Hydrolysis reaction device and hydrolysis method for organic sulfur in blast furnace gas

A hydrolysis reaction and blast furnace gas technology, which is applied in the removal of gas pollutants, catalytic conversion of impurities, gas purification, energy input, etc., can solve problems such as small contact area between catalyst and blast furnace gas, large system pressure drop, imperfection, etc. , to achieve the effect of improving hydrolysis conversion efficiency, small pressure drop and high operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

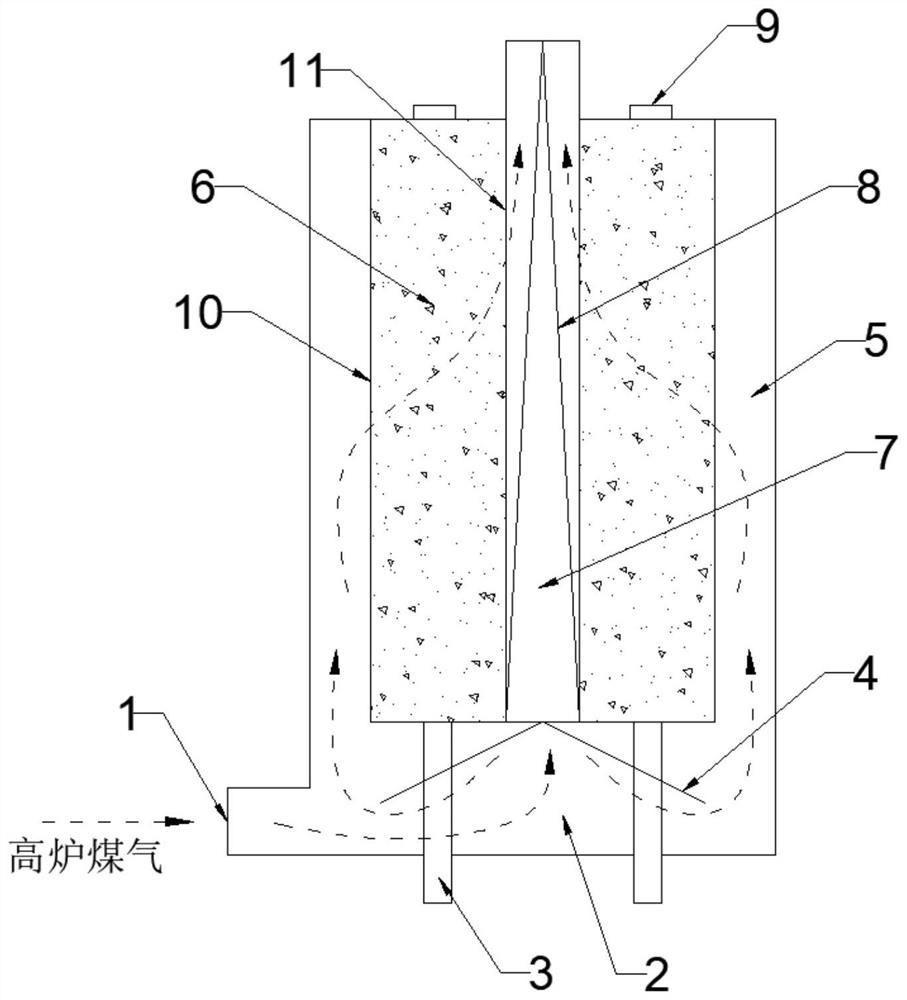

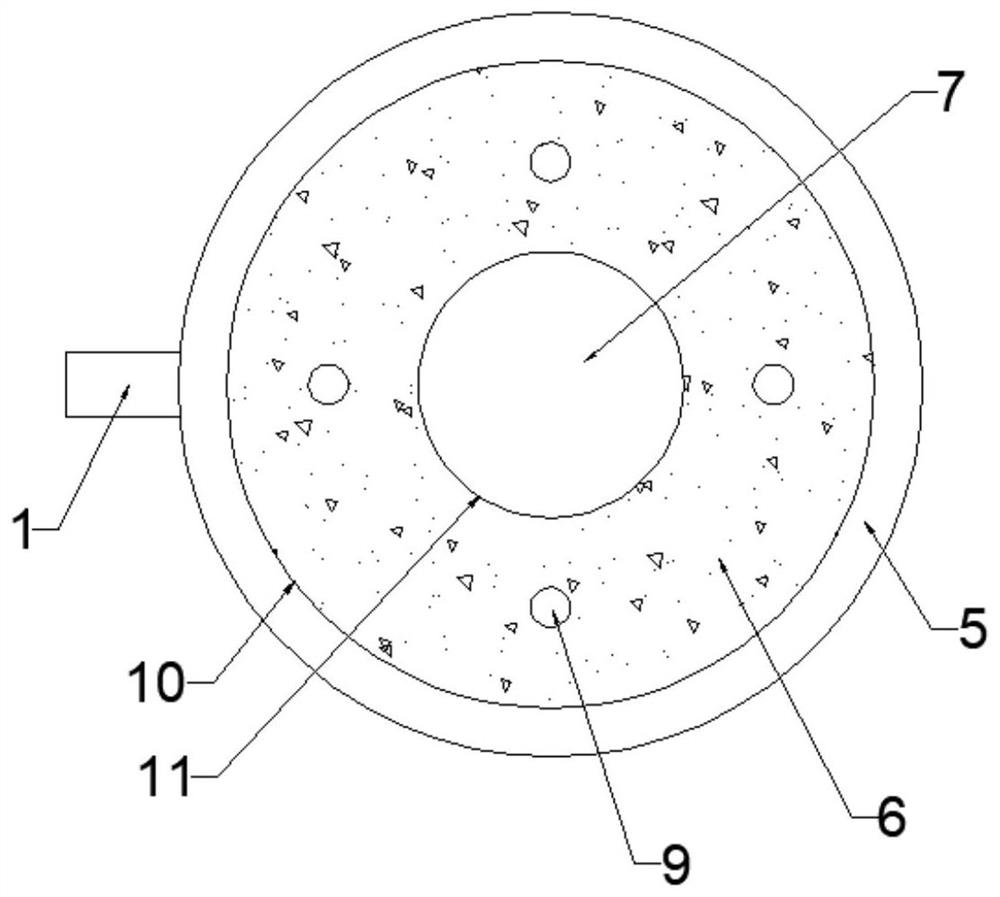

[0058] This embodiment provides a hydrolysis reaction device for organic sulfur in blast furnace gas. The hydrolysis reaction device is as follows: figure 1 As shown, including the housing, the catalyst separator group is arranged axially inside the housing, the top surface of the catalyst separator group is close to the top surface of the housing, and the cavity formed between the bottom surface of the catalyst separator group and the bottom surface of the housing is an inlet. Gas chamber 2. The catalyst separator set includes an inner ring separator 11 and an outer ring separator 10 coaxially nested from the inside to the outside, and the annular cavity formed between the inner ring separator 11 and the outer ring separator 10 is filled. A spherical hydrolysis catalyst 6 is inserted, and an annular bottom plate is fixed on the bottom surface of the catalyst separator group, and the annular bottom plate seals the bottom of the annular cavity. The cavity surrounded by the inn...

Embodiment 2

[0064] This embodiment provides a hydrolysis reaction device for organic sulfur in blast furnace gas. The hydrolysis reaction device includes a casing, and a catalyst separator group is arranged axially inside the casing, and the top surface of the catalyst separator group is close to the casing. The top surface, the cavity formed between the bottom surface of the catalyst separator group and the bottom surface of the casing is the air intake chamber 2 . The catalyst separator set includes an inner ring separator 11 and an outer ring separator 10 coaxially nested from the inside to the outside, and the annular cavity formed between the inner ring separator 11 and the outer ring separator 10 is filled. Insert the cylindrical hydrolysis catalyst 6, and the bottom surface of the catalyst separator group is fixed with an annular bottom plate, which seals the bottom of the annular cavity. The cavity surrounded by the inner ring partition member 11 is the exhaust passage 7, the cavi...

