Two-stage gas-liquid separation device

A gas-liquid separation device and coarse separation technology, which is applied in the direction of combined devices, separation methods, and dispersed particle separation, etc., can solve problems such as unfriendly working environment, poor equipment adaptability, and large on-site impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

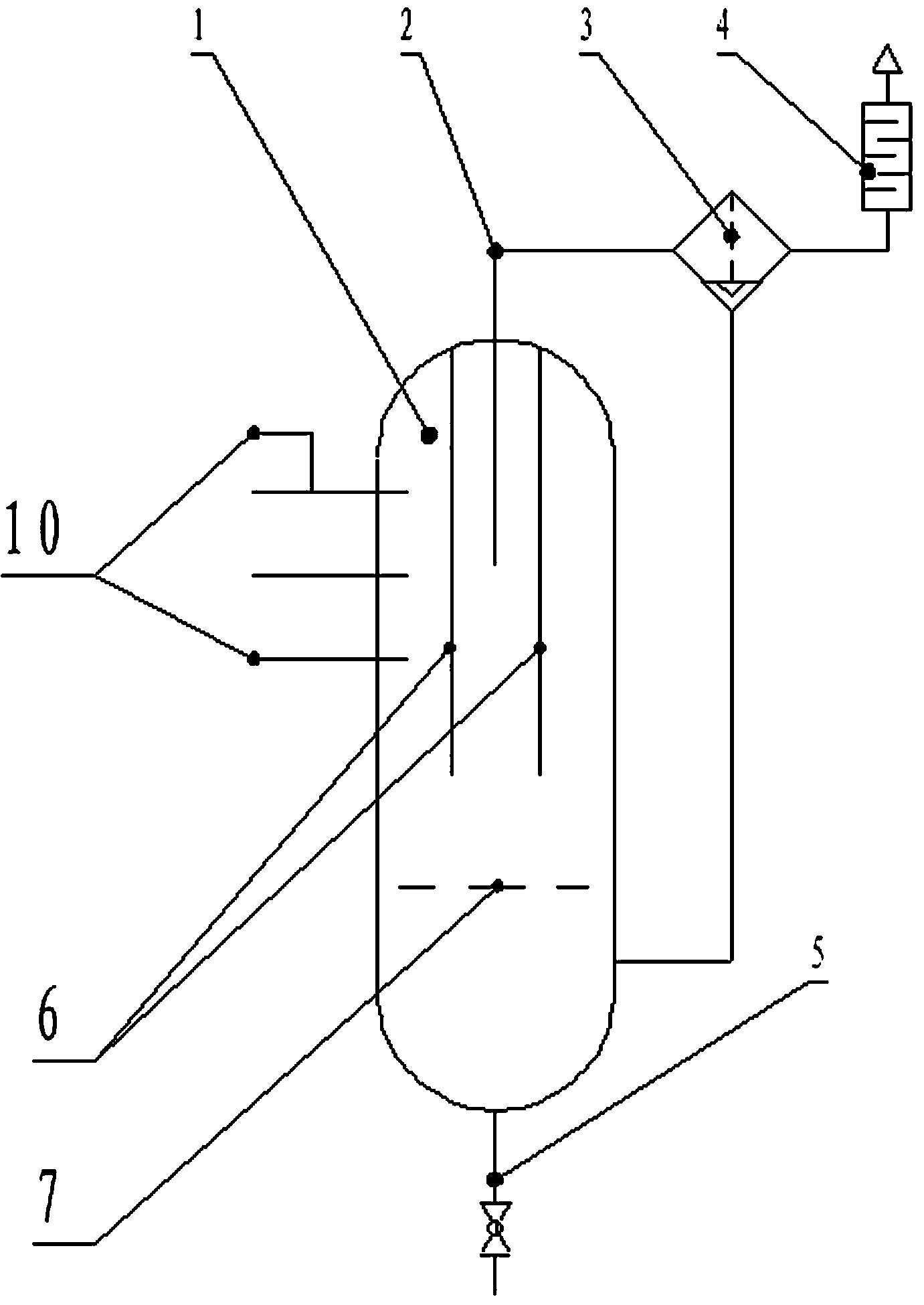

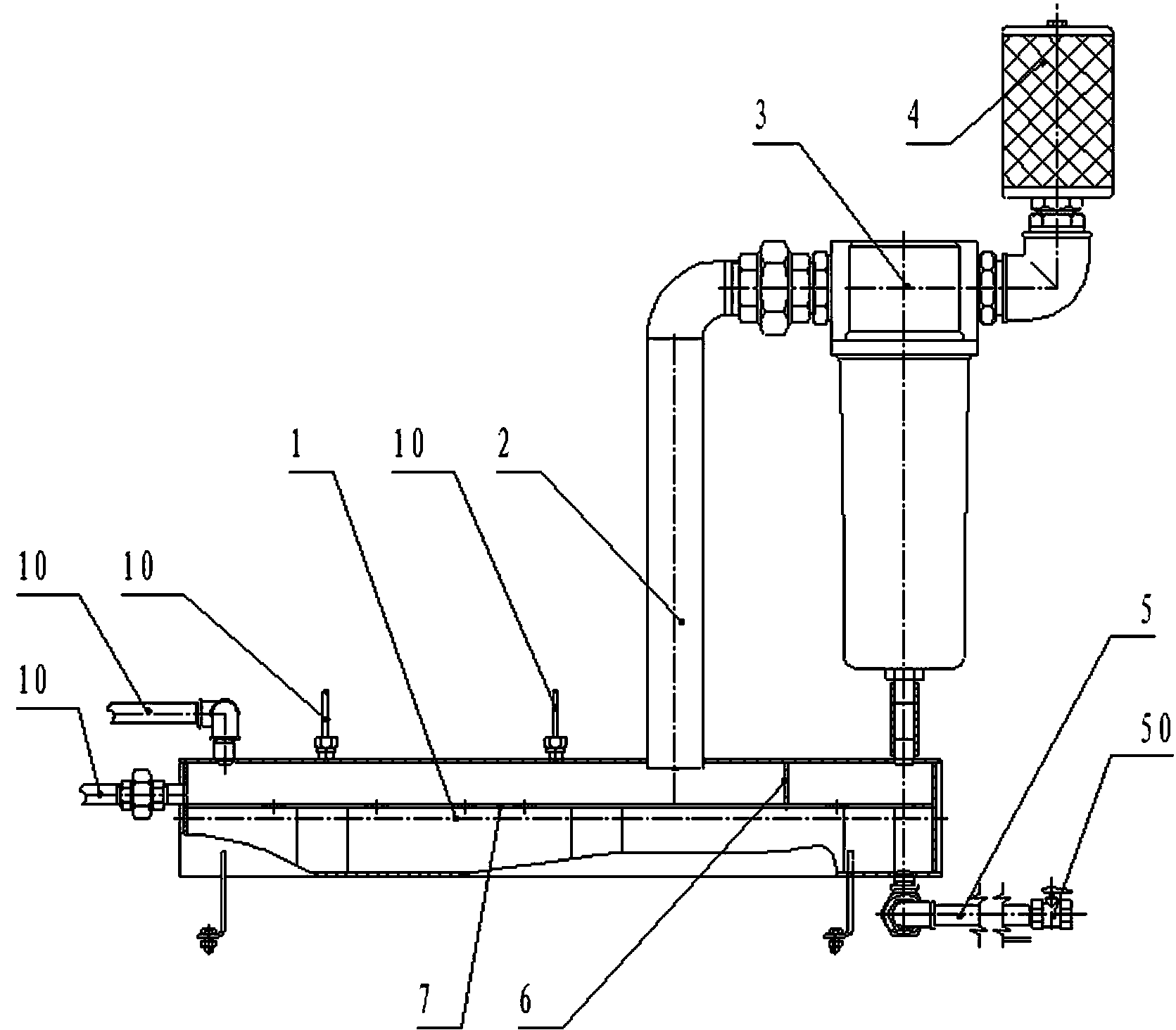

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 , figure 2 It can be seen that the two-stage gas-liquid separation device of this embodiment is applied to gas-making equipment. In the gas-liquid mixture produced by the gas-making equipment, the proportion of gas is relatively large. In addition, within a discharge cycle, the gas-liquid ratio changes greatly. Specifically It is manifested that the proportion of liquid is large at the beginning of discharge, and the proportion of gas is large at the end of discharge.

[0015] The present embodiment includes a coarse separation-stain collection bucket 1, the upper part of the coarse separation-stain collection bucket 1 is connected with a fine filter 3 through a discharge pipe 2, and the fine filter 3 is connected with a muffler 4 through a pipeline; The discharge port at the lower end of the fine filter 3 is connected with the rough separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com