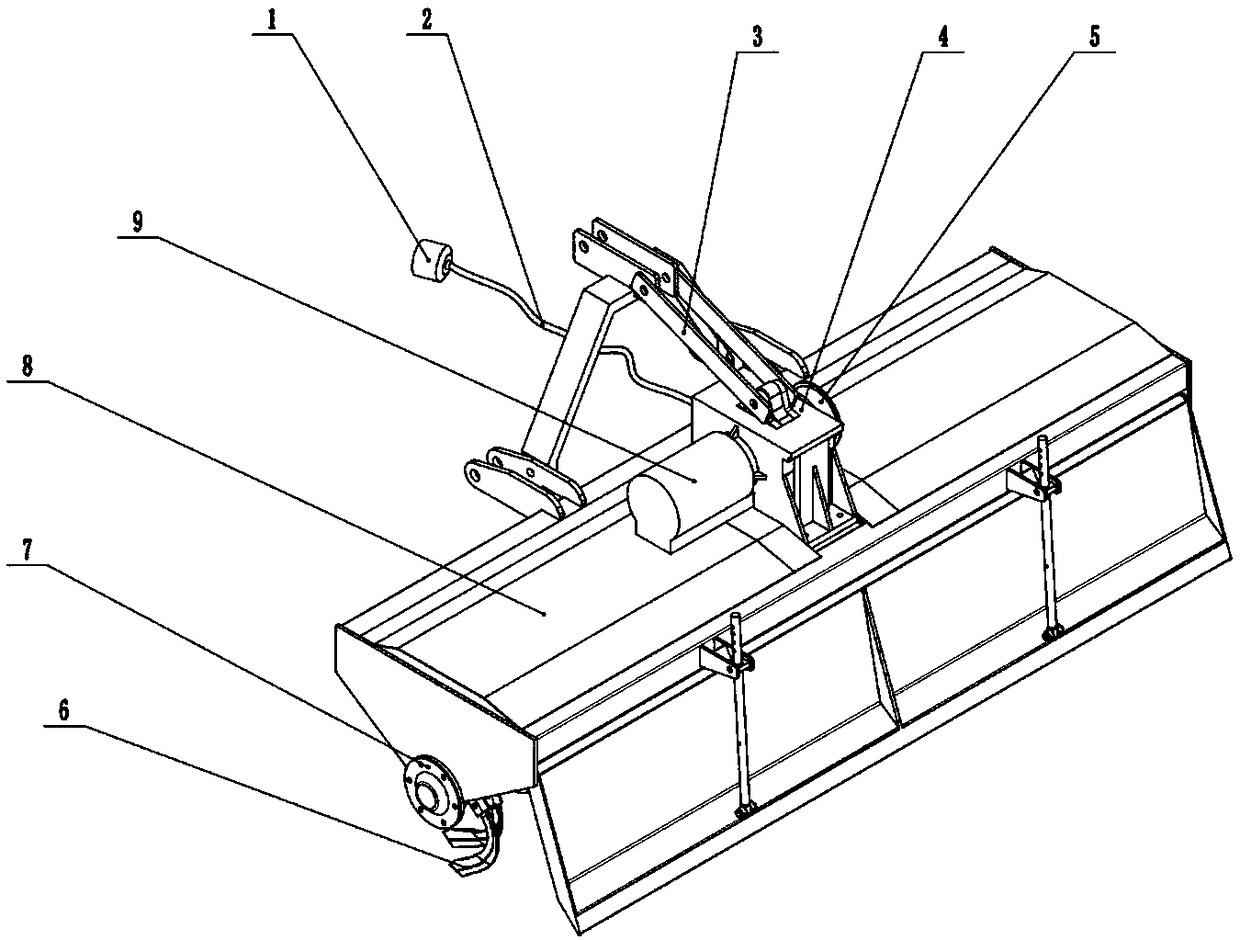

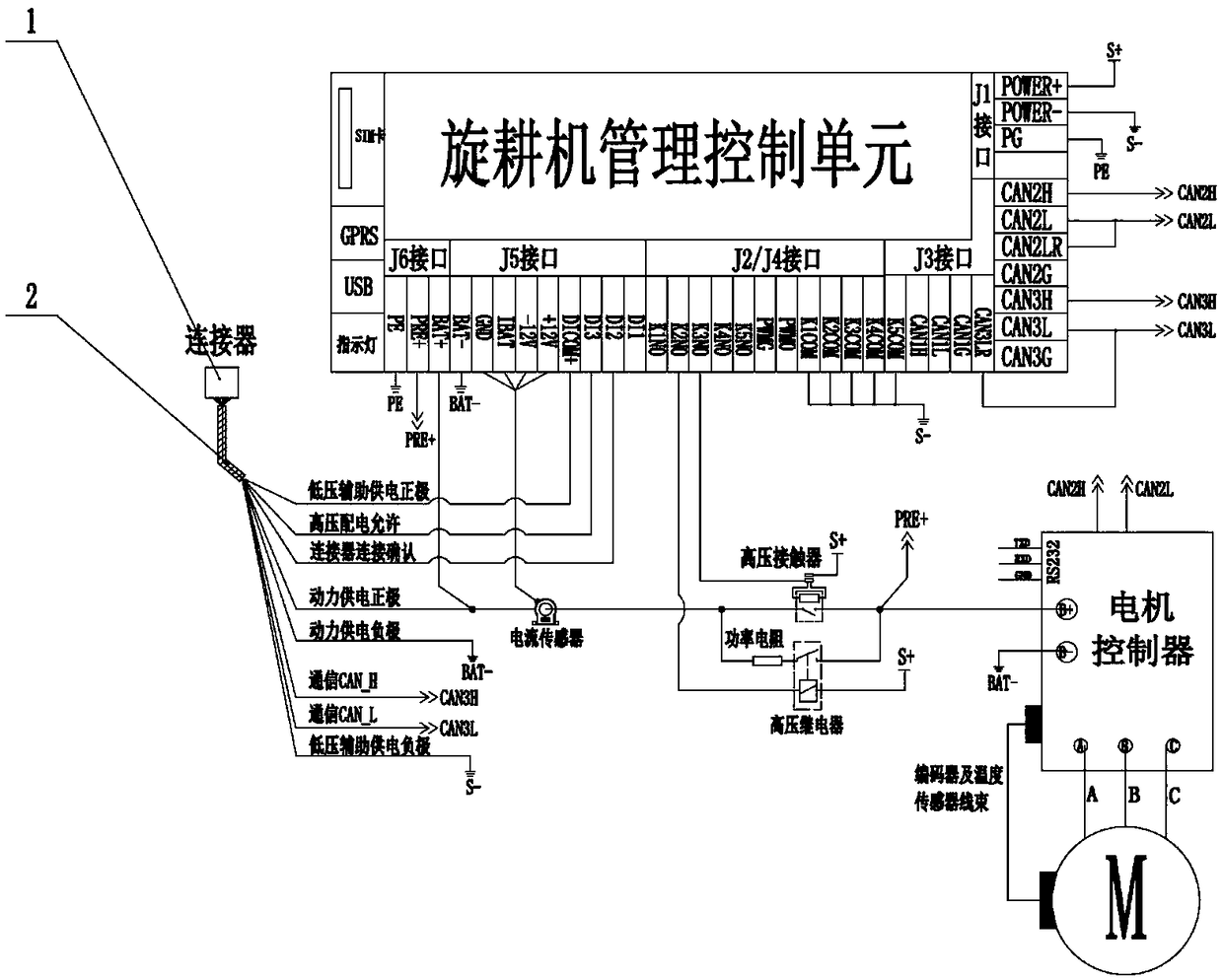

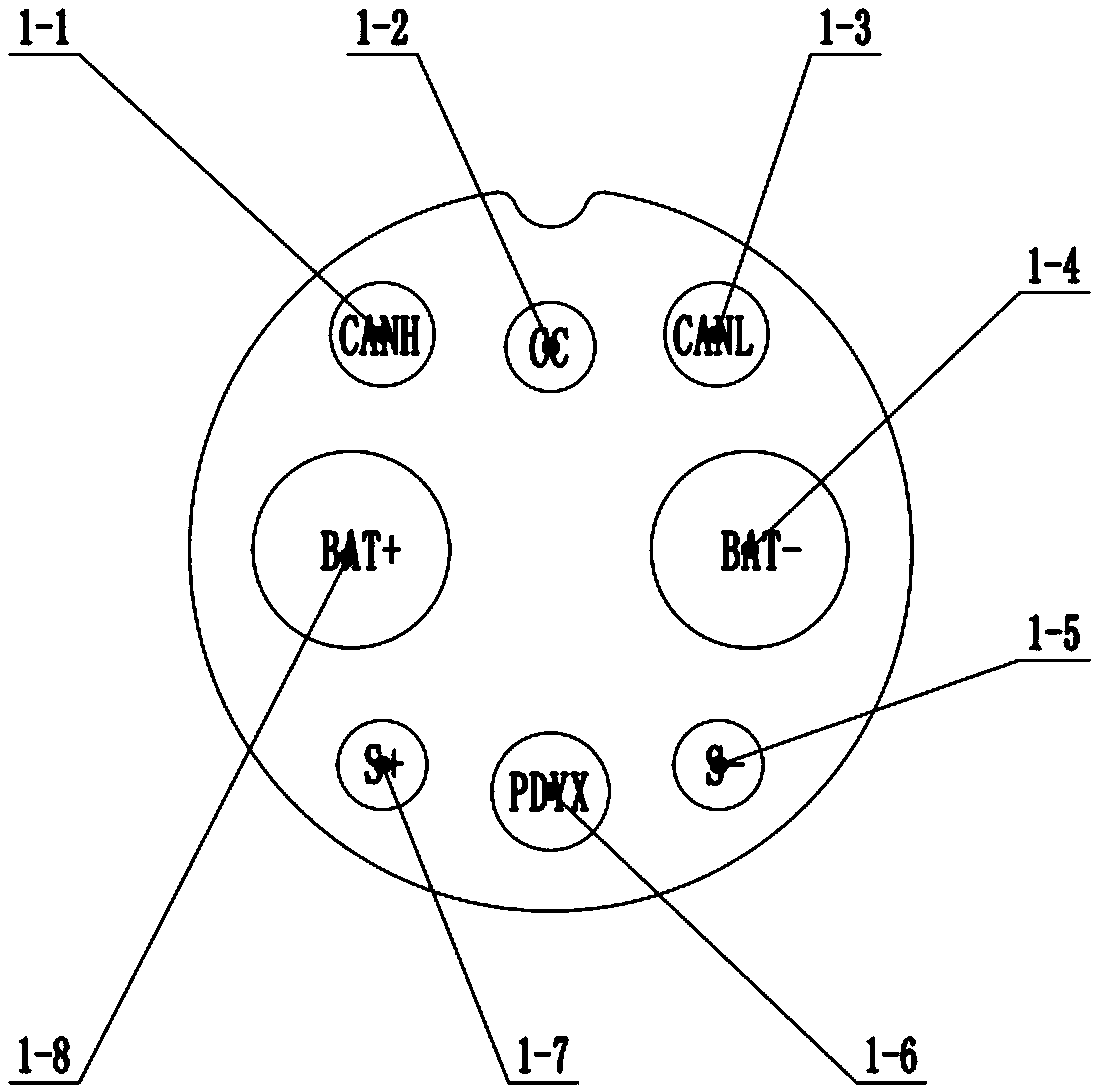

Plug-in electric rotary tiller

The invention relates to a plug-in electric rotary tiller. The plug-in electric rotary tiller comprises a rotary tiller body, a rotary tiller roller cutter, a roller cutter shaft assembly, a suspension rod member, a reducer assembly, an electric control box body and a rotary tiller circuit assembly, wherein the rotary tiller circuit assembly includes an electrical interface part, an implement operation management part and an implement driving part, and the electrical interface part is used for quickly and reliably connecting the rotary tiller with an electric tractor by using a power transmission cable in a multi-contact electrical connector plugging mode, so that the rotary tiller circuit assembly is connected into the whole machine power grid of the electric tractor, and transmission ofelectric energy and data between the tractor and the rotary tiller is achieved; and the implement operation management part is used for performing coordinated management on power-on starting, implement driving, power-off stopping, high-voltage power safety management, implement running state monitoring, an electrical interface connection process and other processes of the rotary tiller, and the implement driving part is used for receiving demands of a rotary tiller management control unit, controlling a driving motor to output a corresponding electromagnetic torque, and driving the rotary tiller to work.

Owner:安徽易疆科技有限公司

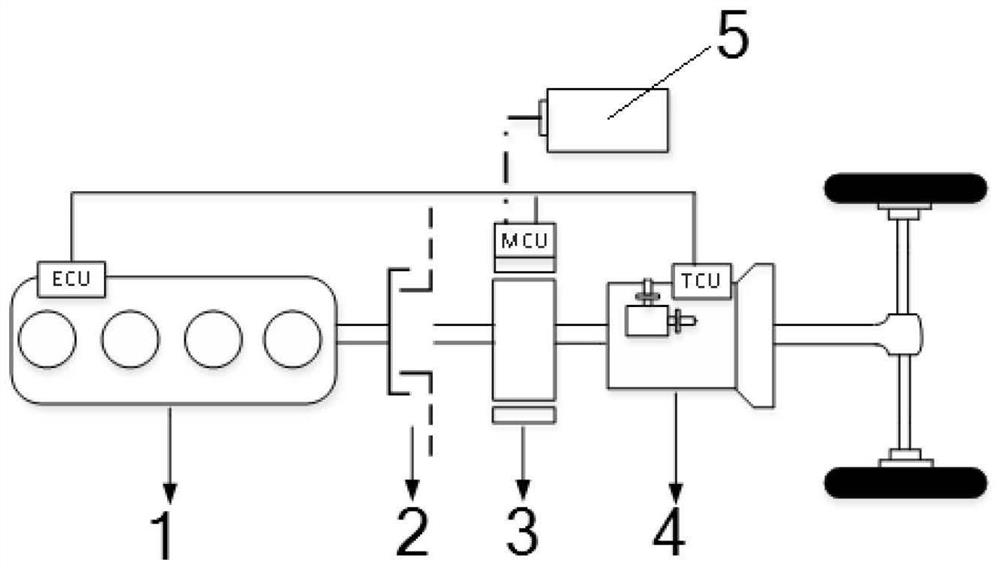

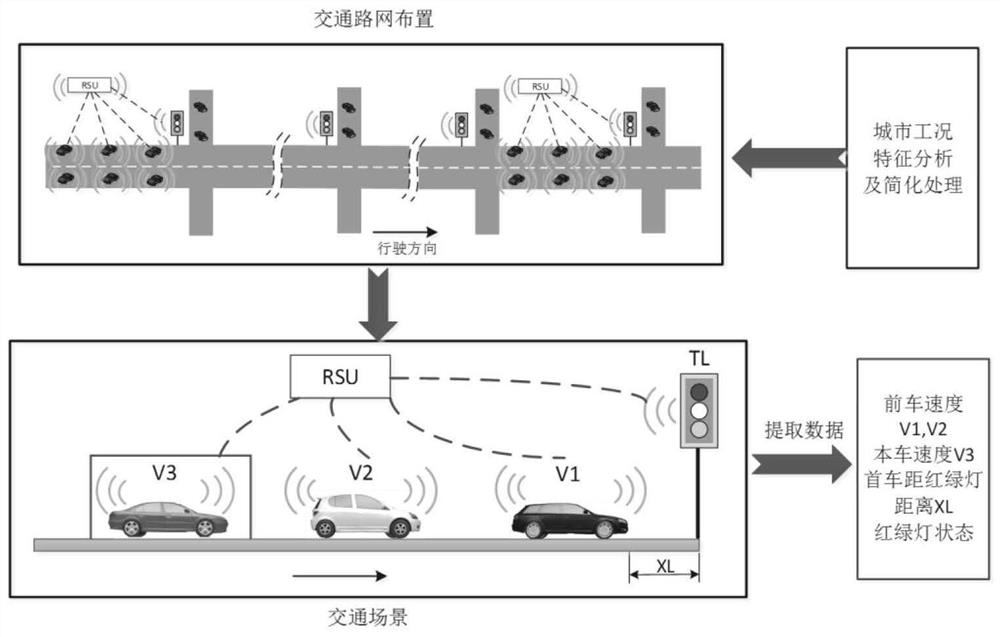

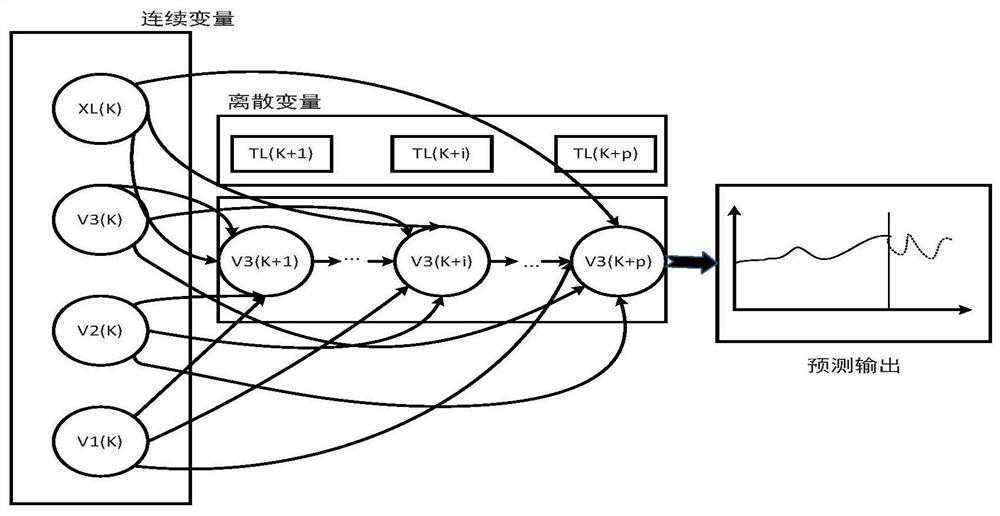

Network-connected hybrid electric vehicle energy management system and method of a distributed MPC

ActiveCN113104023AImprove the prediction accuracy of operating conditionsRealize dynamic optimizationHybrid vehiclesData processing managementRegenerative brakeElectric machinery

A network-connected hybrid electric vehicle energy management system of a distributed MPC comprises an engine, a clutch, a motor, a transmission and batteries. The MCU of the motor is connected with the TCU of the transmission and the ECU of the engine; the batteries are respectively connected with the motors; the batteries transmit power to the motor; working modes comprise pure electric driving, pure engine driving, hybrid driving, driving charging and regenerative braking; the method by means of the network-connected hybrid electric vehicle energy management system comprises the following steps: 1, modeling a parallel hybrid electric vehicle; 2, predicting the speed of the networked hybrid electric vehicle; and 3, constructing a distributed MPC energy management method; the system and the method have the characteristics of good calculation efficiency, fuel economy and working condition adaptability.