Embodiment 3

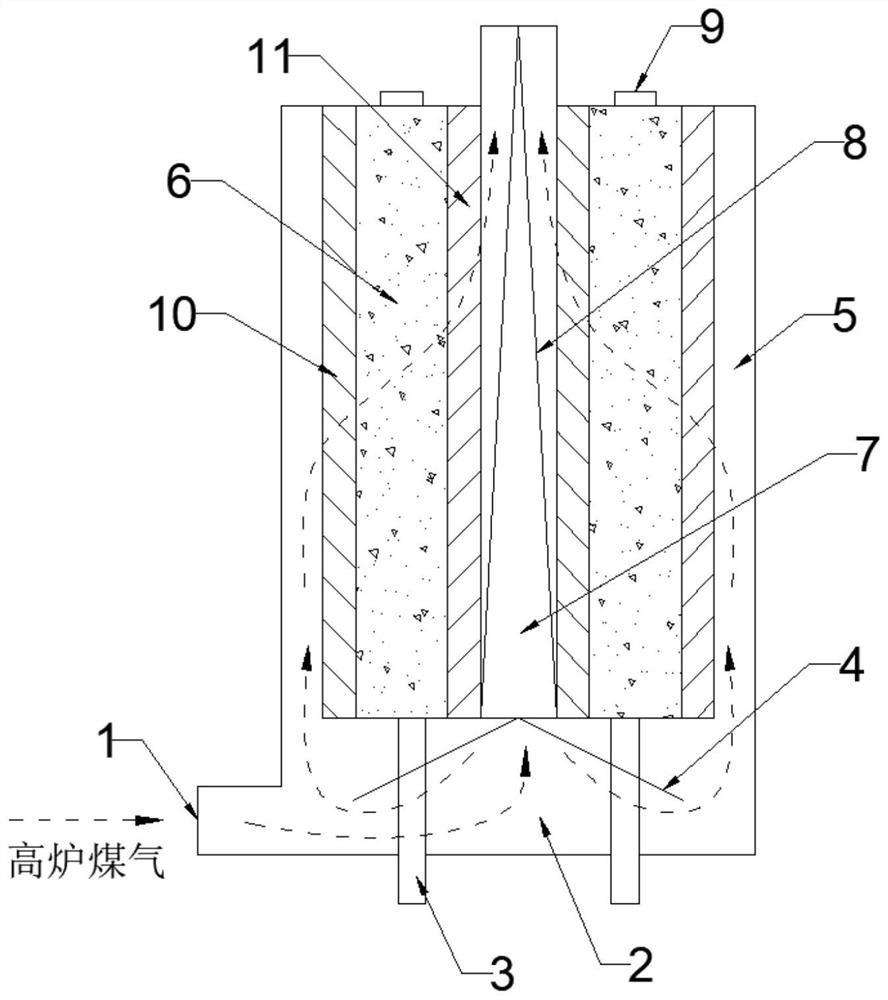

[0070] This embodiment provides a hydrolysis reaction device for organic sulfur in blast furnace gas. The hydrolysis reaction device is as follows: image 3 As shown, including the housing, the catalyst separator group is arranged axially inside the housing, the top surface of the catalyst separator group is close to the top surface of the housing, and the cavity formed between the bottom surface of the catalyst separator group and the bottom surface of the housing is an inlet. Gas chamber 2. The catalyst separator set includes an inner ring separator 11 and an outer ring separator 10 coaxially nested from the inside to the outside, and the annular cavity formed between the inner ring separator 11 and the outer ring separator 10 is filled. A cubic hydrolysis catalyst 6 is inserted, and an annular bottom plate is fixed on the bottom surface of the catalyst separator group, and the annular bottom plate seals the bottom of the annular cavity. The cavity surrounded by the inner r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com