Owner:XIAN UNIV OF TECH

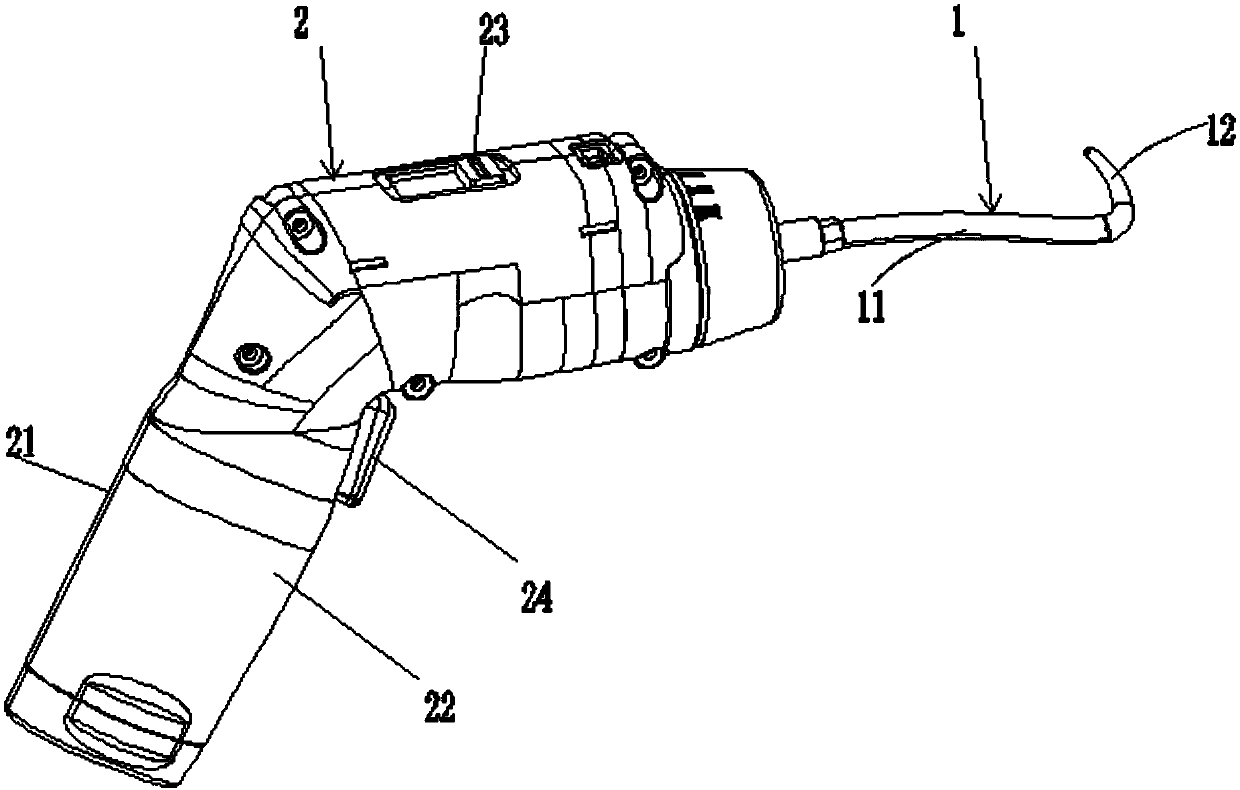

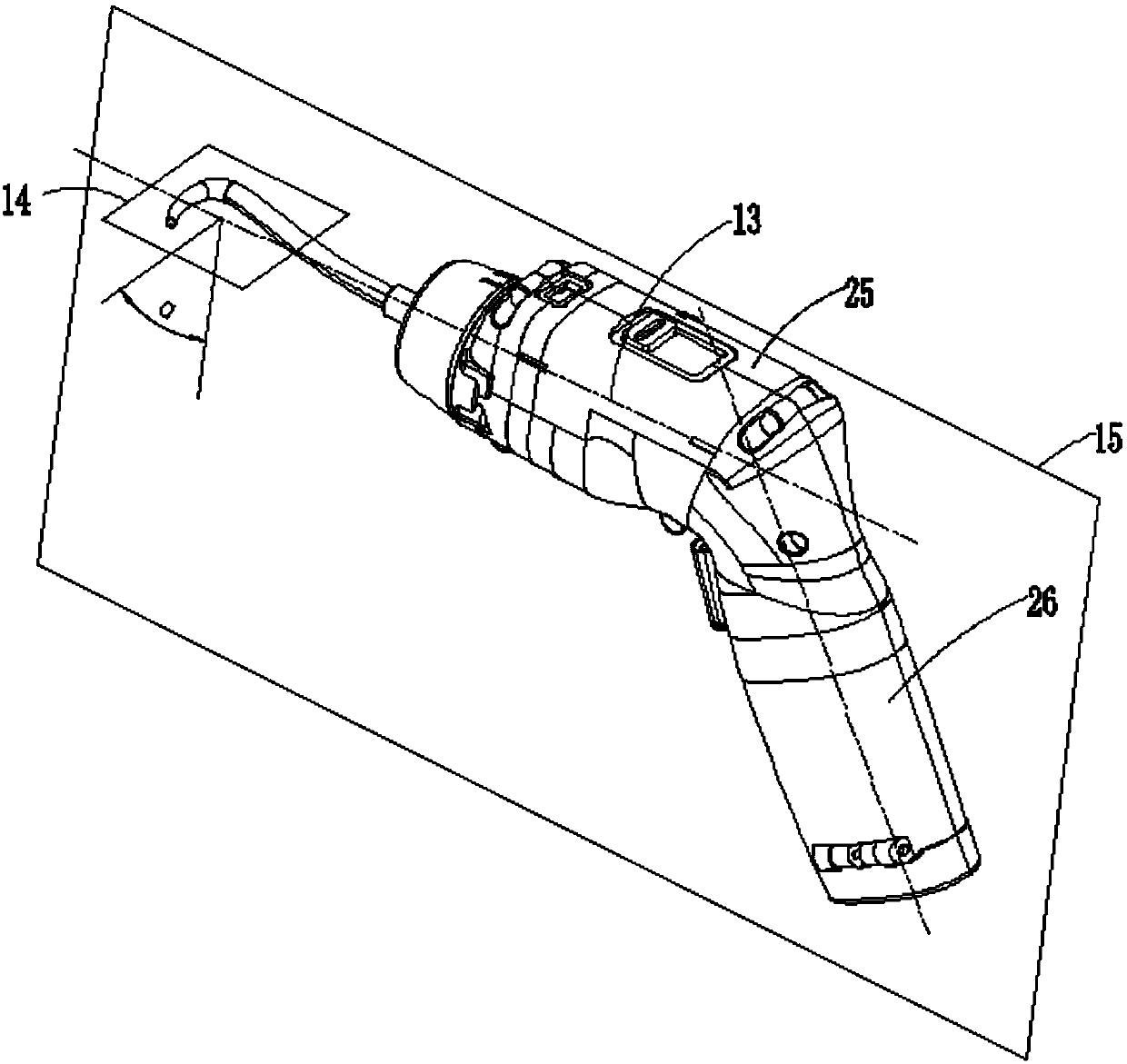

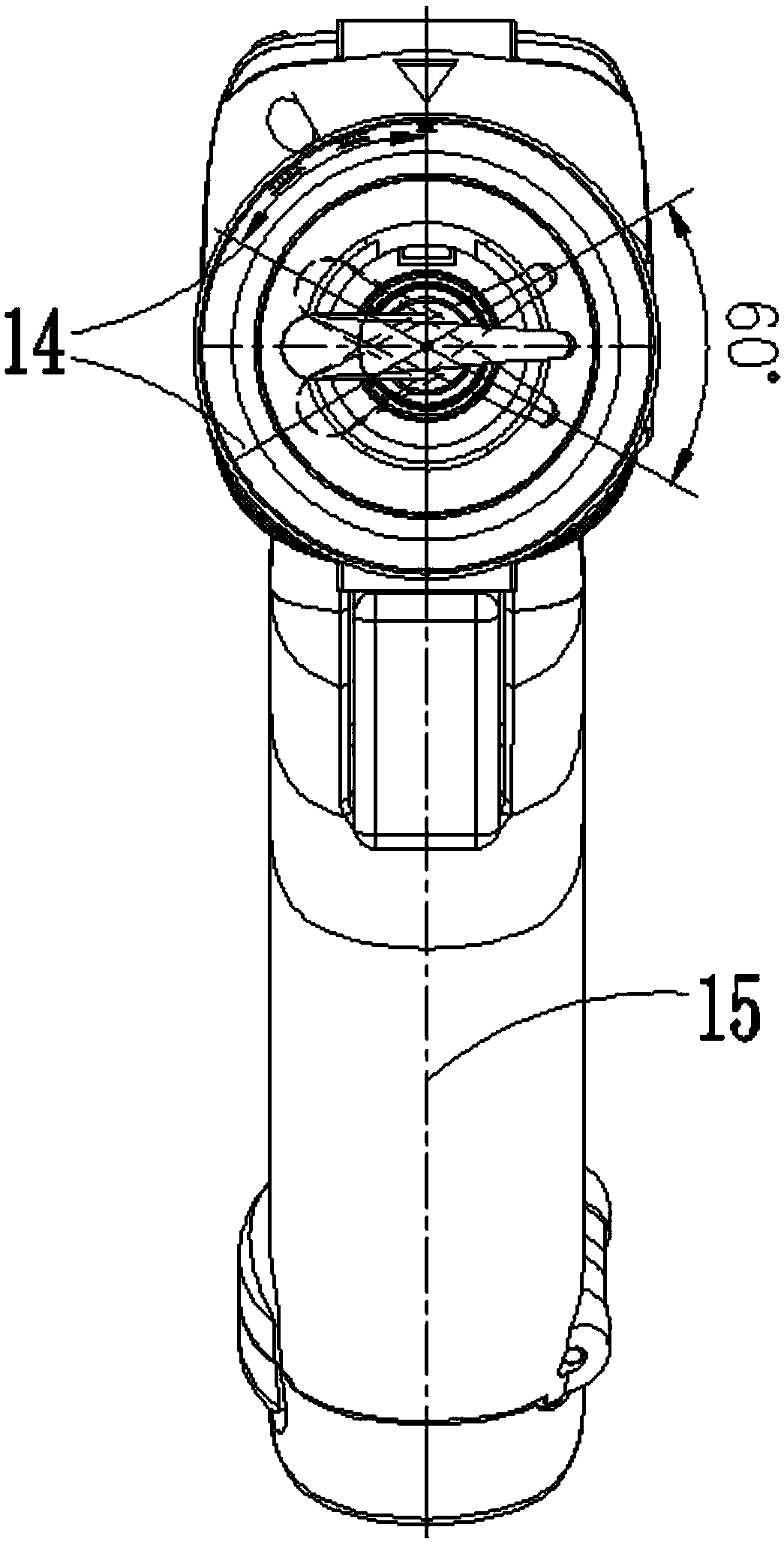

Steel bar binding machine

PendingCN111140017ACompact structureReduce weightBuilding material handlingSteel barMechanical engineering

The invention discloses a steel bar binding machine. The steel bar binding machine comprises a shell, a working head, a power mechanism, a signal acquisition unit and a control unit, wherein the working head is used for twisting joint of steel wires, and the working head comprises a body part extending out of the shell in a first extending direction and a working part arranged at the end, far awayfrom the shell, of the body part; the working part has a second extending direction different from the first extending direction, and the body part defines a first axis in the first extending direction; the power mechanism is used for driving the working head to rotate around the first axis; the signal acquisition unit is used for acquiring a signal representing the twisting joint state of the steel wires; and the control unit is electrically connected with the power mechanism and the signal acquisition unit, and the control unit is used for controlling the working head to stop rotating underthe condition that the signal acquisition unit acquires a signal indicating that the steel wires finish twisting joint. With the steel bar binding machine, the operation convenience can be improved and the working condition adaptability is higher.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

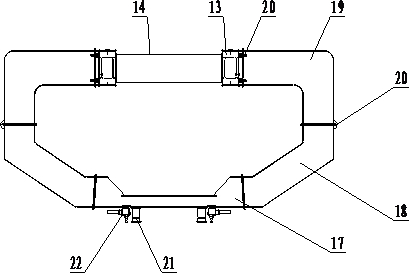

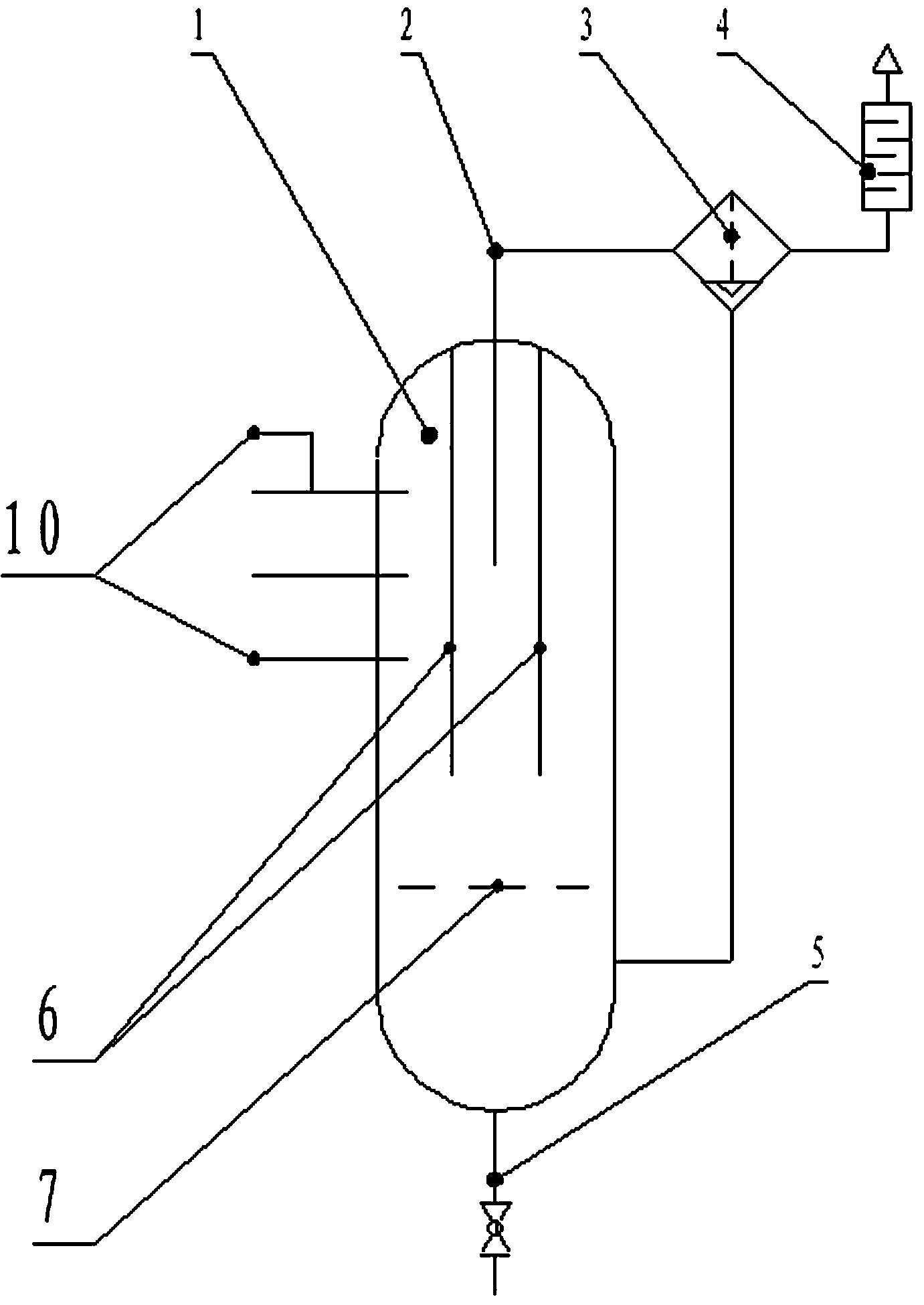

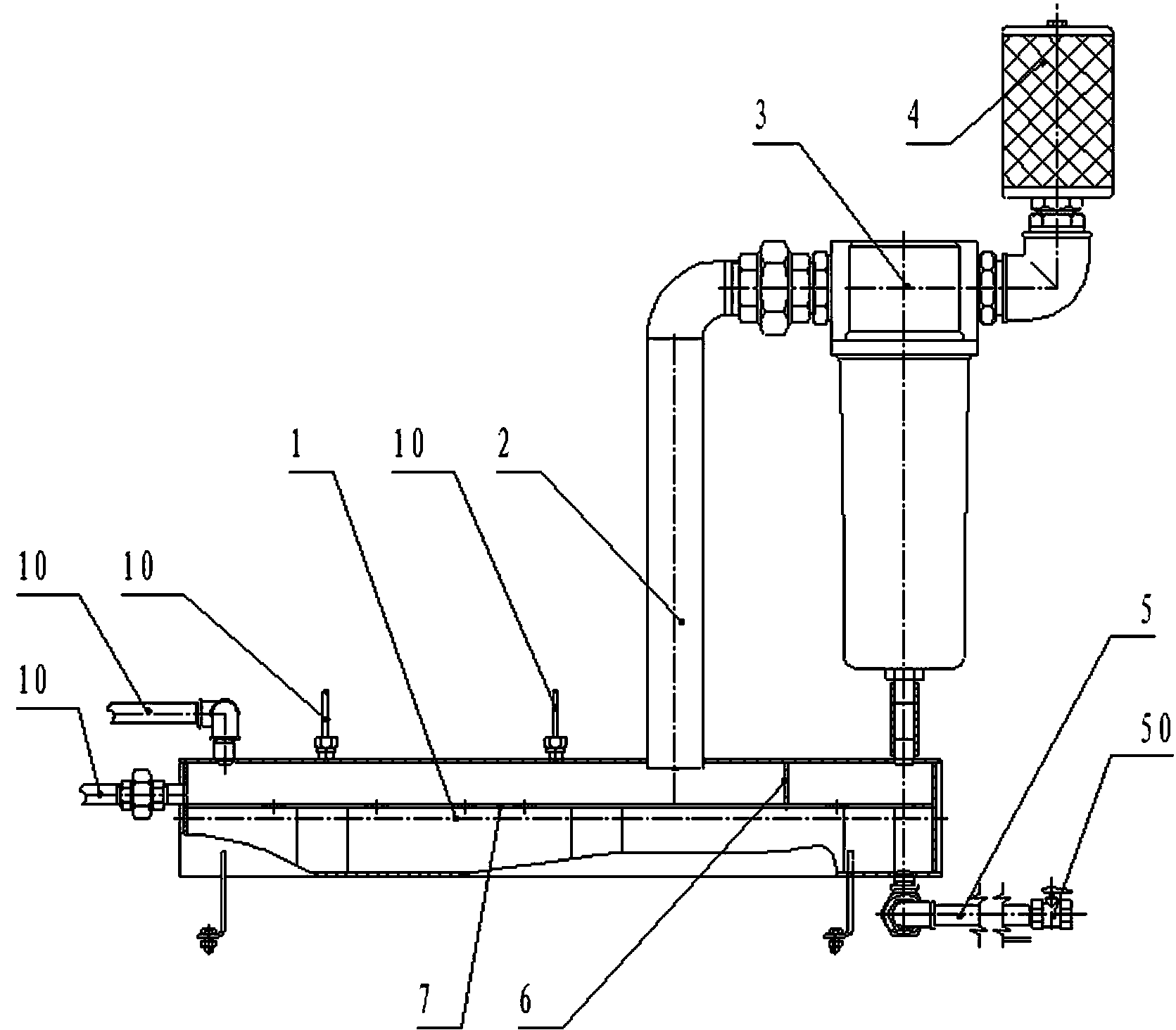

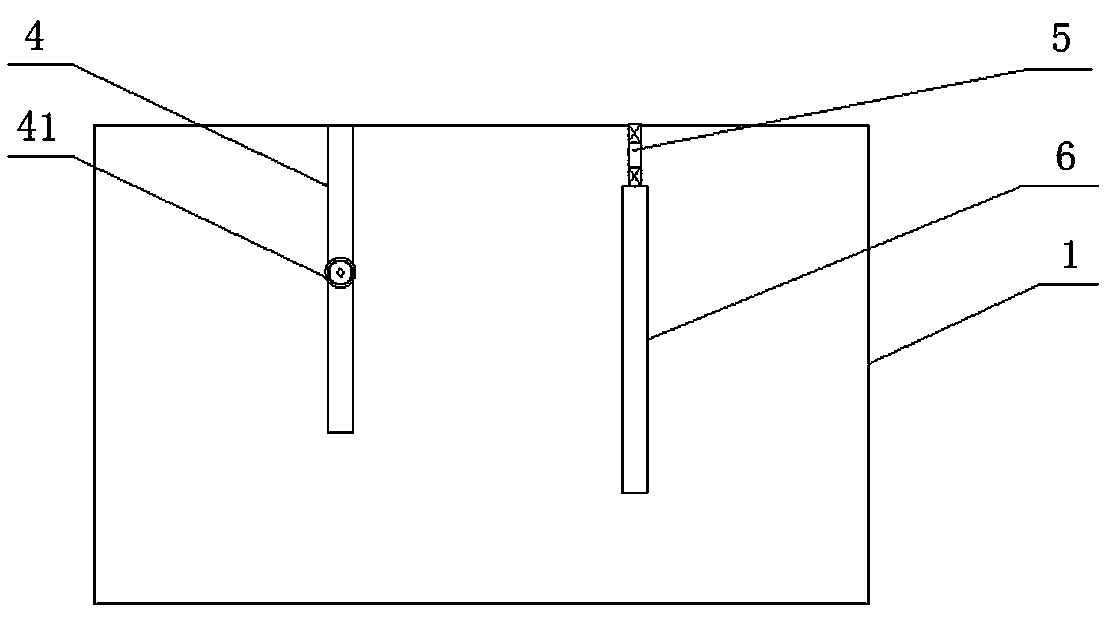

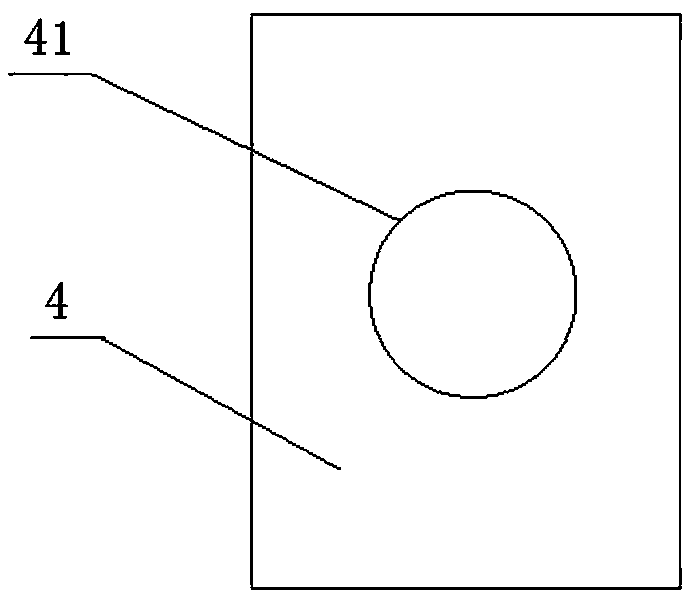

Two-stage gas-liquid separation device

The invention provides a two-stage gas-liquid separation device. With the adoption of the two-stage gas-liquid separation device, gas and liquid in a gas-liquid mixture with unstable flowing speed and flowing rate can be effectively separated and are respectively discharged to realize the environment-protecting effect; and the working load is large and the working-condition adaptability is good. The two-stage gas-liquid separation device comprises a coarse-separation and sewage-collection barrel, wherein the upper part of the coarse-separation and sewage-collection barrel is connected with a fin filter by a discharging pipe and the fine filter is connected with a silencer by a pipeline; a discharging port at the lower end of the fine filter is connected with the coarse-separation and sewage-collection barrel by a pipeline; and a sewage discharging pipe is arranged at the lower part of the coarse-separation and sewage-collection barrel. A plurality of partitioning plates are arranged in coarse-separation and sewage-collection barrel and are partially partitioned, so that the internal contact area is enlarged, and the gas-liquid separation effect can be enhanced. A porous baffle is arranged at the lower end of the coarse-separation and sewage-collection barrel.

Owner:ANHUI HUAJING MACHINERY

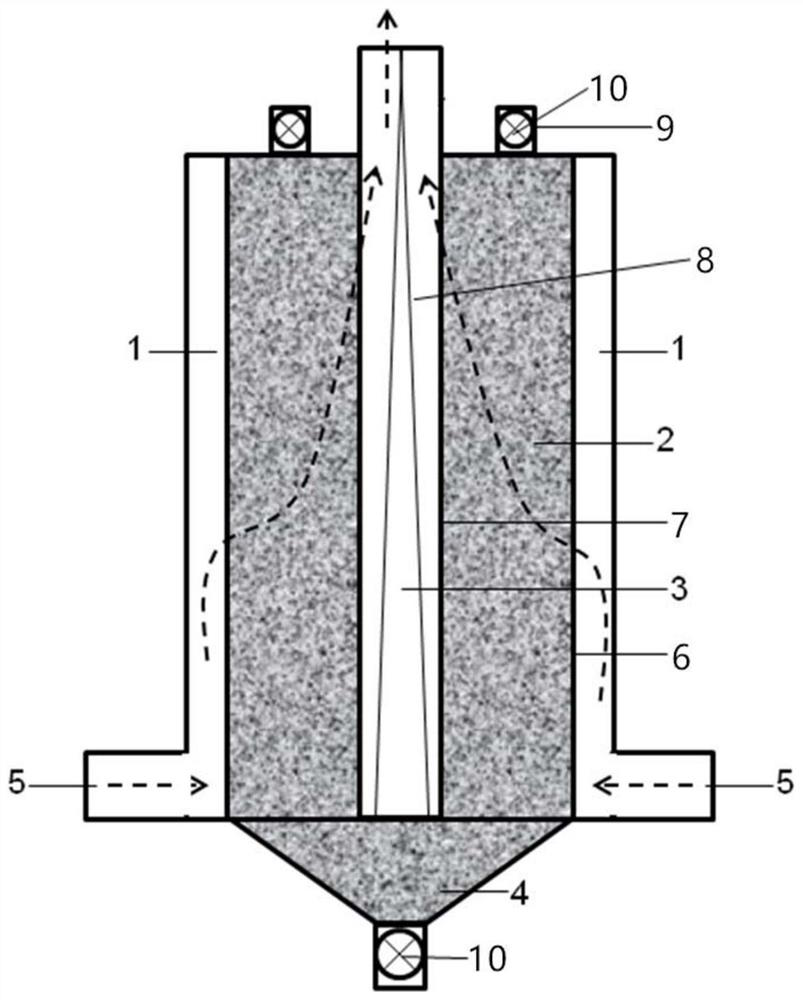

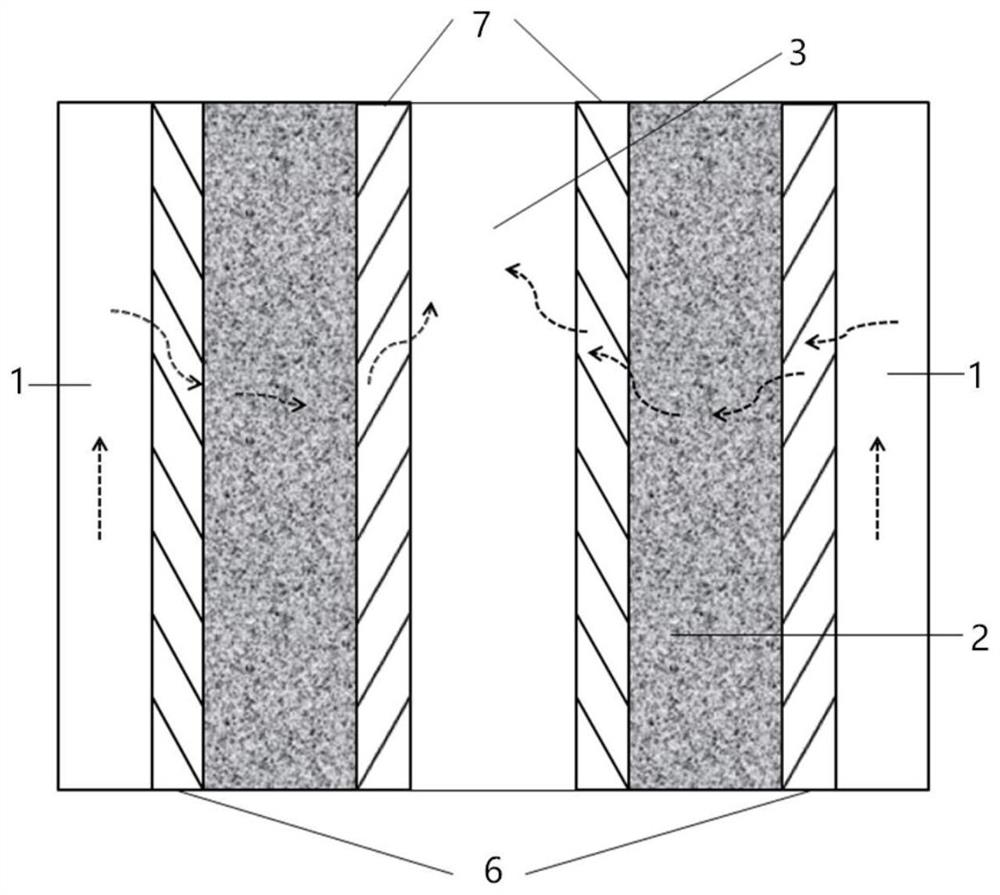

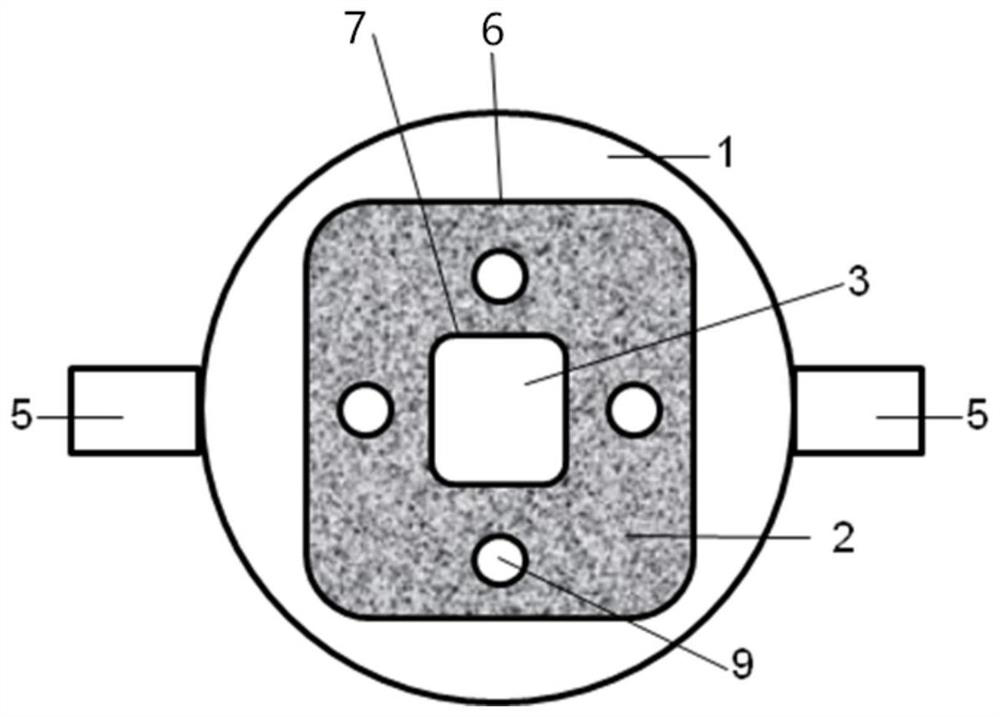

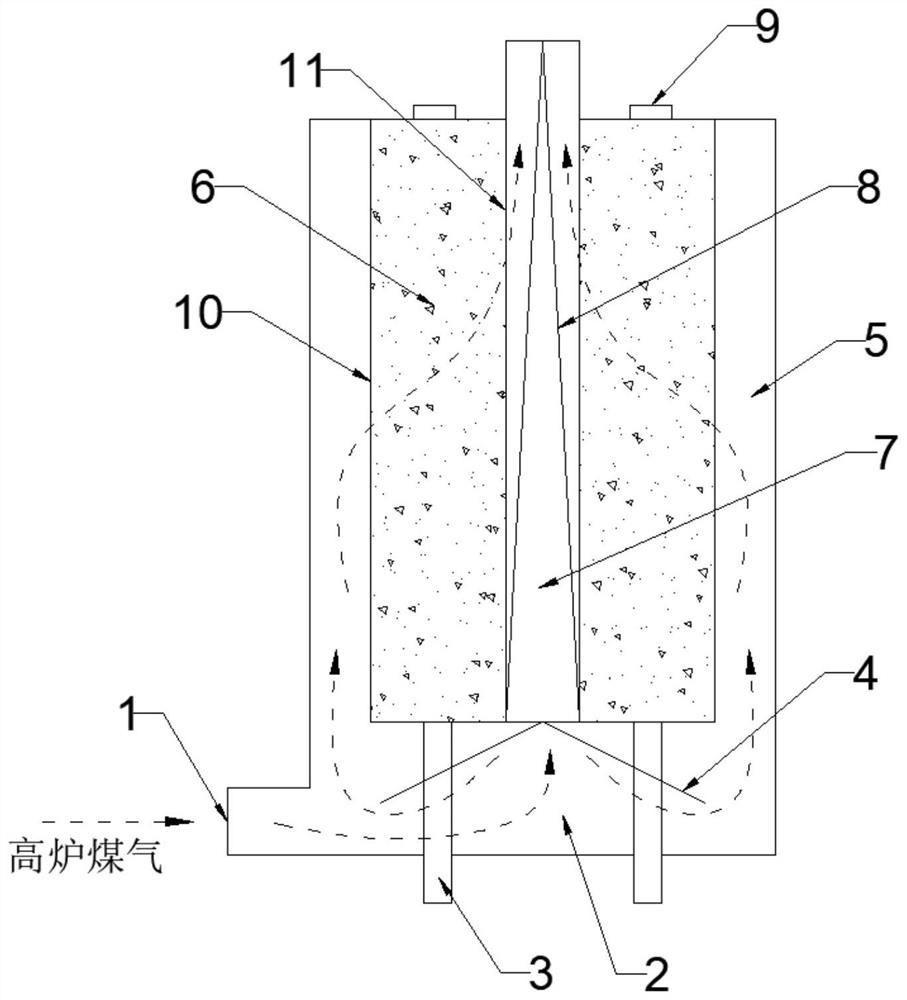

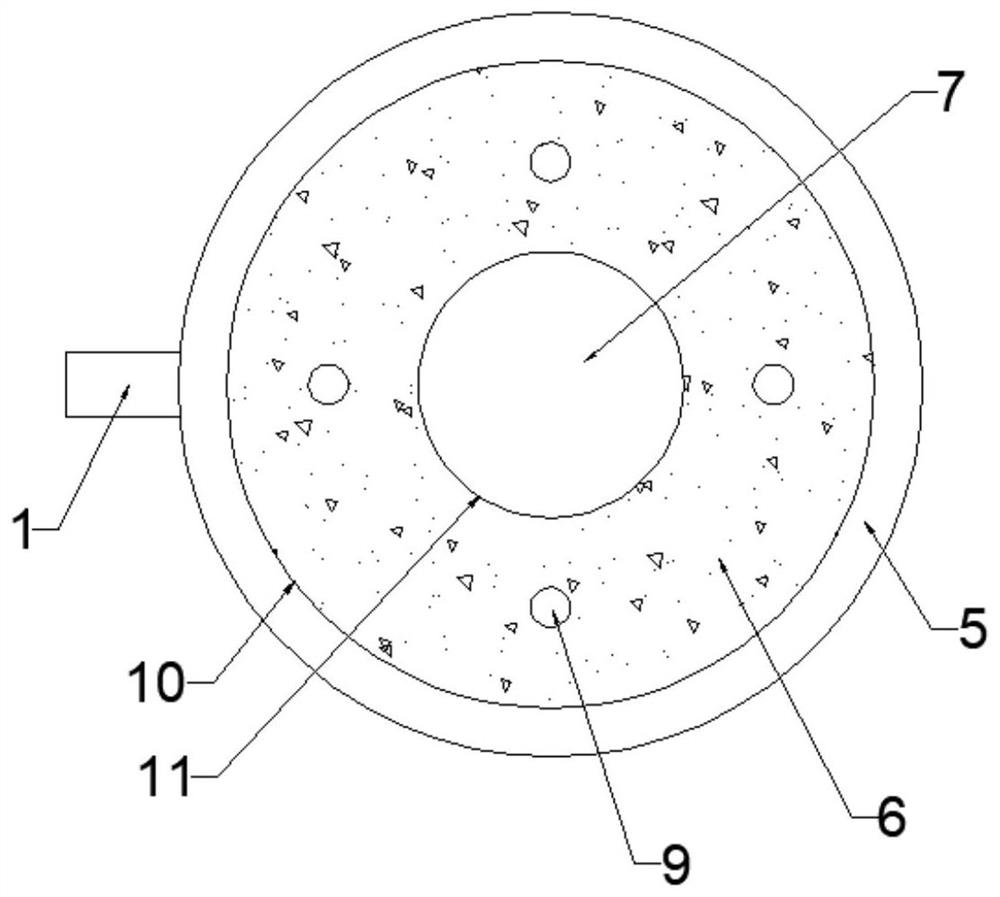

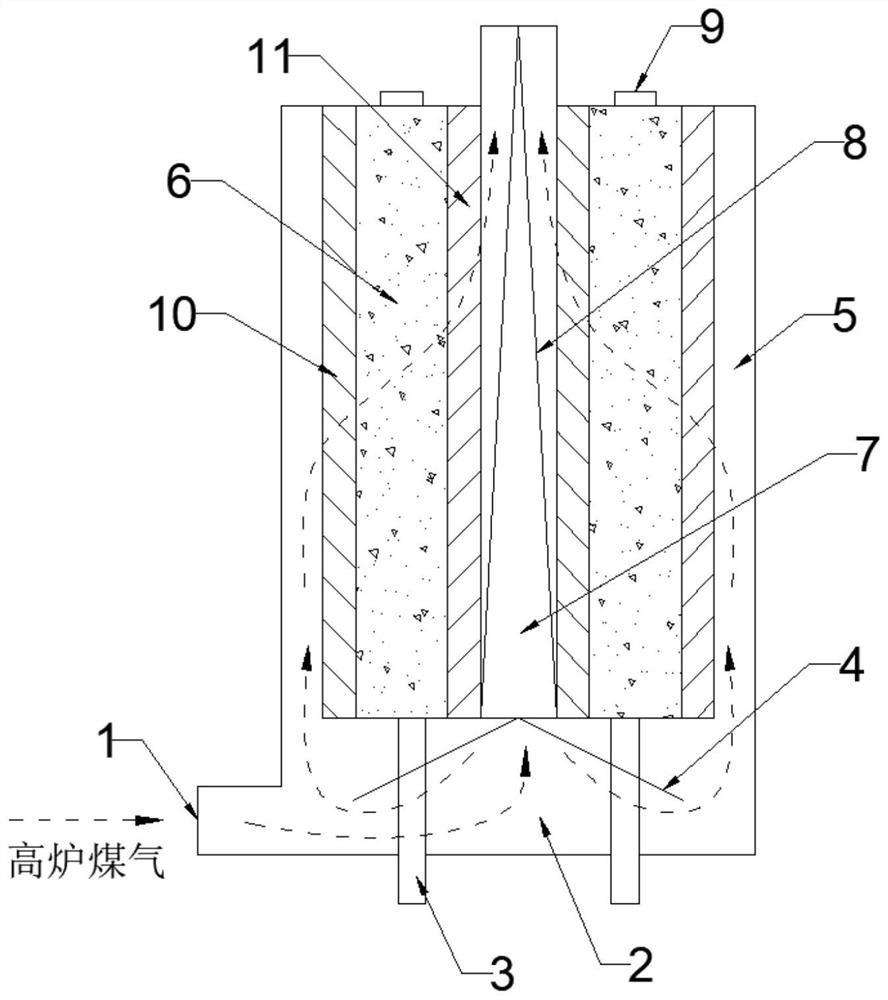

Moving bed type blast furnace gas desulfurization device and desulfurization method thereof

InactiveCN112646614AImprove purification efficiencyReduce resistanceGas purification by catalytic conversionGas contaminants removalPtru catalystPhysical chemistry

The invention provides a moving bed type blast furnace gas desulfurization device and a desulfurization method thereof. The blast furnace gas desulfurization device comprises a shell, a catalyst partition plate set is arranged in the shell in the axial direction, and the catalyst partition plate set comprises an inner ring partition plate piece and an outer ring partition plate piece which are coaxially nested from inside to outside; and an annular cavity formed between the inner ring partition plate piece and the outer ring partition plate piece is filled with a catalyst, and a feeding port is formed in the top, where the annular cavity is located, of the shell. A cavity defined by the inner ring partition plate piece is an exhaust channel, a cavity between the outer ring partition plate piece and the shell is an air inlet channel, and an air inlet communicated with the air inlet channel is formed in the bottom of the shell. Compared with a traditional fixed bed packed tower, the resistance in the tower is reduced, the moving bed improves the utilization rate of the catalyst, and the blast furnace gas desulfurization efficiency can be remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

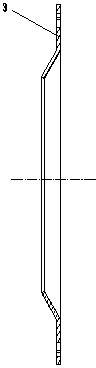

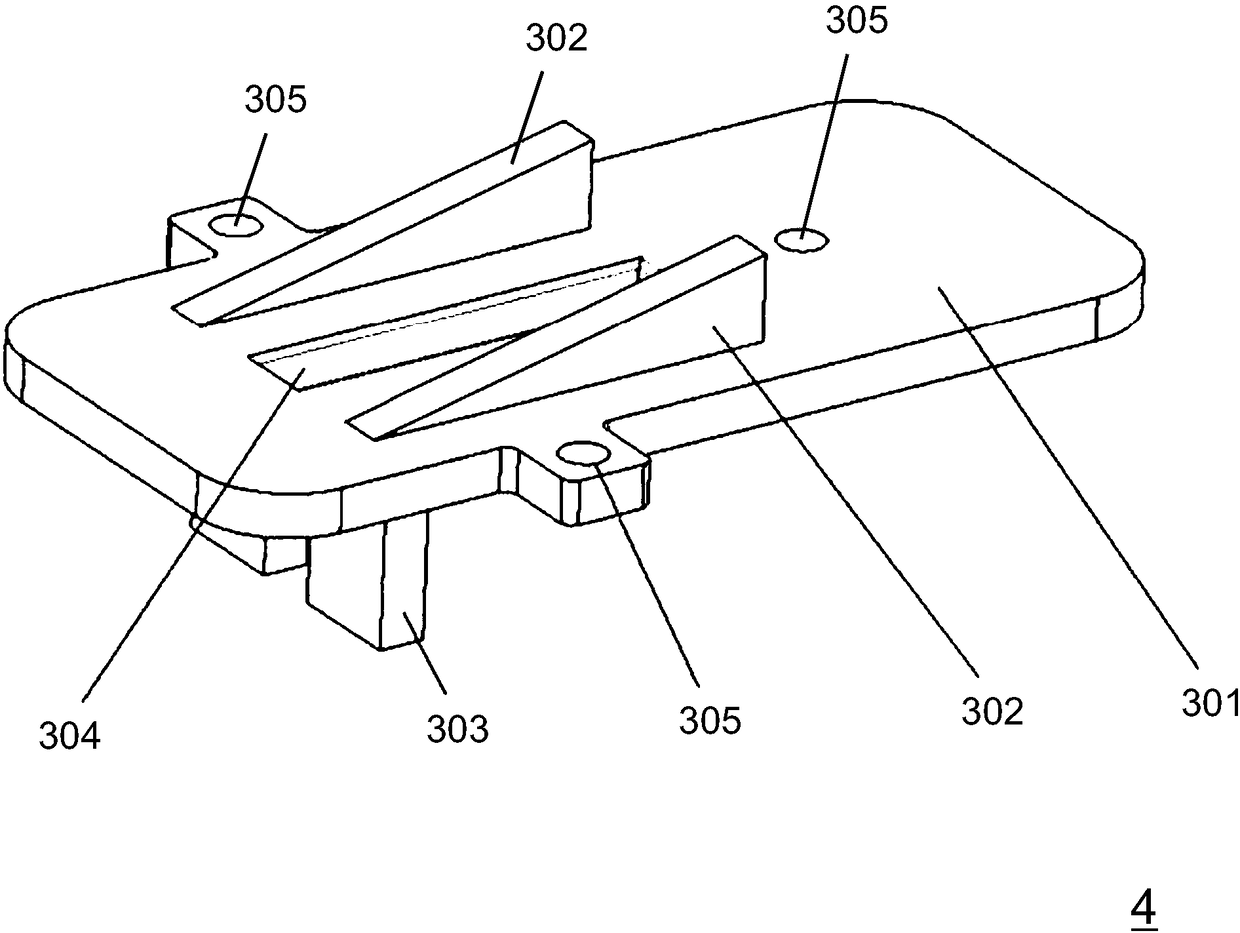

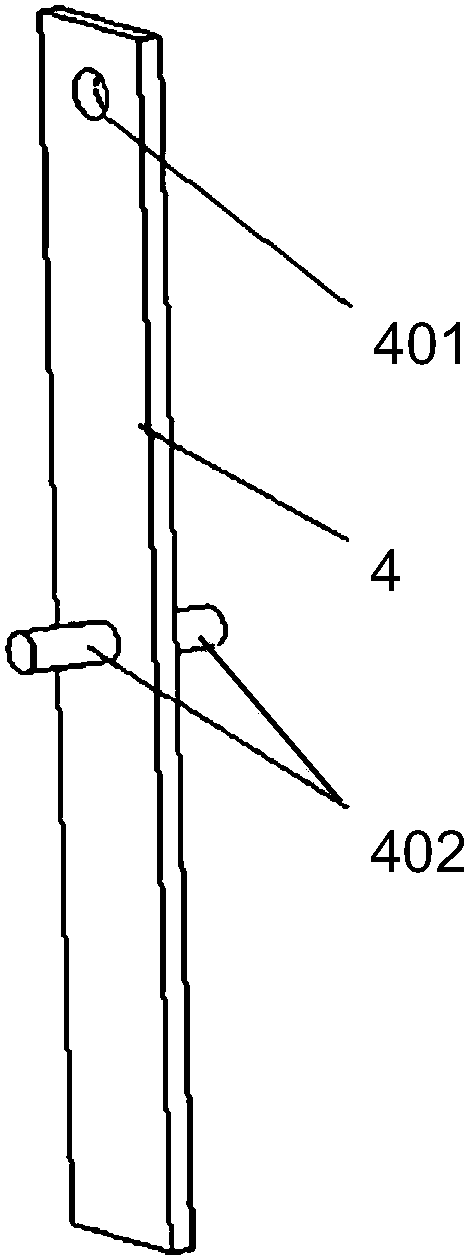

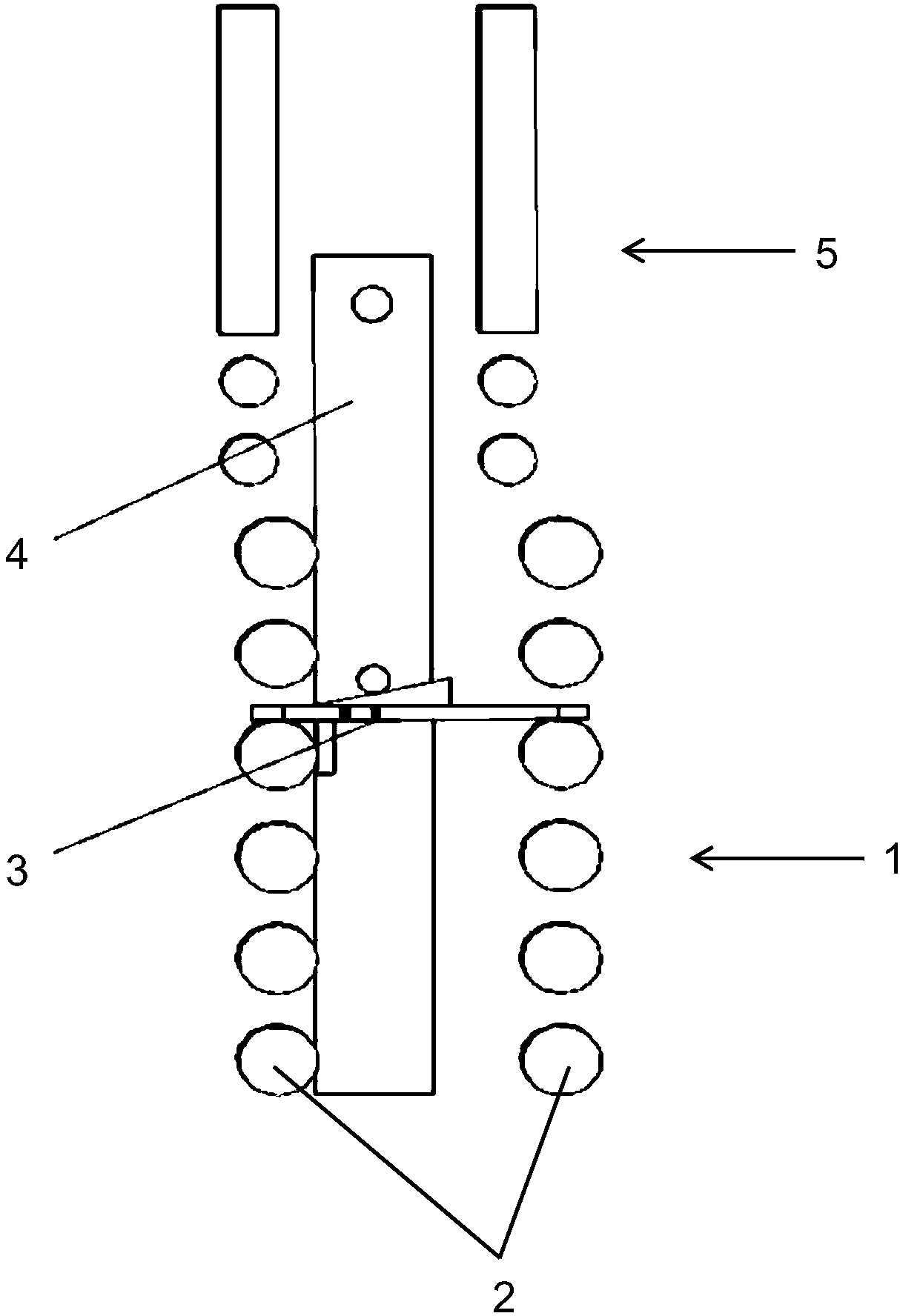

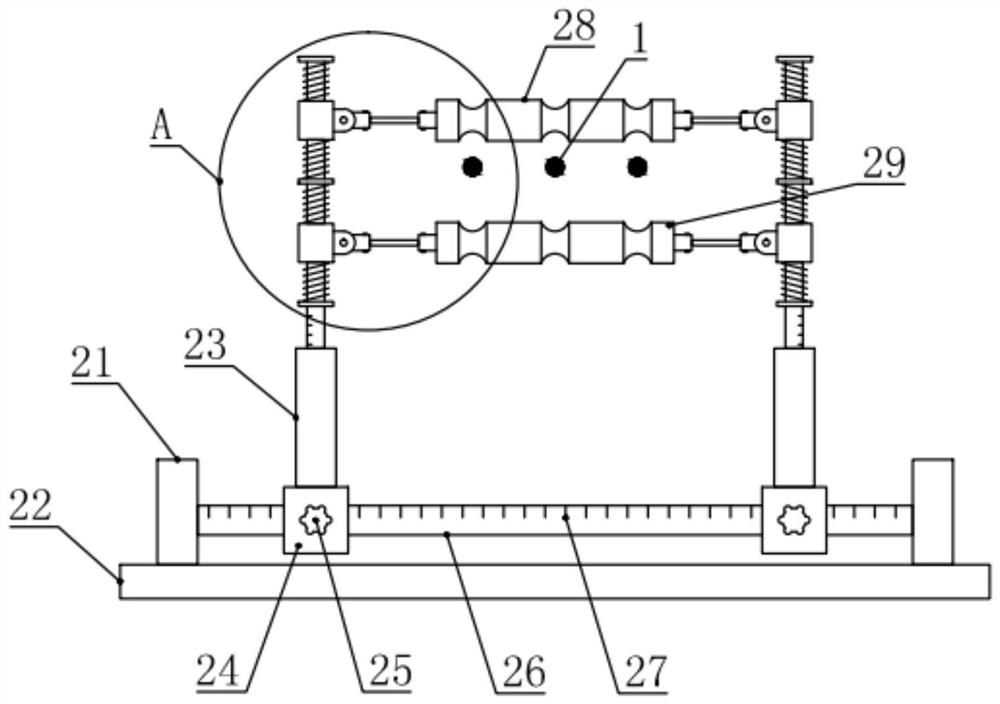

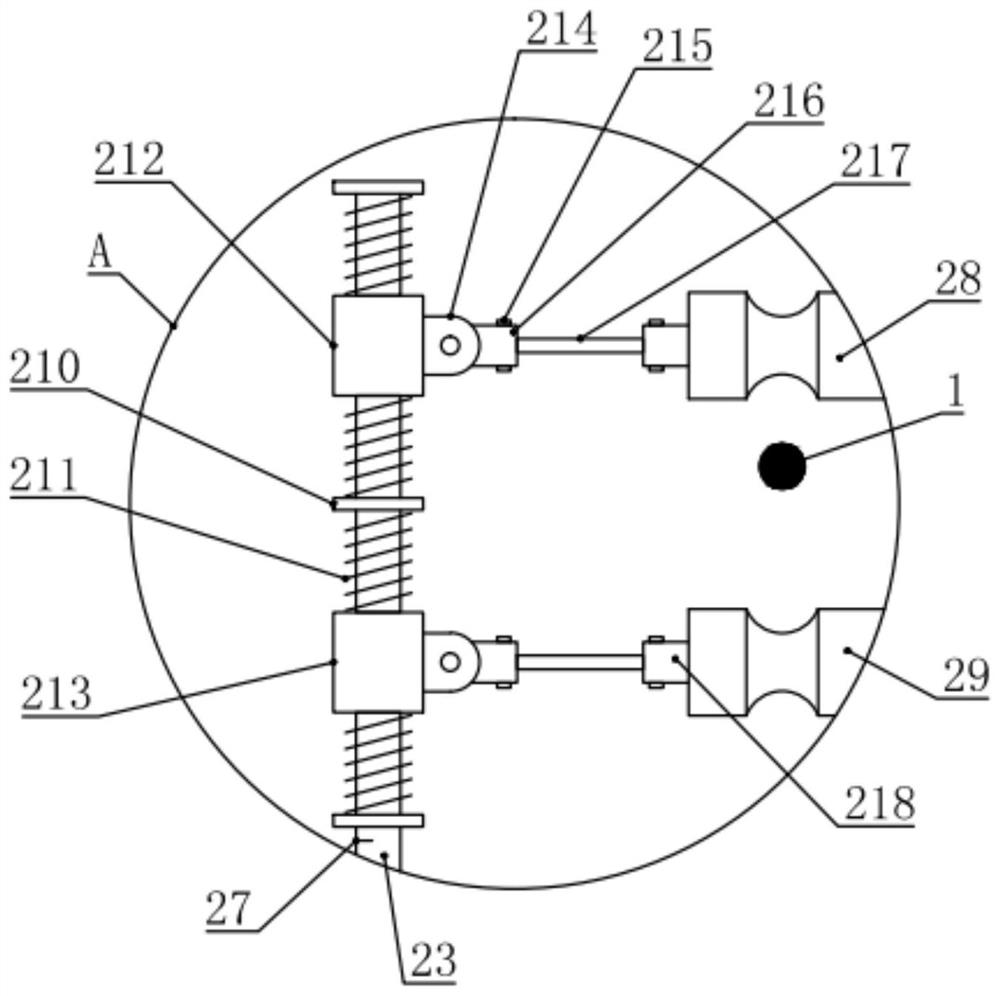

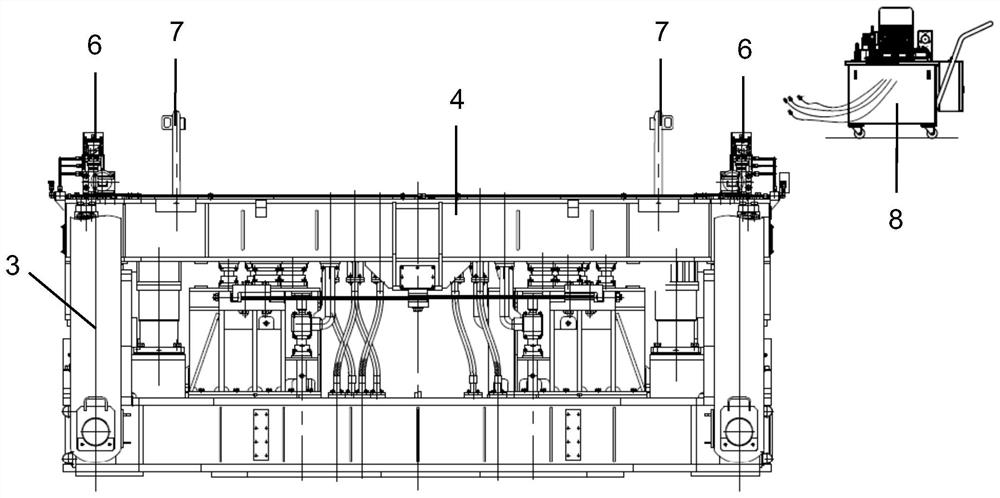

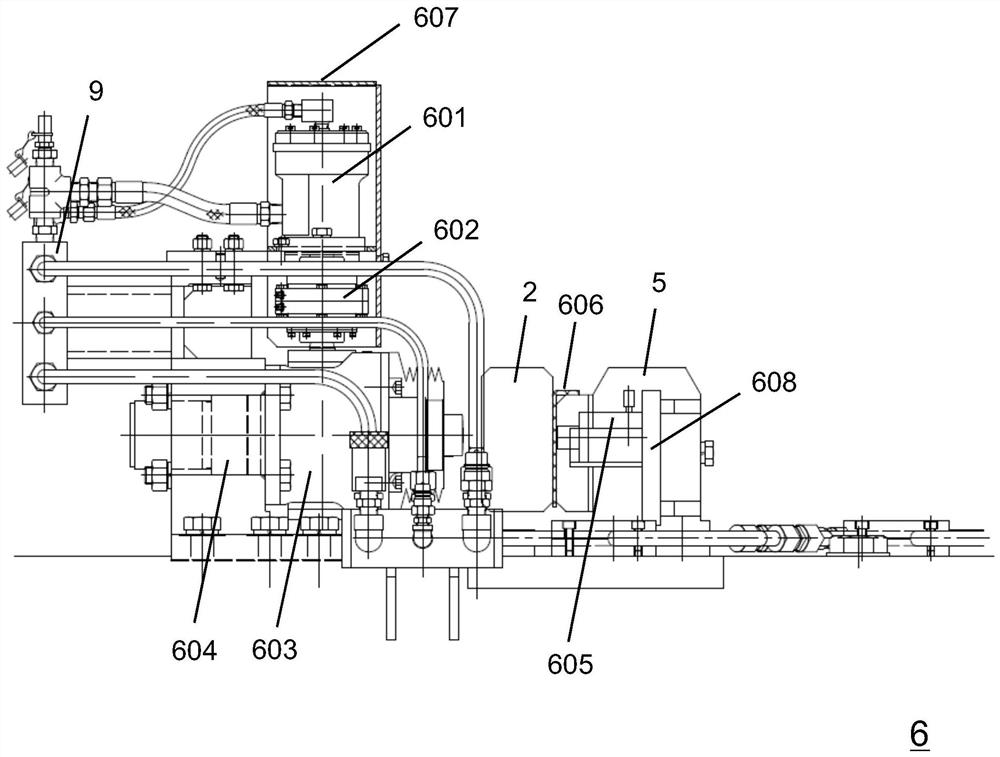

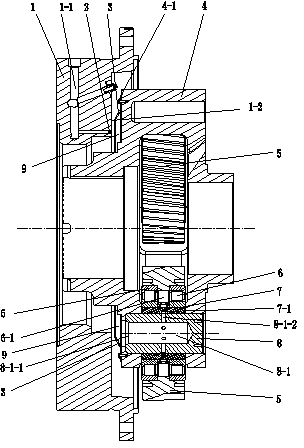

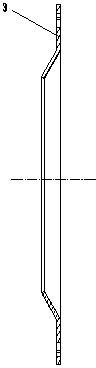

Arc-aligning device and an arc-aligning method used between crystallizer and bending section of continuous casting machine

ActiveCN108927500AAvoiding Safety Issues in Working in Bending SectionsTo achieve closePulp and paper industryContinuous casting

The invention discloses an arc-aligning device and an arc-aligning method used between a crystallizer and a bending section of a continuous casting machine. The arc-aligning device comprises multiplepairs of rollers arranged on the two sides of the bending section, and further comprises an arc-aligning support and an arc-aligning plate; the arc-aligning support is arranged among the rollers at the two sides of the bending section, the arc-aligning support comprises a bottom plate, inclined wedges and a bottom plate positioning backup plate, the bottom plate is arranged to be in a rectangularshape, a guide positioning groove for allowing the arc-aligning plate to penetrate through is formed in the longitudinal central position of the bottom plate, a pair of inclined wedges are arranged and are symmetrically arranged at the parts, on two sides of the guide positioning groove, of the upper surface of the bottom plate, a plurality of hoisting holes are formed in the bottom plate, and thebottom plate positioning backup plate is arranged at the rear end of the lower surface of the bottom plate; and the arc-aligning plate is arranged to be in a rectangular strip shape, a hoisting holeis formed in the upper end of the arc-aligning plate, and a pair of symmetrical arc plate supporting shafts are further connected to the two side faces of the arc-aligning plate. According to the arc-aligning device and the arc-aligning method, during arc-aligning operation, a person does not need to enter the bending section, meanwhile, the arc plate can be automatically attached to the surface of the roller needing to be measured, the operation efficiency is improved, and the arc-aligning operation of straight and bent sections can be safely and quickly carried out.

Owner:BAOSHAN IRON & STEEL CO LTD

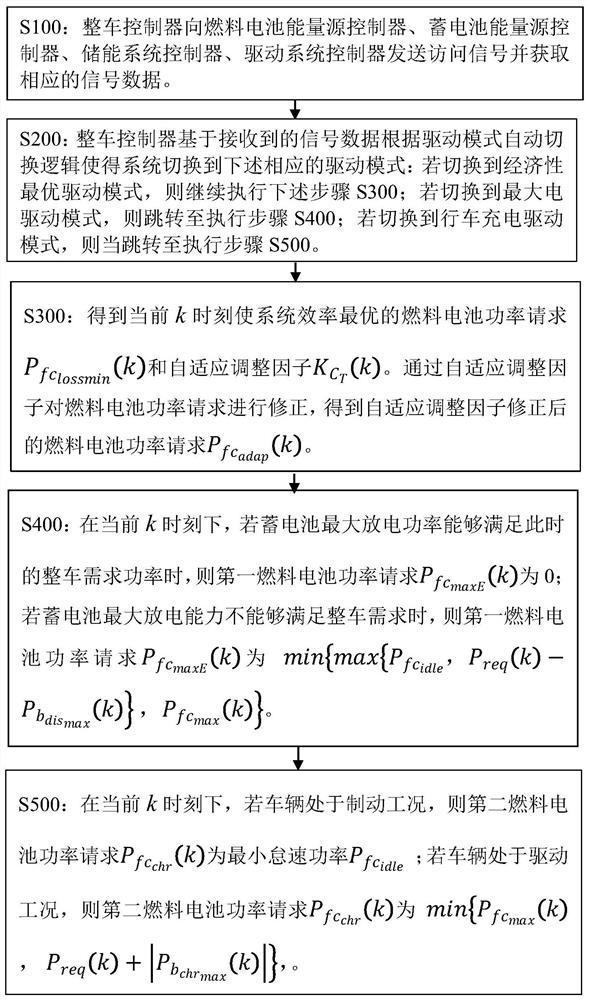

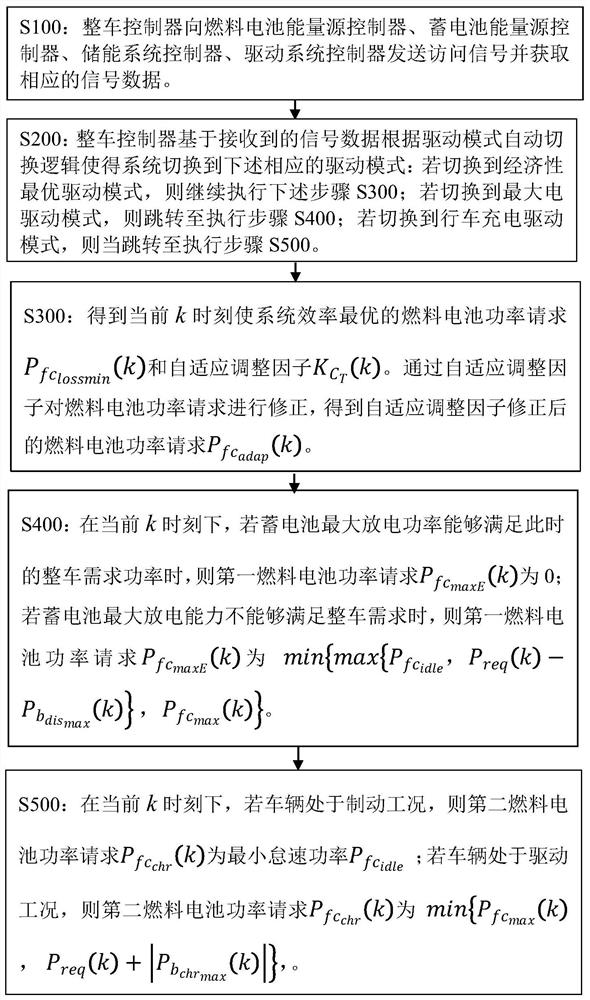

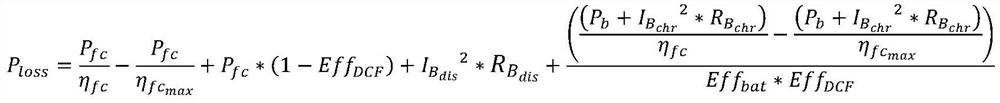

Energy management control method and system for hybrid electric vehicle

ActiveCN112109594ACorrected output powerReduce charge and discharge timesVehicular energy storageBattery/fuel cell control arrangementElectric vehicleEnergy source

The invention discloses an energy management control method for a hybrid electric vehicle. The energy management control method comprises the steps that S100, a vehicle control unit sends access signals to a fuel cell and storage battery energy source controller, an energy storage system controller and a driving system controller and obtains signal data; and S200, the vehicle control unit enablesa system to switch a corresponding driving mode according to the signal data, wherein the step S300 is executed when the system is switched to the driving mode with the optimal economical efficiency,the step S400 is executed when the system is switched to the maximum electric driving mode, and the step S500 is executed when the system is switched to the driving charging driving mode. The workingmode of the hybrid power system can be adjusted according to the working conditions in the steps S300, S400 and S500, so that the optimal system economy in the whole driving working condition range isrealized. Correspondingly, the invention further discloses an energy management control system for the hybrid electric vehicle. The energy management control system comprises a whole vehicle controller, a fuel cell energy source controller, a storage battery energy source controller, an energy storage system controller and a driving system controller, and the system can be used for executing themethod.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

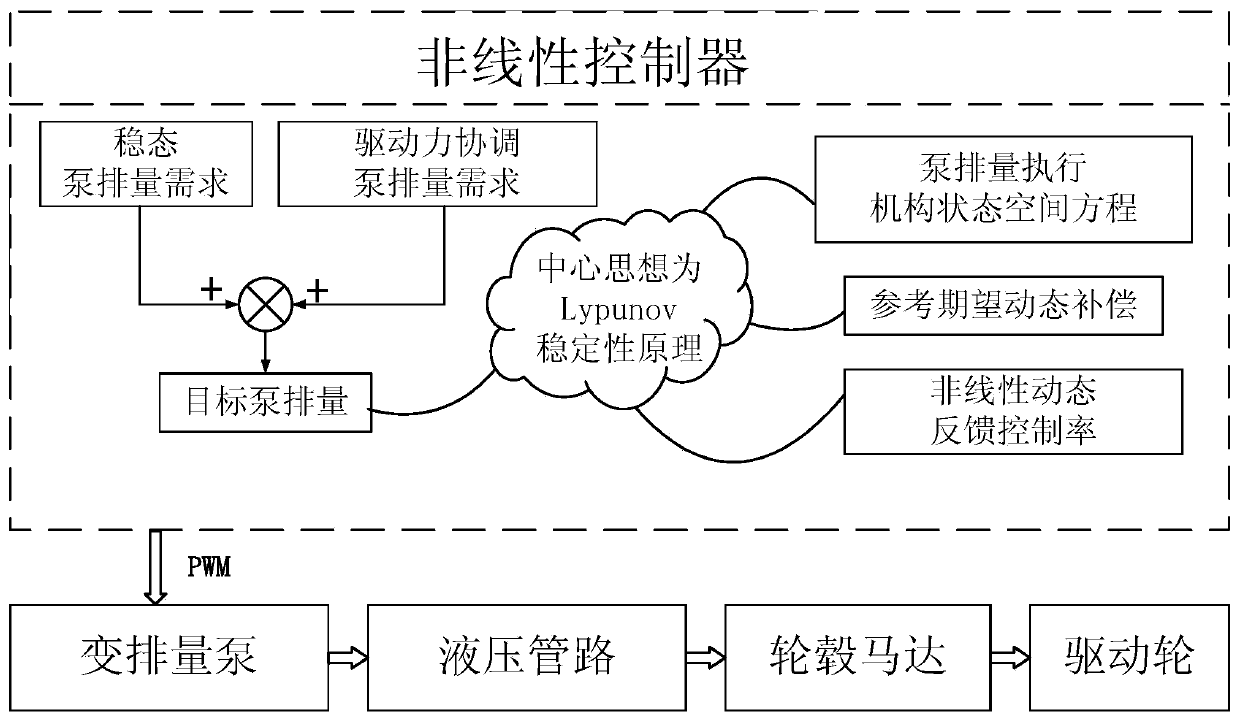

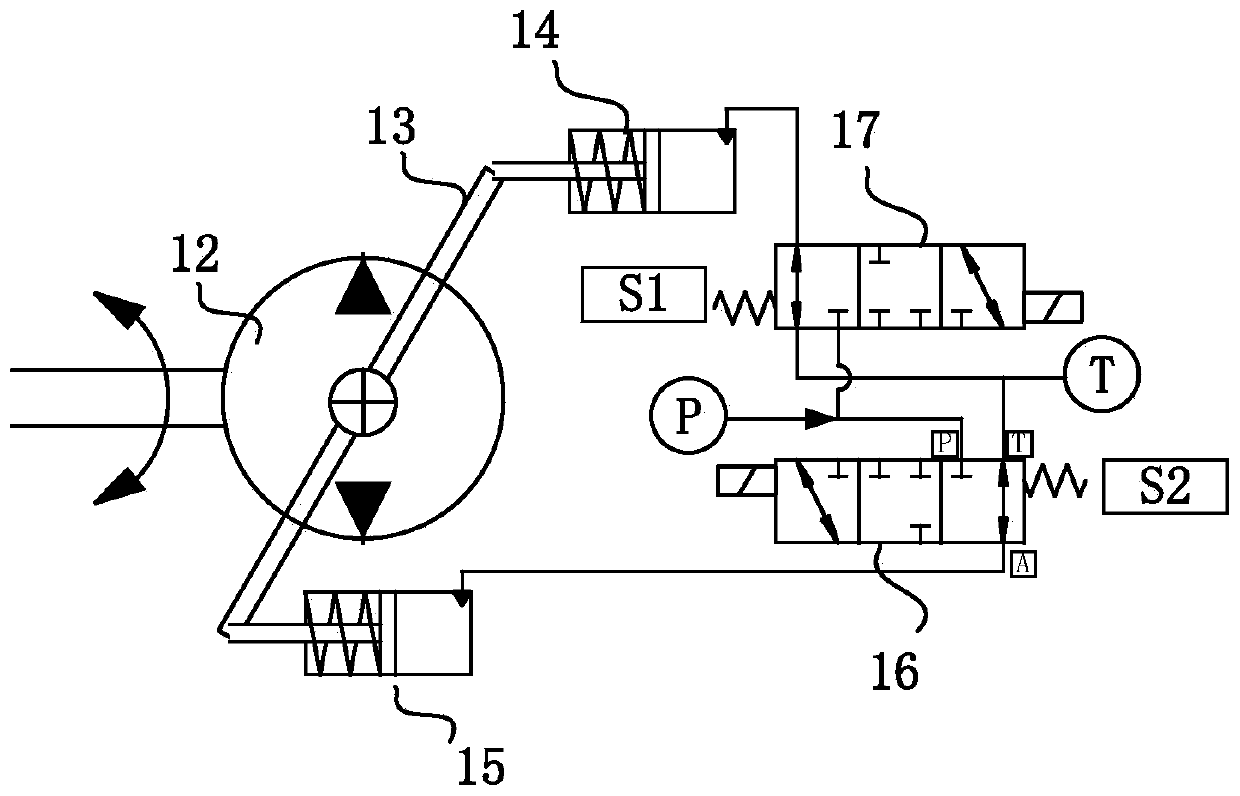

Design method for pump displacement non-linear controller for hub hydraulic hybrid power system

ActiveCN109808677AImprove power densityLow sprung massHybrid vehiclesLyapunov stabilityNon linear dynamic

The invention discloses a design method for a pump displacement non-linear controller for a hub hydraulic hybrid power system, and belongs to the field of hybrid vehicle control. By starting from determination for a pump displacement control target, a state-space equation of a pump displacement execution mechanism is acquired with a least squares identification method, then a steady-state controldemand meeting the pump displacement control target and reference expectation dynamic compensation are calculated respectively, the constructed non-linear dynamic feedback controller is designed by combination with the Lyapunov stability principle, and finally, a final expression form of the pump displacement non-linear controller for the hub hydraulic hybrid power system is obtained. The pump displacement non-linear controller designed with the method takes influence produced by response lag and parameter time-varying of a variable pump displacement regulating mechanism into consideration, has better robustness and resistance to external interference and is quite essential for improvement of displacement tracking control quality of the hub hydraulic hybrid power system.

Owner:JILIN UNIV

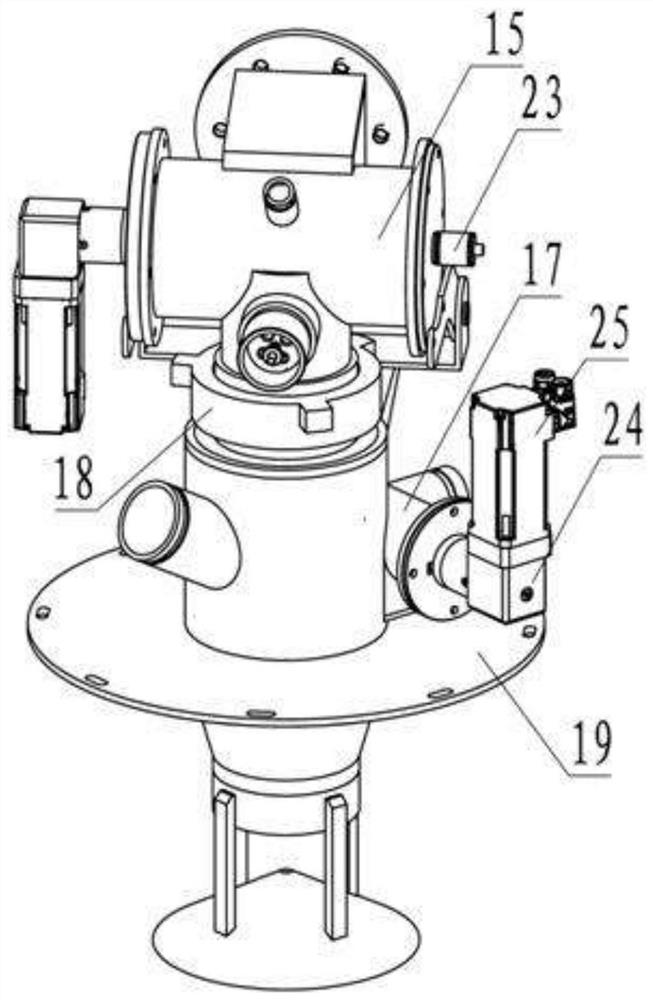

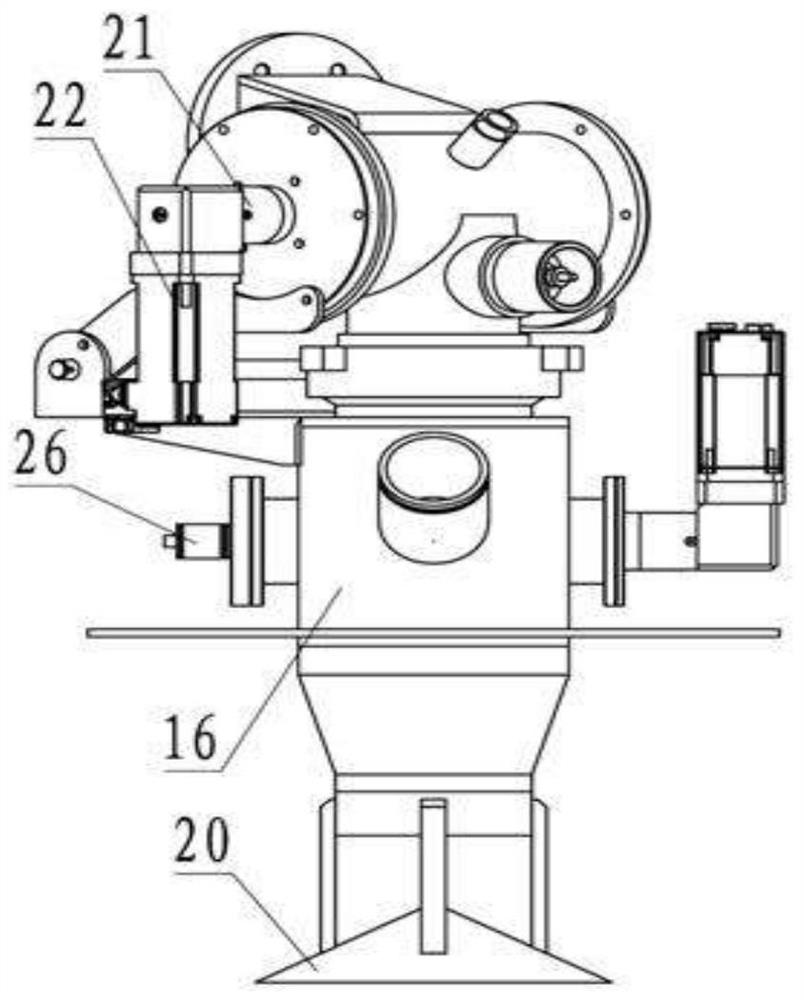

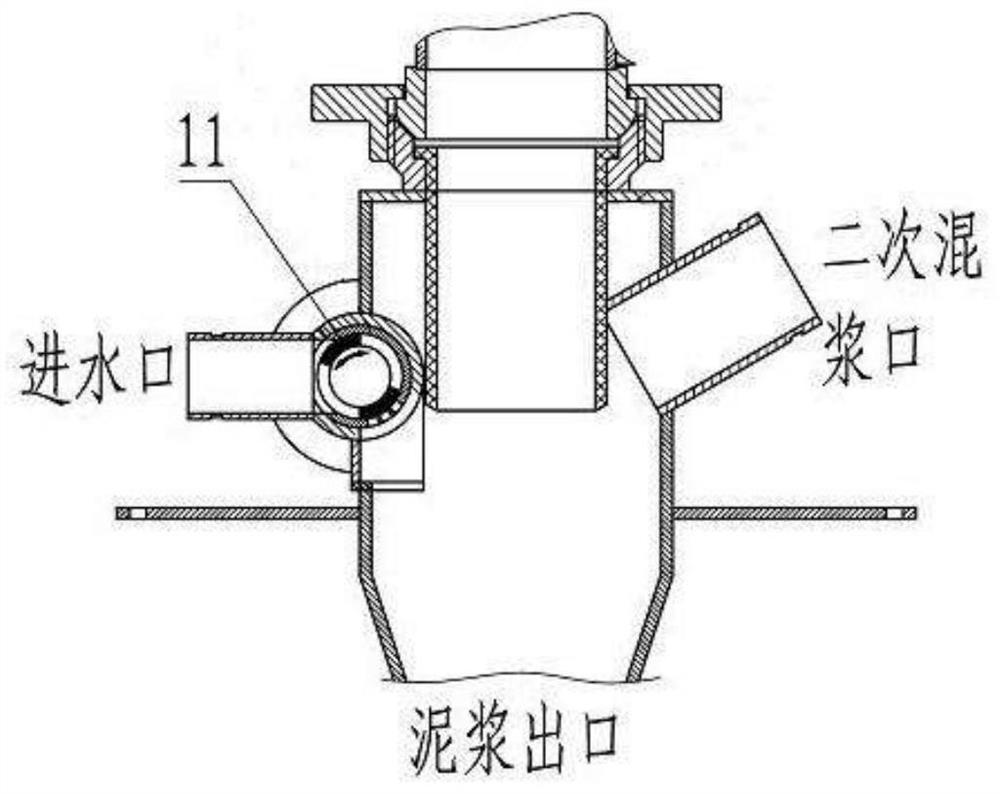

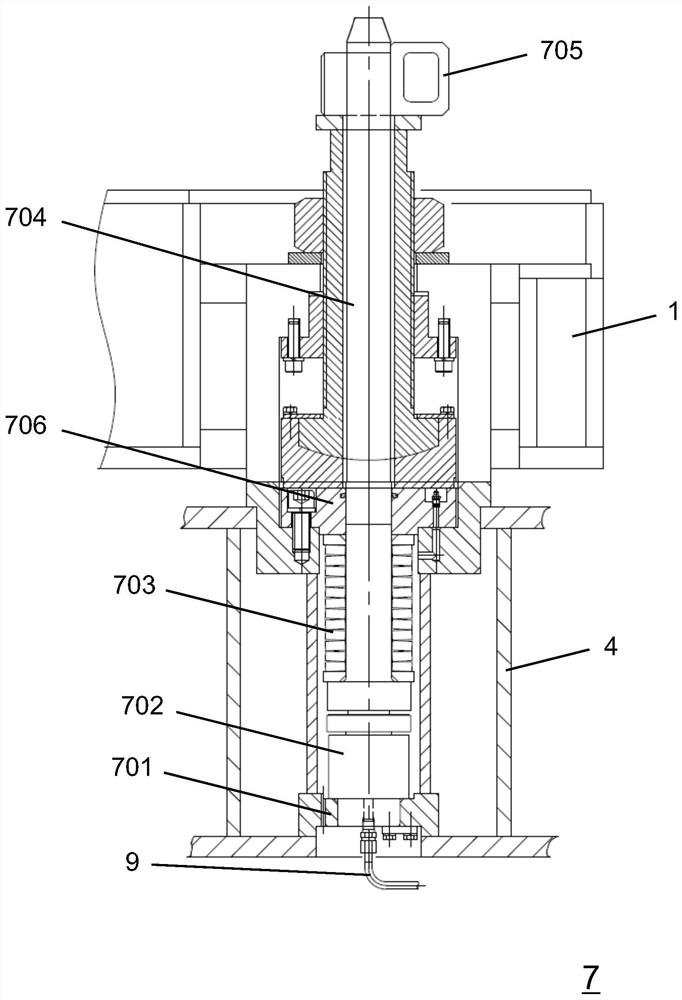

Electric drive type high-energy mixer for well cementation and mud premixing control method

ActiveCN112677314AHigh frequency responseHigh repeatabilityClay mixing apparatusSealing/packingElectric driveWell cementing

The invention discloses an electric drive type high-energy mixer for well cementation. The electric drive type high-energy mixer for well cementation comprises an ash valve main body, the bottom of the ash valve main body is provided with a mixer cavity through a connecting union, the side surface of the mixer cavity is fixedly connected with a water valve main body, a mixer cavity body is provided with a flange plate, the flange plate is positioned below the water valve main body, and the bottom of the mixer cavity is provided with a conical disc. The invention further discloses a mud premixing control method. The problems that in the prior art, a hydraulic drive type high-energy mixer is slow in response, poor in mud premixing effect and high in cost are solved.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

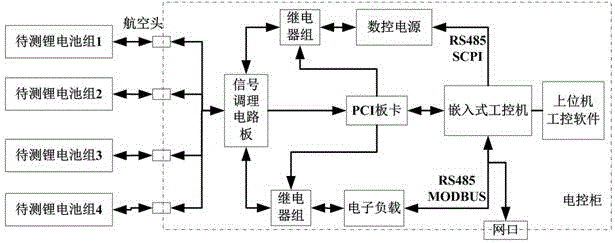

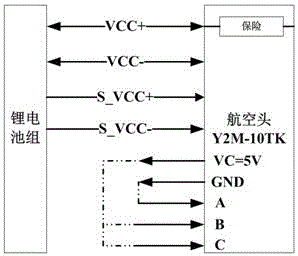

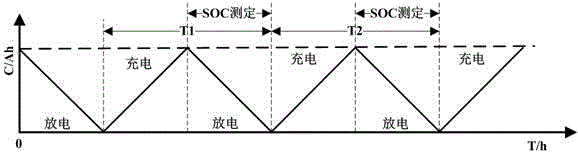

Lithium battery pack SOC measuring device and method

ActiveCN106546926AImprove capacity utilization efficiencyAccurate measurementElectrical testingAviationThree level

The invention relates to a lithium battery pack SOC measuring device and method, and belongs to the field of new energy measurement and control. The method is characterized in that in allusion to a lithium battery pack SOC measurement target, an SOC value is measured accurately through building a lithium battery pack targeted battery maintenance and test system (BMTS) platform; networking control is realized through an RS485 bus mechanism, and an embedded monitor and control generated system (MCGS) and an industrial personal computer (IPC) are equipped to realize local control and remote control; an aviation head is additionally arranged and a jumper identification code is allocated so as to improve the adaptability for various types of lithium battery packs; and three-level protection is realized through additionally arranging an independent protection unit (IPU) in a main charging and discharging circuit. According to the lithium battery pack SOC measuring method, a series charging to equalization charging process is integrated on the basis of constant current (CC) discharge so as to improve the capacity utilization efficiency of the lithium battery packs; and a problem that each single battery is fully charged is solved through constant current (CC) charging to constant voltage (CV) charging mode switching, and effective measurement for the SOC value is realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH

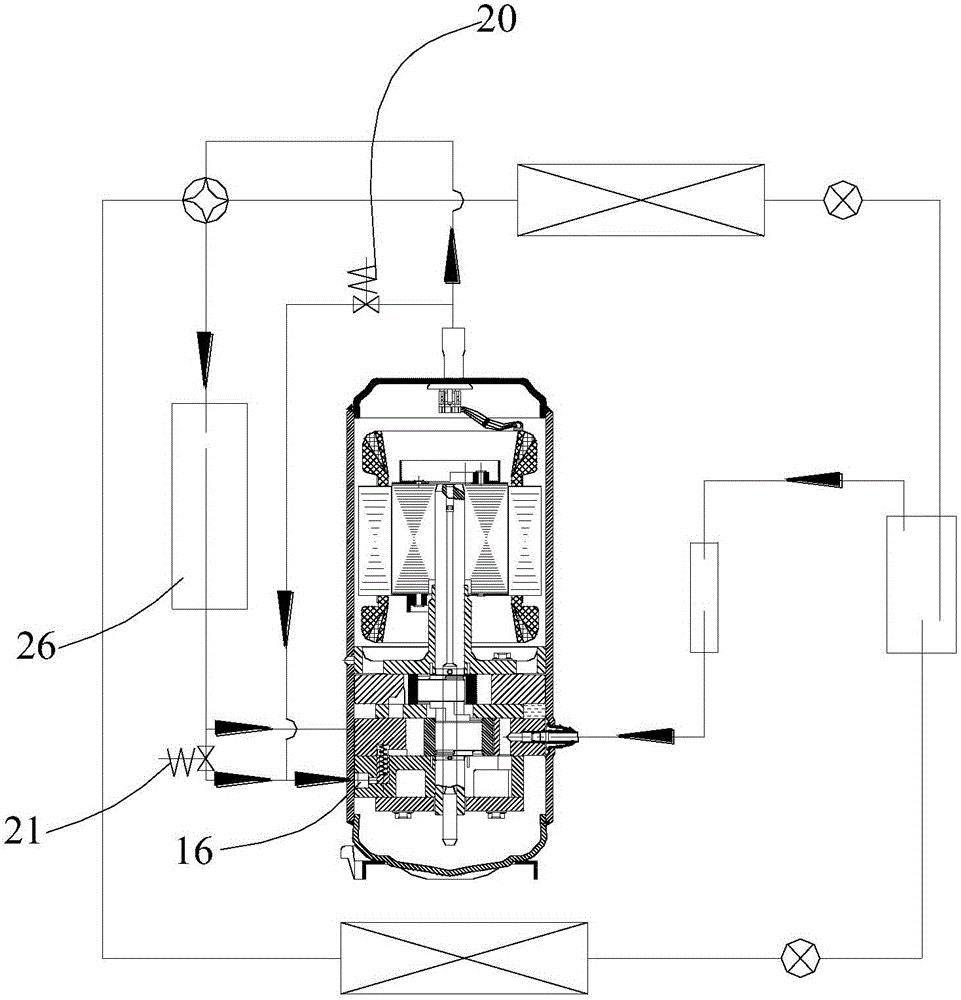

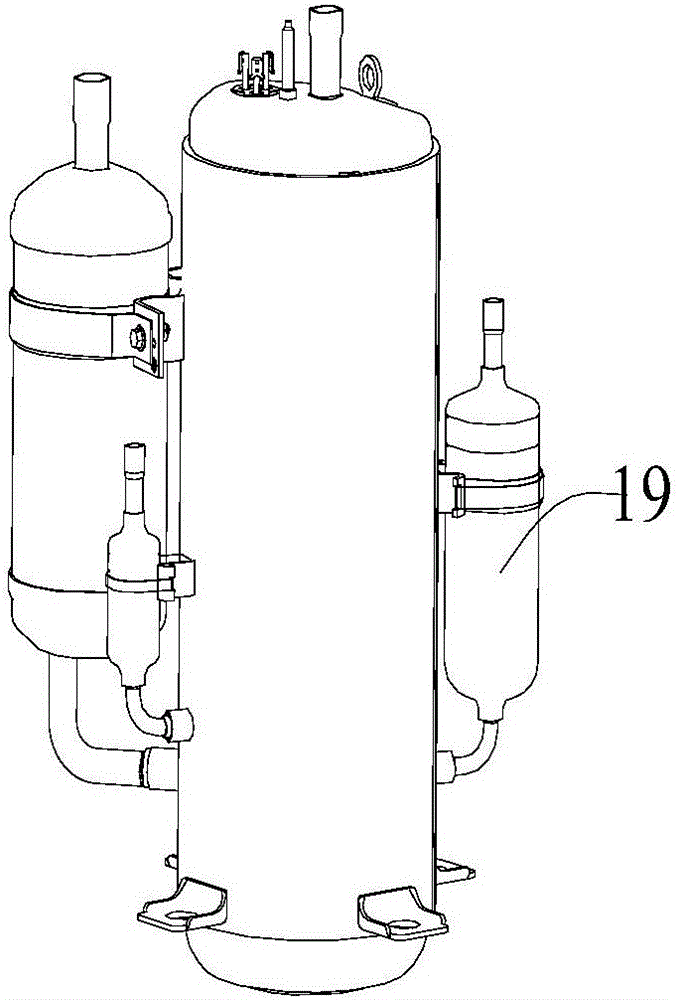

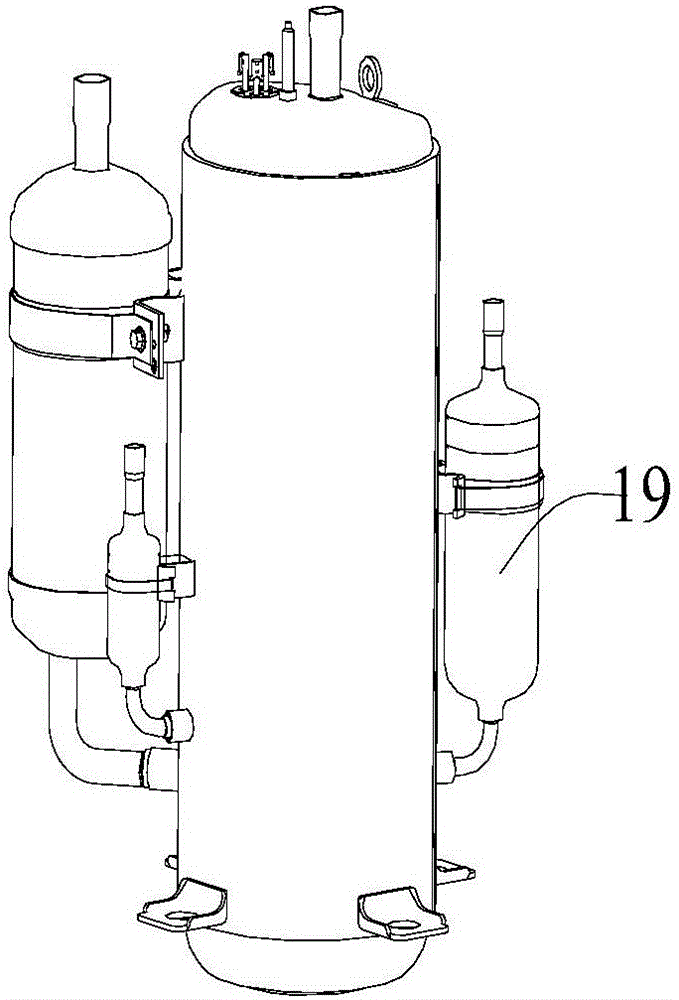

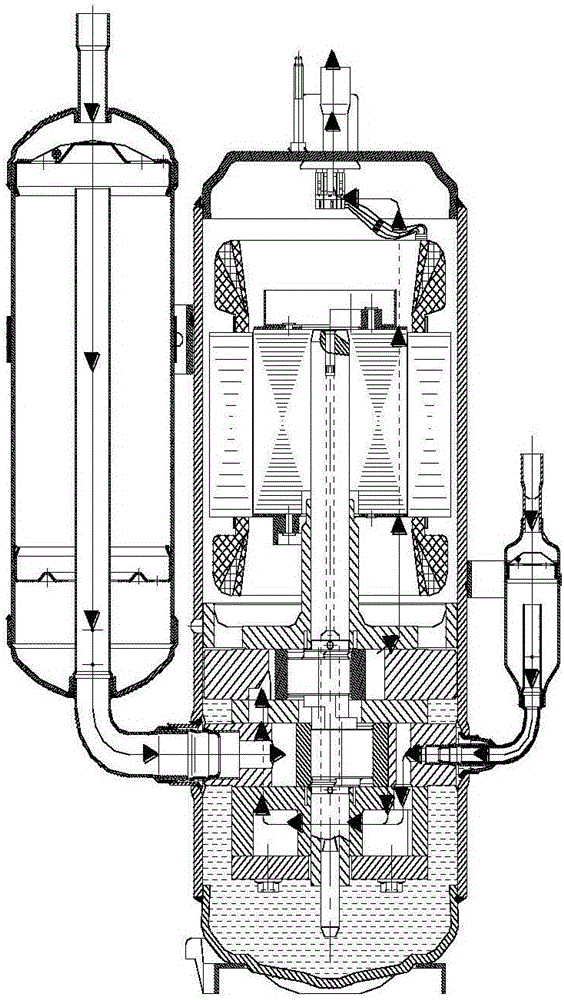

Multi-stage compressor, air conditioner system and control method of multi-stage compressor

InactiveCN105782041AGood adaptability to working conditionsImprove energy efficiencyRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsGas compressorHigh pressure

The invention discloses a multi-stage compressor, an air conditioner system and a control method of the multi-stage compressor. The multi-stage compressor comprises at least one high-pressure-stage air cylinder and at least one low-pressure-stage air cylinder (14), wherein a by-pass port (11) is formed in a side wall, which corresponds to an air suction side, of each low-pressure-stage air cylinder (14); each by-pass port (11) communicates with an air suction opening (13) of the corresponding low-pressure-stage air cylinder (14) through a by-pass backflow channel (12); and a control mechanism which controls switch-on and switch-off of air flow is arranged on each by-pass backflow channel (12). By the arrangement, the volume ratio of the multi-stage compressor provided by the invention can be adjusted, and is not fixed any more, therefore, when the compressor runs at loads under different working conditions, the volume ratio of the compressor can be adjusted to be the optimal volume ratio corresponding to the working conditions, and the working condition adaptability of the compressor is good. Compared with the multi-stage compressor with the fixed volume ratio, the multi-stage compressor is better in integral comprehensive energy efficiency.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Hydrolysis reaction device and hydrolysis method for organic sulfur in blast furnace gas

InactiveCN112646615AIncrease the proportion of spaceSmall pressure lossEnergy inputGas purification by catalytic conversionPtru catalystHydrolysis

The invention provides a hydrolysis reaction device and hydrolysis method for organic sulfur in blast furnace gas, the hydrolysis reaction device comprises a shell, a catalyst partition plate group is arranged in the shell along the axial direction, the top surface of the catalyst partition plate group clings to the top surface of the shell, and the top surface of the catalyst partition plate group clings to the bottom surface of the shell. A cavity formed between the bottom surface of the catalyst partition plate group and the bottom surface of the shell is an air inlet chamber; wherein the catalyst partition plate group comprises an inner ring partition plate piece and an outer ring partition plate piece which are coaxially nested from inside to outside, an annular cavity formed between the inner ring partition plate piece and the outer ring partition plate piece is filled with a hydrolysis catalyst, an annular bottom plate is fixed on the bottom surface of the catalyst partition plate group, and the annular bottom plate seals the bottom of the annular cavity; and a cavity defined by the inner ring partition plate piece is an exhaust channel, a cavity formed between the outer ring partition plate piece and the side wall of the shell is an air inlet channel, and the air inlet chamber is communicated with the air inlet channel. An air inlet communicated with the air inlet chamber is formed in the bottom of the shell.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

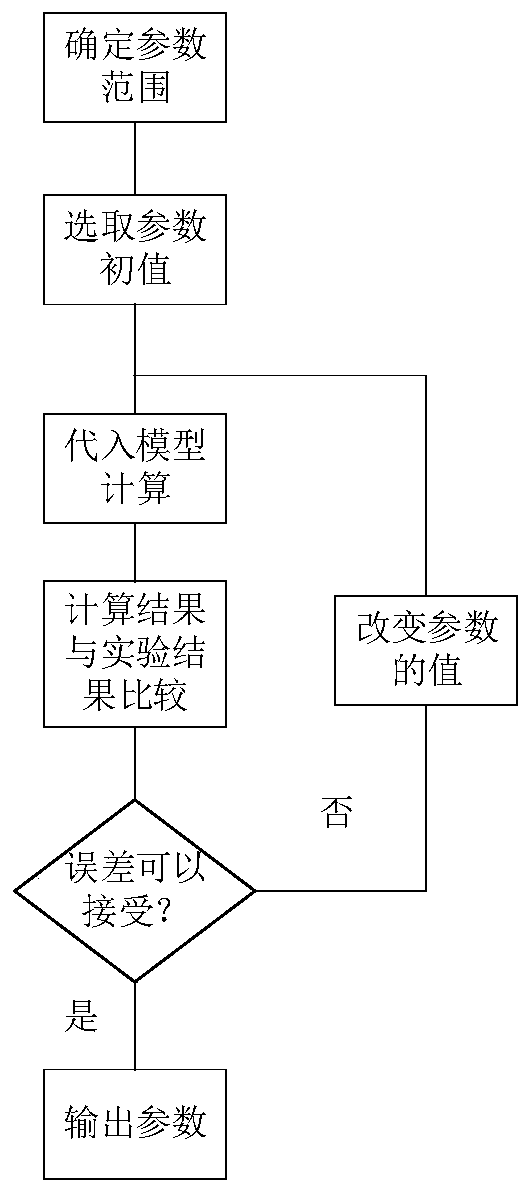

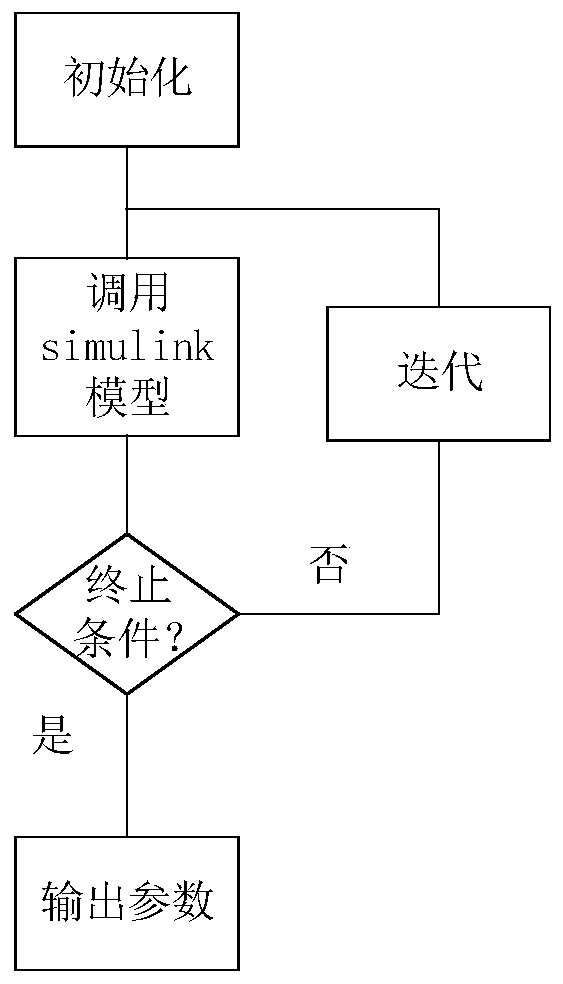

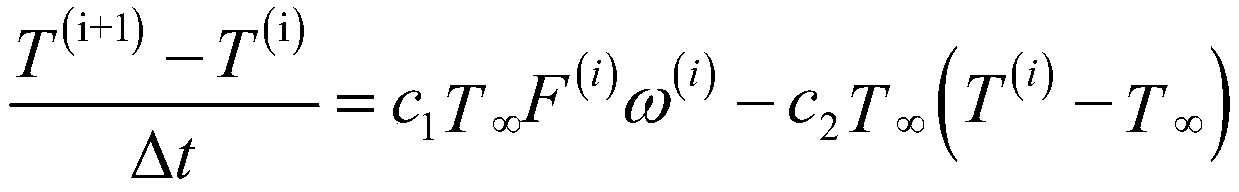

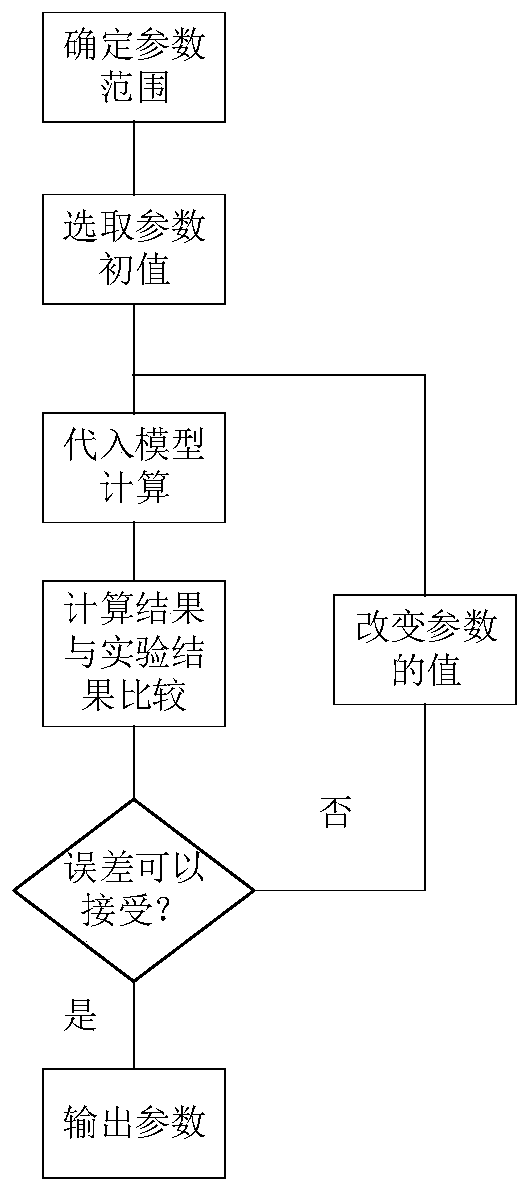

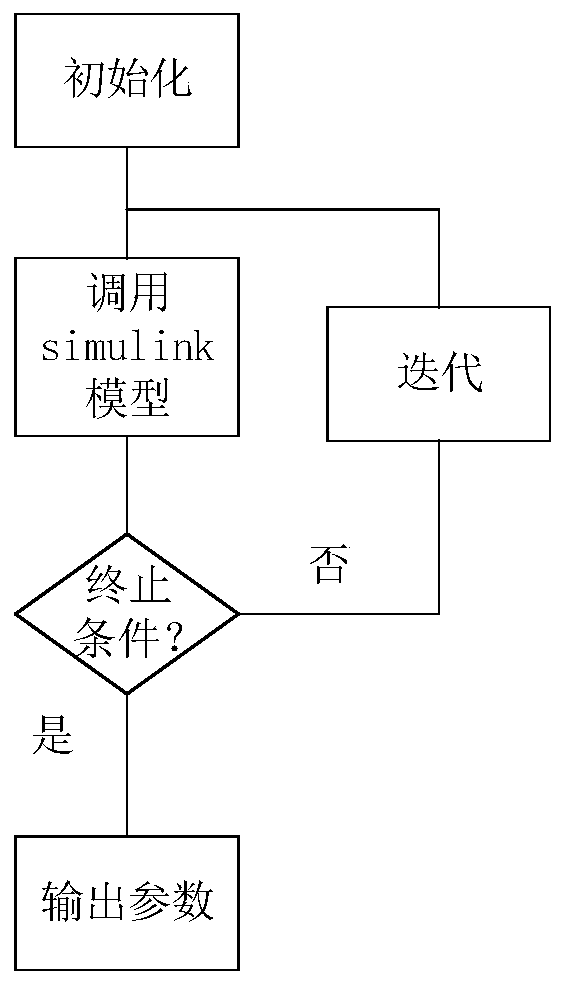

Friction type clutch transient temperature calculation method based on environment temperature coefficient

InactiveCN110134999AImprove applicabilityImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsEngineeringCalculation methods

The invention relates to a friction type clutch transient temperature calculation method based on an environment temperature coefficient. The method is characterized in that an improved two-parametermodel is adopted; iterative calculation is carried out on the clutch transient temperature; in the improved two-parameter model, the temperature rise coefficient is replaced by the product of the environment temperature and the first proportionality coefficient, the heat dissipation coefficient is replaced by the product of the environment temperature and the second proportionality coefficient, the first proportionality coefficient represents the relation between the temperature rise coefficient and the environment temperature, and the second proportionality coefficient represents the relationbetween the heat dissipation coefficient and the environment temperature. Compared with the prior art, the method has the advantages of higher precision, stronger working condition adaptability, quick response and the like.

Owner:SHANGHAI JIAO TONG UNIV

Friction-type clutch transient temperature measuring method and device based on six-parameter model

InactiveCN110426201AGood adaptability to working conditionsHigh Temperature Prediction AccuracyMachine part testingThermometer applicationsEngineeringModel parameters

The invention relates to a friction-type clutch transient temperature measuring method and a device based on a six-parameter model. By using the six-parameter model to replace a two-parameter model, iteration calculation of clutch transient temperature is carried out based on acquired real-time environmental temperature, starting temperature, and speed difference. In the six-parameter model, a temperature rising coefficient and a heat dissipation coefficient are replaced by a linear function adopting the environmental temperature and slipping friction power as variables. Compared with the prior art, the fact that the heat generated by the friction is related to the radius of the clutch is considered, and the acquired model is more accurate than the original model when being compared in theactual condition, and the linear relation between the model parameter of the used model (the temperature rising coefficient and the heat dissipation coefficient) and the environmental temperature andthe slipping friction power is found out, and is brought into the two-parameter model, and then the working condition of the improved model is better; compared with a four-parameter model, because ofadditional providing of constant terms, the completion of the model is compensated, and the accuracy is relatively high.

Owner:SHANGHAI JIAO TONG UNIV

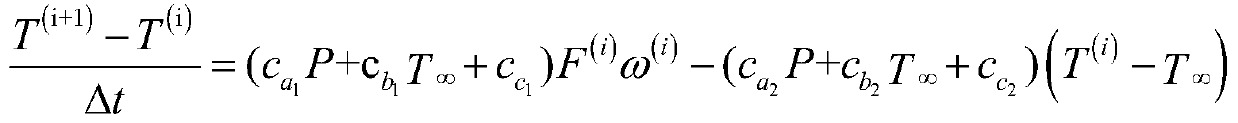

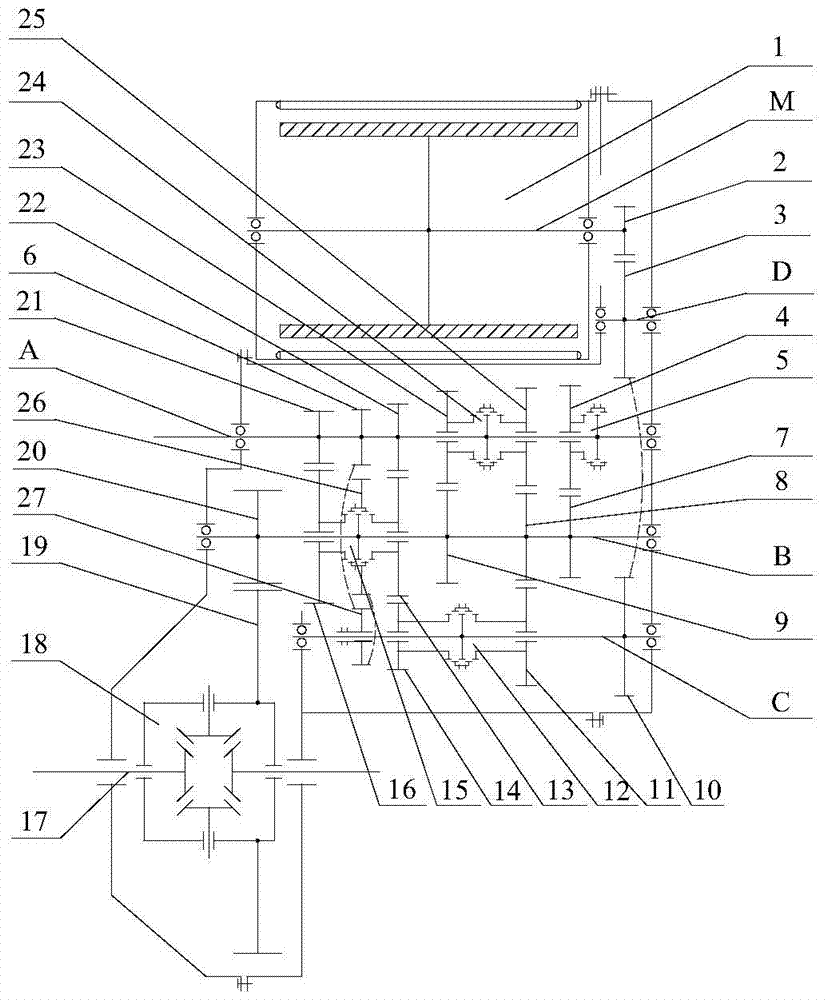

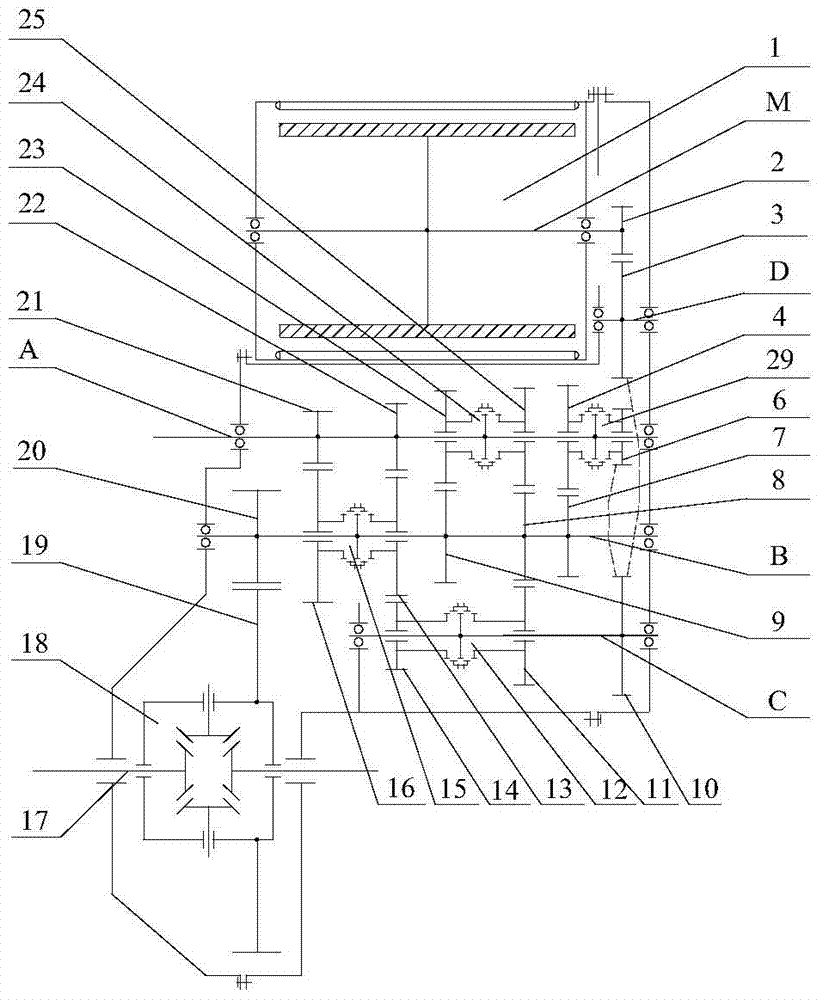

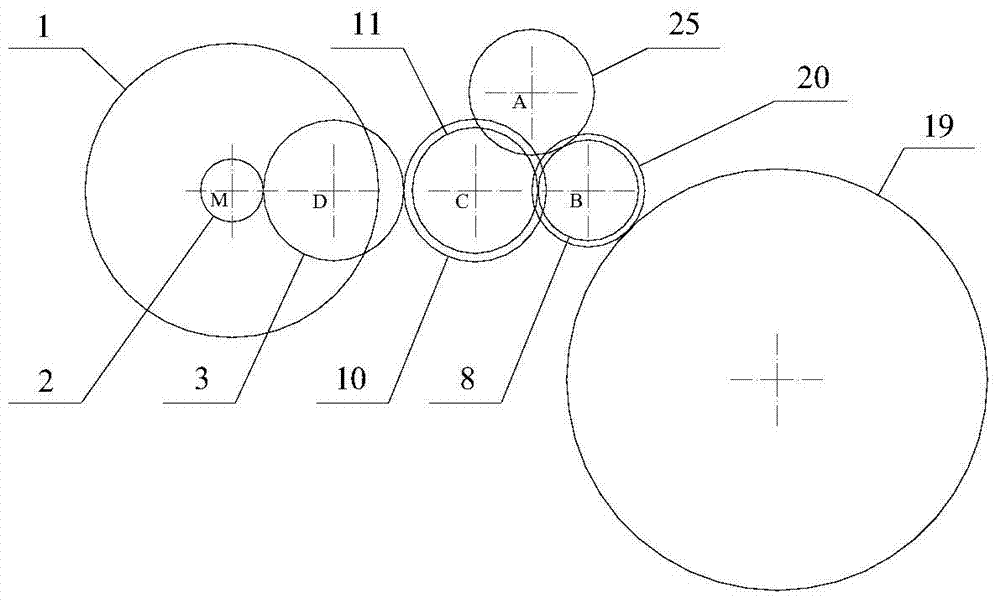

Series-parallel hybrid power system based on single-planet set single gearbox

PendingCN109455080ALow costAvoid interruptionGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringMechanical engineering

The invention provides a series-parallel hybrid power system based on a single-planet set single gearbox. A hybrid power assembly is arranged conveniently, types of hybrid power products are expanded,power transmission continues, and the system is suitable for various complex working conditions. The system comprises an engine, a first motor, a gearbox, a second motor and a planet tooth row structure, the gearbox is integrated with the planet tooth row structure, and the planet tooth row structure specifically comprises a sun wheel, a planet wheel frame and a gear ring; a first output shaft ofthe planet wheel frame penetrates through a second hollow input shaft of the sun wheel and is connected to the output end of the engine, the output part of the first motor sleeves the second hollow input shaft, several planet wheels are distributed on the planet wheel frame annularly, and the inner side of the planet wheel is meshed with the sun wheel radially, and the outer side of the planet wheel is meshed with an inner gear ring of the gear ring radially.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

Multistage compressor, air conditioning system and controlling method of multistage compressor

InactiveCN105782042AGood adaptability to working conditionsExcellent comprehensive energy efficiencyRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringAir conditioning

The invention discloses a multistage compressor, an air conditioning system and a controlling method of the multistage compressor. The multistage compressor comprises at least one high-pressure stage cylinder and at least one low-pressure stage cylinder, wherein a bypass hole is formed in the side wall, corresponding to the suction side of the high-pressure stage cylinder and is communicated with the suction hole of the high-pressure stage cylinder through a bypass backflow passage; and in addition, the bypass backflow passage is provided with a control mechanism for controlling on-off of an airflow. According to the multistage compressor, with the arrangement, adjustable volume ratio of the compressor can be realized, the compressor does not have fixed volume ratio any longer, and therefore, the volume ratio can be adjusted to the optimal volume ratio corresponding to the working condition when the compressor runs under different working condition loads, the working condition adaptation of the compressor is better, and the comprehensive energy efficiency of the compressor is better compared with that of the whole multistage compressor with fixed volume ratio.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

High-performance PTFE (Polytetrafluoroethylene) needled felt filter material and preparation process thereof

ActiveCN103432827BSmall apertureHigh porositySynthetic resin layered productsFiltration separationHeat resistanceFilter material

Owner:辽宁新洪源环保材料有限公司

A fixed shaft hybrid transmission with integrated drive motor

ActiveCN105128648BAchieve simplificationReduce volumeHybrid vehiclesGas pressure propulsion mountingElectric machineEngineering

Owner:TONGJI UNIV

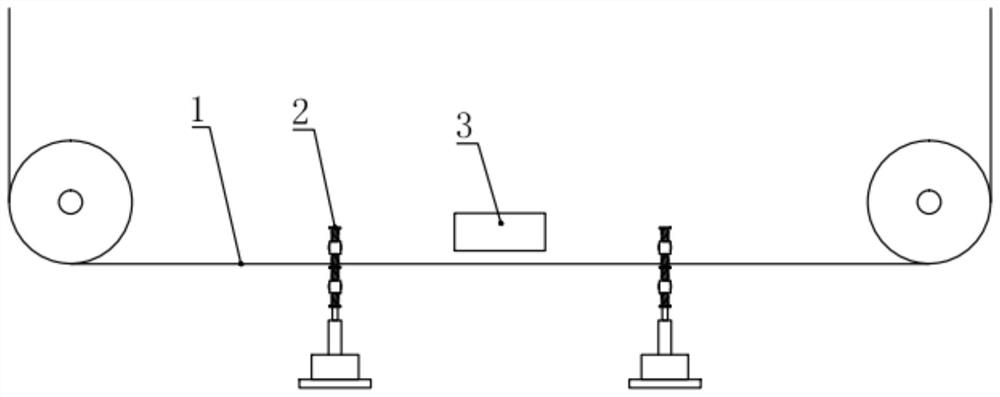

A shock absorbing device for a multi-wire cutting machine

ActiveCN110815611BImprove conduction stabilityFlexible and convenient use of controlsFine working devicesWire cuttingEngineering

The invention relates to the field of multi-wire cutting machine auxiliary devices, in particular to a multi-wire cutting machine shock absorber, which includes two symmetrically placed shock absorbing components, and the wire of the multi-wire cutting machine passes through the two shock absorbing components. There is also a feed workbench matched with the metal wire between the two shock absorbing components; the shock absorbing component includes side support plates, floor seats, telescopic cylinders, sliding sleeves, mounting bars, upper support rollers, lower support rollers and transverse support rollers. Longitudinal elastic support components. The invention has a novel structure, is convenient for control and adjustment, has a better combined damping and supporting effect on the metal wire, and reduces the probability of the metal wire jumping out of the guide wheel groove.

Owner:ZHUZHOU LIANXIN METAL CO LTD

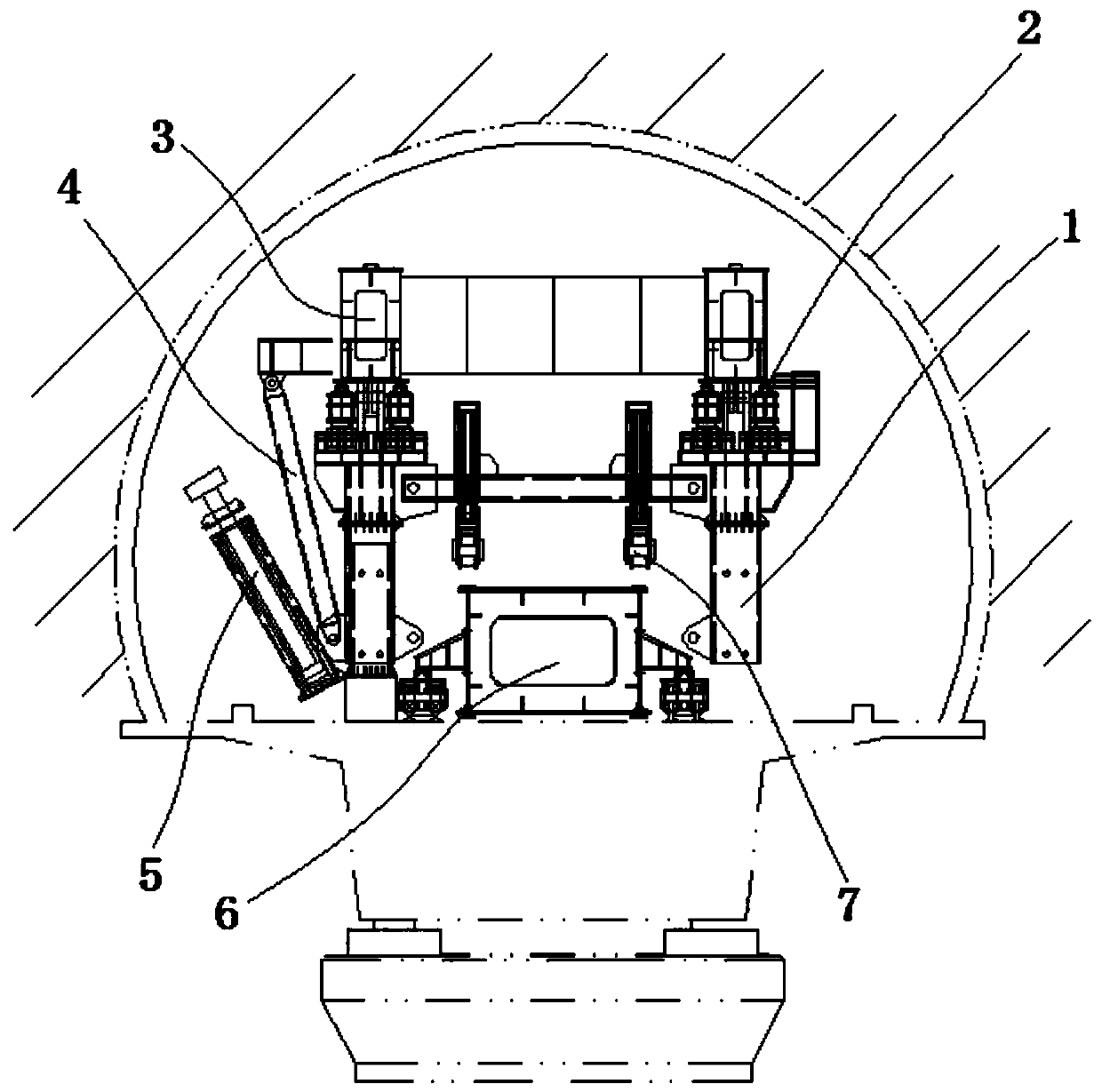

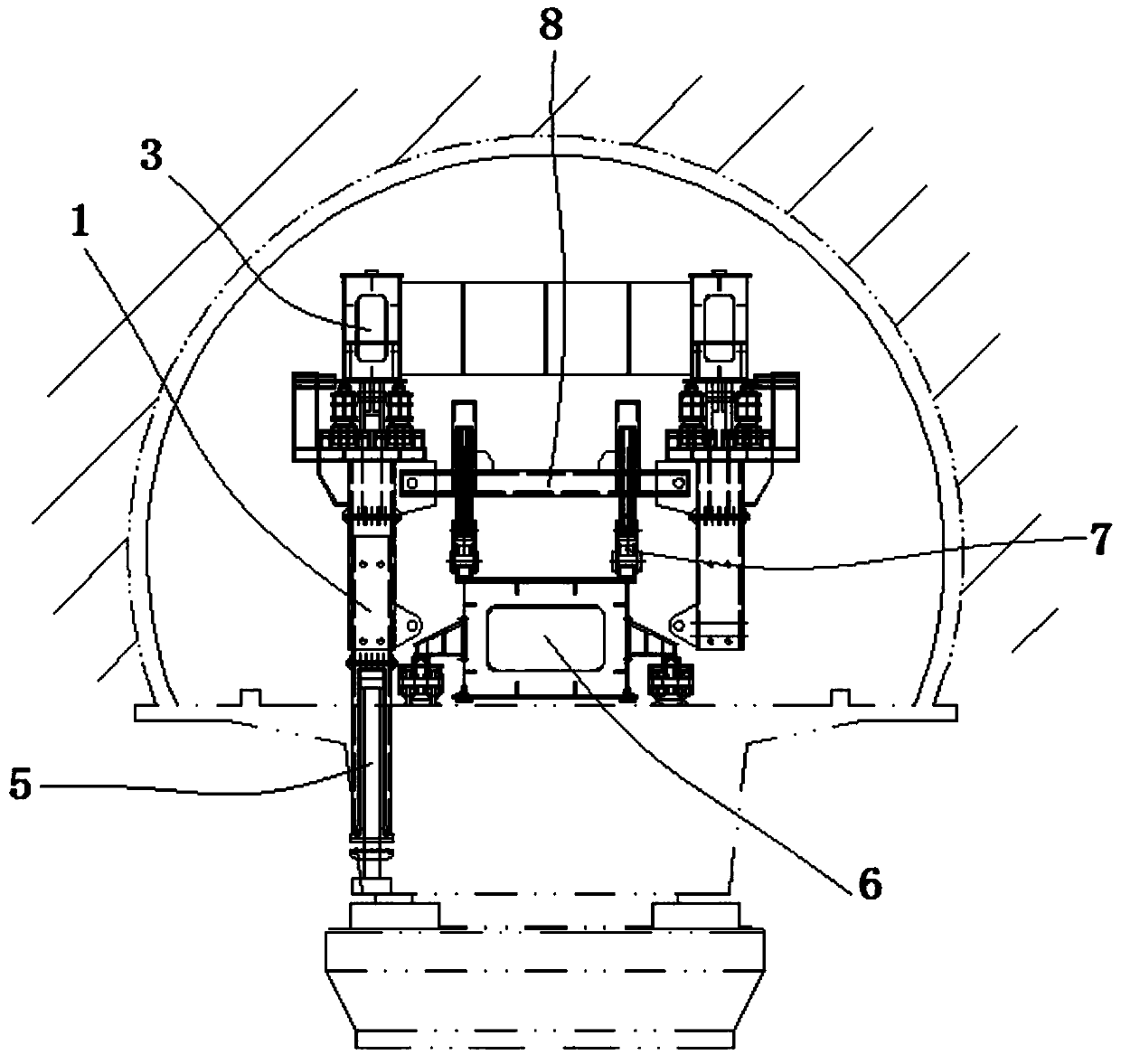

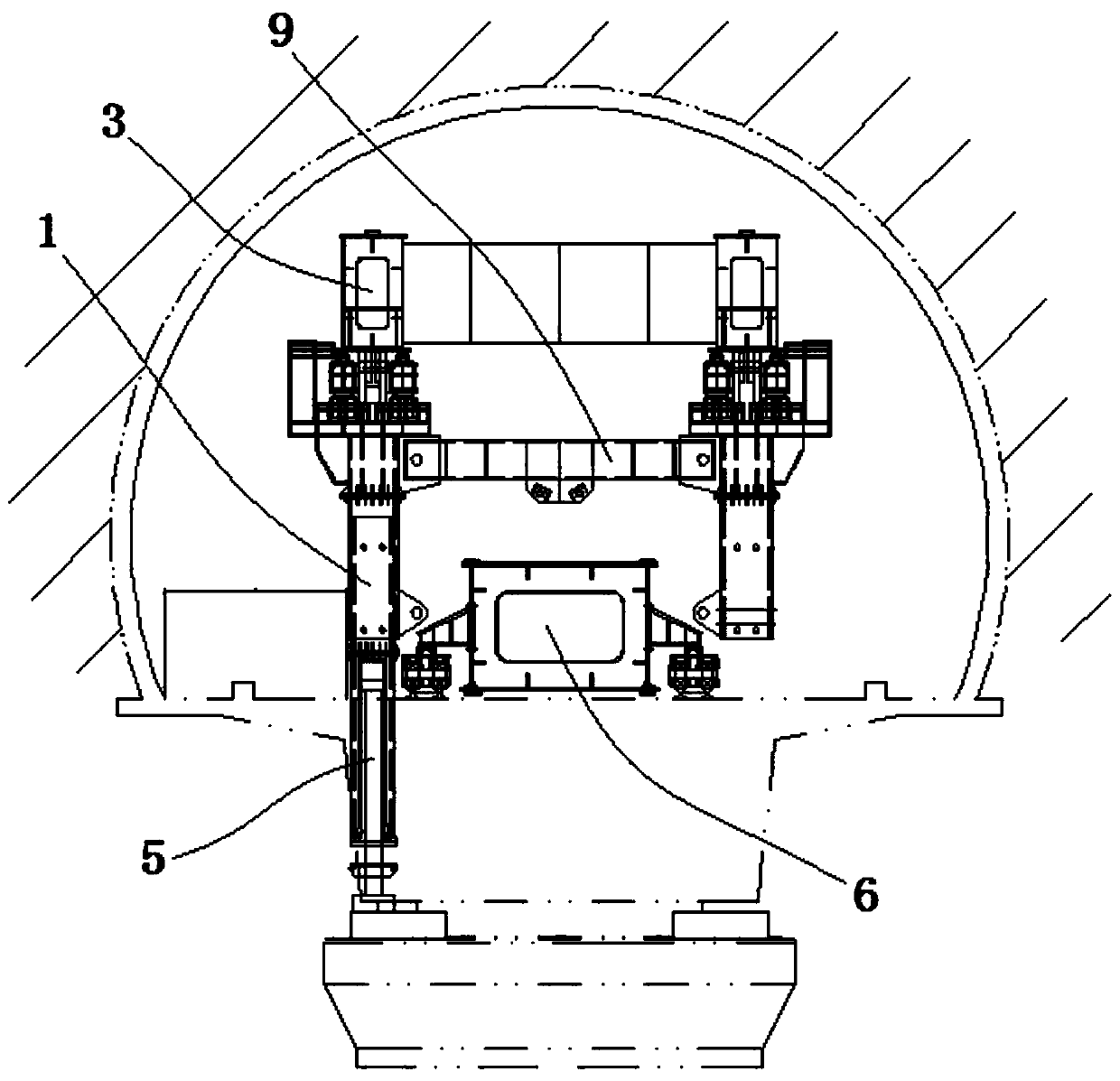

A crystallizer positioning and locking system

ActiveCN109277540BGood adaptability to working conditionsSimple structureControl engineeringProcess engineering

Owner:BAOSHAN IRON & STEEL CO LTD

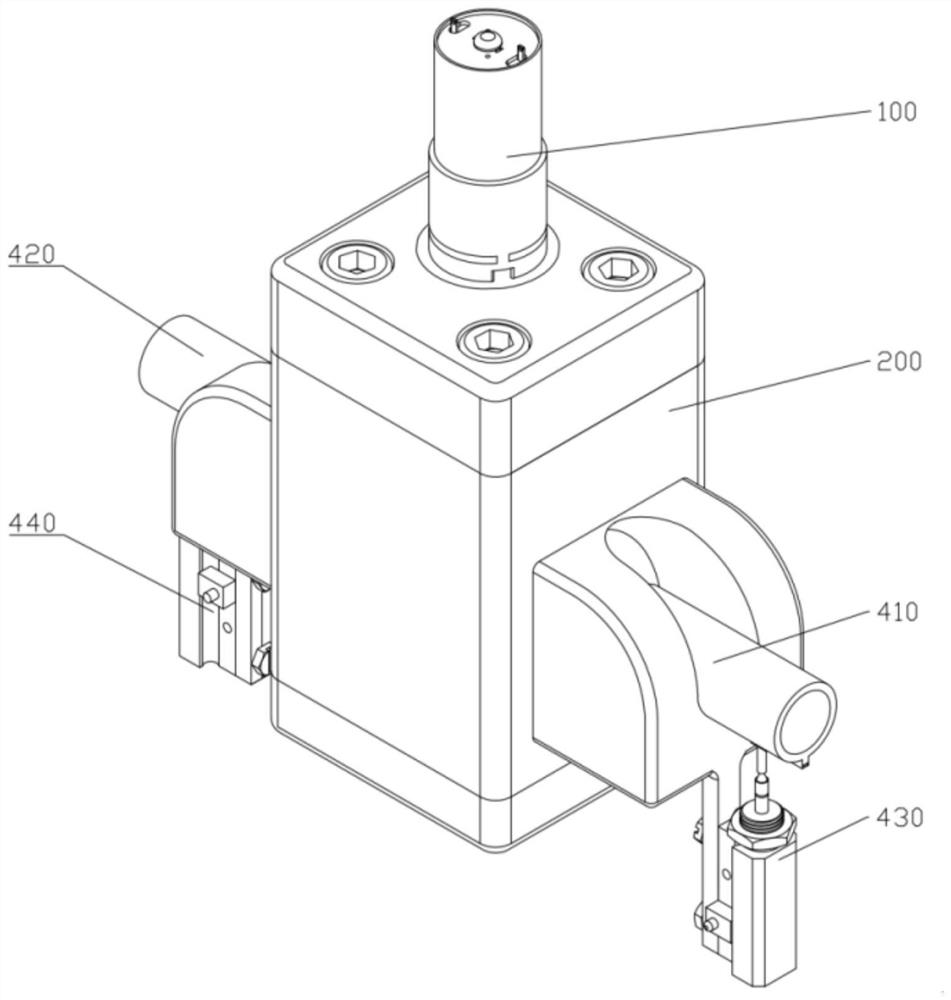

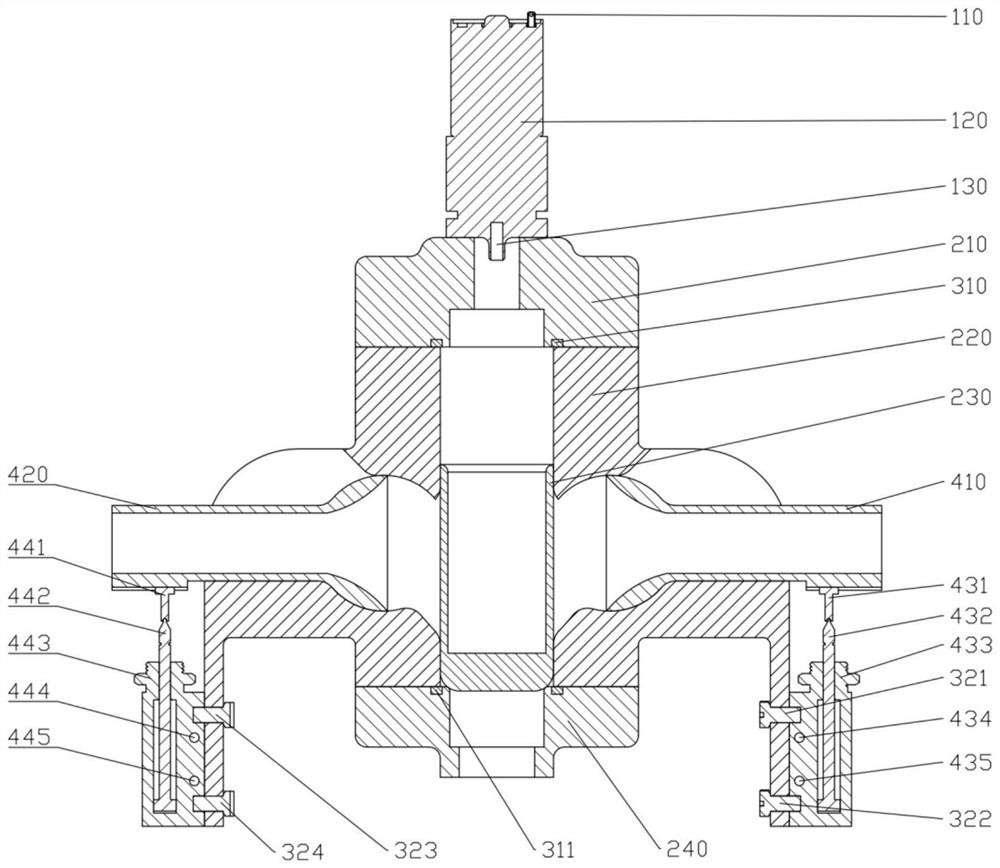

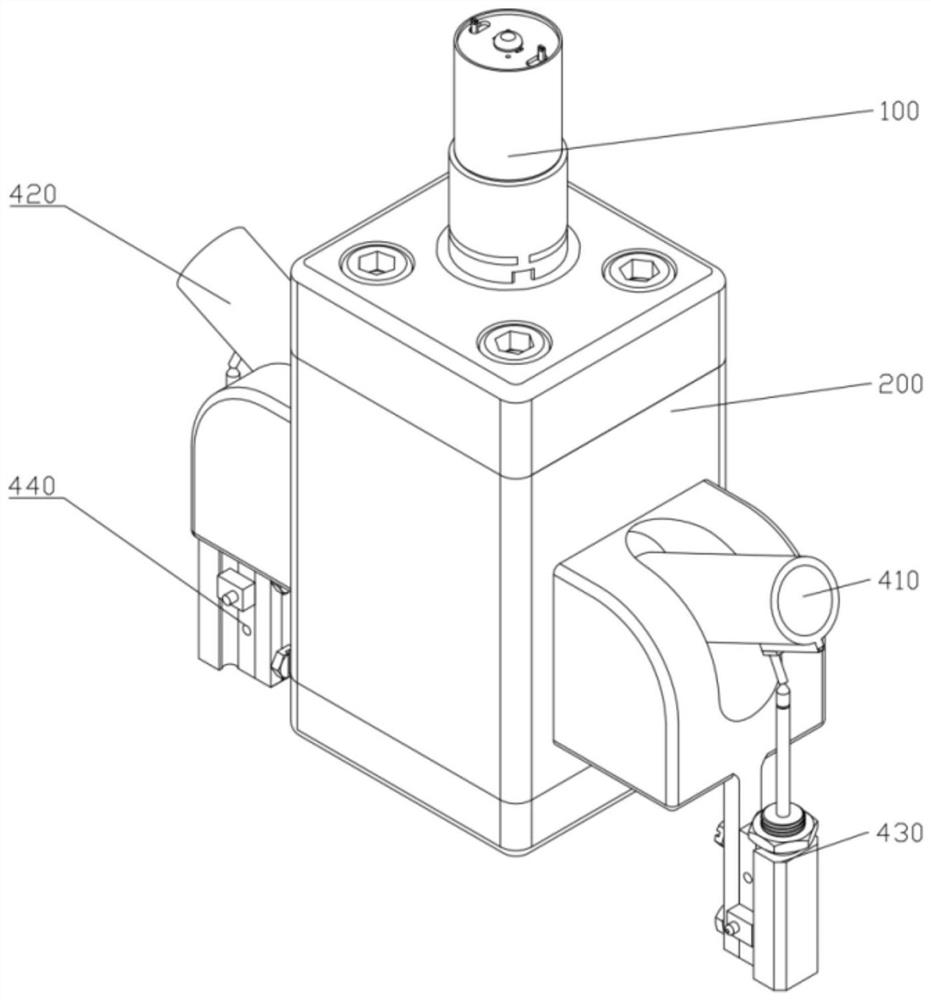

Curvature continuous valve with adjustable flow channel

PendingCN114087409AEasy to assembleReliable cooperationOperating means/releasing devices for valvesValve housingsAir pumpPhysics

The invention discloses a curvature continuous valve with an adjustable flow channel. The curvature continuous valve comprises an air pump module, a valve body module, a connecting module and a flow channel adjusting module; the air pump module comprises an air pump power interface, an air pump main body and an air pump output hole; the valve body module comprises a base body, a valve top, a valve bottom and a valve element; the connecting module comprises an upper gasket, a lower gasket, a valve body fixing bolt and an air cylinder fixing bolt; a flow channel adjusting module comprises a right flow channel adjusting module and a left flow channel adjusting module; and the air pump module is connected to the valve top through the valve body fixing bolt, and the flow channel adjusting module is connected to the base body through the air cylinder fixing bolt. The inclination angles of a right flow channel and a left flow channel in the valve are adjustable, and the angles of the right flow channel and the left flow channel can be adjusted according to the flowing-out angle of a fluid medium so as to facilitate flowing-out of the fluid medium; and the air pump module is adopted to replace an existing setting spring to achieve adjustment of the setting pressure, and the adjustable range of the setting pressure is larger.

Owner:SICHUAN UNIV

Low-grade industrial waste heat recycling system

PendingCN114865950AAchieve one-step recyclingSimple structureInternal combustion piston enginesThermoelectric device with peltier/seeback effectProcess engineeringEnergy recovery

The invention relates to the technical field of industrial waste heat recycling, solves the problem that low-grade waste heat in current industrial production is difficult to recycle, and particularly relates to a low-grade industrial waste heat recycling system which comprises an energy recycling front end for recycling industrial waste heat and converting heat energy into electric energy, the energy utilization rear end is used for utilizing the electric energy converted by the energy recovery front end, the energy recovery front end is connected with the energy utilization rear end through a wire, and the energy recovery front end comprises a heat expansion plate, a first heat conduction layer, a device layer, a second heat conduction layer and a heat dissipation layer which are sequentially arranged from top to bottom. According to the system, the purpose of directly converting low-grade industrial waste heat into electric energy for recycling is achieved, one-step recycling of the industrial waste heat can be achieved, and the system is simple in structure, free of maintenance, free of noise and pollution in work and excellent in working condition adaptability and has very wide application prospects.

Owner:FIRST DESIGN & RES INST MI CHINA

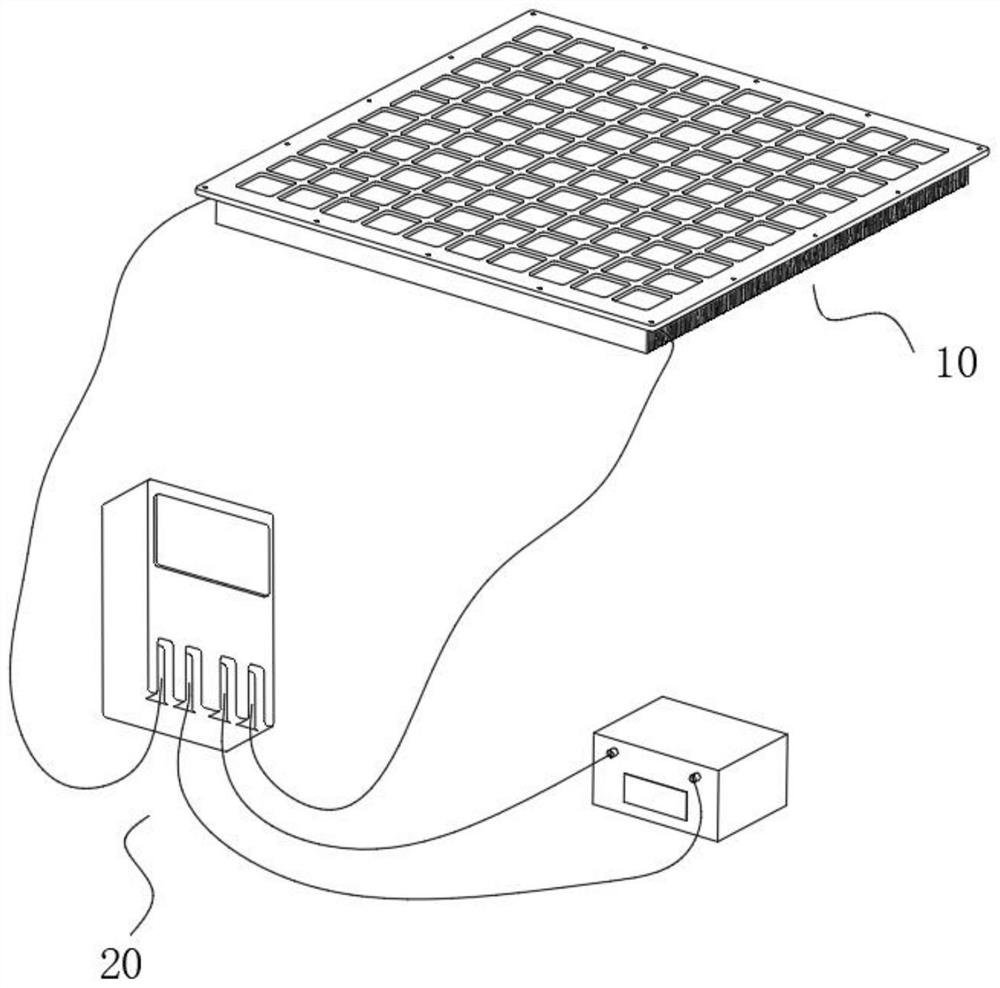

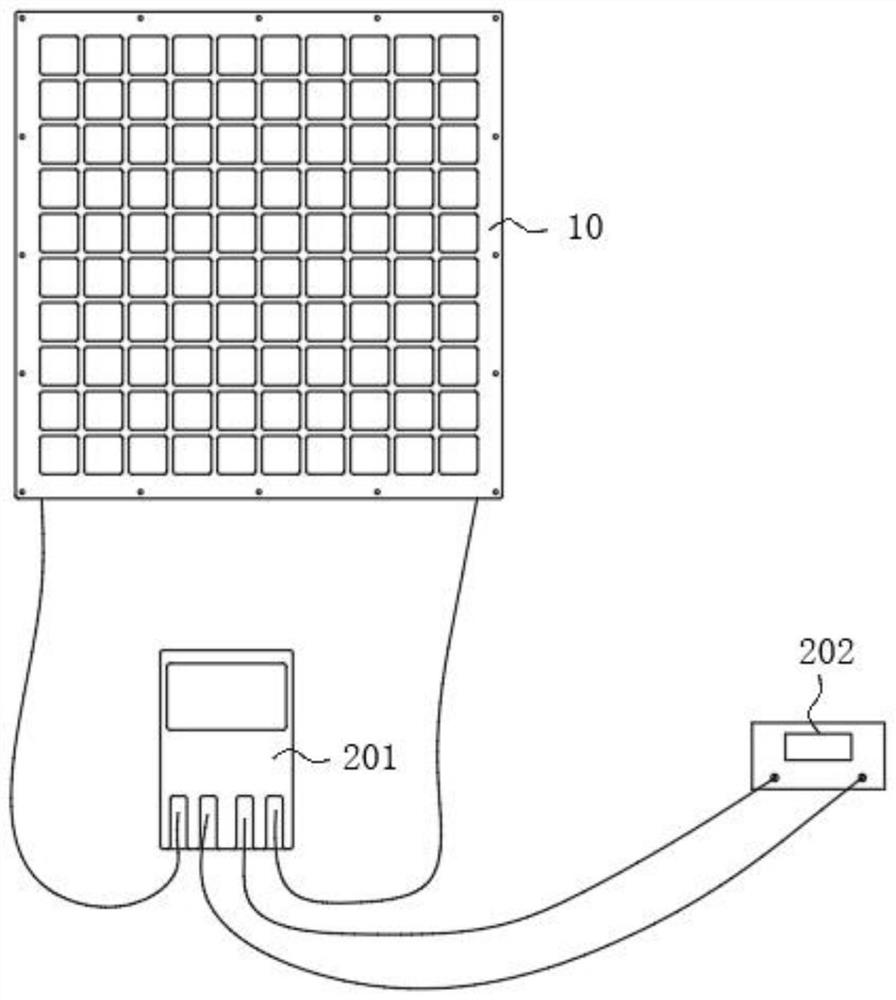

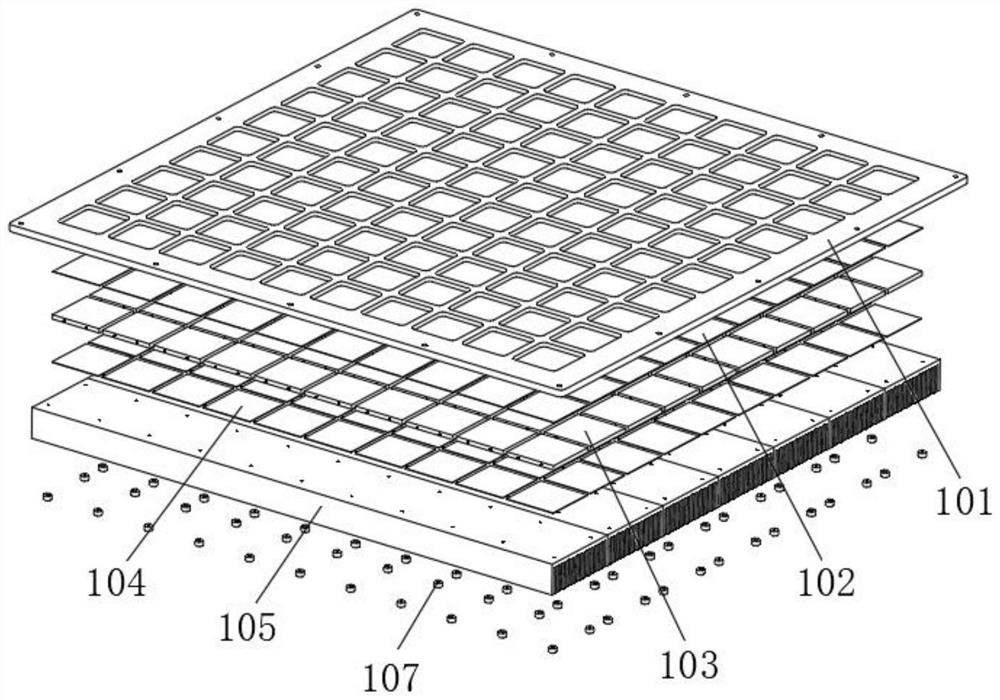

A mobile concrete spraying manipulator screen safety protection device and method

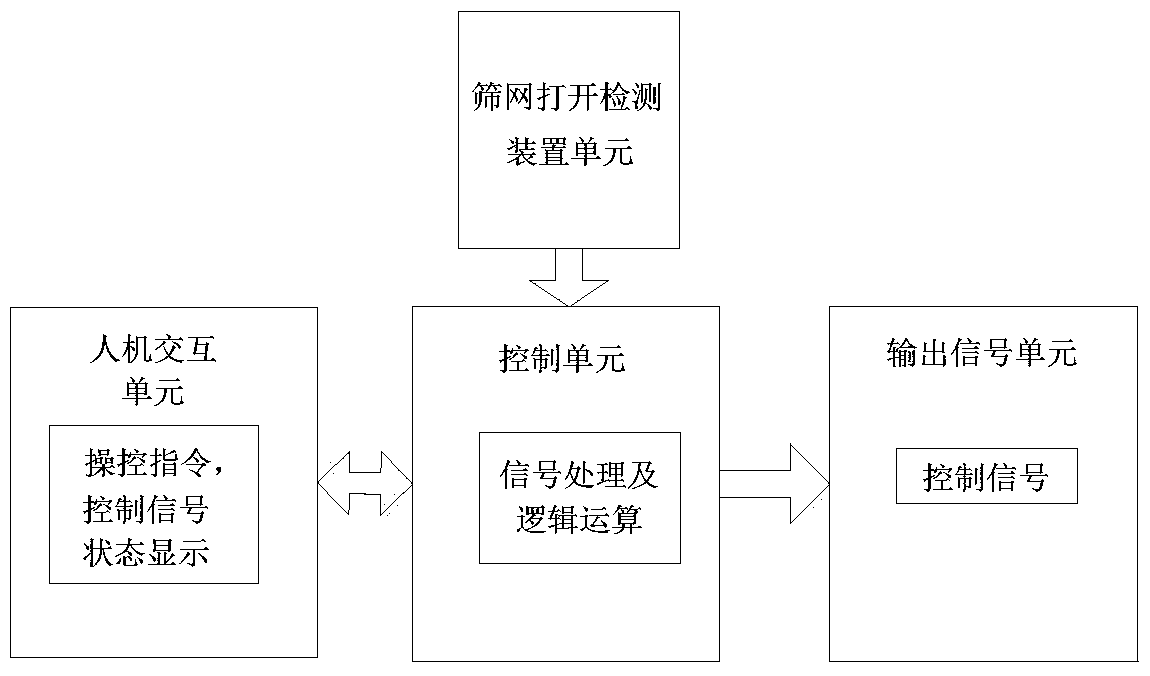

ActiveCN107497676BTo realize the identification signal changeImprove reliabilitySievingPump testingControl signalMovable type

The invention discloses a screen safety protection device and method of a movable-type concrete jetting manipulator. The screen safety protection device comprises a man-machine interaction unit, a screen opening detection device unit, a control unit and a signal output unit. According to the screen safety protection device, on the basis of an output signal of an approaching switch sensor, the perpendicular distance between the signal face of the approaching switch sensor and an approaching switch induction plate is judged, so that the opening / closing state of a screen is judged, and a corresponding screen safety protection control signal is output by combining a control instruction of the man-machine interaction unit; and meanwhile the state of the signal is displayed in a display screen, and under the situation that the screen safety protection device meets operating of various working conditions is ensured, guarantee is provided for personal safety.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

Planet gear bearing forced lubricating device

ActiveCN102829165BImprove delivery efficiencyReduce in quantityGear lubrication/coolingGear wheelSpray nozzle

The invention discloses a planet gear bearing forced lubricating device for a wind power generation gearbox. The planet gear bearing forced lubricating device comprises a box body, a planet carrier, a planet gear, a bearing and a planet pin; the planet carrier is rotationally supported on the box body; the planet pin is arranged on the planet carrier; the planet gear is rotationally supported on the planet carrier by the bearing; the inner lateral surface of the planet carrier, which is opposite to the inner lateral surface of the box body, is provided with a ring-shaped convex retainer; a centrifugal oil collection cavity is formed between the inner lateral surface of the planet carrier and the inner wall of the ring-shaped convex retainer; the box body is provided with an oil injection duct and a spray nozzle is arranged on the box body; the oil injection duct is communicated with the spray nozzle; an outlet of the spray nozzle is toward the centrifugal oil collection cavity on the planet carrier; the planet pin is provided with an oil passage; an inlet of the oil passage is communicated with the centrifugal oil collection cavity; and an outlet of the oil passage is communicated to the position of the bearing positioned outside the planet pin. The planet gear bearing forced lubricating device has reasonable structure and is convenient to process and manufacture; and the oil supply can be regulated according to the working conditions.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

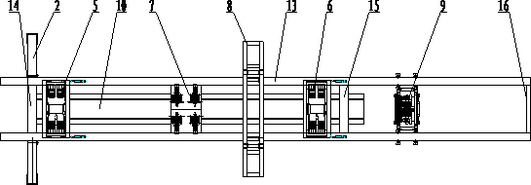

The method of the lower guide beam type fixed-point hoisting bridge erecting machine passing through the tunnel based on the front outrigger

ActiveCN108867404BSimple structureEasy to operateBridge erection/assemblyStructural engineeringMachine

The invention discloses a lower launching nose type fixed-point hoisting bridge girder erection machine through-tunnel method based on a front support leg, and relates to the technical field of bridgegirder erection machines. The method comprises the following steps: anchoring the lower end of the front support leg with the ground; changing span of the bridge girder erection machine; laying downa roller to make the roller completely contact with a launching nose track; turning over the lower section of the front support leg, and driving, by a rear support leg, the bridge girder erection machine go out of the tunnel; removing a lower cross beam and mounting an upper cross beam to original position; recovering support of the lower section of the front support leg, and enabling an oil cylinder at the upper end of the front support leg to work; jacking the front support leg up to a normal girder erection state. According to the method disclosed by the invention, system transformation isrealized through oil cylinder support and hinge pin connection; in combination with the longitudinal shift of an HILMAN roller, the girder erection position of the front support leg of the bridge girder erection machine is changed; the structural form is simple and the operation is convenient; by integrating the longitudinal shift walking drive of the launching nose and the longitudinal shift walking drive of the bridge girder erection machine, the structural form is simple; when passing through the tunnel, the transporting girder vehicle carries the launching nose and the bridge girder erection machine to pass through the tunnel at one time, thus the discharge workload is small, and the working condition adaptability is relatively good.

Owner:袁攀峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com